Study on Blasting Effect Optimization to Promote Sustainable Mining under Frozen Conditions

Abstract

:1. Introduction

2. Joint Blasting Model

2.1. Joint Blasting Geometric Model

2.2. Explosives Equation of State and Rock Material Parameters

2.3. Numerical Simulation Results and Analysis

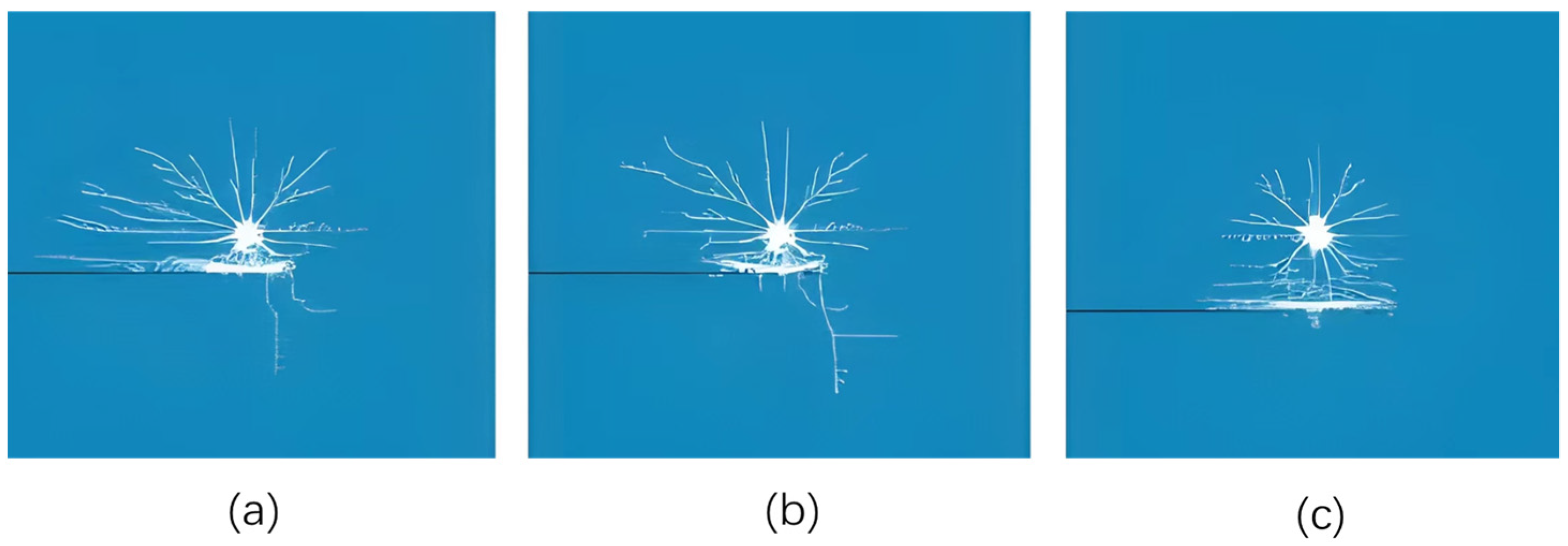

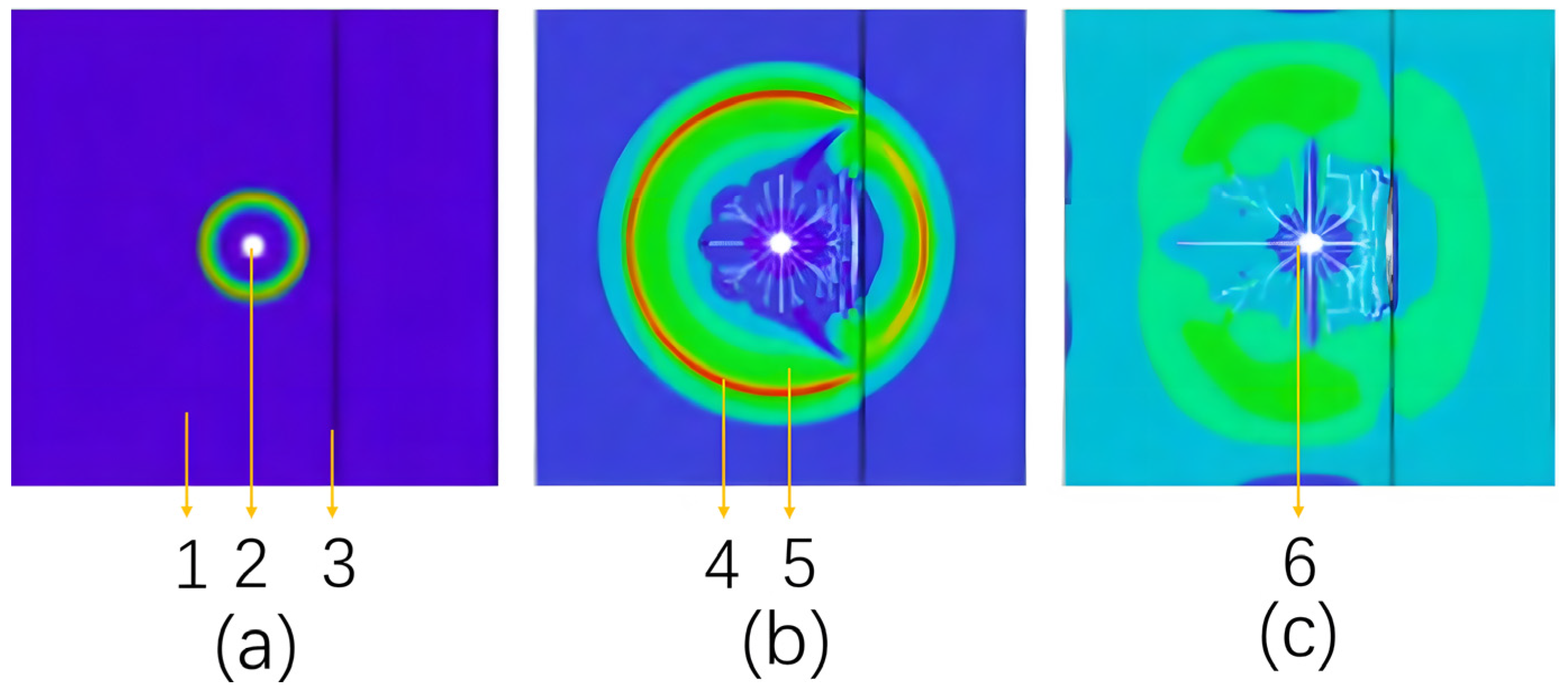

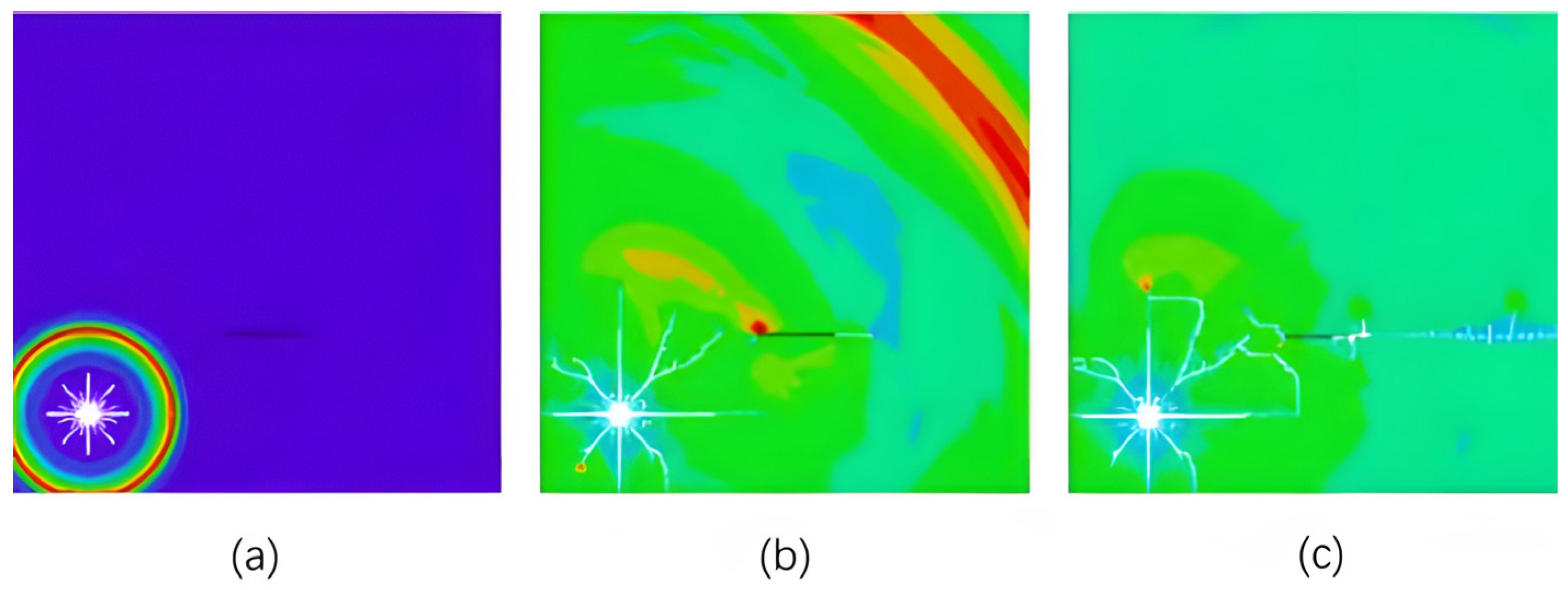

2.3.1. Analysis of Reflections and End Effects at the Nodal Surface of Semi-Infinite Joints

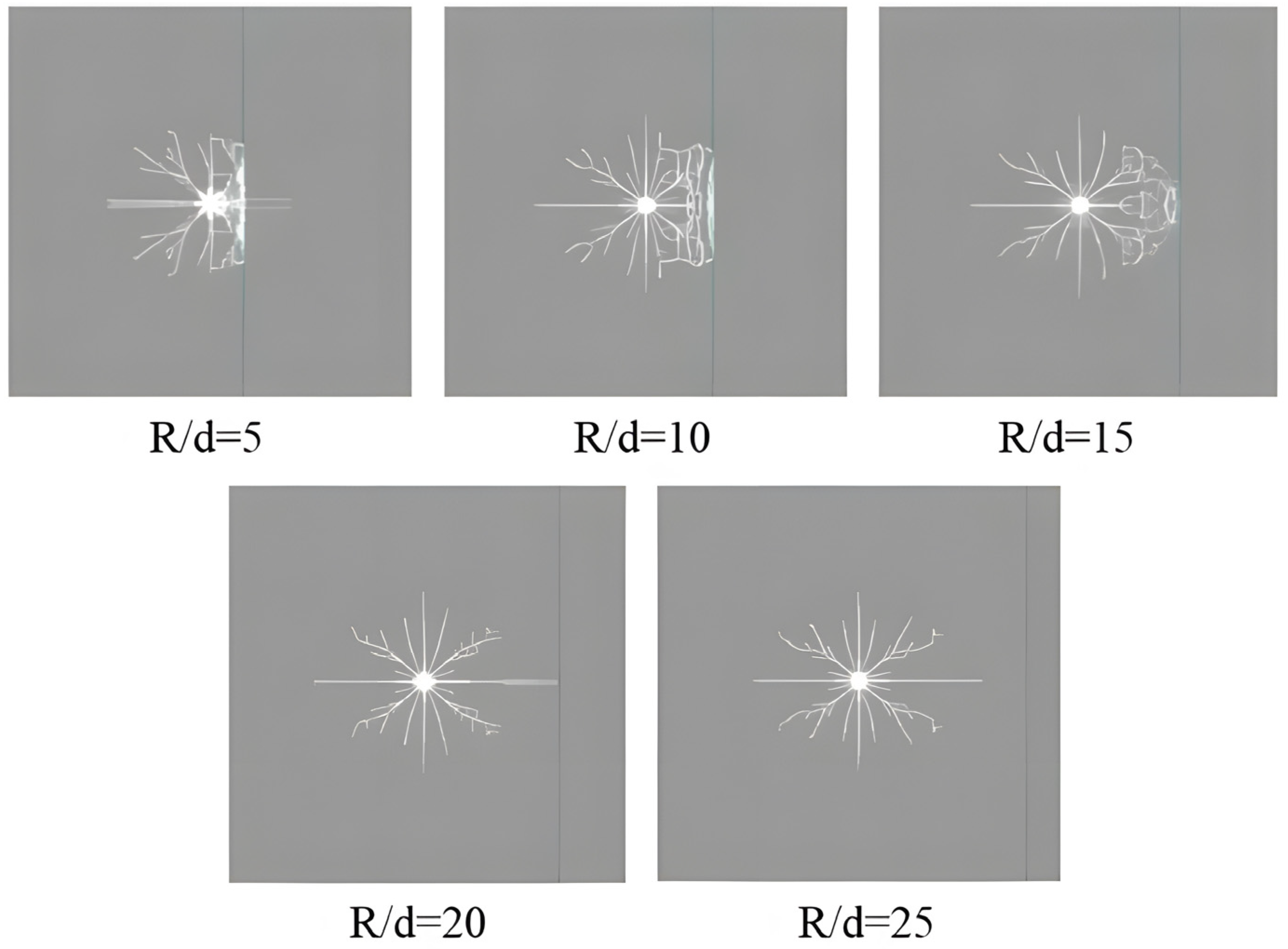

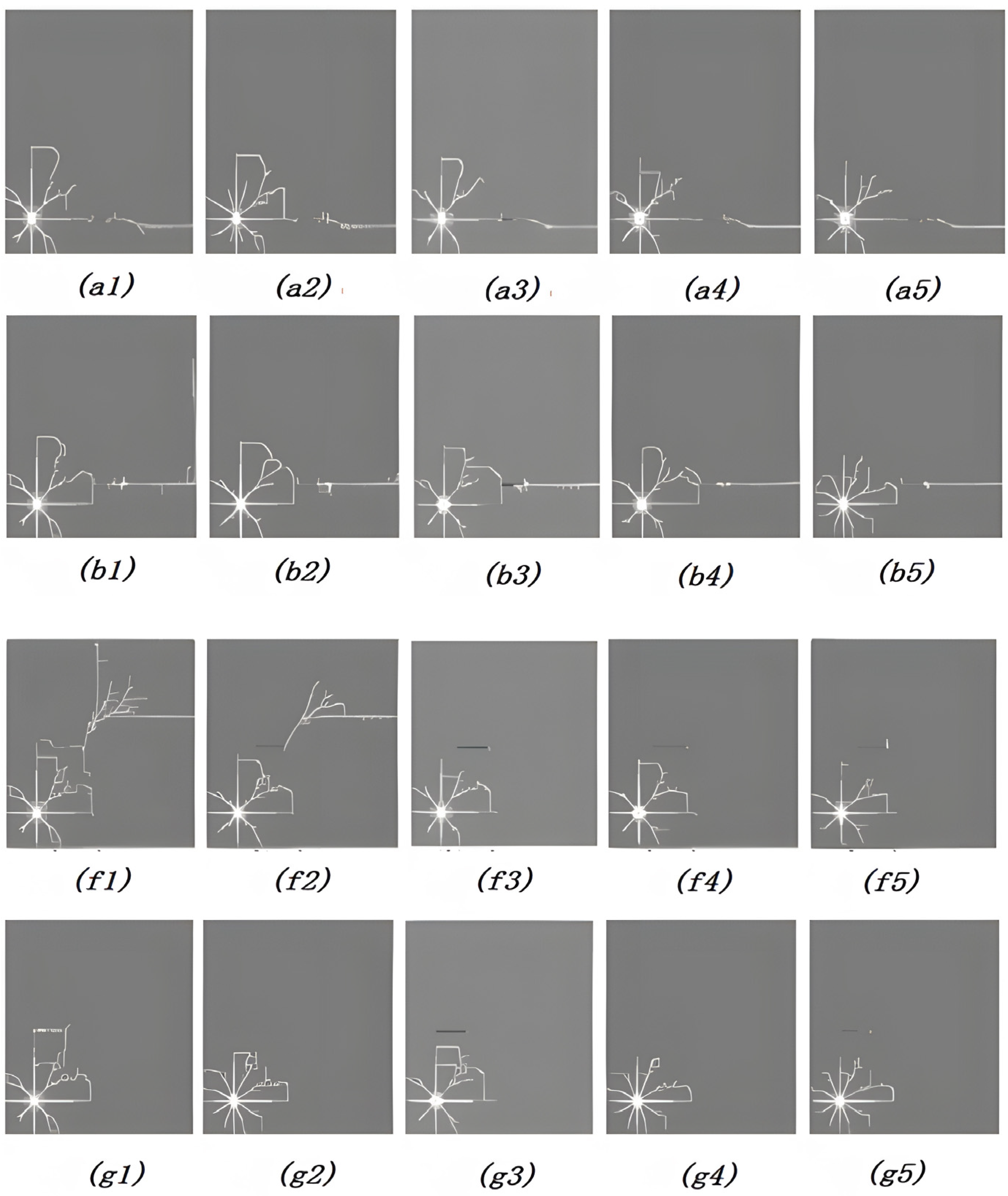

2.3.2. Analysis of the Effect of Nodal and Gun Hole Spacing on Blast Crack Expansion

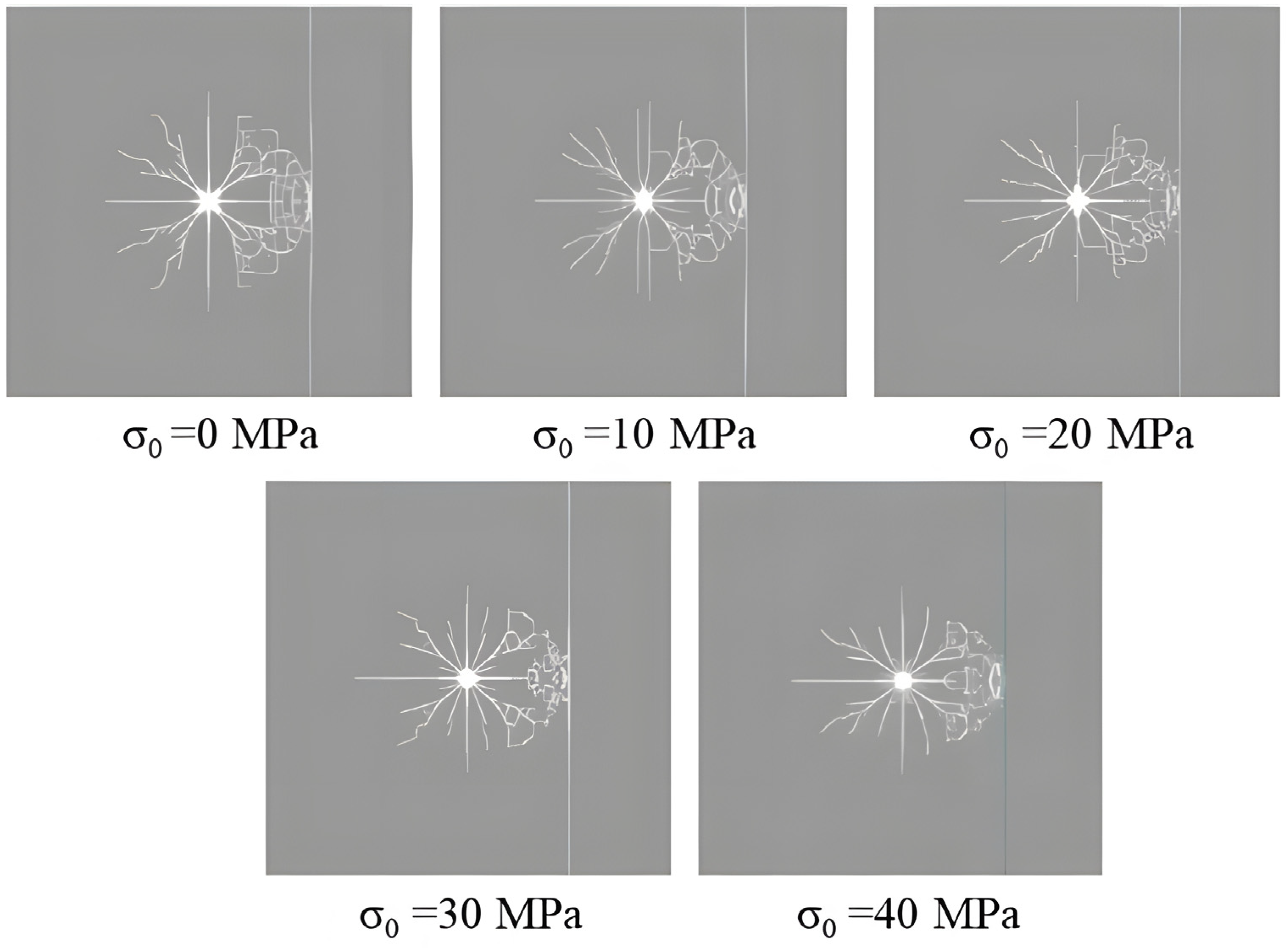

2.3.3. Analysis of the Effect of Static Stress on Blast Crack Expansion

2.3.4. Analysis of Crack Expansion Characteristics of the Nodal End-Derived Wing

3. Frozen Rock Blastability Study

3.1. Blast Funnel Experiment

3.2. Frozen Rock Blasting Block Size Distribution Characteristics

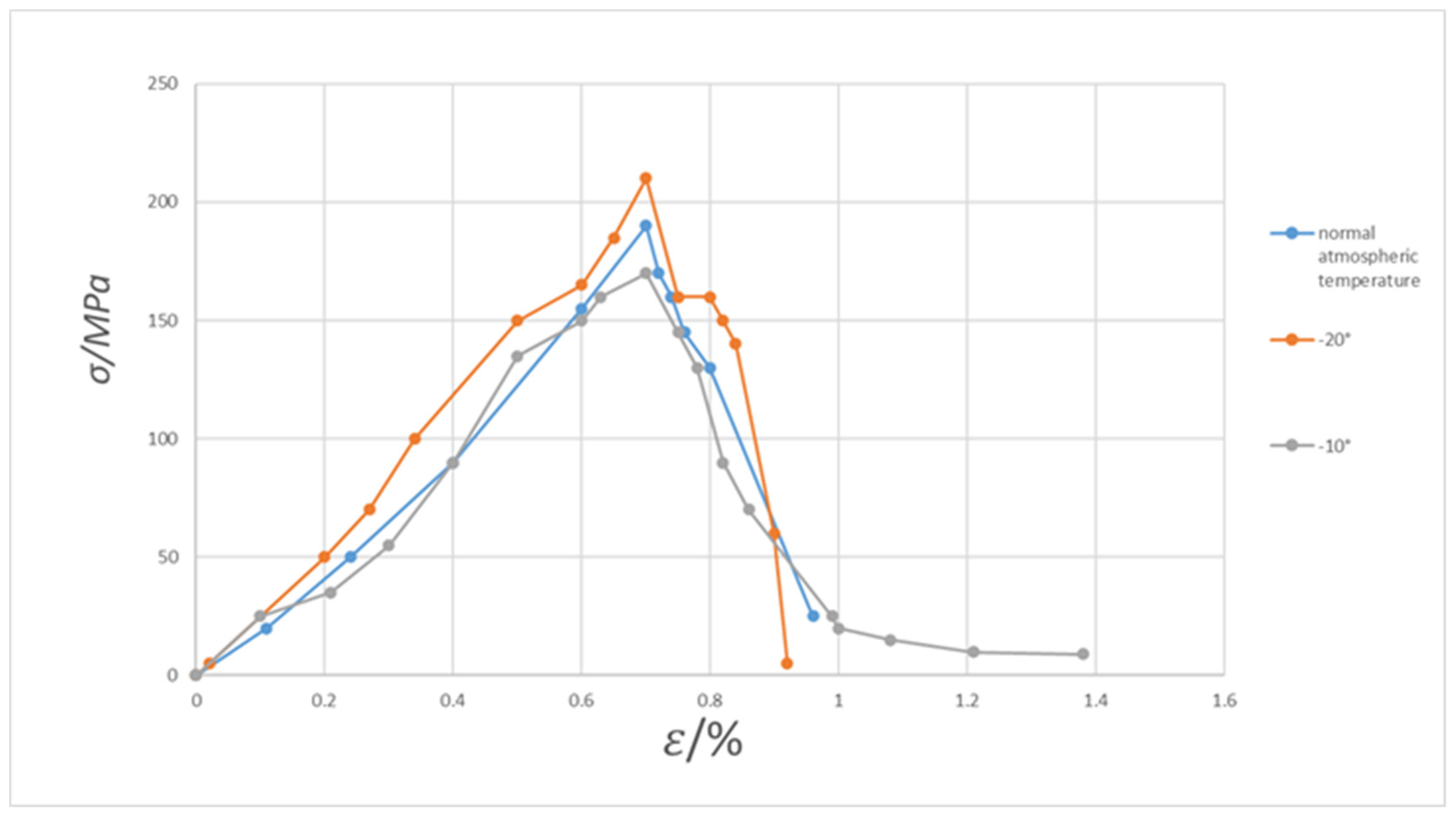

3.3. Study of Mechanical Properties of Frozen Rock

4. Engineering Cases

4.1. Project Overview

4.2. Blasting Problems

4.3. Optimization of Blasting Parameters

4.3.1. Hole Network Parameters

4.3.2. Explosives Unit Consumption

4.3.3. Blasting Interval Time

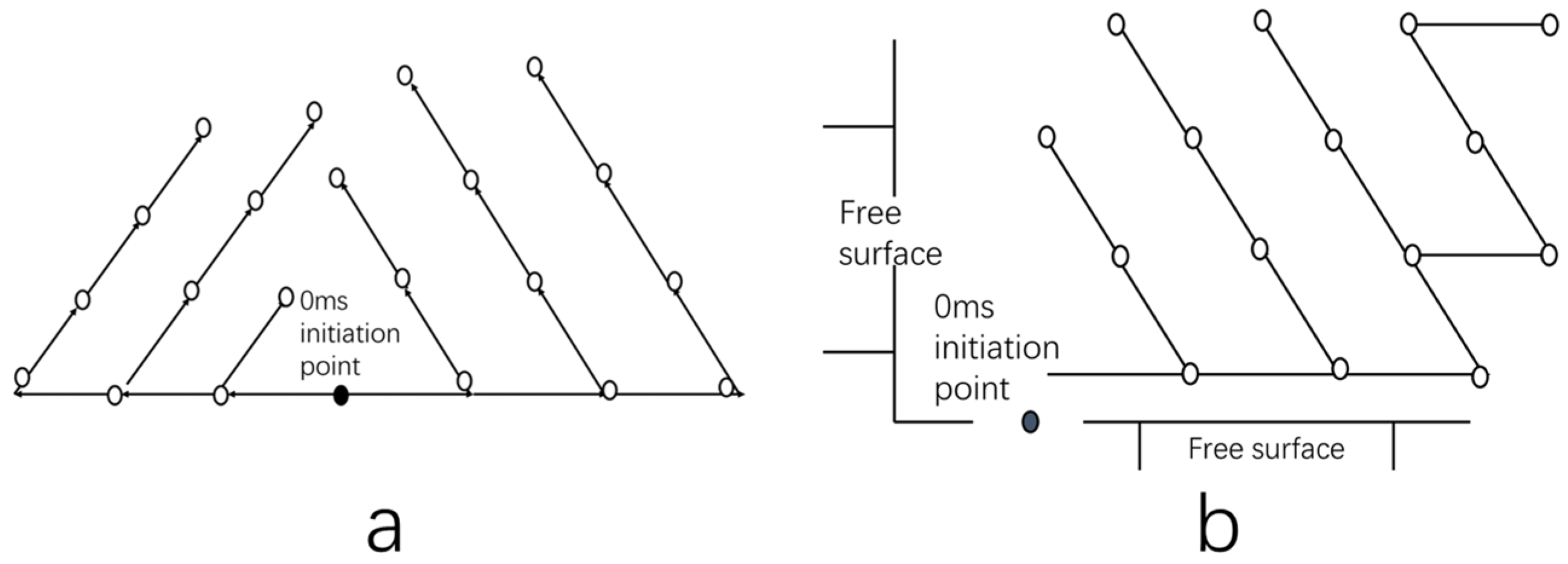

4.3.4. Multi-Nodular Frozen Rock Hole-By-Hole Detonation Technology

4.4. Blasting Optimization Effect

5. Conclusions and Future Work

- (1)

- In this paper, numerical simulation analysis was used to grasp the joint development and frost rock blasting crack propagation law. Therefore, the blasting effect of frozen rock can be judged according to different joint conditions to guide the blasting of jointed frozen rock.

- (2)

- The optimum charging depth and the critical depth of frozen rock were determined by a blasting funnel experiment. The relationship between the stress and strain of frozen rock at different temperatures was compared. Combined with the G-G-S function, the blasting parameters suitable for frozen rock in the mining area were obtained.

- (3)

- According to the environment and geological conditions of the mining area, the V-type hole-by-hole detonation method of multi-row hole oblique line and anti-inclined multi-row hole was determined. This method achieved a good blasting effect and ensured sustainable mining.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, Q.; Liu, Y.; Zhang, J.; Tong, C. A review of recent frozen soil engineering in permafrost regions along Qinghai–Tibet Highway, China. Permafr. Periglac. Process. 2002, 13, 199–205. [Google Scholar]

- Gao, F.; Zhou, K.; Xiong, X. Present Situation and Key Problems of Metal Mineral Resources Exploitation in high Cold Region of China. Min. Reaearch Dev. 2022, 42, 1–5. [Google Scholar] [CrossRef]

- Wei, G.P.; Zhang, S.C.; Zhou, Y.M.; Fei, H.J.; Guo, Z.T. Experimental study on frozen soil blasting in Yihaimuli open coal mine. Eng. Blasting 2017, 23, 1–5+20. [Google Scholar]

- Vyalov, S.S.; Yu, K.Z.; Gorodetsky, S.E. Stability of mine workings in frozen soils. Eng. Geol. 1979, 13, 339–351. [Google Scholar] [CrossRef]

- Wang, X.R.; Pouyan, A.; Chen, H.; Labuz, J.F. Microcracking in tensile fracture of a brittle rock. Eng. Fract. Mech. 2021, 251, 107789. [Google Scholar] [CrossRef]

- Wu, J.Y.; Jing, H.W.; Gao, Y.; Meng, Q.B.; Yin, Q.; Du, Y. Effects of carbon nanotube dosage and aggregate size distribution on mechanical property and microstructure of cemented rockfill. Cem. Concr. Compos. 2022, 127, 104408. [Google Scholar] [CrossRef]

- Huang, Z.; Wu, Y.; Zhang, R.; Zhong, W.; Li, S.; Zhang, C.; Zhao, K. Experimental investigation on the grouting characteristics of fractured sandstones under different confining pressures. Geomech. Geophys. Geo-Energ. Geo-Resour. 2022, 8, 201. [Google Scholar] [CrossRef]

- Wang, T.; Du, B.; Li, C.; Wang, H.; Zhou, W.; Wang, H.; Lin, Z.; Zhao, X.; Xiong, T. Ecological environment rehabilitation management model and key technologies in plateau alpine coal mine. Coal J. 2021, 46, 230–244. [Google Scholar] [CrossRef]

- Liu, W.; Xu, Y.B.; Fan, D.; Li, Y.; Shao, X.F.; Zheng, J.J. Alleviating Corporate Environmental Pollution Threats toward Public Health and Safety: The Role of Smart City and Artificial Intelligence. Saf. Sci. 2021, 143, 105433. [Google Scholar] [CrossRef]

- Chang, Z.G.; Ke-Min, L.I.; Ding, X.H.; Li, M.A.; Tao, L.I. Analysis on Influence of Cold Climate on Blasting Safety of Surface Mine. Eng. Blasting 2011, 17, 100–102. [Google Scholar]

- Wu, F.; Liu, Y.; Li, H.; Yao, Q. Fragmentation distribution prediction of rockfill materials based on statistical results of primary joints and simulation of blasting cracks. Chin. J. Rock Mech. Eng. 2017, 36, 1341–1352. [Google Scholar]

- Gnirk, P.F. On the correlation between explosive crater formation and rock properties. In Proceedings of the 9th U.S. Symposium on Rock Mechanics, Denver, CO, USA, 4 November 1967; pp. 321–345. [Google Scholar]

- Zhu, Z.; Yin, Y.; Chen, M.; Wei, D.; Lu, W.; Liu, J. Study on Prediction of Blasting Fragmentation in Changjiu Shenshan Limestone Mine. Blasting 2021, 38, 17–31. [Google Scholar]

- Xu, B.; Zhang, W.; Shi, W.; Hao, G.; Liu, X.; Mei, J. Experimental study of parameters of tunneling blasting in jointed layered rock mass. J. China Univ. Min. Technol. 2019, 48, 1248–1255. [Google Scholar]

- Li, J.; Zhang, J.; Zou, R.; Wang, S.; He, X. Experimental Study on Bench Blasting of Joint Fissure Rock Mass with High Water Content. Min. Res. Dev. 2018, 38, 6–9. [Google Scholar] [CrossRef]

- Zhong, Q.; Leng, Z.; Peng, Z.; Liu, F. Blasting Excavation of Deep Tunnel with Jointed Rock Mass: Damage Properties and Schemes. J. Yangtze River Sci. Res. Inst. 2018, 35, 89–94. [Google Scholar]

- Zhao, W.K.; Xia, F.; Chen, X. Causes and solutions of surface chunks of open blasting at Yulong copper mine, Tibet. Min. Res. Dev. 2021, 41, 21–25. [Google Scholar]

- Jiang, S.; Li, J.; Zhang, S.; Gu, Q.; Lu, C.; Liu, H. Landslide risk prediction by using GBRT algorithm: Application of artificial intelligence in disaster prevention of energy mining. Process Saf. Environ. Prot. 2022, 166, 384–392. [Google Scholar] [CrossRef]

- Jiang, S.; Liu, H.; Lian, M. Multi-source information fusion and displacement prediction of rock slope based on variable selection and SSA-DELM model. Front. Environ. Sci. 1687, 22, 101–189. [Google Scholar]

- Li, X.S.; Li, Q.H.; Hu, Y.J.; Teng, L.; Yang, S. Evolution Characteristics of Mining Fissures in Overlying Strata of Stope after Converting from Open-Pit to Underground. Arab. J. Geosci. 2021, 14, 1–18. [Google Scholar] [CrossRef]

- Shao, X.F.; Zhong, Y.F.; Liu, W.; Li, Y.R.M. Modeling the effect of green technology innovation and renewable energy on carbon neutrality in N-11 countries? Evidence from advance panel estimations. J. Environ. Manag. 2021, 296, 113189. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.B.; Liu, W.; Pu, R.H.; Xu, Y.H. Be Green to be Innovative: The Role of Government Subsidies. Front. Environ. Sci. 2021, 9, 765100. [Google Scholar] [CrossRef]

- Jin, F. Promoting the development of integration and innovation in Northeast China with new infrastructure as a traction. Learn. Explor. 2021, 4, 120–124. [Google Scholar]

- Dobratz, M. Properties of chemical explosives and explosive simultants. Int. J. Neurosci. 1981, 51, 339–340. [Google Scholar]

- Tang, Y.; Kong, D.-R. Numerical simulation study on the trajectory of three wave points in the explosion field of TNT explosives. J. Test. Technol. 2021, 4, 352–357. Available online: http://kns.cnki.net/kcms/detail/14.1301.TP.20210616.1111.026.html (accessed on 4 November 2022).

- Miao, Y.S.; Li, X.; Yan, H.H.; Wang, X.H.; Sun, J. Symmetric Bilinear Initiation Technique in Engineering Blasting. Eng. Blasting 2017, 23, 6–11. [Google Scholar]

- Tan, Z.; Kuang, C.; Yang, X.; Wang, M. Research on blasting technology for construction of fenghuoshan tunnel in permafrost. Chinese J. Rock Mech. Eng. 2006, 25, 1056–1061. [Google Scholar]

- Ma, Q. Model Test of Explosion Crater and Blast Ability of Frozen Soil. J. China Coal Soc. 1997, 3, 66–71. [Google Scholar]

- Yu, J.-X. Crater test of deep shaft frozen soil blasting in west air shaft of Zhaogu No.2 Mine. Coal Eng. 2021, 53, 29–34. [Google Scholar]

- Li, C.-C. Study on Optimization of Frozen Soil Blasting Effect in High Latitude and Cold Region. Blasting. 2022. Available online: http://kns.cnki.net/kcms/detail/42.1164.tj.20221115.1107.002.html (accessed on 26 October 2022).

| Density ρ (kg/m3) | Explosion Velocity D (m/s) | A (GPa) | B (GPa) | R1 | R2 | ω | EV (GPa) |

|---|---|---|---|---|---|---|---|

| 1630 | 6930 | 371 | 7.43 | 4.15 | 0.95 | 0.3 | 7 |

| Temperature /°C | ρ (g/cm3) | E0 (GPa) | μ | σc (MPa) |

|---|---|---|---|---|

| 10 | 2.60 | 51.8 | 0.33 | 150 |

| −10 | 2.60 | 60.1 | 0.30 | 163 |

| 20 | 2.60 | 65.8 | 0.28 | 176 |

| Ρ (g/cm3) | E0 (GPa) | μ | Etan (GPa) |

|---|---|---|---|

| 1.60 | 20.0 | 0.3 | 2.5 |

| ρ (g/m3) | G (Pa) | SIGY (Pa) | BULK (Pa) | PRF (Pa) |

|---|---|---|---|---|

| 0.9 g/m3 | 2.2 × 109 | 2.12 × 106 | 5.26 × 109 | −4 × 106 |

| ρ (g/m3) | C0 | C4 | C5 | E0 | V0 |

|---|---|---|---|---|---|

| 1.29 × 10−3 | −1 × 10−6 | 0.4 | 0.4 | 2.5 × 10−6 | 1 |

| Name | °C | Best Depth | Critical Depth | V (×10−6 m3) | R (mm) | H (mm) | 0~10 mm | 10~25 mm | 25~40 mm | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (g) | % | Weight (g) | % | Weight (g) | % | |||||||

| L1 | 10 | 56 | 72 | 156 | 60 | 41 | 18 | 8.96 | 85 | 32 | 62 | 18.32 |

| L2 | −10 | 35 | 67 | 112 | 57 | 32 | 14 | 6.93 | 91 | 45.05 | 57 | 28.22 |

| L3 | −10 | 50 | 65 | 54 | 52.7 | 20 | 3 | 2.24 | 22 | 16.42 | 72 | 53.73 |

| L4 | −10 | 65 | 80 | 110 | 52 | 45 | 9 | 4.50 | 11 | 5.50 | 61 | 30.50 |

| L6 | −10 | 55 | 70 | 65 | 46 | 28 | 13 | 9.90 | 19 | 13.29 | 84 | 58.74 |

| L7 | −20 | 36 | 60 | 37 | 37 | 24 | 6 | 8.54 | 19 | 26.76 | 19 | 26.76 |

| L8 | −20 | 42 | 63 | 39 | 38 | 25 | 8 | 8.66 | 21 | 27.23 | 21 | 25.33 |

| L9 | −20 | 35 | 59 | 35 | 36 | 24 | 7 | 8.66 | 18 | 26.37 | 20 | 26.12 |

| Name | R-R Function | Correlation Coefficient | Test Value | D0/D50 | ||

|---|---|---|---|---|---|---|

| D0 (mm) | a | D50 (mm) | ||||

| −20 °C | 30.841 | 2.278 | 26.278 | 0.996 | 115.223 | 1.174 |

| −10 °C | 40.685 | 1.728 | 32.910 | 0.999 | 616.220 | 1.236 |

| −20 °C | 55.509 | 1.968 | 46.076 | 0.945 | 16.694 | 1.205 |

| 10 °C | 37.550 | 1.928 | 31.408 | 0.934 | 6.863 | 1.209 |

| Name | G-G-S Function | Correlation Coefficient | Test Value | D0/D50 | ||

|---|---|---|---|---|---|---|

| D0 (mm) | a | D50 (mm) | ||||

| −10 °C | 45.082 | 1.679 | 29.831 | 0.982 | 52.689 | 1.509 |

| 10 °C | 51.779 | 1.498 | 32.599 | 0.998 | 509.750 | 1.588 |

| −10 °C | 71.106 | 1.693 | 47.215 | 0.958 | 22.063 | 1.506 |

| −20 °C | 51.735 | 1.542 | 33.000 | 0.974 | 32.216 | 1.567 |

| Ore Body Name | Inclination | Thickness | Solid Mineral Rock | Permissible Exposed Area of Roof Plate | Ore Rock Laminations |

|---|---|---|---|---|---|

| Lower plate 3# ore body | 32°−40° | 10 m–20 m | Below medium solid | About 600 m2 | Development, prone to the overall top plate bubble fall |

| 12# ore body | |||||

| North 3# ore body |

| Whether Optimized | Pore Size mm | Step Height m | Hole Depth m | Hole Spacing m | Row Spacing m | Filling Height m | Explosive Consumption kg/m3 |

|---|---|---|---|---|---|---|---|

| Before | 90 | 10 | 12.0 | 4.0 | 2.0 | ≥2 | 0.50 |

| After | 90 | 10 | 11.5 | 5.0 | 2.5 | ≥2 | 0.55 |

| Projects | Explosive Distance ≥cm | Explosive Intensity ≥mm | Explosive Speed ≥m/s | Density g/m3 | Expiration Date | ||

|---|---|---|---|---|---|---|---|

| Days | Valid Period | ||||||

| Explosive Distance ≥cm | Explosive Speed ≥m/s | ||||||

| Performance Indicators | 3 | 12 | 3.2 × 103 | 0.95~1.3 | 180 | 3 | 3.2 × 103 |

| Nodal Type | Frozen Rock Temperature | Inter-Hole Extension Time | Inter-Arrangement Extension Time | In-Hole Extension Time | |||

|---|---|---|---|---|---|---|---|

| Section | Time Delay | Section | Time Delay | Section | Time Delay | ||

| Vertical nodes | Room temperature | MS3 | 50 ms | MS5 | 110 ms | MS11 | 490 ms |

| −10 °C | MS3 | 50 ms | MS5 | 110 ms | MS13 | 720 ms | |

| −20 °C | MS2 | 25 ms | MS4 | 75 ms | MS13 | 720 ms | |

| Parallel nodes | Room temperature | MS2 | 25 ms | MS4 | 75 ms | MS11 | 490 ms |

| −10 °C | MS2 | 25 ms | MS4 | 75 ms | MS13 | 720 ms | |

| −20 °C | MS2 | 25 ms | MS4 | 75 ms | MS13 | 720 ms | |

| Mixed nodes | Room temperature | MS3 | 50 ms | MS5 | 110 ms | MS11 | 490 ms |

| −10 °C | MS3 | 50 ms | MS5 | 110 ms | MS13 | 720 ms | |

| −20 °C | MS2 | 25 ms | MS4 | 75 ms | MS13 | 720 ms | |

| MS2, MS3, MS4, MS5 error is ±10 ms; MS11 error is ±45 ms; MS13 error is ±50 ms. | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, P.; Li, Y.; Lu, C.; Jiang, S.; Xu, H. Study on Blasting Effect Optimization to Promote Sustainable Mining under Frozen Conditions. Sustainability 2022, 14, 16479. https://doi.org/10.3390/su142416479

Cheng P, Li Y, Lu C, Jiang S, Xu H. Study on Blasting Effect Optimization to Promote Sustainable Mining under Frozen Conditions. Sustainability. 2022; 14(24):16479. https://doi.org/10.3390/su142416479

Chicago/Turabian StyleCheng, Ping, Yanbo Li, Caiwu Lu, Song Jiang, and Hanhua Xu. 2022. "Study on Blasting Effect Optimization to Promote Sustainable Mining under Frozen Conditions" Sustainability 14, no. 24: 16479. https://doi.org/10.3390/su142416479

APA StyleCheng, P., Li, Y., Lu, C., Jiang, S., & Xu, H. (2022). Study on Blasting Effect Optimization to Promote Sustainable Mining under Frozen Conditions. Sustainability, 14(24), 16479. https://doi.org/10.3390/su142416479