Optimum Fluid Content in Pavement Cold In-Place Recycling Containing Waste Materials

Abstract

1. Introduction

2. Materials and Methods

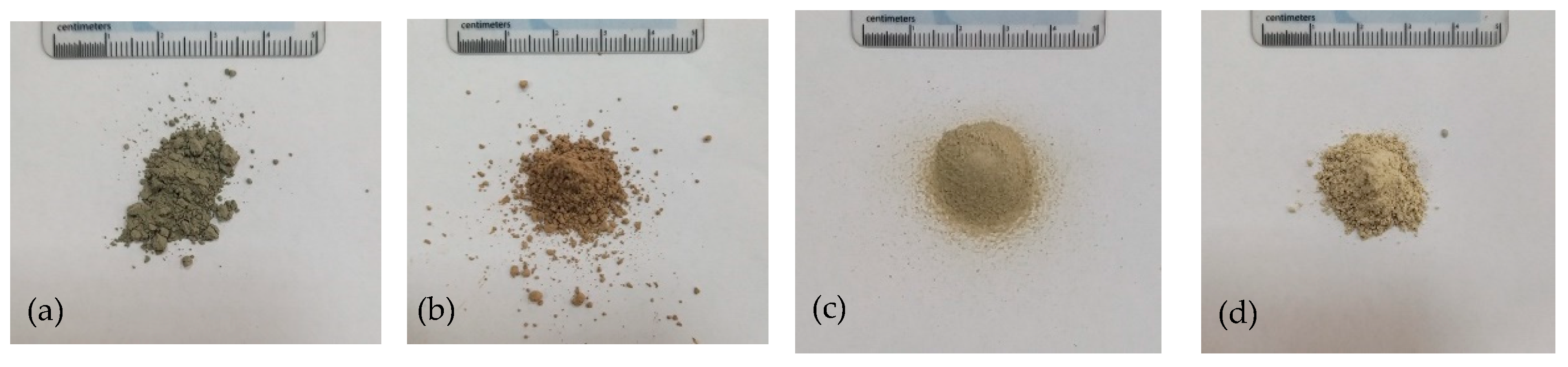

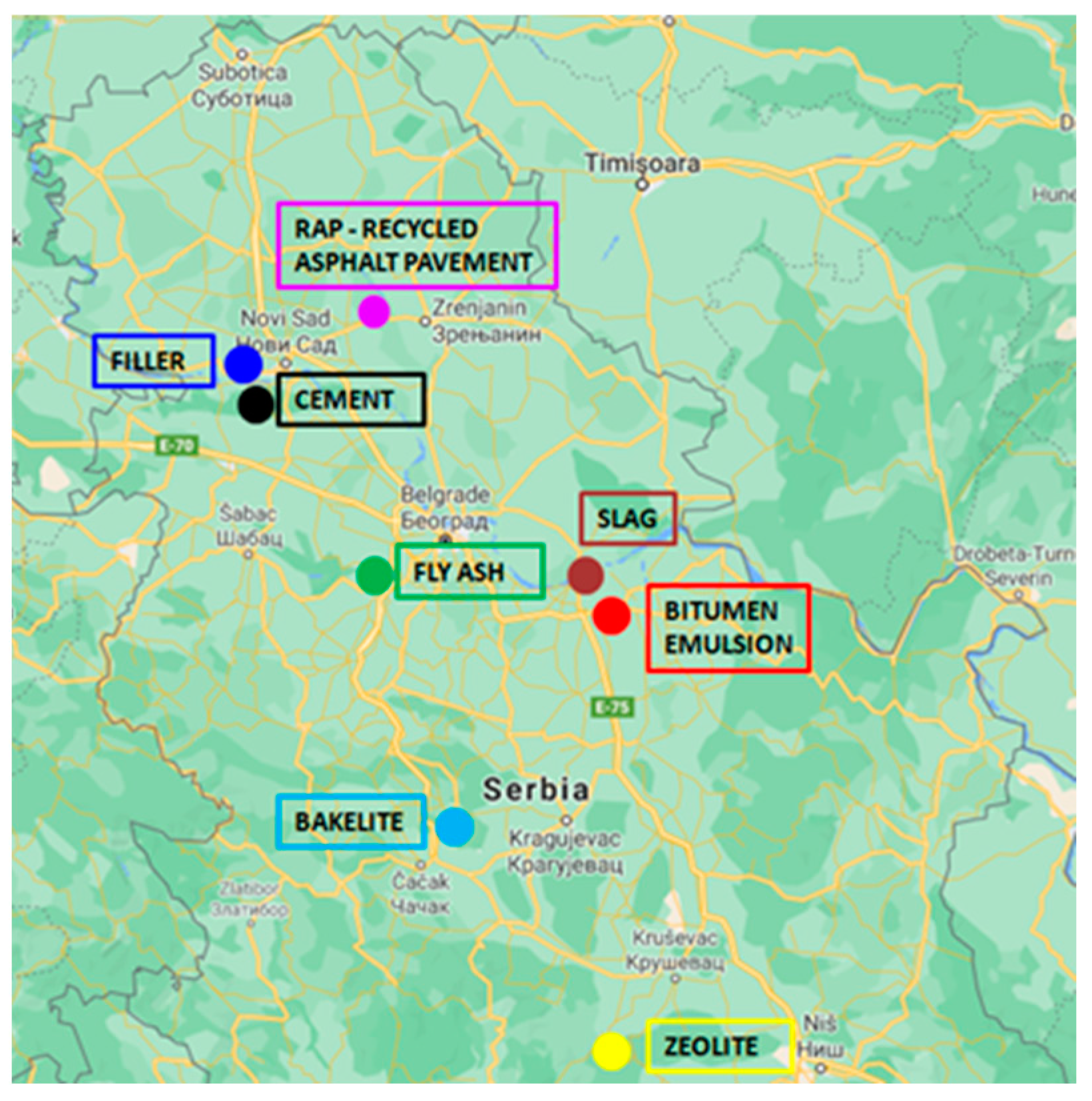

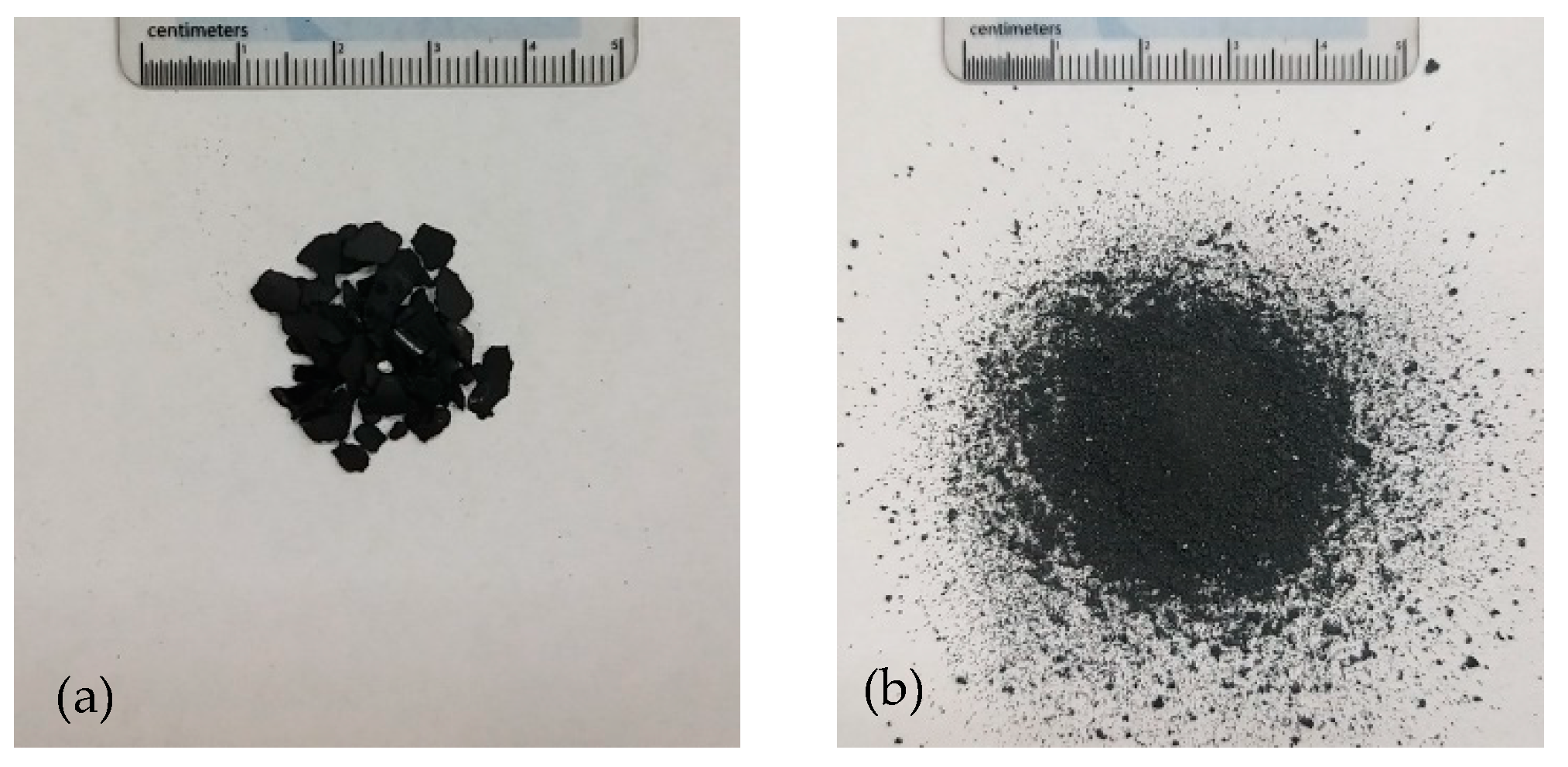

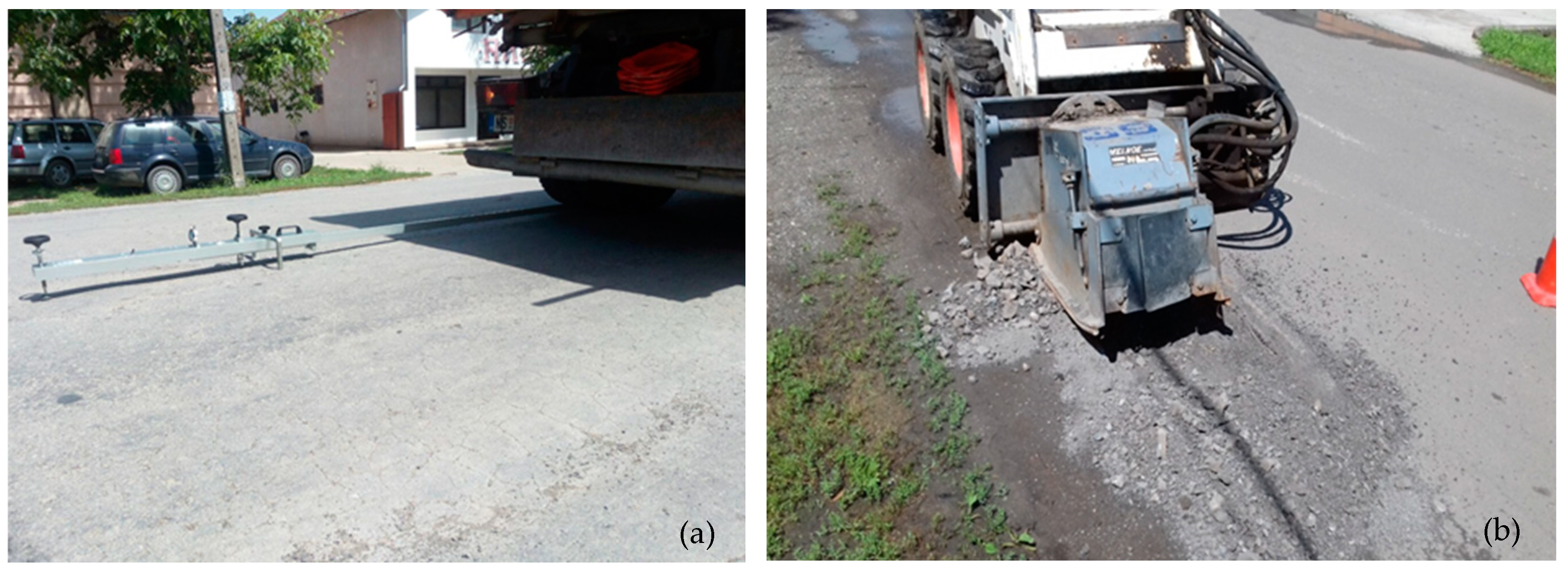

2.1. Component Materials

- Homogenous section 1 (chainage: from km 0 + 000 to 0 + 200);

- Homogenous section 2 (chainage: from km 0 + 200 to 0 + 400);

- Homogenous section 3 (chainage: from km 0 + 400 to 1 + 160).

2.2. Mixture Compositions and Methodology

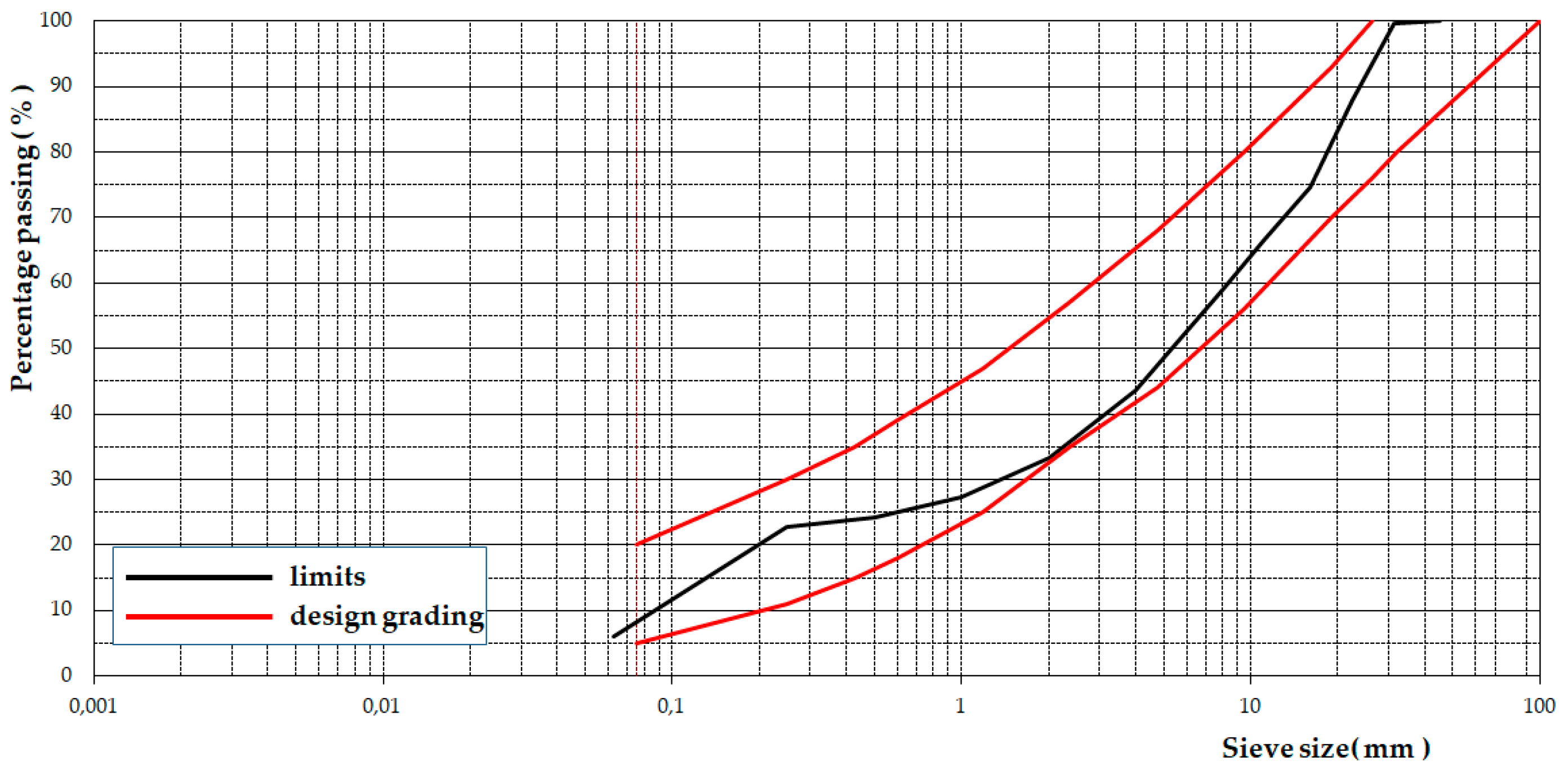

- Testing of sampled RAP and possible correction of granulometric composition;

- Determining OFC;

- Determination of mechanical characteristics of samples made with optimum fluid content (ITS, etc.).

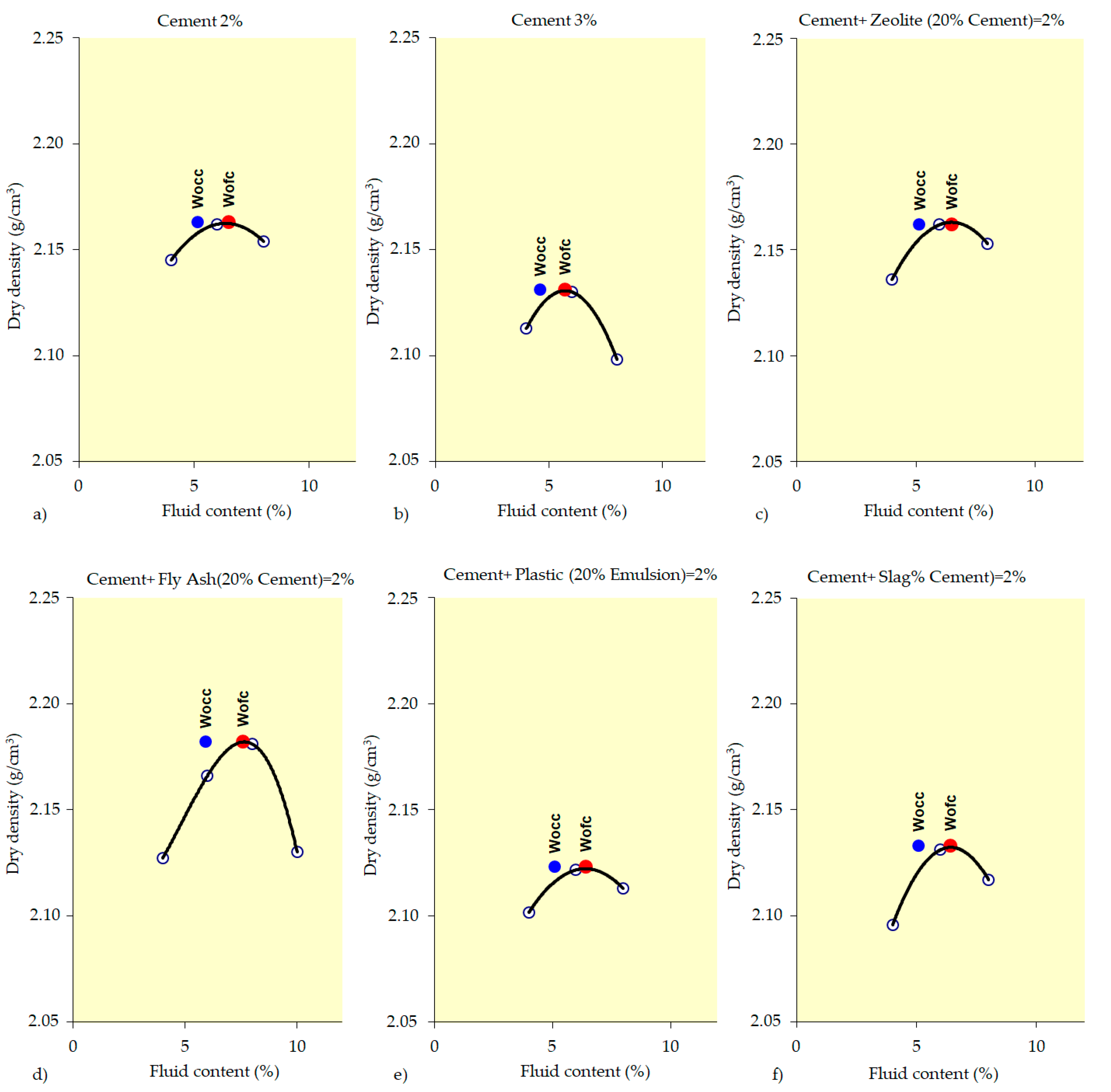

- WOCC—Water content for optimum compaction and workability (% by mass)

- WOFC—Optimum fluid content—OFC (% by mass);

- WRED—Reduction amount (% by mass).

3. Test Results and Discussion

4. Conclusions

- Mixtures with 3% cement had the lowest optimal content (5.7%), while the mixture with the addition of fly ash had the highest one (7.6%) and the highest value of dry density (2.182 g/cm3) in comparison with the remaining tested mixtures;

- The mixture containing bakelite had the lowest maximum dry density (2.123 g/cm3) of all tested mixtures;

- With an increase in cement content from 2% to 3% percent, there was a decrease in OFC of cca 25%;

- The mixture with 2% cement and the mixture containing 20% natural zeolite as a partial replacement for cement, had the same OFC (6.5%) and approximately the same maximum dry density value;

- The mixture with slag had a slightly lower value of OFC (for cca 2%), while the mixture with fly ash had a higher value of OFC (for cca 17%) compared with the mixture with 2% cement;

- The mixture containing bakelite had the same OFC (6.4%) as the mixture with added slag and similar maximum dry density values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sadigov, R. Rapid Growth of the World Population and Its Socioeconomic Results. Sci. World J. 2022, 2022, 8110229. [Google Scholar] [CrossRef] [PubMed]

- Meijer, J.R.; Huijbregts, M.A.J.; Schotten, K.C.G.J.; Schipper, A.M. Global patterns of current and future road infrastructure. Environ. Res. Lett. 2018, 13, 064006. [Google Scholar] [CrossRef]

- Muneer, T.; García, I.I. 1—The automobile. In Electric Vehicles: Prospects and Challenges; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–91. ISBN 9780128030219. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, L.; Zhai, J.; Huang, W. A review of design methods for cold in-place recycling asphalt mixtures: Design processes, key parameters, and evaluation. J. Clean. Prod. 2022, 370, 133530. [Google Scholar] [CrossRef]

- Thom, N.; Dawson, A. Sustainable Road Design: Promoting Recycling and Non-Conventional Materials. Sustainability 2019, 11, 6106. [Google Scholar] [CrossRef]

- Gu, F.; Ma, W.; West, R.C.; Taylor, A.J.; Zhang, Y. Structural performance and sustainability assessment of cold central-plant and in-place recycled asphalt pavements: A case study. J. Clean. Prod. 2019, 208, 1513–1523. [Google Scholar] [CrossRef]

- López, C.; González, A.; Thenoux, G.; Sandoval, G.; Marcobal, J. Stabilized emulsions to produce warm asphalt mixtures with reclaimed asphalt pavements. J. Clean. Prod. 2019, 209, 1461–1472. [Google Scholar] [CrossRef]

- Zarrinkamar, B.T.; Modarres, A. Optimizing the asphalt pavement cold in-place recycling process containing waste pozzolans based on economic-environmental-technical criteria. J. Clean. Prod. 2020, 242, 118505. [Google Scholar] [CrossRef]

- Asphalt Recycling and Reclaiming Association (ARRA). Basic Asphalt Recycling Manual; Asphalt Recycling and Reclaiming Association (ARRA): Glen Ellyn, IL, USA, 2001; pp. 1–302. [Google Scholar]

- Dughaishi, H.A.; Lawati, J.A.; Bilema, M.; Babalghaith, A.M.; Mashaan, N.S.; Yusoff, N.I.M.; Milad, A. Encouraging Sustainable Use of RAP Materials for Pavement Construction in Oman: A Review. Recycling 2022, 7, 35. [Google Scholar] [CrossRef]

- Tebaldi, G.; Dave, E.; Marsac, P.; Muraya, P.; Hugener, M.; Pasetto, M.; Graziani, A.; Grilli, A.; Marradi, A.; Wendling, L.; et al. Classification of recycled asphalt (RA) material. In Proceedings of the 2nd International Symposium on Asphalt Pavement and Environment, France, October 2012; pp. 1–14. Available online: https://hal.archives-ouvertes.fr/hal-00849456 (accessed on 11 October 2022).

- Oke, O.L.; Aribisala, J.O.; Ogundipe, O.M.; Akinkurolere, O.O. Recycling of Asphalt Pavement for Accelerated and Sustainable Road Development in Nigeria. Int. J. Sci. Technol. Res. 2013, 2, 92–98. [Google Scholar]

- PIARC—World Road Association. Review of the Growth and Development of Recyclingin Pavement Construction; PIARC—World Road Association: Paris, France, 2008; 203p. [Google Scholar]

- Al-Qadi, I.L.; Cao, Q.; Abufares, L.; Wang, S.; Ali, U.M.; Renshaw, G. Moisture Content and In-Place Density of Cold-Recycling Treatments; ICT PROJECT R27-227; Illinois Center for Transportation Series No. 22-007; Illinois Center for Transportation: Rantoul, IL, USA, 2022. [Google Scholar] [CrossRef]

- European Asphalt Pavement Association (EAPA). Asphalt the 100% Recyclable Construction Product; EAPA Position Paper; European Asphalt Pavement Association (EAPA): Brussels, Belgium, 2014; pp. 1–21. [Google Scholar]

- Konrad, M.; Simnofske, D.; Valentin, J.; Čížková, Z.; Suda, J.; Batista, F.; McNally, C. Mix Designs for Cold Recycled Pavement Materials Considering Local Weather and Traffic Conditions. In Proceedings of the E&E Congress 2016 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef][Green Version]

- Mignini, C.; Cardone, F.; Graziani, A. Complex modulus of cement-bitumen treated materials produced with different reclaimed asphalt gradations. Mater. Struct. 2022, 55, 169. [Google Scholar] [CrossRef]

- Mignini, C.; Cardone, F.; Graziani, A. Using fine aggregate matrix mortars to predict the curing behaviour of cement bitumen treated materials produced with different cements. Constr. Build. Mater. 2021, 268, 121201. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Flatt, R.J.; Roussel, N.; Cheeseman, C.R. Concrete: An Eco Material That Needs to Be Improved. J. Eur. Ceram. Soc. 2012, 32, 2787–2798. [Google Scholar] [CrossRef]

- Liu, Y.; Su, Y.; Xu, G.; Chen, Y.; You, G. Research Progress on Controlled Low-Strength Materials: Metallurgical Waste Slag as Cementitious Materials. Materials 2022, 15, 727. [Google Scholar] [CrossRef]

- Najimi, M.; Sobhani, J.; Ahmadi, B.; Shekarchi, M. An Experimental Study on Durability Properties of Concrete Containing Zeolite as a Highly Reactive Natural Pozzolan. Constr. Build. Mater. 2012, 35, 1023–1033. [Google Scholar] [CrossRef]

- Uysal, M.; Akyuncu, V. Durability performance of concrete incorporating Class F and Class C fly ashes. Constr. Build. Mater. 2012, 34, 170–178. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Onuralp Özkılıç, Y.; Karalar, M.; Ihsan Çelik, A.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef] [PubMed]

- Vejmelková, E.; Koňáková, D.; Kulovaná, T.; Keppert, M.; Žumár, J.; Rovnaníková, P.; Keršner, Z.; Sedlmajer, M.; Černý, R. Engineering properties of concrete containing natural zeolite as supplementary cementitious material: Strength, toughness, durability and hygrothermal performance. Cem. Concr. Compos. 2015, 55, 259–267. [Google Scholar] [CrossRef]

- Ranjbar, M.M.; Madandoust, R.; Mousavi, S.Y.; Yosefi, S. Effects of nautral zeolite on the fresh and hardened properties of self-compacted concrete. Constr. Build. Mater. 2013, 47, 806–813. [Google Scholar] [CrossRef]

- Ihsan Çelik, A.; Onuralp Özkılıç, Y.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- Qaidi, S.; Mohammed Najm, H.; Abed, S.M.; Onuralp Özkılıç, Y.; Al Dughaishi, H.; Alosta, M.; Sabri Sabri, M.M.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef] [PubMed]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Onuralp Özkiliç, Y.; Sabri Sabri, M.M. Use of recycled coal bottom ash in reinforced concrete beams as replacement for aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Onuralp Özkılıç, Y.; İhsan Çelik, A.; Deifalla, A.F.; Ahmad, M.; Sabri Sabri, M.M. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 1057128. [Google Scholar] [CrossRef]

- Ihsan Çelik, A.; Onuralp Özkılıç, Y.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance Assessment of Fiber-Reinforced Concrete Produced with Waste Lathe Fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Karalar, M.; Onuralp Özkılıç, Y.; Deifalla, A.F.; Aksoylu, C.; Arslan, M.H.; Ahmad, M.; Sabri Sabri, M.M. Improvement in Bending Performance of Reinforced Concrete Beams Produced with Waste Lathe Scraps. Sustainability 2022, 14, 12660. [Google Scholar] [CrossRef]

- Wei, H.; Zhou, W.; Sun, J. Applied Research on Foamed Asphalt Cold-regenerating Technique in Overhaul Engineering of Binshi Expressway. Appl. Mech. Mater. 2014, 477–478, 898–903. [Google Scholar] [CrossRef]

- Bessa, I.S.; Almeida, L.R.; Vasconcelos, K.L.; Bernucci, L.L.B. Design of Cold Recycled Mixes with Asphalt Emulsion and Portland Cement. Can. J. Civ. Eng. 2016, 43, 773–782. [Google Scholar] [CrossRef]

- Jenkins, K.J.; Robroch, S.; Henderson, M.G.; Wilkinson, J.; Molenaar, A.A.A. Advanced Testing for Cold Recycling Treatment Selection on N7 near Cape Town. In Proceedings of the 8th Conference on Asphalt Pavements for Southern Africa, (CAPSA’04), Sun City, South Africa, 12–16 September 2004. [Google Scholar]

- Yan, K.; Yang, K.; Long, Z.; Miljković, M.; Zhou, W.; Liu, K.; You, L. Influence of alternative rice husk ash filler on bitumen emulsion-based recycled asphalt. Road Mater. Pavement Des. 2022, 23, 2081253. [Google Scholar] [CrossRef]

- Zhao, H.; Su, J.; Ma, S.; Su, C.; Wang, X.; Li, Z.; Wei, J.; Cui, S. Study on Cold Recycled Asphalt Mixtures with Emulsified/Foamed Asphalt in the Laboratory and On-Site. Coatings 2022, 12, 1009. [Google Scholar] [CrossRef]

- Smiljanić, M.; Pap, I.; Tatić, U. The Application of Cold Asphalt Recycling as a Factor of the Environmental Protection. In Proceedings of the 4th International Conference Bituminous Mixtures and Pavements, Thessaloniki, Greece, 19 April 2007; Available online: https://trid.trb.org/view/814322 (accessed on 31 October 2022).

- Jakovljević, R. Optimizacija Sastava Nosećeg Sloja Kolovozne Konstrukcije na Bazi Agregata od Hladno Recikliranog Asfalta sa Aspekta Mehaničkih Karakteristika; Fakultet Tehničkih Nauka Novi Sad: Novi Sad, Serbia, 2016. Available online: https://nardus.mpn.gov.rs/bitstream/handle/123456789/7097/Disertacija6479.pdf?sequence=6&isAllowed=y (accessed on 31 October 2022).

- Jenkins, K.J. Mix Design Considerations for Cold and Half-Warm Bituminous Mixes with Emphasis on Foamed Bitumen. Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2000. Available online: https://scholar.sun.ac.za/handle/10019.1/51831?show=full (accessed on 31 October 2022).

- Lewis, A.J.N.; Collings, D.C. Cold in Place Recycling: A Relevant Process for Road Rehabilitation and Upgrading. In Proceedings of the 7th Conference on Asphalt Pavements for Southern Africa, Sun City, South Africa; pp. 1–13. Available online: http://asphalt.csir.co.za/FArefs/CAPSA%20'99%20Lewis%2096.pdf (accessed on 20 October 2022).

- Chakraborty, J.; Banerjee, S. Replacement of Cement by Fly Ash in Concrete. Int. J. Civ. Eng. 2016, 3, 58–60. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Iglesias-Godino, F.J.; Corpas-Iglesias, F.A.; Martínez-García, C. Study of the Incorporation of Ladle Furnace Slag in the Manufacture of Cold In-Place Recycling with Bitumen Emulsion. Materials 2020, 13, 4765. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.; Beddu, S.; Hussain, S.; Manan, A.; binti Itam, Z. Mechanical properties of hot-mix asphalt using waste crumber rubber and phenol formaldehyde polymer. AIMS Mater. Sci. 2019, 6, 1164–1175. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. A Review of the Application of Zeolite Materials in Warm Mix Asphalt Technologies. Appl. Sci. 2017, 7, 293. [Google Scholar] [CrossRef]

- Marinković, M.; Zavadskas, E.K.; Matić, B.; Jovanović, S.; Das, D.K.; Sremac, S. Application of Wasted and Recycled Materials for Production of Stabilized Layers of Road Structures. Buildings 2022, 12, 552. [Google Scholar] [CrossRef]

- BS EN 1097-7:2008; Tests for Mechanical and Physical Properties of Aggregates, Part 7: Determination of the Particle Density of Filler—Pycnometer Method. British Standards Institution: London, UK, 2008.

- BS EN 196-6:2010; Methods of Testing Cement, Part 6: Determination of Fineness. British Standards Institution: London, UK, 2010.

- EN 933-10:2009; Tests for Geometrical Properties of Aggregates—Part 10: Assessment of Fines—Grading of Filler Aggregates (Air Jet Sieving). British Standards Institution: London, UK, 2009.

- BS EN 450-1:2012; Fly Ash for Concrete, Part 1: Definition, Specifications and Conformity Criteria. British Standards Institution: London, UK, 2012.

- BS EN 15167-1:2006; Ground Granulated Blast Furnace Slag for Use in Concrete, Mortar and Grout. Definitions, Specifications and Conformity Criteria. British Standards Institution: London, UK, 2006.

- Ahmadi, B.; Shekarchi, M. Use of Natural Zeolite as a Supplementary Cementitious Material. Cem. Concr. Compos. 2010, 32, 134–141. [Google Scholar] [CrossRef]

- Raggiotti, B.B.; Positieri, M.J.; Locati, F.; Murra, J.; Marfil, S. Zeolite, Study of Aptitude as a Natural Pozzolan Applied to Structural Concrete. Rev. Constr. 2015, 14, 14–20. [Google Scholar] [CrossRef]

- BS EN 12620:2013; Aggregates for Concrete. British Standards Institution: London, UK, 2013.

- Al-Mohammedawi, A.; Mollenhauer, K. Current Research and Challenges in Bitumen Emulsion Manufacturing and Its Properties. Materials 2022, 15, 2026. [Google Scholar] [CrossRef]

- EN 13808:2013; Bitumen and Bituminous Binders—Framework for Specifying Cationic Bituminous Emulsions. European Comission: Brussels, Belgium, 2013.

- BS EN 12591:2009; Bitumen and Bituminous Binders. Specifications for Paving Grade Bitumens. British Standards Institution: London, UK, 2009.

- Gergely, M.; Primusz, P.; Péterfalvi, J. Measuring the Bearing Capacity of Forest Roads with an Improved Benkelman Beam Apparatus. Acta Silv. Lignaria Hung. 2013, 9, 97–109. [Google Scholar] [CrossRef]

- Bhagat, P.; Hadial, C.P.; Solanki, U.J. Mechanistic Design of Overlay Based on Benkelman Beam Deflection Technique (a Case Study of Rajkot-Morbi State Highway-24). In Proceedings of the National Confererence on Transportation Engineering at Ahmedabad, Ahmedabad, India, 25–26 April 2015. [Google Scholar]

- Prabhu, A.; Arpith, S.P.; Vahida, K.K.; Kumar, D.; Bhat, A.; Kumar, A. Overlay Design of Flexible Pavements Using Benkelman Beam Deflection Method—A Case Study. In Trends in Civil Engineering and Challenges for Sustainability; Lecture Notes in Civil Engineering; Springer: Singapore, 2021; Volume 99. [Google Scholar] [CrossRef]

- Abhishek, R.; Nagaraj, S.; Sushmitha, S.; Kumar, N.; Chendan, T.M. Structural Evaluation of Flexible Pavement. Int. J. Eng. Res. Technol. (IJERT) 2019, 8. [Google Scholar] [CrossRef]

- ISO 17892-4:2016; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. International Organization for Standardization: Geneva, Switzerland, 2016.

- BS EN 206:2013; Concrete—Specification, Performance, Production and Conformity. British Standards Institution: London, UK, 2013.

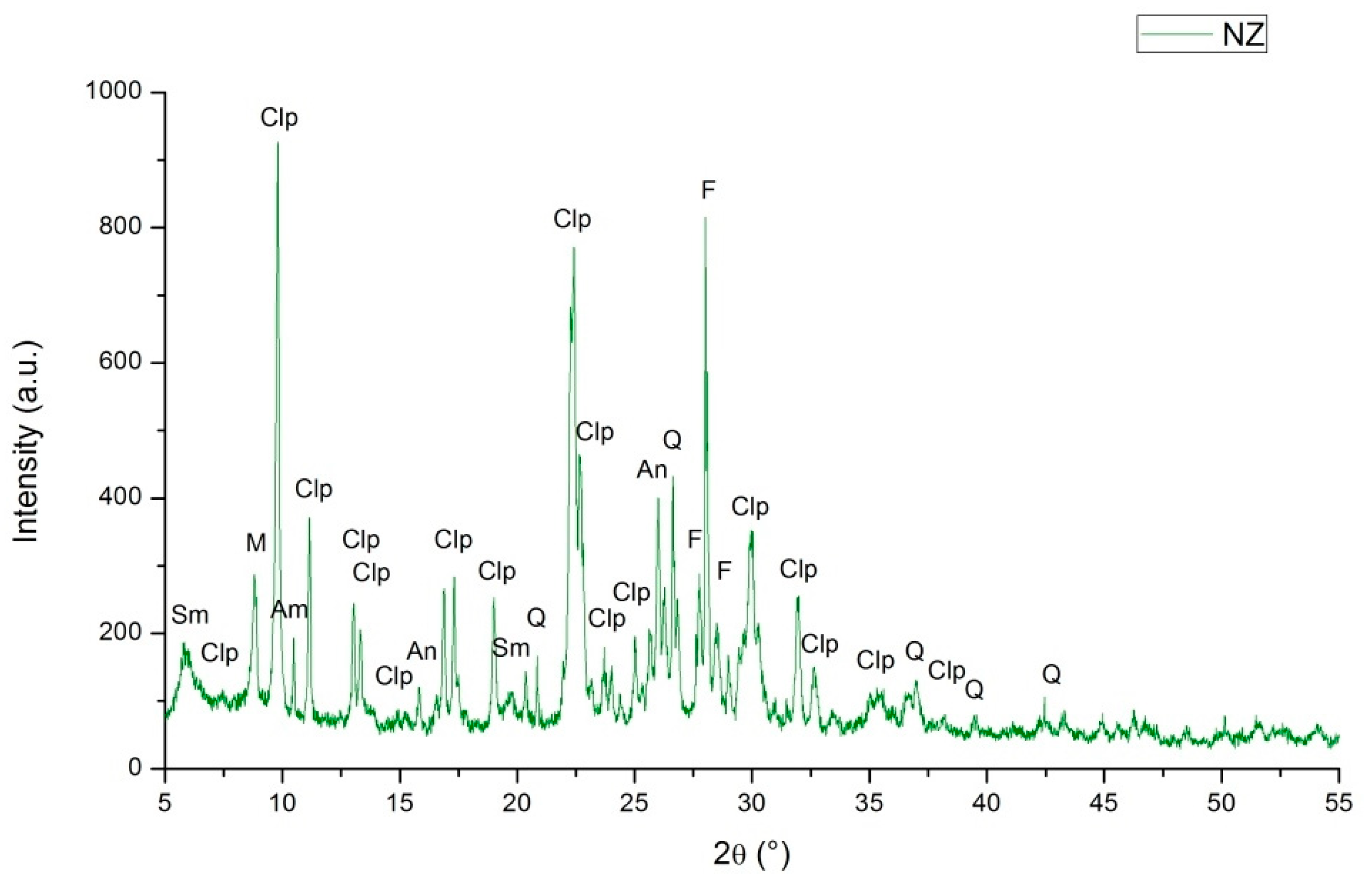

- Kašić, V.; Mihajlović, S.; Životić, D.; Simić, V.; Stojanović, J.; Sekulić, Ž.; Kragović, M. Characterization of the Zeolitic Tuff from the “Igroš-Vidojevići” Deposit Regarding Geological and Technological Aspects. Hem. Ind. 2018, 72, 29–37. [Google Scholar] [CrossRef]

- Cocić, M.; Logar, M.; Tasić, V.; Matović, B.; Miletić-Svirčev, M. Characterization of Material Sintered from the Final Flotation Waste and Zeolitic Tuff. Sci. Sinter. 2022, 54, 59–71. [Google Scholar] [CrossRef]

- Milović, T.; Šupić, S.; Malešev, M.; Radonjanin, V. The Effects of Natural Zeolite as Fly Ash Alternative on Frost Resistance and Shrinkage of Blended Cement Mortars. Sustainability 2022, 14, 2736. [Google Scholar] [CrossRef]

- Milović, T.; Rudić, O.; Furgan, S.O.; Radeka, M.; Malešev, M.; Radonjanin, V.; Baloš, S.; Laban, M. Effects of soft water attack on Portland and natural zeolite blended cements. Chem. Ind. Chem. Eng. Q. 2021, 27, 403–415. [Google Scholar] [CrossRef]

- Wirtgen GmbH. Wirtgen Cold Recycling Technology; Wirtgen: Windhagen, Germany, 2012. [Google Scholar]

- Asphalt Academy. Technical Guideline: Bitumen Stabilised Materials; Asphalt Academy: Pretoria, South Africa, 2009; Volume 2. [Google Scholar]

- Wirtgen GmbH. Wirtgen Road Construction Manual Internal Training Brochure for Sales Managers and Service Engineers; Wirtgen: Windhagen, Germany, 2002. [Google Scholar]

- EN 933-2:2020; Tests for Geometrical Properties of Aggregates—Part 2: Determination of Particle Size Distribution—Test Sieves, Nominal Size of Apertures. British Standards Institution: London, UK, 2020.

- Dave, E.V.; Sias, J.E.; Ogbo, C.; Zegeye, E.; Dai, S. Evaluation of Curing Effects on Cold In-Place Recycled (CIR); Final Report 2022-11; Minnesota Department of Transportation Office of Research & Innovation: St. Paul, MN, USA, 2022; Available online: https://www.dot.state.mn.us/research/reports/2022/202211.pdf (accessed on 31 October 2022).

- Santos, F.; Li, L.; Li, Y.; Amini, F. Geotechnical Properties of Fly Ash and Soil Mixtures for Use in Highway Embankments. In Proceedings of the World of Coal Ash (WOCA) Conference, Denver, CO, USA, 9–12 May 2011. [Google Scholar]

- Kim, B.; Prezzi, M.; Salgado, R. Geotechnical Properties of Fly and Bottom Ash Mixtures for Use in Highway Embankments. J. Geotech. Geoenviron. Eng. 2005, 131, 914–924. [Google Scholar] [CrossRef]

| Mixture | Optimum Water Content (%) | Optimum Asphalt Content (%) |

|---|---|---|

| Emulsified asphalt CRM with RAP | 4.8 | 3.8 |

| Emulsified asphalt CRM with composite RAP and RAI | 5.6 | 4.5 |

| Emulsified asphalt CRM with RAI | 6.4 | 5.0 |

| Foamed asphalt CRM with RAP | 5.0 | 3.2 |

| Foamed asphalt CRM with composite RAP and RAI | 5.8 | 3.6 |

| Foamed asphalt CRM with RAI | 6.6 | 4.4 |

| Chemical Composition (wt.%) | |||||

|---|---|---|---|---|---|

| CEM I 42.5 R | Fly Ash | Slag | Zeolite | Filler | |

| Na2O | 0.32 | 0.33 | 0.45 | 0.96 | 0.90 |

| MgO | 2.75 | 3.28 | 7.05 | 2.28 | 1.04 |

| Al2O3 | 5.10 | 23.59 | 8.14 | 13.84 | 5.64 |

| SiO2 | 21.40 | 41.73 | 39.63 | 60.91 | 76.36 |

| P2O5 | 0.14 | 0.13 | 0.05 | 0.15 | 0.08 |

| SO3 | 3.47 | 3.29 | 1.00 | 0.00 | 0.00 |

| Cl- | 0.02 | 0.00 | 0.03 | 0.00 | 0.00 |

| K2O | 0.76 | 1.19 | 0.57 | 1.00 | 0.96 |

| CaO | 60.66 | 10.87 | 39.76 | 5.12 | 6.46 |

| TiO2 | 0.23 | 1.50 | 0.52 | 0.59 | 0.53 |

| Cr2O3 | 0.02 | 0.08 | 0.01 | 0.01 | 0.20 |

| Mn2O3 | 0.09 | 0.25 | 0.66 | 0.09 | 0.10 |

| FexOy | 2.65 | 11.11 | 1.03 | 4.06 | 3.00 |

| ZnO | 0.05 | 0.12 | 0.00 | 0.01 | 0.01 |

| SrO | 0.10 | 0.09 | 0.10 | 0.27 | 0.03 |

| BaO | 0.04 | 0.14 | 0.11 | 0.71 | 0.03 |

| LOI | 2.20 | 2.30 | 0.90 | 10.00 | 4.65 |

| Cement (%) | Addition | Proportion of Addition (%) | |

|---|---|---|---|

| Mixture 1 | 2 | ||

| Mixture 2 | 1.6 | Fly ash | 0.4 (instead of 20% cement) |

| Mixture 3 | 1.6 | Slag | 0.4 (instead of 20% cement) |

| Mixture 4 | 1.6 | Zeolite | 0.4 (instead of 20% cement) |

| Mixture 5 | 2 | Bakelite | 20% instead of bitumen emulsion |

| Mixture 6 | 3 |

| Sieve Size (mm) | RAR (g) | Filler (g) | Corrected Mass (g) | Passes through Sieves (g) | Passes through Sieves (%) | Passes through Sieves for Unit Sample (g) | Remains on Sieves (g) |

|---|---|---|---|---|---|---|---|

| 75.00 | 0.00 | 0.00 | 15,027.43 | 100 | 5500 | 0.0 | |

| 63.00 | 0.00 | 0.00 | 15,027.43 | 100 | 5500 | 0.0 | |

| 45.00 | 0.00 | 0.00 | 15,027.43 | 100 | 5500 | 0.0 | |

| 31.50 | 48.43 | 48.43 | 14,979.00 | 99.68 | 5482.28 | 17.7 | |

| 22.40 | 1787.25 | 1787.25 | 13,191.75 | 87.78 | 4828.15 | 654.1 | |

| 16.00 | 1961.75 | 1961.75 | 11,230.00 | 74.73 | 4110.15 | 718.0 | |

| 11.00 | 1245.75 | 1245.75 | 9984.25 | 66.44 | 3654.21 | 455.9 | |

| 8.00 | 1130.00 | 1130.00 | 8854.25 | 58.92 | 3240.63 | 413.6 | |

| 4.00 | 2301.25 | 0 | 2301.25 | 6553.00 | 43.61 | 2398.38 | 842.3 |

| 2.00 | 1534.50 | 0 | 1534.50 | 5018.50 | 33.39 | 1836.76 | 561.6 |

| 1.00 | 926.75 | 0 | 926.75 | 4091.75 | 27.23 | 1497.57 | 339.2 |

| 0.50 | 449.50 | 0 | 449.50 | 3642.25 | 24.24 | 1333.05 | 164.5 |

| 0.25 | 213.50 | 0 | 213.50 | 3428.75 | 22.82 | 1254.91 | 78.1 |

| 0.06 | 128.75 | 3300 | 3428.75 | 0.00 | 6.00 | 330.00 | 924.9 |

| bottom | 330.0 | ||||||

| Sum | 11,727.43 | 3300 | 5500.0 |

| Cement (g) | Addition | 4% | 6% | 8% | |||||

|---|---|---|---|---|---|---|---|---|---|

| Type | Mass (g) | W | BE | W | BE | W | BE | ||

| Mixture 1 | 110 | / | 0 | 110 | 110 | 165 | 165 | 220 | 220 |

| Mixture 2 | 88 | Fly ash | 22 | 110 | 110 | 165 | 165 | 220 | 220 |

| Mixture 3 | 88 | Slag | 22 | 110 | 110 | 165 | 165 | 220 | 220 |

| Mixture 4 | 88 | Zeolite | 22 | 110 | 110 | 165 | 165 | 220 | 220 |

| Mixture 5 | 88 | Bakelite | 22/33/44 | 110 | 88 | 165 | 132 | 220 | 176 |

| Mixture 6 | 165 | / | 0 | 110 | 110 | 165 | 165 | 220 | 220 |

| Cement (%) | Proportion of Addition (%) | Maximum Dry Density (g/cm3) | OFC (%) | |

|---|---|---|---|---|

| Mixture 1 | 2 | 2.163 | 6.5 | |

| Mixture 2 | 1.6 | 0.4 Fly ash (instead of 20% cement) | 2.182 | 7.6 |

| Mixture 3 | 1.6 | 0.4 Slag (instead of 20% cement) | 2.133 | 6.4 |

| Mixture 4 | 1.6 | 0.4 Zeolite (instead of 20% cement) | 2.162 | 6.5 |

| Mixture 5 | 2 | Bakelite (instead of 20% bitumen emulsion) | 2.123 | 6.4 |

| Mixture 6 | 3 | 2.131 | 5.7 |

| Author | Cement Content (%) | Additives | Optimum Fluid Content (%) |

|---|---|---|---|

| Wei et al. [33] | 1.5 | none | 4.7 (vibrating compaction method) |

| Wei et al. [33] | 1.5 | none | 5.0 (heavy compaction method) |

| Jenkins, K.J. [35] | 1 | none | 2.1 |

| Kezhen et al. [36] | <1.5 | none | 4.5 |

| Zhao et al. [37] | 1.5 | none | 3.8 |

| Jakovljević [39] | / | none | 3.5 |

| Smiljanić et al. [38] | 2 | none | 6 |

| Mixture 1 | 2 | none | 6.5 |

| Mixture 2 | 1.6 | fly ash (0.4%) | 7.6 |

| Mixture 3 | 1.6 | slag (0.4%) | 6.4 |

| Mixture 4 | 1.6 | zeolite (0.4%) | 6.5 |

| Mixture 5 | 2 | bakelite | 6.4 |

| Mixture 6 | 3 | none | 5.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopić, M.; Milović, T.; Matić, B.; Jovanović, S.; Marinković, M. Optimum Fluid Content in Pavement Cold In-Place Recycling Containing Waste Materials. Sustainability 2022, 14, 16691. https://doi.org/10.3390/su142416691

Kopić M, Milović T, Matić B, Jovanović S, Marinković M. Optimum Fluid Content in Pavement Cold In-Place Recycling Containing Waste Materials. Sustainability. 2022; 14(24):16691. https://doi.org/10.3390/su142416691

Chicago/Turabian StyleKopić, Miloš, Tiana Milović, Bojan Matić, Stanislav Jovanović, and Milan Marinković. 2022. "Optimum Fluid Content in Pavement Cold In-Place Recycling Containing Waste Materials" Sustainability 14, no. 24: 16691. https://doi.org/10.3390/su142416691

APA StyleKopić, M., Milović, T., Matić, B., Jovanović, S., & Marinković, M. (2022). Optimum Fluid Content in Pavement Cold In-Place Recycling Containing Waste Materials. Sustainability, 14(24), 16691. https://doi.org/10.3390/su142416691