Municipal Solid Waste as a Substitute for Virgin Materials in the Construction Industry: A Review

Abstract

1. Introduction

2. Theoretical Framework

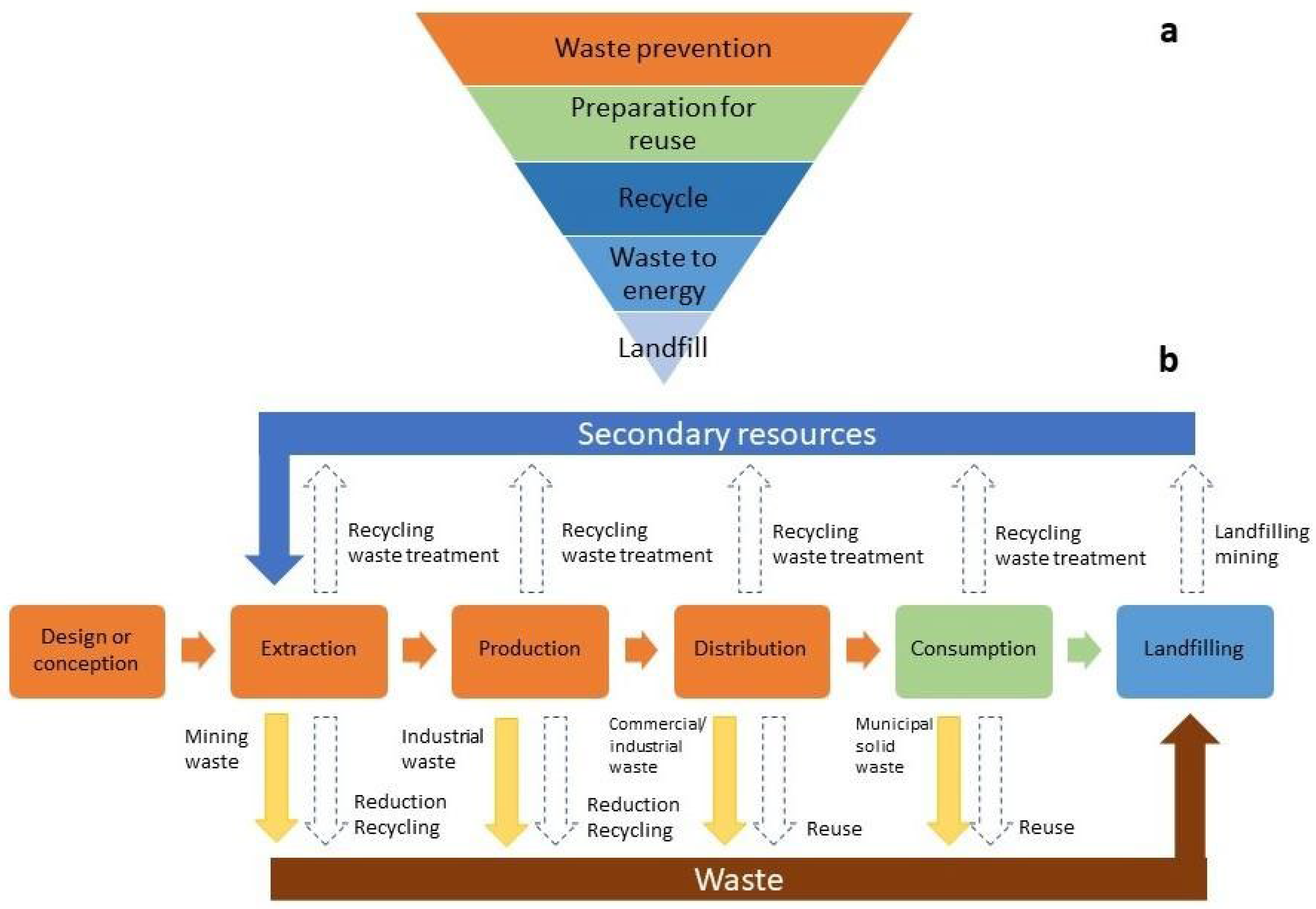

2.1. The Waste Management Hierarchy and the Circular Economy

2.2. Circular Economy Initiatives in Latin America and the Caribbean

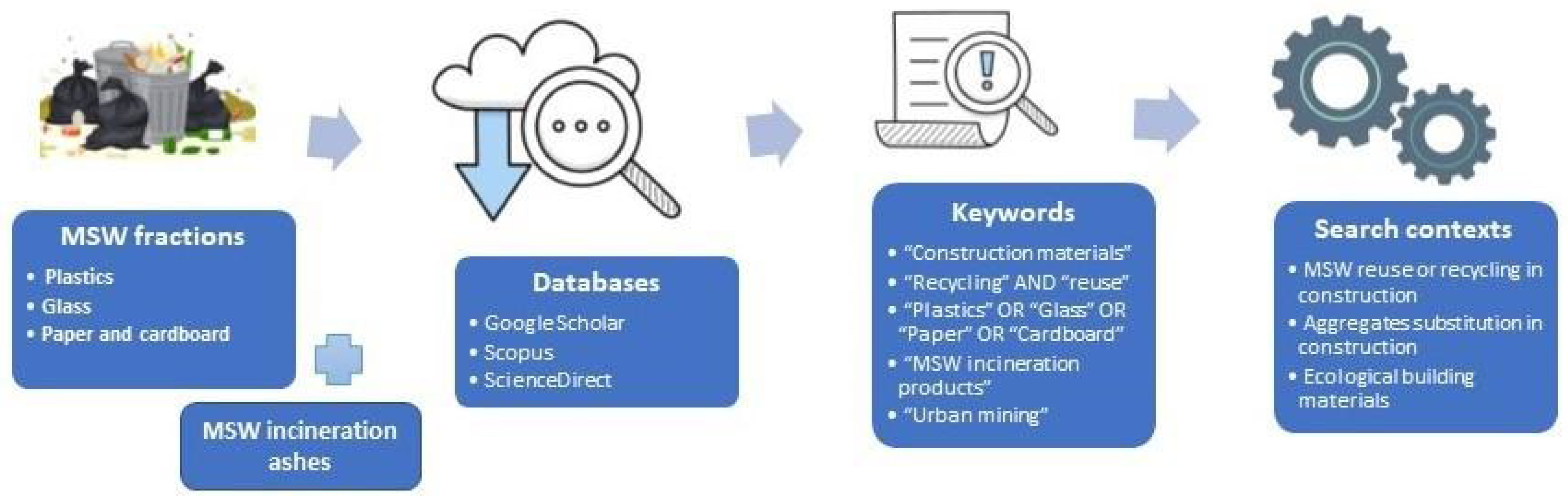

3. Methodology

4. Municipal Solid Waste and Its Use in Construction

4.1. Plastics

| Plastic Waste (PW) Description | Replaced or Added Amount | Effects of the Modification | Recycling/ Reuse | Reference |

|---|---|---|---|---|

| PET aggregates 1 (5–12 mm) | 20%, 30%, 40% | The compressive strength of concrete with 20% PET replacement (30.3 MPa) was only 9% less than in the controls and had higher workability. This concrete can be used for structural purposes. | Recycling | [29] |

| LDPE fibers and/or PW aggregates 2 (4.75–20 mm) | 1% fibers, 6–30% aggregates | Concrete with 1% of fibers had higher compressive and tensile strengths than the control. Replacement of natural materials by up to 30% of PW aggregates led to materials suitable for structural uses. | Reuse | [30] |

| PP fibers 3 (1.5 mm width, 0.7 mm thickness, 47 mm length) | 4–6 kg/m3 | PP fibers had good resistance in concrete and other alkaline media. Concrete modified with PP fibers showed excellent post-cracking performance and ductility. | Recycling | [32] |

| HDPE 4 (0.125–4 mm) or EVA PW4 (diameter < 4 mm) | 5% PW in the binder | Asphalt mix (AC 14 SURF, prepared with aggregates and 70/100 pen-grade bitumen) was modified with PW through the wet process. The PW-modified binders were stiffer and more elastic when compared with the unmodified bitumen. | Recycling | [38] |

| PW 5 strips (12 mm width, 0.4 mm thickness, 12–36 mm length) | 0.25–4% (ratio of PW weight to subbase weight) | Reinforcement with PW strips increased the strength and secant modulus of pavement sub-bases. The maximum improvement was obtained with a 4% addition of 36 mm length PW strips. | Reuse | [39] |

4.2. Glass

4.3. Paper and Cardboard

4.4. Ashes from the MSW Incineration

5. Waste Reuse and Recycling in Sustainable Construction

5.1. Towards a Crisis of Aggregates?

5.2. Barriers Limiting MSW Employment in Construction

5.3. Strategies of Some Countries to Promote Waste Reuse and Recycling in Construction

6. Areas of Opportunity in Latin America and the Caribbean Construction Industry

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chang, N.B.; Pires, A. Sustainable Solid Waste Management: A Systems Engineering Approach; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Bukhkalo, S.I.; Klemeš, J.J.; Tovazhnyanskyy, L.L.; Arsenyeva, O.P.; Kapustenko, P.O.; Perevertaylenko, O.Y. Eco-Friendly Synergetic Processes of Municipal Solid Waste Polymer Utilization. Chem. Eng. Trans. 2018, 70, 1–6. [Google Scholar]

- European Environment Agency. Overview of National Waste Prevention Programmes in Europe; European Environment Agency: Sweden, 2021; p. 14. Available online: https://www.eea.europa.eu/themes/waste/waste-prevention/countries/sweden-waste-prevention-country-profile-2021.pdf (accessed on 5 October 2022).

- Schröder, P.; Albaladejo, M.; Ribas, P.A.; MacEwen, M.; Tilkanen, J. The Circular Economy in Latin America and the Caribbean; The Royal Institute of International Affairs, Chatham House: London, UK, 2020. [Google Scholar]

- ONU Medio Ambiente. Perspectiva de la Gestión de Residuos en América Latina y el Caribe; Programa de las Naciones Unidas para el Medio Ambiente, Oficina para América Latina y el Caribe: Ciudad de Panamá, Panama, 2018. [Google Scholar]

- López-Ruiz, L.A.; Roca-Ramón, X.; Gassó-Domingo, S. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Summary for Policymakers. In Climate Change 2022: Impacts, Adaptation, and Vulnerability. Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Pörtner, H.-O., Roberts, D.C., Tignor, M., Poloczanska, E.S., Mintenbeck, K., Alegría, A., Craig, M., Langsdorf, S., Löschke, S., Möller, V., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022; pp. 3–33. [Google Scholar] [CrossRef]

- Pomponi, F.; Stephan, A. Water, energy, and carbon dioxide footprints of the construction sector: A case study on developed and developing economies. Water Res. 2021, 194, 116935. [Google Scholar] [CrossRef] [PubMed]

- Elhacham, E.; Ben-Uri, L.; Grozovski, J.; Bar-On, Y.M.; Milo, R. Global human-made mass exceeds all living biomass. Nature 2020, 588, 442–444. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Waste and Climate Change. Global Trends and Strategy Framework; International Environmental Technology Centre—UNEP: Osaka, Japan, 2010. [Google Scholar]

- Reike, D.; Vermeulen, W.J.; Witjes, S. The circular economy: New or refurbished as CE 3.0?—Exploring controversies in the conceptualization of the circular economy through a focus on history and resource value retention options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Circular Economy Coalition for Latin America and the Caribbean. Overview. Available online: https://coalicioneconomiacircular.org/en/home/ (accessed on 10 November 2022).

- Red de Economía Circular—Gobierno de la Ciudad de Buenos Aires. Available online: https://ciudadverde.gob.ar/red-de-economia-circular/# (accessed on 10 November 2022).

- Muñoz-Meléndez, G.; Delgado-Ramos, G.C.; Díaz-Chávez, R. Circular Economy in Mexico. In Circular Economy: Recent Trends in Global Perspective; Ghosh, S.K., Ghosh, S.K., Eds.; Springer: Singapore, 2021; pp. 497–523. [Google Scholar]

- Ayora-Sánchez, J.I.; Zárate-Carabajo, A.E.; Jimbo-Días, J.S. La verdadera inclusión: Controversia entre el reciclaje inclusivo y el reciclaje justo, en el marco del desarrollo sostenible. Let. Verdes–Rev. Latinoam. Estud. Socioamb. 2020, 27, 71–89. [Google Scholar] [CrossRef]

- Soliz-Torres, M.F.; Yépez-Fuentes, M.A.; Valencia-Velasco, M.D.; Solíz-Carrión, R.F. Reciclaje sin RecicladorAs es Basura: El Retorno de las Brujas; Universidad Andina Simón Bolívar-Ediciones La Tierra: Quito, Ecuador, 2019. [Google Scholar]

- Calderón-Márquez, A.J.; Rutkowski, E.W. Waste management drivers towards a circular economy in the global south—The Colombian case. Waste Manag. 2020, 110, 53–65. [Google Scholar] [CrossRef]

- Salvador, R.; Pereira, R.B.; Sales, G.F.; de Oliveira, V.C.V.; Halog, A.; De Francisco, A.C. Current Panorama, Practice Gaps, and Recommendations to Accelerate the Transition to a Circular Bioeconomy in Latin America and the Caribbean. Circ. Econ. Sustain. 2022, 2, 281–312. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Lynn, C.J.; Dhir, R.K. Environmental impacts of the use of bottom ashes from municipal solid waste incineration: A review. Resour. Conserv. Recycl. 2019, 140, 23–35. [Google Scholar] [CrossRef]

- United Nations. Millenium Summit, 6–8 September, New York. Available online: https://www.un.org/en/conferences/environment/newyork2000 (accessed on 15 November 2022).

- Organisation for Economic Co-operation and Development. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD Publishing: Paris, France, 2022. [Google Scholar]

- Imteaz, M.; Mohammadinia, A.; Arulrajah, A. Environmental suitability, carbon footprint and cost savings of recycled plastic for railway applications. Int. J. Sustain. Eng. 2021, 14, 725–734. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Šavija, B.; Paul, S.C.; Anggraini, V. Engineering properties of concrete with waste recycled plastic: A review. Sustainability 2018, 10, 3875. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Islam, M.J.; Meherier, M.S.; Islam, A.R. Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Dhanani, M.G.; Bhimani, M.P. Effect of use plastic aggregates as partial replacement of natural aggregates in concrete with plastic fibres. Int. Res. J. Eng. Technol. 2016, 3, 2569–2573. [Google Scholar]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Riella, J.; Chung, D.; Collister, T.; Combe, M.; Sivakugan, N. Comparative evaluation of virgin and recycled polypropylene fibre reinforced concrete. Constr. Build. Mater. 2016, 114, 134–141. [Google Scholar] [CrossRef]

- Ahmadi, M.; Farzin, S.; Hassani, A.; Motamedi, M. Mechanical properties of the concrete containing recycled fibers and ag-gregates. Constr. Build. Mater. 2017, 144, 392–398. [Google Scholar] [CrossRef]

- Foti, D. Use of recycled waste PET bottles fibers for the reinforcement of concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar] [CrossRef]

- Berkowski, P.; Kosior-Kazberuk, M. Effect of fiber on the concrete resistance to surface scaling due to cyclic freezing and thawing. Procedia Eng. 2015, 111, 121–127. [Google Scholar] [CrossRef]

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76–87. [Google Scholar] [CrossRef]

- Ochi, T.; Okubo, S.; Fukui, K. Development of recycled PET fiber and its application as concrete-reinforcing fiber. Cem. Concr. Compos. 2007, 29, 448–455. [Google Scholar] [CrossRef]

- Ranieri, M.; Costa, L.; Oliveira, J.R.; Silva, H.M.; Celauro, C. Asphalt surface mixtures with improved performance using waste polymers via dry and wet processes. J. Mater. Civ. Eng. 2017, 29, 04017169. [Google Scholar] [CrossRef]

- Choudhary, A.K.; Jha, J.N.; Gill, K.S. Utilization of plastic wastes for improving the sub-grades in flexible pavements. Paving Mater. Pavement Anal. 2010, 320–326. [Google Scholar] [CrossRef]

- Enfrin, M.; Myszka, R.; Giustozzi, F. Paving roads with recycled plastics: Microplastic pollution or Eco-friendly solution? J. Hazard. Mater. 2022, 437, 129334. [Google Scholar] [CrossRef]

- Mansour, A.M.H.; Ali, S.A. Reusing waste plastic bottles as an alternative sustainable building material. Energy Sustain. Dev. 2015, 24, 79–85. [Google Scholar] [CrossRef]

- Gedik, A. An exploration into the utilization of recycled waste glass as a surrogate powder to crushed stone dust in asphalt pavement construction. Constr. Build. Mater. 2021, 300, 123980. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Thomas, B. Effect of recycled waste glass on the properties of high-performance concrete: A critical review. Case Stud. Constr. Mater. 2022, 17, e01149. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Influence of fineness of ground recycled glass on mitigation of alkali–silica reaction in mortars. Constr. Build. Mater. 2015, 81, 257–267. [Google Scholar] [CrossRef]

- Lu, J.X.; Poon, C.S. Recycling of waste glass in construction materials. In New Trends in Eco-Efficient and Recycled Concrete; Woodhead Publishing: Cambridge, UK, 2018; pp. 153–167. [Google Scholar] [CrossRef]

- de Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based ma-terials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- Faraj, R.H.; Ali, H.F.H.; Sherwani, A.F.H.; Hassan, B.R.; Karim, H. Use of recycled plastic in self-compacting concrete: A comprehensive review on fresh and mechanical properties. J. Build. Eng. 2020, 30, 101283. [Google Scholar] [CrossRef]

- Tamanna, N.; Tuladhar, R.; Sivakugan, N. Performance of recycled waste glass sand as partial replacement of sand in concrete. Constr. Build. Mater. 2020, 239, 117804. [Google Scholar] [CrossRef]

- Yaghoubi, E.; Yaghoubi, M.; Guerrieri, M.; Sudarsanan, N. Improving expansive clay subgrades using recycled glass: Resilient modulus characteristics and pavement performance. Constr. Build. Mater. 2021, 302, 124384. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; McCarthy, T.J.; Robati, M.; Allen, M. Experimental investigation on foam concrete without and with recycled glass powder: A sustainable solution for future construction. Constr. Build. Mater. 2019, 201, 369–379. [Google Scholar] [CrossRef]

- Ahmad, A.; Adil, M.; Khalil, A.; Rahman, M. Mechanical properties and durability of boardcrete blocks prepared from recycled cardboard. J. Build. Eng. 2021, 33, 101644. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759. [Google Scholar] [CrossRef]

- Haigh, R.; Bouras, Y.; Sandanayake, M.; Vrcelj, Z. The mechanical performance of recycled cardboard kraft fibres within cement and concrete composites. Constr. Build. Mater. 2022, 317, 125920. [Google Scholar] [CrossRef]

- Sair, S.; Mandili, B.; Taqi, M.; El Bouari, A. Development of a new eco-friendly composite material based on gypsum reinforced with a mixture of cork fibre and cardboard waste for building thermal insulation. Compos. Commun. 2019, 16, 20–24. [Google Scholar] [CrossRef]

- Łątka, J.F.; Jasiołek, A.; Karolak, A.; Niewiadomski, P.; Noszczyk, P.; Klimek, A.; Jezierska, D. Properties of paper-based products as a building material in architecture—An interdisciplinary review. J. Build. Eng. 2022, 50, 104135. [Google Scholar] [CrossRef]

- McCracken, A.; Sadeghian, P. Corrugated cardboard core sandwich beams with bio-based flax fiber composite skins. J. Build. Eng. 2018, 20, 114–122. [Google Scholar] [CrossRef]

- Imperadori, M.; Salvalai, G.; Pusceddu, C. Air shelter house technology and its application to shelter units: The case of scaffold house and cardboard shelter installations. Procedia Econ. Financ. 2014, 18, 552–559. [Google Scholar] [CrossRef]

- Asdrubali, F.; Pisello, A.L.; D’Alessandro, F.; Bianchi, F.; Fabiani, C.; Cornicchia, M.; Rotili, A. Experimental and numerical characterization of innovative cardboard based panels: Thermal and acoustic performance analysis and life cycle assessment. Build. Environ. 2016, 95, 145–159. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.; Xue, C. Advanced progress in recycling municipal and construction solid wastes for manufacturing sustainable construction materials. Resour. Conserv. Recycl. 2020, 6, 100036. [Google Scholar] [CrossRef]

- Parkes, B.; Hansell, A.L.; Ghosh, R.E.; Douglas, P.; Fecht, D.; Wellesley, D.; Kurinczukh, J.J.; Rankini, J.; de Hoogh, K.; Fuller, G.W.; et al. Risk of congenital anomalies near municipal waste incinerators in England and Scotland: Retrospective population-based cohort study. Environ. Int. 2020, 134, 104845. [Google Scholar] [CrossRef]

- Tait, P.W.; Brew, J.; Che, A.; Costanzo, A.; Danyluk, A.; Davis, M.; Khalaf, A.; McMahon, K.; Watson, A.; Rowcliff, K.; et al. The health impacts of waste incineration: A systematic review. Aust. N. Z. J. Public Health 2020, 44, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, R.E.; Freni-Sterrantino, A.; Douglas, P.; Parkes, B.; Fecht, D.; de Hoogh, K.; Fuller, G.; Gulliver, J.; Font, A.; Smith, R.B.; et al. Fetal growth, stillbirth, infant mortality and other birth outcomes near UK municipal waste incinerators; retrospective population based cohort and case-control study. Environ. Int. 2019, 122, 151–158. [Google Scholar] [CrossRef]

- Bernardin, A.M. Recycling and reuse of bottom ashes from municipal solid-waste incineration plants in building materials. In Advances in the Toxicity of Construction and Building Materials; Woodhead Publishing: Duxford, UK, 2022; pp. 285–298. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Khan, M.; Nasser, M.S.; Al-Saad, K.; Heng, O.E. Recent advances and applications of municipal solid wastes bottom and fly ashes: Insights into sustainable management and conservation of resources. Environ. Technol. Innov. 2021, 21, 101267. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, H.; Jiang, H.; Zhang, W.; Mao, L. Recycling municipal solid waste incineration fly ash in fired bricks: An evaluation of physical-mechanical and environmental properties. Constr. Build. Mater. 2021, 294, 123476. [Google Scholar] [CrossRef]

- Tan, J.; De Vlieger, J.; Desomer, P.; Cai, J.; Li, J. Co-disposal of construction and demolition waste (CDW) and municipal solid waste incineration fly ash (MSWI FA) through geopolymer technology. J. Clean. Prod. 2022, 362, 132502. [Google Scholar] [CrossRef]

- Oh, K.; Ma, H.; Yi, H.; Kou, R.; Vollero, D.; Schmidenberg, D.; Qiao, Y. Structural parts based on Municipal-Solid-Waste incineration ashes. J. Waste Manag. 2022, 150, 185–190. [Google Scholar] [CrossRef] [PubMed]

- Joseph, A.M.; Snellings, R.; Nielsen, P.; Matthys, S.; De Belie, N. Pre-treatment and utilisation of municipal solid waste incineration bottom ashes towards a circular economy. Constr. Build. Mater. 2020, 260, 120485. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Municipal solid waste incineration bottom ash recycling in concrete: Preliminary approach with Oporto wastes. Constr. Build. Mater. 2022, 323, 126548. [Google Scholar] [CrossRef]

- Fan, Y.; Li, S.; Li, Y.; Liang, H.; Tang, M.; Huang, K.; Zhu, L. Recycling of municipal solid waste incineration fly ash in foam ceramic materials for exterior building walls. J. Build. Eng. 2021, 44, 103427. [Google Scholar] [CrossRef]

- Tafesse, S.; Girma, Y.E.; Dessalegn, E. Analysis of the socio-economic and environmental impacts of construction waste and management practices. Heliyon 2022, 8, e09169. [Google Scholar] [CrossRef] [PubMed]

- Dräger, P.; Letmathe, P. Value losses and environmental impacts in the construction industry—Tradeoffs or correlates? J. Clean. Prod. 2022, 336, 130435. [Google Scholar] [CrossRef]

- Habert, G. Assessing the environmental impact of conventional and ‘green’ cement production. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Duxford, UK, 2014; pp. 199–238. [Google Scholar] [CrossRef]

- Akbar, A.; Liew, K.M. Assessing recycling potential of carbon fiber reinforced plastic waste in production of eco-efficient cement-based materials. J. Clean. Prod. 2020, 274, 123001. [Google Scholar] [CrossRef]

- Casanova, S.; Silva, R.V.; de Brito, J.; Pereira, M.F.C. Mortars with alkali-activated municipal solid waste incinerator bottom ash and fine recycled aggregates. J. Clean. Prod. 2021, 289, 125707. [Google Scholar] [CrossRef]

- Peduzzi, P. Sand, rarer than one thinks. Environ. Dev. 2014, 11, 208–218. [Google Scholar] [CrossRef]

- Bisht, A. Conceptualizing sand extractivism: Deconstructing an emerging resource frontier. Extr. Ind. Soc. 2021, 8, 100904. [Google Scholar] [CrossRef]

- Rodríguez-Revelo, N.; Espejel, I.; Acéves-Calderón, P.; Leyva, C.; Ojeda-Revah, L.; Sánchez-Vázquez, M.A. Análisis retrospectivo de la duna costera El Socorro, Baja California, México. Soc. Amb. 2019, 21, 155–183. [Google Scholar] [CrossRef]

- Torres, A.; Simoni, M.U.; Keiding, J.K.; Müller, D.B.; zu Ermgassen, S.O.; Liu, J.; Lambin, E.F. Sustainability of the global sand system in the Anthropocene. One Earth 2021, 4, 639–650. [Google Scholar] [CrossRef]

- Akanwa, A.O.; Joe-Ikechebelu, N.N. Sustainable natural resources exploitation: Clay/sand mining on diminishing greener security and increased climate risks in Nigeria. In Natural Resources Conservation and Advances for Sustainability; Manoj, K.J., Ram, S.M., Arnab, B., Surya, N.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 545–562. [Google Scholar] [CrossRef]

- Pereira, J.J.; Abd Hamid, Z.; Ismail, S. Minerals security in construction–issues and challenges for sustainable development. Warta Geol. 2006, 32, 54–61. [Google Scholar]

- Briceño, A.E.; Muñoz, A.P. La frontera mercantil del turismo y su dinámica de apropiación y capitalización de la arena como recurso natural. Relig. Rev. Cienc. Soc. Y Humanid. 2021, 6, e210802. [Google Scholar] [CrossRef]

- West, J.; Schandl, H. Material use and material efficiency in Latin America and the Caribbean. Ecol. Econ. 2013, 94, 19–27. [Google Scholar] [CrossRef]

- Infante-Amate, J.; Urrego-Mesa, A.; Pinero, P.; Tello, E. The open veins of Latin America: Long-term physical trade flows (1900–2016). Glob. Environ. Chang. 2022, 76, 102579. [Google Scholar] [CrossRef]

- SGM. 2021. Anuario Estadístico de la Minería Mexicana; Servicio Geológico Mexicano: Ciudad de Mexico, Mexico, 2020; Available online: https://www.sgm.gob.mx/productos/pdf/Anuario_2020_Edicion_2021.pdf (accessed on 7 October 2022).

- Sandberg, L.A. Leave the sand in the land, let the stone alone: Pits, quarries and climate change. ACME Int. J. Crit. Geogr. 2013, 12, 65–87. [Google Scholar]

- Miller, S.A.; Horvath, A.; Monteiro, P.J. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20%. Environ. Res. Lett. 2016, 11, 074029. [Google Scholar] [CrossRef]

- Hama, S.M.; Hilal, N.N. Fresh properties of concrete containing plastic aggregate. In Use of Recycled Plastics in Eco-Efficient Concrete; Pacheco-Torgal, F., Khatib, J., Colangelo, F., Tuladhar, R., Eds.; Woodhead Publishing: Duxford, UK, 2019; pp. 85–114. [Google Scholar] [CrossRef]

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. J. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef] [PubMed]

- Tangtinthai, N.; Heidrich, O.; Manning, D.A.C. 2019. Role of policy in managing mined resources for construction in Europe and emerging economies. J. Environ. Manag. 2019, 236, 613–621. [Google Scholar] [CrossRef] [PubMed]

- Department of Sustainability, Environment, Water, Population and Communities, Queensland Department of Environment and Resource Management. Available online: https://www.dcceew.gov.au/sites/default/files/documents/construction-waste.pdf (accessed on 7 October 2022).

- U.S. Environmental Protection Agency. Sustainable Management of Construction and Demolition Materials. 2022. Available online: https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials (accessed on 7 October 2022).

- U.S. Environmental Protection Agency. Methodology for Estimating Municipal Solid Waste Recycling Benefits. 2007. Available online: https://archive.epa.gov/epawaste/nonhaz/municipal/web/pdf/06benefits.pdf (accessed on 7 October 2022).

- U.S. Environmental Protection Agency. Resource Conservation and Recovery Act in Focus. Construction, Demolition and Renovation. 2004. Available online: https://www.epa.gov/sites/default/files/2015-01/documents/rif-cd.pdf (accessed on 7 October 2022).

- Organisation for Economic Co-Operation and Development. Household Behaviour and the Environment: Reviewing the Evidence. 2008. Available online: https://www.oecd.org/environment/consumption-innovation/42183878.pdf (accessed on 7 October 2022).

- Secretaría del Medio Ambiente y Recursos Naturales. Diagnóstico Básico para la Gestión Integral de los Residuos. Secretaría del Medio Ambiente y Recursos Naturales, México. 2020. Available online: https://www.gob.mx/cms/uploads/attachment/file/554385/DBGIR-15-mayo-2020.pdf (accessed on 7 October 2022).

- Gaceta Oficial de la Ciudad de México. Aviso por el que se da a Conocer la Norma Ambiental para la Ciudad de México NACDMX-007-RNAT-2019, que Establece la Clasificación y Especificaciones de Manejo Integral para los Residuos de la Construcción y la Demolición en la Ciudad de México. 2021. Available online: http://data.sedema.cdmx.gob.mx/sitios/conadf/documentos/proyectos-normas/NACDMX_007_RNAT_2019.pdf (accessed on 7 October 2022).

- Secretaría del Medio Ambiente y Recursos Naturales. Criterios para el Manejo de los Residuos de la Construcción y la Demolición Generados por el Sismo del 19 de Septiembre para los Estados de México, Morelos Puebla y Ciudad de México. México. 2017. Available online: https://www.gob.mx/cms/uploads/attachment/file/259191/Criterios_RIC_Sismo_19_septiembre.pdf (accessed on 7 October 2022).

- Svampa, M.N. Resource extractivism and alternatives: Latin American perspectives on development. J. Entwickl. Polit. 2012, 28, 43–73. [Google Scholar] [CrossRef]

- Construye 2025. Available online: https://construye2025.cl/ (accessed on 14 November 2022).

- Forbes. Fotogalería: Planta de CDMX Enviará 760 Toneladas Menos de Basura al Edomex. 2021. Available online: https://www.forbes.com.mx/fotogaleria-planta-de-cdmx-enviara-760-toneladas-menos-de-basura-al-edomex/ (accessed on 7 October 2022).

- Alcaldes de México. STADLER, Líder en Plantas de RSU y CDR en México. 2020. Available online: https://www.alcaldesdemexico.com/revista/marzo-2020/stadler-lider-en-plantas-de-rsu-y-cdr-en-mexico/ (accessed on 7 October 2022).

- Gaceta Oficial de la Ciudad de México. Aviso por el que se da a Conocer la Convocatoria PTARCD CDMX-2019 para la Instalación y Operación de Plantas de Tratamiento y Aprovechamiento de Residuos de la Construcción y Demolición de la Ciudad de México. 2020. Available online: https://www.sedema.cdmx.gob.mx/storage/app/media/aviso-por-el-que-se-da-a-conocer-la-convocatoria-ptarcd-cdmx-2019-para-la-instalacion-y-operacion-de-plantas-de-tratamiento-y-aprovechamiento-de-residuos-de-la-construccion-y-demolicion-de-la-ciudad-de-mexico.pdf (accessed on 7 October 2022).

| Particle Size | Substitution Ratio | Effects of the Substitution | Reference |

|---|---|---|---|

| 75 µm | 20% and 40% | Glass powder was added as a potential enhancer of the permanent deformation resistance of paving materials (asphalt mortars). | [42] |

| 0.3 mm | 20% | Fine aggregates increased concrete workability data. | [43] |

| <0.60 mm | 20–30%, 10–20% 1 | Both combinations were appropriate for concrete manufacturing. | [44] |

| 4.75 mm | 30% | Glass was added to expansive clay as a non-chemical soil treatment approach (113% increase in resilient modulus of clay). | [50] |

| <45 µm | 20% | Direct replacement of cement by waste glass powder increased the compressive strength of foam concrete. | [51] |

| Waste Description | Enhanced Property | Observations | Reference |

|---|---|---|---|

| Cardboard pulp | Density: 0.8 g/cm3 | Boardcrete (a mix of cardboard pulp, cement, and sand) was employed as lightweight building construction blocks. | [52] |

| Kraft fibers | - | A total 1–15% of natural fibers were used as reinforcement agents in cement-based composites. | [53] |

| Kraft fibers modified with silica fume | - | A total 5% of modified Kraft fibers were added to the concrete mix, reducing its alkaline level. | [54] |

| Cork and paper waste fibers | - | A total 60% (v/v) of fibers were added to gypsum (40%, v/v). The composites provided low thermal insulation. | [55] |

| Corrugated paper | Bulk densities: 170, 127, and 138 kg/m3 | Sandwich beams elaborated with corrugated paper had high shear modulus and low density. | [57] |

| Paper | Thermal conductivity: 0.038 W/mK | Authors employed different layers of paper, compressed by steel bars and coated with gypsum plaster, in a refugee construction. | [58] |

| Cardboard | Thermal conductivity: ∼0.05 W/mK | Insulating cardboard panels from the packaging industry can be considered a promising recycled insulation material. | [59] |

| Ash Description | Addition Ratio | Observations | Reference |

|---|---|---|---|

| BA composed of sand and gravel (60–90%), and silt and clay (5–15%) | - | If it is finely ground, BA might show pozzolanic or hydraulic behavior and be employed as an alternative light aggregate. | [65] |

| FA consisting of light fine-grained particles | 5–20% | FA could be used as a source of lime in the cement industry. | [65] |

| FA (soluble salts content below 10 wt%) | - | The presence of soluble salts in FA was detrimental to physical–mechanical properties. For the production of fired clay brick, FA can be used only after desalination. | [66] |

| FA | <5 wt% | Employment of construction and demolition waste-based geopolymer for the solidification/stabilization of FA. The compressive strength of the geopolymer was improved. | [67] |

| FA | 5 wt% | A strong alkaline activator and a compaction pressure as a thermodynamic process were employed. FA contributed to forming strong solids with relatively high flexural and compressive strengths. | [68] |

| Ash | 25% | Ash was used as a cement replacement in mortar production. A pretreatment assured mitigating expansion, hydration, and strength development. | [69] |

| BA | 40% | BA was used as a cement replacement in paste and mortar. Water demand on paste and workability on mortar were similar to the values presented by common concrete mixtures. | [70] |

| FA | 30 wt% | FA was used to prepare foam ceramic, whose thermal insulation performance was adequate. | [71] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lizárraga-Mendiola, L.; López-León, L.D.; Vázquez-Rodríguez, G.A. Municipal Solid Waste as a Substitute for Virgin Materials in the Construction Industry: A Review. Sustainability 2022, 14, 16343. https://doi.org/10.3390/su142416343

Lizárraga-Mendiola L, López-León LD, Vázquez-Rodríguez GA. Municipal Solid Waste as a Substitute for Virgin Materials in the Construction Industry: A Review. Sustainability. 2022; 14(24):16343. https://doi.org/10.3390/su142416343

Chicago/Turabian StyleLizárraga-Mendiola, Liliana, Luis D. López-León, and Gabriela A. Vázquez-Rodríguez. 2022. "Municipal Solid Waste as a Substitute for Virgin Materials in the Construction Industry: A Review" Sustainability 14, no. 24: 16343. https://doi.org/10.3390/su142416343

APA StyleLizárraga-Mendiola, L., López-León, L. D., & Vázquez-Rodríguez, G. A. (2022). Municipal Solid Waste as a Substitute for Virgin Materials in the Construction Industry: A Review. Sustainability, 14(24), 16343. https://doi.org/10.3390/su142416343