Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review

Abstract

1. Introduction

- Utilization of some expensive natural resources can be reduced by replacing them with by-products [30].

- The use of fly ash by-products instead of the use of Portland cement in geotechnical applications can be a solution to reduce the CO2 emissions caused by cement production.

2. Coal Fly Ash

2.1. Classification of Fly Ash

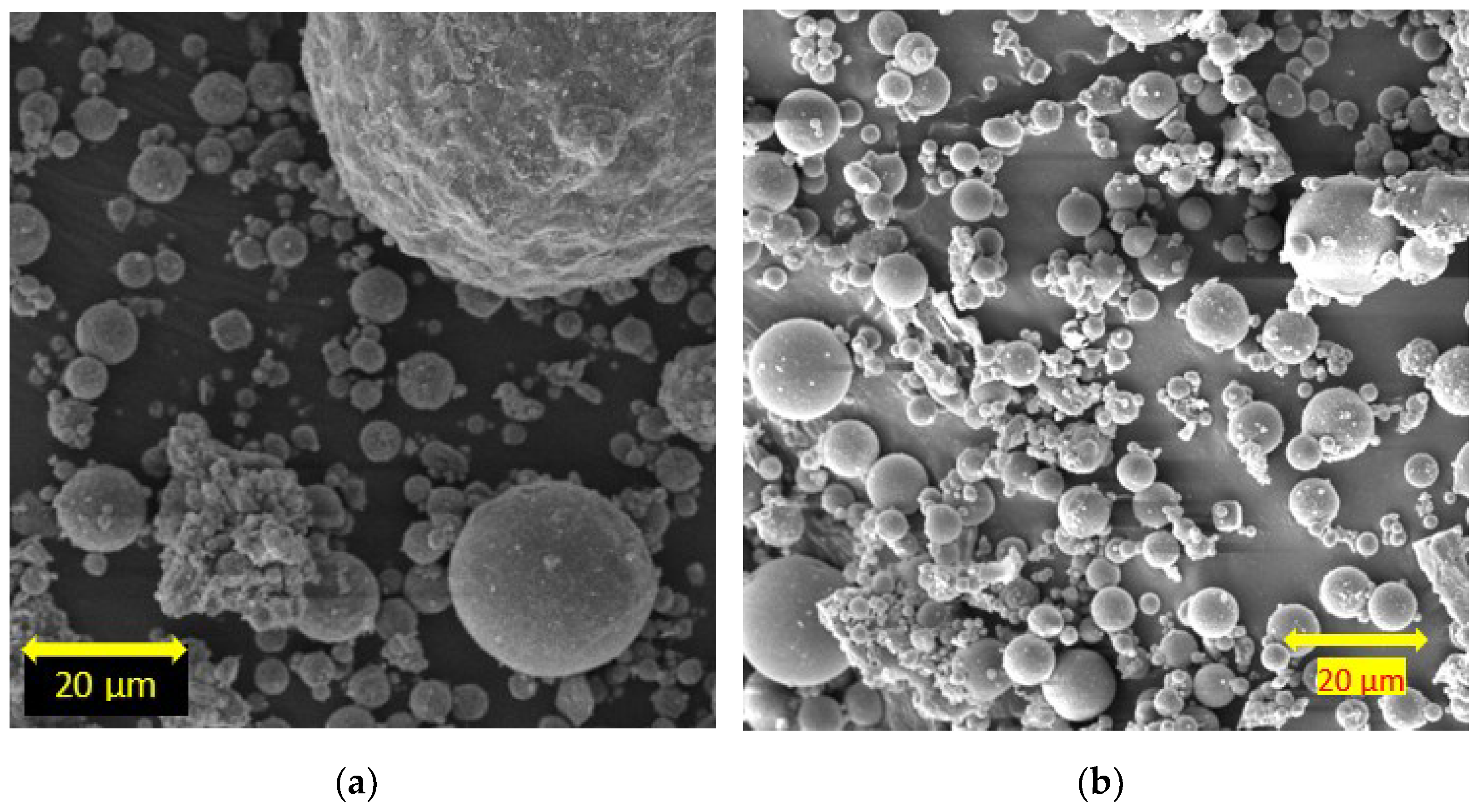

2.2. Properties of Fly Ash

2.2.1. Physical and Geotechnical Properties

2.2.2. Chemical Properties

2.2.3. Mineralogical Properties

2.3. Health Concerns of Fly Ash

2.4. Disposal of Fly Ash

2.5. Availability of Fly Ash

2.6. Cost of Fly Ash

3. Geotechnical Characteristics of Fly Ash-Stabilized Fine-Grained Soils

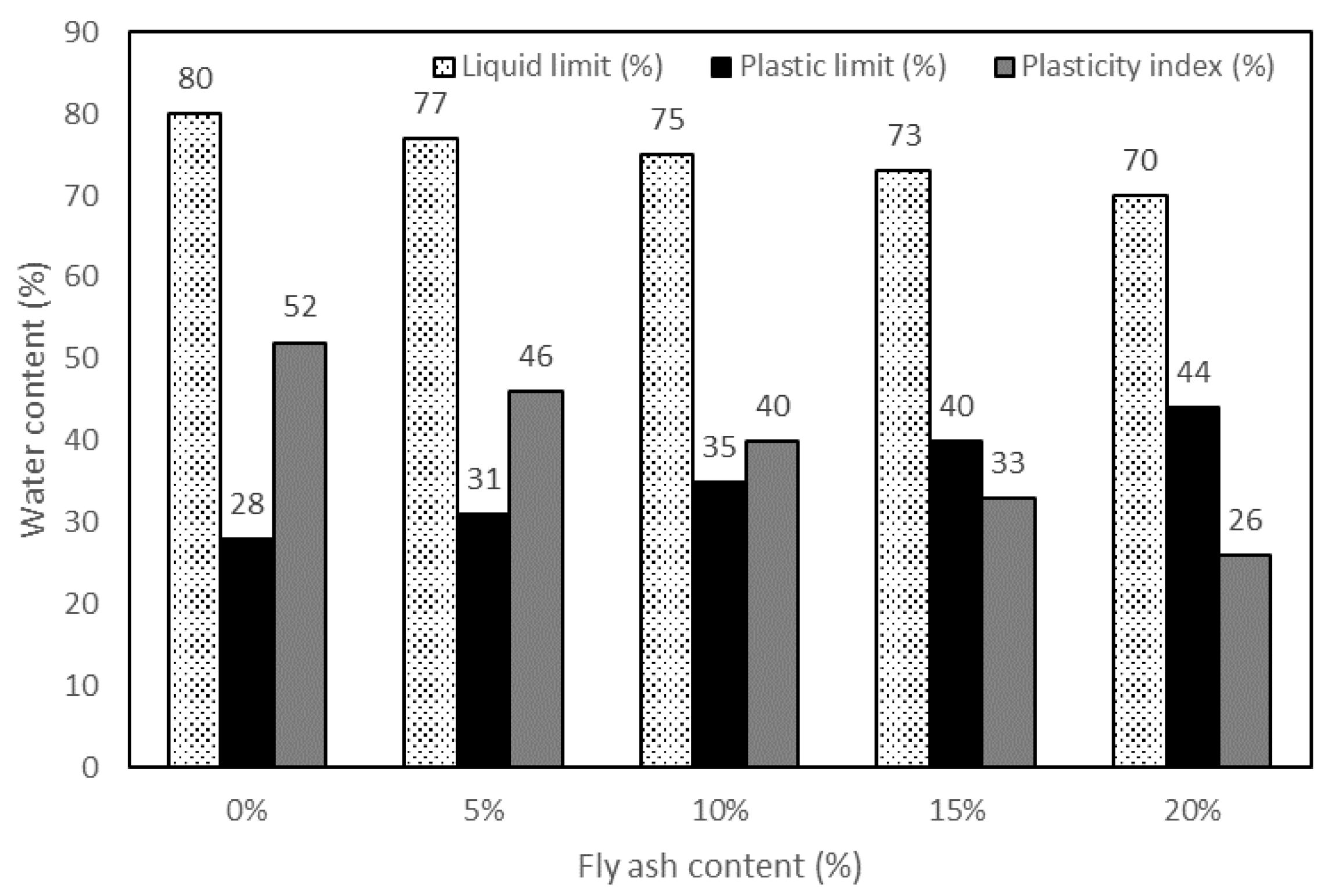

3.1. Effects of Fly Ash Inclusion on Consistency Limits of Soil

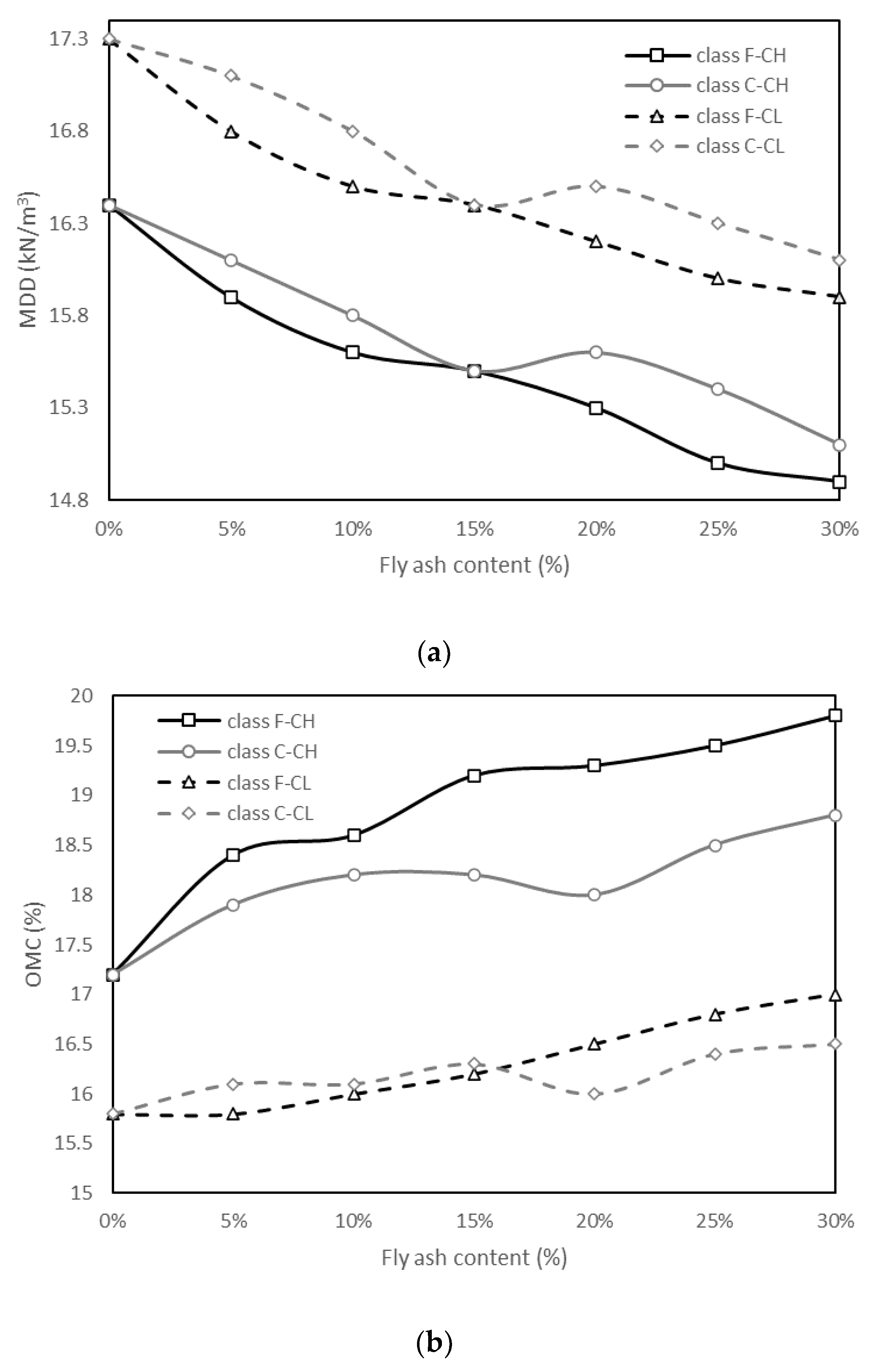

3.2. Effects of Fly Ash Inclusion on Compaction Characteristics of Soil

3.3. Effects of Fly Ash Inclusion on California Bearing Ratio of Soil

3.4. Effects of Fly Ash Inclusion on Unconfined Compressive Strength (UCS) of Soil

3.5. Effects of Fly Ash Inclusion on Shear Strength of Soil

3.6. Effects of Fly Ash Inclusion on Swelling, Consolidation, and Permeability of Soil

4. Field Applications of Fly Ash-Stabilized Soil

5. Future Research and Prospects

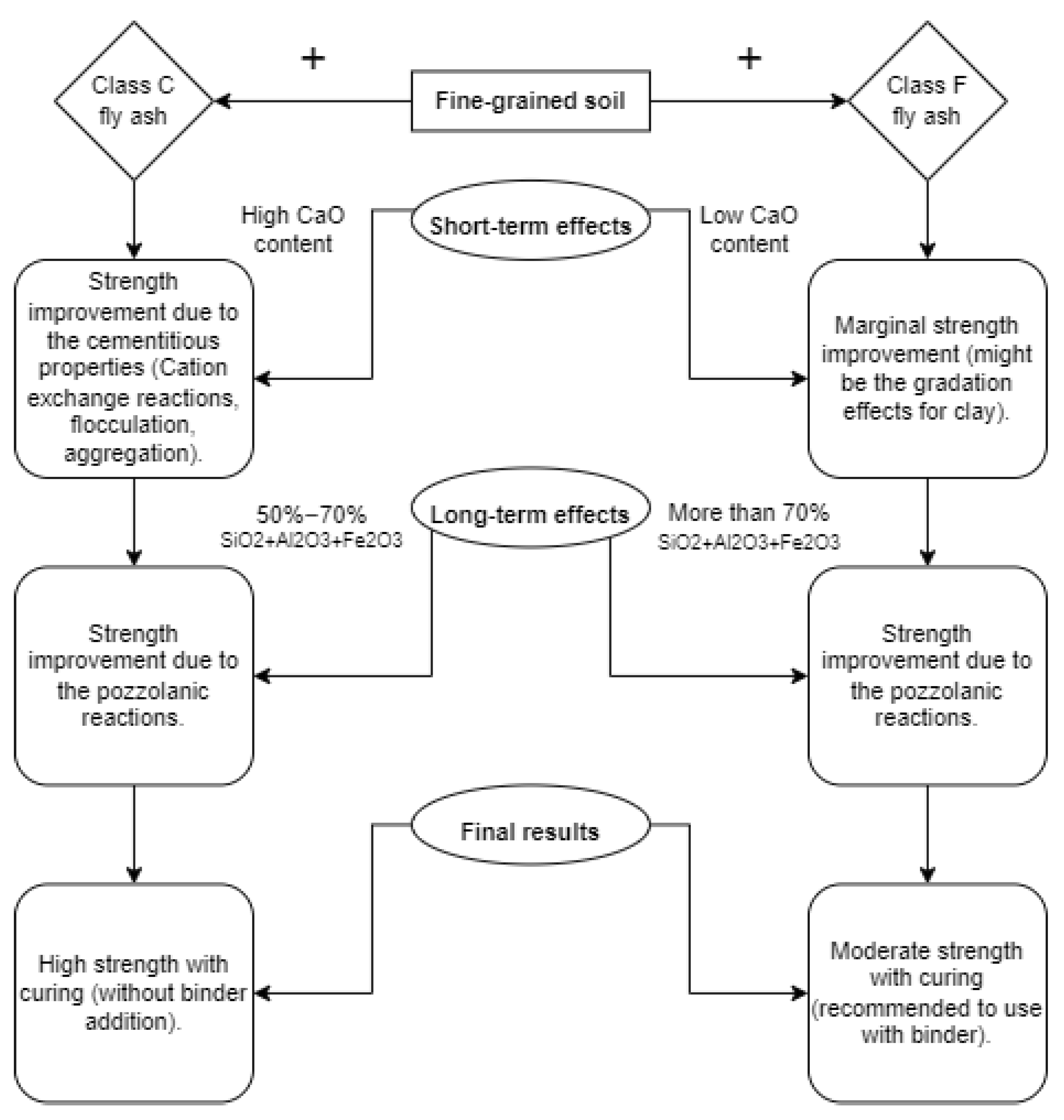

6. Conclusions

- LL decreases, PL increases, and PI decreases with increasing the fly ash content in the soil.

- The addition of fly ash to soil leads to a decrease in MDD and an increase in OMC. However, a number of studies have shown that the MDD increased and OMC decreased with the addition of fly ash. This discrepancy could be due to the differences in the specific gravity of the fly ash used.

- Fly ash-stabilized soil could be used as a subbase or base material for roads, backfilling, or other geotechnical structures.

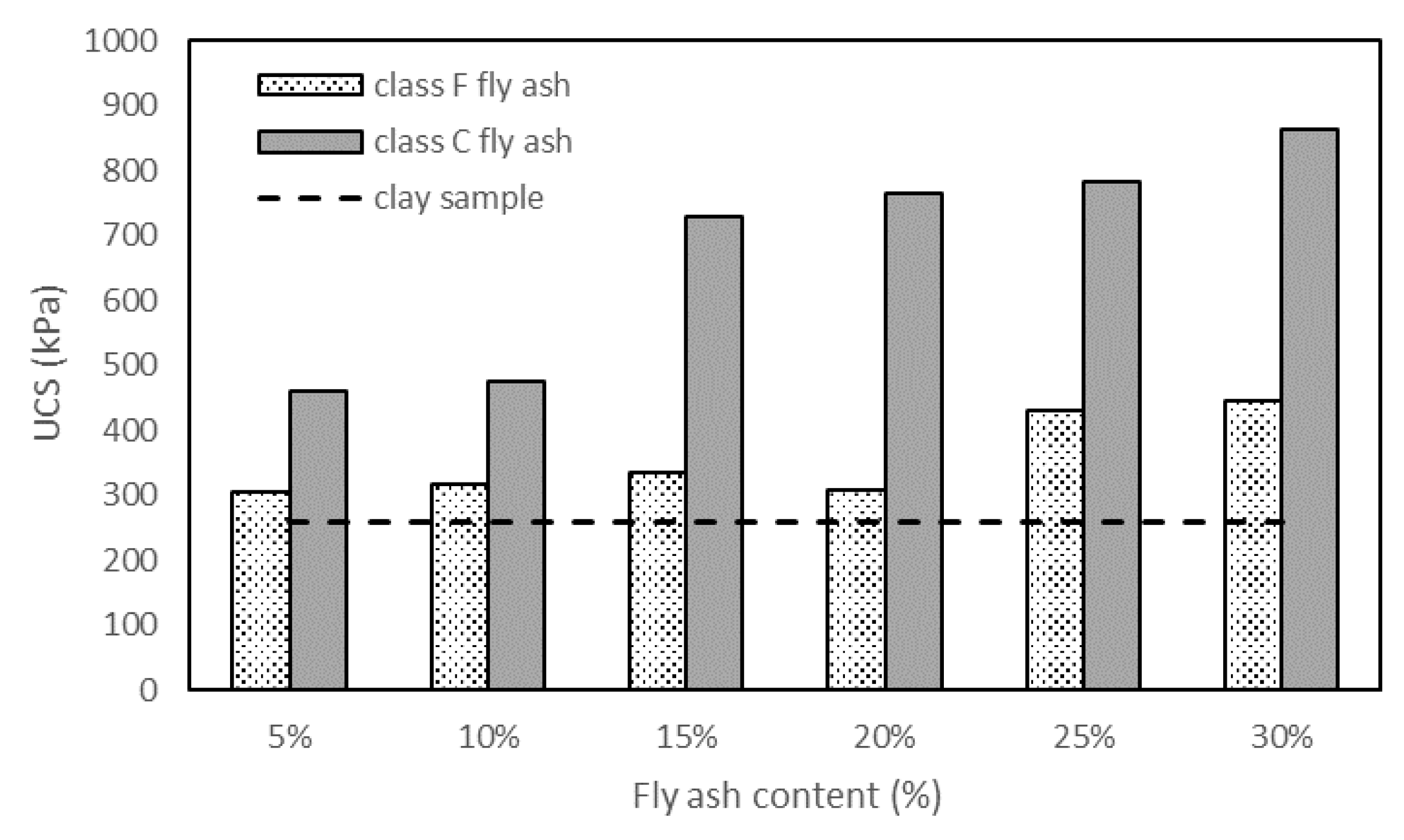

- UCS of soil increases with the addition of fly ash, however, class C fly ash is more effective in comparison with class F fly ash. An increase in curing time has a positive effect on the UCS of soil due to the time-dependent pozzolanic properties of fly ash.

- The shear strength parameters, angle of shearing resistance, and cohesion improve with increasing the fly ash content in the soil.

- Swelling of expansive soils decreases with the addition of fly ash. The compression index (Cc) and coefficient of volume compressibility (mv) of the soil generally decrease and the pre-consolidation pressure increases with the addition of fly ash. Also, the coefficient of consolidation and permeability increase with the addition of fly ash in the soil, hence, the majority of the settlement could be completed during the construction stages when fly ash stabilized soil is used.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Type of Fly Ash | Fly Ash Content | LL (%) | PL (%) | PI (%) | Soil Classification (USCS) | References |

|---|---|---|---|---|---|---|

| class F | unstabilized (0%) | 80 | 28 | 52 | CH | Kumar and Sharma [4] |

| 5% | 77 | 31 | 46 | CH | ||

| 10% | 75 | 35 | 40 | CH | ||

| 15% | 73 | 40 | 33 | MH | ||

| 20% | 70 | 44 | 26 | MH | ||

| Low-Ca fly ash | unstabilized (0%) | 84 | 29 | 55 | CH | Phanikumar and Nagaraju [5] |

| 5% | 79 | 30.5 | 49.5 | CH | ||

| 10% | 74 | 31 | 43 | CH | ||

| 15% | 68 | 31.5 | 36.5 | CH | ||

| 20% | 62 | 32.5 | 29.5 | MH | ||

| 25% | 54 | 33 | 21 | MH | ||

| 30% | 44 | 33.5 | 10.5 | ML | ||

| class F | unstabilized (0%) | 62.2 | 25.1 | 37.1 | CH | Ji-ru and Xing [76] |

| 40% | 54.4 | 27.5 | 26.9 | CH | ||

| 50% | 51.4 | 24.9 | 26.5 | CH | ||

| class C | unstabilized (0%) | - | - | 30 | CH | Parsons and Kneebone [77] |

| 12% | - | - | 16 | - | ||

| 16% | - | - | 12 | - | ||

| unstabilized (0%) | - | - | 15 | CL | ||

| 12% | - | - | 11 | - | ||

| 16% | - | - | 9 | - | ||

| unstabilized (0%) | - | - | 17 | CL | ||

| 12% | - | - | 12 | - | ||

| 16% | - | - | 9 | - | ||

| class F | unstabilized (0%) | 59.8 | 27.5 | 32.3 | CH | Zha et al. [78] |

| 3% | 58.2 | 29.2 | 28.9 | CH | ||

| 6% | 57.3 | 31 | 26.2 | MH | ||

| 9% | 55.1 | 32.5 | 22.6 | MH | ||

| 12% | 53.7 | 33.3 | 20.4 | MH | ||

| 15% | 52.4 | 35.1 | 17.3 | MH | ||

| class F | unstabilized (0%) | 100 | 27 | 73 | CH | Phanikumar [79] |

| 10% | 92 | 32 | 60 | CH | ||

| 20% | 86 | 36 | 50 | CH | ||

| class F | unstabilized (0%) | 84 | 25.4 | 58.6 | CH | Mir and Sridharan [80] |

| 20% | 72 | 33 | 39 | MH | ||

| 40% | 63 | 31.6 | 31.4 | MH | ||

| 60% | 53 | 32.5 | 20.5 | MH | ||

| class C | unstabilized (0%) | 84 | 25.4 | 58.6 | CH | |

| 10% | 81 | 45 | 36 | MH | ||

| 20% | 76 | 49 | 27 | MH | ||

| 40% | 66 | 54 | 12 | MH | ||

| 60% | 56.5 | 45 | 11.5 | MH | ||

| class F | unstabilized (0%) | 159 | 36.9 | 122.1 | CH | Pal and Ghosh [81] |

| 50% | 91.4 | 20.9 | 70.5 | CH | ||

| 60% | 75.1 | 23.4 | 51.8 | CH | ||

| 70% | 60.8 | 24.6 | 36.1 | CH | ||

| 80% | 45.7 | 25.9 | 19.8 | CL | ||

| class C | unstabilized (0%) | 88.7 | 35 | 53.7 | CH | Binal [82] |

| 5% | - | - | - | MH | ||

| 10% | - | - | - | MH | ||

| 15% | - | - | - | MH | ||

| 20% | - | - | - | MH | ||

| 25% | - | - | - | MH | ||

| class C | unstabilized (0%) | 75.8 | 28.5 | - | - | Kolay and Ramesh [83] |

| 10% | 75.2 | 25.5 | - | - | ||

| 20% | 73.9 | 24.4 | - | - | ||

| 30% | 69.3 | 21.3 | - | - | ||

| 40% | 64.9 | 19.6 | - | - | ||

| 50% | 61.5 | 17.9 | - | - | ||

| unstabilized (0%) | 603.1 | 94.5 | - | - | ||

| 10% | 512 | 81.8 | - | - | ||

| 20% | 432 | 73.9 | - | - | ||

| 30% | 346 | 65.8 | - | - | ||

| 40% | 283 | 59.9 | - | - | ||

| 50% | 237 | 54.8 | - | - | ||

| class F | unstabilized (0%) | - | - | - | CH | Seyrek [60] |

| 20% | - | - | - | CL | ||

| class C | unstabilized (0%) | - | - | - | CH | |

| 10% | - | - | - | MH | ||

| 15% | - | - | - | ML | ||

| class F | unstabilized (0%) | - | - | - | CL | |

| 15% | - | - | - | ML | ||

| class C | unstabilized (0%) | - | - | - | CL | |

| 10% | - | - | - | ML | ||

| class F | unstabilized (0%) | 48.3 | 23.4 | 24.9 | CL | Zhou et al. [84] |

| 30% | 43.1 | 26.5 | 16.6 | ML |

| Type of Fly Ash | Type of Soil | Fly Ash Content | MDD (kN/m3) | OMC (%) | References |

|---|---|---|---|---|---|

| class F | CH | unstabilized (0%) | 13.8 | 40 | Kumar and Sharma [4] |

| 5% | 13.9 | 38 | |||

| 10% | 14.1 | 35 | |||

| 15% | 14.2 | 33 | |||

| 20% | 14.3 | 31 | |||

| class C | CH | unstabilized (0%) | 13.8 | 30.5 | Kumar et al. [10] |

| 5% | 13.4 | 30.5 | |||

| 10% | 13.2 | 31 | |||

| 15% | 13.1 | 31.5 | |||

| 20% | 13.0 | 31.5 | |||

| 100% | 11.0 | 39 | |||

| - | CL | unstabilized (0%) | 16.8 | 14.6 | Prabakar et al. [12] |

| 9% | 15.5 | 15.8 | |||

| 20% | 15.4 | 17.9 | |||

| 28.5% | 14.1 | 20.4 | |||

| 35.5% | 13.6 | 22.3 | |||

| 41.2% | 13.3 | 25.2 | |||

| 46% | 13.1 | 27.2 | |||

| 100% | 9.2 | 44.2 | |||

| - | MH | unstabilized (0%) | 14.0 | 30.1 | |

| 9% | 13.5 | 29.5 | |||

| 20% | 13.2 | 29.5 | |||

| 28.5% | 12.8 | 30.1 | |||

| 35.5% | 12.2 | 31.9 | |||

| 41.2% | 12.3 | 33.3 | |||

| 46% | 11.9 | 34.3 | |||

| High-Ca fly ash | Silty clay | unstabilized (0%) | 15.3 | 23 | Jafer et al. [16] |

| 3% | 14.5 | 26 | |||

| 6% | 14.3 | 27.5 | |||

| 9% | 14.2 | 28 | |||

| 12% | 14.1 | 29 | |||

| 15% | 13.7 | 30.5 | |||

| class F | CL | unstabilized (0%) | 17.8 | 16 | Shaunik and Gupta [29] |

| 20% | 16.3 | 20 | |||

| 40% | 12.7 | 22 | |||

| 60% | 11.4 | 24 | |||

| 80% | 10.2 | 26 | |||

| 100% | 9.0 | 28 | |||

| class F | CH | unstabilized (0%) | 17.5 | 17.2 | Ji-ru and Xing [76] |

| 40% | 13.9 | 16.0 | |||

| 50% | 13.3 | 18.4 | |||

| class F | CH | unstabilized (0%) | 13.6 | 34 | Phanikumar [79] |

| 10% | 14.0 | 27 | |||

| 20% | 14.4 | 21 | |||

| class F | CH | unstabilized (0%) | 14.4 | 28.3 | Mir and Sridharan [80] |

| 20% | 13.9 | 30.0 | |||

| 40% | 13.6 | 31.1 | |||

| 60% | 12.7 | 33.0 | |||

| 80% | 11.8 | 35.4 | |||

| 100% | 10.6 | 38.2 | |||

| class C | CH | unstabilized (0%) | 14.4 | 28.3 | |

| 10% | 14.1 | 29.5 | |||

| 20% | 13.9 | 29.7 | |||

| 40% | 13.7 | 29.9 | |||

| 60% | 13.5 | 30.5 | |||

| 80% | 13.1 | 31.1 | |||

| 100% | 12.6 | 32.0 | |||

| class C | CH (kaolinite) | unstabilized (0%) | 13.4 | 30.1 | Kolay and Ramesh [83] |

| 10% | 13.2 | 31.0 | |||

| 20% | 13.0 | 32.2 | |||

| 30% | 12.9 | 33.0 | |||

| 40% | 12.8 | 34.5 | |||

| 50% | 12.7 | 35.4 | |||

| CH (bentonite) | unstabilized (0%) | 11.7 | 40.5 | ||

| 10% | 11.7 | 40.5 | |||

| 20% | 11.5 | 41.3 | |||

| 30% | 11.4 | 41.5 | |||

| 40% | 11.3 | 41.6 | |||

| 50% | 11.3 | 42.5 | |||

| class F | CH | unstabilized (0%) | 16.4 | 17.2 | Seyrek [60] |

| 5% | 15.9 | 18.4 | |||

| 10% | 15.6 | 18.6 | |||

| 15% | 15.5 | 19.2 | |||

| 20% | 15.3 | 19.3 | |||

| 25% | 15.0 | 19.5 | |||

| 30% | 14.9 | 19.8 | |||

| CL | unstabilized (0%) | 17.3 | 15.8 | ||

| 5% | 16.8 | 15.8 | |||

| 10% | 16.5 | 16.0 | |||

| 15% | 16.4 | 16.2 | |||

| 20% | 16.2 | 16.5 | |||

| 25% | 16.0 | 16.8 | |||

| 30% | 15.9 | 17.0 | |||

| class C | CH | unstabilized (0%) | 16.4 | 17.2 | |

| 5% | 16.1 | 17.9 | |||

| 10% | 15.8 | 18.2 | |||

| 15% | 15.5 | 18.2 | |||

| 20% | 15.6 | 18.0 | |||

| 25% | 15.4 | 18.5 | |||

| 30% | 15.1 | 18.8 | |||

| CL | unstabilized (0%) | 17.3 | 15.8 | ||

| 5% | 17.1 | 16.1 | |||

| 10% | 16.8 | 16.1 | |||

| 15% | 16.4 | 16.3 | |||

| 20% | 16.5 | 16.0 | |||

| 25% | 16.3 | 16.4 | |||

| 30% | 16.1 | 16.5 | |||

| - | CL | unstabilized (0%) | 17.9 | 14.0 | Santos et al. [88] |

| 20% | 15.5 | 22.5 | |||

| 40% | 14.6 | 25.0 | |||

| 60% | 13.9 | 28.0 | |||

| 100% | 10.4 | 45.5 | |||

| class C | CL (PI = 20) | unstabilized (0%) | 16.2 | 18.7 | Savas et al. [91] |

| 5% | 15.7 | 20.5 | |||

| 10% | 15.2 | 22.3 | |||

| 15% | 15.0 | 23.0 | |||

| 20% | 14.9 | 23.6 | |||

| 25% | 14.7 | 24.3 | |||

| 30% | 14.6 | 24.9 | |||

| CL (PI-19) | unstabilized (0%) | 16.9 | 15.7 | ||

| 5% | 16.6 | 15.8 | |||

| 10% | 16.2 | 15.9 | |||

| 15% | 15.9 | 15.7 | |||

| 20% | 15.7 | 15.7 | |||

| 25% | 15.5 | 17.1 | |||

| 30% | 15.3 | 17.7 | |||

| class F | CL (PI = 20) | unstabilized (0%) | 16.2 | 18.7 | |

| 5% | 16.0 | 19.0 | |||

| 10% | 15.8 | 19.3 | |||

| 15% | 15.4 | 19.9 | |||

| 20% | 15.1 | 20.5 | |||

| 25% | 15.0 | 21.2 | |||

| 30% | 14.9 | 21.8 | |||

| CL (PI-19) | unstabilized (0%) | 16.9 | 15.7 | ||

| 5% | 16.9 | 15.7 | |||

| 10% | 16.7 | 15.4 | |||

| 15% | 16.4 | 15.6 | |||

| 20% | 16.1 | 15.1 | |||

| 25% | 15.9 | 15.2 | |||

| 30% | 15.8 | 15.5 |

| Type of Fly Ash | Type of Soil | Fly Ash Content | CBR (%) | General Rating, Bowles [83] | Uses, Bowles [83] | References |

|---|---|---|---|---|---|---|

| - | CL | unstabilized (0%) | 4.7 | poor to fair | subgrade | Prabakar et al. [12] |

| 9% | 7 | fair | subbase | |||

| 20% | 8.84 | fair | subbase | |||

| 28.5% | 9.24 | fair | subbase | |||

| 35.5% | 9.93 | fair | subbase | |||

| 41.2% | 10.67 | fair | subbase | |||

| 46% | 11.6 | fair | subbase | |||

| class C | CL | unstabilized (0%) | 1 | very poor | subgrade | Bin-Shafique et al. [33] |

| 12% | 37 | good | base, subbase | |||

| CL-ML | unstabilized (0%) | 3 | very poor | subgrade | ||

| 10% | 32 | good | base, subbase | |||

| class F | CH | unstabilized (0%) | 2 | very poor | subgrade | Ji-ru and Xing [76] |

| 40% | 17 | fair | subbase | |||

| 50% | 20.2 | good | base, subbase | |||

| class C | CH | unstabilized (0%) | 6.7 | poor to fair | subgrade | Binal [82] |

| 28% (28 days cured) | 68.7 | excellent | base | |||

| class C | CL | unstabilized (0%) | 3 | poor to fair | subgrade | Senol et al. [87] |

| 12% (7 days cured) | 34 | good | base, subbase | |||

| 16% (7 days cured) | 51 | excellent | base | |||

| 20% (7 days cured) | 56 | excellent | base | |||

| ML | unstabilized (0%) | 5 | poor to fair | subgrade | ||

| 10% (7 days cured) | 32 | good | base, subbase | |||

| 14% (7 days cured) | 36 | good | base, subbase | |||

| 18% (7days cured) | 38 | good | base, subbase | |||

| OH | unstabilized (0%) | 2 | very poor | subgrade | ||

| 18% (7 days cured) | 5 | poor to fair | subgrade | |||

| - | CH | unstabilized (0%) | 2.1 | very poor | subgrade | Than and Zaw [97] |

| 4% | 4.9 | poor to fair | subgrade | |||

| 8% | 11.5 | fair | subbase | |||

| 12% | 21.3 | good | base, subbase | |||

| 16% | 30.7 | good | base, subbase | |||

| 20% | 25.1 | good | base, subbase | |||

| class C | CL | unstabilized (0%) | 2 | very poor | subgrade | Trzebiatowski et al. [98] |

| 10% | 57 | excellent | base | |||

| CL | unstabilized (0%) | 3 | poor to fair | subgrade | ||

| 10% | 47 | good | base, subbase | |||

| class C | CH | unstabilized (0%) | 2 | very poor | subgrade | Edil et al. [100] |

| 10% (7 days cured) | 8 | fair | subbase | |||

| 18% (7 days cured) | 24 | good | base, subbase | |||

| CL | unstabilized (0%) | 5 | poor to fair | subgrade | ||

| 10% (7 days cured) | 11 | fair | subbase | |||

| 18% (7 days cured) | 30 | good | base, subbase | |||

| CH | unstabilized (0%) | 3 | poor to fair | subgrade | ||

| 10% (7 days cured) | 12 | fair | subbase | |||

| 18% (7 days cured) | 15 | fair | subbase | |||

| class F | expansive soil | unstabilized (0%) | 7.5 | fair | subbase | Jose et al. [101] |

| 10% | 12.6 | fair | subbase | |||

| 15% | 13.2 | fair | subbase |

| Type of Fly Ash | Type of Soil | Curing Days | Fly Ash Content | UCS (kPa) | References |

|---|---|---|---|---|---|

| class F | CH | 1 | unstabilized (0%) | 285.7 | Seyrek [60] |

| 28 | 25% | 1088.3 | |||

| class C | CH | 1 | unstabilized (0%) | 285.7 | |

| 1 | 25% | 559.9 | |||

| 7 | 25% | 948.4 | |||

| 28 | 30% | 1442.5 | |||

| class F | CL | 1 | unstabilized (0%) | 215.4 | |

| 28 | 25% | 657 | |||

| class C | CL | 1 | unstabilized (0%) | 215.4 | |

| 28 | 30% | 915.5 | |||

| class C | CL | 7 | unstabilized (0%) | 140 | Senol et al. [87] |

| 12% | 772 | ||||

| 16% | 828 | ||||

| 20% | 863 | ||||

| ML | 7 | unstabilized (0%) | 133 | ||

| 10% | 566 | ||||

| 14% | 614 | ||||

| 18% | 649 | ||||

| class C | CL (PI = 20) | 1 | unstabilized (0%) | 257.6 | Savas et al. [91] |

| 5% | 459.9 | ||||

| 10% | 476.5 | ||||

| 15% | 729.5 | ||||

| 20% | 765.2 | ||||

| 25% | 784.3 | ||||

| 30% | 862.9 | ||||

| class F | CL (PI = 20) | 1 | unstabilized (0%) | 257.6 | |

| 5% | 305.7 | ||||

| 10% | 317.5 | ||||

| 15% | 336.1 | ||||

| 20% | 307.9 | ||||

| 25% | 430.7 | ||||

| 30% | 444.9 | ||||

| class C | CL (PI = 19) | 1 | unstabilized (0%) | 234.8 | |

| 5% | 308.9 | ||||

| 10% | 426.1 | ||||

| 15% | 559.6 | ||||

| 20% | 761.7 | ||||

| 25% | 790.4 | ||||

| 30% | 845 | ||||

| class F | CL (PI = 19) | 1 | unstabilized (0%) | 234.8 | |

| 5% | 315.8 | ||||

| 10% | 366.5 | ||||

| 15% | 358.9 | ||||

| 20% | 365.2 | ||||

| 25% | 435.1 | ||||

| 30% | 448 | ||||

| class C | CL | 7 | unstabilized (0%) | 200 | Trzebiatowski et al. [98] |

| 10% | 448 | ||||

| CL | 7 | unstabilized (0%) | 145 | ||

| 10% | 490 | ||||

| class C | CL | 7 | unstabilized (0%) | 212 | Bin-Shafique et al. [105] |

| 5% | 520 | ||||

| 10% | 713 | ||||

| 20% | 804 | ||||

| CH | 7 | unstabilized (0%) | 180 | ||

| 5% | 364 | ||||

| 10% | 456 | ||||

| 20% | 567 | ||||

| High-Ca fly ash | CI | 1 | unstabilized (0%) | - | Premkumar et al. [109] |

| 3% | 514 | ||||

| 6% | 536 | ||||

| 9% | 437 | ||||

| 12% | 388 | ||||

| CL | 1 | unstabilized (0%) | - | ||

| 3% | 401 | ||||

| 6% | 415 | ||||

| 9% | 445 | ||||

| 12% | 407 | ||||

| class C | CH | 1 | unstabilized (0%) | 182 | Mir and Sridharan [112] |

| 10% | 189 | ||||

| 7 | unstabilized (0%) | 202 | |||

| 10% | 446 | ||||

| 28 | unstabilized (0%) | 268.5 | |||

| 10% | 557 | ||||

| class C | CI | 1 | unstabilized (0%) | 226 | Turan et al. [113] |

| 30% | 295 | ||||

| 7 | unstabilized (0%) | 245 | |||

| 25% | 517 | ||||

| 28 | unstabilized (0%) | 235 | |||

| 25% | 599 |

| Type of Fly Ash | Type of Soil | Fly Ash Content | Free Swell Index (%) | Swell Potential (%) | Swell Pressure (kPa) | References |

|---|---|---|---|---|---|---|

| class F | CH | unstabilized (0%) | 250 | 10.8 | 90 | Kumar and Sharma [4] |

| 5% | 200 | 8.8 | 72 | |||

| 10% | 165 | 7.2 | 60 | |||

| 15% | 140 | 6.0 | 50 | |||

| 20% | 125 | 5.5 | 45 | |||

| Low-Ca fly ash | CH | unstabilized (0%) | 125 | - | 120 | Phanikumar and Nagaraju [5] |

| 5% | 118 | - | - | |||

| 10% | 100 | - | 105 | |||

| 15% | 85 | - | - | |||

| 20% | 70 | - | 60 | |||

| 25% | 50 | - | - | |||

| 30% | 35 | - | 20 | |||

| class F | CH | unstabilized (0%) | 165 | 26.7 | 330 | Phanikumar [79] |

| 10% | 130 | 13.9 | 90 | |||

| 20% | 110 | 8.9 | 74 | |||

| class C | CH (kaolinite) | unstabilized (0%) | 84 | - | 1116.19 | Kolay and Ramesh [83] |

| 10% | 75.7 | - | 755.31 | |||

| 20% | 70.8 | - | 514.72 | |||

| 30% | 64.5 | - | 240.71 | |||

| 40% | 59.1 | - | 150.40 | |||

| 50% | 54.8 | - | 75.13 | |||

| CH (bentonite) | unstabilized (0%) | 477.1 | - | 3522.1 | ||

| 10% | 340.8 | - | 3281.5 | |||

| 20% | 307.4 | - | 2680.0 | |||

| 30% | 273.3 | - | 2078.5 | |||

| 40% | 263.8 | - | 1356.8 | |||

| 50% | 246.9 | - | 1248.5 | |||

| class F | CH | unstabilized (0%) | - | 7.03 | 57.6 | Seyrek [60] |

| 30% | - | 2.58 | 25.5 | |||

| class C | CH | unstabilized (0%) | - | 7.03 | 57.6 | |

| 30% | - | 1.04 | 14.8 | |||

| class F | CL | unstabilized (0%) | - | 4.09 | 16.4 | |

| 30% | - | 1.39 | 7.9 | |||

| class C | CL | unstabilized (0%) | - | 4.09 | 16.4 | |

| 30% | - | 0.60 | 4.6 | |||

| class F | CL | unstabilized (0%) | 59.4 | - | - | Zhou et al. [84] |

| 20% | 35.3 | - | - | |||

| class F | CH (PI = 352) | unstabilized (0%) | 377 | 22 | 425 | Kate [118] |

| 20% | 260 | 11 | 305 | |||

| CH (PI = 307) | unstabilized (0%) | 326 | 17.5 | 345 | ||

| 20% | 214 | 8.7 | 207 | |||

| CH (PI = 215) | unstabilized (0%) | 230 | 13.7 | 259 | ||

| 20% | 105 | 6.8 | 185 | |||

| CH (PI = 116) | unstabilized (0%) | 168 | 9 | 167 | ||

| 20% | 116 | 4.7 | 110 | |||

| class C | CH | unstabilized (0%) | - | 19.6 | - | Nalbantoglu [58] |

| 15% | - | 5 | - | |||

| 25% | - | 3.7 | - | |||

| 25% (30 days cured) | - | 0 | - | |||

| class C | CH | unstabilized (0%) | 155 | 15.3 | 350 | Phanikumar et al. [125] |

| 5% | 124 | 13.5 | 270 | |||

| 10% | 110 | 12.7 | 330 | |||

| 15% | 83 | 12 | 380 | |||

| 20% | 77 | 11.4 | 290 | |||

| 25% | 77 | 10.3 | 420 |

| Type of Fly Ash | Type of Soil | Fly Ash Content | Compression Index (Cc) | Swelling Index (Cs) | References |

|---|---|---|---|---|---|

| class F | CH | unstabilized (0%) | 0.5 | - | Phanikumar [79] |

| 10% | 0.65 | - | |||

| 20% | 0.5 | - | |||

| class F | CH | unstabilized (0%) | 0.645 | - | Pal and Ghosh [81] |

| 50% | 0.271 | - | |||

| 60% | 0.200 | - | |||

| 70% | 0.125 | - | |||

| 80% | 0.071 | - | |||

| 100% | 0.112 | - | |||

| class C | CH (kaolinite) | unstabilized (0%) | 1.00 | 0.23 | Kolay and Ramesh [83] |

| 10% | 0.37 | 0.21 | |||

| 30% | 0.15 | 0.12 | |||

| 50% | 1.53 | 0.09 | |||

| CH (bentonite) | unstabilized (0%) | 1.07 | 0.21 | ||

| 10% | 1.23 | 0.14 | |||

| 30% | 1.54 | 0.11 | |||

| 50% | 1.42 | 0.07 | |||

| - | ML | unstabilized (0%) | 0.118 | - | Shil and Pal [89] |

| 20% | 0.063 | - | |||

| 30% | 0.056 | - | |||

| class F (1) | CL | unstabilized (0%) | 0.503 | 0.079 | Bryson et al. [119] |

| 10% | 0.508 | 0.080 | |||

| 20% | 0.377 | 0.043 | |||

| 40% | 0.432 | 0.069 | |||

| 100% | 0.041 | 0.017 | |||

| class F (2) | unstabilized (0%) | 0.503 | 0.079 | ||

| 10% | 0.472 | 0.073 | |||

| 20% | 0.425 | 0.064 | |||

| 40% | 0.354 | 0.044 | |||

| 100% | 0.096 | 0.013 | |||

| class F (3) | unstabilized (0%) | 0.503 | 0.079 | ||

| 10% | 0.508 | 0.090 | |||

| 20% | 0.431 | 0.063 | |||

| 40% | 0.356 | 0.044 | |||

| 100% | 0.065 | 0.013 | |||

| class C | unstabilized (0%) | 0.503 | 0.079 | ||

| 10% | 0.469 | 0.061 | |||

| 20% | 0.469 | 0.050 | |||

| 40% | 0.376 | 0.025 | |||

| 100% | 0.036 | 0.012 |

| Type of Fly Ash | Type of Soil | Fly Ash Content | Coefficient of Consolidation (cv) | Permeability (k) | References |

|---|---|---|---|---|---|

| Low-Ca fly ash | CH | unstabilized (0%) | - | 4.6 × 10−7 cm/s | Phanikumar and Nagaraju [5] |

| 10% | - | 6.0 × 10−7 cm/s | |||

| 20% | - | 8.5 × 10−7 cm/s | |||

| 30% | - | 1.8 × 10−6 cm/s | |||

| class F | CH | unstabilized (0%) | 0.32 × 10−3 cm2/s | 0.10 × 10−9 cm/s | Phanikumar [79] |

| 10% | 0.8 × 10−3 cm2/s | 1 × 10−9 cm/s | |||

| 20% | 2.71 × 10−3 cm2/s | 2.5 × 10−9 cm/s | |||

| class F | CH | unstabilized (0%) | 6.343 × 10−9 m2/s | 8.211 × 10−11 m/s | Pal and Ghosh [81] |

| 50% | 1.418 × 10−8 m2/s | 1.72 × 10−10 m/s | |||

| 60% | 2.005 × 10−8 m2/s | 3.63 × 10−10 m/s | |||

| 70% | 2.197 × 10−8 m2/s | 5.70 × 10−10 m/s | |||

| 80% | 0.026 × 10−4 m2/s | 9.44 × 10−10 m/s | |||

| 100% | 2.874 × 10−4 m2/s | 2 × 10−7 m/s | |||

| - | ML | unstabilized (0%) | 9.07 × 10−3 cm2/s | 3.38 × 10−6 cm/s | Shil and Pal [89] |

| 20% | 11.4 × 10−3 cm2/s | 3.43–2.21 × 10−6 cm/s | |||

| 30% | 13.4 × 10−3 cm2/s | 2.93–1.58 × 10−6 cm/s |

References

- Ramaji, A.E. A review on the soil stabilization using low-cost methods. J. Appl. Sci. Res. 2012, 8, 2193–2196. [Google Scholar]

- Rajpura, A.S.; Shah, B.R.; Dave, H.K. Review of Industrial Waste Used in Stabilization of Expansive Soil in Road Subgrade. Int. J. Adv. Res. Ideas Innov. Technol. 2017, 3, 1124–1127. [Google Scholar]

- Bandara, N.; Hettiarachchi, H.; Jensen, E.; Binoy, T.H. Upcycling Potential of Industrial Waste in Soil Stabilization: Use of Kiln Dust and Fly Ash to Improve Weak Pavement Subgrades Encountered in Michigan, USA. Sustainability 2020, 12, 7226. [Google Scholar] [CrossRef]

- Kumar, B.R.P.; Sharma, R.S. Effect of fly ash on engineering properties of expansive soils. J. Geotech. Geoenviron. Eng. 2004, 130, 764–767. [Google Scholar] [CrossRef]

- Phanikumar, B.R.; Nagaraju, T.V. Effect of Fly Ash and Rice Husk Ash on Index and Engineering Properties of Expansive Clays. Geotech. Geol. Eng. 2018, 36, 3425–3436. [Google Scholar] [CrossRef]

- Behnood, A. Soil and clay stabilization with calcium- and non-calcium-based additives: A state-of-the-art review of challenges, approaches and techniques. Transp. Geotech. 2018, 17, 14–32. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Zuber, S.Z.S.; Kamarudin, H.; Abdullah Binhussain, M.; Salwa, M.S.S. Review on Soil Stabilization Techniques. Aust. J. Basic Appl. Sci. 2013, 7, 258–265. [Google Scholar]

- Petry, T.; Little, D. Review of Stabilization of Clays and Expansive Soils in Pavements and Lightly Loaded Structures—History, Practice, and Future. J. Mater. Civ. Eng. 2002, 14, 447–460. [Google Scholar] [CrossRef]

- Kumar, T.A.; Thyagaraj, T.; Robinson, R.G. Swell–shrink behaviour of fly ash-stabilised expansive soils. Proc. Inst. Civ. Eng. Ground Improv. 2021; ahead of print. [Google Scholar] [CrossRef]

- Mahvash, S.; López-Querol, S.; Bahadori-Jahromi, A. Effect of fly ash on the bearing capacity of stabilised fine sand. Proc. Inst. Civ. Eng. Ground Improv. 2018, 171, 82–95. [Google Scholar] [CrossRef]

- Prabakar, J.; Dendorkar, N.; Morchhale, R. Influence of fly ash on strength behavior of typical soils. Constr. Build. Mater. 2004, 18, 263–267. [Google Scholar] [CrossRef]

- BS EN 1697-4; Earthworks Part 4: Soil Treatment with Lime and/or Hydraulic Binders. British Standard Institution: London, UK, 2018.

- Britpave. Soil Improvement and Soil Stabilization. Definitive Industry Guide. 2017. Available online: https://www.britpave.org.uk/Publications/Soil-Stabilisation/ (accessed on 7 December 2021).

- Raj, S.S.; Sharma, A.K.; Anand, K.B. Performance appraisal of coal ash stabilized rammed earth. J. Build. Eng. 2018, 18, 51–57. [Google Scholar] [CrossRef]

- Jafer, H.; Atherton, W.; Sadique, M.; Ruddock, F.; Loffill, A. Stabilisation of soft soil using binary blending of high calcium fly ash and palm oil fuel ash. Appl. Clay Sci. 2018, 152, 323–332. [Google Scholar] [CrossRef]

- Cheng, G.; Zhu, H.-H.; Wen, Y.-W.; Shi, B.; Gao, L. Experimental Investigation of Consolidation Properties of Nano-Bentonite Mixed Clayey Soil. Sustainability 2020, 12, 459. [Google Scholar] [CrossRef]

- Zimar, Z.; Robert, D.; Zhou, A.; Giustozzi, F.; Setunge, S.; Kodikara, J. Application of coal fly ash in pavement subgrade stabilisation: A review. J. Environ. Manag. 2022, 312, 114926. [Google Scholar] [CrossRef]

- Correa-Silva, M.; Araujo, N.; Cristelo, N.; Miranda, T.; Gomes, A.T.; Coelho, J. Improvement of a clayey soil with alkali activated low-calcium fly ash for transport infrastructures applications. Road Mater. Pavement Des. 2018, 20, 1912–1926. [Google Scholar] [CrossRef]

- Ghadir, P.; Ranjbar, N. Clayey soil stabilization using geopolymer and Portland cement. Constr. Build. Mater. 2018, 188, 361–371. [Google Scholar] [CrossRef]

- Ridtirud, C.; Leekongbub, S.; Chindaprasirt, P. Compressive Strength of Soil Cement Base Mixed with Fly Ash—Based Geopolymer. Int. J. GEOMATE 2018, 14, 82–88. [Google Scholar] [CrossRef]

- Firdous, R.; Stephan, D. Effect of silica modulus on the geopolymerization activity of natural pozzolans. Constr. Build. Mater. 2019, 219, 31–43. [Google Scholar] [CrossRef]

- Wong, B.; Wong, K.; Phang, I. A review on geopolymerisation in soil stabilization. IOP Conf. Ser. Mater. Sci. Eng. 2019, 495, 012070. [Google Scholar] [CrossRef]

- Nissanka, N.A.N.M.; Nimesha, K.M.D.; Nasvi, M.C.M. Prediction of Geotechnical Properties of Stabilized Soil Using Fly Ash Based Stabilizer Systems. ICSECM 2021, 2021, 160. [Google Scholar] [CrossRef]

- Asokan, P.; Saxena, M.; Asolekar, S.R. Coal combustion residues- environmental implications and recycling potentials. Resour. Conserv. Recycl. 2005, 43, 239–262. [Google Scholar] [CrossRef]

- Nawaz, I. Disposal and utilization of fly ash to protect the environment. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 5259–5266. [Google Scholar]

- Turan, C.; Javadi, A.; Vinai, R.; Cuisinier, O.; Russo, G.; Consoli, N.C. Mechanical Properties of Calcareous Fly Ash Stabilized Soil. In Proceedings of the EUROCOALASH Conference, Dundee, UK, 10–12 July 2019. [Google Scholar]

- Dharsini, M.K.; Akalya, K.; Ragul, P.S.; Sathyaseelan, K.; Narayanan, N.; Kumar, D.S. Enhancement of soil properties using bottom ash, fly ash and coconut ash—An application of waste to wealth. IOP Conf. Ser. Mater. Sci. Eng. 2020, 955, 012090. [Google Scholar] [CrossRef]

- Shaunik, D.; Gupta, S.S. Modification of Geotechnical Properties of Local Soil Mixed with Fly Ash. In Proceedings of the Indian Geotechnical Conference 2020, online, 17–19 December 2020. [Google Scholar]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Consoli, N.C.; Lopes, L.S.; Rosa, A.D.; Masuero, J.R. The strength of soil–industrial by-products–lime blends. Proc. Inst. Civ. Eng. Geotech. Eng. 2012, 5, 431–440. [Google Scholar] [CrossRef]

- Consoli, N.C.; Rocha, C.G.; Saldanha, R.B. Coal fly ash–carbide lime bricks: An environment friendly building product. Constr. Build. Mater. 2014, 69, 301–309. [Google Scholar] [CrossRef]

- Bin-Shafique, S.; Edil, T.; Benson, C.; Senol, A. Incorporating a fly-ash stabilised layer into pavement design. Proc. Inst. Civ. Eng. Geotech. Eng. 2004, 157, 239–249. [Google Scholar] [CrossRef]

- Amiralian, S.; Chegenizadeh, A.; Nikraz, H. A Review on the Lime and Fly ash Application in Soil Stabilization. Int. J. Biol. Ecol. Environ. Sci. 2012, 1, 3. [Google Scholar]

- Karim, M.A.; Hassan, A.S.; Kaplan, A. Optimization of Soil to Fly-Ash Mix Ratio for Enhanced Engineering Properties of Clayey Sand for Subgrade Use. Appl. Sci. 2020, 10, 7038. [Google Scholar] [CrossRef]

- Zimar, Z.; Robert, D.; Sidiq, A.; Zhou, A.; Giustozzi, F.; Setunge, S.; Kodikara, J. Waste-to-energy ash for treating highly expansive clays in road pavements. J. Clean. Prod. 2022, 374, 133854. [Google Scholar] [CrossRef]

- Dahale, P.; Nagarnaik, P.; Gajbhiye, A. Engineering Behavior of Remolded Expansive Soil with Lime and Flyash. Mater. Today Proc. 2017, 4, 10581–10585. [Google Scholar] [CrossRef]

- WWCCPN. Worldwide Coal Combustion Products Network. 2020. Available online: http://www.wwccpn.com/glossary.html (accessed on 7 December 2021).

- Kelly, R.P. Parallels and Nonconformities in Worldwide Fly Ash Classification: The Need for a Robust, Universal Classification System for Fly Ash. In Proceedings of the World of Coal Ash (WOCA) Conference, Nashville, TN, USA, 5–7 May 2015. [Google Scholar]

- ASTM C618-05; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2005. Available online: www.astm.org (accessed on 7 December 2021).

- Bhatt, A.; Priyadarshini, S.; Mohanakrishnan, A.A.; Abri, A.; Sattler, M.; Techapaphawit, S. Physical, chemical, and geotechnical properties of coal fly ash: A global review. Case Stud. Constr. Mater. 2019, 11, e00263. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Moghal, A.A.B. State-of-the-art Review on the Role of Fly Ashes in Geotechnical and Geoenvironmental Applications. J. Mater. Civ. Eng. 2017, 29, 04017072. [Google Scholar] [CrossRef]

- Ohenoja, K.; Pesonen, J.; Yliniemi, J.; Illikainen, M. Utilization of Fly Ashes from Fluidized Bed Combustion: A Review. Sustainability 2020, 12, 2988. [Google Scholar] [CrossRef]

- Ram, L.C.; Masto, R.E. Fly ash for soil amelioration: A review on the influence of ash blending with inorganic and organic amendments. Earth-Sci. Rev. 2014, 128, 52–74. [Google Scholar] [CrossRef]

- American Coal Ash Association (ACAA). Fly Ash Facts for Highway Engineers; Report No: FHWA-IF-03-019; American Coal Ash Association: Aurora, CO, USA, 2003. [Google Scholar]

- González, A.; Navia, R.; Moreno, N. Fly ashes from coal and petroleum coke combustion: Current and innovative potential applications. Waste Manag. Res. 2009, 27, 976–987. [Google Scholar] [CrossRef]

- Martin, J.P.; Collins, R.A.; Browning, J.S.; Biehl, F.J. Properties and Use of Fly Ashes for Embankments. J. Energy Eng. 1989, 116, 71–86. [Google Scholar] [CrossRef]

- Prakash, K.; Sridharan, A. Beneficial Properties of Coal Ashes and Effective Solid Waste Management. Pract. Period. Hazard. Toxic Radioact. Waste Manag. 2009, 13, 239–248. [Google Scholar] [CrossRef]

- Schure, M.R.; Soltys, P.A.; Natusch, D.F.S.; Mauney, T. Surface Area and Porosity of Coal Fly Ash. Environ. Sci. Technol. 1985, 19, 82–86. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R. Effects of Class C and Class F Fly Ash on Mechanical and Microstructural Behavior of Clay Soil—A Comparative Study. Materials 2022, 15, 1845. [Google Scholar] [CrossRef] [PubMed]

- Craig, R.F. Craig’s Soil Mechanics, 7th ed.; Spon Press-Taylor and Francis Group: London, UK, 2004. [Google Scholar]

- Toth, P.S.; Chan, H.T.; Cragg, C.B. Coal ash as structural fill, with special reference to Ontario experience. Can. Geotech. J. 1988, 25, 694–704. [Google Scholar] [CrossRef]

- McLaren, R.J.; Digioia, A.M. The typical engineering properties of fly ash. In Geotechnical Practice for Waste Disposal’87; ASCE: Reston, VA, USA, 1987; pp. 683–697. [Google Scholar]

- United States Geological Survey (USGS). Radioactive Elements in Coal and Fly Ash: Abundance, Forms, and Environmental Significance FS-163-97 Reston VA. 1997. Available online: https://pubs.usgs.gov/fs/1997/fs163-97/FS-163-97.html (accessed on 20 January 2022).

- World Nuclear Association. Naturally Occurring Radioactive Materials (NORM). 2020. Available online: https://www.world-nuclear.org/ (accessed on 20 January 2022).

- Sas, Z.; Vandevenne, N.; Doherty, R.; Vinai, R.; Kwasny, J.; Russell, M.; Sha, W.; Soutsos, M.; Schroeyers, W. Radiological evaluation of industrial residues for construction purposes correlated with their chemical properties. Sci. Total Environ. 2019, 658, 141–151. [Google Scholar] [CrossRef]

- Nalbantoğlu, Z. Effectiveness of Class C fly ash as an expansive soil stabilizer. Constr. Build. Mater. 2004, 18, 377–381. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Prashanth, J.P.; Sridharan, A.; Narayana, B.V. Reactive silica and strength of fly ashes. Geotech. Geol. Eng. 1998, 16, 239–250. [Google Scholar] [CrossRef]

- Seyrek, E. Engineering behaviour of clay soils stabilized with class C and class F fly ashes. Sci. Eng. Compos. Mater. 2016, 25, 273–287. [Google Scholar] [CrossRef]

- Panda, L.; Dash, S. Characterization and utilization of coal fly ash: A review. Emerg. Mater. Res. 2020, 9, 921–934. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly ash properties, characterization, and applications: A review. J. King Saud Univ. Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Consoli, N.C.; Filho, H.C.S.; Godoy, V.B.; Rosembach, C.M.D.C.; Carraro, A.H. Durability of reclaimed asphalt pavement–coal fly ash–carbide lime blends under severe environmental conditions. Road Mater. Pavement Des. 2018, 21, 557–569. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency Office of Solid Waste. Human and Ecological Risk Assessment of Coal Combustion Wastes; Report No. NC 27709; U.S. Environmental Protection Agency Office of Solid Waste: Washington, DC, USA, 2007.

- Borm, P.J.A. Toxicity and occupational health hazards of coal fly ash (CFA). A review of data and comparison to coal mine dust. Ann. Occup. Hyg. 1997, 41, 659–676. [Google Scholar] [CrossRef]

- Lokeshappa, B.; Dikshit, A.K. Disposal and Management of Fly ash. IPCBEE 2011, 3. [Google Scholar]

- Artiola, J.F. Industrial Waste and Municipal Solid Waste Treatment and Disposal. In Environmental and Pollution Science; Academic Press: Cambridge, MA, USA, 2019; pp. 377–391. [Google Scholar] [CrossRef]

- Sun, X.; Li, J.; Zhao, X.; Zhu, B.; Zhang, G. A review on the management of municipal solid waste fly ash in American. Procedia Environ. Sci. 2016, 31, 535–540. [Google Scholar] [CrossRef]

- Harris, D.; Feuerborn, H.-J.; Heidrich, C. Global Aspects on Coal Combustion Products. In Proceedings of the EUROCOALASH Conference, Dundee, UK, 10–12 July 2019. [Google Scholar]

- Sifton, J.B.; Arato, C. 2020 to 2070 and Beyond: Transitioning from Production to Post-production Coal Ash Use. In Proceedings of the EUROCOALASH Conference, Dundee, UK, 10–12 July 2019. [Google Scholar]

- UKQAA United Kingdom Quality Ash Association. 2020. Available online: http://www.ukqaa.org.uk/ (accessed on 10 January 2022).

- Boral Resources, Fly Ash Slides for Investors. 2018. Available online: https://www.boral.com.au/products/cement-and-lime/bulk-cement-fly-ash-and-slag/fly-ash (accessed on 10 January 2022).

- Kumar, S.; Patil, C. Estimation of Resource Savings Due to Fly Ash Utilization in Road Construction. Resour. Conserv. Recycl. 2006, 48, 125–140. [Google Scholar] [CrossRef]

- Geomax Soil Stabilization, Cost Comparison. 2022. Available online: http://www.geomaxsoil.com/cost-comparison/ (accessed on 29 November 2022).

- Suryawanshi, N.T.; Bansode, S.S.; Nemade, P.D. Use of Eco-friendly Material like Fly Ash in Rigid Pavement Construction & It’s Cost Benefit Analysis. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 795–800. [Google Scholar]

- Ji-ru, Z.; Xing, C. Stabilization of expansive soil by lime and fly ash. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2002, 17, 73–77. [Google Scholar] [CrossRef]

- Parsons, R.L.; Kneebone, E. Field performance of fly ash stabilised subgrades. Proc. Inst. Civ. Eng. Ground Improv. 2005, 9, 33–38. [Google Scholar] [CrossRef]

- Zha, F.; Liu, S.; Du, Y.; Cui, K. Behavior of expansive soils stabilized with fly ash. Nat. Hazards 2008, 47, 509–523. [Google Scholar] [CrossRef]

- Phanikumar, B. Effect of lime and fly ash on swell, consolidation and shear strength characteristics of expansive clays: A comparative study. Geomech. Geoengin. 2009, 4, 175–181. [Google Scholar] [CrossRef]

- Mir, B.; Sridharan, A. Physical and Compaction Behaviour of Clay Soil–Fly Ash Mixtures. Geotech. Geol. Eng. 2013, 31, 1059–1072. [Google Scholar] [CrossRef]

- Pal, S.; Ghosh, A. Volume Change Behavior of Fly Ash–Montmorillonite Clay Mixtures. Int. J. Geomech. 2014, 14, 59–68. [Google Scholar] [CrossRef]

- Binal, A. The Effects of High Alkaline Fly Ash on Strength Behaviour of a Cohesive Soil. Adv. Mater. Sci. Eng. 2016, 2016, 3048716. [Google Scholar] [CrossRef]

- Kolay, P.; Ramesh, K. Reduction of Expansive Index, Swelling and Compression Behavior of Kaolinite and Bentonite Clay with Sand and Class C Fly Ash. Geotech. Geol. Eng. 2016, 34, 87–101. [Google Scholar] [CrossRef]

- Zhou, S.; Zhou, D.; Zhang, Y.; Wang, W. Study on Physical-Mechanical Properties and Microstructure of Expansive Soil Stabilized with Fly Ash and Lime. Adv. Civ. Eng. 2019, 2019, 4693757. [Google Scholar] [CrossRef]

- Striprabu, S.; Siti, N.L.T.; Norazzlina, M.S.; Fauziah, A. Chemical Stabilization of Sarawak Clay Soil with Class F fly Ash. J. Eng. Sci. Technol. 2018, 13, 3029–3042. [Google Scholar]

- Çokça, E. Use of Class C Fly Ashes for the Stabilization of an Expansive Soil. J. Geotech. Geoenviron. Eng. 2001, 128, 966. [Google Scholar] [CrossRef]

- Senol, A.; Edil, T.; Bin-Shafique, M.; Acosta, H.; Benson, C. Soft subgrades’ stabilization by using various fly ashes. Resour. Conserv. Recycl. 2006, 46, 365–376. [Google Scholar] [CrossRef]

- Santos, F.; Li, L.; Li, Y.; Amini, F. Geotechnical Properties of Fly Ash and Soil Mixtures for Use in Highway Embankments. In Proceedings of the World of Coal Ash (WOCA) Conference, Denver, CO, USA, 9–12 May 2011. [Google Scholar]

- Shil, S.; Pal, S.K. Permeability and Volume Change Behaviour of Soil Stabilized with Fly Ash. Int. J. Eng. Res. Technol. 2015, 4, 840–846. [Google Scholar]

- Nath, B.; Molla, M.; Sarkar, G. Study on Strength Behavior of Organic Soil Stabilized with Fly Ash. Int. Sch. Res. Not. 2017, 2017, 5786541. [Google Scholar] [CrossRef]

- Savaş, H.; Türköz, M.; Seyrek, E.; Ünver, E. Comparison of the effect of using class C and F fly ash on the stabilization of dispersive soils. Arab. J. Geosci. 2018, 11, 612. [Google Scholar] [CrossRef]

- Rajak, T.R.; Yadu, L.; Pal, S.K. Analysis of slope stability of fly ash stabilized soil slope. Geotech. Appl. 2019, 4, 119–126. [Google Scholar] [CrossRef]

- Siddiqua, S.; Barreto, P.N.M. Chemical stabilization of rammed earth using calcium carbide residue and fly ash. Constr. Build. Mater. 2018, 169, 364–371. [Google Scholar] [CrossRef]

- Mackiewicz, S.M.; Ferguson, E.G. Stabilizing of Soil with Self-Cementing Coal Ashes. In Proceedings of the World of Coal Ash Conference, Lexington, KY, USA, 11–15 April 2005. [Google Scholar]

- Mahvash, S.; Lopez-Querol, S.; Bahadori-Jahromi, A. Effect of class F fly ash on fine sand compaction through soil stabilization. Heliyon 2017, 3, e00274. [Google Scholar] [CrossRef]

- Hosamani, S.R.; Hulagabali, A.M. Comparative study on stabilization of expansive soil using fly ash, rice husk ash, bagasse ash & marble dust. In Proceedings of the International Conference on Soil and Environment, Bangalore, India, 22–23 July 2016. [Google Scholar]

- Than, S.N.; Zaw, T. Study on Stabilization of Expansive Soil with Fly-ash. IRE J. 2019, 3, 395–399. [Google Scholar]

- Trzebiatowski, B.D.; Edil, T.B.; Benson, C.H. Case study of subgrade stabilisation using fly ash: State Highway 32, Port Washington, Wisconsin. In Proceedings of the Recycled Material in Geotechnics at ASCE Civil Engineering Conference, Baltimore, MD, USA, 19–21 October 2004. [Google Scholar]

- Bowles, J.E. Engineering Properties of Soils and Their Measurement; McGraw-Hill: New York, NY, USA, 1992. [Google Scholar]

- Edil, T.; Acosta, H.; Benson, C. Stabilizing Soft Fine-Grained Soils with Fly Ash. J. Mater. Civ. Eng. 2006, 18, 283–294. [Google Scholar] [CrossRef]

- Jose, J.; Jose, A.; Kurian, J.M.; Francis, K.J.; James, S.K. Stabilization of expansive soil using fly ash. Int. Res. J. Eng. Technol. 2018, 5, 3075–3078. [Google Scholar]

- Sharma, L.; Singh, T. Regression-based models for the prediction of unconfined compressive strength of artificially structured soil. Eng. Comput. 2017, 34, 175–186. [Google Scholar] [CrossRef]

- Senol, A.; Bin-Shafique, M.; Edil, T.; Benson, C. Use of class C fly ash for stabilization of soft subgrade. In Proceedings of the Fifth International Congress on Advances in Civil Engineering, Istanbul, Turkey, 25–27 September 2002. [Google Scholar]

- Sezer, A.; İnan, G.; Yılmaz, H.; Ramyar, K. Utilization of a very high lime fly ash for improvement of Izmir clay. Build. Environ. 2006, 41, 150–155. [Google Scholar] [CrossRef]

- Bin-Shafique, S.; Rahman, K.; Yaykiran, M.; Azfar, I. The long-term performance of two fly ash stabilized fine-grained soil subbases. Resour. Conserv. Recycl. 2009, 54, 666–672. [Google Scholar] [CrossRef]

- Kolias, S.; Kasselouri-Rigopoulou, V.; Karahalios, A. Stabilisation of clayey soils with high calcium fly ash and cement. Cem. Concr. Compos. 2005, 27, 301–313. [Google Scholar] [CrossRef]

- Silitonga, E.; Levacher, D.; Mezazigh, S. Effects of the use of fly ash as a binder onthe mechanical behaviour of treated dredged sediments. Environ. Technol. 2009, 30, 799–807. [Google Scholar] [CrossRef]

- Tastan, E.O.; Edil, T.B.; Benson, C.H.; Aydilek, A.H. Stabilization of Organic Soils with Fly Ash. J. Geotech. Geoenvironmental Eng. 2011, 137, 819–833. [Google Scholar] [CrossRef]

- Premkumar, S.; Piratheepan, J.; Rajeev, P. Effect of brown coal fly ash on dispersive clayey soils. Proc. Inst. Civ. Eng. Ground Improv. 2017, 170, 231–244. [Google Scholar] [CrossRef]

- Samidurai, V.; Gokulan, Y.; Krishnan, N. Influence of Fly ash on expansive Soils. Int. J. Emerg. Trends Sci. Technol. 2017, 3, 4998–5003. [Google Scholar] [CrossRef]

- Efthymiou, S.; Anagnostopoulos, A.; Kavvadas, M. Effect of fly ash on the behaviour of a high plasticity clay. In Proceedings of the XVII ECSMGE-2019, Reykjavík, Iceland, 1–6 September 2019. [Google Scholar] [CrossRef]

- Mir, B.; Sridharan, A. Mechanical behaviour of fly-ash-treated expansive soil. Proc. Inst. Civ. Eng. Ground Improv. 2019, 172, 12–24. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.; Vinai, R.; Shariatmadari, N.; Farmani, R. Use of class C fly ash for stabilization of fine-grained soils. In Proceedings of the EUNSAT conference, Lisbon, Portugal, 19–21 October 2020. [Google Scholar]

- Turan, C.; Javadi, A.A.; Vinai, R.; Russo, G. Effects of Fly Ash Inclusion and Alkali Activation on Physical, Mechanical, and Chemical Properties of Clay. Materials 2022, 15, 4628. [Google Scholar] [CrossRef]

- Kumar, P.G.; Harika, S. Stabilization of expansive subgrade soil by using fly ash. Mater. Today Proc. 2021, 45, 6558–6562. [Google Scholar] [CrossRef]

- Feng, M.; Liu, S.; Wang, J.; Hu, Y. Influence of stabilisers on the unconfined compressive strength of a fine soil. Geotech. Res. 2020, 7, 209–217. [Google Scholar] [CrossRef]

- Tamang, P.; Sriskantharajah, A.; Ferreira, P.; Lopez-Querol, S. Experimental evaluation of kaolin stabilised with class F fly ash. Bull. Eng. Geol. Environ. 2021, 80, 6781–6798. [Google Scholar] [CrossRef]

- Kate, J.M. Strength and Volume change Behavior of Expansive soils treated with Fly Ash. In Proceedings of the Geo-Frontiers Congress, Austin, TX, USA, 24–26 January 2005. [Google Scholar] [CrossRef]

- Bryson, L.S.; Mahmoodabadi, M.; Adu-Gyamfi, K. Prediction of Consolidation and Shear Behavior of Fly Ash–Soil Mixtures Using Mixture Theory. J. Mater. Civ. Eng. 2017, 29, 04017222. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H.; Sabbar, A. Effect of fly ash on liquefaction behaviour of sand-bentonite mixture. Soils Found. 2018, 58, 1288–1296. [Google Scholar] [CrossRef]

- Phanikumar, B.; Sharma, R. Volume Change Behavior of Fly Ash-Stabilized Clays. J. Mater. Civ. Eng. 2007, 19, 67–74. [Google Scholar] [CrossRef]

- Amiralian, S.; Chegenizadeh, A.; Nikraz, H. Laboratory Investigation on the Effect of Fly Ash on the Compressibility of Soil. In Proceedings of the International Conference on Civil and Architectural Applications, Phuket, Thailand, 18–19 December 2012. [Google Scholar]

- Mir, B.; Sridharan, A. Volume change behavior of clayey soil–fly ash mixtures. Int. J. Geotech. Eng. 2014, 8, 72–83. [Google Scholar] [CrossRef]

- Vindula, S.K.; Chavali, R.V.P.; Reddy, P.H.P. Role of fly ash in control of alkali induced swelling in kaolinitic soils: A microlevel investigation. Int. J. Geotech. Eng. 2016, 12, 46–52. [Google Scholar] [CrossRef]

- Phanikumar, B.R.; Dembla, S.; Yatindra, A. Swelling Behaviour of an Expansive Clay Blended with Fine Sand and Fly Ash. Geotech. Geol. Eng. 2021, 39, 583–591. [Google Scholar] [CrossRef]

- Kassim, K.A.; Chow, S.H. Consolidation Characteristics of Lime Stabilized Soil. Malays. J. Civ. Eng. 2000, 12, 31–42. [Google Scholar]

- Chew, S.; Kamruzzaman, A.; Lee, F. Physicochemical and Engineering Behavior of Cement Treated Clays. J. Geotech. Geoenviron. Eng. 2004, 130, 696–706. [Google Scholar] [CrossRef]

- U.S. Federal Highway Administration (FHWA). Fly Ash Facts for Highway Engineers; Report No. FHWA-IF-03-019; U.S. Federal Highway Administration: Washington, DC, USA, 2003.

- ASTM D7762-18; Standard Practice for Design of Stabilization of Soil and Soil-Like Materials with Self-Cementing Fly Ash. ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 7 December 2021).

- Bhuvaneshwari, S.; Robinson, R.G.; Gandhi, S.R. Fly Ash Utilization Programme (FAUP) TIFAC, DST; TIFAC: New Delhi, India, 2005. [Google Scholar]

- Li, L.; Edil, T.B.; Benson, C.H. Mechanical Performance of Pavement Geomaterials Stabilized with Fly Ash in Field Applications. Coal Combust. Gasif. Prod. 2009, 1, 43–49. [Google Scholar] [CrossRef]

- Sinha, A.K.; Havanagi, V.G.; Mahtur, S.; Guruvittal, U.K. Investigation and design of a fly ash road embankment in India by CPT. In Proceedings of the 2nd International Conference on CPT, Huntington Beach, CA, USA, 9–12 May 2010. [Google Scholar]

| Country | CCPs Production (Mt) | CCPs Utilization (Mt) | Utilization Rate (%) |

|---|---|---|---|

| USA | 107.4 | 60.1 | 56 |

| China | 565 | 396 | 70.1 |

| Korea | 10.3 | 8.8 | 85.4 |

| India | 197 | 132 | 67.1 |

| Japan | 12.3 | 12.3 | 99.3 |

| Other Asian countries | 18.2 | 12.3 | 67.6 |

| Europe (EU15) | 40.3 | 38 | 94.3 |

| Middle East & Africa | 32.2 | 3.4 | 10.6 |

| Israel | 1.1 | 1 | 90.9 |

| Canada | 4.8 | 2.6 | 54.2 |

| Russia | 21.3 | 5.8 | 27.2 |

| Australia | 12.3 | 5.4 | 43.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turan, C.; Javadi, A.A.; Vinai, R.; Beig Zali, R. Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review. Sustainability 2022, 14, 16710. https://doi.org/10.3390/su142416710

Turan C, Javadi AA, Vinai R, Beig Zali R. Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review. Sustainability. 2022; 14(24):16710. https://doi.org/10.3390/su142416710

Chicago/Turabian StyleTuran, Canan, Akbar A. Javadi, Raffaele Vinai, and Ramiz Beig Zali. 2022. "Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review" Sustainability 14, no. 24: 16710. https://doi.org/10.3390/su142416710

APA StyleTuran, C., Javadi, A. A., Vinai, R., & Beig Zali, R. (2022). Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review. Sustainability, 14(24), 16710. https://doi.org/10.3390/su142416710