Design Optimization and Carbon Footprint Analysis of an Electrodeionization System with Flexible Load Regulation

Abstract

1. Introduction

2. Case Study and Methods

2.1. Principle of UPW Preparation by EDI

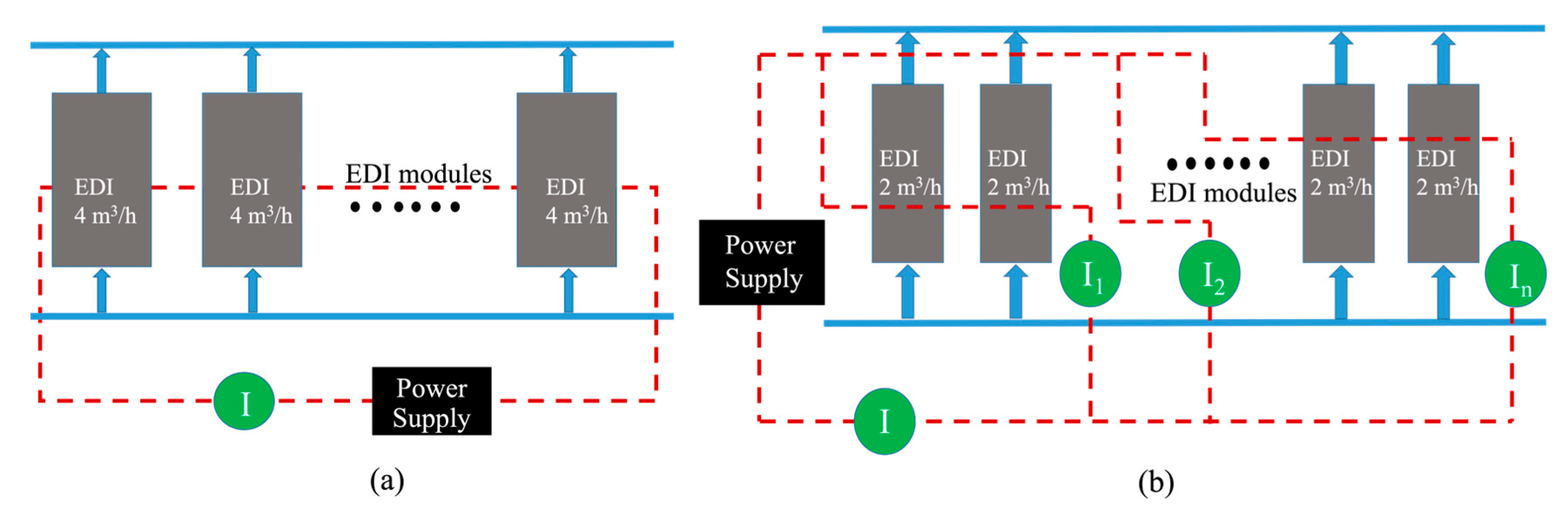

2.2. EDI System

2.3. Modeling of EDI Modules

2.4. Construction of the EDI System Optimization Model

- (1)

- Ion exchange membrane:

- (2)

- Ion exchange resin:

- (3)

- Enclosed shell:

- (4)

- Electrodes:

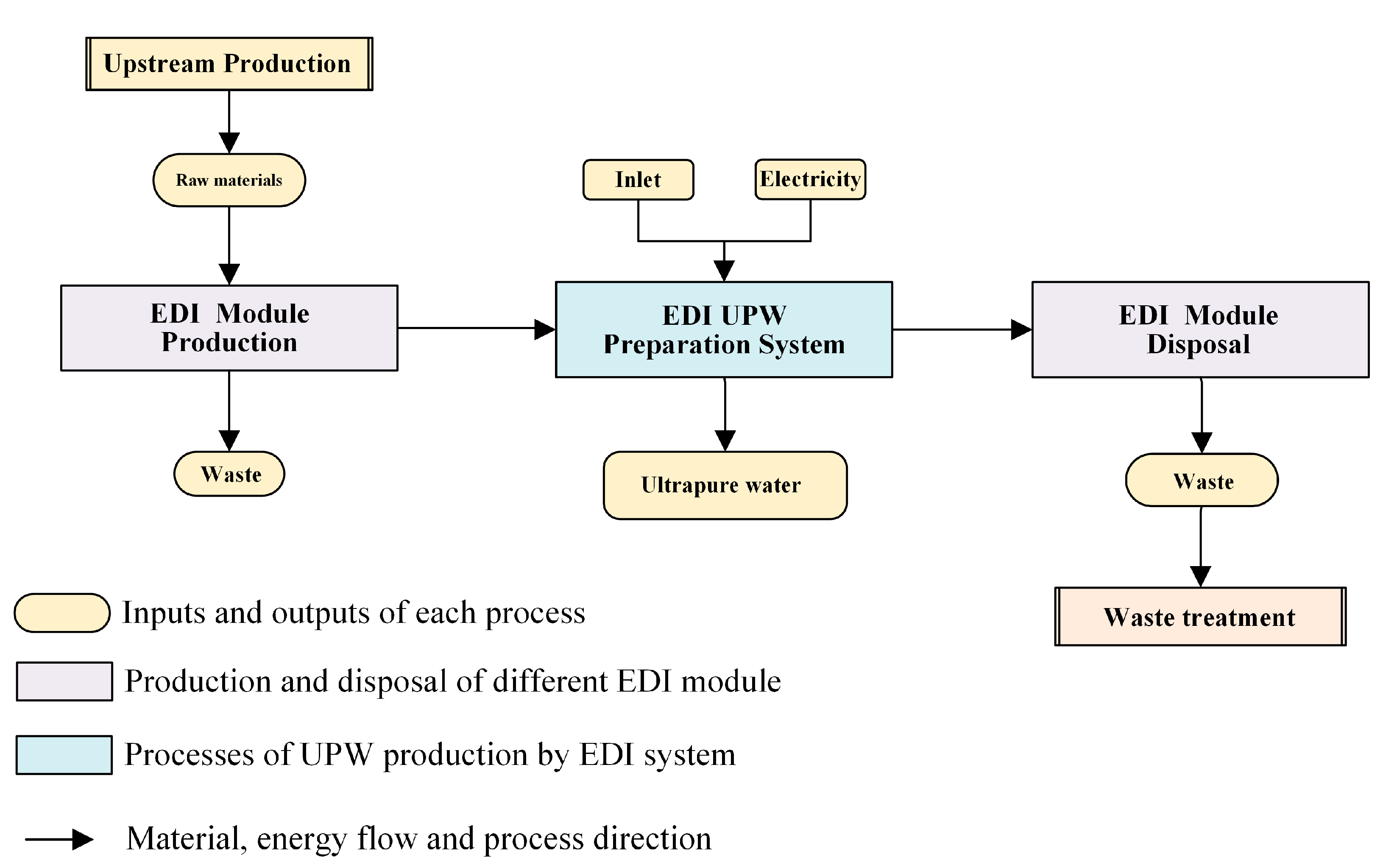

2.5. Life Cycle Assessment of Optimization of the EDI System

3. Results and Discussion

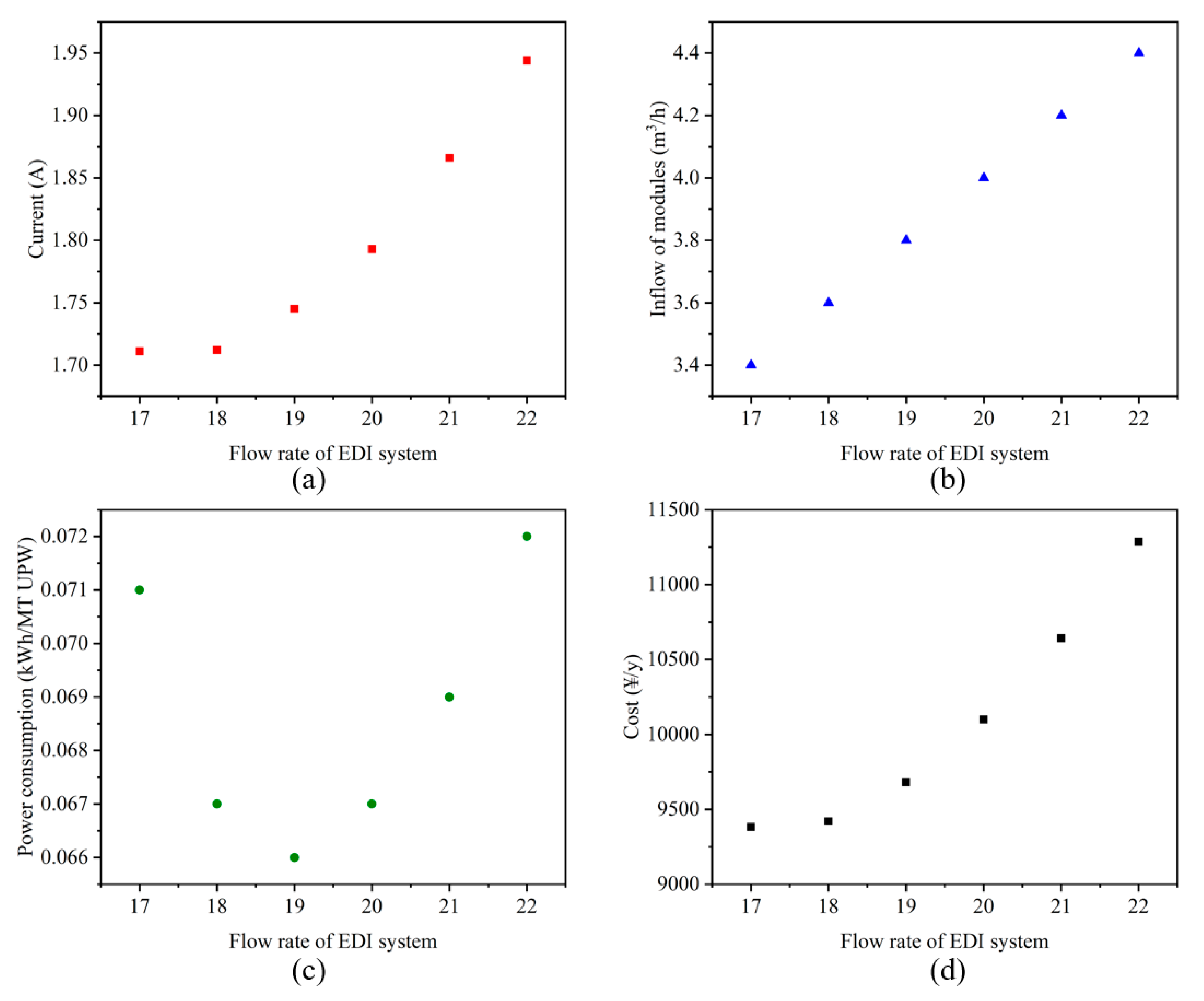

3.1. Sensitivity Analysis

3.2. Design Optimization of 20-m3/h UPW Preparation System by EDI

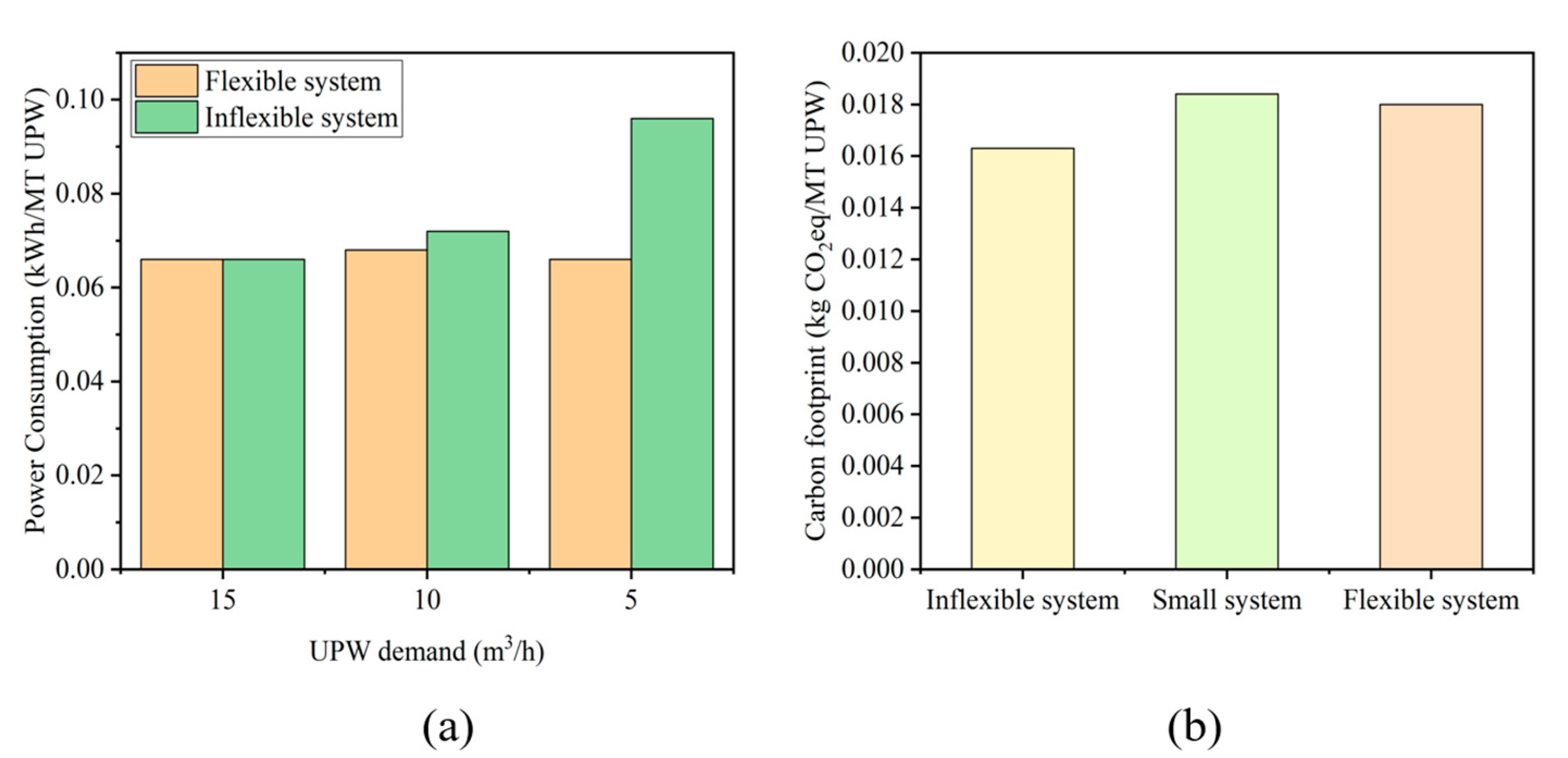

3.3. Energy-Saving Effect of Operation Optimization under Flexible Peak Load Regulation

3.4. Comparative Analysis of Carbon Footprint for Different Designs

3.5. Further Discussion and Suggestions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| A | Membrane area (cm2) |

| C | The concentration of the liquid phase (Equiv/cm3) |

| CostE | Electricity fee (¥/kWh) |

| CostM | Price of ion exchange membrane (¥/cm2) |

| CostR | Price of ion exchange resin (¥/L) |

| Costshell | Price of ion shell (¥/cm2) |

| d | Width of the membrane (cm) |

| F | The flow rate of dilute chamber (cm3/s) |

| Fc | The flow rate of each cell (cm3/s) |

| g | The lifespan of EDI (year) |

| h | Interest rate |

| i | Cation |

| I | Current (A) |

| Iline | Row current (A) |

| j | Anion |

| L | Membrane length (water flow direction) (cm) |

| lo | Variable lower limitation |

| m | Number of columns |

| Nd | Number of dilute chambers |

| Nc | Number of concentrate chambers |

| n | Number of rows |

| PC | Energy consumption per ton of water treated (Wh/m3) |

| R | Membrane stack resistance (Ω) |

| TH | Annual working time (h) |

| up | Variable upper limitation |

| w | Width of the dilute chamber (current direction) (m) |

References

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef] [PubMed]

- Elahi, E.; Khalid, Z.; Tauni, M.Z.; Zhang, H.; Lirong, X. Extreme weather events risk to crop-production and the adaptation of innovative management strategies to mitigate the risk: A retrospective survey of rural Punjab, Pakistan. Technovation 2022, 117, 102255. [Google Scholar] [CrossRef]

- Yu, H. The Paris Climate Agreement and China’s Role in Global Climate Governance. China Q. Int. Strateg. Stud. 2016, 2, 185–200. [Google Scholar] [CrossRef]

- Li, J.; Ho, M.S.; Xie, C.; Stern, N. China’s flexibility challenge in achieving carbon neutrality by 2060. Renew. Sustain. Energy Rev. 2022, 158, 112112. [Google Scholar] [CrossRef]

- Agency, I.E. Global Energy Review: CO2 Emissions in 2021; IEA: Paris, France, 2022. [Google Scholar]

- Zhang, T.; Zhang, S.; Qu, J. The impact of China’s carbon neutrality target on its energy consumption structure by 2050. Energy Sources Part B Econ. Plan. Policy 2022, 17, 2088896. [Google Scholar] [CrossRef]

- Basit, M.A.; Dilshad, S.; Badar, R.; Sami ur Rehman, S.M. Limitations, challenges, and solution approaches in grid-connected renewable energy systems. Int. J. Energy Res. 2020, 44, 4132–4162. [Google Scholar] [CrossRef]

- Guang, P. Applicarion of Energy Saving and Consumption Reduction Technology in Boiler Operation of Power Plant. Electron. Technol. 2022, 51, 178–179. (In Chinese) [Google Scholar]

- Zhang, X.; Yang, Y.; Ngo, H.H.; Guo, W.; Wen, H.; Wang, X.; Zhang, J.; Long, T. A critical review on challenges and trend of ultrapure water production process. Sci. Total Environ. 2021, 785, 147254. [Google Scholar] [CrossRef]

- Dalane, K.; Hillestad, M.; Deng, L. Subsea natural gas dehydration with membrane processes: Simulation and process optimization. Chem. Eng. Res. Des. 2019, 142, 257–267. [Google Scholar] [CrossRef]

- Lv, Y.; Yan, H.; Yang, B.; Wu, C.; Zhang, X.; Wang, X. Bipolar membrane electrodialysis for the recycling of ammonium chloride wastewater: Membrane selection and process optimization. Chem. Eng. Res. Des. 2018, 138, 105–115. [Google Scholar] [CrossRef]

- Iaquinta, M.; Stoller, M.; Merli, C. Optimization of a nanofiltration membrane process for tomato industry wastewater effluent treatment. Desalination 2009, 245, 314–320. [Google Scholar] [CrossRef]

- Al-Zoubi, H.; Rieger, A.; Steinberger, P.; Pelz, W.; Haseneder, R.; Härtel, G. Optimization Study for Treatment of Acid Mine Drainage Using Membrane Technology. Sep. Sci. Technol. 2010, 45, 2004–2016. [Google Scholar] [CrossRef]

- Valentukeviciene, M.; Zurauskiene, R.; Youssef, A.B. Fluoride removal from groundwater by technological process optimization. Ecol. Chem. Eng. 2019, 26, 133–147. [Google Scholar] [CrossRef]

- Glueckauf, E. Electro-deionization through a packed bed. Brit. Chem. Eng. 1959, 4, 646–651. [Google Scholar]

- Kurup, A.S.; Ho, T.; Hestekin, J.A. Simulation and optimal design of electrodeionization process: Separation of multicomponent electrolyte solution. Ind. Eng. Chem. Res. 2009, 48, 9268–9277. [Google Scholar] [CrossRef]

- Mahmoud, A.; Muhr, L.; Grévillot, G.; Lapicque, F. Experimental tests and modelling of an electrodeionization cell for the treatment of dilute copper solutions. Can. J. Chem. Eng. 2007, 85, 171–179. [Google Scholar] [CrossRef]

- Monzie, I.; Muhr, L.; Lapicque, F.; Grévillot, G. Mass transfer investigations in electrodeionization processes using the microcolumn technique. Chem. Eng. Sci. 2005, 60, 1389–1399. [Google Scholar] [CrossRef]

- Schab, F.; Muhr, L.; Bounaceur, R.; Théoleyre, M.-A.; Grévillot, G. Modelling of Weak Acid Conversion in an EDl Cell. Sep. Sci. Technol. 2010, 45, 1015–1024. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M. Application of life cycle assessment for desalination: Progress, challenges and future directions. Environ. Pollut. 2021, 268, 115948. [Google Scholar] [CrossRef]

- Nie, Z.-R.; Feng, G.; Gong, X.-Z.; Wang, Z.-H.; Zuo, T.-Y. Recent progress and application of materials life cycle assessment in China. Prog. Nat. Sci. Mater. Int. 2011, 21, 1–11. [Google Scholar] [CrossRef][Green Version]

- Tarnacki, K.; Meneses, M.; Melin, T.; Van Medevoort, J.; Jansen, A. Environmental assessment of desalination processes: Reverse osmosis and Memstill®. Desalination 2012, 296, 69–80. [Google Scholar] [CrossRef]

- Supandy, M. Life Cycle Assessment of Ultra Pure Water Plant in Semiconductor Industry. 2009. Available online: http://eprints.usq.edu.au/id/eprint/8438 (accessed on 29 June 2022).

- Chiriaco, M.V.; Belli, C.; Chiti, T.; Trotta, C.; Sabbatini, S. The potential carbon neutrality of sustainable viticulture showed through a comprehensive assessment of the greenhouse gas (GHG) budget of wine production. J. Clean. Prod. 2019, 225, 435–450. [Google Scholar] [CrossRef]

- Semba, T.; Sakai, Y.; Sakanishi, T.; Inaba, A. Greenhouse gas emissions of 100% bio-derived polyethylene terephthalate on its life cycle compared with petroleum-derived polyethylene terephthalate. J. Clean. Prod. 2018, 195, 932–938. [Google Scholar] [CrossRef]

- Voss, R.; Lee, R.P.; Fröhling, M. Chemical Recycling of Plastic Waste: Comparative Evaluation of Environmental and Economic Performances of Gasification-and Incineration-based Treatment for Lightweight Packaging Waste. Circ. Econ. Sustain. 2022, 1–30. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, D.; Hu, S.; Guo, S. Modelling of energy consumption and carbon emission from the building construction sector in China, a process-based LCA approach. Energy Policy 2019, 134, 110949. [Google Scholar] [CrossRef]

- Raluy, G.; Serra, L.; Uche, J. Life cycle assessment of MSF, MED and RO desalination technologies. Energy 2006, 31, 2361–2372. [Google Scholar] [CrossRef]

- Bonton, A.; Bouchard, C.; Barbeau, B.; Jedrzejak, S. Comparative life cycle assessment of water treatment plants. Desalination 2012, 284, 42–54. [Google Scholar] [CrossRef]

- Bhakar, V.; Kumar, D.H.; Sai, N.K.; Sangwan, K.S.; Raghuvanshi, S. Life cycle assessment of filtration systems of reverse osmosis units: A case study of a university campus. Procedia CIRP 2016, 40, 268–273. [Google Scholar] [CrossRef]

- Shahabi, M.P.; McHugh, A.; Anda, M.; Ho, G. Environmental life cycle assessment of seawater reverse osmosis desalination plant powered by renewable energy. Renew. Energy 2014, 67, 53–58. [Google Scholar] [CrossRef]

- Qian, F.; Lu, J.; Gu, D.; Li, G.; Liu, Y.; Rao, P.; Fang, S.; Zhang, N. Modeling and optimization of electrodeionization process for the energy-saving of ultrapure water production. J. Clean. Prod. 2022, 372, 133754. [Google Scholar] [CrossRef]

- Rathi, B.S.; Kumar, P.S. Electrodeionization theory, mechanism and environmental applications. A review. Environ. Chem. Lett. 2020, 18, 1209–1227. [Google Scholar] [CrossRef]

- Park, S.; Kwak, R. Microscale electrodeionization: In situ concentration profiling and flow visualization. Water Res. 2020, 170, 115310. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization of Standardization: Geneva, Switzerland, 2006.

- Muñoz, I.; Schmidt, J.H. Methane oxidation, biogenic carbon, and the IPCC’s emission metrics. Proposal for a consistent greenhouse-gas accounting. Int. J. Life Cycle Assess. 2016, 21, 1069–1075. [Google Scholar] [CrossRef]

- Ervan, Y.; Wenten, I.G. Study on the influence of applied voltage and feed concentration on the performance of electrodeionization. Songklanakarin J. Sci. Technol. 2002, 24, 955–963. [Google Scholar]

- Simons, R. Electric field effects on proton transfer between ionizable groups and water in ion exchange membranes. Electrochim. Acta 1984, 29, 151–158. [Google Scholar] [CrossRef]

- Wang, F.; Xu, J.; Liu, L.; Yin, G.; Wang, J.; Yan, J. Optimal design and operation of hybrid renewable energy system for drinking water treatment. Energy 2021, 219, 119673. [Google Scholar] [CrossRef]

- Siddiqui, O.; Dincer, I. Development and analysis of a new renewable energy-based industrial wastewater treatment system. J. Environ. Manag. 2021, 290, 112564. [Google Scholar] [CrossRef] [PubMed]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Bio/Technol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Nuss, P.; Eckelman, M.J. Life cycle assessment of metals: A scientific synthesis. PloS ONE 2014, 9, e101298. [Google Scholar] [CrossRef]

- Havukainen, J.; Zhan, M.; Dong, J.; Liikanen, M.; Deviatkin, I. Environmental impact assessment of municipal solid waste management incorporating mechanical treatment of waste and incineration in Hangzhou, China. J. Clean. Prod. 2017, 141, 453–461. [Google Scholar] [CrossRef]

| A (cm2) | L (cm) | d (cm) | W (cm) | F (m3/h) | Number of Dilute/Concentrate Chambers | qi, qj (mmol/mL) | Ki, Kj (-) |

|---|---|---|---|---|---|---|---|

| 507 | 39 | 13 | 0.8 | 3.5 | 36/37 | 2 | 1.55 |

| UPW Demand (m3/h) | 20 | |||

|---|---|---|---|---|

| System | Inflexible System | Small System | Flexible System | |

| Module number | 5 large | 8 small | 4 large | 1 small |

| Inflow (m3/h) | 4 | 2.5 | 4.2 | 2.4 |

| I (A) | 1.79 | 1.791 | 1.786 | 1.787 |

| A (cm2) | 600 | 600 | 600 | 600 |

| d (cm) | 0.6 | 0.6 | 0.6 | 0.6 |

| Nd | 38 | 24 | 42 | 24 |

| Power consumption (kWh/MT UPW) | 0.067 | 0.067 | 0.067 | |

| Annual cost (¥/y) | 10,200.2 | 10,457.7 | 10,101.1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Qian, F.; Lu, J.; Gu, D.; Lou, Y.; Xue, N.; Li, G.; Liao, W.; Zhang, N. Design Optimization and Carbon Footprint Analysis of an Electrodeionization System with Flexible Load Regulation. Sustainability 2022, 14, 15957. https://doi.org/10.3390/su142315957

Yuan Y, Qian F, Lu J, Gu D, Lou Y, Xue N, Li G, Liao W, Zhang N. Design Optimization and Carbon Footprint Analysis of an Electrodeionization System with Flexible Load Regulation. Sustainability. 2022; 14(23):15957. https://doi.org/10.3390/su142315957

Chicago/Turabian StyleYuan, Yuan, Fengting Qian, Jiaqi Lu, Dungang Gu, Yuhang Lou, Na Xue, Guanghui Li, Wenjie Liao, and Nan Zhang. 2022. "Design Optimization and Carbon Footprint Analysis of an Electrodeionization System with Flexible Load Regulation" Sustainability 14, no. 23: 15957. https://doi.org/10.3390/su142315957

APA StyleYuan, Y., Qian, F., Lu, J., Gu, D., Lou, Y., Xue, N., Li, G., Liao, W., & Zhang, N. (2022). Design Optimization and Carbon Footprint Analysis of an Electrodeionization System with Flexible Load Regulation. Sustainability, 14(23), 15957. https://doi.org/10.3390/su142315957