Abstract

Considering constantly increasing global competition in the market and developing technologies, information systems (ISs) have become an important component of the business world and a vital component of intelligent systems. An IS provides support for planning, controlling, analyzing activities, and support in decisions by managing data throughout the organization to assist executives in their decisions. The main function of an IS is to collect data spread between various parts of the organization and business partners and to process these collected data to form reliable information, which is required for decision making. Another critical function of an IS is to transfer the necessary information to the point-of-need in a timely manner. ISs assist in the conversion of data and information into meaningful outcomes. An IS is a combination of software, data storage hardware, related infrastructure, and people in the organization that use the system. Many business organizations rely on management information systems (MISs), and they conduct their critical operations based on these systems. The existence of an efficient MIS is a requirement for the sustainability of any business. However, MIS’s efficiency depends on the business’s requirements and nature. The compatibility of MIS with business in the company is vital for the successful implementation of these systems. The current study analyzes differences in expectations of manufacturing and service industries from MISs. For this aim, a fuzzy multi-criteria group decision-making (F-MCGDM) model is proposed to determine the differentiating success factors of MIS in both manufacturing and service industries. Findings indicate that there are considerable differences in the needs of both industries from MIS.

1. Introduction

The availability of processed data is critical for any type of business, especially in a highly competitive environment, because real-time access to correct information provides executives of an organization to achieve an advantage against their competitors by taking efficient, effective, timely, and strategically reliable decisions. Collecting the required data, processing to convert it into information, and storing this information are the main functions of an IS. These systems are defined as the combination of people, hardware, software, data, procedures, and policies [1]. People in the system are called end users or clients, who use, develop and operate the system. IS design is made toward end users’ requirements by system analysts. Hardware includes computers and other equipment related to the process, storage, and transfer of data. Additionally, this hardware is a physical interface between the IS software and the end user. All these components interact with each other to handle information that flows inside the organization, and in many cases between peers in the supply chain.

Most organizations require an information technology (IT) infrastructure. IT is concerned with modern enterprise management functions such as manufacturing, marketing, banking, and financing [2]. A well-designed IT infrastructure is a necessity for a well-performing IS. If IS is thought of as a production process in a manufacturing facility, information can be assumed as the final product. If the final product (information) cannot be delivered under a certain lead time and if it does not meet the customers’ (clients’) requirements, customers will not be satisfied with the product, and the company will lose its customers and future revenues [3]. IT contributes to innovation efforts by supplying increased communication and coordination between different departments and helps reduce the cost of transactions in an organization [4]. A successfully implemented IS, supported by a sufficient IT infrastructure, increases the performance of the whole supply chain of the organization via increased flexibility achieved in all operations between the peers in the chain [5].

Information is one of the vital resources for an organization and the community. The management efficiency of all modern business organizations is closely related to the performance of the MIS used in the organization. As an important part of IS, MIS includes data processing, database design, information system analysis, and design. The performance of MIS can be evaluated with capabilities such as reporting accuracy, and delivery of timely and correct information to different levels of the management hierarchy [6]. MIS is defined as an integrated human–machine system for providing information to support the operations, managerial activities, and decision-making functions of an organization [7]. However, ensuring the compatibility of MIS with the specific needs and business nature of the organization is vital for the performance of the management. Hence, determining the needs of the company and selecting the best MIS that satisfies these requirements is a crucial process.

From the development viewpoint, IS is responsible for covering three main activities to support the management of organizations, which are the business context, business processes, and strategic content [8]. The business context covers all competitive variables identified in the environment of the company. Business processes include analysis of all business activities and their support systems, whereas strategic content supports the implementation planning of the owner’s vision for the company. These activities promote feedback, monitoring, recommendation, and opportunities for management [9]. One of the most important benefits of an IS, especially an MIS, is that it allows many time-saving opportunities in business processes. Therefore, in today’s highly competitive market conditions, the ability to compensate for lost time caused by changes in business processes by adopting proactive measures in the system is crucial. Hence, the importance of selecting the right MIS system for the organization is one of the most important strategic decisions companies face.

There are three key points of IS for business management applications: support of business processes and operations, support of decision making by employees and managers, and support of strategies for competitive advantage [10]. Therefore, the amount of accessible high-quality information is obtaining an increasing amount of importance for today’s business organizations. ISs provide managers with easy and quick access to the available information. ISs also include the ability to interact with other decision support systems, external information sources, and data mining tools [11], which are all important resources that assist executives of enterprises in their strategic and operational-level decisions.

Organizational strategy is identified with long-term goals and short-term practical decisions that are taken accordingly to achieve the missions of the organization. An organization’s view of decisions made can be shaped by different cross-functional enterprise systems with the help of available information resources [12]. Using enterprise systems is a strategic way to improve the efficiency and effectiveness of business processes. Therefore, companies being managed with reliable information develop strong relationships with their customers, suppliers, and business partners for much longer terms. Therefore, information flowing through MIS should also be visible and available for business partners when needed.

MIS provides managers with quick access to necessary information. External information and potential data mining techniques are being used for information inquiries in MISs, which may include interactions with other decision support systems [11]. By using these systems, managers can compare the strategic goals of their company with practical decisions they are making to control how their decisions would fit with the organizational strategy. For these reasons, implementing an IS with the correct combination of software and hardware infrastructure, including fault detection and automatic correction functions, is important to ensure maintaining the high availability of the system whenever needed throughout the enterprise [13].

The high visibility of information feature assists the process of sharing critical data within the organization by providing a constant connection with the management. By doing so, all components of the business processes, such as the flow of products, services, and information, can be shared by the IS in real time between all business partners and users [14]. Currently, IT and virtual supply chain management and protracted enterprises attract increasing attention in supply chain management (SCM) literature and specific issues within IS regarding inter-organizational information sharing [15]. Therefore, ISs are responsible for making information visible to other organizations and business peers. Consequently, the definition of the organizational link is redefined, and this new structure forces the companies’ value chains to include all business partners. A reliable IS infrastructure with an effective MIS and real-time data-sharing capability are some of the main requirements of using Internet of Things (IoT)-related technologies. Especially considering the latest requirements of Industry 4.0, a well-implemented and effective MIS is a must for organizations that want to keep their competitive advantage in the market.

Rapidly changing market conditions and the structure of an increasing number of globally distributed organizations increase the dependence of managerial activities on high-quality information availability, and MISs attracts more attention. According to the Chief Information Officers’ survey, “Improving the IT quality” is one of the most important issues for executives currently [16]. IT and software are the main components of any IS. IT is a significant resource that should be deployed to foster enterprise-wide quality efforts [17]. Based on Dray’s traditional software quality measures, ISs are composed of features such as correctness, reliability, usability, and maintainability [18]. Since quality is described as a proportion to specifications, coming up to customers’ expectations, value, and excellence by Reves and Bednar [19], all of these components contribute to creating high-quality information by the ISs in the same way. Information quality is highly correlated with the reliability of the information and business outputs considering that all data in the system are wields used by business users of MIS. Thus, an MIS consisting only of relevant data will help executives in making better decisions by providing easy-to-understand information to its users. Therefore, any type of IS should provide reliable and high-quality information to system users [20].

In many business sectors, IT infrastructure is constantly being upgraded so that it can be developed and improved to assist in maintaining the quality of the IS. According to the well-known IS success model developed by DeLone and McLean [21], information quality has to be at an acceptable level in an IS to deliver reliable outputs to its users, which can be tracked with reports or online screens [22]. Data quality is also a vital part of an MIS since the usage of poor data results in poor-quality decisions. Furthermore, poor data and ineffective IS performance negatively affect business organizations’ strategies [23]. Another important issue for ISs is that software used in the system must be determined by considering all the components of the system, and it should be consistent with the overall IS structure, since all components affect the overall performance of the system. Providing an easy-to-use system certainly assists in efficiency increases throughout the company. Consequently, the ease of use is influenced by the capabilities of users and the efficiency of the IS [24], which can be acquired by ensuring a good fit between them. Therefore, the selection of the correct IS system according to the structure and actual needs of the organization is crucial for the success of the system and the organization.

Many organizations are investing in new MISs to improve the quality and reliability of their business processes. However, sometimes MISs encounter unexpected results such as vague and redundant data because of incompatibility issues that affect the performance of MIS application areas throughout the organization. For this reason, most ISs provide a usability analysis framework for users that can help classification, identification, and prioritization of potential errors [25]. In most of the current MISs, the classification of errors includes usability and functional misfit issues. The most common cause of functional misfit is due to system design, while usability misfit issues are caused by the system users’ faults and their actions in the system [26]. All these issues can be easily reduced by selecting the right system by considering the profile of the users in the company and planning the implementation process before actual implementation by considering the type and needs of the users.

IS provides increased performance and competitiveness for organizations and reduces costs, lost time in nonvalue-added processes, and communication problems. Sarnikar and Murphy [25] propose that an IS should be designed carefully so that it can be integrated into the organizational actions by detailed analysis of each process. It is concluded that correctly selected and implemented MISs support the flow of accurate and timely information in business organizations and by doing so help managers maintain easy control of operations to take effective decisions.

The main purpose of this study is to compare manufacturing and service industries by considering different MIS success factors to determine the differences between these two industries. Even though there are many studies inspecting success factors of MISs and sector-specific analyses in the literature, it is difficult to find any studies that compare manufacturing and service industries from the aspect of MIS performance criteria. The main novelty of this study is to differentiate the success factors of MISs according to the industry they will be used in. These differences will provide precious information for both software developers and managers to design or select the best system for their needs. Especially considering the high investment cost of these systems and their direct effect on the performance of organizations, differentiating industry-specific expectations and success factors for MISs is crucial for selecting the best system for organizations to achieve a competitive advantage in the market, which depends on the improvement in the efficiency of every single source in the organization from the strategic management point of view. Another novelty of this study is the application of group-based fuzzy logic on an industrial comparison of success factors of MISs.

The remainder of this study is organized as follows: In Section 2.1, an overview of multi-criteria decision-making (MCDM) methodologies is presented, followed by a discussion of using a fuzzy group decision-making methodology. Then, explanations of the evaluation criteria used in the model are given in Section 2.2; next, the general structure of the proposed framework of the study is presented. In Section 2.3, the steps of the fuzzy MCDM method used in the study are explained. After that, the application of the fuzzy decision-making model is demonstrated for the determination of criteria weights for both manufacturing and service industries separately in Section 2.4. Finally, in Section 3, differentiating factors are determined according to weight differences of criteria among manufacturing and service industries.

2. Methodology

2.1. Multi-Criteria Decision-Making Methods

Determining the factors affecting the success of MIS requires the evaluation of different performance indicators. Different statistical analyses can be used to measure the achievement rates of each indicator for each company for different industries. Correlations between these indicators and their effect on the success of the company can also be measured with statistical methods. However, these analyses require extensive real-world data collection from a high number of companies to achieve reliable results. Even then, the findings of these analyses will be limited to reflect the current situation in these companies rather than comparing the factors that affect the intended success levels, which can only be expressed by the experts according to their experiences. To make a comparison of the effects of different criteria and to use them together to evaluate the fitment of an MIS to a specific business a framework that both weights the criteria and scores each to calculate the overall success level is needed. Hence, personal preferences are the main type of data to be used in the analysis; the need for fuzzy logic also arises to compensate for human misjudgment in the aforementioned framework. Therefore, to design the intended framework, a fuzzy MCDM approach is needed. Furthermore, consideration of different industries requires different experts with different experiences; thus, implementation of group decision-making rules is also necessary to develop the framework to strategically align MIS functions for different industries.

Evaluations should be made by different experts from different industries to make a comparison of different weights assigned to evaluation criteria according to the priorities of different industries. An evaluation study as such requires the usage of MCDM methods. All types of MCDM methods embody a series of iterative numerical procedures to weight evaluation criteria and rank alternatives under these criteria by using the determined weights to select the best [27]. Numerous different MCDM methods are applied to various fields in the literature [28] since the structure of these methods allows researchers to apply them in any area that requires a comparison of different notions. Although most of these methods can be used alone, they can also be combined in a hybrid fashion to be used together if necessary.

Among the wide range of methodologies developed throughout the years, the Analytical Hierarchy Process (AHP) is still preferred in recent studies because of its accuracy [29]. AHP has a more than 65% preference rate among authors in the literature [30]. AHP forms the decision problem as a hierarchical structure that gives a chance to decision makers (DMs) to make a more accurate and efficient decision by understanding the individual effect of each criterion in the model [31]. As a powerful tool to assist DMs in complex problems, AHP gives opportunities to synthesize the outputs to aid the decision-making process [32]. However, in real life, not all evaluations can be made with certain expressions, and not all criteria can be distinguished from each other with clear precision. Hence, the availability of a fuzzy evaluation scale should include human ambiguity and uncertainty in some cases when required by the model structure for more accurate and efficient decisions. Therefore, the Fuzzy Analytical Hierarchy Processes (FAHP) can be applied to large-scale problems by subjective consideration of different criteria by using pairwise comparison matrices and then converting these decision matrices by applying fuzzy logic [33].

2.2. Industrial Difference Determination Framework for MIS Success

MISs are the backbone of any organization today. The importance of a well-performing MIS cannot be neglected regardless of the industry; especially considering the requirements of Industry 4.0, MIS systems have gained more importance. However, companies in the service industry have differently structured organizational processes and requirements than the ones in the manufacturing industry. Therefore, to differentiate the factors affecting the success and performance of MISs in different types of organizations, a common set of evaluation metrics should be used so that all these metrics can be applied to both industries without any compatibility issues.

As an environmental factor, the industrial difference is an accepted factor in the literature that affects the success of ISs [34]. However, it is difficult to come across any studies focused on the analysis of industrial differences in the literature. The most related study for industrial comparisons is by Ruivo et al. [35], who compared the manufacturing and service industries from the aspect of assessed ERP value in companies, instead of focusing on the industrial expectations from the MISs. An important portion of studies in the literature is evaluating MIS success in specific sectors such as health care [36] or construction [37] to define sectoral specifications and needs instead of conducting sectoral or industrial comparison studies. Among these studies, the most popular research field is related to the confirmation and interrelation of IS success factors suggested by DeLone and McLean [21] in different organizational populations [38] or specific sectoral applications such as eGovernment IS success evaluation [39].

Most studies in the literature focus on the determination of success factors in companies being studied regardless of the industrial differences. A study by Rezaei et al. [40] evaluated MIS success by using similar criteria in this study such as systems quality, information quality, and perceived ease of use by using multiple regression analyses and confirmed the effects of these variables on MIS success. Lee and Kim [41] focused on organization-specific contingencies such as top management support, size of the organization, size of the MIS department, age of the MIS department, and level of structure of the task to be replaced or supported by IS to evaluate the success of MIS during development life cycle phases. A similar study focused on evaluating system success over different MIS growth stages by considering relationships between management styles and user participation [42]. Another study found that consultant effectiveness, the level of vendor support, the length of the small business’s CBIS experience, the sufficiency of financial resources, the level of CEO support, and the level of user participation are the factors affecting the success of ISs in small businesses [43].

Some groups of studies focused on the business administration aspects of companies while evaluating the MIS success factors. Agourram [44] suggests that culture affects the perceived success of ISs. Another study conducted a cross-cultural analysis and found that factors determining the success of ISs are also affected by the value orientations of the culture [45]. While some other studies focused on the effects of user-specific factors such as user training [46] and perception differences of different user groups [47], others focused on the organizational theory and inspected the effects of organizational citizenship behaviors [48] and transformational leadership [49] on the IS success.

Raymond [50] suggests that user satisfaction provides the most useful assessment of MIS success in small organizations, and it is impossible to evaluate the effects of MISs on company performance. However, the introduction of MCDM methods conducted assessment studies to be applied using a wider range of evaluation metrics in analytic applications. Thus, a study determining the success factors of executive ISs by using the AHP method revealed that technical elements are less critical than information and human factors and that adequate knowledge of the information requirements of users is the most important critical success factor [51]. Therefore, matching the information needs of an organization with the features presented by the IS emerges as an important aspect of success.

Although reviewed studies in the literature contributed to the understanding of IS success factors, a gap remained in the literature for studies focusing on industrial differences that affect these factors. However, understanding the industrial differences will assist developers of MISs to customize their systems for the needs of service or manufacturing companies in many general means and with ease. In addition, knowing the industrial requirements would help executives select a better-performing MIS for their organizations. The fitment of MIS to the organization is accepted as a success factor for an IS in the literature [52]. In addition, understanding the specific requirements of different industries will assist in uncertainty reduction and equivocality resolution during the MIS implementation stages to increase the success of the system in the organization [53]. Therefore, this study fills the gap in the literature by determining differentiating factors of MIS success in manufacturing and service industries. Results of the proposed F-MCGDM model state the main differences between the manufacturing and service industries from the aspect of their expectations from MISs, and these differences give an insight into the general nature of these industries. Unlike similar studies in the literature, the findings of this study consider industrial differences and results can be used for selecting a more promising MIS for a specific type of industry.

The aforementioned specifications of MIS were merged to form fundamental success components for these systems. Overall, MIS should include some components for better-managed organizations. The most important components of MISs were determined by thirteen experts by consensus in this study, who were selected from different industries and sectors. These criteria can be listed and summarized as follows:

- Support for the business processes (C1): Compatibility of MIS’s functions with the actual processes and other systems in the organization.

- The visibility of information (C2): Ability to access all the information in the system by all departments in the organization.

- The availability of information (C3): Existence and variety of data in the system.

- Quality and reliability of information (C4): Overall quality, real-time access possibility, and validity of information processed by the system.

- Usability and functionality (C5): Ergonomics perspective of the user interface of the system.

As can be seen, by the criteria definitions, they are all in subjective nature. Using an MCDM method for comparisons and importance rating of such criteria is preferred over using actual measurement approaches such as statistical methods. Moreover, the main purpose of this study is to compare the importance of different criteria weights in different industries instead of measuring the real-world data related to these metrics or comparing different MISs. Hence, no quantitative evaluation scale is needed for this study, and the pairwise comparison approach is preferred by using a 1–9 scale that is given in Table 1.

Table 1.

Saaty’s 1–9 scale for AHP comparisons [56].

Evaluation of MISs’ success requires the evaluation of the aforementioned subjective criteria. The subjective nature of these criteria and the lack of an exact measurement scale for each complicate the evaluation phase of such criteria. Because of the structure of MIS systems, as in all IS systems, the main success determination metrics depend on the experience of users; this situation brings the need for consideration of the inexplicit relative preferences of different persons. Hence, these criteria are difficult to measure with objective measurement tools and methods, use of fuzzy logic in the evaluation of the MIS success model is necessary to ensure the accuracy of the comparisons. Using crisp comparison scales is difficult to evaluate subjective criteria accurately, and this structure of the criteria provides suitable conditions for the FAHP application. The application of the FAHP method requires pairwise comparison matrices filled by experts in the field. Hence, the purpose of this study is to differentiate industrial differences, two groups of expert comparison matrices have been collected from manufacturing and service industries. The integration of group decision-making rules into MCDM methods improves the quality of the results of these methods. However, most studies rely on a single DM in their analysis by sacrificing the accuracy of findings for the ease of application procedures. In this study, a fuzzy multi-criteria group decision-making (F-MCGDM) framework is proposed with the use of triangular fuzzy numbers (TFN). For this purpose, six experts were selected from the manufacturing industry, and seven experts were selected from the service industry to form two groups of DMs. Evaluation of MIS success criteria is performed separately by these two groups of DMs according to group decision-making rules by aggregating the individual expert evaluations together by calculating the geometric mean for each group [54].

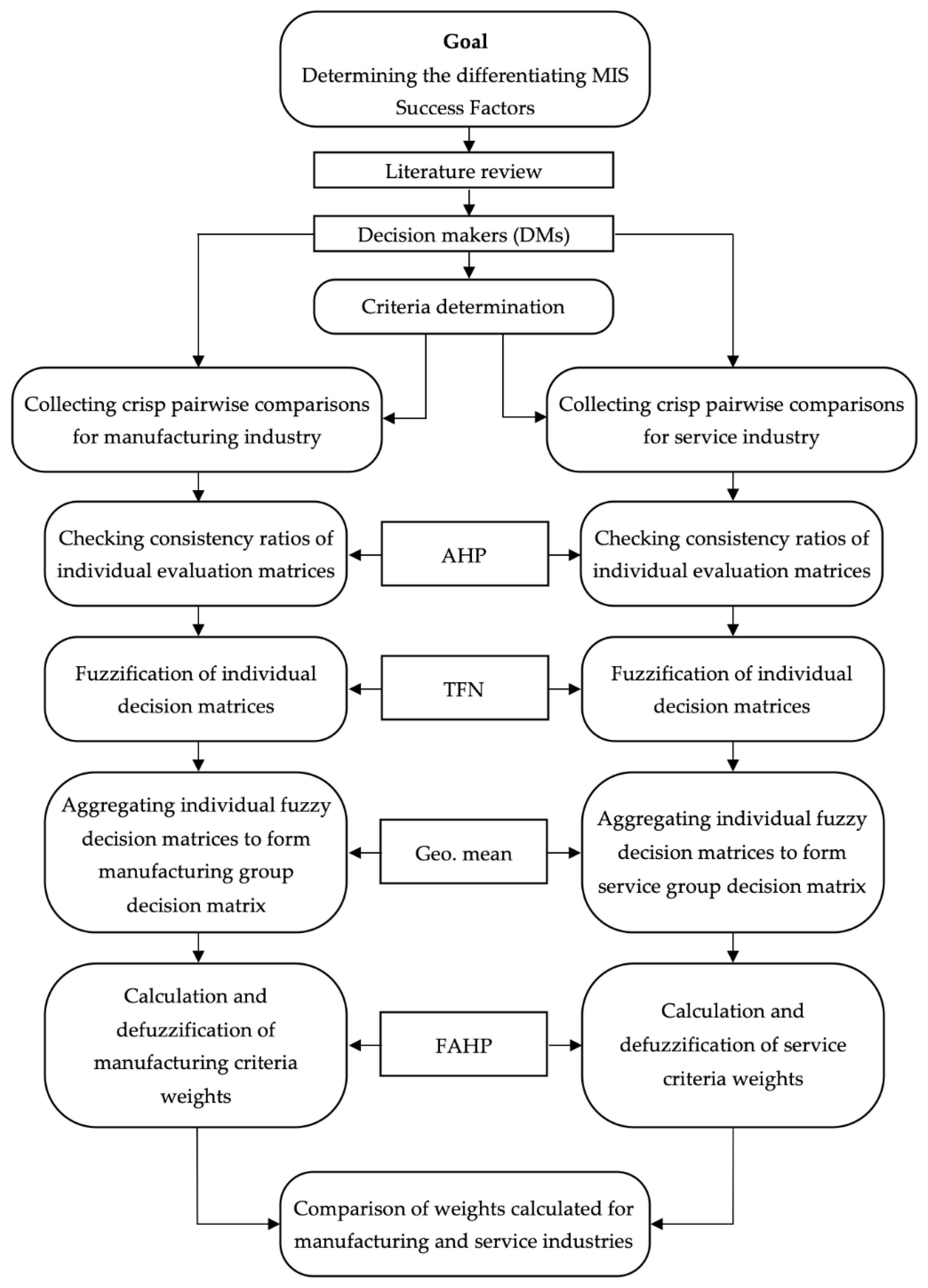

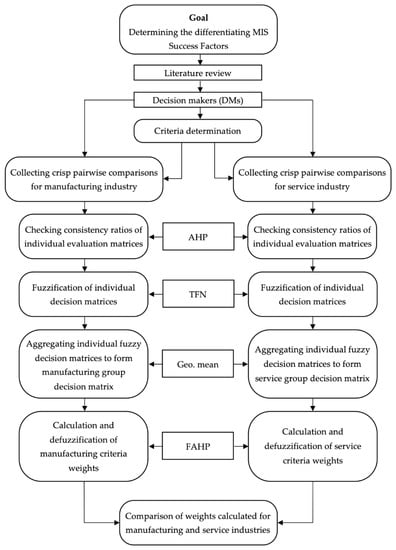

The proposed framework to evaluate the success of MISs and differentiate the manufacturing and service industries according to weights assigned to each criterion can be summarized as shown in Figure 1. The aforementioned evaluation criteria (C1–C5), which are determined by the consensus of thirteen experts and literature reviews, are first compared with each other by each DM, and the resulting pairwise comparison matrices are grouped into two categories according to DMs’ industrial expertise. All DMs are selected among executives of well-known companies in Turkey and were asked to evaluate specific branches of their business. Six DMs from the manufacturing industry evaluated sectors from automotive, plastics manufacturing, bedding and furniture manufacturing, food manufacturing, and metal manufacturing. Seven DMs from the service industry evaluated their business branches, which are a hospital, a bank, a restaurant chain, an insurance company, an investment consulting company, a hotel chain, and a shopping mall.

Figure 1.

The framework of the proposed MIS success evaluation model.

For the pairwise comparisons, a nine-point scale was used as suggested by Saaty, which is given in Table 1. This pairwise comparison scale rates the strength of the relationship between items (where 1: represents equal importance, 9: represents absolute importance, and reciprocals can also be used to represent less important choices) [55].

All collected individual evaluation matrices are checked for consistency by using the AHP method, and after ensuring that no issues are related to consistencies, all individual matrices are converted into fuzzy individual decision matrices with the use of TFN. After that, to form group decision matrices, all individual matrices in each group are aggregated with the use of geometric mean calculation. Finally, criteria weights in the resulting two groups of decision matrices, for the manufacturing and service sectors, are then calculated using the FAHP method.

2.3. Fuzzy Multi-Criteria Group Decision-Making (F-MCGDM) Framework

The fuzzy set theory was first introduced by Zadeh in 1965. Fuzzy set theory may represent indistinguishable data [57]. The most popular fuzzy numbers in the literature are triangular and trapezoidal fuzzy numbers, which are special types of fuzzy numbers that are used to capture the uncertainty of the parameters [58]. Fuzzy decision making was first used for the problems faced in the military services. In this study, weapon systems were evaluated with fuzzy theory by considering technological levels, resistance times, the capability of high mobility, and maintainability aspects. Fuzzy AHP was developed in the following years to improve the accuracy of decision-making problems. Chang developed a new method of the application of FAHP in 1999 using TFN for comparison, which uses extent analysis to achieve each goal realized in the decision model [59].

Generally, fuzzy numbers are the natural generalizations of ordinary numbers. The membership function () of an ordinary number such as can be shown with

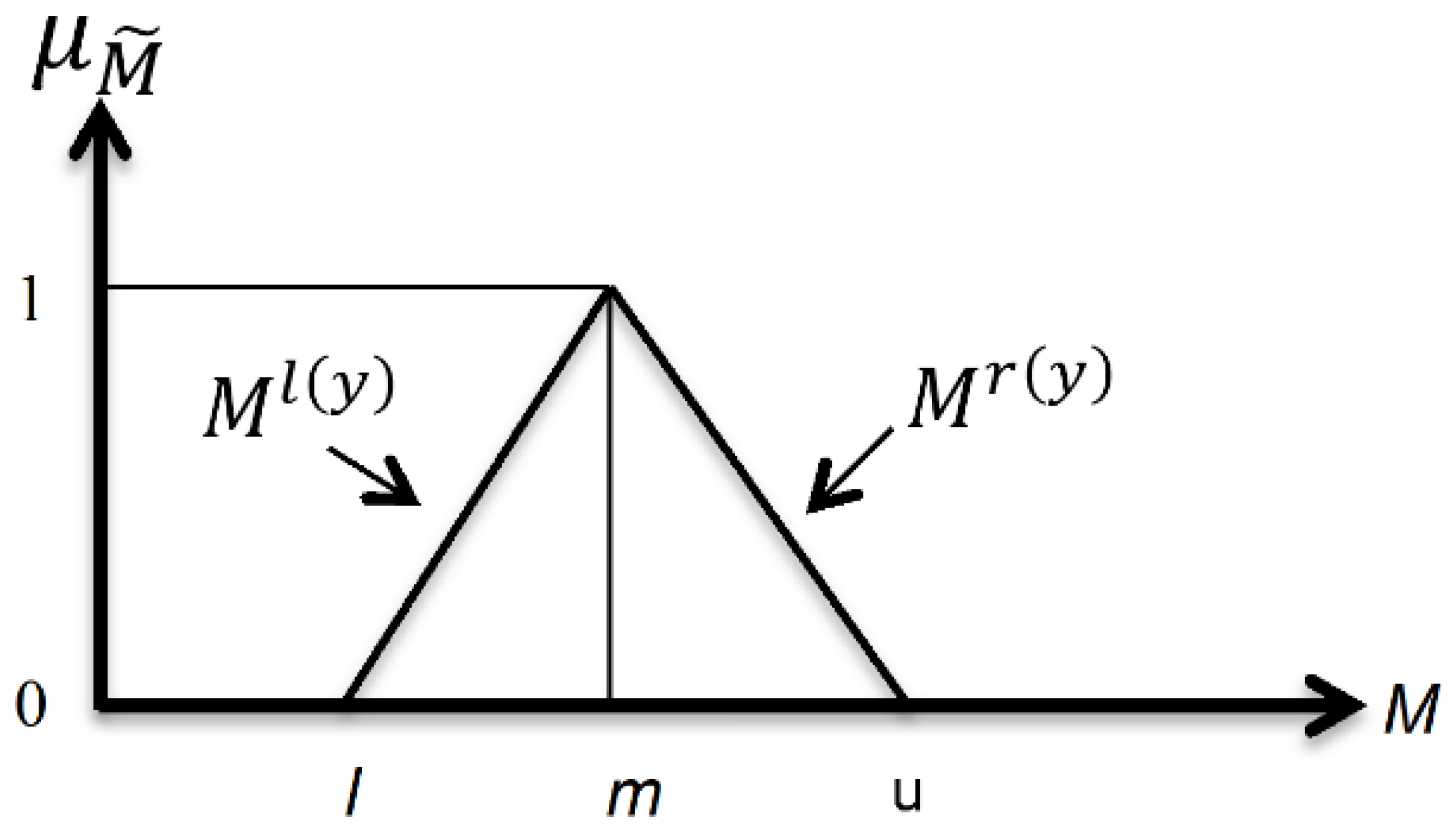

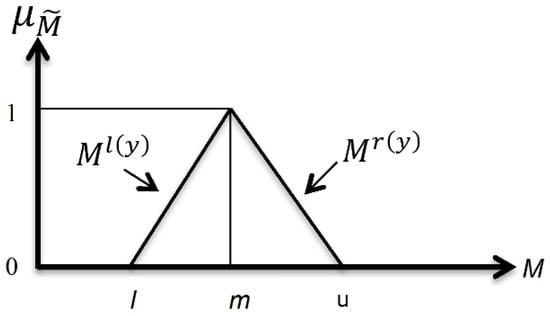

Therefore, any real number can be stated as a fuzzy number [60]. Each TFN has a linear representation on its right and left side, and the membership function of a fuzzy set () can be described as [61]:

Three real number parameters, , , and , describing a fuzzy event, indicate the smallest probable value, the most promising value, and the largest possible value, respectively [62]. A fuzzy number should always be given by its corresponding right and left representation of each degree of membership [61]:

In Equation (3), and denote the left-side representation and the right-side representation of a fuzzy number. is a fuzzy number if only is a normal and convex fuzzy set of [63]. Fuzzy numbers indicate the membership grade ranging between 0 and 1 as illustrated in Figure 2.

Figure 2.

A triangular fuzzy number [64].

There are special operations regarding the TFNs. Assuming that are two positive TFNs, then various operations on TFNs can be demonstrated with Equations (4)–(8).

The above-mentioned functions and operations can be used during the application of the FAHP method.

However, there are no consistency control or group decision aggregation steps embodied in the FAHP algorithm. Hence, in the framework of this study, AHP consistency ratio calculation steps were implemented first to ensure that the consistencies of all individual DM evaluations are satisfied [29,56,65]. Second, calculation steps of the aggregated group decision matrix are added to the FAHP algorithm to propose the F-MCGDM framework that uses TFN and FAHP as the evaluation model of the study. The steps of the proposed framework are as follows:

- Step 1: Structure the hierarchy of the decision model.

- Step 2: Collect all l DM evaluations to form the individual pairwise comparison matrices for n criteria in the following matrix form:

- Step 3: To control the consistency of each l individual pairwise comparison matrix Ak, computation of each maximum eigenvalue () by using Equation (10) is needed. To be used in these calculations, eigenvectors () and Wk′ matrices can be calculated using Equations (11) and (12), respectively.

The random consistency index (RI) value used in Equation (14) is the result of a large number of simulations. It differentiates according to the order of the matrix, as seen in Table 2.

Table 2.

Random consistency index (RI) values [56].

If a crisp pairwise comparison matrix (Ak) is found to be consistent, this implies that the related fuzzy pairwise comparison matrix () is also consistent for the kth DM [69].

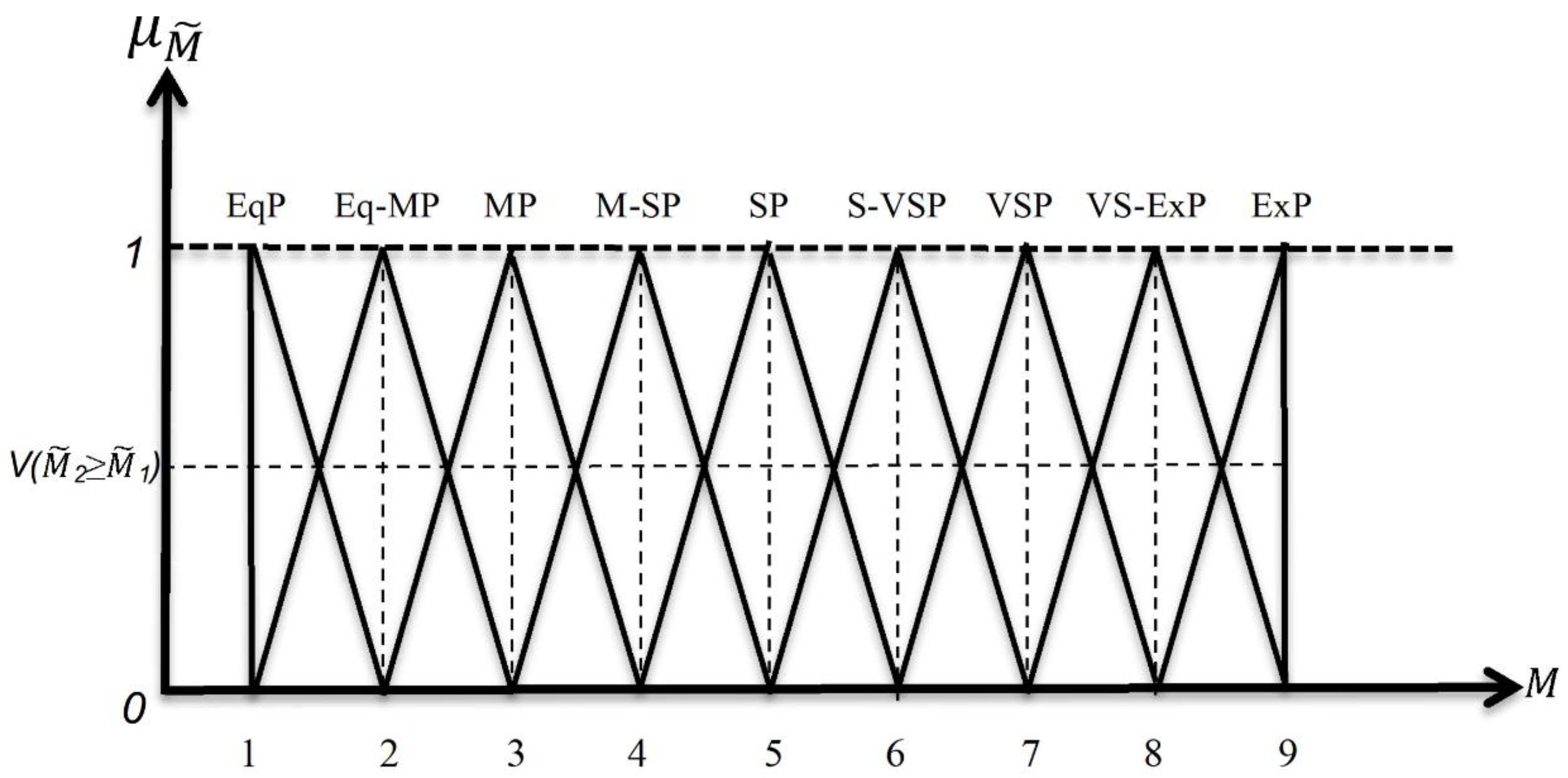

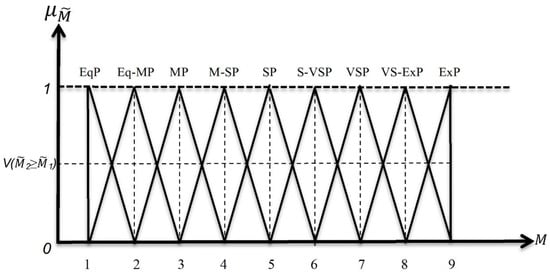

- Step 4: Individual pair-wise comparisons of each DM (Ak) should be converted into fuzzy pairwise comparison matrices () according to the linguistic scale presented in Table 3. The membership function of the linguistic variables is also given in Figure 3.

Table 3. The fuzzy scale of preferences [70].

Table 3. The fuzzy scale of preferences [70]. Figure 3. Membership function of linguistic variables used in the FAHP model.

Figure 3. Membership function of linguistic variables used in the FAHP model.

Therefore, the fuzzy pairwise comparison matrix for kth DM () is represented as follows:

- Step 5: According to group decision-making rules, l number of individual DM evaluations should be aggregated using geometric means to form the initial group decision matrix before proceeding to MCDM analysis [29]. The inclusion of this operation converts the model into the MCGDM model. However, for TFN, geometric mean should be calculated for each parameter separately in the TFN to calculate each member () of the aggregated fuzzy decision matrix (). Computation of geometric mean on fuzzy numbers can be performed using Equation (16) [71]. matrix constructed can be used in the remaining steps of Chang’s extent analysis [58,59].

- Step 6: Calculate the fuzzy synthetic extent values (Si) of the ith object for m goals by using Equation (17) [61].

To calculate Equation (17), perform the fuzzy addition operation of m extent analysis values for a special matrix as shown below.

The inverse of the vector is calculated as follows:

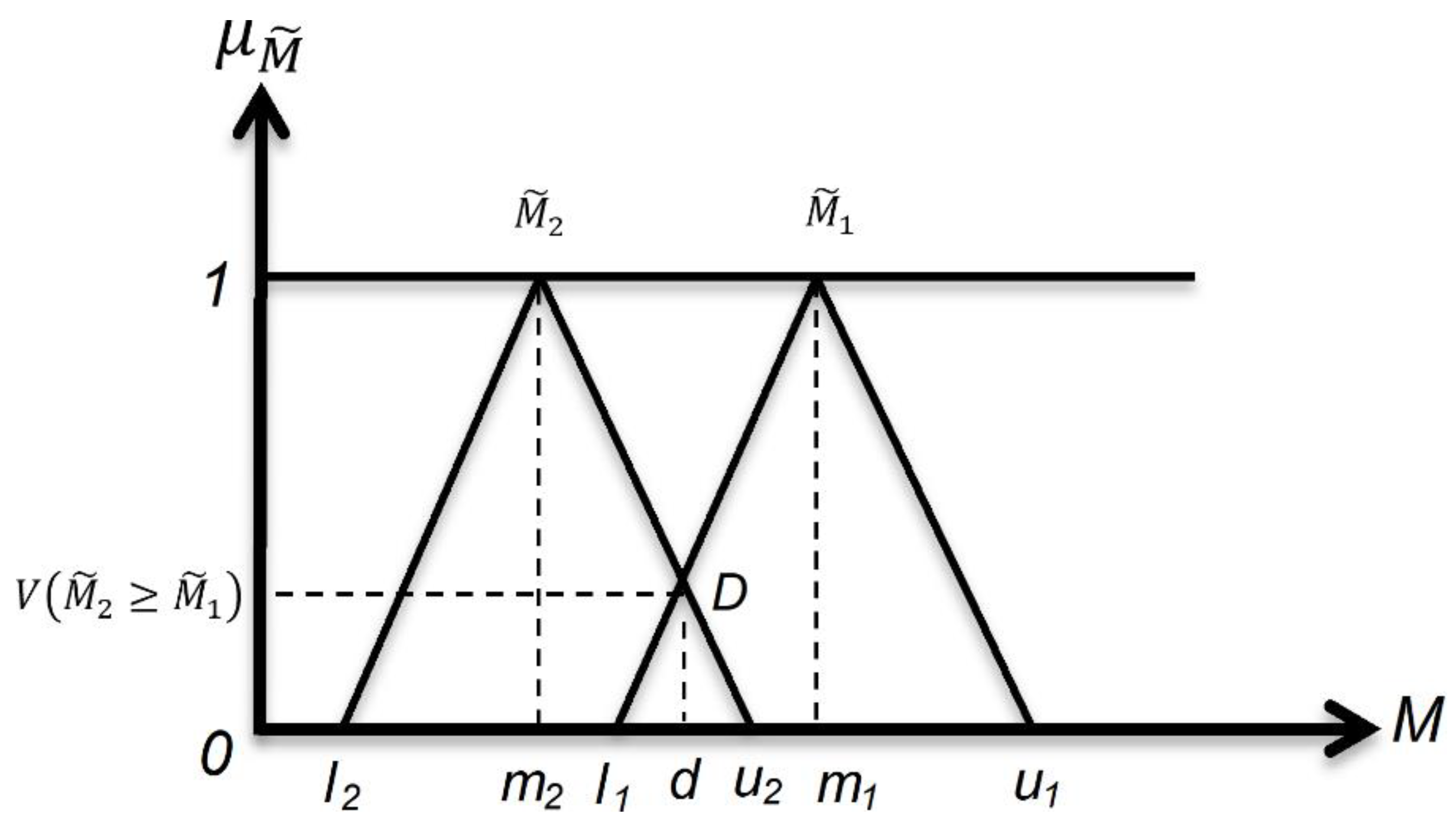

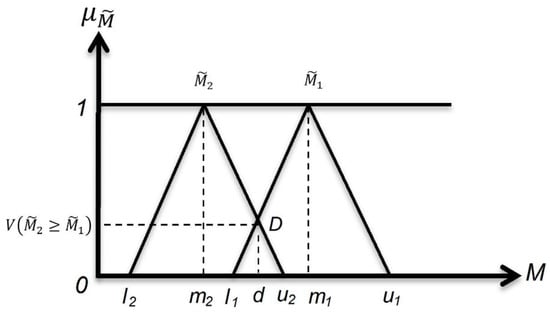

- Step 7: The level of probability of is described as given in Equation (20), and calculation of the degree of possibilities can be performed as described in Equation (21) [72].

In Equation (21), d is the ordinate of the highest intersection point (D) between and as shown in Figure 4.

Figure 4.

The intersection between and values with and for the comparison of and .

- Step 8: Calculate the weight vector by taking the minimum of the vectors for each criterion [63]. The level of probability for a convex fuzzy number that is greater than convex fuzzy numbers can be described as:

- Step 9: Assuming that for , calculate the normalized weights using Equation (23) where W is a non-fuzzy number.where

2.4. Application of F-MCGDM Model in Manufacturing and Service Industries

The evaluation framework of differentiating success factors of MISs for manufacturing and service sectors is previously given in Figure 1, and evaluation criteria (C1–C5) are explained in Section 2.2. For the application of the proposed F-MCGDM model, six experts from manufacturing and seven experts from service industries evaluated the criteria as DMs according to the scale in Table 1. Individual decision matrices () filled by all thirteen DMs are given in Appendix A with their corresponding weights calculated using the AHP method. CI, and CR values are calculated using Equations (10), (13) and (14) respectively, and they are presented in Table 4.

Table 4.

Consistency calculations for crisp individual pairwise comparison matrices of DMs.

As can be seen from Table 4, all consistency ratios are less than 0.10, which means that all comparisons made by the DMs are consistent. In the next step of the F-MCGDM framework, by using the linguistic scale given in Table 3, all matrices given in Appendix A in Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10, Table A11, Table A12 and Table A13 are converted into fuzzy pairwise comparison matrices () as described in Equation (15). To demonstrate the conversion of a crisp evaluation matrix into a fuzzy linguistic comparison matrix, the converted version of A13 is given in the fuzzy form () in Table A14, in Appendix B. Following the fuzzification of comparison matrices, according to group decision-making rules, each group of matrices under each industry are aggregated with the use of Equation (16) to form matrix for each industry. The resulting aggregated fuzzy decision matrices for manufacturing and service industries are given in Table 5 and Table 6, respectively.

Table 5.

Aggregated fuzzy decision matrix for the manufacturing industry.

Table 6.

Aggregated fuzzy decision matrix for the service industry.

Synthetic extent values (Si) for all criteria are calculated with Equation (17) for each industry separately by using the data in Table 5 and Table 6, and the results are given in Table 7 and Table 8.

Table 7.

Synthetic extent values for the manufacturing industry.

Table 8.

Synthetic extent values for the service industry.

For all synthetic extent values in Table 7 and Table 8, the degrees of possibility of superiority are determined using Equation (21) and are presented in Table 9 and Table 10 for manufacturing and service industries, respectively.

Table 9.

Degree of possibilities for the manufacturing industry.

Table 10.

Degree of possibilities for the service industry.

The weight vector for each criterion is calculated by finding the minimum degree of possibility of the superiority of each criterion over another with Equation (22). Fuzzy weight vectors calculated for each industry are then used for defuzzification to calculate the normalized weight vector by using Equation (23). Weight vectors and normalized final weights for manufacturing and service industries are given in Table 11 and Table 12, respectively.

Table 11.

Weight vector for the manufacturing industry.

Table 12.

Weight vector for the service industry.

In certain situations, some criteria weights can be calculated as zero in the FAHP method, which cause inefficiencies during comparisons. When fuzzy weight vectors for each industry are inspected, it can be seen that none of the elements resulted in zero value. These results verify the effective use of FAHP in the proposed F-MCGDM framework, and the findings confirm that the results can be used for the comparison and evaluation of MIS success factors in manufacturing and service industries.

3. Results and Discussion

Calculation results of the proposed F-MCGDM model are ranked according to criteria weights for each industry and are summarized in Table 13 for comparison. The weights of each criterion are rounded up with two decimals and are converted into percentages for ease of comparison. Initial findings indicate that there is a considerable difference in the rankings of MIS success factors for each industry, especially in the most important three criteria.

Table 13.

Comparative weights and criteria rankings for manufacturing and service industries.

Considering the weight totals of each criterion, the quality and reliability of information (C4) factor was found to be the most important success factor of MISs in the service industry with a weight of 42.22%. C4 is also the second most important criterion for the manufacturing industry with 31.19% weight. The difference in the ranking can be understandable when service business is considered. In the service industry, products (services) are consumed at the point of production, which means that service companies have much closer relations with their customers compared with manufacturing companies. This service business property requires much faster and more reliable information available to maintain service quality. Toleration buffer customers are much lower in the service industry compared with the manufacturing industry, which results in a considerable difference in the weights of quality and reliability of information factors for both industries. In service companies, any time lost during accessing information directly reflects on the customer-waiting times in the system. In addition, there is much less chance of compensation and errors made because of faulty information in the service business. Hence, quality and reliability of information found are the most important requirements of an MIS in the service industry.

According to total criteria weights, it can be said that the usability and functionality (C5) factor was found as the second most important criterion in the service industry with 39.30% weight, whereas C5 ranked the third most important criterion for the manufacturing industry with a weight of 26.62%, which makes it another differentiating factor. The reason behind this can be explained by the higher usage frequency of these systems in service companies and that prolonged usage times of MISs resulted in more weight to be assigned to this factor. The main factor affecting the importance of C5 is the time-sensitivity of service businesses since all nonvalue-added times to the processes to deliver services are directly affecting the total waiting times of customers in the system. In manufacturing companies, adjusting the following operations to compensate for the lost time can be an option. In addition, the total time lost because of usability issues has a lower share in the total cycle time of production compared to the service industry. Therefore, usability and functionality factors are found to be considerably more important factors in service companies compared with companies in the manufacturing industry.

Support for the business processes (C1) is found as the third most important MIS success factor in total weights, and the third-ranking criterion for the service industry with a weight of 9.63%, whereas C1 is the most important success factor in the manufacturing industry with 35.07% weight. Considering the difference in weights, this criterion is the most important differentiating factor in the manufacturing and service industries. The dependence of manufacturing companies on their supply chains enforces these companies to rely on their enterprise resource planning (ERP) infrastructure more than service companies. Considering the complexity of business processes in manufacturing companies, especially if the company plays a role as a peer in a global supply chain, real-time information-sharing capabilities among the peers to coordinate activities play the most crucial role in the manufacturing industry. Therefore, full support of all business processes including the activities related to the tiers in the supply chain and integration with other business software in the company is the most important factor that should be satisfied by a successful MIS in manufacturing companies. Compared with manufacturing companies, the relatively simpler business structure of service companies gives this industry an advantage of finding more MIS vendors for their business, which are suitable for their companies. However, the vendor of fitting MIS for the business structure is more limited for the manufacturing companies; hence, support for the business processes criterion ranked first in the manufacturing industry as the most important MIS success factor according to findings.

The availability of information (C3) MIS success factor ranked fourth in both manufacturing and service industries with weights of 5.99% and 4.80% for manufacturing and service companies, respectively. Since C3 has the same rank and close weight values, it cannot be said that this factor is a differentiating factor. However, manufacturing companies give slightly more importance to this criterion than service companies. Low weight values for this factor can be explained by the purchasing and implementation phase of MIS systems. Currently, most vendors of MIS systems offer the possibility of customization of the systems during the implementation phase according to the needs of the company. Therefore, when an MIS has been purchased, all the data and information expected to be saved in the system are predefined by the company, and these requirements are implemented by the vendors according to agreed conditions to satisfy the needs of the customer. This procedure ensures the existence and expected variety of data in the system.

Finally, the visibility of information (C2) criterion to evaluate MIS success ranked last for both manufacturing and service industries. However, weights associated with this success factor are different from each other to a degree. C2 has a weight of only 1.13% in the manufacturing industry, whereas it has a 4.05% weight in the service industry. It can be said that service companies give more importance to the ability to access all the information in the system by all departments in the organization by a small difference than the manufacturing companies. The reasons behind the last place ranking of visibility of information can be explained by the preference of executives to restrict the data and information that can be accessed by some groups of users. In most companies, accessing all the information in the system by all users is not a requirement. However, defining user access permissions granted by the system administrator defines the information and data accessible by each user in most MISs.

4. Conclusions

Requirements of today’s businesses increased the importance of ISs. Rapidly changing market conditions and customer needs force companies to react quickly to these changes. Adapting to constantly developing technological trends requires the existence of an effective MIS in organizations to aid executives in their decisions to acquire a sustainable business. However, ensuring the successful implementation of MIS requires a good fit of these systems with the organization’s business. Understanding the differences in business needs and differentiating factors related to MIS’s success must be determined for different industries. Therefore, an F-MCGDM framework is proposed in this study to fill the gap in the literature by determining the differences in expectations of manufacturing and service industries from MIS.

The application of the proposed F-MCGDM framework to manufacturing and service industries to evaluate the success factors of MISs revealed a considerable difference between the expectations and requirements of companies in these industries from the MISs. Selecting the right MIS according to the most important factors of the company by considering the differentiating factors is important for the actual performance of MISs after the implementation.

4.1. Implications of the Study

Differentiating factors of MIS success according to industries to which organizations belong directly affect the selection criteria of these systems. The right selection of MIS, which is suitable for the business that the company performs, has a positive effect on the managerial performance of the organization. Results of the proposed F-MCGDM framework clearly state the differences in priorities of manufacturing and service industries. Weights associated with each success factor can be used by related companies during the evaluation phase of MISs. By doing so, the efficiency and effectiveness acquired from the MIS can be increased.

Industrial differences are emphasized because this study can also be used by system developers to offer better and different customizations to manufacturing and service companies. Understanding the need of these industries will aid developers in making the required customizations with less effort and with more accuracy.

From the academic perspective, the application of a fuzzy group decision-making-based MCDM model on the comparison problem of industries for the success factors of MIS is a novel approach. The use of fuzzy logic in this area proved to give successful results to reflect the different needs of different industries. It is expected that the findings of this study will encourage researchers to conduct studies on similar applications in the same field.

4.2. Limitations and Future Work

Nevertheless, this study has some limitations. Success criteria selected to evaluate the success of MISs were deliberately limited for the application compatibility to both manufacturing and service sectors. The number and variety of these criteria can be increased in future studies to evaluate differences between different business sectors by defining additional sector-specific criteria. Finally, different MCDM methods can be used to determine the differences in MIS success factors in various industries and sectors.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

Appendix A

Table A1.

Individual pairwise comparison matrix of DM1 for the manufacturing industry.

Table A1.

Individual pairwise comparison matrix of DM1 for the manufacturing industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 3.00 | 1.00 | 0.33 | 0.33 | 0.1304 |

| C2 | 0.33 | 1.00 | 1.00 | 0.33 | 0.33 | 0.0675 |

| C3 | 1.00 | 1.00 | 1.00 | 0.20 | 0.20 | 0.1063 |

| C4 | 3.00 | 3.00 | 5.00 | 1.00 | 1.00 | 0.3479 |

| C5 | 3.00 | 3.00 | 5.00 | 1.00 | 1.00 | 0.3479 |

Table A2.

Individual pairwise comparison matrix of DM2 for the manufacturing industry.

Table A2.

Individual pairwise comparison matrix of DM2 for the manufacturing industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 3.00 | 3.00 | 3.00 | 3.00 | 0.4101 |

| C2 | 0.33 | 1.00 | 0.33 | 0.50 | 0.50 | 0.0707 |

| C3 | 0.33 | 3.00 | 1.00 | 0.33 | 1.00 | 0.1367 |

| C4 | 0.33 | 2.00 | 3.00 | 1.00 | 1.00 | 0.2121 |

| C5 | 0.33 | 2.00 | 1.00 | 1.00 | 1.00 | 0.1703 |

Table A3.

Individual pairwise comparison matrix of DM3 for the manufacturing industry.

Table A3.

Individual pairwise comparison matrix of DM3 for the manufacturing industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 5.00 | 5.00 | 0.33 | 3.00 | 0.2947 |

| C2 | 0.20 | 1.00 | 0.33 | 0.20 | 0.20 | 0.0414 |

| C3 | 0.20 | 3.00 | 1.00 | 0.20 | 0.33 | 0.0760 |

| C4 | 3.00 | 5.00 | 5.00 | 1.00 | 3.00 | 0.4276 |

| C5 | 0.33 | 5.00 | 3.00 | 0.33 | 1.00 | 0.1603 |

Table A4.

Individual pairwise comparison matrix of DM4 for the manufacturing industry.

Table A4.

Individual pairwise comparison matrix of DM4 for the manufacturing industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 3.00 | 2.00 | 2.00 | 2.00 | 0.4317 |

| C2 | 0.33 | 1.00 | 1.00 | 0.33 | 0.33 | 0.0607 |

| C3 | 0.50 | 1.00 | 1.00 | 0.33 | 0.33 | 0.1043 |

| C4 | 0.50 | 3.00 | 3.00 | 1.00 | 1.00 | 0.2016 |

| C5 | 0.50 | 3.00 | 3.00 | 1.00 | 1.00 | 0.2016 |

Table A5.

Individual pairwise comparison matrix of DM5 for the manufacturing industry.

Table A5.

Individual pairwise comparison matrix of DM5 for the manufacturing industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 2.00 | 3.00 | 3.00 | 3.00 | 0.4058 |

| C2 | 0.50 | 1.00 | 2.00 | 3.00 | 3.00 | 0.2099 |

| C3 | 0.33 | 0.50 | 1.00 | 3.00 | 3.00 | 0.2099 |

| C4 | 0.33 | 0.33 | 0.33 | 1.00 | 1.00 | 0.0872 |

| C5 | 0.33 | 0.33 | 0.33 | 1.00 | 1.00 | 0.0872 |

Table A6.

Individual pairwise comparison matrix of DM6 for the manufacturing industry.

Table A6.

Individual pairwise comparison matrix of DM6 for the manufacturing industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 3.00 | 1.00 | 0.33 | 0.33 | 0.1355 |

| C2 | 0.33 | 1.00 | 1.00 | 0.33 | 0.33 | 0.0873 |

| C3 | 1.00 | 1.00 | 1.00 | 0.33 | 0.33 | 0.1088 |

| C4 | 3.00 | 3.00 | 3.00 | 1.00 | 1.00 | 0.2619 |

| C5 | 3.00 | 3.00 | 3.00 | 1.00 | 1.00 | 0.4065 |

Table A7.

Individual pairwise comparison matrix of DM7 for the service industry.

Table A7.

Individual pairwise comparison matrix of DM7 for the service industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 3.00 | 0.33 | 0.33 | 0.33 | 0.1095 |

| C2 | 0.33 | 1.00 | 0.33 | 0.20 | 0.20 | 0.0637 |

| C3 | 3.00 | 3.00 | 1.00 | 1.00 | 0.33 | 0.2345 |

| C4 | 3.00 | 5.00 | 1.00 | 1.00 | 1.00 | 0.2637 |

| C5 | 3.00 | 5.00 | 3.00 | 1.00 | 1.00 | 0.3285 |

Table A8.

Individual pairwise comparison matrix of DM8 for the service industry.

Table A8.

Individual pairwise comparison matrix of DM8 for the service industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 3.00 | 3.00 | 0.33 | 0.33 | 0.1695 |

| C2 | 0.33 | 1.00 | 1.00 | 0.50 | 0.50 | 0.0877 |

| C3 | 0.33 | 1.00 | 1.00 | 0.33 | 0.33 | 0.0877 |

| C4 | 3.00 | 2.00 | 3.00 | 1.00 | 1.00 | 0.3276 |

| C5 | 3.00 | 2.00 | 3.00 | 1.00 | 1.00 | 0.3276 |

Table A9.

Individual pairwise comparison matrix of DM9 for the service industry.

Table A9.

Individual pairwise comparison matrix of DM9 for the service industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 1.00 | 0.50 | 0.33 | 1.00 | 0.1531 |

| C2 | 1.00 | 1.00 | 0.50 | 0.50 | 2.00 | 0.1229 |

| C3 | 2.00 | 3.00 | 1.00 | 1.00 | 1.00 | 0.2375 |

| C4 | 3.00 | 2.00 | 1.00 | 1.00 | 1.00 | 0.2959 |

| C5 | 1.00 | 0.50 | 1.00 | 1.00 | 1.00 | 0.1907 |

Table A10.

Individual pairwise comparison matrix of DM10 for the service industry.

Table A10.

Individual pairwise comparison matrix of DM10 for the service industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 3.00 | 3.00 | 0.33 | 0.33 | 0.1695 |

| C2 | 0.33 | 1.00 | 2.00 | 0.33 | 0.33 | 0.0877 |

| C3 | 0.33 | 0.50 | 1.00 | 0.33 | 0.33 | 0.0877 |

| C4 | 3.00 | 3.00 | 3.00 | 1.00 | 1.00 | 0.3276 |

| C5 | 3.00 | 3.00 | 3.00 | 1.00 | 1.00 | 0.3276 |

Table A11.

Individual pairwise comparison matrix of DM11 for the service industry.

Table A11.

Individual pairwise comparison matrix of DM11 for the service industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 3.00 | 3.00 | 1.00 | 0.33 | 0.2151 |

| C2 | 0.33 | 1.00 | 1.00 | 0.33 | 0.33 | 0.0717 |

| C3 | 0.33 | 1.00 | 1.00 | 0.33 | 0.33 | 0.1113 |

| C4 | 1.00 | 3.00 | 3.00 | 1.00 | 1.00 | 0.2680 |

| C5 | 3.00 | 3.00 | 3.00 | 1.00 | 1.00 | 0.3339 |

Table A12.

Individual pairwise comparison matrix of DM12 for the service industry.

Table A12.

Individual pairwise comparison matrix of DM12 for the service industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 1.00 | 1.00 | 0.33 | 0.33 | 0.1093 |

| C2 | 1.00 | 1.00 | 2.00 | 0.33 | 0.33 | 0.1093 |

| C3 | 1.00 | 0.50 | 1.00 | 0.33 | 0.33 | 0.1093 |

| C4 | 3.00 | 3.00 | 3.00 | 1.00 | 3.00 | 0.4086 |

| C5 | 3.00 | 3.00 | 3.00 | 0.33 | 1.00 | 0.2633 |

Table A13.

Individual pairwise comparison matrix of DM13 for the service industry.

Table A13.

Individual pairwise comparison matrix of DM13 for the service industry.

| Evaluation Criteria | C1 | C2 | C3 | C4 | C5 | AHP Weight |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 0.33 | 0.33 | 0.14 | 0.20 | 0.0466 |

| C2 | 3.00 | 1.00 | 2.00 | 0.33 | 0.33 | 0.1191 |

| C3 | 3.00 | 0.50 | 1.00 | 0.20 | 0.33 | 0.1075 |

| C4 | 7.00 | 3.00 | 5.00 | 1.00 | 3.00 | 0.4707 |

| C5 | 5.00 | 3.00 | 3.00 | 0.33 | 1.00 | 0.2560 |

Appendix B

Table A14.

The fuzzy linguistic converted decision matrix of DM13.

Table A14.

The fuzzy linguistic converted decision matrix of DM13.

| C1 | C2 | C3 | C4 | C5 | |

|---|---|---|---|---|---|

| C1 | (1.00, 1.00, 1.00) | (0.25, 0.33, 0.50) | (0.25, 0.33, 0.50) | (0.13, 0.14, 0.17) | (0.17, 0.20, 0.25) |

| C2 | (2.00, 3.00, 4.00) | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | (0.25, 0.33, 0.50) | (0.25, 0.33, 0.50) |

| C3 | (2.00, 3.00, 4.00) | (0.33, 0.50, 1.00) | (1.00, 1.00, 1.00) | (0.17, 0.20, 0.25) | (0.25, 0.33, 0.50) |

| C4 | (6.00, 7.00, 8.00) | (2.00, 3.00, 4.00) | (2.00, 3.00, 4.00) | (1.00, 1.00, 1.00) | (2.00, 3.00, 4.00) |

| C5 | (4.00, 5.00, 6.00) | (2.00, 3.00, 4.00) | (2.00, 3.00, 4.00) | (0.25, 0.33, 0.50) | (1.00, 1.00, 1.00) |

References

- O’Brien, J.A.; Marakas, G.M. Foundation of information systems in business. In Management Information Systems, 10th ed.; McGraw-Hill: Boston, MA, USA, 2011; pp. 65–67. [Google Scholar]

- Kroenke, D.; Hatch, R. Introduction to information system. In Business Information Systems, an Introduction, 5th ed.; McGraw-Hill: New York, NY, USA, 1993; pp. 7–27. [Google Scholar]

- Clikeman, P.M. Improving information quality. Intern. Audit. 1999, 56, 32–34. [Google Scholar]

- Benjamin, R.; Wigand, R. Electronic market and virtual value chains on the information superhighway. Sloan Manag. Rev. 1995, 36, 62–72. [Google Scholar]

- Baç, U.; Erkan, T.E. A model to evaluate supply chain performance and flexibility. Afr. J. Bus. Manag. 2011, 5, 4263–4271. [Google Scholar]

- Minimol, M.C.; Sarngadharan, M. Management information system and computer applications. In Management Information System, 2nd ed.; Himalaya Pub. House: Mumbai, India, 2010; pp. 30–35. [Google Scholar]

- Davis, G.B.; Olson, M.H. Management Information Systems: Conceptual Foundations, Structure, and Development, 2nd ed.; McGraw-Hill: New York, NY, USA, 1985; pp. 25–58. [Google Scholar]

- Levy, M.; Powell, P. Information system strategy for small and medium sized enterprises: An organizational perspective. J. Inf. Syst. 2000, 9, 63–84. [Google Scholar] [CrossRef]

- Jarvenpaa, S.L.; Ives, B. The global network organization of the future: Information management opportunities and challenges. J. Manag. Inform. Syst. 2015, 10, 25–57. [Google Scholar] [CrossRef]

- Bidgoli, H. Group support systems: A new productivity tool for the 90′s. J. Syst. Manag. 1996, 47, 56–62. [Google Scholar]

- Lawyer, O.; Justin, G. Management information systems and corporate decision–making: A literature review. Int. J. Manag. 2013, 2, 78–82. [Google Scholar]

- O’Brien, J.A.; Marakas, G.M. Enterprise Business System. In Management Information Systems with MISource, 8th ed.; McGraw-Hill: Boston, MA, USA, 2008; pp. 169–178. [Google Scholar]

- Fan, L.; Tiejun, W.; Livyi, W. Research and implementation on model for high availability of enterprise information system. IERI Proc. 2012, 3, 181–185. [Google Scholar] [CrossRef][Green Version]

- Handfield, R.; Barnhardt, R.; Powell, N. Mapping the automotive textile supply chain: The importance of information visibility. J. Text. Appar. Technol. Manag. 2004, 3, 1–19. [Google Scholar]

- Kim, K.K.; Ryoo, S.Y.; Jung, M.D. Inter-organizational information systems visibility in buyer–supplier relationships: The case of telecommunication equipment component manufacturing industry. Omega-Int. J. Manag. Sci. 2011, 39, 667–676. [Google Scholar] [CrossRef]

- Luftman, J.; Kempaiah, R. Key issues for IT executives 2007. MIS Q. Exec. 2008, 7, 99–112. [Google Scholar]

- Davenport, T.H. Process Innovation: Reengineering Work through Information Technology; Harvard Business School Press: Boston, MA, USA, 1993. [Google Scholar]

- Dromey, R.G. A model of software product quality. IEEE Trans. Softw. Eng. 1995, 21, 146–162. [Google Scholar] [CrossRef]

- Reeves, C.A.; Bednar, D.A. Defining quality: Alternatives and implications. Acad. Manag. Rev. 1994, 19, 419–445. [Google Scholar] [CrossRef]

- Gorla, N.; Somers, T.M.; Wong, B. Organizational impact of system quality, information quality, and service quality. J. Strateg. Inf. Syst. 2010, 19, 207–228. [Google Scholar] [CrossRef]

- Delone, W.H.; McLean, E.R. Information systems success: The quest for the dependent variable. Inform. Syst. Res. 1992, 3, 60–95. [Google Scholar] [CrossRef]

- Huh, Y.U.; Keller, F.R.; Redman, T.C.; Watkins, A.R. Data quality. Inform. Softw. Techn. 1990, 32, 559–565. [Google Scholar] [CrossRef]

- Redman, T.C. The impact of poor data quality on the typical enterprise. Commun. ACM 1998, 41, 79–82. [Google Scholar] [CrossRef]

- Gorla, N.; Lin, S.-C. Determinants of software quality: A survey of information systems project managers. Inform. Softw. Tech. 2010, 52, 602–610. [Google Scholar] [CrossRef]

- Sarnikar, S.; Murphy, M. A usability analysis framework for healthcare information technology. Int. J. Technol. Diffus. 2012, 3, 20–28. [Google Scholar] [CrossRef]

- Zapf, D. Errors in working with office computers: A first validation of a taxonomy for observed errors in a field setting. Int. J. Hum-Comput. Int. 1992, 4, 311–339. [Google Scholar] [CrossRef]

- Fu, C.; Chang, W.; Liu, W.; Yang, S. Data-Driven Selection of Multi-Criteria Decision-Making Methods and its Application to Diagnosis of Thyroid Nodules. Comput. Ind. Eng. 2020, 145, 106490. [Google Scholar] [CrossRef]

- Lo, W.C.; Lu, C.H.; Chou, Y.C. Application of Multicriteria Decision Making and Multi-Objective Planning Methods for Evaluating Metropolitan Parks in Terms of Budget and Benefits. Mathematics 2020, 8, 1304. [Google Scholar] [CrossRef]

- Bac, U. The role of environmental factors in the investment prioritization of facilities using recycled PVC. Pol. J. Environ. Stud. 2021, 30, 2981–2993. [Google Scholar] [CrossRef]

- Soltani, A.; Hewage, K.; Reza, B.; Sadiq, R. Multiple stakeholders in multicriteria decision making in the context of municipal solid waste management: A review. Waste Manag. 2015, 35, 318–328. [Google Scholar] [CrossRef] [PubMed]

- Hillermant, T.; Souza, J.C.F.; Reis, A.C.B.; Carvalho, R.N. Applying clustering and AHP methods for evaluating suspect healthcare claims. J. Comput. Sci. 2017, 19, 97–111. [Google Scholar] [CrossRef]

- Lin, C.-T.; Yeh, C.-C.; Ye, F. Applying the multi-criteria decision-making approach for lawyer selection from law firms’ perspective in China. Mathematics 2020, 8, 1370. [Google Scholar] [CrossRef]

- Kulak, O.; Kahraman, C. Fuzzy multi-attribute selection among transportation companies using axiomatic design and analytic hierarchy process. Inform. Sci. 2005, 170, 191–210. [Google Scholar] [CrossRef]

- Kim, Y.J.; Garrity, E.J.; Sanders, G.L. Success measures of information systems. In Encyclopedia of Information Systems; Bidgoli, H., Ed.; Elsevier: Amsterdam, The Netherlands, 2003; pp. 299–313. [Google Scholar]

- Ruivo, P.; Robrigues, J.; Johansson, B.; Oliveira, T.; Rebelo, J. Differences in ERP value between Iberian manufacturing and services SMEs. Procedia Comput. Sci. 2017, 121, 707–715. [Google Scholar] [CrossRef]

- Kivinen, T.; Lammintakanen, J. The success of a management information system in health care—A case study from Finland. Int. J. Med. Inform. 2013, 82, 90–97. [Google Scholar] [CrossRef]

- Lee, S.-K.; Yu, J.-H. Success model of project management information system in construction. Automat. Constr. 2012, 25, 82–93. [Google Scholar] [CrossRef]

- Jeyaraj, A. DeLone & McLean models of information system success: Critical meta-review and research directions. Int. J. Inform. Manag. 2020, 54, 102139. [Google Scholar]

- Wang, Y.-S.; Liao, Y.-W. Assessing eGovernment systems success: A validation of the DeLone and McLean model of information systems success. Gov. Inform. Q. 2008, 25, 717–733. [Google Scholar] [CrossRef]

- Rezaei, A.; Asadi, A.; Rezvanfar, A.; Hassanshahi, H. The impact of organizational factors on management information system success: An investigation in the Iran’s agricultural extension providers. Int. Inf. Libr. Rev. 2009, 41, 163–172. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.-H. The relationship between procedural formalization in MIS development and MIS success: A contingent analysis. Inform. Manag. 1992, 22, 89–111. [Google Scholar] [CrossRef]

- Lu, H.-P.; Wang, J.-Y. The relationships between management styles, user participation, and system success over MIS growth stages. Inform. Manag. 1997, 32, 203–213. [Google Scholar] [CrossRef]

- Yap, C.S.; Soh, C.P.P.; Raman, K.S. Information systems success factors in small business. Omega-Int. J. Manag. Sci. 1992, 20, 597–609. [Google Scholar] [CrossRef]

- Agourram, H. Defining information system success in Germany. Int. J. Inform. Manag. 2009, 29, 129–137. [Google Scholar] [CrossRef]

- Ishman, M.D.; Pegels, C.C.; Sanders, G.L. Managerial information system success factors within the cultural context of North America and a former Soviet Republic. J. Strateg. Inf. Syst. 2001, 10, 291–312. [Google Scholar] [CrossRef]

- Nath, R. Associations between user training and information systems success. Int. J. Inform. Manag. 1989, 9, 259–265. [Google Scholar] [CrossRef]

- Li, E.Y. Perceived importance of information system success factors: A meta analysis of group differences. Inform. Manag. 1997, 32, 15–28. [Google Scholar] [CrossRef]

- Yen, H.R.; Li, E.Y.; Niehoff, B.P. Do organizational citizenship behaviors lead to information system success?: Testing the mediation effects of integration climate and project management. Inform. Manag. 2008, 45, 394–402. [Google Scholar] [CrossRef]

- Cho, J.; Park, I.; Michel, J.W. How does leadership affect information systems success? The role of transformational leadership. Inform. Manag. 2011, 48, 270–277. [Google Scholar]

- Raymond, L. Validating and applying user satisfaction as a measure of MIS success in small organizations. Inform. Manag. 1987, 12, 173–179. [Google Scholar] [CrossRef]

- Salmeron, J.L.; Herrero, I. An AHP-based methodology to rank critical success factors of executive information systems. Comput. Stand. Inter. 2005, 28, 1–12. [Google Scholar] [CrossRef]

- Whyte, G.; Bytheway, A.; Edwards, C. Understanding user perceptions of information systems success. J. Strateg. Inf. Syst. 1997, 6, 35–68. [Google Scholar] [CrossRef]

- Jones, L.H.; Kydd, C.T. An information processing framework for understanding success and failure of MIS development methodologies. Inform. Manag. 1988, 15, 263–271. [Google Scholar] [CrossRef]

- Baç, U. An integrated SWARA-WASPAS group decision making framework to evaluate smart card systems for public transportation. Mathematics 2020, 8, 1723. [Google Scholar] [CrossRef]

- Shakiba, S.; Asghari, O.; Khan, N.K.F. A combined approach based on MAF analysis and AHP method to fault detection mapping: A case study from a gas field, southwest of Iran. J. Appl. Geophys. 2018, 148, 8–15. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Isaai, M.T.; Kanani, A.; Tootoonchi, M.; Afzali, H.R. Intelligent timetable evaluation using fuzzy AHP. Expert Syst. Appl. 2011, 38, 3718–3723. [Google Scholar] [CrossRef]

- Chang, D.-Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Zhu, K.-J.; Jing, Y.; Chang, D.-Y. A discussion on extent analysis method and applications on fuzzy AHP, theory and methodology. Eur. J. Oper. Res. 1999, 116, 450–456. [Google Scholar] [CrossRef]

- Sheikhi, F. Using fuzzy analytical hierarchy process for selecting the native and non-native music portfolio in reducing of stress. Adv. Nat. Appl. Sci. 2012, 6, 100–109. [Google Scholar]

- Ataei, M.; Mikaeil, R.; Hoseinie, S.H.; Hosseini, S.M. Fuzzy analytical hierarchy process approach for ranking the sawability of carbonate rock. Int. J. Rock Mech. Min. 2012, 50, 83–93. [Google Scholar] [CrossRef]

- Chatterjee, D.; Mukherjee, B. Study of fuzzy-AHP model to search the criterion in the evaluation of the best technical institutions: A case study. Int. J. Eng. Sci. Technol. 2010, 2, 2499–2510. [Google Scholar]

- Kabir, G.; Hasin, M.A.A. Multiple criteria inventory classification using fuzzy analytic hierarchy process. Int. J. Ind. Eng. Comput. 2012, 3, 123–132. [Google Scholar] [CrossRef]

- Wang, Y.M.; Chin, K.S. A linear goal programming priority method for fuzzy analytic hierarchy process and its applications in new product screening. Int. J. Approx. Reason. 2008, 49, 451–465. [Google Scholar] [CrossRef]

- Lima, E.; Gorski, E.; Loures, E.F.L.; Santos, E.A.P.; Deschamps, F. Applying machine learning to AHP multicriteria decision making method to assets prioritization in the context of industrial maintenance 4.0. IFAC-PapersOnLine 2019, 52, 2152–2157. [Google Scholar] [CrossRef]

- Piltan, M.; Mehmanchi, E.; Ghaderi, S.F. Proposing a decision-making model using analytical hierarchy process and fuzzy expert system for prioritizing industries in installation of combined heat and power systems. Expert Syst. Appl. 2012, 39, 1124–1133. [Google Scholar] [CrossRef]

- Chiu, W.Y.; Lee, Y.D.; Lin, T.Y. Performance evaluation criteria for personal trainers: An analytical hierarchy process approach. Soc. Behav. Personal. 2010, 38, 895–906. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; RWS Publications: Pittsburgh, PA, USA, 1998. [Google Scholar]

- Csutora, R.; Buckley, J.J. Fuzzy hierarchical analysis: The lambda-max Method. Fuzzy Sets Syst. 2001, 120, 181–195. [Google Scholar] [CrossRef]

- Anagnostopoulos, K.P.; Gratziou, M.; Vavatsikos, A.P. Using the Fuzzy Analytic Hierarchy Process for Selecting Wastewater Facilities at Prefecture Level. Eur. Water 2007, 19, 15–24. [Google Scholar]

- Klir, G.J.; Folger, T.A. Fuzzy Sets, Uncertainty, and Information; Prentice-Hall of India Pvt. Ltd.: New Delhi, India, 1988. [Google Scholar]

- Dağdeviren, M.; Yüksel, İ. Developing a fuzzy analytic hierarchy process (AHP) model for behavior-based safety management. Inform. Sci. 2008, 178, 1717–1733. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).