A Numerical Study of Turbulent Combustion of a Lignocellulosic Gas Mixture in an Updraft Fixed Bed Reactor

Abstract

:1. Introduction

2. Validation Experiments and Feedstock Variability

3. Modeling Tools

3.1. Flow, Turbulence, and Combustion Model

- The governing equations are implemented in an unsteady state

- The fuel gas mixture is compressible

- Soret (diffusion) effect, gravitational acceleration effect, and radiant effect are neglected.

- The pressure follows the equation-of-state of an ideal gas (Equation (7))

3.2. Simulation Setup

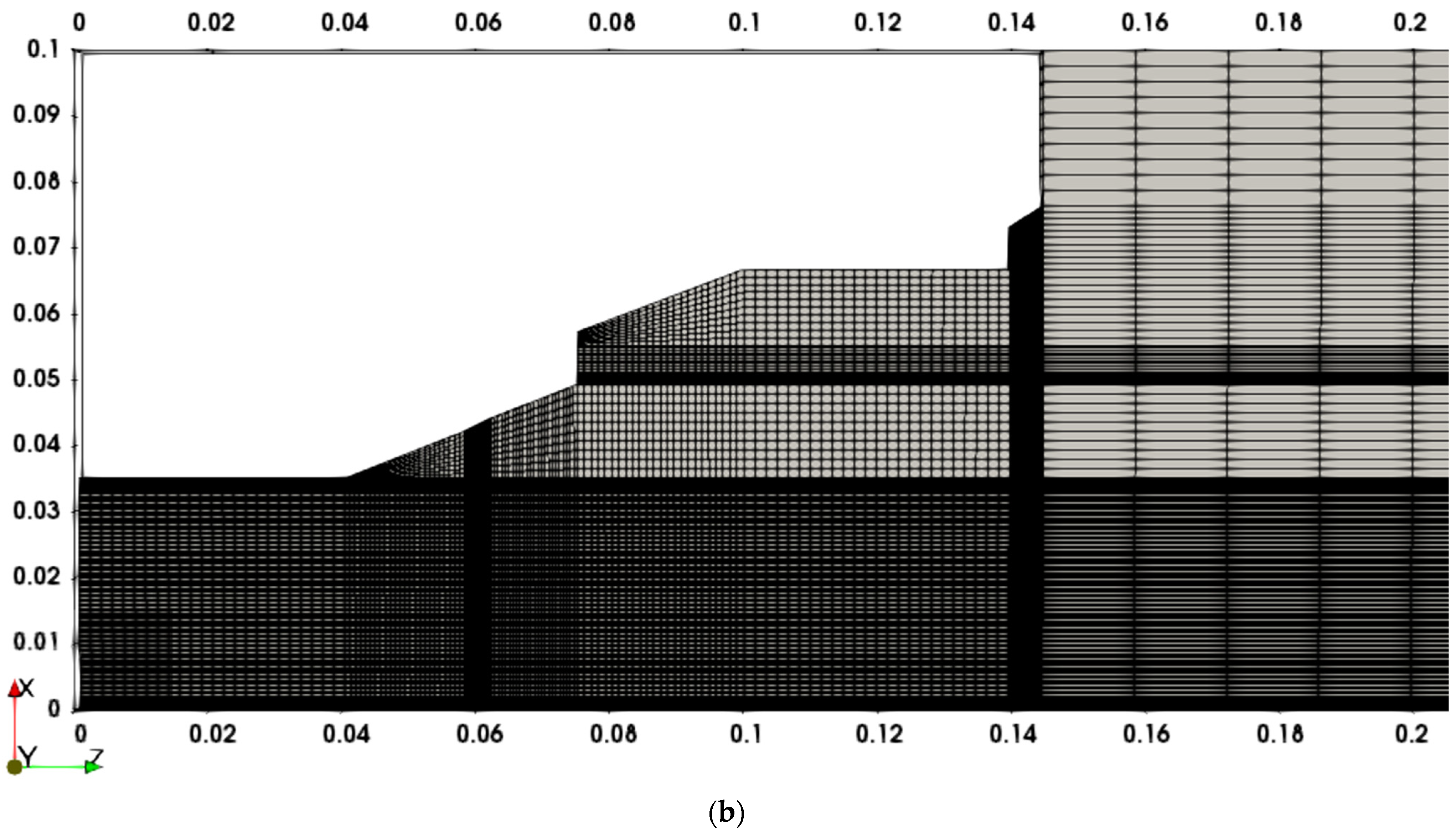

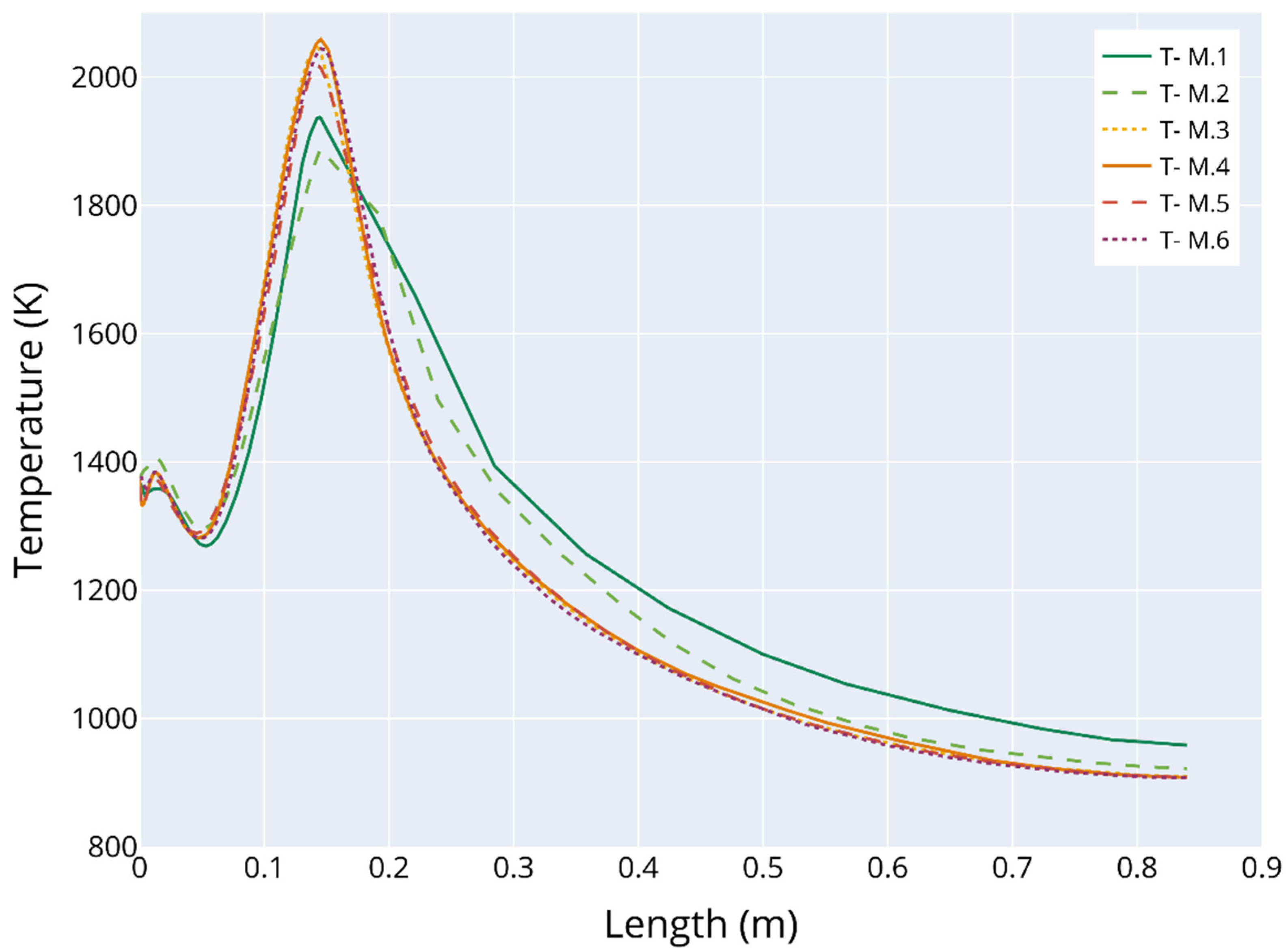

3.3. Mesh Convergence

4. Simulation Results and Discussion

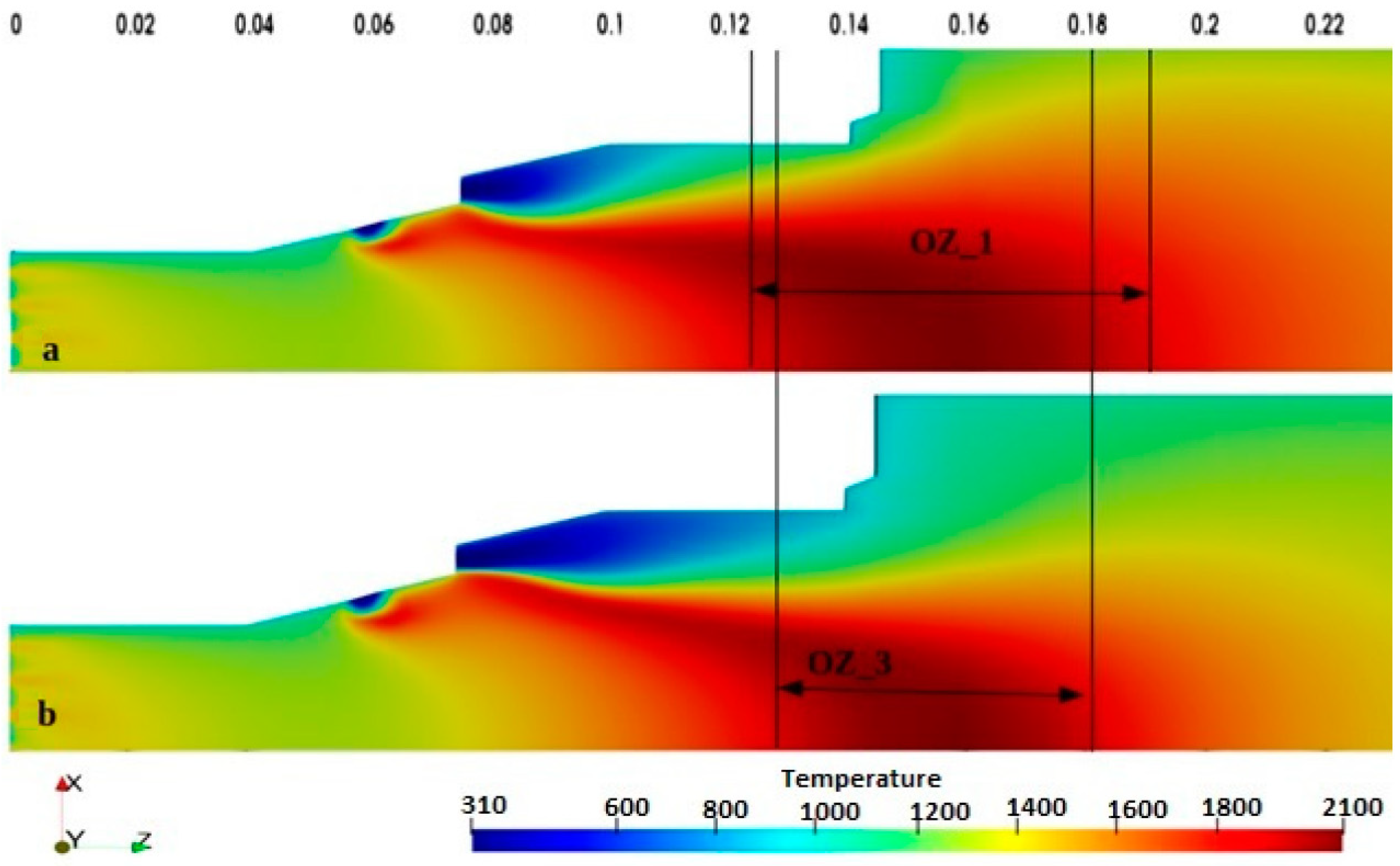

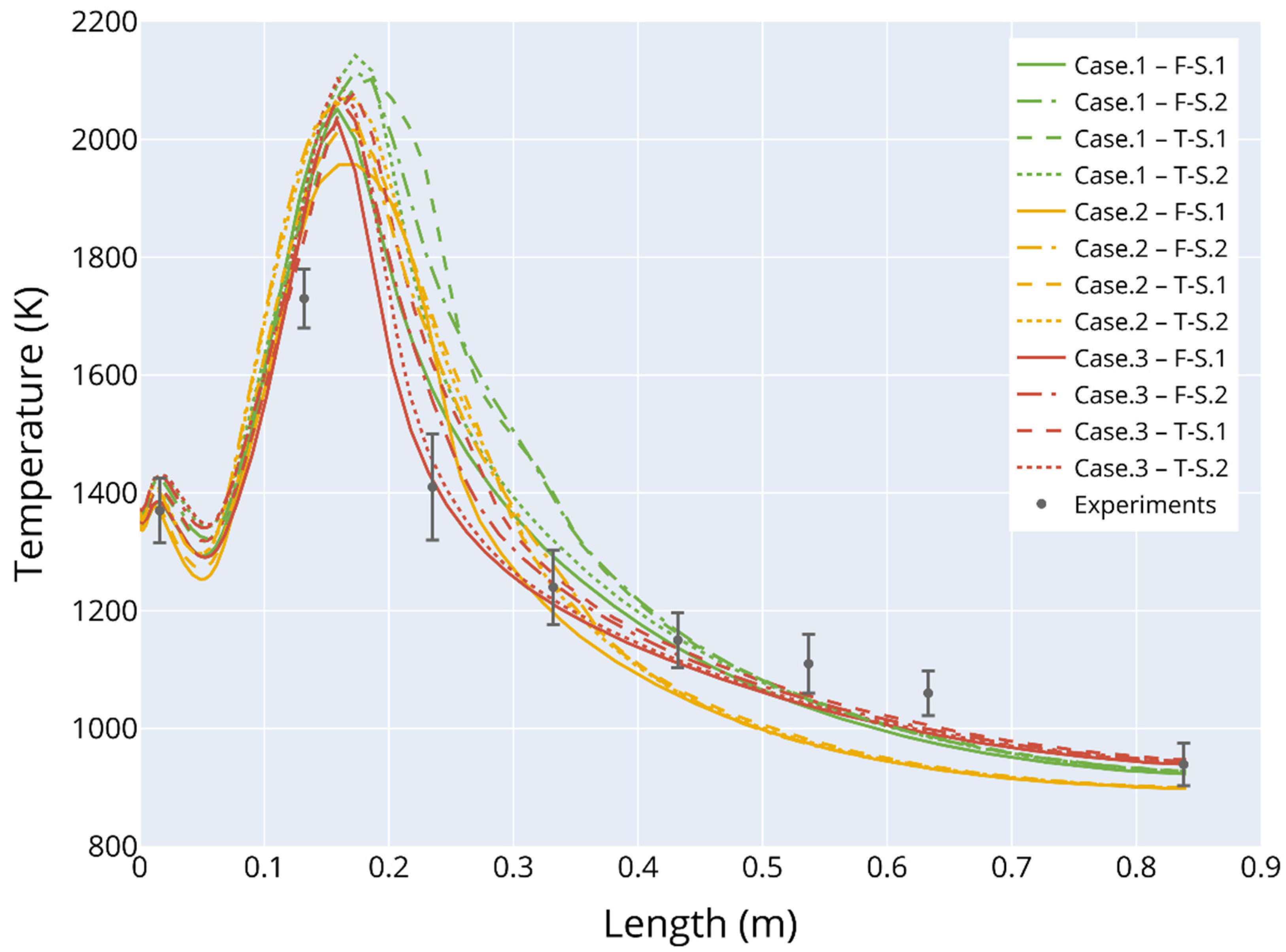

4.1. Axial Temperature Profile

4.2. Chemical Species Concentrations

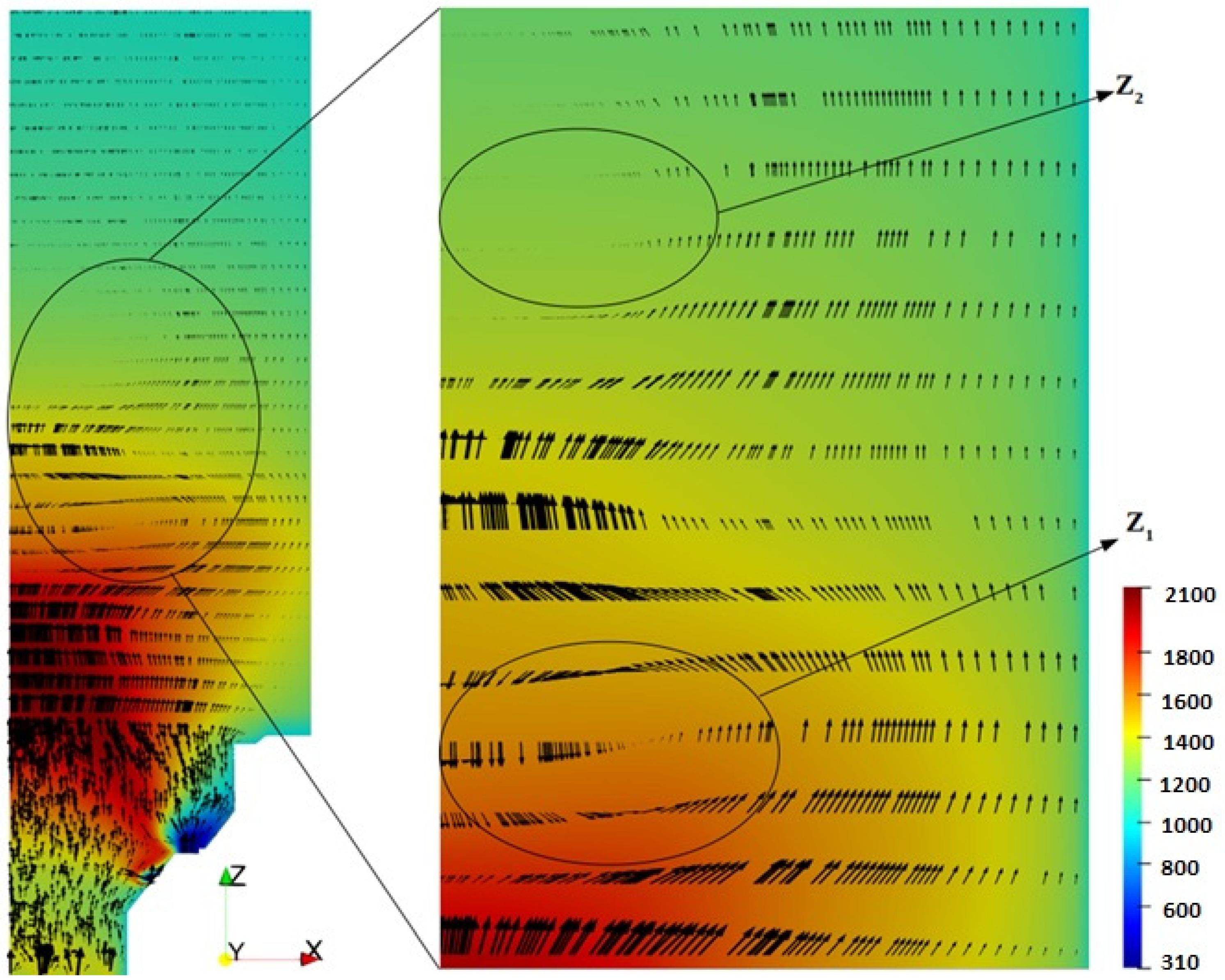

4.3. Effect of the Mass Flow Rate on the Velocity Field

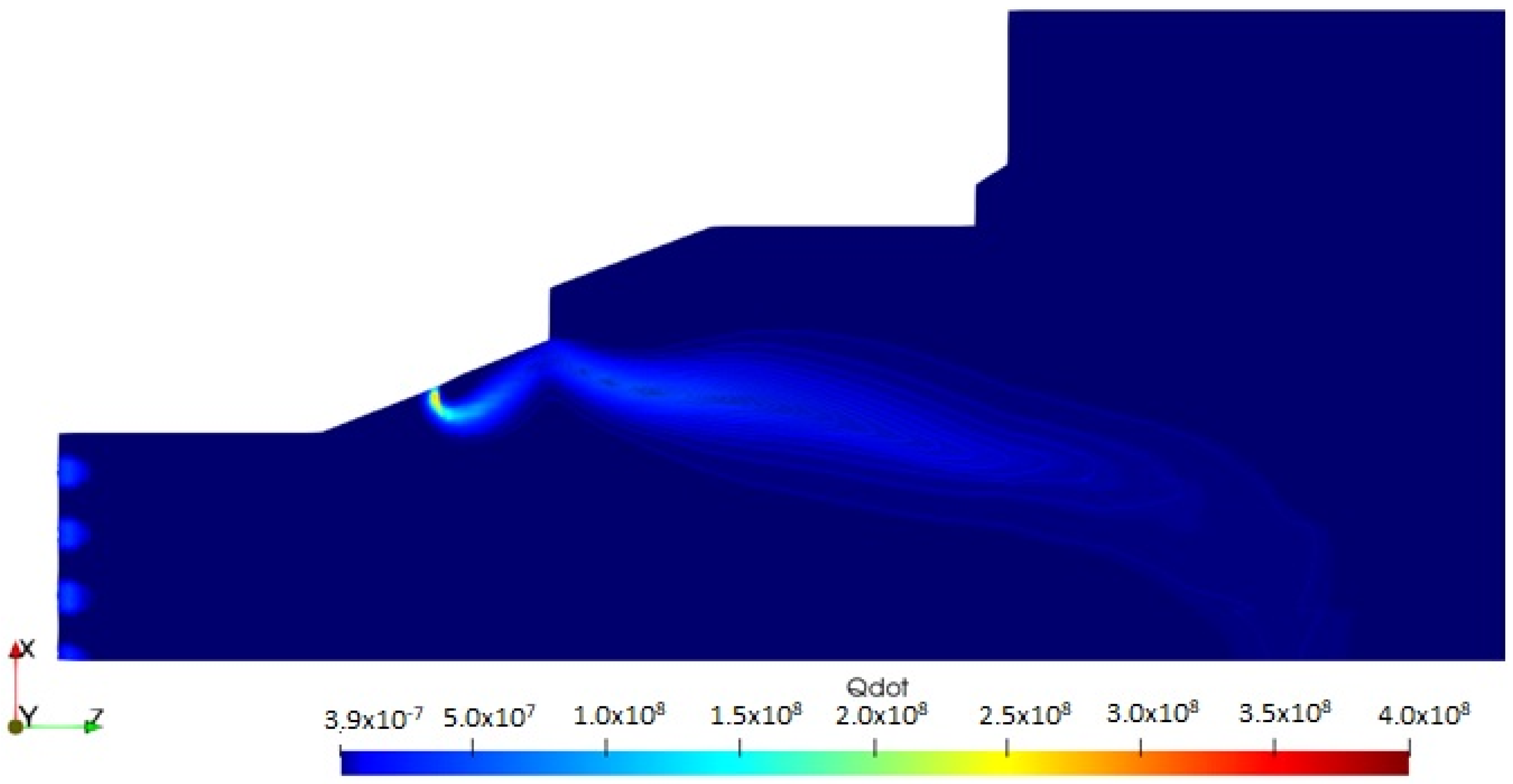

4.4. Heat Generation Spatial Distribution

5. Conclusions

- Case 3-FS1 was the best combination for predicting the temperature profile despite the peak temperature being under estimated and for all combinations. This may be due to not taking into account of radiative transfer during our calculations;

- Case 1-TS1 was the best for predicting CO2 emissions;

- Case 1-FS2, Case 1-TS1 and Case 1-FS1 were better for predicting O2 concentrations;

- Case 1-TS1 predicted better CO concentration for a length < 0.4 m, but Case 2-TS2 was the best one for length > 0.4 m.

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Contributing of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Synthesis Report; IPCC: Geneva, Switzerland, 2014; Available online: https://www.ipcc.ch/pdf/assessment-report/ar5/syr/SYR_AR5_FINAL_full.pdf (accessed on 1 April 2020).

- Mami, M.A.; Mätzing, H.; Gehrmann, H.J.; Stapf, D.; Bolduan, R.; Lajili, M. Investigation of olive mill solid wastes pellets combustion in a counter-current fixed bed reactor. Energies 2018, 11, 1965. [Google Scholar] [CrossRef] [Green Version]

- Morin, M.; Pécate, S.; Hémati, M. Kinetic study of biomass char combustion in a low temperature fluidized bed reactor. Chem. Eng. J. 2018, 331, 265–277. [Google Scholar] [CrossRef] [Green Version]

- Khlifi, S.; Lajili, M.; Belghith, S.; Mezlini, S.; Tabet, F.; Jeguirim, M. Briquettes production from olive mill waste under optimal temperature and pressure conditions: Physico-chemical and mechanical characterizations. Energies 2020, 13, 1214. [Google Scholar] [CrossRef] [Green Version]

- Zribi, M.; Lajili, M. Study of the pyrolysis of biofuels pellets blended from sawdust and oleic by-products: A kinetic study. Int. J. Renew. Energy Res. 2019, 9, 561–571. [Google Scholar]

- Lopez, G.; Alvarez, J.; Amtio, M.; Hooshdaran, B.; Cortazar, M.; Haghshenasfard, M.; Hosseini, S.H.; Olazar, M. Kinetic modelling and experimental validation of biomass fast pyrolysis in a conical spouted bed reactor. Chem. Eng. J. 2019, 373, 677–686. [Google Scholar] [CrossRef]

- Zhang, L.; Tan, Y.; Cai, D.; Sun, J.; Zhang, Y.; Li, L.; Zhang, Q.; Zou, G.; Song, Z.; Bai, Y. Enhanced pyrolysis of woody biomass under interaction of microwave and needle-shape metal and its production properties. Energy 2022, 249, 123667. [Google Scholar] [CrossRef]

- Condori, O.; Garcia-Labiano, F.; Diego, L.F.; Izquierdo, M.T.; Abad, A.; Adanez, J. Biomass chemical looping gasification for syngas production using ilmenite as oxygen carrier in a 1.5 kWth unit. Chem. Eng. J. 2020, 405, 126679. [Google Scholar] [CrossRef]

- Zribi, M.; Lajili, M.; Escudero-Sanz, F.J. Gasification of biofuels blended from olive mill solid wastes and pine sawdust under different carbon dioxide/nitrogen atmospheres. Fuel 2020, 282, 118822. [Google Scholar] [CrossRef]

- Jha, S.; Nanda, S.; Acharya, B.; Dalai, A. A review of thermochemical conversion of waste biomass to biofuels. Energies 2022, 15, 6352. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X. The thermochemical conversion of biomass into biofuels. In Biomass, Biopolymer-Based Materials, and Bioenergy; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar] [CrossRef]

- Maitlo, G.; Ali, I.; Mangi, K.; Ali, S.; Maitlo, H.; Unar, I.; Pirzada, A. Thermochemical conversion of biomass for syngas production: Current status and future trends. Sustainability 2022, 14, 2596. [Google Scholar] [CrossRef]

- Kousheshi, N.; Yari, M.; Paykani, A.; Mehr, S.A.; De la Fuente, G.F. Effect of syngas composition on the combustion and emissions characteristics of a syngas/diesel RCCI engine. Energies 2020, 13, 212. [Google Scholar] [CrossRef] [Green Version]

- Nielson, S.; Okosun, T.; Damstedt, B.; Jampani, M.; Zhou, C.Q. Tuyere-level syngas injection in the blast furnace: A computational fluid dynamics investigation. Processes 2021, 9, 1447. [Google Scholar] [CrossRef]

- Henao, N.; Venturini, O.; Santiago, Y.; Lora, E.; Maya, D.; Pamplona, E.; Hoyos, J.; Junior, O. Energy and economic assessment of a system integrated by a biomass downdraft gasifier and a gas microturbine. Processes 2022, 10, 2377. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in biofuel production from gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Lajili, M.; Guizani, C.; EscuderoSanz, F.J.; Jeguirim, M. Fast pyrolysis and steam gasification of pellets prepared from olive oil mill residues. Energy 2018, 150, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Zribi, M.; Lajili, M.; Escudero-Sanz, F.J. Hydrogen enriched syngas production via gasification of biofuels pellets/powders blended from olive mill solid wastes and pine sawdust under different water steam/nitrogen atmospheres. Int. J. Hydrogen Energy 2019, 44, 11280–11288. [Google Scholar] [CrossRef] [Green Version]

- Hu, Z.; Zhou, T.; Tian, H.; Feng, L.; Yao, C.; Yin, Y.; Chen, D. Effects of pyrolysis parameters on the distribution of pyrolysis products of Miscanthus. Prog. React. Kinet. Mech. 2021, 46, 14686783211010970. [Google Scholar] [CrossRef]

- Khlifi, S.; Lajili, M.; Tabet, F.; Boushaki, T.; Sarh, B. Investigation of the combustion characteristics of briquettes prepared from olive mill solid waste blended with and without a natural binder in a fixed bed reactor. Biomass Convers. Biorefinery 2019, 10, 535–544. [Google Scholar] [CrossRef]

- Montoya, J.; Pecha, B.; Roman, D.; Janna, F.; Garcia-Perez, M. Effect of temperature and heating rate on product distribution from the pyrolysis of sugarcane bagasse in a hot plate reactor. J. Anal. Appl. Pyrolysis 2017, 123, 347–363. [Google Scholar] [CrossRef] [Green Version]

- Mishra, A.; Gautam, S.; Sharma, T. Effect of operating parameters on coal gasification. Int. J. Coal Sci. Technol. 2018, 5, 113–125. [Google Scholar] [CrossRef]

- Marathe, P.S.; Westerhof, R.J.M.; Kersten, S.R.A. Effect of pressure and hot vapor residence time on the fast pyrolysis of biomass: Experiments and modeling. Energy Fuels 2020, 34, 1773–1780. [Google Scholar] [CrossRef]

- Szwaja, S.; Poskart, A.; Zajemska, M.; Szwaja, M. Theoretical and experimental analysis on co-gasification of sewage sludge with energetic crops. Energies 2019, 12, 1750. [Google Scholar] [CrossRef] [Green Version]

- Xiang, X.; Gong, G.; Wang, C.; Cai, N.; Zhou, X.; Li, Y. Exergy analysis of updraft and downdraft fixed bed gasification of village-level solid waste. Int. J. Hydrogen Energy 2020, 46, 221–233. [Google Scholar] [CrossRef]

- You, S.; Ok, Y.S.; Tsang, D.C.W.; Kwon, E.E.; Wang, C.-H. Towards practical application of gasification: A critical review from syngas and biochar perspectives. Crit. Rev. Env. Sci. Tech. 2018, 48, 1165–1213. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Wan, K.; Chen, H.; Zheng, F.; Zhang, Z.; Niu, B.; Zhang, Y.; Long, D. Value-added products from catalytic pyrolysis of lignocellulosic biomass and waste plastics over biochar-based catalyst: A state-of-the-art review. Catalysts 2022, 12, 1067. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef] [Green Version]

- Farokhi, M.; Birouk, M.; Tabet, F. A computational study of a small-scale biomass burner: The influence of chemistry, turbulence and combustion sub-models. Energy Convers. Manag. 2017, 143, 203–217. [Google Scholar] [CrossRef]

- Wright, M.L.; Lewis, A.C. Decarbonisation of heavy-duty diesel engines using hydrogen fuel: A review of the potential impact on NOx emissions. Environ. Sci. Atmos. 2022, 2, 852. [Google Scholar] [CrossRef]

- Zhang, X.; Munjat, N.F.; Jayasuriya, J.; Fakhrai, R.; Fransson, T. Evaluation of reduced kinetics in simulation of Gasified Biomass Gas combustion. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar]

- Solarte-Toro, J.C.; Chacón-Pérez, Y.; Cardona-Alzate, C.A. Evaluation of biogas and syngas as energy vectors for heat and power generation using lignocellulosic biomass as raw material. Electron. J. Biotechnol. 2018, 33, 52–62. [Google Scholar] [CrossRef]

- Zhou, A.; Xu, H.; Meng, X.; Yang, W.; Sun, R. Development of a numerical model for co-combustion of the blended solid waste fuel in the grate boiler. Chem. Eng. J. 2021, 405, 126604. [Google Scholar] [CrossRef]

- Stylianidis, N.; Azimov, U.; Birkett, M. Investigation of the effect of hydrogen and methane on combustion of multicomponent syngas mixtures using a constructed reduced chemical kinetics mechanism. Energies 2019, 12, 2442. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Li, X.; Yao, Z.; Cui, X.; Wang, C.H. CO2 gasification of woody biomass: Experimental study from a lab-scale reactor to a small-scale autothermal gasifier. Energy 2019, 170, 497–506. [Google Scholar] [CrossRef]

- Bboluwaji, E.F.; Babatunde, O.O.; Abosede, O.O.; Onose, M.A.; Fakinle, B.S. Proximate analysis of the properties of some southwestern Nigeria sawdust of different wood species. Int. J. Civ. Eng. Technol. 2019, 10, 51–59. [Google Scholar]

- Álvarez-Álvarez, P.; Pizarro, C.; Barrio-Anta, M.; Cámara-Obregón, A.; María Bueno, J.L.; Álvarez, A.; Gutiérrez, I.; Burslem, D.F.R.P. Evaluation of tree species for biomass energy production in Northwest Spain. Forests 2018, 9, 160. [Google Scholar] [CrossRef] [Green Version]

- Bibbiani, C.; Fantozzi, F.; Gargari, C.; Campiotti, C.A.; Schettini, E.; Vox, G. Wood biomass as sustainable energy for greenhouses heating in Italy. Agric. Agric. Sci. Procedia 2016, 8, 637–645. [Google Scholar] [CrossRef]

- Mierzwa-Hersztek, M.; Gondek, K.; Jewiarz, M.; Dziedzic, K. Assessment of energy parameters of biomass and biochars, leachability of heavy metals and phytotoxicity of their ashes. J. Mater. Cycles Waste Manag. 2019, 21, 786–800. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Słowik, T. Comparison and assessment of emission factors for toxic exhaust components during combustion of biomass fuels. Rocz. Ochr. Srodowiska 2019, 21, 378–394. [Google Scholar]

- Dai, J.; Saayman, J.; Grace, J.R.; Ellis, N. Gasification of woody biomass. Annu. Rev. Chem. Biomol. Eng. 2015, 6, 77–99. [Google Scholar] [CrossRef]

- El-Shafay, A.S.; Hegazi, A.A.; Zeidan, E.S.B.; El-Emam, S.H.; Okasha, F.M. Experimental and numerical study of sawdust air-gasification. Alex. Eng. J. 2020, 59, 3665–3679. [Google Scholar]

- Ramos, A.; Rouboa, A. Syngas production strategies from biomass gasification: Numerical studies for operational conditions and quality indexes. Renew. Energy 2020, 155, 1211–1221. [Google Scholar] [CrossRef]

- Chojnacki, J.; Najser, J.; Rokosz, K.; Peer, V.; Kielar, J.; Berner, B. Syngas composition: Gasification of wood pellet with water steam through a reactor with continuous biomass feed system. Energies 2020, 13, 4376. [Google Scholar] [CrossRef]

- Xu, T.; Zheng, X.; Xu, J.; Wu, Y. Hydrogen-rich gas production from two-stage catalytic pyrolysis of pine sawdust with Nano-NiO/Al2O3 catalyst. Catalysts 2022, 12, 256. [Google Scholar] [CrossRef]

- Awais, M.; Li, W.; Munir, A.; Omar, M.M.; Ajmal, M. Experimental investigation of downdraft biomass gasifier fed by sugarcane bagasse and coconut shells. Biomass Convers. Biorefin. 2020, 11, 429–444. [Google Scholar] [CrossRef]

- Couto, N.; Rouboa, A.; Silva, V.; Monteiro, E.; Bouziane, K. Influence of the biomass gasification processes on the final composition of syngas. Energy Procedia 2013, 36, 596–606. [Google Scholar] [CrossRef] [Green Version]

- OpenFOAM Foundation. OpenFOAM R Documentation 2018. Available online: https://www.openfoam.com/releases/openfoam-v1812/ (accessed on 3 April 2019).

- Gutiérrez, L.F.; Tamagno, J.P.; Elaskar, S.A. RANS simulation of turbulent diffusive combustion using open foam. J. Appl. Fluid Mech. 2016, 9, 669–682. [Google Scholar] [CrossRef]

- Kamali, R.; Mousavi, S.M.; Binesh, A.R.; Abolfazli-Esfahani, J. Large eddy simulation of the flameless oxidation in the IFRF furnace with varying inlet conditions. Int. J. Spray Combust. Dyn. 2017, 9, 102–115. [Google Scholar] [CrossRef] [Green Version]

- Ding, C.; Li, P.; Wang, K.; Shi, G.; Wang, F.; Liu, Z. Experimental and Kinetic Study on the Oxidation of Syngas-Ammonia under Both N2 and CO2 atmospheres in a jet-stirred reactor. Energy Fuels 2021, 35, 11445–11456. [Google Scholar] [CrossRef]

- Johnson, R.F.; VanDine, A.C.; Esposito, G.L.; Chelliah, H.K. On the axisymmetric counterflow flame simulations: Is there an optimal nozzle diameter and separation distance to apply quasi one-dimensional theory? Combust. Sci. Technol. 2015, 187, 37–59. [Google Scholar] [CrossRef]

- Yilmaz, H.; Cam, O.; Tangoz, S.; Yilmaz, I. Effect of different turbulence models on combustion and emission characteristics of hydrogen/air flames. Int. J. Hydrogen Energy 2017, 42, 25744–25755. [Google Scholar] [CrossRef]

- Noor, M.M.; Wandel, A.P.; Yusaf, T. The simulation of biogas combustion in a mild burner. J. Mech. Eng. Sci. 2014, 6, 995–1013. [Google Scholar] [CrossRef]

- Prieler, R.; Bĕlohradský, P.; Mayr, B.; Rinner, A.; Hochenauer, C. Validation of turbulence/chemistry interaction models for use in oxygen enhanced combustion. Energy Procedia 2017, 120, 548–555. [Google Scholar] [CrossRef]

- Shih, T.; Liou, W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ϵ eddy viscosity model for high Reynolds number turbulent flows. Comput. Fluids. 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Magnussen, B.F. On the structure of turbulence and a generalized eddy dissipation concept for chemical reaction in turbulent flow. In Proceedings of the 19th AIAA Meetin, St. Louis, MO, USA, 12–15 January 1981. [Google Scholar] [CrossRef]

- Kai, C.; Bing, L.; Yuxin, W.; Hairui, Y.; Junfu, L.; Hai, Z. Numerical simulation of oxy-coal combustion for a swirl burner with EDC model. Chin. J. Chem. Eng. 2014, 22, 193–201. [Google Scholar]

- Parente, A.; Malik, M.R.; Contino, F.; Cuoci, A.; Dally, B.B. Extension of the eddy dissipation concept for turbulence/chemistry interactions to MILD combustion. Fuel 2016, 163, 98–111. [Google Scholar] [CrossRef]

- Magnussen, B.F. The eddy dissipation concept—A bridge between science and technology. In Proceedings of the ECCOMAS Thematic Conference on Computational Combustion, Lisbon, Portugal, 21 January 2005. [Google Scholar]

- He, D.; Yu, Y.; Ma, H.; Liang, H.; Wang, C. Extensive discussions of the eddy dissipation concept constants and numerical simulations of the sandia flame D. Appl. Sci. 2022, 12, 9162. [Google Scholar] [CrossRef]

- Klason, T.; Bai, X.S. Computational study of the combustion process and NO formation in a small-scale wood pellet furnace. Fuel 2007, 86, 1465–1474. [Google Scholar] [CrossRef]

- Farokhi, M.; Birouk, M. Application of eddy dissipation concept for modeling biomass combustion, part 2: Gas-phase combustion modeling of a small-scale fixed bed furnace. Energy Fuels 2016, 30, 10800–10808. [Google Scholar] [CrossRef]

- Abou-Taouk, A.; Eriksson, L.E. Optimized global mechanisms for CFD analysis of swirl-stabilized syngas burner for Gas turbines. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2011. [Google Scholar]

- Westbrook, C.K.; Dryer, F.L. Chemical kinetic modeling of hydrocarbon combustion. Prog. Energy. Combust. Sci. 1984, 10, 1–57. [Google Scholar] [CrossRef]

- Park, S.S.; Jeong, H.J.; Hwang, J. 3-D CFD modeling for parametric study in a 300-Mwe one-stage oxygen-blown entrained-bed coal gasifier. Energies 2015, 8, 4216–4236. [Google Scholar] [CrossRef] [Green Version]

- Collazo, J.; Porteiro, J.; Patiño, D.; Granada, E. Numerical modeling of the combustion of densified wood under fixed-bed conditions. Fuel 2012, 93, 149–159. [Google Scholar] [CrossRef]

- Lu, W.; Li, X.; Wu, X.; Sun, L.; Li, Z. Investigation on the oxidation behavior and multistep reaction mechanism of nuclear graphite SNG742. J. Nucl. Sci. Technol. 2019, 57, 263–275. [Google Scholar] [CrossRef]

- Howard, J.B.; Williams, G.C.; Fine, D.H. Kinetics of carbon monoxide oxidation in post flame gases. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1973; Volume 14, pp. 975–986. [Google Scholar]

- Boz, Z.; Erdogdu, F.; Tutar, M. Effects of mesh refinement, time step size and numerical scheme on the computational modeling of temperature evolution during natural-convection heating. J. Food Eng. 2014, 123, 8–16. [Google Scholar] [CrossRef]

- Mohapatra, S.; Rajguru Mohapatro, M.B.; Pasha, A.A.; Alsulami, R.A.; Dash, S.K.; Reddy, V.M. Adaptability of diferent mechanisms and kinetic study of methane combustion in steam diluted environments. Sci. Rep. 2022, 12, 4577. [Google Scholar] [CrossRef]

- Soloklou, M.N.; Golneshan, A.A. Numerical investigation on effects of fuel tube diameter and co-flow velocity in a methane/air non-premixed flame. Heat Mass Transf. 2020, 56, 1697–1711. [Google Scholar] [CrossRef]

- Plotnikov, L.; Grigoriev, N.; Osipov, L.; Slednev, V.; Shurupov, V. Stationary gas dynamics and heat transfer of turbulent flows in straight pipes at different turbulence intensity. Energies 2022, 15, 7250. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Jiang, B.; Chen, Z.; Zhang, X. Effect of secondary air mass flow rate on the airflow and combustion characteristics and NOx formation of the low-volatile coal-fired swirl burner. Asia-Pac. J. Chem. Eng. 2015, 10, 858–875. [Google Scholar] [CrossRef]

- Sher, F.; Pans, M.A.; Afilaka, D.T.; Sun, C.; Liu, H. Experimental investigation of woody and non-woody biomass combustion in a bubbling fluidized bed combustor focusing on gaseous emissions and temperature profiles. Energy 2017, 141, 2069–2080. [Google Scholar] [CrossRef]

- Kikuchi, K.; Hori, T.; Akamatsu, F. Fundamental study on hydrogen low-NOx combustion using exhaust gas self-recirculation. Processes 2022, 10, 130. [Google Scholar] [CrossRef]

| Case 1 | Case 2 | Case 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 6.0 | 5.0 | 6.0 | |||||||

| 0.20 | 0.20 | 0.16 | |||||||

| 1.50 | 1.0 | 2.50 | |||||||

| Kinetic energy of turbulence k | Gas 3.18 × 10−2 | P. air 2.98 × 10−5 | S. air 1.06 × 10−5 | Gas 2.21 × 10−2 | P. air 2.98 × 10−5 | S. air 0.47 × 10−5 | Gas 3.18 × 10−2 | P. air 1.90 × 10−5 | S. air 2.96 × 10−5 |

| Dissipation rate of turbulence | Gas 1.33 × 10−2 | P. air 6.68 × 10−5 | S. air 4.51 × 10−5 | Gas 0.77 × 10−2 | P. air 6.68 × 10−5 | S. air 1.33 × 10−5 | Gas 1.33 × 10−2 | P. air 3.40 × 10−5 | S. air 20.92 × 10−5 |

| Flow velocity U (m·s−1) | Gas 2.90 | P. air 0.61 | S. air 1.45 | Gas 2.41 | P. air 0.61 | S. air 0.97 | Gas 2.9 | P. air 0.49 | S. air 2.42 |

| Gas Mixture | Primary Air | Secondary Air | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Case 1 | Case 1 | Case 1 | |||||||||

| K 3.18 | 1.33 | Ret 3.80 × 106 | 5.0 × 10−4 | K 2.98 | 6.68 | Ret 6.6 × 105 | 5.4 × 10−4 | K 1.06 | 4.51 | Ret 1.2 × 105 | 2.7 × 10−4 |

| Case 2 | Case 2 | Case 2 | |||||||||

| K 2.21 | 0.77 | Ret 3.17 × 106 | 6.5 × 10−4 | K 2.98 | 6.68 | Ret 6.6 × 105 | 5.4 × 10−4 | K 0.47 | 1.33 | Ret 0.83 × 105 | 5.0 × 10−4 |

| Case 3 | Case 3 | Case 3 | |||||||||

| K 3.18 | 1.33 | Ret 3.8 × 105 | 5.0 × 10−4 | K 1.90 | 3.40 | Ret 5.3 × 105 | 3.1 × 10−4 | K 2.96 | 20.92 | Ret 2.1 × 105 | 1.2 × 10−4 |

| Mechanism Number | Chemical Kinetics Mechanism | A (s−1) | β | Ta (K) | Reaction Order | References |

|---|---|---|---|---|---|---|

| T-S.1 | CH4 + 1.5O2 = CO + 2H20 | 1.398 × 10+10 | −0.062 | 14,038 | [CH4]0.5 [O2]1.066 | [64] |

| CO + 0.5O2 = CO2 | 7.66 × 10+11 | 0.215 | 9213 | [CO] [O2] | [64] | |

| C6H6 + 4.5O2 = 6CO + 3H2O | 2.4 × 10+11 | 0 | 15,098 | [C6H6]−0.1 [O2]1.85 | [65] | |

| T-S.2 | CH4 + 1.5O2 = CO + 2H2O | 1.400 × 10+10 | −0.062 | 14,040 | [CH4]0.5 [O2]1.066 | [31] |

| CO + 0.5O2 = CO2 | 7.380 × 10+11 | 0.215 | 9209 | [CO] [O2]0.5 | [31] | |

| C6H6 + 4.5O2 = 6CO2 + 3H2O | 1.7 × 10+11 | 0 | 15,098 | [C6H6]−0.1 [O2]1.85 | [65,66] | |

| F-S.1 | CH4 + 1.5O2 = CO + 2H2O | 1.4 × 10+10 | −0.062 | 14,038 | [CH4]0.5 [O2]1.066 | [64] |

| CO + 0.5O2 = CO2 | 2.24 × 10+12 | 0 | 20,471 | [O2]0.25 | [67] | |

| CO2 = CO + 0.5O2 | 5 × 10+8 | 0 | 20,471 | [CO2] | [67] | |

| C6H6 + 4.5O2 = 6CO2 + 3H2O | 2.4 × 10+11 | 0 | 15,098 | [C6H6]−0.1 [O2]1.85 | [65,66] | |

| F-S.2 | CH4 + 0.5O2 = CO + 2H2 | 4.4 × 10+11 | 0 | 15,034 | [CH4]0.5 [O2]1.25 | [66] |

| CO + 0.5O2 = CO2 | 7.66 × 10+11 | 0.215 | 9213 | [CO] [O2]0.25 | [31,68,69] | |

| H2 + 0.5O2 = H2O | 6.8 × 10+15 | −1 | 20,086 | [H2]0.25 [O2]1.5 | [65,66] | |

| C6H6 + 4.5O2 = 6CO + 3H2O | 2.4 × 10+11 | 0 | 15,098 | [C6H6]−0.1 [O2]1.85 |

| Species | C6H6 | CH4 | CO2 | O2 | H2O | CO | N2 | Primary Air | Secondary Air | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mass fraction | 0.130 | 0.029 | 0.264 | 0.019 | 0.109 | 0.015 | 0.432 | 0.233 | 0.767 | 0.233 | 0.767 |

| Temperature (K) | 1373 | 300 | 300 | ||||||||

| Intensity of turbulence (%) | 5 | 23 | 58 | ||||||||

| Turbulence length scale L(m) | 7 × 10−2 | 4 × 10−2 | 4 × 10−2 | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khlifi, S.; Lajili, M.; Perré, P.; Pozzobon, V. A Numerical Study of Turbulent Combustion of a Lignocellulosic Gas Mixture in an Updraft Fixed Bed Reactor. Sustainability 2022, 14, 16587. https://doi.org/10.3390/su142416587

Khlifi S, Lajili M, Perré P, Pozzobon V. A Numerical Study of Turbulent Combustion of a Lignocellulosic Gas Mixture in an Updraft Fixed Bed Reactor. Sustainability. 2022; 14(24):16587. https://doi.org/10.3390/su142416587

Chicago/Turabian StyleKhlifi, Saaida, Marzouk Lajili, Patrick Perré, and Victor Pozzobon. 2022. "A Numerical Study of Turbulent Combustion of a Lignocellulosic Gas Mixture in an Updraft Fixed Bed Reactor" Sustainability 14, no. 24: 16587. https://doi.org/10.3390/su142416587

APA StyleKhlifi, S., Lajili, M., Perré, P., & Pozzobon, V. (2022). A Numerical Study of Turbulent Combustion of a Lignocellulosic Gas Mixture in an Updraft Fixed Bed Reactor. Sustainability, 14(24), 16587. https://doi.org/10.3390/su142416587