Research on Rheological Energy Characteristics of Fractured Sandstone Strengthened with CFRP

Abstract

1. Introduction

2. Materials and Methods

2.1. Laboratory Equipment

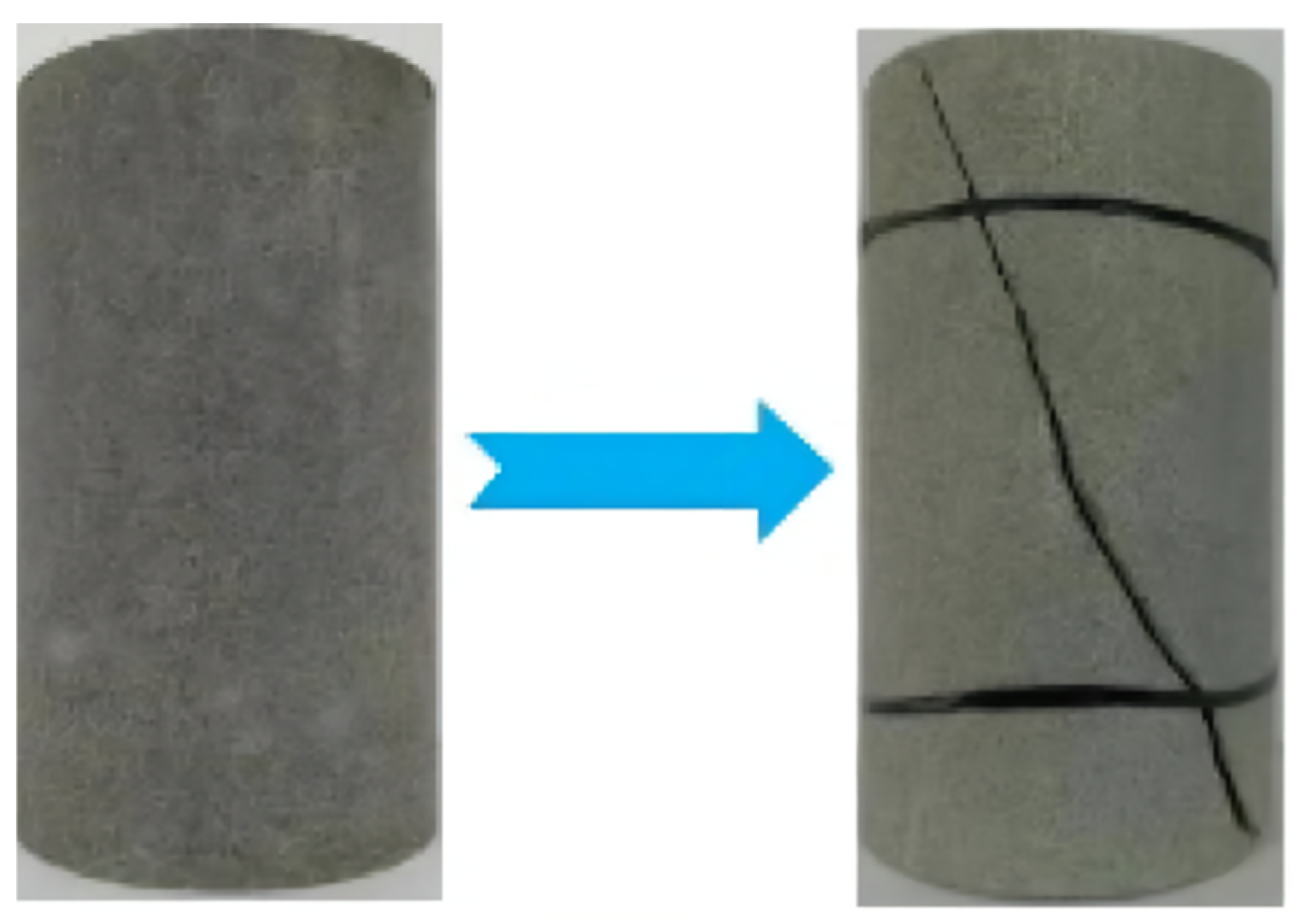

2.2. Fractured Sandstone Preparation

2.3. Reinforcing Material

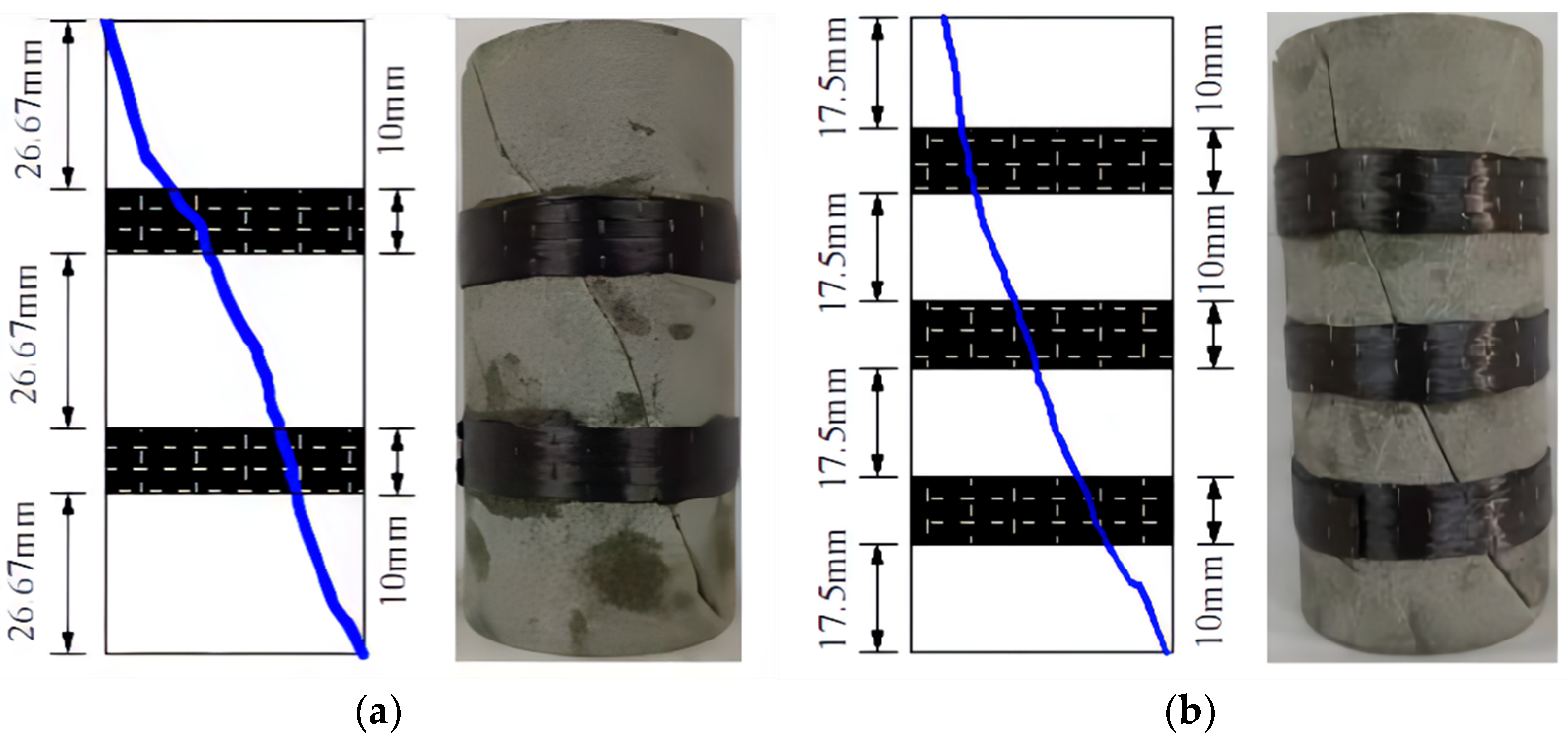

2.4. The Determination of the Unit of Optimum Reinforcement Area

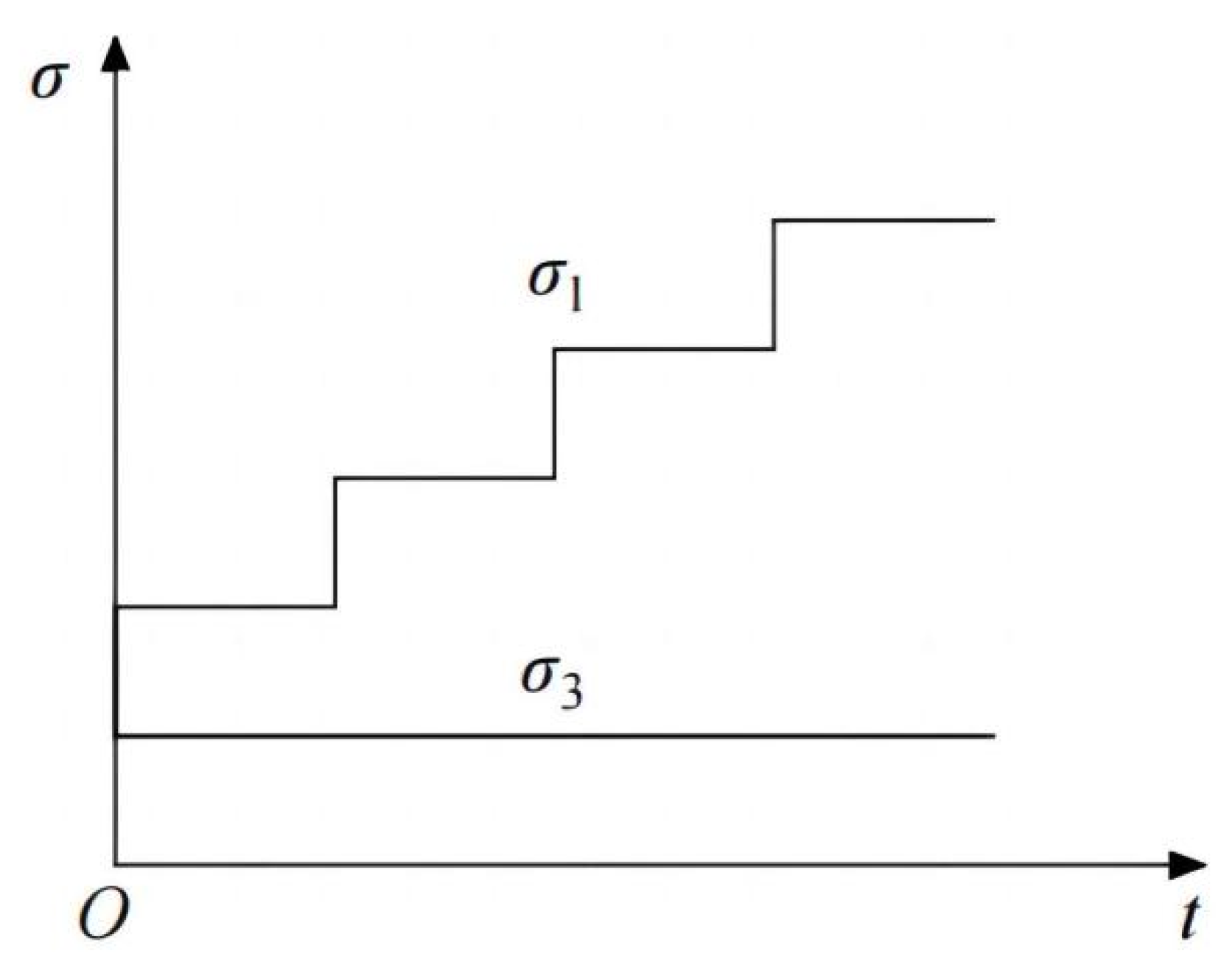

2.5. Graded Rheological Test Scheme

3. Results

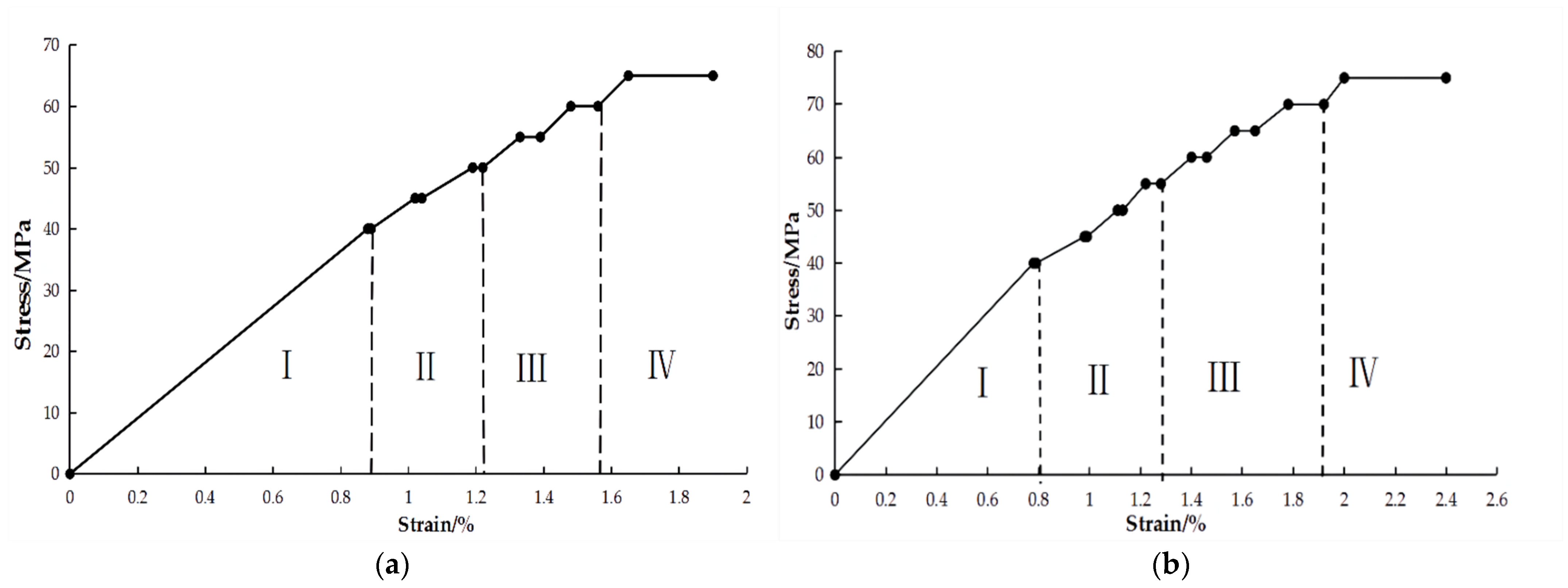

3.1. Analysis of Rheological Curve

3.2. Interval Analysis of Rheological Stress

4. Energy Signature Analysis

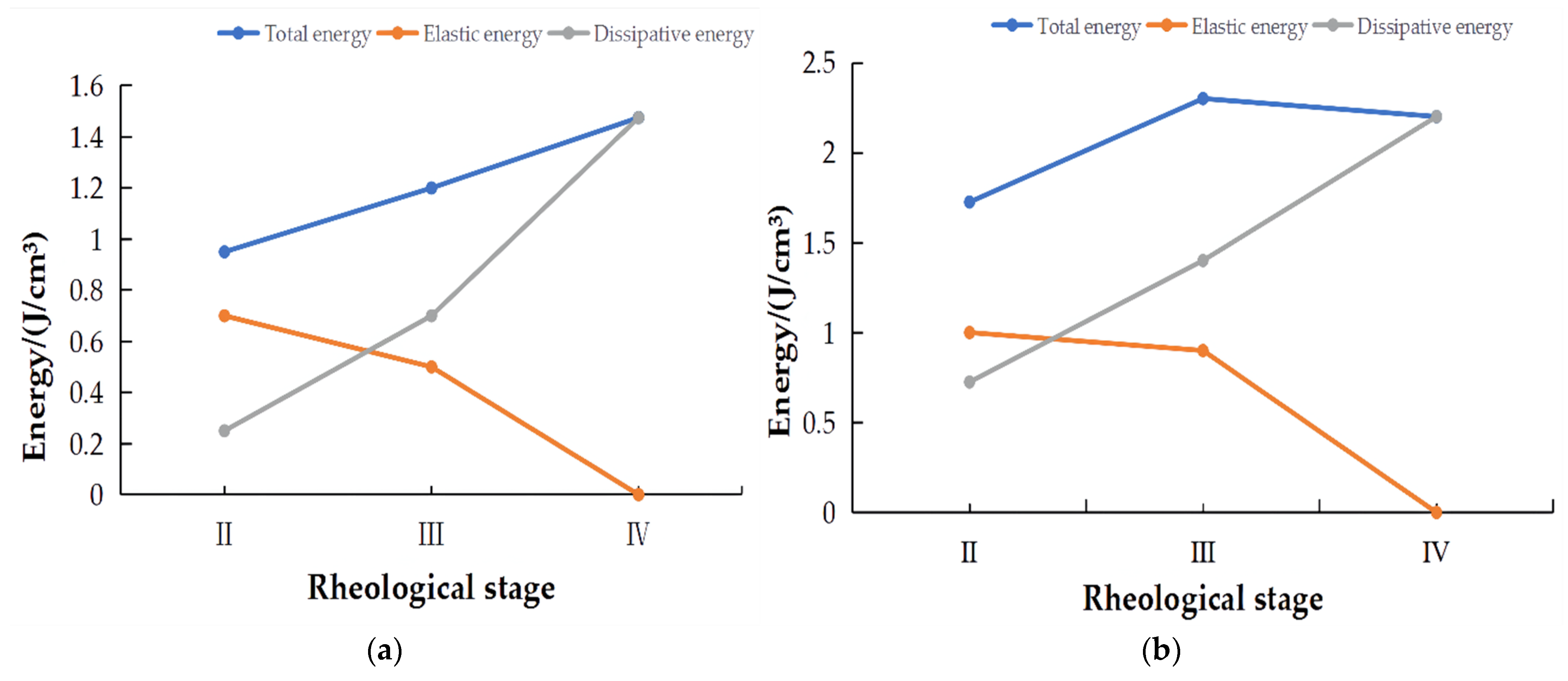

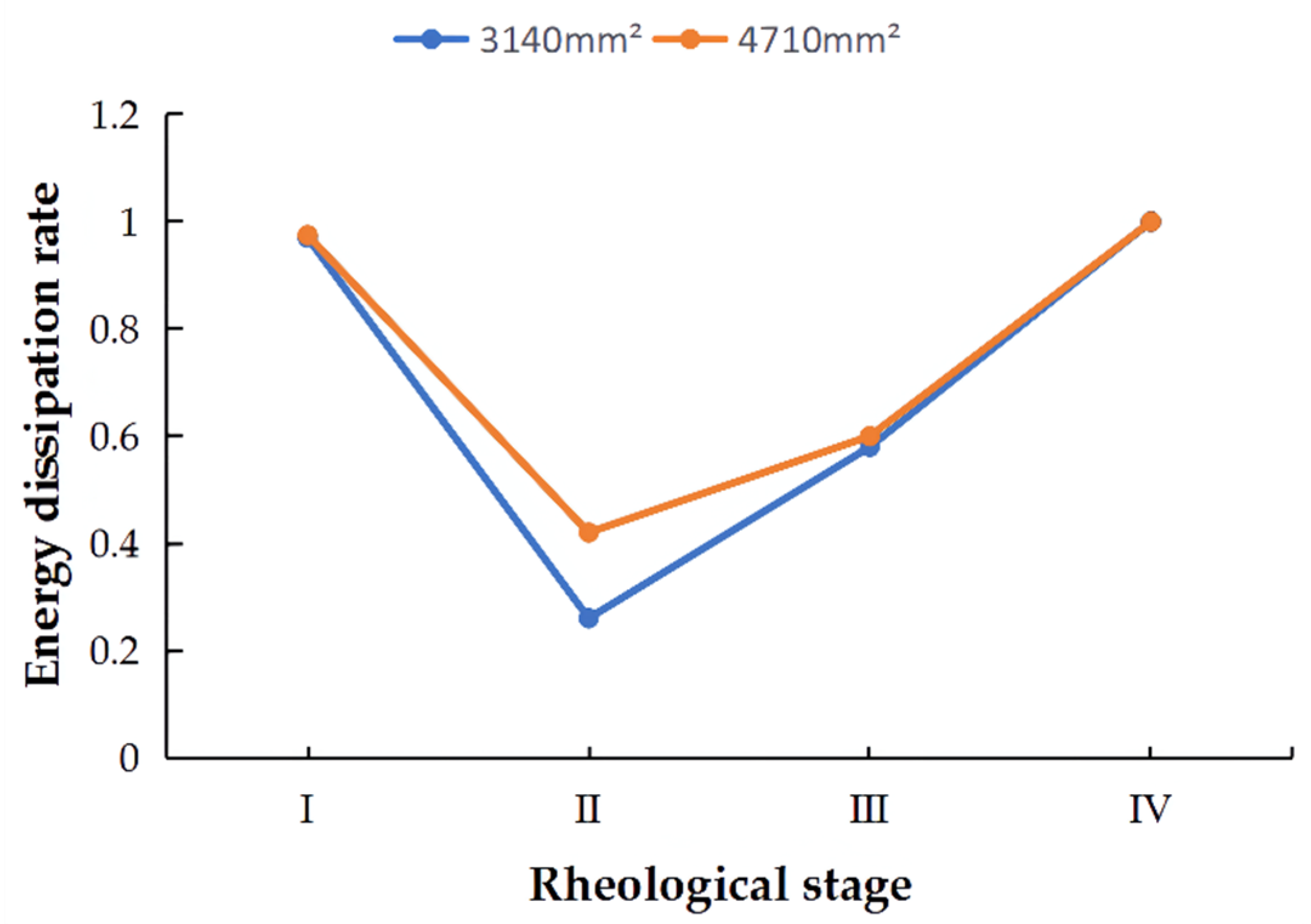

4.1. Energy Evolution Analysis of Rheological Processes

4.2. Energy Calculation Analysis

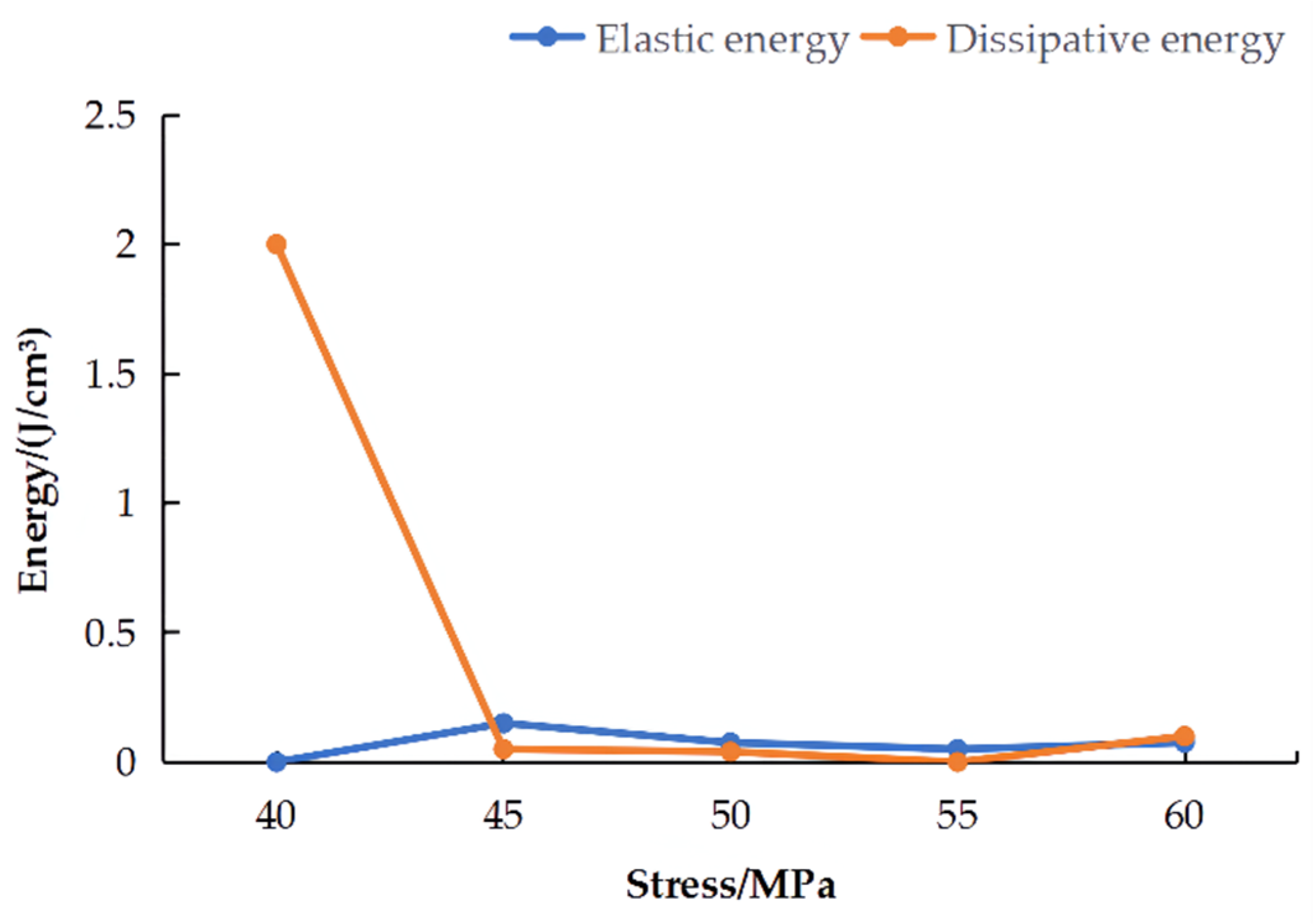

4.3. Analysis of Energy Mechanism of CFRP

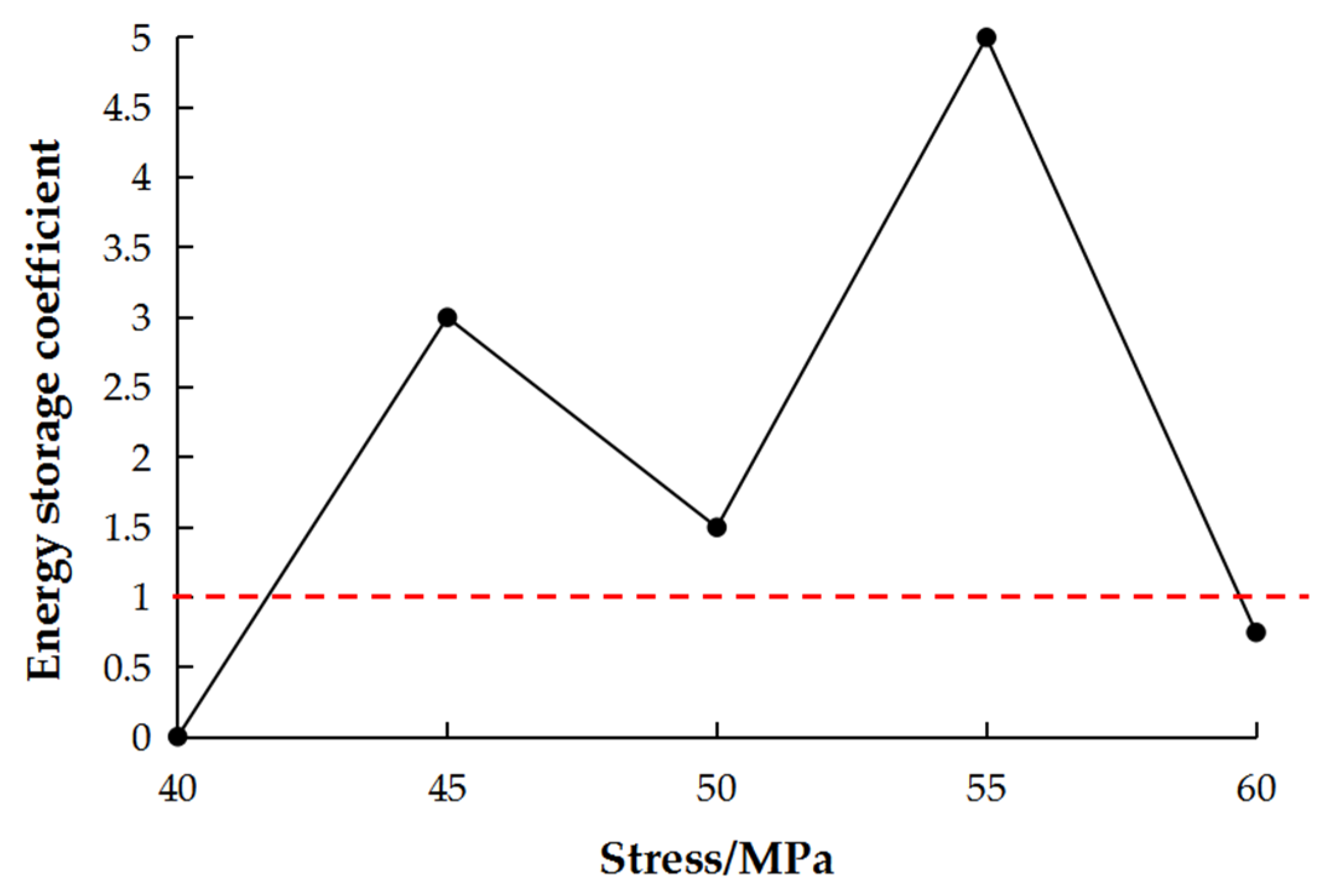

4.4. Energy Storage Coefficient Analysis of CFRP

5. Conclusions

- The larger the area of CFRP reinforcement, the greater the failure rheological stress of sandstone, the smaller the rheological variation under the same stress, the longer the rheological duration, and the better the effect of restraining deformation. The rheology of fractured sandstone strengthened with CFRP can be divided into four stages: initial rheology, stable rheology, accelerated rheology, and post-peak rheology. The loading stress can be divided into three zones: low stress, middle stress, and high stress.

- In the process of rheological failure of fractured sandstone strengthened with CFRP, the elastic energy decreases and the dissipative energy increases from the stable rheological stage. Further, the absorbed energy is completely converted into dissipative energy at the post-peak rheological stage. Rock no longer carries out elastic energy storage, and the elastic energy accumulated in the previous stage is released. The energy dissipation rate of the two areas reached the minimum in the stable rheological stage, indicating that most of the energy in this stage was stored in the form of elastic energy. Moreover, the rock had the best compactness, which is convenient for elastic energy storage. Rock damage is minimal.

- The energy mechanism of CFRP is that CFRP consumes energy first, then stores energy in the low-stress region. In this region, the mechanism of CFRP is primary energy storage and secondary energy consumption. When in the middle stress region after the energy inflexion, the mechanism of CFRP changes to primary energy consumption and secondary energy storage. CFRP has the minimum energy storage and the maximum energy consumption in the initial rheological stage. The energy storage coefficient of CFRP can describe the damage degree of it. When the energy storage coefficient T > 1, the damage of CFRP is small. When the energy storage coefficient T < 1, the damage of CFRP is large. Among them, the damage of CFRP is the biggest in the initial rheological stage, and the damage of energy inflexion is the smallest.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Li, L.; Peng, R.; Ju, Y. Energy analysis and criteria for structural failure of rocks. J. Rock Mech. Geotech. Eng. 2009, 1, 11–20. [Google Scholar] [CrossRef]

- Wang, H.Y.; Arcady, D.; Phil, D.; Elena, P.; Ariel, H. Review of unloading tests of dynamic rock failure in compression. Eng. Fract. Mech. 2020, 225, 106289. [Google Scholar] [CrossRef]

- Cong, L.; Hu, X. Triaxial rheological property of sandstone under low confining pressure. Eng. Geol. 2017, 231, 45–55. [Google Scholar] [CrossRef]

- Wu, L.; Li, B.; Huang, R.; Sun, P. Experimental study and modeling of shear rheology in sandstone with non-persistent joints. Eng. Geol. 2017, 222, 201–211. [Google Scholar] [CrossRef]

- Nguyen-Sy, T.; Minh-Ngoc, V.; Quy-Dong, T.; Minh-Quan, T.; Nguyen-Thoi, T. On the effective viscoelastic properties of a fractured rock mass. J. Appl. Geophys. 2019, 169, 125–133. [Google Scholar] [CrossRef]

- Patton, T.L.; Raymond, C.F. A rheological model for fractured rock. J. Struct. Geol. 1998, 20, 491–502. [Google Scholar] [CrossRef]

- Hamza, O.; Stace, R. Creep properties of intact and fractured muddy siltstone. Int. J. Rock Mech. Min. Sci. 2018, 106, 109–116. [Google Scholar] [CrossRef]

- Li, M.; Li, K.; Zhang, D.; Liu, C.; Ma, D. Study on Creep Characteristics and Constitutive Relation of Fractured Rock Mass. Shock Vib. 2020, 2020, 8833512. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, S. Unloading Rheological Test and Model Research of Hard Rock under Complex Conditions. Adv. Mater. Sci. Eng. 2020, 2020, 3576181. [Google Scholar] [CrossRef]

- Khramchenkov, M. Rheological double-porosity model for clayey rocks. Int. J. Rock Mech. Min. Sci. 2005, 42, 1006–1014. [Google Scholar] [CrossRef]

- Osipov, Y.V.; Voznesenskii, A.S. Investigation of the Rheological Properties of Rocks in Experiments on Stepwise Loading of Cylindrical Samples. J. Appl. Mech. Tech. Phys. 2022, 63, 347–355. [Google Scholar] [CrossRef]

- Liu, L.; Wang, G.-M.; Chen, J.-H.; Yang, S. Creep experiment and rheological model of deep saturated rock. Trans. Nonferrous Met. Soc. China 2013, 23, 478–483. [Google Scholar] [CrossRef]

- Wang, J.; Xu, J.; Nie, Z.; Liu, L.; Qin, M.; Ou, R. Creep Fracture Characteristics of Fractured Rock Mass Strengthened with Toughened Epoxy Resin. Adv. Civ. Eng. 2021, 2021, 1582745. [Google Scholar] [CrossRef]

- Lyakhovsky, V.; Podladchikov, Y.; Alexei, P. A rheological model of a fractured solid. Tectonophysics 1993, 226, 187–198. [Google Scholar] [CrossRef]

- Zakharov, V.N.; Trofimov, V.A.; Filippov, Y.A. Numerical Modeling of Rock Bolt Support in Case of Rheological Behavior of Rock Mass in Deformation. J. Min. Sci. 2021, 57, 883–893. [Google Scholar] [CrossRef]

- Lukic, D.C.; Zlatanovic, E.M.; Jokanovic, I.M. Tunnel lining load with consideration of the rheological properties of rock mass and concrete. Geomech. Eng. 2020, 21, 53–62. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, F. Energy evolution mechanism in process of Sandstone failure and energy strength criterion. J. Appl. Geophys. 2018, 154, 21–28. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Li, X.; Cao, W.; Du, X. Dynamic Response and Energy Evolution of Sandstone Under Coupled Static–Dynamic Compression: Insights from Experimental Study into Deep Rock Engineering Applications. Rock Mech. Rock Eng. 2020, 53, 1305–1331. [Google Scholar] [CrossRef]

- Wasantha, P.; Ranjith, P.; Shao, S. Energy monitoring and analysis during deformation of bedded-sandstone: Use of acoustic emission. Ultrasonics 2014, 54, 217–226. [Google Scholar] [CrossRef]

- Arsalan, N.; Palayangoda, S.S.; Burnett, D.J.; Buiting, J.J.; Nguyen, Q.P. Surface energy characterization of sandstone rocks. J. Phys. Chem. Solids 2013, 74, 1069–1077. [Google Scholar] [CrossRef]

- Seth, S.; Morrow, N.R. Efficiency of the Conversion of Work of Drainage to Surface Energy for Sandstone and Carbonate. SPE Reserv. Eval. Eng. 2007, 10, 338–347. [Google Scholar] [CrossRef]

- Sufian, A.; Russell, A.R. Microstructural pore changes and energy dissipation in Gosford sandstone during pre-failure loading using X-ray CT. Int. J. Rock Mech. Min. Sci. 2013, 57, 119–131. [Google Scholar] [CrossRef]

- Wang, P.; Xu, J.Y.; Fang, X.Y.; Wang, P.X. Energy dissipation and damage evolution analyses for the dynamic compression failure process of red-sandstone after freeze-thaw cycles. Eng. Geol. 2017, 221, 104–113. [Google Scholar] [CrossRef]

- Zhang, J.; Song, Z.; Wang, S. Experimental investigation on permeability and energy evolution characteristics of deep sandstone along a three-stage loading path. Bull. Eng. Geol. Environ. 2021, 80, 1571–1584. [Google Scholar] [CrossRef]

- Li, T.; Pei, X.; Guo, J.; Meng, M.; Huang, R. An Energy-Based Fatigue Damage Model for Sandstone Subjected to Cyclic Loading. Rock Mech. Rock Eng. 2020, 53, 5069–5079. [Google Scholar] [CrossRef]

- Khan, N.M.; Ma, L.; Cao, K.; Hussain, S.; Liu, W.; Xu, Y.; Yuan, Q.; Gu, J. Prediction of an early failure point using infrared radiation characteristics and energy evolution for sandstone with different water contents. Bull. Eng. Geol. Environ. 2021, 80, 6913–6936. [Google Scholar] [CrossRef]

- He, Z.; Gong, F.; Wu, W.; Wang, W. Experimental investigation of the mechanical behaviors and energy evolution characteristics of red sandstone specimens with holes under uniaxial compression. Bull. Eng. Geol. Environ. 2021, 80, 5845–5865. [Google Scholar] [CrossRef]

- Wen, T.; Tang, H.; Ma, J.; Liu, Y. Energy Analysis of the Deformation and Failure Process of Sandstone and Damage Constitutive Model. KSCE J. Civ. Eng. 2019, 23, 513–524. [Google Scholar] [CrossRef]

- Li, M.; Mao, X.; Lu, A.; Tao, J.; Zhang, G.; Zhang, L.; Li, C. Effect of specimen size on energy dissipation characteristics of red sandstone under high strain rate. Int. J. Min. Sci. Technol. 2014, 24, 151–156. [Google Scholar] [CrossRef]

- Gautam, P.K.; Jha, M.K.; Verma, A.K.; Singh, T.N. Evolution of absorption energy per unit thickness of damaged sandstone. J. Therm. Anal. Calorim. 2019, 136, 2305–2318. [Google Scholar] [CrossRef]

- Wang, B.; Ning, Y.; Feng, T.; Wang, W.J.; Guo, Z.Y. Uniaxial mechanical properties of anchored sandstone and control machanism of buckling rock burst. J. Cen Sou Uni. 2019, 50, 2285–2294. (In Chinese) [Google Scholar] [CrossRef]

| Indicators | CFRP |

|---|---|

| Tensile strength/MPa | ≥3400 |

| Tensile modulus/GPa | ≥230 |

| Elongation/% | ≥1.6 |

| Bending strength/MPa | ≥700 |

| Compressive strength/MPa | — |

| Area of Reinforcement/mm2 | Uniaxial Compressive Strength/MPa | Peak Strain/% | Elastic Modulus /GPa |

|---|---|---|---|

| 0 | 95.55 | 0.2589 | 27.43 |

| 1256 | 98.47 | 0.2786 | 29.03 |

| 1570 | 99.35 | 0.2801 | 29.21 |

| 1884 | 101.21 | 0.2845 | 29.49 |

| 2198 | 103.21 | 0.2891 | 29.68 |

| 2512 | 106.39 | 0.3123 | 29.97 |

| 2826 | 108.47 | 0.3189 | 30.12 |

| Area of Reinforcement/mm2 | Axial Peak Strength/MPa | Strength of Deviated Stress /MPa | Elastic Modulus /GPa |

|---|---|---|---|

| 3140 | 74.68 | 64.68 | 15.36 |

| 4710 | 81.34 | 71.34 | 18.13 |

| Serial Number | 1 | 2 | 3 |

|---|---|---|---|

| Stress interval | Low stress | Middle stress | High stress |

| Interval range | (50~65%) σc | (65~80%) σc | (80~95%) σc |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Yang, J.; Li, Y.; Guo, J.; Yun, X. Research on Rheological Energy Characteristics of Fractured Sandstone Strengthened with CFRP. Sustainability 2022, 14, 16212. https://doi.org/10.3390/su142316212

Zhang S, Yang J, Li Y, Guo J, Yun X. Research on Rheological Energy Characteristics of Fractured Sandstone Strengthened with CFRP. Sustainability. 2022; 14(23):16212. https://doi.org/10.3390/su142316212

Chicago/Turabian StyleZhang, Shuguang, Juefeng Yang, Yanmo Li, Jiahao Guo, and Xiao Yun. 2022. "Research on Rheological Energy Characteristics of Fractured Sandstone Strengthened with CFRP" Sustainability 14, no. 23: 16212. https://doi.org/10.3390/su142316212

APA StyleZhang, S., Yang, J., Li, Y., Guo, J., & Yun, X. (2022). Research on Rheological Energy Characteristics of Fractured Sandstone Strengthened with CFRP. Sustainability, 14(23), 16212. https://doi.org/10.3390/su142316212