Sustainable Proposal for Plant-Based Cementitious Composites, Evaluation of Their Mechanical, Durability and Comfort Properties

Abstract

1. Introduction

2. Materials and Mixtures

2.1. Cementitious Materials

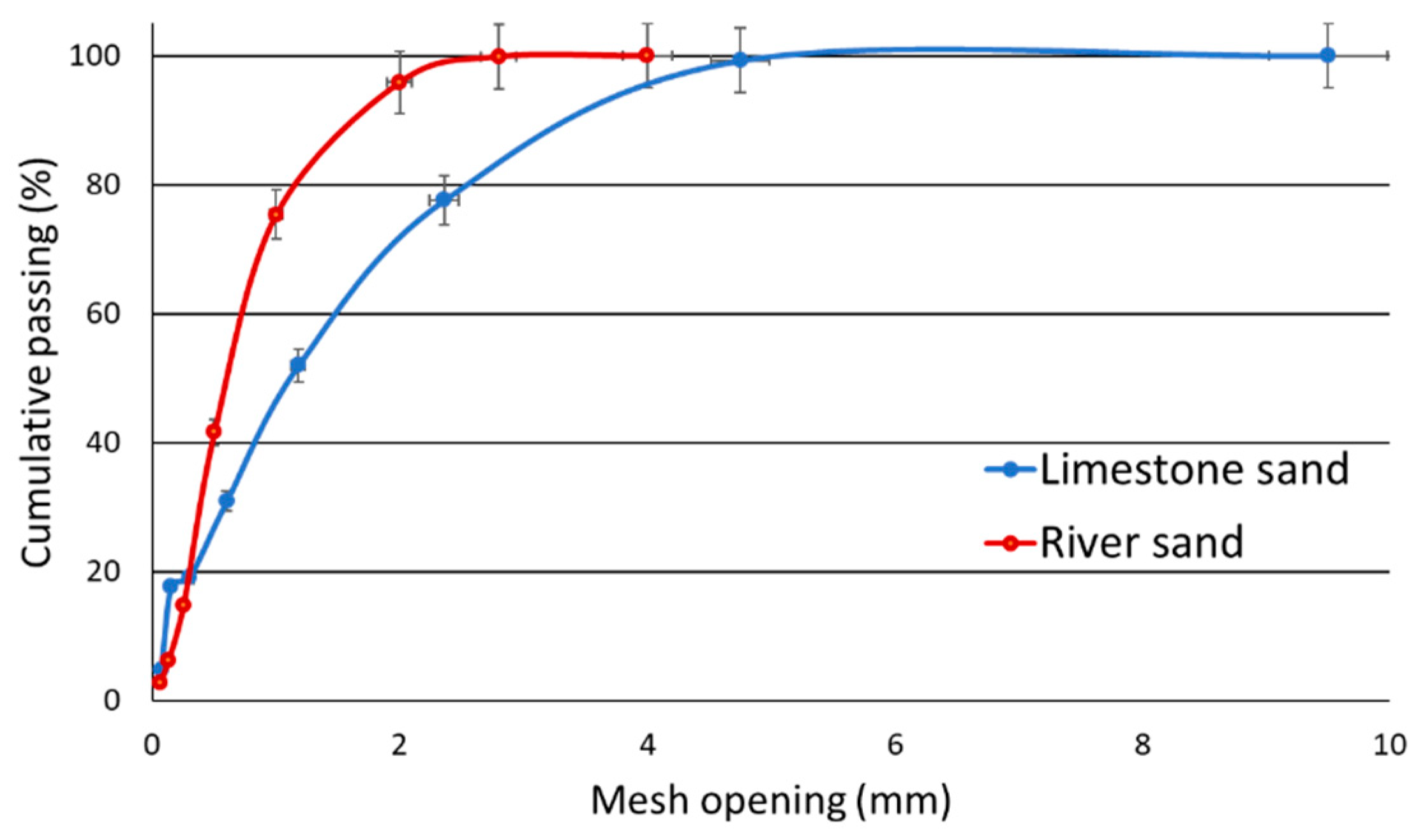

2.2. Aggregates

2.3. Organic Materials

2.4. Composition of the Mixtures

3. Experimental Procedure

3.1. Testing of LFC and FFC Specimens

3.2. Testing of WSC and HSC Specimens

4. Analysis and Discussion of the Results

4.1. Results of LFC and FFC Specimens

4.1.1. Flexural Strength

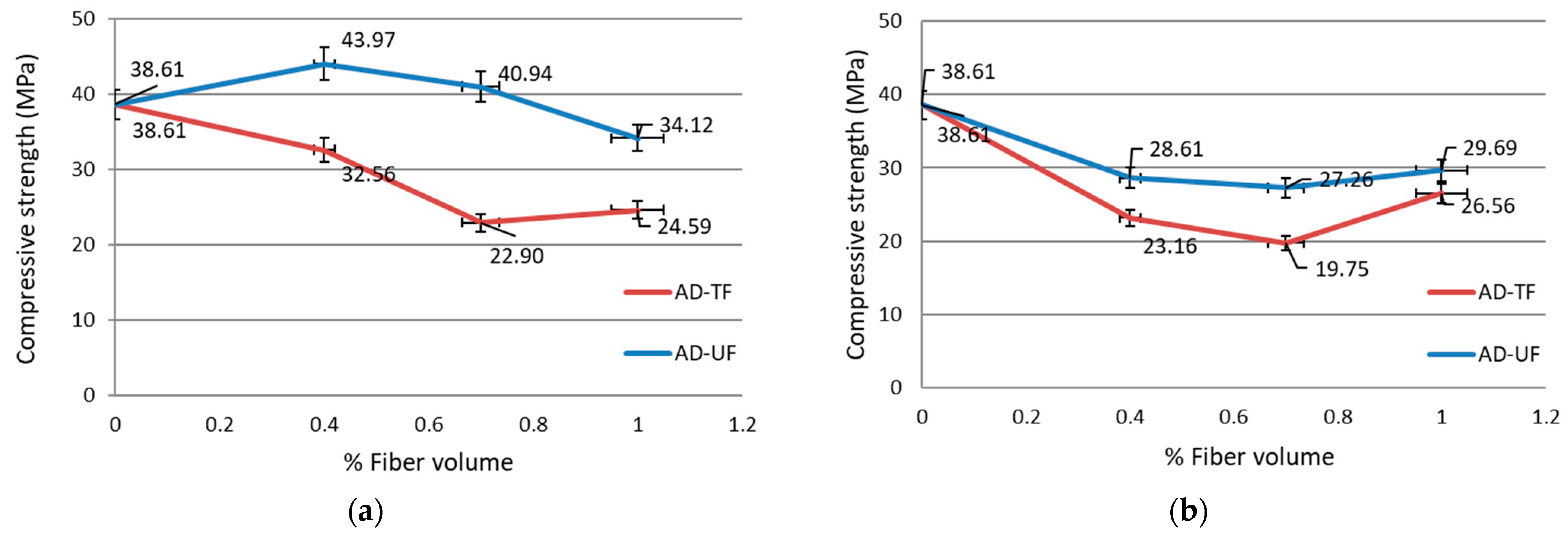

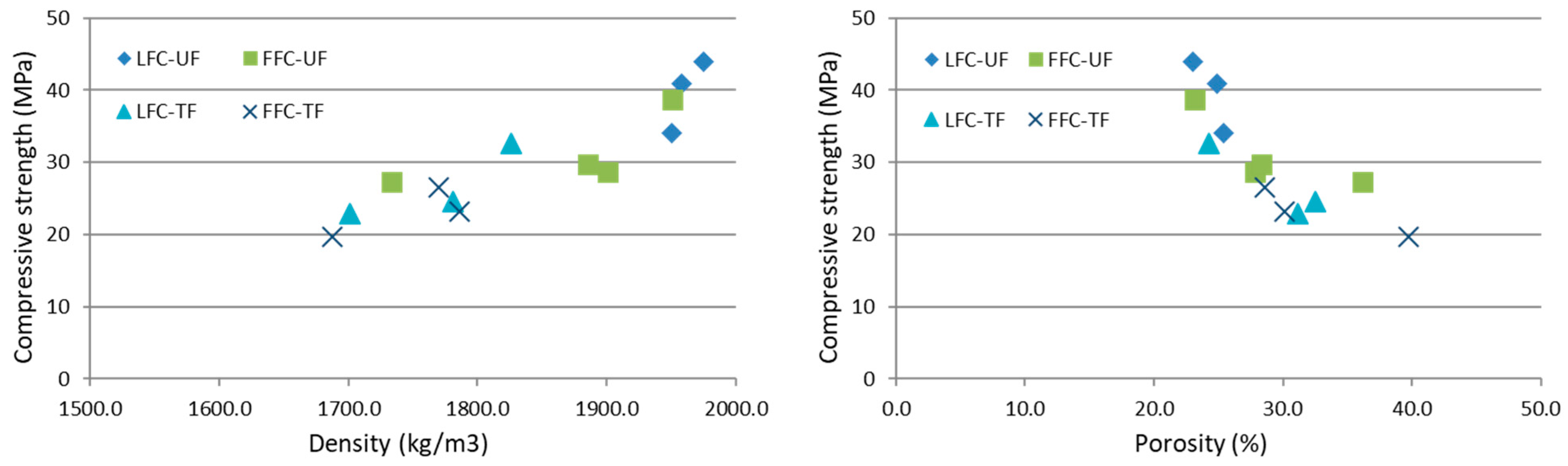

4.1.2. Compressive Strength

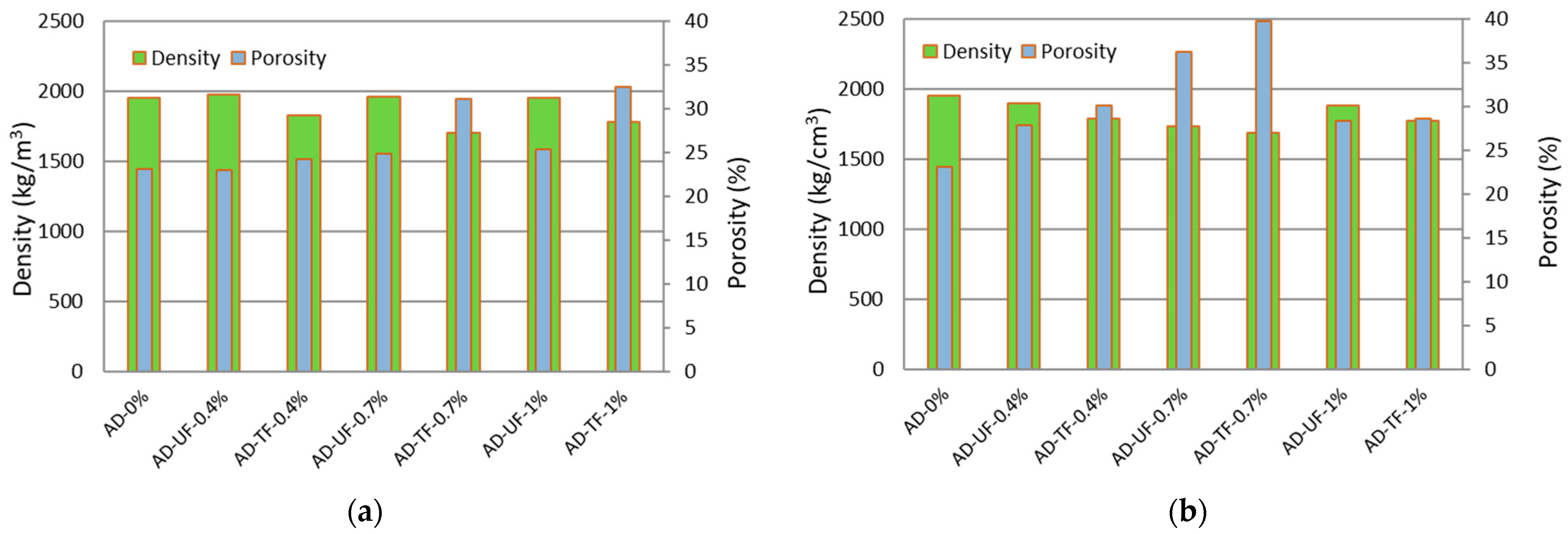

4.1.3. Porosity and Density

4.1.4. Microstructure of LFC and FFC with Deterioration

4.2. Results of WSC and HSC Specimens

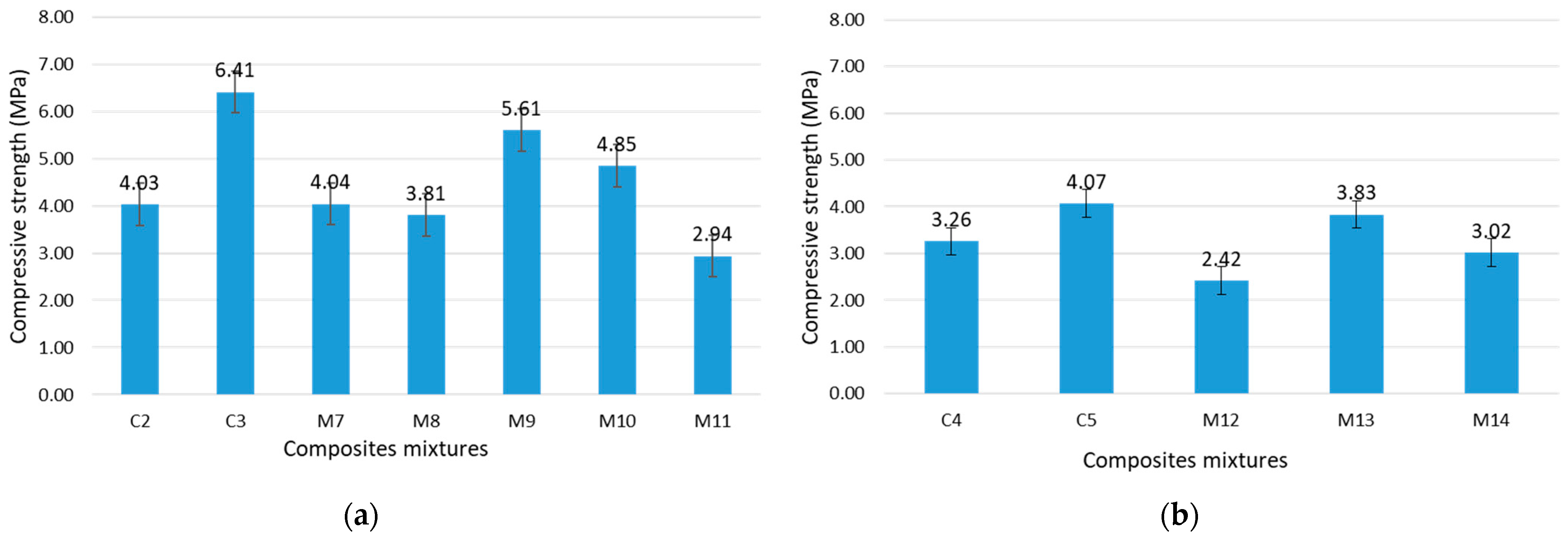

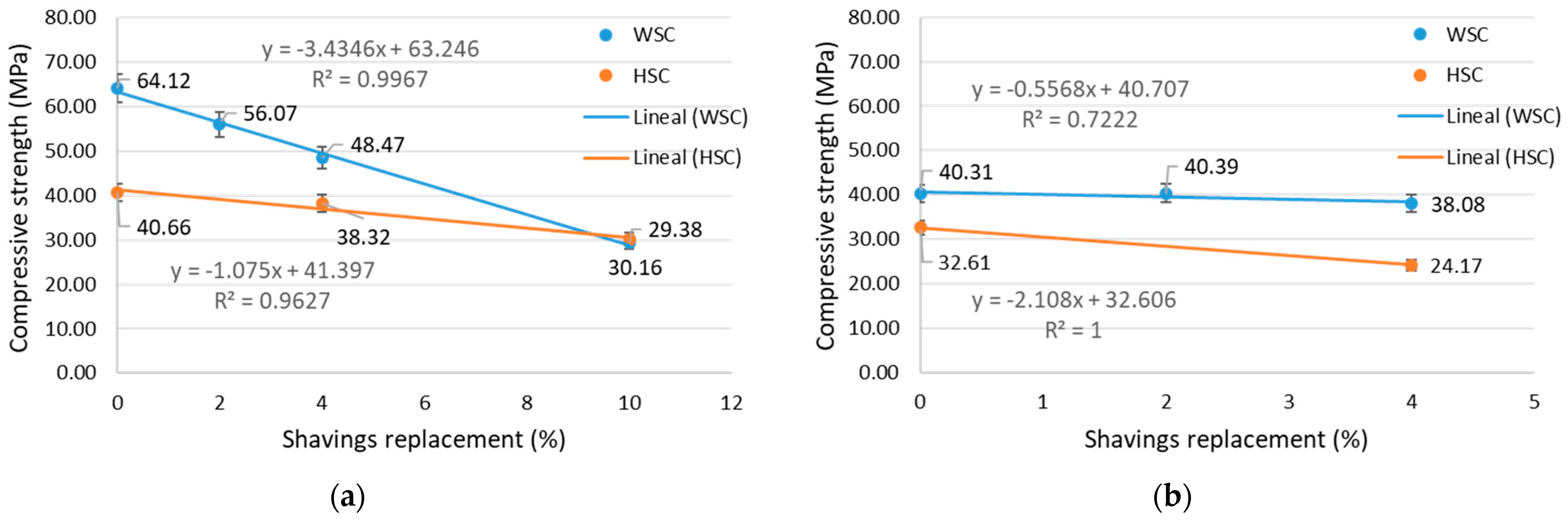

4.2.1. Compressive Strength

4.2.2. Density

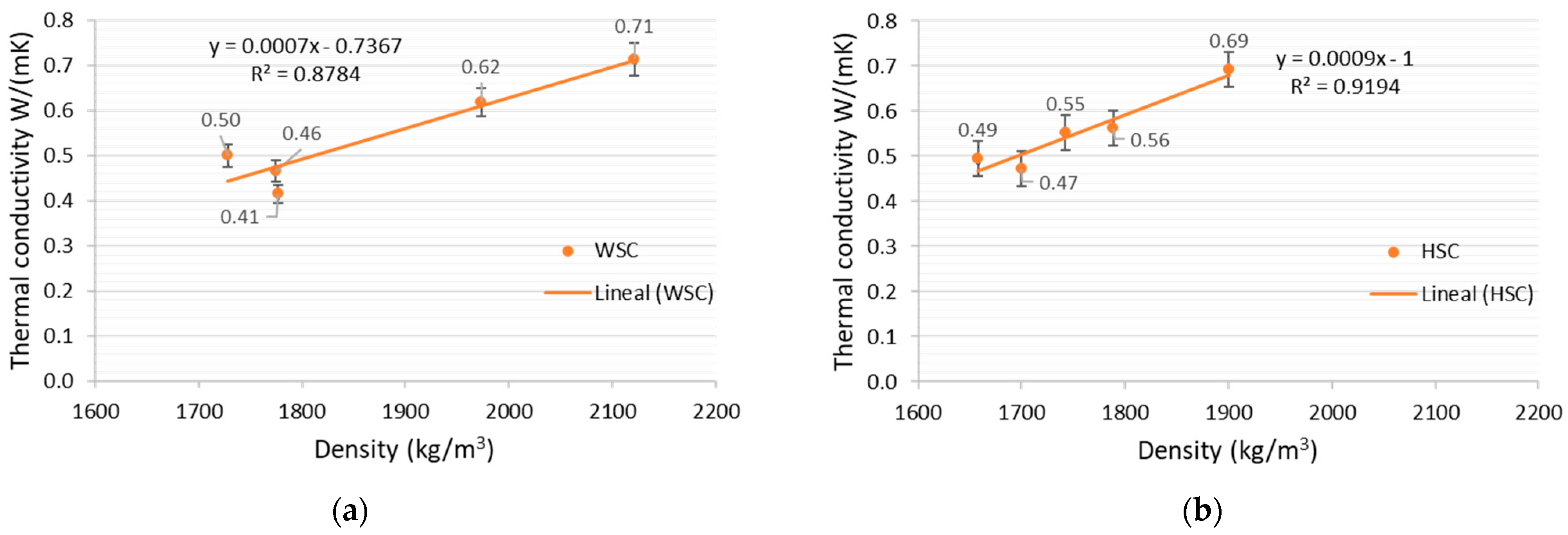

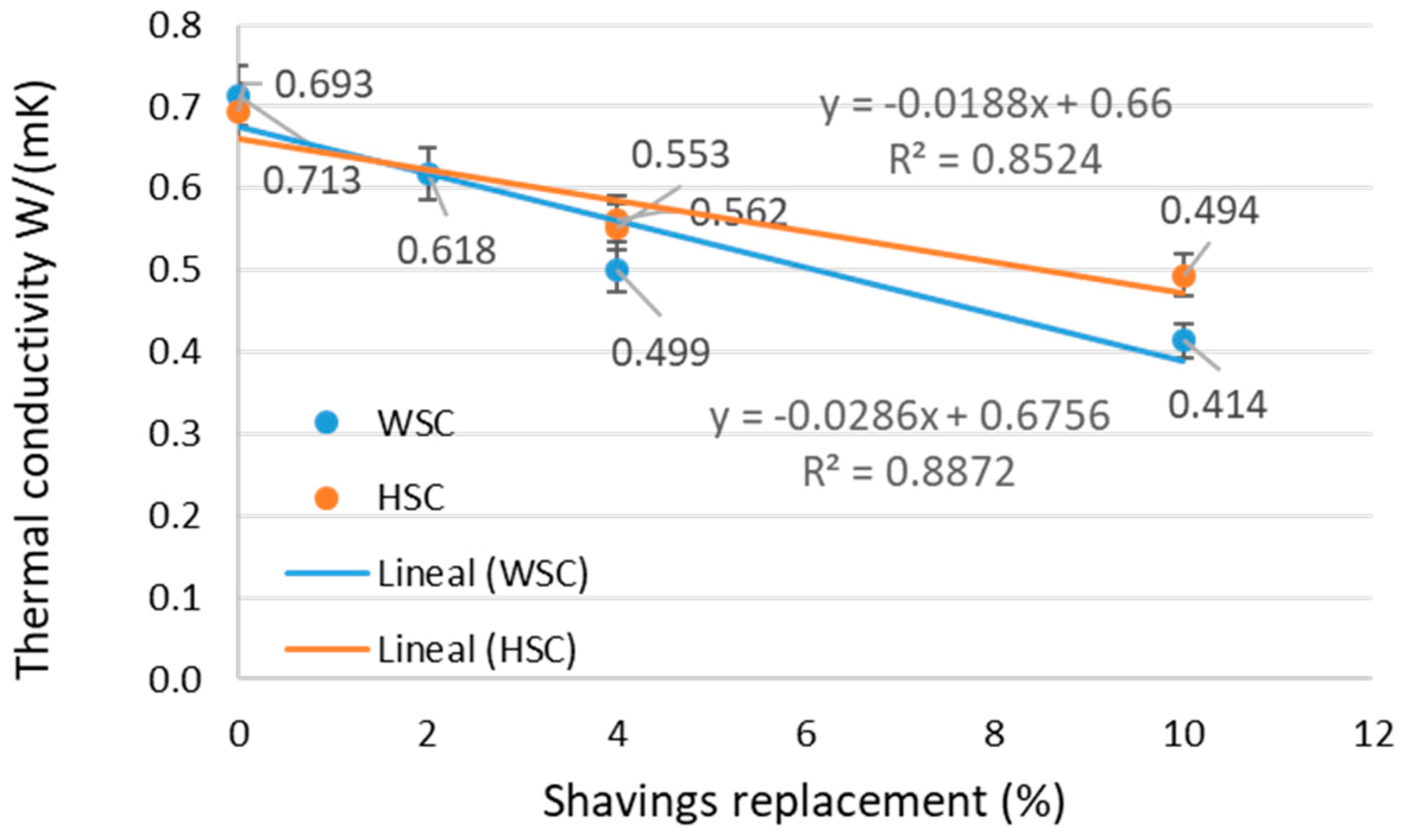

4.2.3. Thermal Conductivity

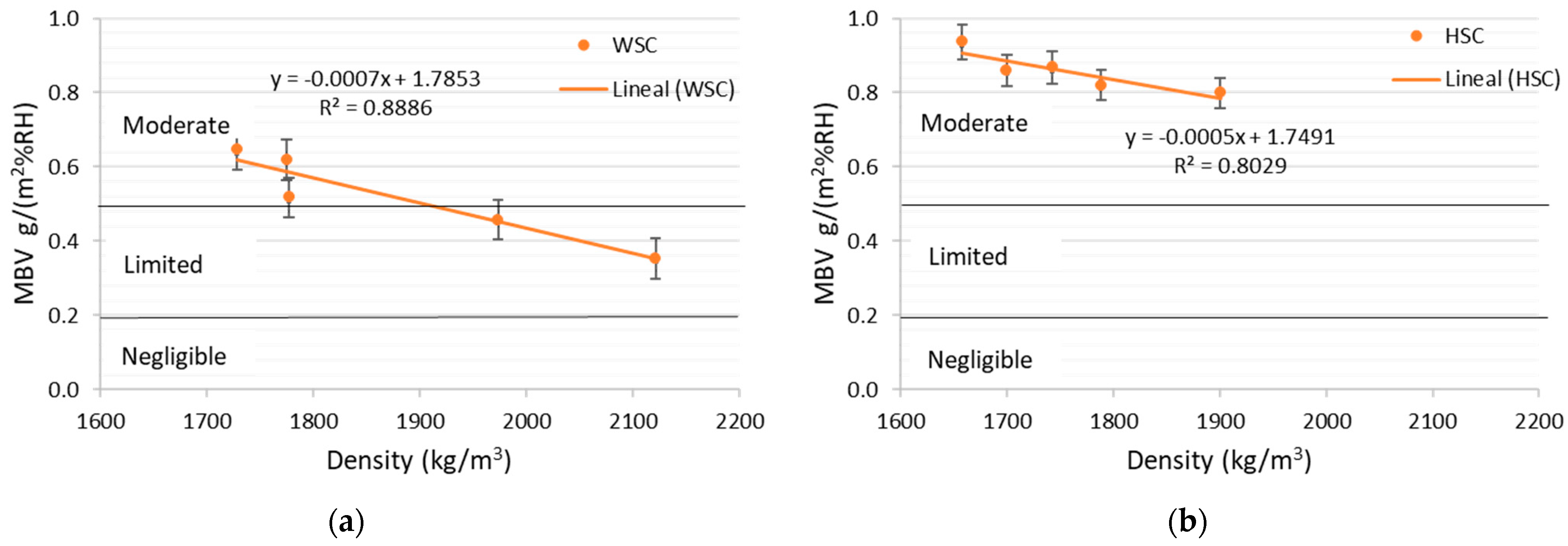

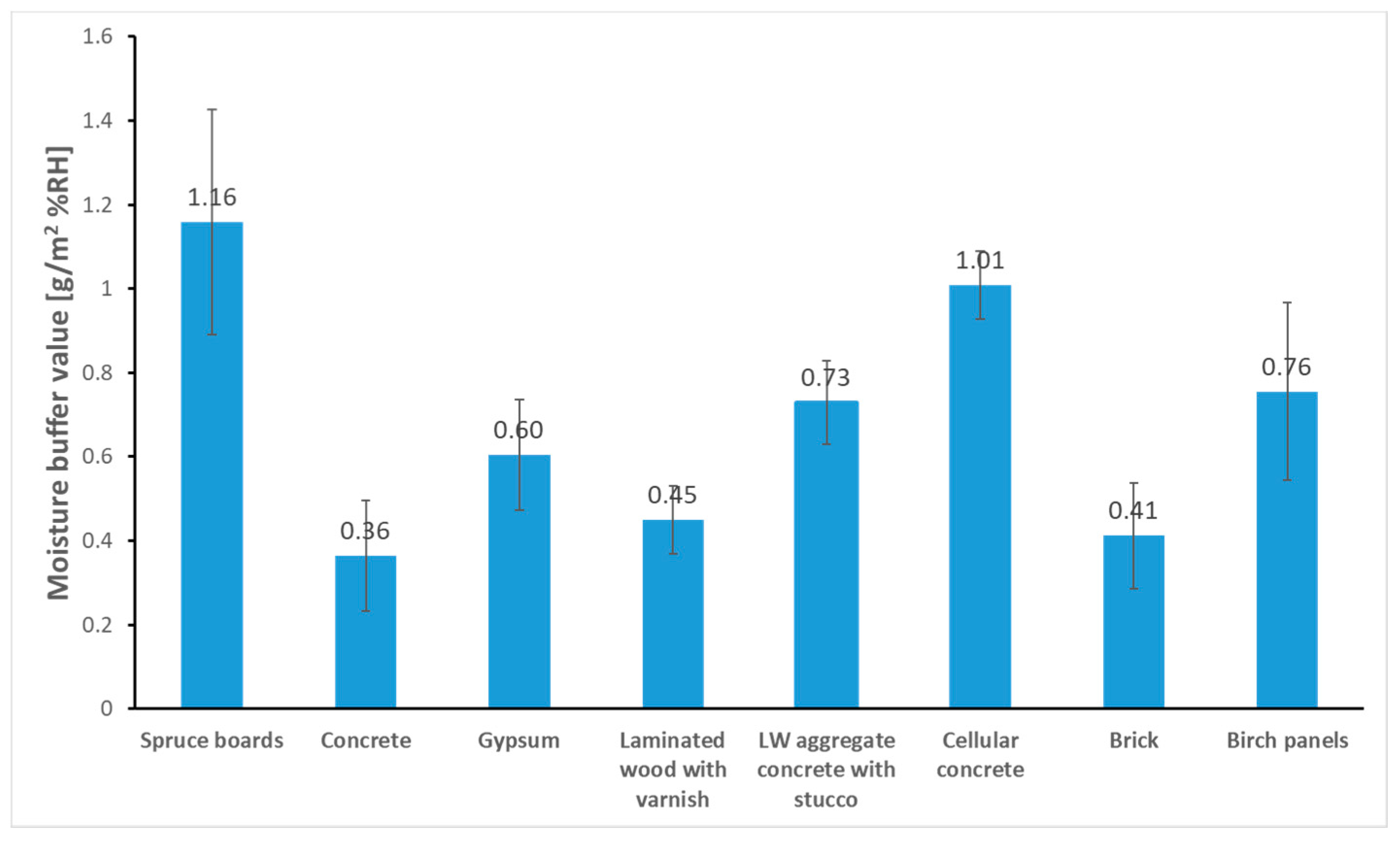

4.2.4. Moisture Buffering Value (MBV)

4.2.5. Water Vapor Permeability

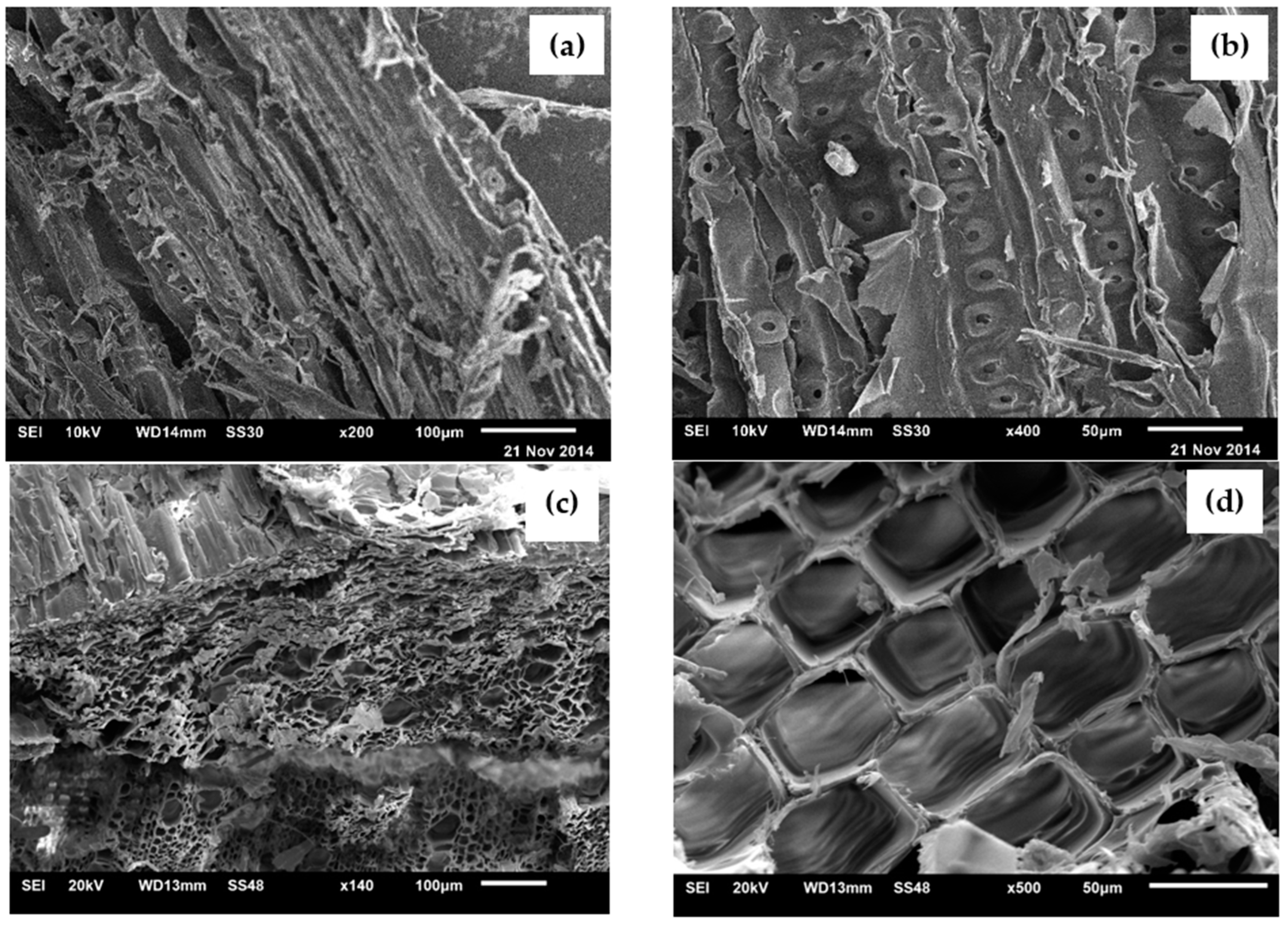

4.2.6. Microstructures of WS and HS

5. Conclusions

- (1)

- LFC and FFC with wax treatment on the fibers had an adverse effect on flexural strength; on the other hand, untreated fibers and those with accelerated deterioration showed better mechanical behavior, since they had an increase in flexural strength with respect to the control of 38% and 19%, respectively, for a Vf = 0.4%. Flexural and compressive strength decreased with increasing Vf. Although the fibers may not improve the flexural strength still they contribute to reducing the brittleness of the material by allowing performance to be maintained after the first cracks appear.

- (2)

- Porosity increases while density decreases when there is the presence of fibers in the matrix. The FFC presented higher porosity than LFC, which could be due to the higher porosity of the FF; in addition, the agglomeration shown in the micrographs is evidence that the FF does not have a uniform distribution within the matrix, and this could cause larger voids in the matrix, which influenced the low flexural and compressive strength shown by the FFC.

- (3)

- Micrographs of LFC and FFC with accelerated deterioration showed no signs of fiber embrittlement in any case, even in the untreated fibers. The failure mode for the untreated LF was the rupture type and with treatment was the pull-out type, which explains the flexural and compressive behavior of the composites.

- (4)

- The microstructure of WS and HS had a significant effect on all physical and mechanical properties of the composites. The high porosity influenced the experimental results obtained since it decreased the compressive strength and bulk density; however, for the thermal conductivity, hygroscopicity, and vapor resistance, it showed a behavior in most cases better than the controls that did not have bio-aggregates.

- (5)

- The incorporation of WS and HS was important in improving the hygrothermal properties of the composites. On the other hand, WSC and HSC showed reductions in thermal conductivity values of 43% and 31%, respectively, with respect to the controls without bio-aggregates. These results are comparable with those established in the current regulations for low conductivity or insulating materials. The WSC and HSC are classified in the moderate category according to the MBV classification, and in comparison with values established for other materials with respect to the efficiency of moisture regulation, the HSC with the highest volume of bio-aggregate (10%); the MBV values are of the order of cellular concrete.

- (6)

- Although the results demonstrate the positive effects of using vegetable raw materials as reinforcement or aggregate in cementitious matrices, future research should focus on the variability of the raw materials by incorporating local agricultural residues and on the long-term durability of the developed composites considering the incompatibility that may exist on the use of natural fibers in alkaline environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Department of Economic and Social Affairs, Population Division. World Population Prospects 2022: Summary of Results; United Nations Publication: New York, NY, USA, 2022. [Google Scholar]

- Silva, F.D.A.; Mobasher, B.; Filho, R.T. Cracking mechanisms in durable sisal fiber reinforced cement composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- García, G.A. Energía en Edificaciones. Rev. Mex. Física 2013, 59, 44–51. [Google Scholar]

- Agudelo, H.A.; Hernández, A.V.; Cardona, D.A.R. Sostenibilidad: Actualidad y necesidad en el sector de la construcción en Colombia. Gestión Y Ambiente 2012, 15, 105–118. [Google Scholar]

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Berger, S.; Caud, N.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; et al. IPCC: Summary for Policymakers. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2021; Volume 32. [Google Scholar]

- Becchio, C.; Corgnati, S.P.; Kindinis, A.; Pagliolico, S. Improving environmental sustainability of concrete products: Investigation on MWC thermal and mechanical properties. Energy Build 2009, 41, 1127–1134. [Google Scholar] [CrossRef]

- Rosas-Díaz, F.; García-Hernández, D.G.; Mendoza-Rangel, J.M.; Terán-Torres, B.T.; Galindo-Rodríguez, S.A.; Juárez-Alvarado, C.A. Development of a Portland Cement-Based Material with Agave salmiana Leaves Bioaggregate. Materials 2022, 15, 6000. [Google Scholar] [CrossRef] [PubMed]

- Mora, E.P. Life cycle, sustainability and the transcendent quality of building materials. Build. Environ. 2007, 42, 1329–1334. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T.; Selke, S.E.; Harte, B.R.; Hinrichsen, G. Natural Fibers, Biopolymers, and Biocomposites; Taylor & Francis Group: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Krishna, N.K.; Prasanth, M.; Gowtham, R.; Karthic, S.; Mini, K.M. Enhancement of properties of concrete using natural fibers. Mater. Today Proc. 2018, 5, 23816–23823. [Google Scholar] [CrossRef]

- Amziane, S.; Sonebi, M. Overview on Biobased Building Material made with plant aggregate. RILEM Tech. Lett. 2016, 1, 31. [Google Scholar] [CrossRef]

- Mohammadkazemi, F.; Doosthoseini, K.; Ganjian, E.; Azin, M. Manufacturing of bacterial nano-cellulose reinforced fiber-cement composites. Constr. Build. Mater. 2015, 101, 958–964. [Google Scholar] [CrossRef]

- Mythili, R.; Venkatachalam, P.; Subramanian, P.; Uma, D. Characterization of bioresidues for biooil production through pyrolysis. Bioresour. Technol. 2013, 138, 71–78. [Google Scholar] [CrossRef]

- Cury R, K.; Aguas M, Y.; Martinez M, A.; Olivero V, R.; Chams Ch, L. Residuos agroindustriales su impacto, manejo y aprovechamiento. Rev. Colomb. De Cienc. Anim.—RECIA 2017, 9, 122. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Restrepo, S.M.V.; Arroyave, G.J.P.; Vásquez, D.H.G. Uso de Fibras Vegetales en Materiales Compuestos de Matriz Polimérica: Una Revisión Con Miras a SU Aplicación en El Diseño de Nuevos Productos Use of Vegetable Fibers in Polymer Matrix Composites: A Review. Informador Técnico 2016, 80, 77–86. [Google Scholar] [CrossRef]

- Chabannes, M.; Nozahic, V.; Amziane, S. Design and multi-physical properties of a new insulating concrete using sunflower stem aggregates and eco-friendly binders. Mater. Struct. Constr. 2015, 48, 1815–1829. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- ASTM C150/C150M-2021; Standard Specification for Portland Cement. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2021; Volume I, pp. 1–10.

- UNE-EN 197-1; Cemento. Parte 1. Composición, Especificaciones y Criterios de Conformidad de los Cementos Comunes. Asociación Española de Normalización y Certificación: Madrid, Spain, 2011; pp. 1–38.

- ASTM C-618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2019; pp. 1–4.

- ASTM C-33-18; Standard Specification for Concrete Aggregates. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2018; pp. 1–8.

- NF P18-545; Granulats—Elément de Définition, Conformité et Codification, Normes Nationales et Documents Normatifs Nationaux. Association Française de Normalisation Editions: Paris, France, 2011; pp. 1–11.

- ACI Committe 544.1R-96; State-of-the-Art Report on Fiber Reinforced Concrete. ACI Manual of Concrete Practice. American Concrete Institute: Farmington Hills, MI, USA, 1996; pp. 544.1R-1–544.1R-66.

- Bederina, M.; Marmoret, L.; Mezreb, K.; Khenfer, M.; Bali, A.; Quéneudec, M. Effect of the addition of wood shavings on thermal conductivity of sand concretes: Experimental study and modelling. Constr. Build. Mater. 2007, 21, 662–668. [Google Scholar] [CrossRef]

- Jiang, Y.; Ansell, M.P.; Jia, X.; Hussain, A.; Lawrence, M. Physical characterisation of hemp shiv: Cell wall structure and porosity. Acad. J. Civ. Eng. 2017, 35, 22–28. [Google Scholar]

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2020; pp. 1–4.

- NF-EN 196-1; Méthodes D’essais des Ciments—Partie 1: Détermination des Résistances Mécaniques. Normes Nationales et Documents Normatifs Nationaux. Association Française de Normalisation Editions: Paris, France, 2011; pp. 1–12.

- NF P 18-459; Béton—Essai Pour Béton Durci—Essai de Porosité et de Masse Volumique. Normes Nationales et Documents Normatifs Nationaux. Association Française de Normalisation Editions: Paris, France, 2011; pp. 1–8.

- ASTM C192/C192M-19; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2019; pp. 1–8.

- ASTM C511-21; Standard Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2021; pp. 1–3.

- ASTM C39/C39M-18; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2018; pp. 1–7.

- RILEM-13; Round Robin Test for Hemp Shiv Characterisation: Committee Report of tc—236 Bio-Based Building Materials. Springer: Berlin, Germany, 2013.

- Dresden, L.-M.G. Système de Mesure de Conductivité Thermique; Université Paul Sabatier—Toulouse III: Toulouse, France, 2008. [Google Scholar]

- Peuhkuri, R.H.; Mortensen, L.H.; Hansen, K.K.; Time, B.; Gustavsen, A.; Ojanen, T.; Ahonen, J.; Svennberg, K.; Arfvidsson, J.; Harderup, L.-E. Moisture Buffering of Building Materials; Rode, C., Ed.; BYG Report No. R-127; Technical University of Denmark, Department of Civil Engineering: Lyngby, Denmark, 2005; pp. 1–79. [Google Scholar]

- NF EN ISO 12572:2001-10; Détermination des Propriétés de Transmission de la Vapeur D’eau. Norme Fracaise—European Norme: Association Française de Normalisation Editions: Paris, France, 2010; pp. 1–33.

- Juarez, C.; Duran, A.; Valdez, P.; Fajardo, G. Performance of “Agave lecheguilla” natural fiber in portland cement composites exposed to severe environment conditions. Build. Environ. 2007, 42, 1151–1157. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolín on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 342–400. [Google Scholar] [CrossRef]

- Sabathier, V.; Magniont, C.; Escadeillas, G.; Juarez, C.A. Flax and hemp fibre reinforced pozzolanic matrix: Evaluation of impact of time and natural weathering. Eur. J. Environ. Civ. Eng. 2016, 21, 1403–1417. [Google Scholar] [CrossRef]

- Melo Filho, J.D.A.; Silva, F.D.A.; Filho, R.T. Degradation kinetics and aging mechanisms on sisal fiber cement composite systems. Cem. Concr. Compos. 2013, 40, 30–39. [Google Scholar] [CrossRef]

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Sezer, G.İ.; Ramyar, K. Comparison of fly ash, silica fume and metakaolin from mechanical properties and durability performance of mortar mixtures view point. Constr. Build. Mater. 2014, 70, 17–25. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Wang, L. Properties of hemp fibre reinforced concrete composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 497–505. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Abdullahi, M.; Hoong, C.K. Statistical models for concrete containing wood chipping as partial replacement to fine aggregate. Constr. Build. Mater. 2014, 55, 13–19. [Google Scholar] [CrossRef]

- Coatanlem, P.; Jauberthie, R.; Rendell, F. Lightweight wood chipping concrete durability. Constr. Build. Mater. 2006, 20, 776–781. [Google Scholar] [CrossRef]

- NMX-AA-164-SCFI-2013; Edificación Sustentable: Criterios Y Requerimientos Ambientales Mínimos. Normas Mexicanas, Secretaría de Economía: Cd. de México, Mexico, 2013; pp. 1–158.

- Uysal, H.; Demirbog, R. The effects of different cement dosages, slumps, and pumice aggregate ratios on the thermal conductivity and density of concrete. Cem. Concr. Res. 2004, 34, 845–848. [Google Scholar] [CrossRef]

- Lagouin, M.; Magniont, C.; Sénéchal, P.; Moonen, P.; Aubert, J.-E.; Laborel-préneron, A. Influence of types of binder and plant aggregates on hygrothermal and mechanical properties of vegetal concretes. Constr. Build. Mater. 2019, 222, 852–871. [Google Scholar] [CrossRef]

- Haba, B.; Agoudjil, B.; Boudenne, A.; Benzarti, K. Hygric properties and thermal conductivity of a new insulation material for building based on date palm concrete. Constr. Build. Mater. 2017, 154, 963–971. [Google Scholar] [CrossRef]

- Bennai, F.; Issaadi, N.; Abahri, K.; Belarbi, R.; Tahakourt, A. Experimental characterization of thermal and hygric properties of hemp concrete with consideration of the material age evolution. Heat Mass Transf. 2017, 54, 1189–1197. [Google Scholar] [CrossRef]

- Thoemen, H.; Irle, M.; Sernek, M. Wood-Based Panels an Introduction for Specialists; Brunel University Press: London, UK, 2010; ISBN 978-1-902316-82-6. [Google Scholar]

- Ansell, M.P. (Ed.) 1—Wood microstructure—A cellular composite. In Wood Composites; Woodhead Publishing Ltd.: Cambridge, UK, 2015; pp. 3–26. [Google Scholar] [CrossRef]

- Jiang, Y.; Lawrence, M.; Ansell, M.P.; Hussain, A. Cell wall microstructure, pore size distribution and absolute density of hemp shiv. R. Soc. Open Sci. 2018, 5, 171945. [Google Scholar] [CrossRef] [PubMed]

| Material | Chemical Composition (%) | |||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | |

| Cement Type III | 14.99 | 4.26 | 3.15 | 68.11 | 1.23 | 0.37 |

| Cement Type II | 15.20 | 3.82 | 2.12 | 59.90 | - | - |

| Fly ash | 59.95 | 25.98 | 4.92 | 2.66 | 0.12 | - |

| Metakaolin | 65.90 | 25.10 | 4.26 | 1.63 | 0.10 | - |

| Bulk Density kg/m3 | Dry Weight kg/m3 | Surface Dry Saturated Weight kg/m3 | Water Absorption % | Specific Weight kg/m3 | Water Content % | Fineness Modulus | |

|---|---|---|---|---|---|---|---|

| Limestone | 1651 | 2600 | 2617 | 1.60 | 2600 | 0.10 | 2.71 |

| River | 1660 | 2628 | 2660 | 1.54 | 2660 | 0.15 | 2.70 |

| Material | Physical and Mechanical Properties | ||||||

|---|---|---|---|---|---|---|---|

| Diameter/Width mm | Average Length mm | Absorption % | Specific Weight | Tensile Strength MPa | Elongation % | Porosity % | |

| Lechuguilla | 0.16–0.26 | 45 | 92.3 | 1.38 | 275–627 | 2.0–2.5 | 21–25 |

| Flax | 0.009–0.049 | 45 | 120.0 | 1.54 | 1015 | 1.8–2.0 | 3–21 |

| Wood | 1.0 | 4.1 | 180.0 | 1.05 | 710 | 2.0–3.0 | 56 |

| Hemp | 1.8 | 7.6 | 105.0 | 1.50 | 900 | 1.6–1.8 | 51 |

| Mixture | Composite | LF | FF | WS | HS | MK | FA |

|---|---|---|---|---|---|---|---|

| M1 | LFC | 0.4 | 15 | ||||

| M2 | 0.7 | 15 | |||||

| M3 | 1.0 | 15 | |||||

| M4 | FFC | 0.4 | 15 | ||||

| M5 | 0.7 | 15 | |||||

| M6 | 1.0 | 15 | |||||

| M7 | WSC | 2.0 | |||||

| M8 | 4.0 | ||||||

| M9 | 2.0 | 20 | |||||

| M10 | 4.0 | 20 | |||||

| M11 | 10.0 | 20 | |||||

| M12 | HSC | 4.0 | |||||

| M13 | 4.0 | 20 | |||||

| M14 | 10.0 | 20 |

| Mixture | Mix Proportion (LFC–FFC) (kg/m3) | |||||

| Type II Cement | Water | River Sand | Metakaolin | W/C Ratio | Slump (mm) | |

| C-1 | 383 | 169 | 1350 | 68 | 0.50 | 50 |

| Mixture | Mix Proportion (WSC) (kg/m3) | |||||

| Type III Cement | Water | Limestone Sand | Fly Ash | W/C Ratio | Slump (mm) | |

| C-2 | 150 | 150 | 1928 | 0 | 1.00 | 72 |

| C-3 | 150 | 150 | 1893 | 30 (20%) | 1.00 | 75 |

| Mixture | Mix Proportion (HSC) (kg/m3) | |||||

| Type II Cement | Water | River Sand | Metakaolin | W/C Ratio | Slump (mm) | |

| C-4 | 150 | 150 | 1973 | 0 | 1.00 | 70 |

| C-5 | 150 | 150 | 1941 | 30 (20%) | 1.00 | 73 |

| Composite | Mixtures | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-2 | C-3 | C-4 | C-5 | M7 | M8 | M9 | M10 | M11 | M12 | M13 | M14 | |

| WSC | 2121 | 2052 | 1786 | 1777 | 1775 | 1792 | 1728 | |||||

| HSC | 1900 | 1699 | 1788 | 1742 | 1658 | |||||||

| MBV Practical Class | Minimum MBV Level | Maximum MBV Level |

|---|---|---|

| g/(m2%RH) | ||

| Negligible | 0 | 0.2 |

| Limited | 0.2 | 0.5 |

| Moderate | 0.5 | 1.0 |

| Good | 1.0 | 2.0 |

| Excellent | 2.0 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juárez-Alvarado, C.A.; Magniont, C.; Escadeillas, G.; Terán-Torres, B.T.; Rosas-Diaz, F.; Valdez-Tamez, P.L. Sustainable Proposal for Plant-Based Cementitious Composites, Evaluation of Their Mechanical, Durability and Comfort Properties. Sustainability 2022, 14, 14397. https://doi.org/10.3390/su142114397

Juárez-Alvarado CA, Magniont C, Escadeillas G, Terán-Torres BT, Rosas-Diaz F, Valdez-Tamez PL. Sustainable Proposal for Plant-Based Cementitious Composites, Evaluation of Their Mechanical, Durability and Comfort Properties. Sustainability. 2022; 14(21):14397. https://doi.org/10.3390/su142114397

Chicago/Turabian StyleJuárez-Alvarado, César A., Camille Magniont, Gilles Escadeillas, Bernardo T. Terán-Torres, Felipe Rosas-Diaz, and Pedro L. Valdez-Tamez. 2022. "Sustainable Proposal for Plant-Based Cementitious Composites, Evaluation of Their Mechanical, Durability and Comfort Properties" Sustainability 14, no. 21: 14397. https://doi.org/10.3390/su142114397

APA StyleJuárez-Alvarado, C. A., Magniont, C., Escadeillas, G., Terán-Torres, B. T., Rosas-Diaz, F., & Valdez-Tamez, P. L. (2022). Sustainable Proposal for Plant-Based Cementitious Composites, Evaluation of Their Mechanical, Durability and Comfort Properties. Sustainability, 14(21), 14397. https://doi.org/10.3390/su142114397