Devising a Mechanism for Analyzing the Barriers of Blockchain Adoption in the Textile Supply Chain: A Sustainable Business Perspective

Abstract

1. Introduction

1.1. Research Questions

1.2. Research Objectives

1.3. BCT-Based Research Gap in a Developing Country Context

2. Theoretical Background

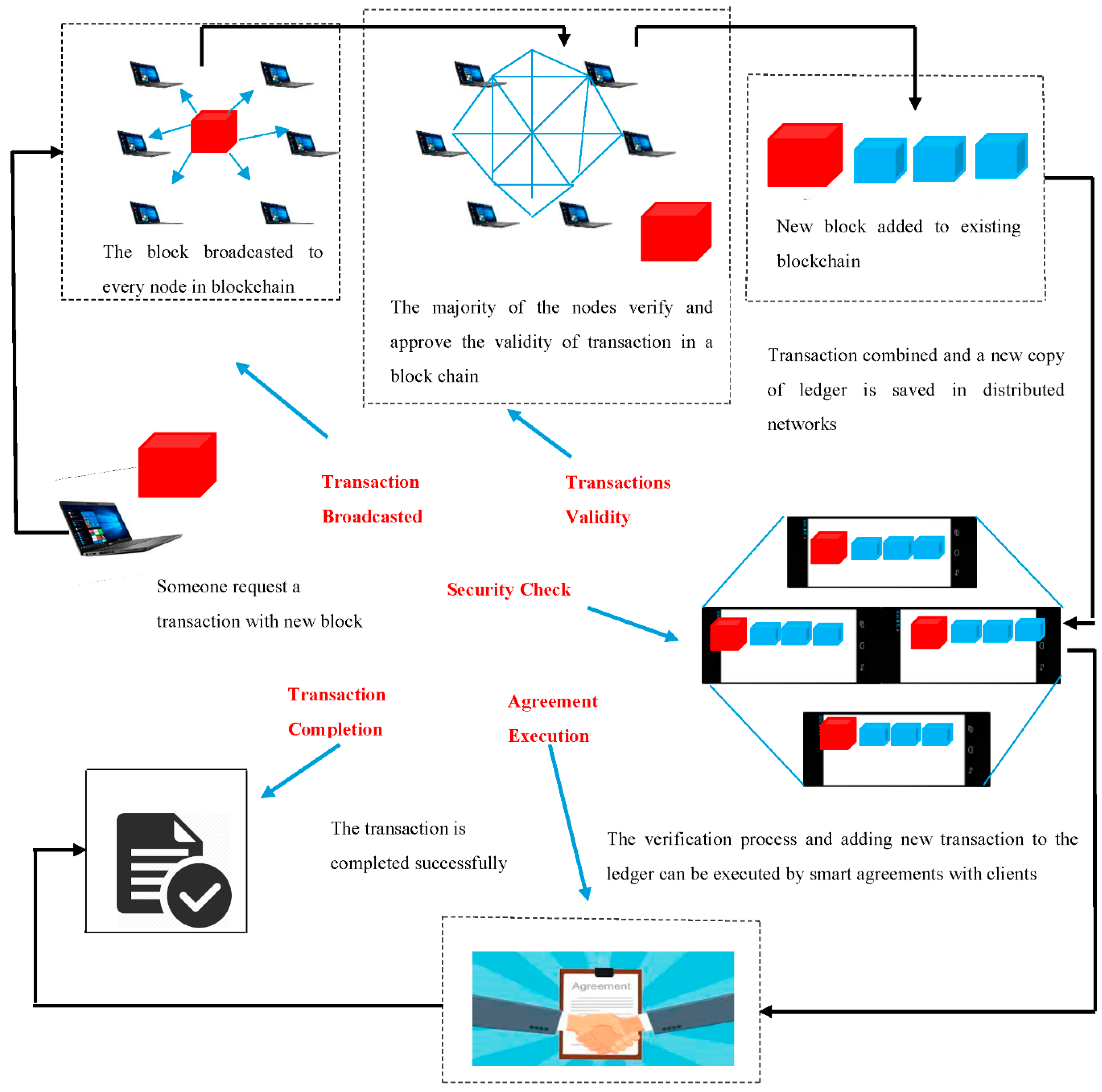

2.1. Blockchain Technology Architecture and Mechanism

2.2. Blockchain Technology Integrated with Sustainable Supply Chain (BCTSC)

2.2.1. Economic Perspective

2.2.2. Social Perspective

2.2.3. Environmental Perspective

2.3. Understanding BCTSC in the Textile Industry and Potential Barriers

2.4. Problem Statement and Research Highlights

- This study bridged the research gap in the BCTSC agenda by identifying the key barriers in implementation of BCT in the textile sector along with an extensive review of the literature and feedback from experts using fuzzy Delphi technique.

- The identified barriers were analyzed using fuzzy AHP for acquiring priority weight vector which would facilitate decision makers in grasping their relative significance in terms of understanding BCTSC in the textile industry.

2.5. Motivation of the Study

3. Solution Methodology

3.1. Research Design

3.2. Fuzzy Set Theory

3.3. Fuzzy Delphi Method

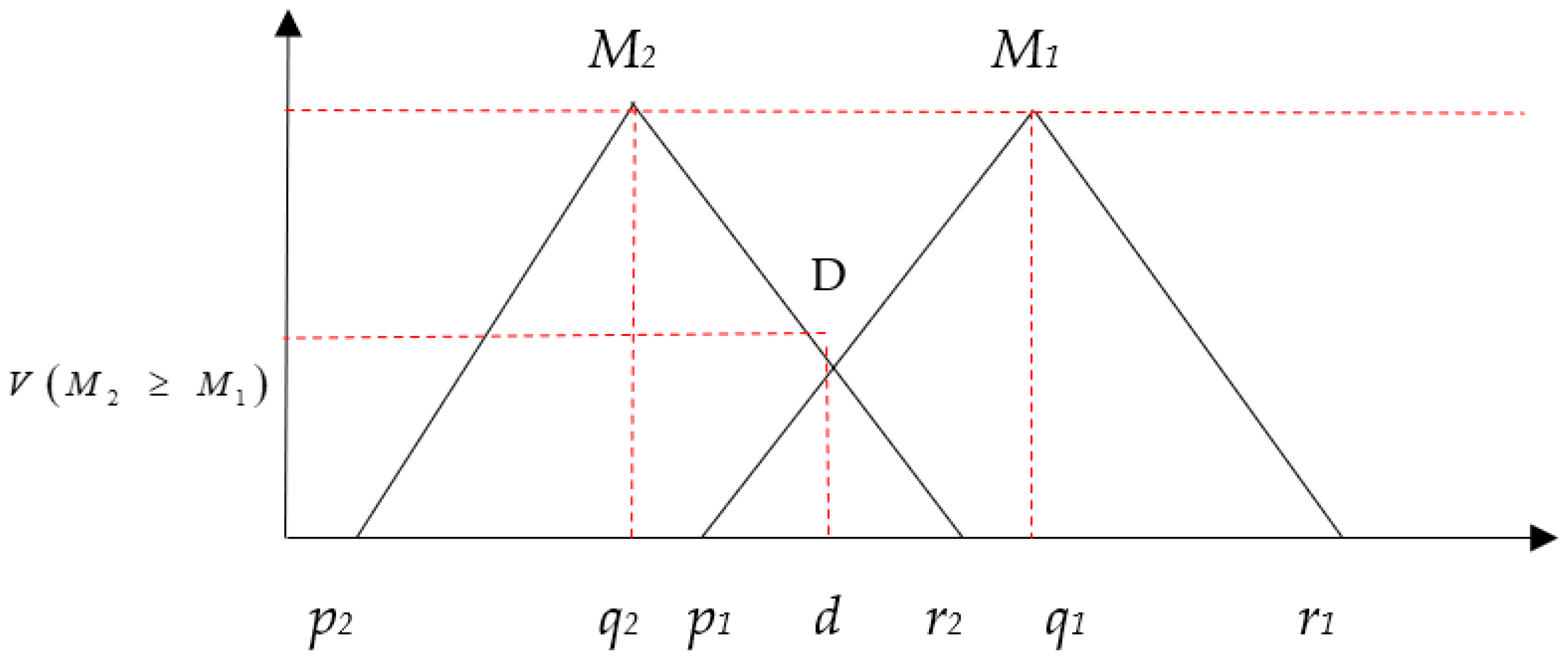

3.4. Fuzzy Analytic Hierarchy Process (FAHP)

4. An Illustrative Case

4.1. Phase 1: Finalization of Barriers and Selection of Expert Team

4.2. Construction of Pairwise Comparison Matrix to Compute Weight of Criterion

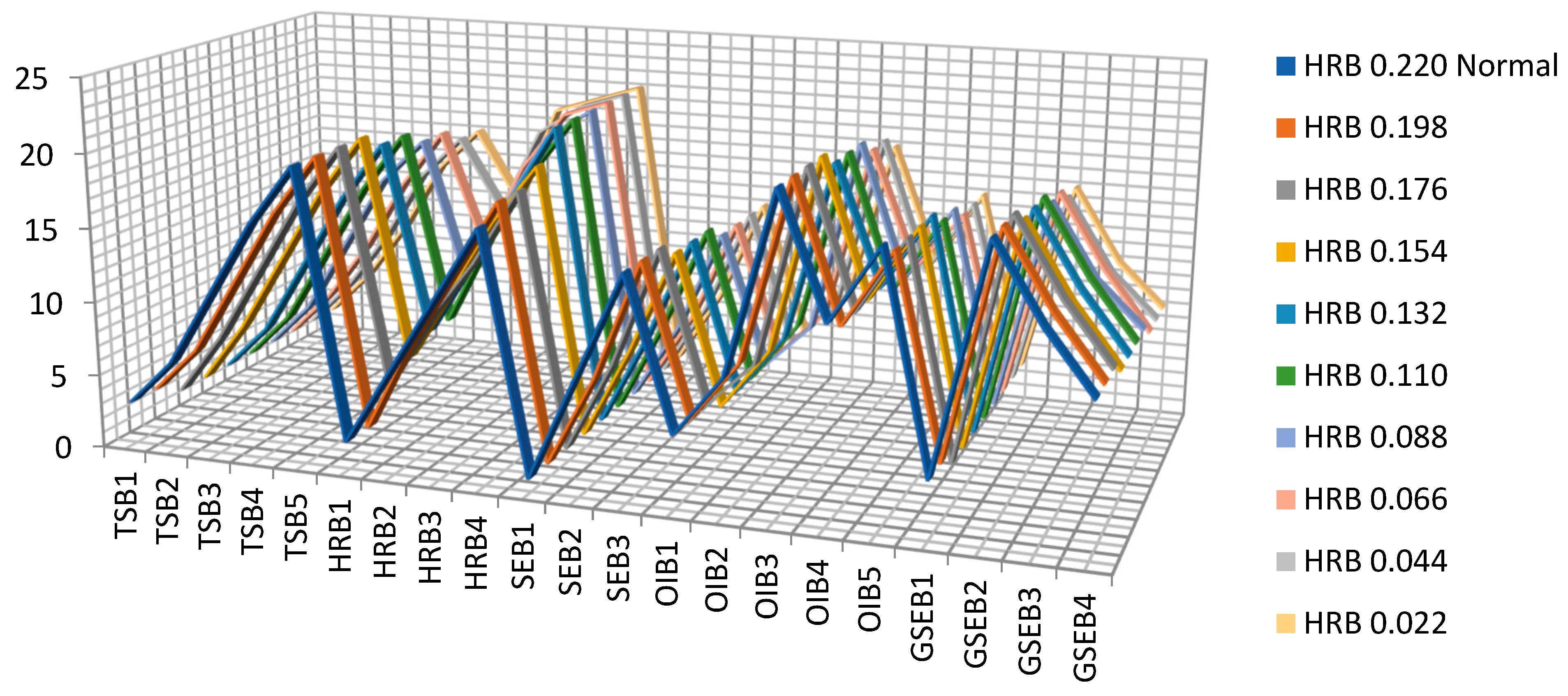

4.3. Sensitivity Analysis

5. Discussion of Findings

5.1. Key Barrier Dimensions

5.2. Barriers Ranking for BCTSC Adoption in Pakistani Textile Industries

5.2.1. Technological and System Barriers (TSB)

5.2.2. Human Resources and R&D Barriers (HRB)

5.2.3. Socio-Economic and Environmental Barriers (SEB)

5.2.4. Organizational and Individual Barriers (OIB)

5.2.5. Governmental and External Stakeholder Barriers (GESB)

5.3. Comparison with the Existing Literature

6. Implications of the Research

6.1. Managerial Implications

- Implementing BCT into Supply Chain and Arranging a Training Program

- Empowering Human Resource Departments and Establishing R&D Units

- Formulating Strategic Policy for Implementing BCT-Based Practices in the Supply Chain

- Understanding the Science of Peoples and Organizational Dynamics

- Convincing Government and External Stakeholders Regarding the Benefits of BCT

6.2. Social Implications

6.3. Global Implications

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pan, X.; Pan, X.; Song, M.; Ai, B.; Ming, Y. Blockchain technology and enterprise operational capabilities: An empirical test. Int. J. Inf. Manag. 2020, 52, 101946. [Google Scholar] [CrossRef]

- Lambert, D.M.; Enz, M.G. Issues in Supply Chain Management: Progress and potential. Ind. Mark. Manag. 2017, 62, 1–16. [Google Scholar] [CrossRef]

- Lohmer, J.; da Silva, E.R.; Lasch, R. Blockchain Technology in Operations & Supply Chain Management: A Content Analysis. Sustainability 2022, 14, 6192. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Ronaghi, M.H.; Mosakhani, M. The effects of blockchain technology adoption on business ethics and social sustainability: Evidence from the Middle East. Environ. Dev. Sustain. 2022, 24, 6834–6859. [Google Scholar] [CrossRef]

- Sarpong, S. Traceability and supply chain complexity: Confronting the issues and concerns. Eur. Bus. Rev. 2014, 26, 271–284. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Kampan, K.; Tsusaka, T.W.; Anal, A.K. Adoption of Blockchain Technology for Enhanced Traceability of Live-stock-Based Products. Sustainability 2022, 14, 13148. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sharma, A.; Vaidya, O.S. Achieving sustainable operational excellence through IT implemen-tation in Indian logistics sector: An analysis of barriers. Resour. Conserv. Recycl. 2020, 152, 104506. [Google Scholar] [CrossRef]

- Costa, C.; Antonucci, F.; Pallottino, F.; Aguzzi, J.; Sarriá, D.; Menesatti, P. A Review on Agri-food Supply Chain Traceability by Means of RFID Technology. Food Bioprocess Technol. 2013, 6, 353–366. [Google Scholar] [CrossRef]

- Imran, M.; Hameed, W.U.; Haque, A.U. Influence of Industry 4.0 on the Production and Service Sectors in Pakistan: Evidence from Textile and Logistics Industries. Soc. Sci. 2018, 7, 246. [Google Scholar] [CrossRef]

- Paliwal, V.; Chandra, S.; Sharma, S. Blockchain technology for sustainable supply chain management: A sys-tematic literature review and a classification framework. Sustainability 2020, 12, 7638. [Google Scholar] [CrossRef]

- Beck, R. Beyond Bitcoin: The Rise of Blockchain World. Computer 2018, 51, 54–58. [Google Scholar] [CrossRef]

- Reyna, A.; Martín, C.; Chen, J.; Soler, E.; Díaz, M. On blockchain and its integration with IoT. Challenges and opportunities. Futur. Gener. Comput. Syst. 2018, 88, 173–190. [Google Scholar] [CrossRef]

- Hawlitschek, F.; Notheisen, B.; Teubner, T. The limits of trust-free systems: A literature review on blockchain technology and trust in the sharing economy. Electron. Commer. Res. Appl. 2018, 29, 50–63. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. 2008. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 30 September 2022).

- Kapil, V. BitCoin: A New Paradigm in E–Commerce. Int. J. Adv. Res. Comput. Commun. Eng. 2014, 3, 8072–8077. [Google Scholar]

- Rajak, S.; Parthiban, P.; Dhanalakshmi, R. Sustainable transportation systems performance evaluation using fuzzy logic. Ecol. Indic. 2016, 71, 503–513. [Google Scholar] [CrossRef]

- Wamba, S.F.; Queiroz, M.M. Industry 4.0 and the supply chain digitalisation: A blockchain diffusion perspective. Prod. Plan. Control. 2020, 33, 193–210. [Google Scholar] [CrossRef]

- Sousa, P.R.; Resende, J.S.; Martins, R.; Antunes, L. The case for blockchain in IoT identity management. J. Enterp. Inf. Manag. 2020, 35, 1477–1505. [Google Scholar] [CrossRef]

- Flynn, B.B.; Koufteros, X.; Lu, G. On Theory in Supply Chain Uncertainty and its Implications for Supply Chain Integration. J. Supply Chain Manag. 2016, 52, 3–27. [Google Scholar] [CrossRef]

- ElMessiry, M.; ElMessiry, A. Blockchain Framework for Textile Supply Chain Management. In International Conference on Blockchain; Springer: Cham, Switzerland, 2018; pp. 213–227. [Google Scholar]

- Biswas, B.; Gupta, R. Analysis of barriers to implement blockchain in industry and service sectors. Comput. Ind. Eng. 2019, 136, 225–241. [Google Scholar] [CrossRef]

- Zhu, S.; Song, J.; Hazen, B.T.; Lee, K.; Cegielski, C. How Supply Chain Analytics Enables Operational Supply Chain Transparency: An Organizational Information Processing Theory Perspective. Int. J. Phys. Distribution Logist. Manag. 2018, 48, 47–68. [Google Scholar] [CrossRef]

- Scott, B.; Loonam, J.; Kumar, V. Exploring the rise of blockchain technology: Towards distributed collaborative organizations. Strat. Chang. 2017, 26, 423–428. [Google Scholar] [CrossRef]

- Zheng, Z.; Xie, S.; Dai, H.; Chen, X.; Wang, H. An Overview of Blockchain Technology: Architecture, Consensus, and Future Trends. In 2017 IEEE International Congress on Big Data; BigData congress; IEEE: New York, NY, USA, 2017; pp. 557–564. [Google Scholar]

- Yli-Huumo, J.; Ko, D.; Choi, S.; Park, S.; Smolander, K. Where Is Current Research on Blockchain Technology?—A Systematic Review. PLOS ONE 2016, 11, e0163477. [Google Scholar] [CrossRef] [PubMed]

- Zadeh, L.A. Fuzzy sets. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Hsu, Y.L.; Lee, C.H.; Kreng, V.B. The application of Fuzzy Delphi Method and Fuzzy AHP in lubricant regen-erative technology selection. Expert Syst. Appl. 2010, 37, 419–425. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Khanfar, A.A.; Iranmanesh, M.; Ghobakhloo, M.; Senali, M.G.; Fathi, M. Applications of Blockchain Technology in Sustainable Manufacturing and Supply Chain Management: A Systematic Review. Sustainability 2021, 13, 7870. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain technology and the sustainable supply chain: Theoretically ex-ploring adoption barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Abramova, S.; Böhme, R. Perceived benefit and risk as multidimensional determinants of bitcoin use: A quan-titative exploratory study. Inf. Secur. 2016, 1–20. [Google Scholar]

- Ahmad, N.; Kalim, R. Implications of export competitiveness, and performance of Textile and Clothing Sector of Pakistan: Pre and post quota analysis. Pak. J. Commer. Soc. Sci. 2014, 8, 696–714. [Google Scholar]

- Chang, S.E.; Chen, Y.-C.; Lu, M.-F. Supply chain re-engineering using blockchain technology: A case of smart contract based tracking process. Technol. Forecast. Soc. Chang. 2019, 144, 1–11. [Google Scholar] [CrossRef]

- Li, Z.; Guo, H.; Barenji, A.V.; Wang, W.M.; Guan, Y.; Huang, G.Q. A sustainable production capability evaluation mechanism based on blockchain, LSTM, analytic hierarchy process for supply chain network. Int. J. Prod. Res. 2020, 58, 7399–7419. [Google Scholar] [CrossRef]

- Rajak, S.; Vinodh, S. Application of fuzzy logic for social sustainability performance evaluation: A case study of an Indian automotive component manufacturing organization. J. Clean. Prod. 2015, 108, 1184–1192. [Google Scholar] [CrossRef]

- Lahkani, M.J.; Wang, S.; Urbański, M.; Egorova, M. Sustainable B2B E-Commerce and Blockchain-Based Supply Chain Finance. Sustainability 2020, 12, 3968. [Google Scholar] [CrossRef]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain. Manag. Int. J. 2019, 1–43. [Google Scholar] [CrossRef]

- Jain, G.; Singh, H.; Chaturvedi, K.R.; Rakesh, S. Blockchain in logistics industry: In fizz customer trust or not. J. Enterp. Inf. Manag. 2020, 33, 541–558. [Google Scholar] [CrossRef]

- Nofer, M.; Gomber, P.; Hinz, O.; Schiereck, D. Blockchain. Bus. Inf. Syst. Eng. 2017, 59, 183–187. [Google Scholar] [CrossRef]

- Gong, Y.; Zhang, Y.; Alharithi, M. Supply Chain Finance and Blockchain in Operations Management: A Literature Review. Sustainability 2022, 14, 13450. [Google Scholar] [CrossRef]

- Akins, B.W.; Chapman, J.L.; Gordon, J.M. A Whole New World: Income Tax Considerations of the Bitcoin Economy. Pittsburgh Tax Rev. 2014, 12, 24–56. [Google Scholar] [CrossRef][Green Version]

- Rajak, S.; Parthiban, P.; Dhanalakshmi, R. Selection of Transportation Channels in Closed-Loop Supply Chain Using Meta-Heuristic Algorithm. Int. J. Inf. Syst. Supply Chain Manag. 2018, 11, 64–86. [Google Scholar] [CrossRef]

- Tozanlı, Ö.; Kongar, E.; Gupta, S.M. Trade-in-to-upgrade as a marketing strategy in disassembly-to-order systems at the edge of blockchain technology. Int. J. Prod. Res. 2020, 58, 7183–7200. [Google Scholar] [CrossRef]

- Abeyratne, S.A.; Monfared, R.P. Blockchain ready manufacturing supply chain using distributed ledger. Inter-national Journal of Research in Engineering and Technology 2016, 5, 1–10. [Google Scholar]

- Chang, S.E.; Chen, Y. When blockchain meets supply chain: A systematic literature review on current devel-opment and potential applications. IEEE Access 2020, 8, 62478–62494. [Google Scholar] [CrossRef]

- Lim, M.K.; Li, Y.; Wang, C.; Tseng, M.-L. A literature review of blockchain technology applications in supply chains: A comprehensive analysis of themes, methodologies and industries. Comput. Ind. Eng. 2021, 154, 107133. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. J. Clean. Prod. 2017, 152, 242–258. [Google Scholar] [CrossRef]

- Adams, R.; Kewell, B.; Parry, G. Blockchain for Good? Digital Ledger Technology and Sustainable Development Goals. In Handbook of Sustainability and Social Science Research; Leal Filho, W., Marans, R., Callewaert, J., Eds.; World Sustainability Series; Springer: Cham, Switzerland, 2018; pp. 127–140. [Google Scholar] [CrossRef]

- Erol, I.; Ar, I.M.; Ozdemir, A.I.; Peker, I.; Asgary, A.; Medeni, I.T.; Medeni, T. Assessing the feasibility of blockchain technology in industries: Evidence from Turkey. J. Enterp. Inf. Manag. 2020, 34, 746–769. [Google Scholar] [CrossRef]

- Siegfried, N.; Rosenthal, T.; Benlian, A. Blockchain and the Industrial Internet of Things. J. Enterp. Inf. Manag. 2020, 35, 1454–1476. [Google Scholar] [CrossRef]

- Böhme, R.; Christin, N.; Edelman, B.; Moore, T. Bitcoin: Economics, technology, and governance. J. Econ. Perspect. 2015, 29, 213–238. [Google Scholar] [CrossRef]

- Swan, M. Blockchain: Blueprint for a New Economy; O’Reilly Media, Inc.: Newton, MA, USA, 2015. [Google Scholar]

- Baud-Lavigne, B.; Agard, B.; Penz, B. Environmental constraints in joint product and supply chain design optimization. Comput. Ind. Eng. 2014, 76, 16–22. [Google Scholar] [CrossRef]

- Choi, T.-M.; Feng, L.; Li, R. Information disclosure structure in supply chains with rental service platforms in the blockchain technology era. Int. J. Prod. Econ. 2020, 221, 107473. [Google Scholar] [CrossRef]

- Di Vaio, A.; Varriale, L. Blockchain technology in supply chain management for sustainable performance: Ev-idence from the airport industry. Int. J. Inf. Manag. 2020, 52, 102014. [Google Scholar] [CrossRef]

- Zohar, A. Bitcoin: Under the hood. Commun. ACM 2015, 58, 104–113. [Google Scholar] [CrossRef]

- Sternberg, H.S.; Hofmann, E.; Roeck, D. The Struggle is Real: Insights from a Supply Chain Blockchain Case. J. Bus. Logist. 2021, 42, 71–87. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. A supply chain transparency and sustainability technology appraisal model for blockchain technology. Int. J. Prod. Res. 2020, 58, 2142–2162. [Google Scholar] [CrossRef]

- Khaqqi, K.N.; Sikorski, J.J.; Hadinoto, K.; Kraft, M. Incorporating seller/buyer reputation-based system in blockchain-enabled emission trading application. Appl. Energy 2018, 209, 8–19. [Google Scholar] [CrossRef]

- Pérez, J.J.; Queiruga-Dios, A.; Martínez, V.G.; Del Rey, M. Traceability of Ready-to-Wear Clothing through Blockchain Technology. Sustainability 2020, 12, 7491. [Google Scholar] [CrossRef]

- Nandi, S.; Sarkis, J.; Hervani, A.A.; Helms, M.M. Redesigning Supply Chains using Blockchain-Enabled Circular Economy and COVID-19 Experiences. Sustain. Prod. Consum. 2021, 27, 10–22. [Google Scholar] [CrossRef]

- Niranjanamurthy, M.; Nithya, B.N.; Jagannatha, S. Analysis of Blockchain technology: Pros, cons and SWOT. Clust. Comput. 2019, 22, 14743–14757. [Google Scholar] [CrossRef]

- Kapse, C.P.; Kumar, A.; Dash, M.K.; Zavadskas, E.K.; Luthra, S. Developing textile entrepreneurial inclination model by integrating experts mining and ISM-MICMAC. Int. J. Prod. Res. 2018, 56, 4709–4728. [Google Scholar] [CrossRef]

- Mendling, J.; Weber, I.; Van Der Aalst, W.; Brocke, J.V.; Cabanillas, C.; Daniel, F.; Debois, S.; Di Ciccio, C.; Dumas, M.; Dustdar, S.; et al. Blockchains for Business Process Management - Challenges and Opportunities. ACM Trans. Manag. Inf. Syst. 2018, 9, 1–16. [Google Scholar] [CrossRef]

- Mubarik, M.; Rasi, R.Z.R.M.; Mubarak, M.F.; Ashraf, R. Impact of blockchain technology on green supply chain practices: Evidence from emerging economy. Manag. Environ. Qual. Int. J. 2021, 32, 1023–1039. [Google Scholar] [CrossRef]

- Osmani, M.; El-Haddadeh, R.; Hindi, N.; Janssen, M.; Weerakkody, V. Blockchain for next generation services in banking and finance: Cost, benefit, risk and opportunity analysis. J. Enterp. Inf. Manag. 2020, 34, 884–899. [Google Scholar] [CrossRef]

- Nazam, M.; Hashim, M.; Baig, S.A.; Abrar, M.; Shabbir, R. Modeling the key barriers of knowledge management adoption in sustainable supply chain. J. Enterp. Inf. Manag. 2020, 33, 1077–1109. [Google Scholar] [CrossRef]

- Kumar, A.; Kaviani, M.A.; Hafezalkotob, A.; Zavadskas, E.K. Evaluating innovation capabilities of real estate firms: A combined fuzzy delphi and dematel approach. Int. J. Strat. Prop. Manag. 2017, 21, 401–416. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.A. The technology and economic determinants of cryptocurrency exchange rates: The case of Bitcoin. Decis. Support Syst. 2017, 95, 49–60. [Google Scholar] [CrossRef]

- Nazam, M.; Xu, J.; Tao, Z.; Ahmad, J.; Hashim, M. A Fuzzy AHP-TOPSIS Framework for the Risk Assessment of Green Supply Chain Implementation in the Textile Industry. Int. J. Supply Oper. Manag. 2015, 2, 548–568. [Google Scholar] [CrossRef]

- Tahriri, F.; Mousavi, M.; Haghighi, S.H.; Dawal, S.Z.M. The application of fuzzy Delphi and fuzzy inference system in supplier ranking and selection. J. Ind. Eng. Int. 2014, 10, 1–16. [Google Scholar] [CrossRef][Green Version]

- Andrychowicz, M.; Masny, D.; Persichetti, E. Leakage-Resilient Cryptography over Large Finite Fields: Theory and Practice. In International Conference on Applied Cryptography and Network Security; Springer: Cham, Switzerland, 2015; pp. 655–674. [Google Scholar] [CrossRef]

- Huberman, G.; Leshno, J.D.; Moallemi, C. Monopoly without a Monopolist: An Economic Analysis of the Bitcoin Payment System. Rev. Econ. Stud. 2021, 88, 3011–3040. [Google Scholar] [CrossRef]

- Shen, Y.-C.; Chang, S.-H.; Lin, G.T.; Yu, H.-C. A hybrid selection model for emerging technology. Technol. Forecast. Soc. Chang. 2010, 77, 151–166. [Google Scholar] [CrossRef]

- Giungato, P.; Rana, R.; Tarabella, A.; Tricase, C. Current Trends in Sustainability of Bitcoins and Related Blockchain Technology. Sustainability 2017, 9, 2214. [Google Scholar] [CrossRef]

- Hughes, L.; Dwivedi, Y.K.; Misra, S.K.; Rana, N.P.; Raghavan, V.; Akella, V. Blockchain research, practice and policy: Applications, benefits, limitations, emerging research themes and research agenda. Int. J. Form. Manag. 2019, 49, 114–129. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Arha, H. Understanding the Blockchain technology adoption in supply chains-Indian context. Int. J. Prod. Res. 2018, 57, 2009–2033. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. Int. J. Inf. Manag. 2019, 52, 101967. [Google Scholar] [CrossRef]

- Kewell, B.; Adams, R.; Parry, G. Blockchain for good? Strateg. Chang. 2017, 26, 429–437. [Google Scholar] [CrossRef]

- Lu, Q.; Xu, X. Adaptable Blockchain-Based Systems: A Case Study for Product Traceability. IEEE Softw. 2017, 34, 21–27. [Google Scholar] [CrossRef]

- Schuetz, S.; Venkatesh, V. Blockchain, adoption, and financial inclusion in India: Research opportunities. Int. J. Inf. Manag. 2019, 52, 101936. [Google Scholar] [CrossRef]

- Thakur, V.; Doja, M.; Dwivedi, Y.K.; Ahmad, T.; Khadanga, G. Land records on Blockchain for implementation of Land Titling in India. Int. J. Inf. Manag. 2019, 52, 101940. [Google Scholar] [CrossRef]

- Vranken, H. Sustainability of bitcoin and blockchains. Curr. Opin. Environ. Sustain. 2017, 28, 1–9. [Google Scholar] [CrossRef]

- Wong, L.-W.; Leong, L.-Y.; Hew, J.-J.; Tan, G.W.-H.; Ooi, K.-B. Time to seize the digital evolution: Adoption of blockchain in operations and supply chain management among Malaysian SMEs. Int. J. Inf. Manag. 2019, 52, 101997. [Google Scholar] [CrossRef]

- Zimmermann, H.J. Fuzzy Control. In Fuzzy Set Theory—And Its Applications; Springer: Dordrecht, The Netherlands, 1996; pp. 203–240. [Google Scholar]

- Moktadir, A.; Rahman, T.; Jabbour, C.J.C.; Ali, S.M.; Kabir, G. Prioritization of drivers of corporate social re-sponsibility in the footwear industry in an emerging economy: A fuzzy AHP approach. J. Clean. Prod. 2018, 201, 369–381. [Google Scholar] [CrossRef]

- Mangla, S.K.; Govindan, K.; Luthra, S. Prioritizing the barriers to achieve sustainable consumption and pro-duction trends in supply chains using fuzzy Analytical Hierarchy Process. J. Clean. Prod. 2017, 151, 509–525. [Google Scholar] [CrossRef]

- Ishikawa, A.; Amagasa, M.; Shiga, T.; Tomizawa, G.; Tatsuta, R.; Mieno, H. The max-min Delphi method and fuzzy Delphi method via fuzzy integration. Fuzzy Sets Syst. 1993, 55, 241–253. [Google Scholar] [CrossRef]

- Yadav, G.; Mangla, S.K.; Luthra, S.; Jakhar, S. Hybrid BWM-ELECTRE-based decision framework for effective offshore outsourcing adoption: A case study. Int. J. Prod. Res. 2018, 56, 6259–6278. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kumar, P.; Barua, M.K. Risk analysis in green supply chain using fuzzy AHP approach: A case study. Resour. Conserv. Recycl. 2015, 104, 375–390. [Google Scholar] [CrossRef]

- Ahmed, W.A.H.; MacCarthy, B.L. Blockchain-Enabled Supply Chain Traceability in the Textile and Apparel Supply Chain: A Case Study of the Fiber Producer, Lenzing. Sustainability 2021, 13, 10496. [Google Scholar] [CrossRef]

- Hader, M.; Tchoffa, D.; El Mhamedi, A.; Ghodous, P.; Dolgui, A.; Abouabdellah, A. Applying integrated Block-chain and Big Data technologies to improve supply chain traceability and information sharing in the textile sector. J. Ind. Inf. Integr. 2022, 28, 100345. [Google Scholar]

- Ztürk, C.; Yildizbaşi, A. Barriers to implementation of blockchain into supply chain management using an integrated multi-criteria decision-making method: A numerical example. Soft Comput. 2020, 24, 14771–14789. [Google Scholar] [CrossRef]

| Categories of Barriers | Codes | Key Barriers to Implement BCT in SSC | Source |

|---|---|---|---|

| Technological and System Barriers (TSB) | TSB1 | Immaturity of technology | [66] |

| TSB2 | Transparency and traceability-related issues | [67] | |

| TSB3 | Challenges in sustainable practices and blockchain technology | [68] | |

| TSB4 | Risks of cyber attacks | [69] | |

| TSB5 | Lack of expertise and technical support in IT | [70] | |

| Human Resources and R&D Barriers (HRB) | HRB1 | Negative perception of IT among workers’ minds | [71] |

| HRB2 | Lack of professional technical labor | [72] | |

| HRB3 | Lack of research and development departments | [73] | |

| HRB4 | Lack of financial resources for technological infrastructure | [74] | |

| Socio-economic and Environmental Barriers (SEB) | SEB1 | Poor economic behavior in the long run | [75] |

| SEB2 | Social and cultural constraints | [76] | |

| SEB3 | Neglecting environmental standards | [77] | |

| Organizational and Individual Barriers (OIB) | OIB1 | Lack of management commitment and support | [78] |

| OIB2 | Information sharing obstacles | [79] | |

| OIB3 | Lack of organizational new policies for adopting technology | [80] | |

| OIB4 | Employees reluctance to accept change | [81] | |

| OIB5 | Unwillingness to change the conventional ways | [82] | |

| Governmental and External Stakeholder Barriers (GESB) | GESB1 | Unclear issue of taxation and regulatory uncertainties | [83] |

| GESB2 | Lack of government interest in blockchain | [84] | |

| GESB3 | Market competition and uncertainty | [85] | |

| GESB4 | Lack of external stakeholders’ involvement | [86] |

| Linguistic Variables | Notations | Fuzzy Number | Fuzzy Score |

|---|---|---|---|

| Very Low | VL | (0, 0, 0.1) | |

| Low | L | (0, 0.1, 0.3) | |

| Medium Low | ML | (0.1, 0.3, 0.5) | |

| Medium | M | (0.3, 0.5, 0.7) | |

| Medium High | MH | (0.5, 0.7, 0.9) | |

| High | H | (0.7, 0.9, 1.0) | |

| Very High | VH | (0.9, 1.0, 1.0) |

| Barriers | Fuzzy Weight | Defuzzification | S/R |

|---|---|---|---|

| 1 | (0.30, 0.82, 1.00) | 0.7067 | S |

| 2 | (0.00, 0.48, 1.00) | 0.4933 | R |

| 3 | (0.00, 0.40, 1.00) | 0.4667 | R |

| 4 | (0.30, 0.84, 1.00) | 0.7133 | S |

| 5 | (0.10, 0.70, 1.00) | 0.6000 | S |

| 6 | (0.10, 0.58, 1.00) | 0.5600 | R |

| 7 | (0.00, 0.44, 1.00) | 0.4800 | R |

| 8 | (0.00, 0.80, 1.00) | 0.6000 | S |

| 9 | (0.10, 0.84, 1.00) | 0.6467 | S |

| 10 | (0.30, 0.74, 1.00) | 0.6800 | S |

| 11 | (0.00, 0.52, 1.00) | 0.5067 | R |

| 12 | (0.30, 0.90, 1.00) | 0.7333 | S |

| 13 | (0.00, 0.58, 1.00) | 0.5267 | R |

| 14 | (0.30, 0.72, 1.00) | 0.6733 | S |

| 15 | (0.00, 0.58, 1.00) | 0.5267 | R |

| 16 | (0.10, 0.76, 1.00) | 0.6200 | S |

| 17 | (0.70, 0.94, 1.00) | 0.8800 | S |

| 18 | (0.00, 0.42, 1.00) | 0.4733 | R |

| 19 | (0.00, 0.30, 0.70) | 0.3333 | R |

| 20 | (0.10, 0.84, 1.00) | 0.6467 | S |

| 21 | (0.30, 0.82, 1.00) | 0.7067 | S |

| 22 | (0.00, 0.36, 1.00) | 0.4533 | R |

| 23 | (0.50, 0.90, 1.00) | 0.8000 | S |

| 24 | (0.00, 0.50, 1.00) | 0.5000 | R |

| 25 | (0.10, 0.78, 1.00) | 0.6267 | S |

| 26 | (0.00, 0.46, 1.00) | 0.4867 | R |

| 27 | (0.10, 0.64, 1.00) | 0.5800 | R |

| 28 | (0.30, 0.86, 1.00) | 0.7200 | S |

| 29 | (0.00, 0.80, 1.00) | 0.6000 | S |

| 30 | (0.00, 0.22, 0.70) | 0.3067 | R |

| 31 | (0.00, 0.10, 0.50) | 0.2000 | R |

| 32 | (0.00, 0.34, 0.90) | 0.4133 | R |

| 33 | (0.10, 0.84, 1.00) | 0.6467 | S |

| 34 | (0.00, 0.80, 1.00) | 0.6000 | S |

| 35 | (0.10, 0.76, 1.00) | 0.6200 | S |

| 36 | (0.00, 0.24, 0.50) | 0.2467 | R |

| 37 | (0.00, 0.50, 0.90) | 0.4667 | R |

| 38 | (0.50, 0.88, 1.00) | 0.7933 | S |

| 39 | (0.70, 0.96, 1.00) | 0.8867 | S |

| 40 | (0.00, 0.34, 0.70) | 0.3467 | R |

| 41 | (0.00, 0.60, 1.00) | 0.5333 | R |

| TSB | HRB | SEB | OIB | GSEB | |

|---|---|---|---|---|---|

| TSB | (1.00, 1.00, 1.00) | (3.00, 5.40, 9.00) | (0.20, 2.04, 3.00) | (0.14, 2.29, 5.00) | (0.14, 1.57, 7.00) |

| HRB | (0.11, 0.19, 0.33) | (1.00, 1.00, 1.00) | (0.14, 2.82, 5.00) | (0.20, 3.64, 7.00) | (3.00, 3.80, 7.00) |

| SEB | (0.33, 0.49, 5.00) | (0.20, 0.35, 7.00) | (1.00, 1.00, 1.00) | (0.20, 3.64, 7.00) | (0.14, 2.69, 5.00) |

| OIB | (0.20, 0.44, 7.00) | (0.14, 0.27, 5.00) | (0.14, 0.27, 5.00) | (1.00, 1.00, 1.00) | (0.14, 2.26, 5.00) |

| GSEB | (0.14, 0.64, 7.00) | (0.14, 0.26, 0.33) | (0.20, 0.44, 7.00) | (0.20, 0.44, 7.00) | (1.00, 1.00, 1.00) |

| Weight | Ranking | |

|---|---|---|

| TSB | 0.233 | 1 |

| HRB | 0.220 | 2 |

| SEB | 0.194 | 3 |

| OIB | 0.179 | 4 |

| GSEB | 0.173 | 5 |

| Barrier Category | Main Barriers Weight | Sub-Barriers | Sub-Barriers Weight | Final Weight | Ranking |

|---|---|---|---|---|---|

| TSB | 0.233 | TSB1 | 0.4511 | 0.1052 | 3 |

| TSB2 | 0.2901 | 0.0676 | 6 | ||

| TSB3 | 0.1422 | 0.0332 | 11 | ||

| TSB4 | 0.0748 | 0.0175 | 16 | ||

| TSB5 | 0.0417 | 0.0097 | 20 | ||

| HRB | 0.220 | HRB1 | 0.5545 | 0.1222 | 2 |

| HRB2 | 0.2474 | 0.0545 | 7 | ||

| HRB3 | 0.1257 | 0.0277 | 12 | ||

| HRB4 | 0.0724 | 0.0159 | 17 | ||

| SEB | 0.194 | SEB1 | 0.6378 | 0.1237 | 1 |

| SEB2 | 0.2577 | 0.0500 | 8 | ||

| SEB3 | 0.1045 | 0.0203 | 15 | ||

| OIB | 0.179 | OIB1 | 0.4683 | 0.0838 | 5 |

| OIB2 | 0.2542 | 0.0455 | 9 | ||

| OIB3 | 0.0500 | 0.0089 | 21 | ||

| OIB4 | 0.1476 | 0.0264 | 13 | ||

| OIB5 | 0.0800 | 0.0143 | 18 | ||

| GSEB | 0.173 | GSEB1 | 0.5812 | 0.1008 | 4 |

| GSEB2 | 0.0638 | 0.0111 | 19 | ||

| GSEB3 | 0.1211 | 0.0210 | 14 | ||

| GSEB4 | 0.2383 | 0.0413 | 10 |

| Barrier Categories | Normal Weight | Incremental Changes | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TSB | 0.233 | 0.210 | 0.187 | 0.163 | 0.140 | 0.117 | 0.093 | 0.070 | 0.047 | 0.023 |

| HRB | 0.220 | 0.225 | 0.231 | 0.236 | 0.242 | 0.247 | 0.253 | 0.259 | 0.265 | 0.271 |

| SEB | 0.194 | 0.199 | 0.203 | 0.208 | 0.213 | 0.218 | 0.223 | 0.228 | 0.233 | 0.239 |

| OIB | 0.179 | 0.183 | 0.188 | 0.192 | 0.196 | 0.201 | 0.206 | 0.210 | 0.215 | 0.220 |

| GSEB | 0.173 | 0.178 | 0.182 | 0.186 | 0.190 | 0.195 | 0.199 | 0.204 | 0.209 | 0.213 |

| TSB = 0.233 Normal | TSB = 0.210 | TSB = 0.187 | TSB = 0.163 | TSB = 0.140 | TSB = 0.117 | TSB = 0.093 | TSB = 0.070 | TSB = 0.047 | TSB = 0.023 | |

|---|---|---|---|---|---|---|---|---|---|---|

| TSB1 | 3 | 4 | 5 | 5 | 5 | 7 | 8 | 10 | 13 | 17 |

| TSB2 | 6 | 6 | 7 | 9 | 10 | 10 | 11 | 14 | 16 | 18 |

| TSB3 | 11 | 11 | 13 | 13 | 15 | 16 | 16 | 19 | 19 | 19 |

| TSB4 | 16 | 17 | 18 | 18 | 19 | 20 | 19 | 20 | 20 | 20 |

| TSB5 | 20 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 |

| HRB1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| HRB2 | 7 | 7 | 6 | 6 | 6 | 5 | 5 | 5 | 5 | 5 |

| HRB3 | 12 | 12 | 11 | 11 | 11 | 11 | 9 | 9 | 9 | 9 |

| HRB4 | 17 | 16 | 16 | 16 | 16 | 15 | 14 | 15 | 14 | 13 |

| SEB1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| SEB2 | 8 | 8 | 8 | 7 | 7 | 6 | 6 | 6 | 6 | 6 |

| SEB3 | 15 | 15 | 15 | 15 | 14 | 14 | 12 | 13 | 12 | 12 |

| OIB1 | 5 | 5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OIB2 | 9 | 9 | 9 | 8 | 8 | 8 | 7 | 7 | 7 | 7 |

| OIB3 | 21 | 20 | 20 | 20 | 20 | 19 | 18 | 18 | 18 | 16 |

| OIB4 | 13 | 13 | 12 | 12 | 12 | 12 | 10 | 11 | 10 | 10 |

| OIB5 | 18 | 18 | 17 | 17 | 17 | 17 | 15 | 16 | 15 | 14 |

| GSEB1 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| GSEB2 | 19 | 19 | 19 | 19 | 18 | 18 | 20 | 17 | 17 | 15 |

| GSEB3 | 14 | 14 | 14 | 14 | 13 | 13 | 17 | 12 | 11 | 11 |

| GSEB4 | 10 | 10 | 10 | 10 | 9 | 9 | 13 | 8 | 8 | 8 |

| Barrier Categories | Normal Weight | Incremental Changes | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TSB | 0.233 | 0.238 | 0.244 | 0.249 | 0.254 | 0.260 | 0.266 | 0.272 | 0.278 | 0.284 |

| HRB | 0.220 | 0.198 | 0.176 | 0.154 | 0.132 | 0.110 | 0.088 | 0.066 | 0.044 | 0.022 |

| SEB | 0.194 | 0.198 | 0.203 | 0.207 | 0.212 | 0.216 | 0.221 | 0.226 | 0.231 | 0.236 |

| OIB | 0.179 | 0.183 | 0.187 | 0.191 | 0.195 | 0.200 | 0.204 | 0.209 | 0.213 | 0.218 |

| GSEB | 0.173 | 0.177 | 0.181 | 0.185 | 0.189 | 0.193 | 0.198 | 0.202 | 0.207 | 0.211 |

| HRB = 0.220 Normal | HRB = 0.198 | HRB = 0.176 | HRB = 0.154 | HRB = 0.132 | HRB = 0.110 | HRB = 0.088 | HRB = 0.066 | HRB = 0.044 | HRB = 0.022 | |

|---|---|---|---|---|---|---|---|---|---|---|

| TSB1 | 3 | 3 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| TSB2 | 6 | 6 | 6 | 6 | 5 | 5 | 5 | 5 | 5 | 5 |

| TSB3 | 11 | 11 | 11 | 11 | 10 | 10 | 10 | 9 | 9 | 9 |

| TSB4 | 16 | 16 | 16 | 16 | 15 | 15 | 15 | 14 | 14 | 14 |

| TSB5 | 20 | 20 | 20 | 20 | 19 | 19 | 18 | 18 | 17 | 17 |

| HRB1 | 2 | 2 | 4 | 5 | 6 | 6 | 8 | 10 | 12 | 12 |

| HRB2 | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 | 18 | 19 |

| HRB3 | 12 | 13 | 13 | 15 | 16 | 17 | 19 | 20 | 20 | 20 |

| HRB4 | 17 | 18 | 18 | 19 | 21 | 21 | 21 | 21 | 21 | 21 |

| SEB1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| SEB2 | 8 | 7 | 7 | 7 | 7 | 7 | 6 | 6 | 6 | 6 |

| SEB3 | 15 | 15 | 15 | 14 | 14 | 14 | 13 | 13 | 13 | 13 |

| OIB1 | 5 | 5 | 5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OIB2 | 9 | 9 | 8 | 8 | 8 | 8 | 7 | 7 | 7 | 7 |

| OIB3 | 21 | 21 | 21 | 21 | 20 | 20 | 20 | 19 | 19 | 18 |

| OIB4 | 13 | 12 | 12 | 12 | 12 | 11 | 11 | 11 | 10 | 10 |

| OIB5 | 18 | 17 | 17 | 17 | 17 | 16 | 16 | 15 | 15 | 15 |

| GSEB1 | 4 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| GSEB2 | 19 | 19 | 19 | 18 | 18 | 18 | 17 | 17 | 16 | 16 |

| GSEB3 | 14 | 14 | 14 | 13 | 13 | 13 | 12 | 12 | 11 | 11 |

| GSEB4 | 10 | 10 | 10 | 9 | 9 | 9 | 9 | 8 | 8 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazam, M.; Hashim, M.; Nută, F.M.; Yao, L.; Zia, M.A.; Malik, M.Y.; Usman, M.; Dimen, L. Devising a Mechanism for Analyzing the Barriers of Blockchain Adoption in the Textile Supply Chain: A Sustainable Business Perspective. Sustainability 2022, 14, 16159. https://doi.org/10.3390/su142316159

Nazam M, Hashim M, Nută FM, Yao L, Zia MA, Malik MY, Usman M, Dimen L. Devising a Mechanism for Analyzing the Barriers of Blockchain Adoption in the Textile Supply Chain: A Sustainable Business Perspective. Sustainability. 2022; 14(23):16159. https://doi.org/10.3390/su142316159

Chicago/Turabian StyleNazam, Muhammad, Muhammad Hashim, Florian Marcel Nută, Liming Yao, Muhammad Azam Zia, Muhammad Yousaf Malik, Muhammad Usman, and Levente Dimen. 2022. "Devising a Mechanism for Analyzing the Barriers of Blockchain Adoption in the Textile Supply Chain: A Sustainable Business Perspective" Sustainability 14, no. 23: 16159. https://doi.org/10.3390/su142316159

APA StyleNazam, M., Hashim, M., Nută, F. M., Yao, L., Zia, M. A., Malik, M. Y., Usman, M., & Dimen, L. (2022). Devising a Mechanism for Analyzing the Barriers of Blockchain Adoption in the Textile Supply Chain: A Sustainable Business Perspective. Sustainability, 14(23), 16159. https://doi.org/10.3390/su142316159