Detection Method of Crushing Mouth Loose Material Blockage Based on SSD Algorithm

Abstract

1. Introduction

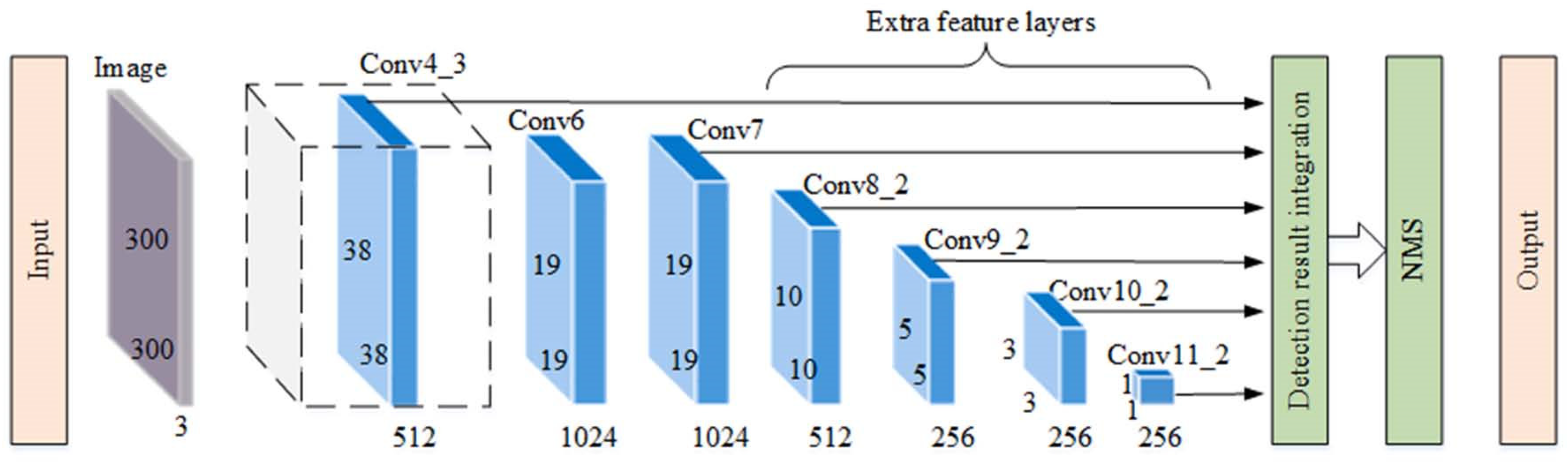

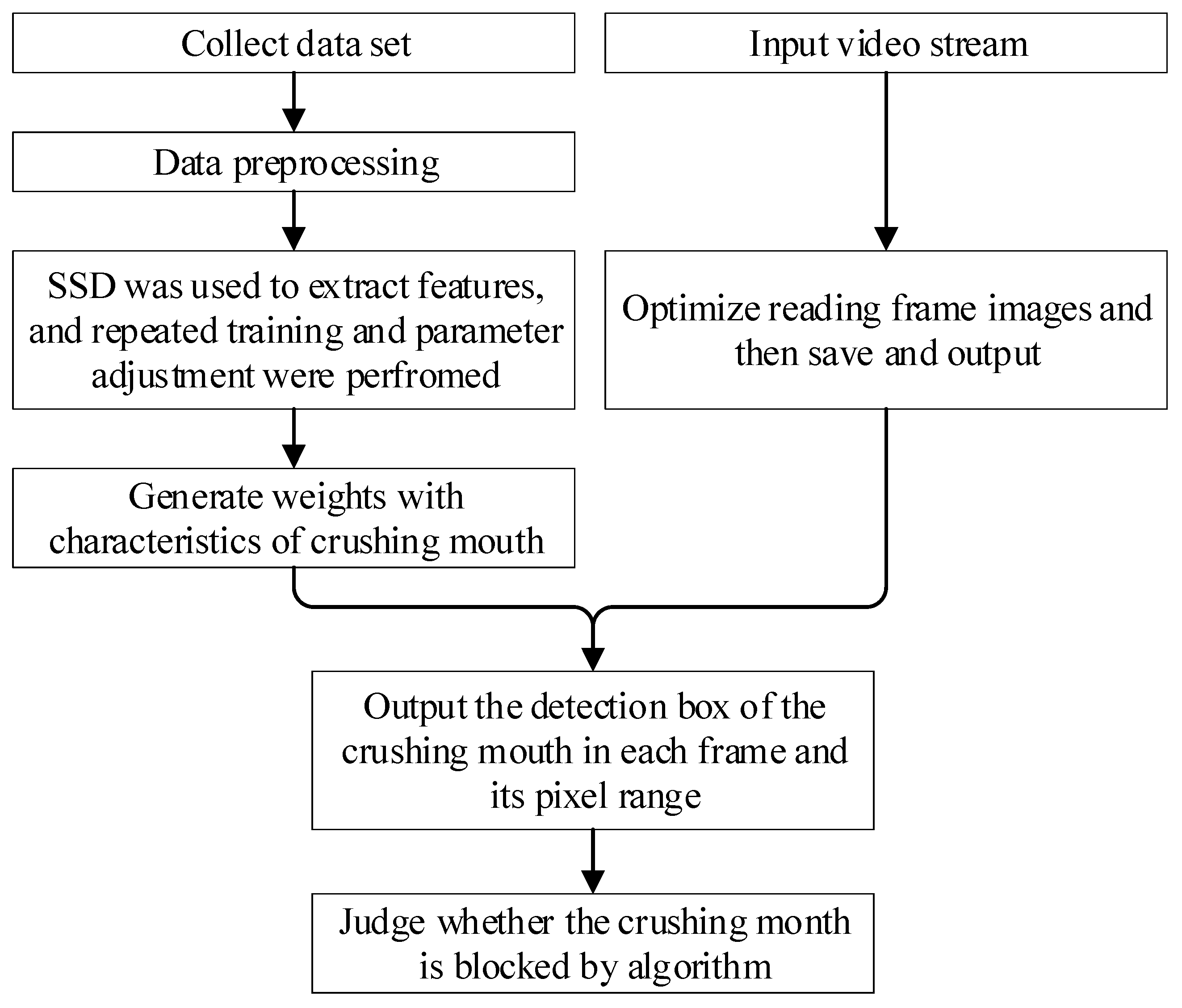

2. SSD Algorithm

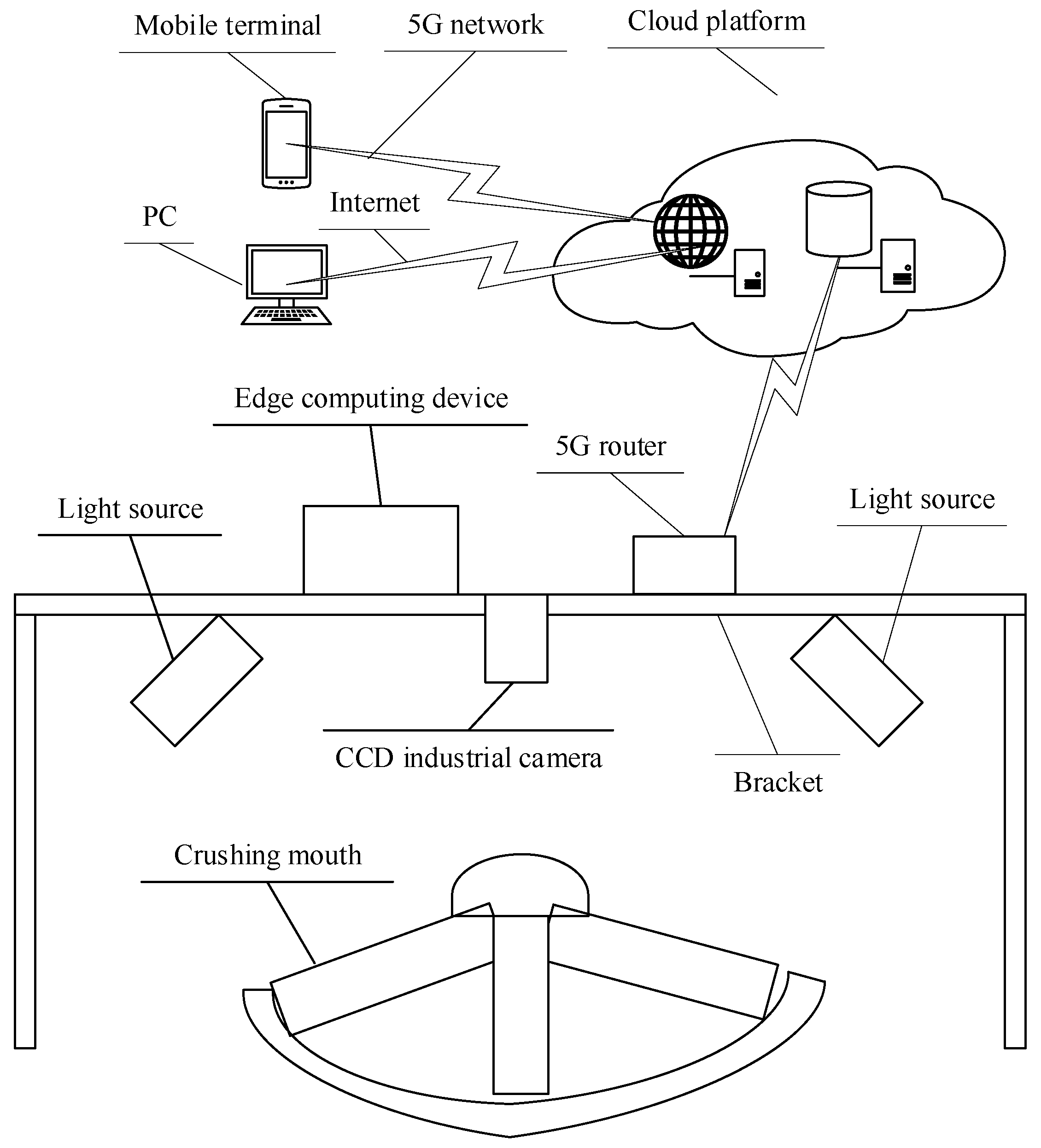

3. Composition of Crushing Mouth Blockage Detection

3.1. System Structure of Crushing Mouth Blockage Detection

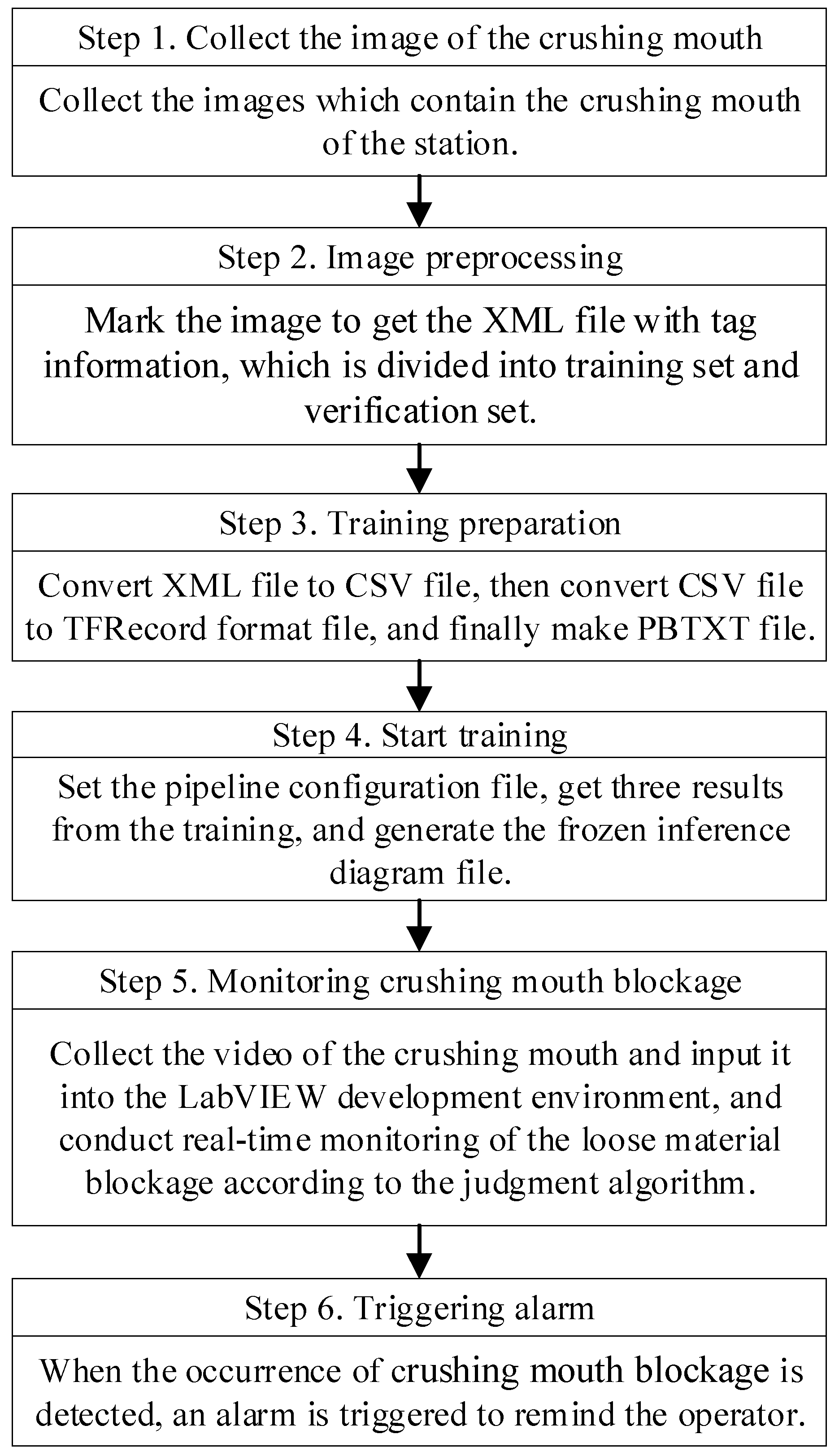

3.2. The Flow Diagram of Crushing Mouth Blockage Detection

4. Data Acquisition and Model Building

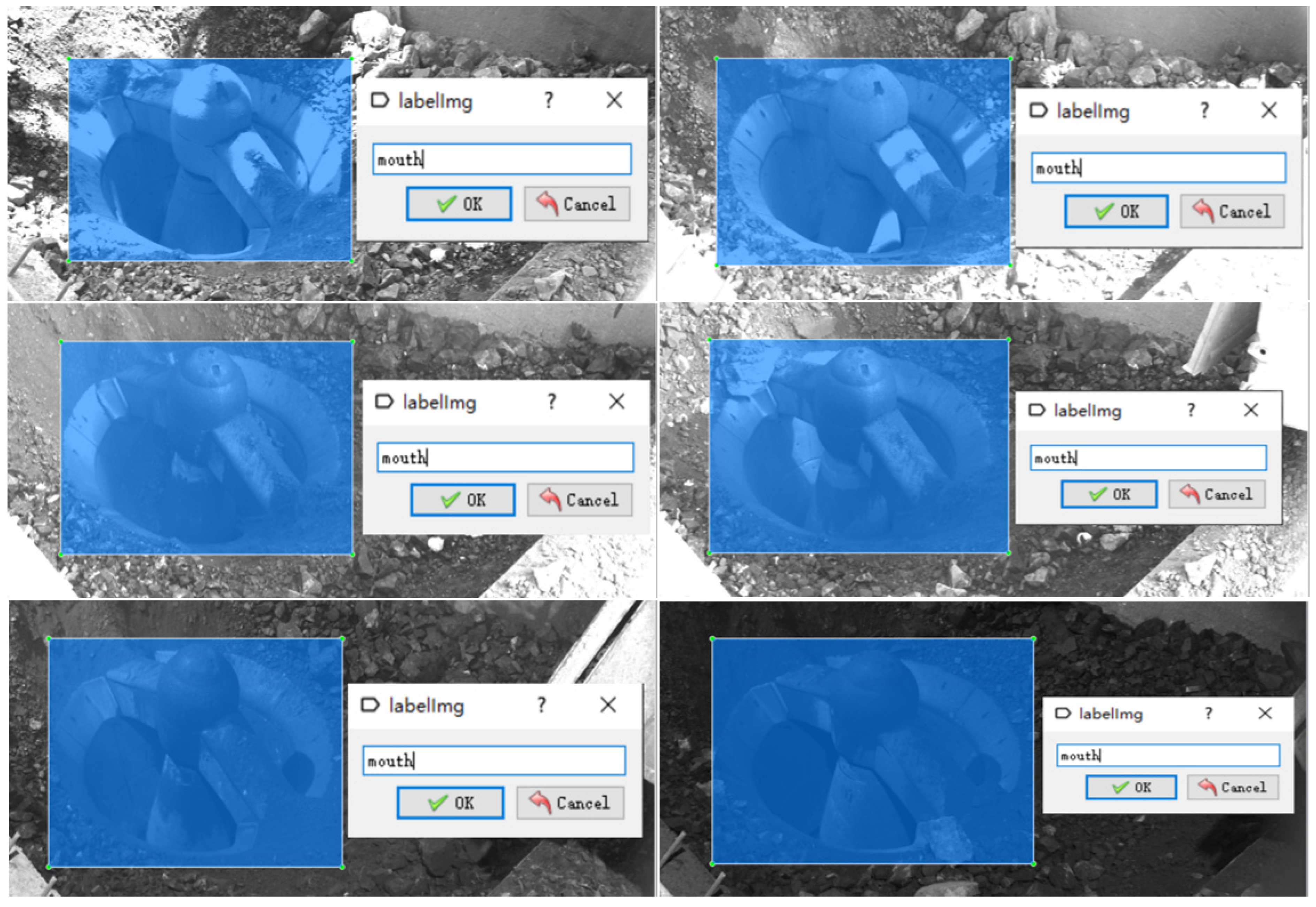

4.1. Collect the Image of the Crushing Mouth

4.2. Image Preprocessing

4.3. Training Preparation

- item {id: 1 name: ‘mouth’};

4.4. Start Training

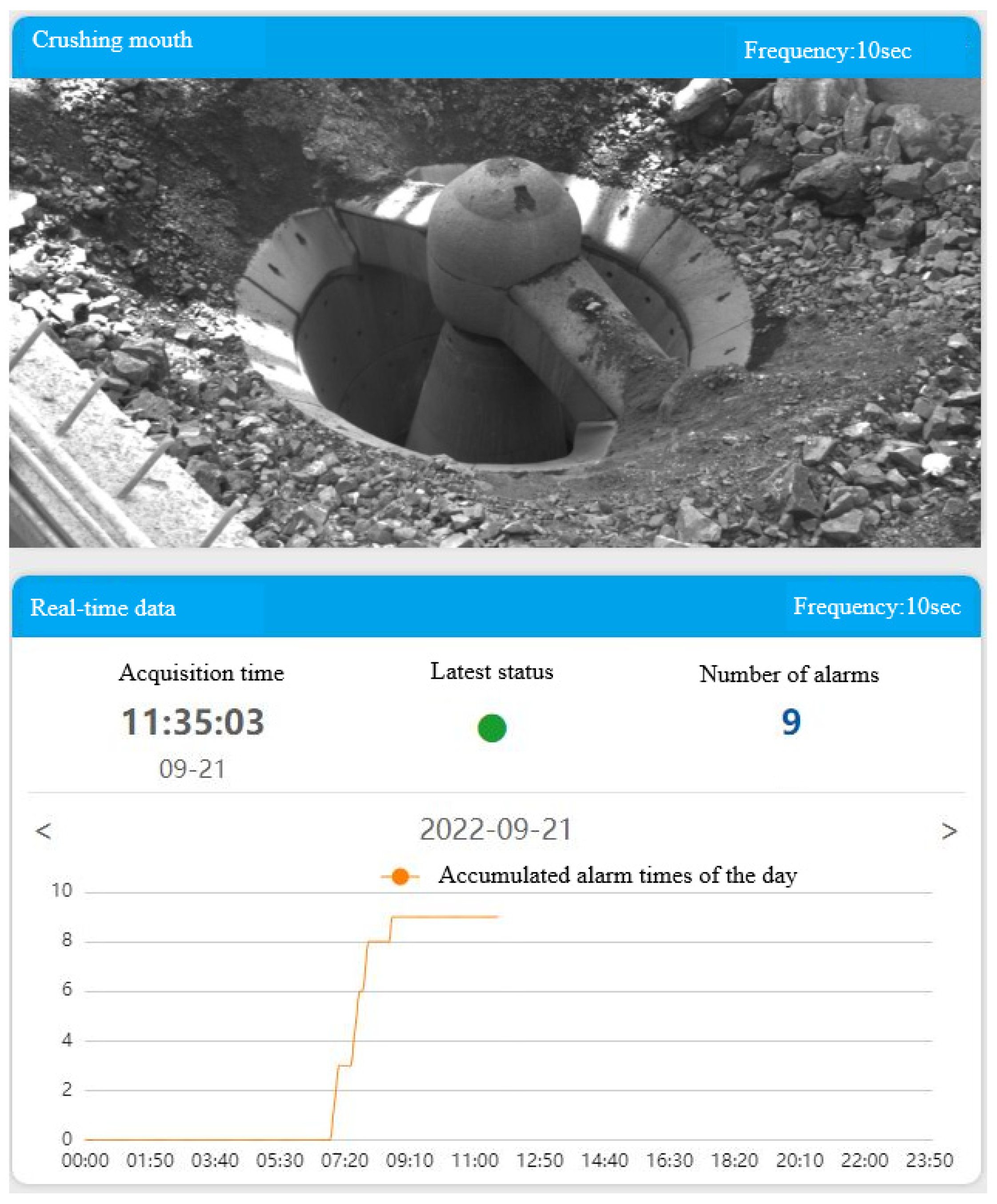

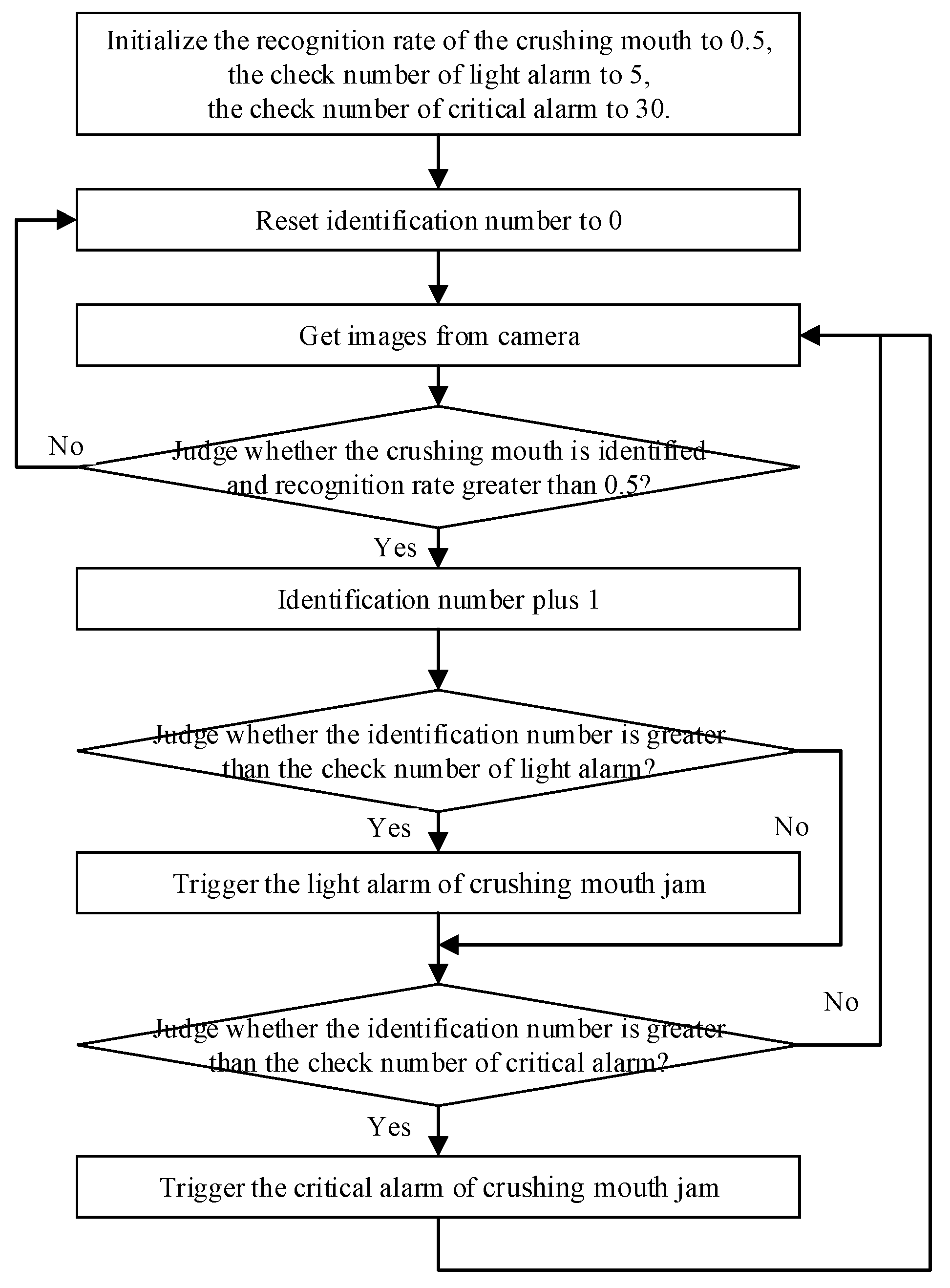

4.5. Monitoring of Crushing Mouth Blockage

4.6. Trigger Alarm

5. Experiment and Results

5.1. Experimental Procedure and Parameters

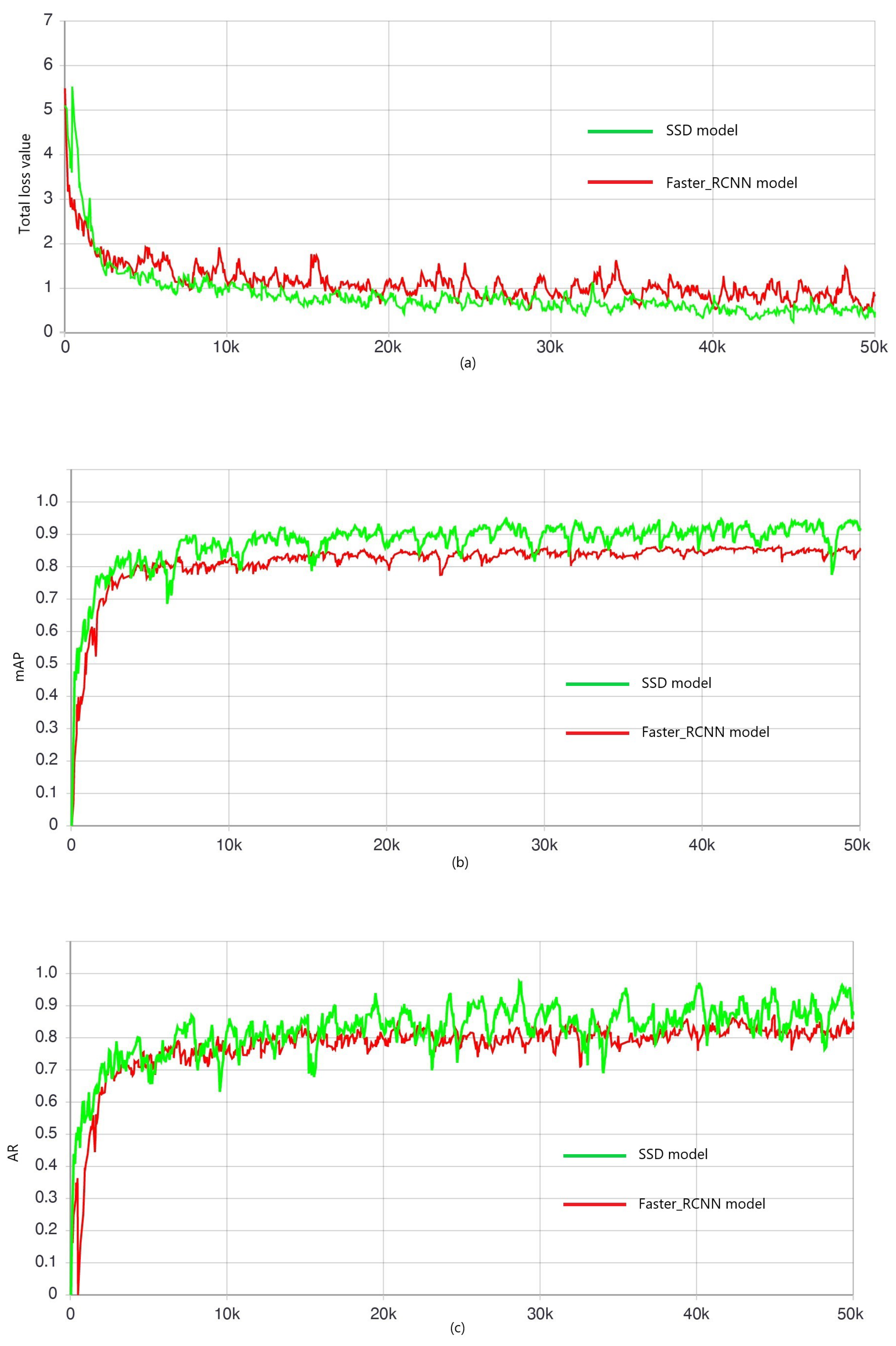

5.2. Experimental Results

6. Discussion

7. Conclusions

- (1)

- This work obtains an automatic crushing mouth blockage identification model by adopting the SSD model with training and verification functions using a series of images. The results indicate that the mAP of the model on the data set reached approximately 0.92. Moreover, compared with the Faster RCNN, the SSD algorithm is more suitable for this research.

- (2)

- This study solves the problem that the traditional method can only identify the crushing mouth blockage by human eyes. Can meet the requirement of continuous video capture in the mine around the clock all year round.

- (3)

- This study is based on MV to detect the crushing mouth blockage, to provide basic support for unattended crushing station.

- (4)

- This study can provide some reference for the identification of tarpaulin in other similar concentrators, and provide support for the construction of dark factory in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Znamenskaya, I.A.; Doroshchenko, I.A.; Sysoev, N.N.; Tatarenkova, D.I. Results of Quantitative Analysis of High-Speed Shadowgraphy of Shock Tube Flows Using Machine Vision and Machine Learning. Dokl. Phys. 2021, 66, 93–96. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, Y.; Deng, F.; Mu, Y.; Zhong, Y.; Jiao, D. Detection of Bubble Defects on Tire Surface Based on Line Laser and Machine Vision. Processes 2022, 10, 255. [Google Scholar] [CrossRef]

- Li, J.; Zhao, B.; Wu, J.; Zhang, S.; Lv, C.; Li, L. Stress-Crack detection in maize kernels based on machine vision. Comput. Electron. Agric. 2022, 194, 106795. [Google Scholar] [CrossRef]

- Mirbod, M.; Ghatari, A.R.; Saati, S.; Shoar, M. Industrial parts change recognition model using machine vision, image processing in the framework of industrial information integration. J. Ind. Inf. Integr. 2022, 26, 100277. [Google Scholar] [CrossRef]

- Dlamini, S.; Kao, C.-Y.; Su, S.-L.; Jeffrey Kuo, C.-F. Development of a real-time machine vision system for functional textile fabric defect detection using a deep YOLOv4 model. Text. Res. J. 2022, 92, 675–690. [Google Scholar] [CrossRef]

- Singh, S.A.; Desai, K.A. Automated surface defect detection framework using machine vision and convolutional neural networks. J. Intell. Manuf. 2022. [Google Scholar] [CrossRef]

- Yang, B.; Zhu, X.; Liu, M.; Lv, Z. Review on the Application of Machine Vision in Defrosting and Decondensation on the Surface of Heat Exchanger. Sustainability 2022, 14, 11606. [Google Scholar] [CrossRef]

- Wang, Y.D.; Blunt, M.J.; Armstrong, R.T.; Mostaghimi, P. Deep learning in pore scale imaging and modeling. Earth-Sci. Rev. 2021, 215, 103555. [Google Scholar] [CrossRef]

- Haghighi, F.; Omranpour, H. Stacking ensemble model of deep learning and its application to Persian/Arabic handwritten digits recognition. Knowl. Based Syst. 2021, 220, 106940. [Google Scholar] [CrossRef]

- Abed, A.K.; Qahwaji, R.; Abed, A. The automated prediction of solar flares from SDO images using deep learning. Adv. Space Res. 2021, 67, 2544–2557. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Sohel, F.; Diepeveen, D.; Laga, H.; Jones, M.G.K. A survey of deep learning techniques for weed detection from images. Comput. Electron. Agric. 2021, 184, 106067. [Google Scholar] [CrossRef]

- Said, O.; Tolba, A. Accurate performance prediction of IoT communication systems for smart cities: An efficient deep learning based solution. Sustain. Cities Soc. 2021, 69, 102830. [Google Scholar] [CrossRef]

- Rohila, V.S.; Gupta, N.; Kaul, A.; Sharma, D.K. Deep learning assisted COVID-19 detection using full CT-scans. Internet Things 2021, 14, 100377. [Google Scholar] [CrossRef]

- Pawar, P.; Ainapure, B.; Rashid, M.; Ahmad, N.; Alotaibi, A.; Alshamrani, S.S. Deep Learning Approach for the Detection of Noise Type in Ancient Images. Sustainability 2022, 14, 11786. [Google Scholar] [CrossRef]

- Al Duhayyim, M.; Mohamed, H.G.; Aljebreen, M.; Nour, M.K.; Mohamed, A.; Abdelmageed, A.A.; Yaseen, I.; Mohammed, G.P. Artificial Ecosystem-Based Optimization with an Improved Deep Learning Model for IoT-Assisted Sustainable Waste Management. Sustainability 2022, 14, 11704. [Google Scholar] [CrossRef]

- Patel, A.K.; Chatterjee, S.; Gorai, A.K. Development of machine vision-based ore classification model using support vector machine (SVM) algorithm. Arab. J. Geosci. 2017, 10, 107. [Google Scholar] [CrossRef]

- Wang, T.; Dong, Z.; Liu, J. Research of Mine Conveyor Belt Deviation Detection System Based on Machine Vision. J. Min. Sci. 2021, 57, 703–712. [Google Scholar] [CrossRef]

- Xiao, B.; Miao, S.; Gao, Q. Quantifying particle size and size distribution of mine tailings through deep learning approach of autoencoders. Powder Technol. 2022, 397, 117088. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, Q.; Luo, H.; Long, T. Mineral Identification Based on Deep Learning Using Image Luminance Equalization. Appl. Sci. 2022, 12, 7055. [Google Scholar] [CrossRef]

- Lesego, S.; Jo, S.; Yoshino, K.; Hisatoshi, T.; Masaya, H.; Youhei, K. One-Dimensional Convolutional Neural Network for Drill Bit Failure Detection in Rotary Percussion Drilling. Mining 2021, 1, 297–314. [Google Scholar]

- Nguyen, H.; Bui, X.N.; Tran, Q.H.; Nguyen, D.A.; Hoa, L.T.T.; Le, Q.T.; Giang, L.T.H. Predicting Blast-Induced Ground Vibration in Open-Pit Mines Using Different Nature-Inspired Optimization Algorithms and Deep Neural Network. Nat. Resour. Res. 2021, 30, 4695–4717. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Liu, X.; Wang, L.; Xia, X. Deep Learning Based Mineral Image Classification Combined with Visual Attention Mechanism. IEEE Access 2021, 9, 98091–98109. [Google Scholar] [CrossRef]

- Girshick, R. Fast R-CNN. In Proceedings of the IEEE International Conference on Computer Vision, Santiago, Chile, 11–18 December 2015. [Google Scholar]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef] [PubMed]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 27–30 June 2016. [Google Scholar]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.-Y.; Berg, A.C. SSD: Single Shot MultiBox Detector. In Proceedings of the 14th European Conference on Computer Vision (ECCV), Amsterdam, The Netherlands, 8 October 2016. [Google Scholar]

- Jiang, H.; Wang, Y.; Yang, Y. Fast Traffic Accident Identification Method Based on SSD Model. In Proceedings of the 2019 International Conference on Robotics Systems and Vehicle Technology, Wuhan, China, 18–20 October 2019. [Google Scholar]

- Sun, X.; Gu, J.; Huang, R. A modified SSD method for Electronic Components Fast Recognition. Optik 2020, 205, 163767. [Google Scholar] [CrossRef]

- Li, L.; Fu, M.; Zhang, T.; Ying Wu, H. Research on workpiece location algorithm based on improved SSD. Ind. Robot.-Int. J. Robot. Res. Appl. 2022, 49, 108–119. [Google Scholar] [CrossRef]

- Wang, J.G. Application of Chute Material Blockage Detection Method in Coal Preparation Plant. Coal Eng. 2019, 51, 127–130. [Google Scholar]

- Luo, X.; Liu, C.; Tang, W.; Wang, X. Research on identification and location of blocked ore at ore bin inlet based on Mask RCNN. Nonferrous Met. Sci. Eng. 2022, 13, 101–107. [Google Scholar]

- Xiao, J.L. Application of Photoelectric Sensor in the Device for Detecting the Blockage of Tape Funnel, China Mining Science and Technology Conference—2016. Mod. Min. Mag. 2016, 243–244+247. [Google Scholar]

- Dai, J.; Li, Y.; He, K.; Sun, J. R-FCN: Object Detection via Region-based Fully Convolutional Networks. In Proceedings of the 30th Conference on Neural Information Processing Systems (NIPS), Barcelona, Spain, 5–10 December 2016. [Google Scholar]

| Filename | Width | Height | Class | xmin | ymin | xmax | ymax |

|---|---|---|---|---|---|---|---|

| 20220613154238.jpg | 1920 | 1200 | mouth | 566 | 402 | 1312 | 925 |

| 20220613154244.jpg | 1920 | 1200 | mouth | 587 | 397 | 1307 | 926 |

| 20220613154250.jpg | 1920 | 1200 | mouth | 579 | 391 | 1324 | 926 |

| 20220616122934.jpg | 1920 | 1200 | mouth | 565 | 382 | 1351 | 975 |

| 20220616131045.jpg | 1920 | 1200 | mouth | 557 | 371 | 1361 | 963 |

| 20220616131239.jpg | 1920 | 1200 | mouth | 564 | 380 | 1357 | 955 |

| 20220616133704.jpg | 1920 | 1200 | mouth | 572 | 378 | 1365 | 965 |

| 20220616133904.jpg | 1920 | 1200 | mouth | 566 | 386 | 1381 | 957 |

| 20220616134104.jpg | 1920 | 1200 | mouth | 580 | 366 | 1349 | 963 |

| 20220617101303.jpg | 1920 | 1200 | mouth | 584 | 408 | 1307 | 928 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, J.; Wang, Z.; Liu, C.; Huang, G.; Yuan, Q.; Xu, K.; Zhang, W. Detection Method of Crushing Mouth Loose Material Blockage Based on SSD Algorithm. Sustainability 2022, 14, 14386. https://doi.org/10.3390/su142114386

Yao J, Wang Z, Liu C, Huang G, Yuan Q, Xu K, Zhang W. Detection Method of Crushing Mouth Loose Material Blockage Based on SSD Algorithm. Sustainability. 2022; 14(21):14386. https://doi.org/10.3390/su142114386

Chicago/Turabian StyleYao, Jiang, Zhiqiang Wang, Chunhui Liu, Guichen Huang, Qingbo Yuan, Kai Xu, and Wenhui Zhang. 2022. "Detection Method of Crushing Mouth Loose Material Blockage Based on SSD Algorithm" Sustainability 14, no. 21: 14386. https://doi.org/10.3390/su142114386

APA StyleYao, J., Wang, Z., Liu, C., Huang, G., Yuan, Q., Xu, K., & Zhang, W. (2022). Detection Method of Crushing Mouth Loose Material Blockage Based on SSD Algorithm. Sustainability, 14(21), 14386. https://doi.org/10.3390/su142114386