Robust Counterpart Models for Fresh Agricultural Product Routing Planning Considering Carbon Emissions and Uncertainty

Abstract

1. Introduction

- ◆

- We include constraints such as carbon emission limits into the research on fresh agricultural product routing planning, and comprehensively consider multiple costs to study the timeliness of transportation, operation economy, and environmental sustainability.

- ◆

- We extend deterministic parameters to uncertain scenarios and propose to establish two robust corresponding models to solve the thorny problem of parameter data scarcity in uncertain scenarios.

- ◆

- In order to improve the compatibility of the algorithm, we introduce a Benders decomposition algorithm to verify the model and compare the feasibility of the routing planning scheme through real cases.

2. Literature Review

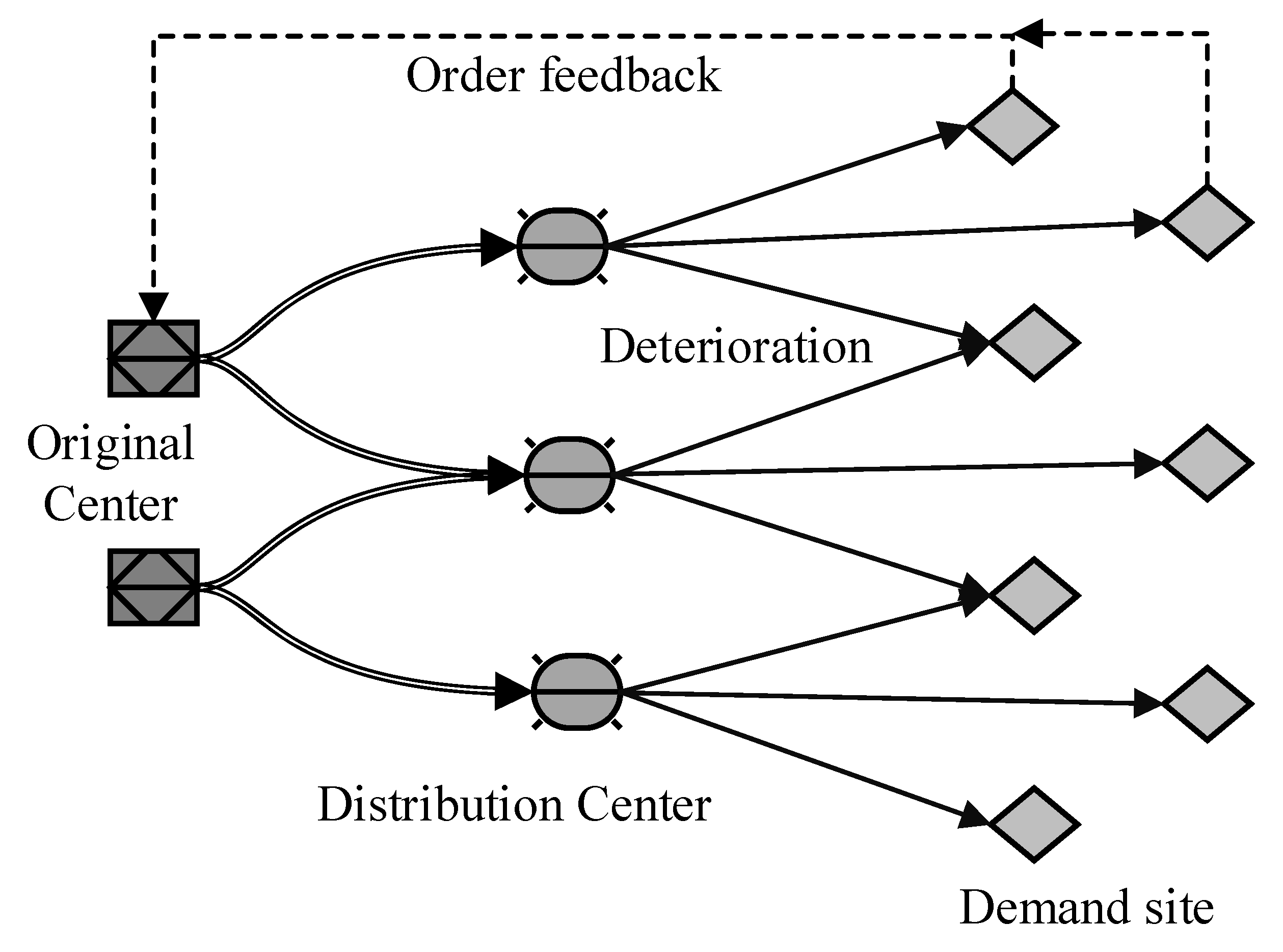

3. Problem Description

3.1. Problem Description

3.2. Assumptions

- ◆

- It is assumed that logistics transportation is one-way transportation [30], that is, the direction is from the origin to the demand place;

- ◆

- All agricultural products supplied are from the origin sites, and there is no input from outside the industrial chain [31];

- ◆

- Transport vehicles of the same model (fuel consumption and capacity) are used in the same phase;

- ◆

- Know the location of candidate demand sites in advance [32];

- ◆

- The speed of the vehicle varies depending on the actual situation [33].

4. Model

4.1. Mixed Integer Linear Programming Model

4.2. Interval Robust Counterpart Model

4.3. Ellipsoid Robust Counterpart Model

5. Data and Algorithm

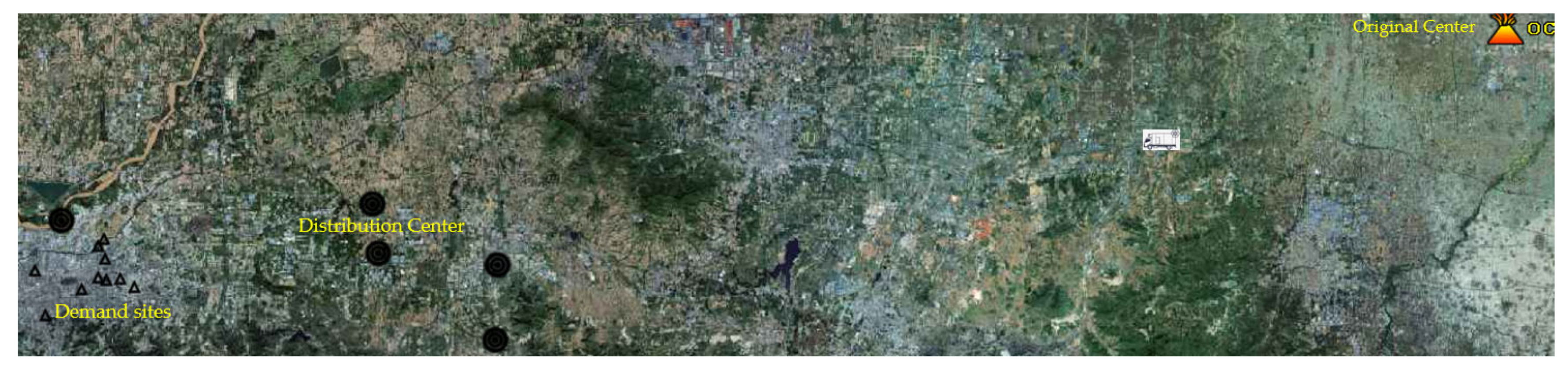

5.1. Data

5.2. Algorithm

| Algorithm 1. Benders decomposition algorithm |

| 1 Identify Master problem , Sub-problem |

| 2 Repeat |

| 3 for MILP model, |

| 4 for IRC model, |

| 5 for ERC model, |

| 6 SP Dual Sub-problem (DSP) |

| 7 solving DSP by Gurobi get ) with constraints |

| 8 if DSP is unbounded, add benders feasibility cut in MP |

| 9 if |

| 10 |

| 11 if DSP is bounded, add benders optimality cut in MP |

| 12 if |

| 13 |

| 14 if no feasible solution for DSP |

| 15 end |

| 16 Obtain by solving MP |

| 17 if |

| 18 else, |

| 19 |

| 20 until () |

| Return value {} |

6. Simulation

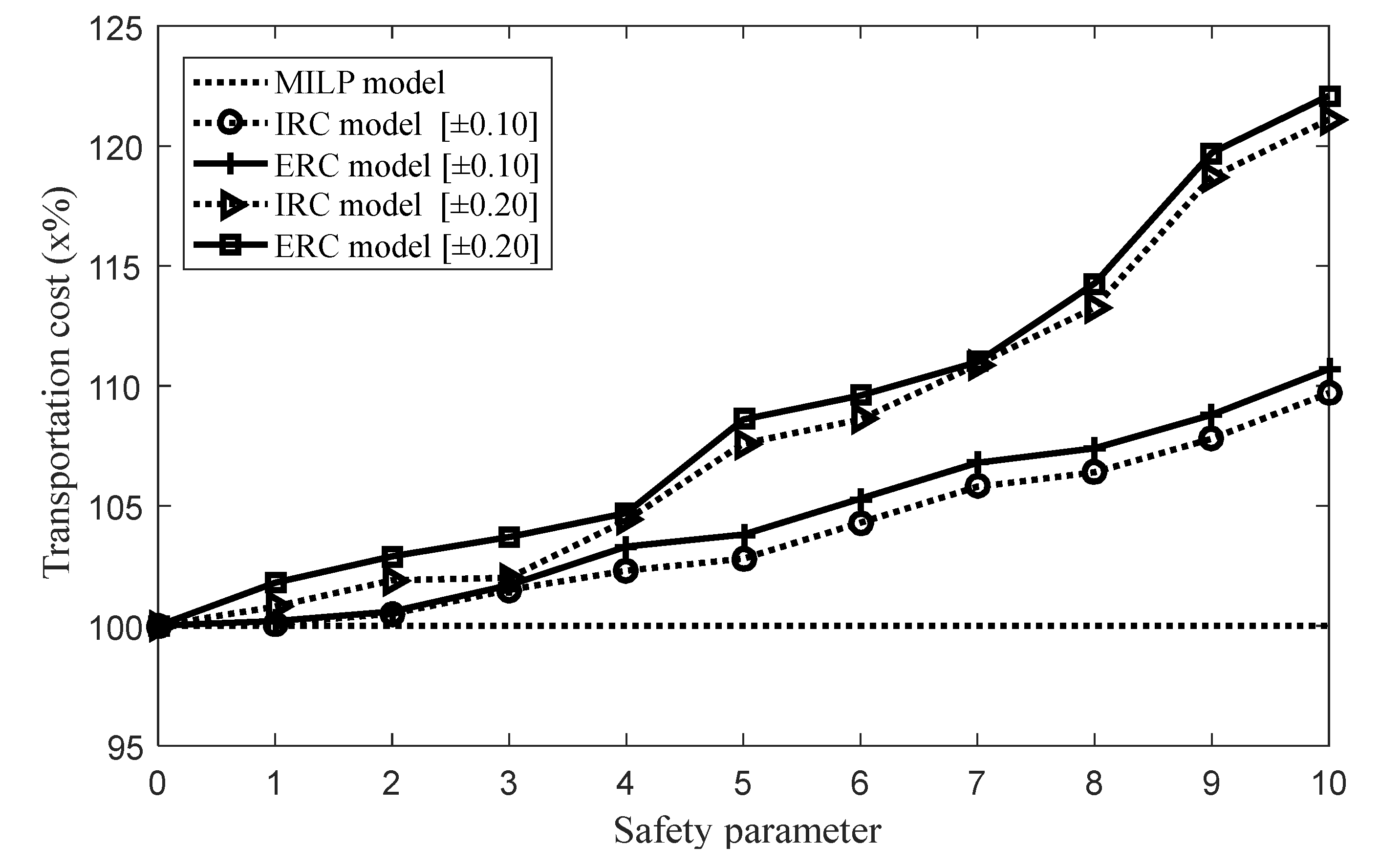

6.1. Influence of Safety Parameters

6.2. Influence of Volatility

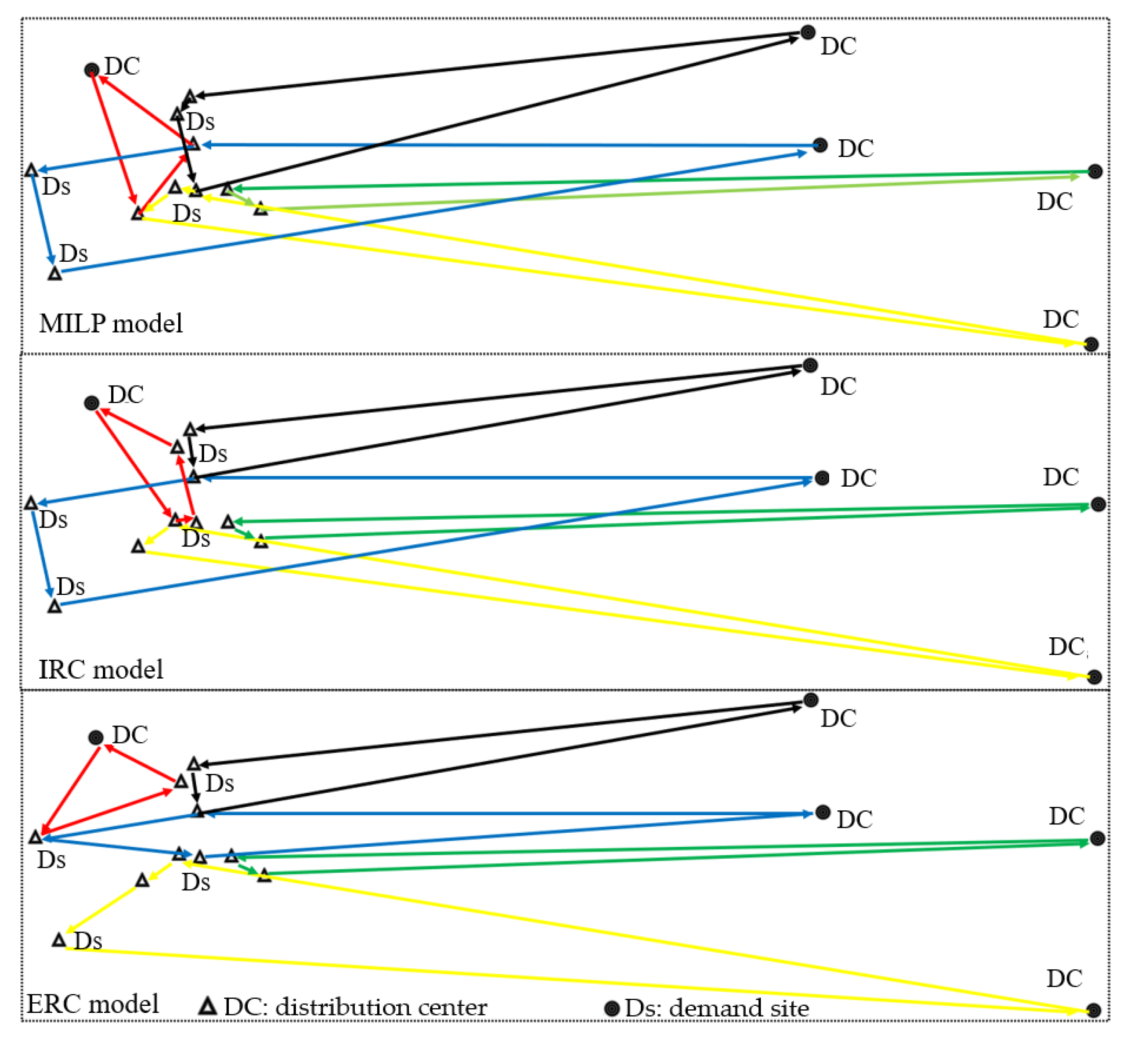

6.3. Routing Planning Design

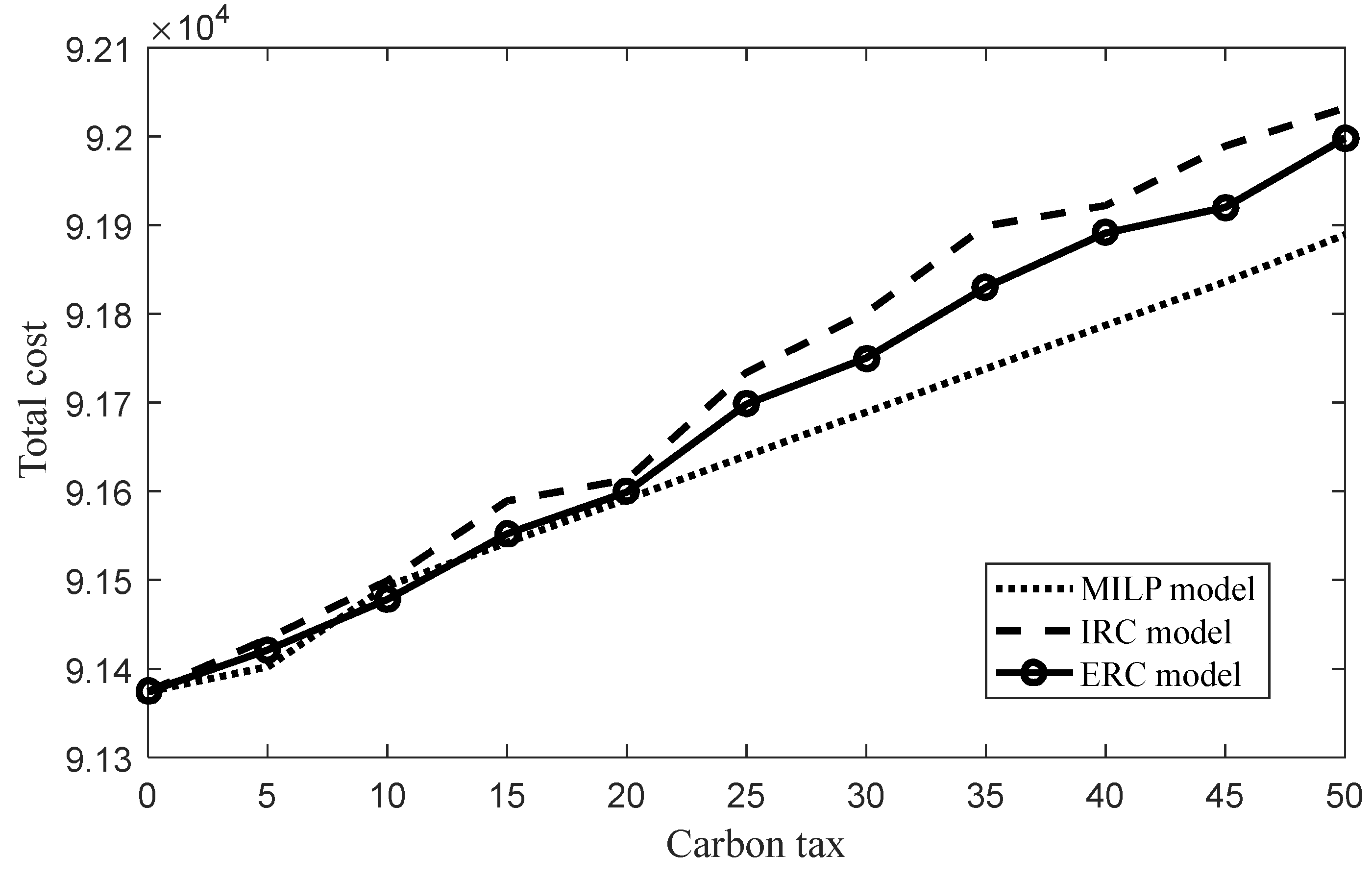

6.4. Impact of Carbon Tax Changes

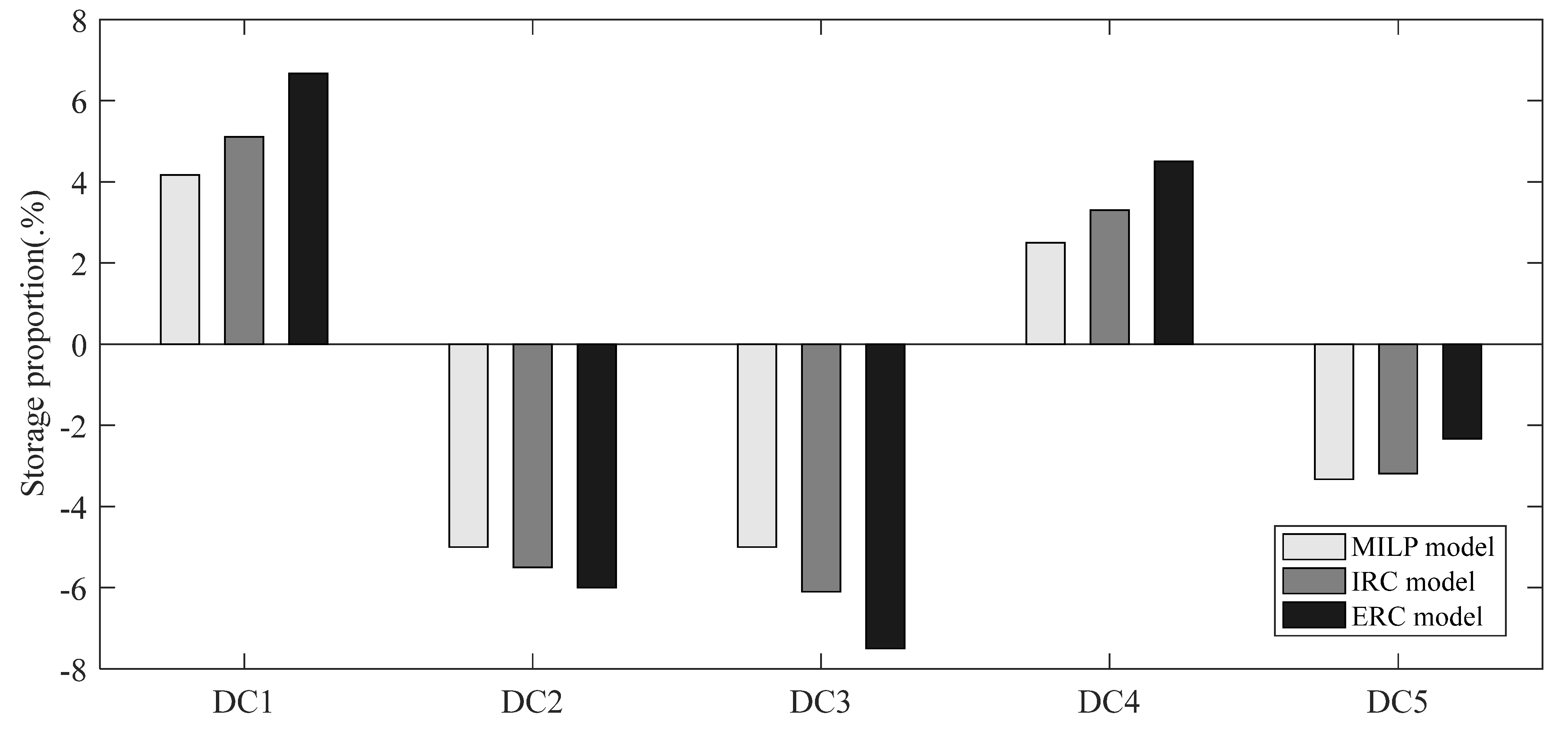

6.5. Storage Proportion of Distribution Center

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Notion | Explanation |

| The fixed cost of | |

| The distance | |

| The rated cargo capacity of trucks | |

| The corruption rate of the fresh agricultural product | |

| The scheduled arrival time | |

| The accumulated mileage limit | |

| The time windows for delivery | |

| The maximum load of the distribution center | |

| The maximum carbon emission limit | |

| , selection, or not | |

| , the number of trucks at the distribution center | |

| , is selected; otherwise, not. | |

| The safety parameter in the IRC model | |

| The uncertain parameter in the IRC model | |

| The float value | |

| The base value of demand | |

| The floating value of demand | |

| Nominal parameter expression in the IRC model | |

| The volatility parameter expression in the IRC model | |

| The safety parameter in the ERC model | |

| The uncertain parameter in the ERC model | |

| Nominal parameter expression in the ERC model | |

| The volatility parameter expression in the ERC model | |

| in the IRC model | |

| in the ERC model | |

| N-dimensional complete sets |

References

- Chen, J.; Fan, T.; Pan, F. Urban delivery of fresh products with total deterioration value. Int. J. Prod. Res. 2021, 59, 2218–2228. [Google Scholar] [CrossRef]

- De Oliveira, J.G.; Silva, G.D.; Cipriano, L.; Gomes, M.; Egea, M.B. Control of postharvest fungal diseases in fruits using external application of RNAi. J. Food Sci. 2021, 86, 3341–3348. [Google Scholar] [CrossRef] [PubMed]

- Saif, A.; Elhedhli, S. Cold supply chain design with environmental considerations: A simulation-optimization approach. Eur. J. Oper. Res. 2016, 251, 274–287. [Google Scholar] [CrossRef]

- Teng, S. Route planning method for cross-border e-commerce logistics of agricultural products based on recurrent neural network. Soft Comput. 2021, 25, 12107–12116. [Google Scholar] [CrossRef]

- Hariga, M.; As’Ad, R.; Shamayleh, A. Integrated Economic and Environmental Models for a Multi Stage Cold Supply Chain under Carbon Tax Regulation. J. Clean. Prod. 2017, 166, 1357–1371. [Google Scholar] [CrossRef]

- Evans, J.A.; Russell, S.L.; James, C.; Corry, J.E.L. Microbial contamination of food refrigeration equipment. J. Food Eng. 2004, 62, 225–232. [Google Scholar] [CrossRef]

- Shishov, V.V.; Talyzin, M.S. Efficiency of Refrigeration Equipment on Natural Refrigerants. Chem. Pet. Eng. 2020, 56, 385–392. [Google Scholar] [CrossRef]

- Melillo, J.M.; McGuire, A.D.; Kicklighter, D.W.; Moore, B.; Vorosmarty, C.J.; Schloss, A.L. Global climate change and terrestrial net primary production. Nature 1993, 363, 234–240. [Google Scholar] [CrossRef]

- Johansson, B.; Hman, M. A comparison of technologies for carbon-neutral passenger transport. Transp. Res. Part D Transp. Environ. 2002, 7, 175–196. [Google Scholar] [CrossRef]

- Krammer, P.; Dray, L.; Kohler, M.O. Climate-neutrality versus carbon-neutrality for aviation biofuel policy. Transp. Res. Part D-Transp. Environ. 2013, 23, 64–72. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, Z.; He, G.; Wang, H.L.; Zhang, X.; Lin, J.; Qi, Y.; Liang, X. Challenges and opportunities for carbon neutrality in China. Nat. Rev. Earth Environ. 2022, 3, 141–155. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Mac Kinnon, M.; Brouwer, J. California end-use electrification impacts on carbon neutrality and clean air. Appl. Energy 2018, 213, 435–449. [Google Scholar] [CrossRef]

- Dulebenets, M.A.; Ozguven, E.E.; Moses, R.; Ulak, M.B. Intermodal freight network design for transport of perishable products. Open J. Optim. 2016, 5, 120. [Google Scholar] [CrossRef]

- Theophilus, O.; Dulebenets, M.A.; Pasha, J.; Lau, Y.-Y.; Fathollahi-Fard, A.M.; Mazaheri, A. Truck scheduling optimization at a cold-chain cross-docking terminal with product perishability considerations. Comput. Ind. Eng. 2021, 156, 107240. [Google Scholar] [CrossRef]

- Dulebenets, M.A.; Ozguven, E.E. Vessel scheduling in liner shipping: Modeling transport of perishable assets. Int. J. Prod. Econ. 2017, 184, 141–156. [Google Scholar] [CrossRef]

- Zheng, F.; Pang, Y.; Xu, Y.; Liu, M. Heuristic algorithms for truck scheduling of cross-docking operations in cold-chain logistics. Int. J. Prod. Res. 2021, 59, 6579–6600. [Google Scholar] [CrossRef]

- Qu, S.J.; Xu, L.; Mangla, S.K.; Chan, F.T.S.; Zhu, J.L.; Arisian, S. Matchmaking in reward-based crowdfunding platforms: A hybrid machine learning approach. Int. J. Prod. Res. 2022, 1–22. [Google Scholar] [CrossRef]

- Feldmann, C.; Hamm, U. Consumers’ perceptions and preferences for local food: A review. Food Qual. Prefer. 2015, 40, 152–164. [Google Scholar] [CrossRef]

- He, Q.Z.; Tong, H.; Liu, J.B. How Does Inequality Affect the Residents’ Subjective Well-Being: Inequality of Opportunity and Inequality of Effort. Front. Psychol. 2022, 13, 843854. [Google Scholar] [CrossRef]

- Li, B.X.; Hu, H. Logistics Model Based on Agricultural Product Transportation. Agro Food Ind. Hi-Tech 2017, 28, 3370–3373. [Google Scholar]

- Li, P.J. Logistics transportation route for agricultural products based on an improved ant colony algorithm. Agro Food Ind. Hi-Tech 2017, 28, 1876–1880. [Google Scholar]

- Qi, C.; Hu, L. Optimization of vehicle routing problem for emergency cold chain logistics based on minimum loss. Phys. Commun. 2020, 40, 101085. [Google Scholar] [CrossRef]

- Wang, M.; Cheng, Q.; Huang, J.C.; Cheng, G.Q. Research on optimal hub location of agricultural product transportation network based on hierarchical hub-and-spoke network model. Phys. A-Stat. Mech. Its Appl. 2021, 566, 125412. [Google Scholar] [CrossRef]

- Khan, Z.A.; Koondhar, M.A.; Khan, I.; Ali, U.; Liu, T.J. Dynamic linkage between industrialization, energy consumption, carbon emission, and agricultural products export of Pakistan: An ARDL approach. Environ. Sci. Pollut. Res. 2021, 28, 43698–43710. [Google Scholar] [CrossRef] [PubMed]

- Al-Mansour, F.; Jejcic, V. A model calculation of the carbon footprint of agricultural products: The case of Slovenia. Energy 2017, 136, 7–15. [Google Scholar] [CrossRef]

- Sanye-Mengual, E.; Ceron-Palma, I.; Oliver-Sola, J.; Montero, J.I.; Rieradevall, J. Environmental analysis of the logistics of agricultural products from roof top greenhouses in Mediterranean urban areas. J. Sci. Food Agric. 2013, 93, 100–109. [Google Scholar] [CrossRef]

- Zhu, S.J.; Fu, H.M.; Li, Y.H. Optimization Research on Vehicle Routing for Fresh Agricultural Products Based on the Investment of Freshness-Keeping Cost in the Distribution Process. Sustainability 2021, 13, 8110. [Google Scholar] [CrossRef]

- Ahmed, W.; Sarkar, B. Management of next-generation energy using a triple bottom line approach under a supply chain framework. Resour. Conserv. Recycl. 2019, 150, 104431. [Google Scholar] [CrossRef]

- Pan, F.; Fan, T.; Qi, X.; Chen, J.; Zhang, C. Truck scheduling for cross-docking of fresh produce with repeated loading. Math. Probl. Eng. 2021, 2021, 5592122. [Google Scholar] [CrossRef]

- Drezner, Z.; Wesolowsky, G.O. Selecting an optimum configuration of one-way and two-way routes. Transp. Sci. 1997, 31, 386–394. [Google Scholar] [CrossRef]

- Chen, J.; Gui, P.; Ding, T.; Na, S.; Zhou, Y. Optimization of transportation routing problem for fresh food by improved ant colony algorithm based on tabu search. Sustainability 2019, 11, 6584. [Google Scholar] [CrossRef]

- Toole, J.L.; Colak, S.; Sturt, B.; Alexander, L.P.; Evsukoff, A.; González, M.C. The path most traveled: Travel demand estimation using big data resources. Transp. Res. Part C Emerg. Technol. 2015, 58, 162–177. [Google Scholar] [CrossRef]

- Taghvaeeyan, S.; Rajamani, R. Portable roadside sensors for vehicle counting, classification, and speed measurement. IEEE Trans. Intell. Transp. Syst. 2013, 15, 73–83. [Google Scholar] [CrossRef]

- Purba, D.S.D.; Kontou, E.; Vogiatzis, C. Evacuation route planning for alternative fuel vehicles. Transp. Res. Part C-Emerg. Technol. 2022, 143, 103837. [Google Scholar] [CrossRef]

- Karak, A.; Abdelghany, K. The hybrid vehicle-drone routing problem for pick-up and delivery services. Transp. Res. Part C-Emerg. Technol. 2019, 102, 427–449. [Google Scholar] [CrossRef]

- Schneider, M.; Stenger, A.; Goeke, D. The electric vehicle-routing problem with time windows and recharging stations. Transp. Sci. 2014, 48, 500–520. [Google Scholar] [CrossRef]

- Jiang, L.; Dhiaf, M.; Dong, J.F.; Liang, C.Y.; Zhao, S.P. A traveling salesman problem with time windows for the last mile delivery in online shopping. Int. J. Prod. Res. 2020, 58, 5077–5088. [Google Scholar] [CrossRef]

- Soyster, A.L.; Murphy, F.H. Data driven matrix uncertainty for robust linear programming. Omega-Int. J. Manag. Sci. 2017, 70, 43–57. [Google Scholar] [CrossRef]

- Wiesemann, W.; Kuhn, D.; Sim, M. Distributionally Robust Convex Optimization. Oper. Res. 2014, 62, 1358–1376. [Google Scholar] [CrossRef]

- Ji, Y.; Li, H.H.; Zhang, H.J. Risk-Averse Two-Stage Stochastic Minimum Cost Consensus Models with Asymmetric Adjustment Cost. Group Decis. Negot. 2022, 31, 261–291. [Google Scholar] [CrossRef]

- Qu, S.J.; Wei, J.P.; Wang, Q.H.; Li, Y.M.; Jin, X.W.; Chaib, L. Robust minimum cost consensus models with various individual preference scenarios under unit adjustment cost uncertainty. Inf. Fusion 2023, 89, 510–526. [Google Scholar] [CrossRef]

- Shi, Y.; Boudouh, T.; Grunder, O. A robust optimization for a home health care routing and scheduling problem with consideration of uncertain travel and service times. Transp. Res. Part E-Logist. Transp. Rev. 2019, 128, 52–95. [Google Scholar] [CrossRef]

- Gorissen, B.L.; Yanıkoğlu, İ.; den Hertog, D. A practical guide to robust optimization. Omega 2015, 53, 124–137. [Google Scholar] [CrossRef]

- Bai, D.; Carpenter, T.; Mulvey, J. Making a case for robust optimization models. Manag. Sci. 1997, 43, 895–907. [Google Scholar] [CrossRef]

- Yu, C.-S.; Li, H.-L. A robust optimization model for stochastic logistic problems. Int. J. Prod. Econ. 2000, 64, 385–397. [Google Scholar] [CrossRef]

- Baron, O.; Milner, J.; Naseraldin, H. Facility location: A robust optimization approach. Prod. Oper. Manag. 2011, 20, 772–785. [Google Scholar] [CrossRef]

- Qu, S.; Li, Y.; Ji, Y. The mixed integer robust maximum expert consensus models for large-scale GDM under uncertainty circumstances. Appl. Soft Comput. 2021, 107, 107369. [Google Scholar] [CrossRef]

- Matthews, L.R.; Guzman, Y.A.; Floudas, C.A. Generalized robust counterparts for constraints with bounded and unbounded uncertain parameters. Comput. Chem. Eng. 2018, 116, 451–467. [Google Scholar] [CrossRef]

- Abdel-Aal, M.A.M.; Selim, S.Z. Robust optimization for selective newsvendor problem with uncertain demand. Comput. Ind. Eng. 2019, 135, 838–854. [Google Scholar] [CrossRef]

- Liang, Z.; Wu, J.; Li, J.; Yang, Z.; Li, J.; Li, J. Application and Popularization of New Green Prevention and Control Technology for Greenhouse Vegetables in Shouguang City, Shandong Province. Asian Agric. Res. 2019, 11, 78–81. [Google Scholar]

- Gao, J.; Wang, L.W.; Gao, P.; An, G.L.; Wang, Z.X.; Xu, S.Z.; Wang, R.Z. Performance investigation of a freezing system with novel multi-salt sorbent for refrigerated truck. Int. J. Refrig.-Rev. Int. Du Froid 2019, 98, 129–138. [Google Scholar] [CrossRef]

- Romijn, T.C.J.; Donkers, M.C.F.; Kessels, J.; Weiland, S. A Distributed Optimization Approach for Complete Vehicle Energy Management. Ieee Trans. Control Syst. Technol. 2019, 27, 964–980. [Google Scholar] [CrossRef]

- Rahmaniani, R.; Crainic, T.G.; Gendreau, M.; Rei, W. The Benders decomposition algorithm: A literature review. Eur. J. Oper. Res. 2017, 259, 801–817. [Google Scholar] [CrossRef]

- Hooker, J.N.; Ottosson, G. Logic-based Benders decomposition. Math. Program. 2003, 96, 33–60. [Google Scholar] [CrossRef]

- Hooker, J.N. Planning and scheduling by logic-based Benders decomposition. Oper. Res. 2007, 55, 588–602. [Google Scholar] [CrossRef]

- Jeyakumar, V.; Lee, G.M. Complete characterizations of stable Farkas’ lemma and cone-convex programming duality. Math. Program. 2008, 114, 335–347. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, Z.J.; Hang, J.Q.; He, Q.Z. How do stock price indices absorb the COVID-19 pandemic shocks? N. Am. J. Econ. Financ. 2022, 60, 101672. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, L.; Fu, Y. Real-Time Price-Based Demand Response Management for Residential Appliances via Stochastic Optimization and Robust Optimization. Ieee Trans. Smart Grid 2012, 3, 1822–1831. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Jiang, H. A robust counterpart approach to the bi-objective emergency medical service design problem. Appl. Math. Model. 2014, 38, 1033–1040. [Google Scholar] [CrossRef]

| Literature | Agricultural Product Transportation | Quantitative Analysis | Carbon Emissions | Uncertainty | Real Cases |

|---|---|---|---|---|---|

| [20] | * | * | |||

| [21] | * | * | * | ||

| [22] | * | * | |||

| [23] | * | * | * | ||

| [24] | * | * | * | ||

| [25] | * | * | * | ||

| [26] | * | * | * | ||

| [27] | * | * | |||

| [28] | * | * | * | * | |

| [29] | * | * | * | ||

| This paper | * | * | * | * | * |

| Item | Data |

|---|---|

| The load of transportation tools | 1000–1500 kg |

| The unit energy consumption | 25 L |

| The maximum speed limit | 60 km/h |

| The average speed | 30–45 km/h |

| The Distribution Center | |||||

|---|---|---|---|---|---|

| The fixed cost | 15,000 CNY | 20,000 CNY | 10,000 CNY | 20,000 CNY | 20,000 CNY |

| The maximum stock | 9000 kg | 7000 kg | 8000 kg | 6000 kg | 6000 kg |

| Longitude (E) | 117.019473 | 117.531636 | 117.5187 | 117.388586 | 117.391322 |

| Latitude (N) | 36.719945 | 36.678218 | 36.882706 | 36.690375 | 36.740998 |

| The demand site | |||||

| The nominal demand | 2000 kg | 3500 kg | 4000 kg | 2500 kg | 3000 kg |

| The demand site | |||||

| The nominal demand | 2500 kg | 3000 kg | 4500 kg | 3000 kg | 3500 kg |

| 16.4 km | 11.2 km | 10.8 km | 7.2 km | 13.9 km | |

| 39.9 km | 62.3 km | 60.9 km | 57.1 km | 58.2 km | |

| 52.2 km | 54.4 km | 53.3 km | 59.7 km | 55.2 km | |

| 66.8 km | 60.4 km | 57.9 km | 56.6 km | 56.1 km | |

| 36.1 km | 50.1 km | 36.1 km | 32.2 km | 45.3 km | |

| 7.8 km | 11.7 km | 12.3 km | 10.4 km | 8.5 km | |

| 58.7 km | 41.9 km | 62.4 km | 60.5 km | 58.5 km | |

| 64.2 km | 51.1 km | 53.2 km | 53.1 km | 56.5 km | |

| 50.5 km | 62.2 km | 59.2 km | 60.8 km | 56.4 km | |

| 41.2 km | 36.9 km | 37.5 km | 35.6 km | 33.5 km |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Wu, Z.; Teng, X.; Qu, S. Robust Counterpart Models for Fresh Agricultural Product Routing Planning Considering Carbon Emissions and Uncertainty. Sustainability 2022, 14, 14992. https://doi.org/10.3390/su142214992

Yang F, Wu Z, Teng X, Qu S. Robust Counterpart Models for Fresh Agricultural Product Routing Planning Considering Carbon Emissions and Uncertainty. Sustainability. 2022; 14(22):14992. https://doi.org/10.3390/su142214992

Chicago/Turabian StyleYang, Feng, Zhong Wu, Xiaoyan Teng, and Shaojian Qu. 2022. "Robust Counterpart Models for Fresh Agricultural Product Routing Planning Considering Carbon Emissions and Uncertainty" Sustainability 14, no. 22: 14992. https://doi.org/10.3390/su142214992

APA StyleYang, F., Wu, Z., Teng, X., & Qu, S. (2022). Robust Counterpart Models for Fresh Agricultural Product Routing Planning Considering Carbon Emissions and Uncertainty. Sustainability, 14(22), 14992. https://doi.org/10.3390/su142214992