Abstract

Laundry balls are promoted as a sustainable washing option because they do not contain chemical elements, unlike laundry detergent, which causes water pollution. However, little research exists to showcase the impact of laundry balls on microfiber pollution during home laundering. Using a cradle-to-cradle framework, this study aimed to investigate the effect of laundry balls on microfiber shedding during the home laundering process of synthetic clothing with different washing cycles. A factorial experimental design, consisting of 4 (washing options) × 3 (washing cycles) × 2 (repetitions) was used for this study. The ANOVA test was applied using SAS software. The findings revealed that different laundry balls including a ceramic laundry ball, lint remover laundry ball, and scrubbing laundry ball, did not reduce microfiber shedding of synthetic clothing. In fact, the use of the ceramic laundry ball accelerated microfiber shedding. It also presented the effects of different washing cycles on microfiber shedding of synthetic clothing. The study findings point towards the need to educate consumers about choosing the right washing options to minimize microfiber shedding. The findings also have implications for the industry and researchers to develop more sustainable washing options to reduce negative environmental effects by controlling microfiber pollution in home laundering.

1. Introduction

Laundry detergent is a regular household product across the globe that consumers have been using for more than 100 years for washing and cleaning garments [1,2]. Because of the increase in consumers’ overall consumption expenditure, the market value of detergent has consistently increased worldwide [3]. According to Statista [4], the global market value of laundry detergent will be USD 141 billion in 2022 and is projected to be around USD 181 billion by 2026. However, environmentalists are concerned about the excessive usage of detergent in home laundering because of its harmful effect on the aquatic environment [5]. Detergent contains various ingredients such as bleaching chemicals (chlorine-releasing agent), stabilizers, fillers, builders (e.g., phosphate, zeolite, and polycarboxylic acid), foam agents, soil-suspending agents, perfume agents, dyes, optical brightener, enzyme, and bactericide agents [6,7]. The byproducts of detergent create a white foam that blocks the entry of oxygen and light into the water, affecting marine lives and plants [8,9,10]. In addition, detergent degrades water quality due to the high toxicity of the chemical compounds, resulting in a negative environmental impact on natural ecosystems [11,12]. Environmental activists therefore demand the substitution of laundry detergent to preserve nature.

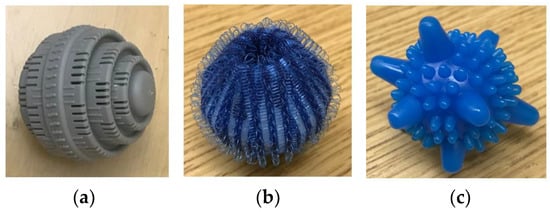

Recently, laundry balls have appeared as an alternative to detergent that is used to perform cleaning of clothing items during home laundering [13]. In the market, several types of laundry balls are available, such as the ceramic laundry ball, the lint remover laundry ball, and the scrubbing laundry ball [14]. The ceramic laundry ball is made of thermoplastic elastomers containing large quantities of ceramic beads. It cleans mechanically, creating friction with the garments during home laundering. The lint remover laundry ball is generally made of nylon, and executes cleaning by removing pet hair or lint from garments, and the scrubbing laundry ball consists of polyvinyl chloride material that performs cleaning through mechanical friction with the garments [15]. Some users claim that the laundry ball is a sustainable washing option because it does not contain any chemical formulation, unlike detergent, which is responsible for water pollution. Thus, using a laundry ball during home laundering is beneficial for the marine environment [16]. However, cradle-to-cradle, an eco-effective product designing concept, strongly emphasizes that a sustainable or environment-friendly product should not harm any aspect of the environment [17,18]. During home laundering, various washing options, including detergent, fabric softener, and washing temperature produce microfibers, which is the leading reason for ocean pollution [19,20,21]. Now the question remains, “does laundry ball have any influence on microfiber shedding of synthetic clothing during home laundering?”

Clothing made of synthetic materials (e.g., polyester, nylon, acrylic) is one of the major sources of microfiber pollution in home laundering [22,23]. According to the International Union for Conservation of Nature (IUCN), a global organization for protecting nature, around 35% of the total microfibers in the oceans are released from laundering synthetic clothing [24]. The residues of synthetic material with a dimension of less than 5 mm in length are called microfibers [25]. They are too tiny to be trapped in the filter of home laundering machine, and eventually flow out with the rinse water reaching rivers and oceans [26]. Microfibers are prevalent from the ocean surface to the bottom of rivers, and even in Arctic Sea ice and the deepest trenches of oceans [27]. Microfibers form bonds with other chemical pollutants in water and are consumed by small animals such as plankton, as well as large marine creatures that eat plankton. Thus, microfibers with attached chemical pollutants affect the physiology and health of marine species by disturbing their food chain [26]. Furthermore, microfibers block the digestive systems of small fish, cause injury, and may even alter the animal’s behavior [28]. Microfibers also have been identified in human lung biopsies and found in freshwater lakes, drinking water, and soil samples [29,30,31]. The growing microfiber pollution has become a global concern and the United Nations recommended and encouraged individual and collective actions to tackle it [32].

Previous studies identified that fabric properties, washing cycles, and different washing options, including detergent, fabric softener, and washing temperature, have an effect on microfiber shedding during home laundering [19,20,21,33,34]. For instance, the woven structured fabric with highly twisted and less hairy filament yarn produced less microfiber compared to the loosely structured fabric with less twisted and very hairy filament yarn [33]. Lim et al. [34] demonstrated that the first five wash cycles released the largest number of microfibers during the laundering. A higher washing temperature, usage of detergent, and fabric softener accelerated microfiber release during clothes washing [19,20,21]. In contrast, the study of Pirc et al. [35] found that detergent and fabric softener have less effect on microfiber shedding. However, little research exists to showcase whether using laundry balls causes harm to the environment by producing microfiber. This study aimed to investigate the effect of laundry balls on microfiber shedding of synthetic clothing during home laundering. The specific objectives were to: (a) examine the effect of laundry balls on microfiber pollution in different washing cycles using the t-test and F-test; and (b) compare the effects of different types of laundry balls on microfiber pollution in different washing cycles using the Tukey HSD test. The findings of this study provide guidance to determine whether laundry balls are a sustainable washing option according to the cradle-to-cradle design model.

Cradle-to-Cradle: Less Bad Is No Good

This study was grounded in the cradle-to-cradle design framework developed by the American architect William McDonough and the German chemist Michael Braungart [17]. Being inspired by nature, they introduced the cradle-to-cradle model aiming to increase the positive environmental impacts of a product, or of a manufacturing process, buildings, or cities, aiming to make them beneficial for mankind and healthy for the planet [17,36].

The cradle-to-cradle model introduced a closed-loop system that opposed the traditional linear system or one-way cradle-to-grave model, where after-use materials turn into waste and generate pollution. Within a closed-loop system, materials constantly circulate as the original and resourceful elements without contaminating the environment. The cradle-to-cradle method classifies materials into biological and technical nutrients. Biological nutrients are made from natural materials that can easily re-enter nature after use without contaminating the environment. For example, natural fibers such as cotton, wool, and silk are biodegradable and can return to the soil. Technical nutrients are manufactured materials that are made to be constantly captured within the closed-loop system; for example, synthetic materials such as polyester, nylon, and acrylic can be considered technical nutrients when they are recycled or reused [17].

Within the cradle-to-cradle design model, McDonough and Braungart stated the “less bad is no good” concept since they believed that it is important to use strategies that are “good” instead of merely “less bad.” For instance, incineration is a strategy of waste reduction that is considered environment-friendly compared to landfilling. However, when incinerated, paper and plastic materials produce highly toxic compounds (e.g., dioxins) causing severe air pollution and affecting human health [36,37]. By the final decade of the 20th century, the manufacturers realized the concerns of environmental degradation caused by industries and started adopting a “less bad” strategy in product development and the production process for the reduction in environmental pollution [17]. However, these strategies led to a linear cradle-to-grave model where materials transformed into waste that eventually contaminated the earth [38].

This study adopts the “less bad is no good” concept from the cradle-to-cradle design model to examine the claim that laundry balls are a sustainable washing option since they do not contaminate the aquatic environment compared to detergent [16]. The cradle-to-cradle design model is widely applied in diverse areas, including sustainable practices in the agricultural farms [39], life cycle assessment of PET water bottles [40], carbon emission of electric vehicles batteries [41], usage of eco-friendly materials in the construction industry [42], and sustainable waste management [43]. However, limited research exists to showcase the application of the cradle-to-cradle model within washing options used in the home laundering process. Thus, this study is unique and distinctive because it (a) implements the “less bad is no good” concept from the cradle-to-cradle design in the home laundering process of synthetic clothing; and (b) validates whether laundry balls are a sustainable washing option by examining its effect on microfiber shedding through the experimental design method.

2. Materials and Methods

2.1. Experimental Design, Instruments and Procedures

This study used a factorial design experiment consisting of 4 (washing options) × 3 (washing cycles) × 2 (repetition) to conduct the experiment in random order. In this experiment, the response variable is microfiber content in mg/L and the two independent variables are washing options with four levels and washing cycles with three levels. The factorial experiment was designed to examine the main and interaction effects between two or more independent variables on the outcome of the response variable [44]. Thus, this study adopted a factorial design experiment to investigate the effect of washing options, washing cycles, and the interaction of both on microfiber shedding of synthetic clothing. A 100% polyester fleece blanket (weight: 176.26 g/m2) was used as synthetic clothing since previous research exhibited the contribution of polyester fleece fabric towards microfiber pollution [45]. Three types of laundry balls: ceramic laundry ball (8 cm diameter), lint remover laundry ball (length: 19.98 cm, width: 15.01 cm, height: 3.50 cm), and scrubbing laundry ball (length: 14.47 cm, width:10.4 cm, height: 3.30 cm) were procured from the market (see Figure 1).

Figure 1.

Three types of laundry balls used in this study: (a) ceramic laundry ball; (b) lint remover laundry ball; (c) scrubbing laundry ball.

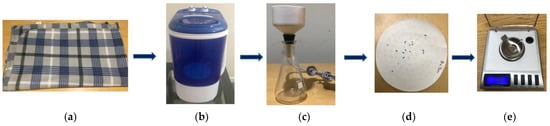

In this experiment, washing options are the treatment with four levels: (a) control group with polyester clothing, (b) polyester clothing with ceramic laundry ball, (c) polyester clothing with lint remover laundry ball, and (d) polyester clothing with scrubbing laundry ball. A top-loaded portable washing machine (brand name: Zeny, Fontana, FL, USA; model no.: H03-1020A; laundry capacity: 3 kg; machine speed: 1300 rpm) was used for laundering. Filter papers (diameter: 9 cm; pore size: 10 micrometers; thickness: 150 micrometers; weight: 86 g/m2) were used for filtering the discharged water from the washing machine, using a vacuum filtration system, consisting of a 500 mL vacuum filtering flask, 60 cm length of plastic vacuum tubing, a 200 mL Buchner funnel, and a hand vacuum pump with a pressure gauge. A digital scale with 0.001 g accuracy was used to weigh the filter paper to measure the microfiber content during the experiment.

At first, a 100% polyester blanket was cut into sections of 12 × 12 inches, making 4 samples for the experiment. The edge of each sample was stitched by overlock threads to prevent fraying during laundering. Here, each sample was assigned to each level of treatment. For the control group of the treatment level, a sample was laundered in the washing machine with 2 L of water at 30 °C temperature. After 15 min of washing, the water was discharged through the hose pipe of the washing machine and collected in a water bucket. This 250 mL of discharged water was filtered through filter paper, using a vacuum filtration system, and this process of filtering 250 mL of discharged water was repeated once more. Each filter paper from 250 mL of discharged water was stored for 24 h for drying and later measured by a digital scale in milligrams. Thus, this study collected two filter papers with microfiber contents after the first washing cycle of the control group (100% polyester blanket). This process was continued for the second and third washing cycles. The microfiber contents were measured as total suspended solids (TSS) following Equation (1) where W1 = filter paper weight in milligram before filtration, and W2 = filter paper weight in milligram after filtration:

TSS (mg/L) = ((W2 − W1) × 1000)/250

The experimental procedure for the control group treatment level is shown in Figure 2. The same procedure was followed for the three other treatment levels where a sample was laundered together with a ceramic laundry ball, a lint remover laundry ball, or a scrubbing laundry ball. This study performed rinsing at the beginning and the end of any experimental process to remove dirt, fibers, or foreign materials from the instruments. First, the polyester clothing and laundry balls were removed from the washing machine before starting the rinsing operation. The washing machine was cleaned with 2 L of water at a temperature of 30 °C for 5 min at a speed of 1300 rpm. After rinsing, the water was discharged through the drain pipe. This process was repeated one more time to ensure the complete discharge of any remaining impurities from the inside of the washing machine. In addition, other instruments (e.g., filtration system, water bucket) were also thoroughly rinsed with water to remove the residues from the previous operation.

Figure 2.

Experimental procedure of collecting and measuring microfibers: (a) control group: 100% polyester fleece blanket; (b) top-loaded portable washing machine; (c) vacuum filtration system; (d) collected microfibers in filter paper; (e) digital scale to measure microfibers.

2.2. Data Analysis

Data were analyzed using SAS 9.4 software (SAS Institute Inc., Cary, NC, USA), considering p < 0.05 with the residual maximum likelihood (REML) estimation technique. A t-test was used to check the effect of individual laundry balls and washing cycles on microfiber shedding. An F-test in ANOVA was used to determine the significant effects of different laundry balls, washing cycles, and their interactions on microfiber shedding. A post hoc comparison with the Tukey HSD test was also performed to compare the effect of different laundry balls against the control group. This study also performed a Shapiro–Wilk test of normality, which was not significant (W = 0.979, p > 0.05). It confirmed that the data followed the normal distribution [46].

3. Results

3.1. Effect of Laundry Balls and Washing Cycles on Microfiber Pollution

The effects of individual washing options and washing cycles on microfiber shedding of synthetic clothing are shown in Table 1. The t-test results show that each washing option, including the control group (M = 58; SD = 7.48), ceramic laundry ball (M = 73.33; SD = 4.84), lint remover laundry ball (M = 57.33; SD = 3.26), and scrubbing laundry ball (M = 56.66; SD = 6.40), has a significant effect on microfiber pollution. It suggests that each washing option contributes to microfiber shedding of synthetic clothing during home laundering. In addition, the t-test of washing cycles also shows a significant effect on microfiber pollution, meaning that each washing cycle, including the first (M = 58; SD = 9.56), second (M = 63; SD = 9.97), and third cycle (M = 63; SD = 7.01), releases microfibers in the process of home laundering. The results show that washing options produce microfibers ranging from 73.33 to 56.66 mg/L and the washing cycles release 63 to 58 mg/L of microfibers during home laundering.

Table 1.

The t-test results for the individual effect of laundry balls and washing cycles on microfiber shedding.

Table 2 shows the F-test results to showcase the effects of washing options, washing cycles, and the interaction of both, on microfiber shedding. The findings reveal that different washing options have significantly different effects on microfiber shedding of synthetic clothing. The effect of different washing cycles on microfiber shedding is not significant. It indicates that the first, second, and third washing cycles produce similar quantities of microfibers during home laundering. The results also show an insignificant relation between washing options and washing cycles, suggesting the effect of washing options on microfiber pollution is not dependent on the effect of washing cycles.

Table 2.

The F-test results for the effect of laundry balls, washing cycles, and their interaction on microfiber shedding.

3.2. Comparison of the Effect of Different Laundry Balls on Microfiber Pollution

Table 3 presents the Tukey HSD pairwise comparison test results of different washing options. The results show that the ceramic laundry ball is significantly different from the control group, lint remover laundry ball, and scrubbing laundry ball. The ceramic laundry ball releases 20.90%, 21.81%, and 22.73% more microfibers than the control group, lint remover laundry ball, and scrubbing laundry ball, respectively, while washing synthetic clothing in different washing cycles during home laundering.

Table 3.

The Tukey HSD pairwise comparison test results.

4. Discussion and Conclusions

This study aimed to determine the effect of different laundry balls on microfiber shedding of synthetic clothing in different washing cycles during home laundering at a washing temperature of 30 °C, using the cradle-to-cradle design model. We also investigated the individual effects of different laundry balls and washing cycles on microfiber shedding. Later, we examined the significant differences among laundry balls, washing cycles, and their interactions on microfiber shedding during home laundering. Finally, we compared laundry balls with each other to identify which laundry ball is the most responsible for accelerating microfiber shedding during home laundering. This experimental study led to some key findings.

First, it was found that each laundry ball, namely, the ceramic laundry ball, lint remover laundry ball, and scrubbing laundry ball, contributed to microfiber pollution while laundering synthetic clothing. The working mechanism of laundry balls may influence microfiber shedding during laundering. Laundry balls are designed to perform cleaning using friction created with garments without using detergent or cleaning soap [15]. Inside the washing machine, clothing continuously rotates with water at a high speed, which damages fabric properties [47,48]. In such a situation, mechanical friction of the laundry balls may enhance the release of microfibers from the surface of synthetic clothing. In addition, the findings revealed that each washing cycle influenced microfiber shedding. The findings related to these impacts of washing cycles on microfiber pollution supported a previous study, which found that the first five washing cycles produced the largest number of microfibers when washing garments [34].

Second, the findings revealed that the laundering of synthetic clothing with the ceramic laundry ball produced more microfibers compared to the lint remover and scrubbing laundry balls. The ceramic laundry ball consisted of a thermoplastic elastomer containing numerous ceramic beads, whereas the lint remover and scrubbing laundry balls were composed of nylon and polyvinyl chloride, respectively [15]. Ceramic beads of the ceramic laundry ball may cause robust friction with the garment, producing more microfibers compared to laundering clothing with the lint remover and scrubbing laundry ball. This study found that the first three washing cycles released around the same quantities of microfibers while laundering synthetic clothing. There is no scientific consensus about the quantities of microfibers released in each washing cycle. Lim et al. [34] found the first five washing cycles emitted maximum microfibers in a study that showed microfiber shedding decreased after one or two washing cycles [35]. However, our research finding confirmed that all three consecutive washing cycles contribute to microfiber pollution. This study did not find any interaction effect between laundry balls and washing cycles on microfiber pollution. This suggests that laundry balls and washing cycles act independently while causing microfiber shedding of synthetic clothing during home laundering.

Third, this research applied the cradle-to-cradle design model to investigate the claim that the laundry ball is a sustainable washing option since it does not contain chemical formulations, unlike detergent, which contaminates the marine environment. This study found that the negative environmental impact of laundry balls makes its claim over sustainability quite questionable. Recently, the terms “sustainable product,” “green product,” and “green consumption” have become familiar to public because of the effort of governments across the world to reduce negative environmental effects and companies’ marketing strategies to promote their eco-friendly products to consumers [49]. Several studies confirmed that consumers have positive attitudes and intentions towards soft-goods labeled as “sustainable products” or “green products” [50,51,52]. Though promoting environment-friendly products is one of the effective ways of convincing consumers to participate in environmental issues [53], McDonough and Braungart [17] stated that environmental issues can be resolved following a closed-loop system by designing a product that is resourceful in terms of nature, instead of being a pollutant.

In this study, we used 100% polyester clothing since it is one of the most widely used synthetic fibers for apparel products [22]. However, it does not represent other synthetic fibers such as nylon and acrylic, which is one of the limitations of this study. In addition, this study did not showcase the impact of fabric properties such as fabric construction, fabric weight, fabric strength, and yarn twist on microfiber shedding while using a laundry ball. Future research is suggested to examine the influence of laundry balls on microfiber pollution when used with various types of synthetic fibers. This study showed the impact of laundry balls on microfiber shedding up to three consecutive washing cycles, which restricts capturing the total microfiber shedding pattern in different washing cycles. In future, this experiment may be run with more washing cycles. The laundry balls used in this experiment were sourced from the market. Further research is recommended to test other commercially available laundry balls from the market to validate their effects on microfiber shedding compared to the outcome of this study. This study was performed using a portable washing machine with 1300 rpm at a constant temperature (30 °C) in different washing cycles to control the variability of the entire experimental process. In the future, it is recommended that the experiment is run at different washing temperatures and machine speeds to determine the interaction effect of the laundry ball, washing temperature, machine speed, and washing cycles on microfiber pollution during home laundering.

Despite the study’s limitations, this research contributes to the existing literature by proposing the cradle-to-cradle design model to reveal the negative environmental effect of laundry balls, although they were considered as a substitute washing option for consumers in the current market. This study demonstrates the effectiveness of the cradle-to-cradle design model for determining the overall environmental impact of a supposedly sustainable product. Thus, future investigators can integrate the cradle-to-cradle model with other design frameworks to create a sustainable product that should satisfy consumer requirements without damaging the environment. Specifically, the findings signal the need for industry professionals and academic researchers to think about and develop better sustainable washing options than using laundry balls, to minimize the negative environmental impact by controlling microfiber pollution during home laundering. Overall, this study provides great educational insights for consumers to choose appropriate washing options in order to minimize microfiber pollution.

Author Contributions

Conceptualization, M.S. and Y.-A.L.; methodology, M.S. and Y.-A.L.; formal analysis, M.S.; investigation, M.S. and Y.-A.L.; data curation, M.S. and Y.-A.L.; writing—original draft preparation, M.S.; writing—review and editing, Y.-A.L. and M.S.; supervision, Y.-A.L.; project administration, M.S. and Y.-A.L.; funding acquisition, M.S. and Y.-A.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the 2020 American Association of Textile Chemists and Colorists Foundation Student Research Support Grant.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Inquiries about data can be sent to mzs0174@auburn.edu.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kogawa, A.C.; Cernic, B.G.; do Couto, L.G.D.; Salgado, H.R.N. Synthetic detergents: 100 years of history. Saudi Pharm. J. 2017, 25, 934–938. [Google Scholar] [CrossRef] [PubMed]

- Tsompou, A.; Kocherbitov, V. The effects of water purity on removal of hydrophobic substances from solid surfaces without surfactants. J. Colloid Interface Sci. 2022, 608, 1929–1941. [Google Scholar] [CrossRef] [PubMed]

- Laundry Detergent Market Predicted to Garner a Revenue of $1,03,286.00 Million in the 2021–2028 Timeframe, Growing at a Healthy CAGR of 6.70%. Available online: https://www.globenewswire.com/en/news-release/2022/03/30/2412947/0/en/Laundry-Detergent-Market-Predicted-to-Garner-a-Revenue-of-1-03-286-00-Million-in-the-2021-2028-Timeframe-Growing-at-a-Healthy-CAGR-of-6-70-165-Pages-Report-by-Research-Dive.html (accessed on 22 September 2022).

- Laundry Detergent Market Value Worldwide From 2018 to 2026 (in Billion U.S. Dollars). Available online: https://www.statista.com/statistics/921440/laundry-detergent-market-value-worldwide/ (accessed on 22 September 2022).

- Pradhan, A.; Bhattacharyya, A. Quest for an eco-friendly alternative surfactant: Surface and foam characteristics of natural surfactants. J. Clean. Prod. 2017, 150, 127–134. [Google Scholar] [CrossRef]

- Abd El-Gawad, H.S. Aquatic environmental monitoring and removal efficiency of detergents. Water Sci. 2014, 28, 51–64. [Google Scholar] [CrossRef]

- Mousavi, S.A.; Khodadoost, F. Effects of detergents on natural ecosystems and wastewater treatment processes: A review. Environ. Sci. Pollut. Res. 2019, 26, 26439–26448. [Google Scholar] [CrossRef]

- Schmitt, C.; Grassl, B.; Lespes, G.; Desbrières, J.; Pellerin, V.; Reynaud, S.; Hackley, V.A. Saponins: A renewable and biodegradable surfactant from its microwave-assisted extraction to the synthesis of monodisperse lattices. Biomacromolecules 2014, 15, 856–862. [Google Scholar] [CrossRef] [PubMed]

- Sobrino-Figueroa, A. Toxic effect of commercial detergents on organisms from different trophic levels. Environ. Sci. Pollut. Res. 2018, 25, 13283–13291. [Google Scholar] [CrossRef]

- Pandey, P.; Gopal, B. Effect of detergents on the growth of two aquatic plants: Azolla pinnata and Hydrilla verticillata. Environ. We: Int. J. Sci. Technol. 2010, 5, 107–114. [Google Scholar]

- Rajan, D.S. An evaluation of the effect of a detergent on dissolved oxygen consumption rate of Anabas testudineus. Int. J. Fish. Aquat. Stud 2015, 2, 46–48. [Google Scholar]

- Uzma, S.; Khan, S.; Murad, W.; Taimur, N.; Azizullah, A. Phytotoxic effects of two commonly used laundry detergents on germination, growth, and biochemical characteristics of maize (Zea mays L.) seedlings. Environ. Monit. Assess. 2018, 190, 651. [Google Scholar] [CrossRef]

- Laundry Balls: Ditch the Detergent to Save Money on Laundry. Available online: https://piggybankprinciples.com/laundry-balls/ (accessed on 22 September 2022).

- Laundry Ball. Available online: https://www.walmart.com/c/kp/laundry-ball (accessed on 22 September 2022).

- 10 Best Laundry Balls. Available online: https://washmode.com/washing-machine/laundry-ball/?amp (accessed on 22 September 2022).

- 6 Reasons Why You should be Using Laundry Balls. Available online: https://www.sanitizer.com/blogs/news/6-reasons-why-you-should-be-using-laundry-balls (accessed on 22 September 2022).

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things, 1st ed.; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Toxopeus, M.E.; De Koeijer, B.L.A.; Meij, A.G.G.H. Cradle to cradle: Effective vision vs. efficient practice? Procedia Cirp 2015, 29, 384–389. [Google Scholar] [CrossRef]

- Yang, L.; Qiao, F.; Lei, K.; Li, H.; Kang, Y.; Cui, S.; An, L. Microfiber release from different fabrics during washing. Environ. Pollut. 2019, 249, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Zambrano, M.C.; Pawlak, J.J.; Daystar, J.; Ankeny, M.; Venditti, R.A. Impact of dyes and finishes on the aquatic biodegradability of cotton textile fibers and microfibers released on laundering clothes: Correlations between enzyme adsorption and activity and biodegradation rates. Mar. Pollut. Bull. 2021, 165, 112030. [Google Scholar] [CrossRef] [PubMed]

- Zambrano, M.C.; Pawlak, J.J.; Daystar, J.; Ankeny, M.; Cheng, J.J.; Venditti, R.A. Microfibers generated from the laundering of cotton, rayon and polyester based fabrics and their aquatic biodegradation. Mar. Pollut. Bull. 2019, 142, 394–407. [Google Scholar] [CrossRef]

- Hernandez, E.; Nowack, B.; Mitrano, D.M. Polyester textiles as a source of microplastics from households: A mechanistic study to understand microfiber release during washing. Environ. Sci. Technol. 2017, 51, 7036–7046. [Google Scholar] [CrossRef]

- Napper, I.E.; Thompson, R.C. Release of synthetic microplastic plastic fibres from domestic washing machines: Effects of fabric type and washing conditions. Mar. Pollut. Bull. 2016, 112, 39–45. [Google Scholar] [CrossRef]

- Boucher, J.; Friot, D. Primary Microplastics in the Oceans: A Global Evaluation of Sources, 1st ed.; IUCN: Gland, Switzerland, 2017. [Google Scholar]

- Carr, S.A. Sources and dispersive modes of micro-fibers in the environment. Integr. Environ. Assess. Manag. 2017, 13, 466–469. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Saad, M.; Mirande, C.; Tassin, B. Synthetic fibers in atmospheric fallout: A source of microplastics in the environment? Mar. Pollut. Bull. 2016, 104, 290–293. [Google Scholar] [CrossRef]

- Courtene-Jones, W.; Quinn, B.; Gary, S.F.; Mogg, A.O.; Narayanaswamy, B.E. Microplastic pollution identified in deep-sea water and ingested by benthic invertebrates in the Rockall Trough, North Atlantic Ocean. Environ. Pollut. 2017, 231, 271–280. [Google Scholar] [CrossRef]

- Jovanović, B. Ingestion of microplastics by fish and its potential consequences from a physical perspective. Integr. Environ. Assess. Manag. 2017, 13, 510–515. [Google Scholar] [CrossRef]

- Machado, A.A.; Kloas, W.; Zarfl, C.; Hempel, S.; Rillig, M.C. Microplastics as an emerging threat to terrestrial ecosystems. Glob. Change Biol. 2018, 24, 1405–1416. [Google Scholar] [CrossRef] [PubMed]

- Prata, J.C. Airborne microplastics: Consequences to human health? Environ. Pollut. 2018, 234, 115–126. [Google Scholar] [CrossRef] [PubMed]

- Wagner, M.; Scherer, C.; Alvarez-Muñoz, D.; Brennholt, N.; Bourrain, X.; Buchinger, S.; Fries, E.; Grosbois, C.; Klasmeier, J.; Marti, T.; et al. Microplastics in freshwater ecosystems: What we know and what we need to know. Environ. Sci. Eur. 2014, 26, 12. [Google Scholar] [CrossRef] [PubMed]

- Tackling Marine Pollution: Individual Action, Key to Ocean Restoration. Available online: https://news.un.org/en/story/2022/06/1121452 (accessed on 23 September 2022).

- De Falco, F.; Cocca, M.; Avella, M.; Thompson, R.C. Microfiber release to water, via laundering, and to air, via everyday use: A comparison between polyester clothing with differing textile parameters. Environ. Sci. Technol. 2020, 54, 3288–3296. [Google Scholar] [CrossRef]

- Lim, J.; Choi, J.; Won, A.; Kim, M.; Kim, S.; Yun, C. Cause of microfibers found in the domestic washing process of clothing; focusing on the manufacturing, wearing, and washing processes. Fash. Text. 2022, 9, 24. [Google Scholar] [CrossRef]

- Pirc, U.; Vidmar, M.; Mozer, A.; Kržan, A. Emissions of microplastic fibers from microfiber fleece during domestic washing. Environ. Sci. Pollut. Res. 2016, 23, 22206–22211. [Google Scholar] [CrossRef]

- Environmental Protection Encouragement Agency. Available online: https://epea.com/en/about-us/cradle-to-cradle (accessed on 19 September 2022).

- Dioxins and Their Effects on Human Health. Available online: https://www.who.int/news-room/fact-sheets/detail/dioxins-and-their-effects-on-human-health (accessed on 19 September 2022).

- McDonough, W.; Braungart, M.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions–a strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar]

- Capezza, A.J.; Cui, Y.; Numata, K.; Lundman, M.; Newson, W.R.; Olsson, R.T.; Hedenqvist, M.S. High capacity functionalized protein superabsorbents from an agricultural co-product: A cradle-to-cradle approach. Adv. Sustain. Syst. 2020, 4, 2000110. [Google Scholar] [CrossRef]

- Tamoor, M.; Samak, N.A.; Yang, M.; Xing, J. The cradle-to-cradle life cycle assessment of polyethylene terephthalate: Environmental perspective. Molecules 2022, 27, 1599. [Google Scholar] [CrossRef]

- Chen, Q.; Lai, X.; Gu, H.; Tang, X.; Gao, F.; Han, X.; Zheng, Y. Investigating carbon footprint and carbon reduction potential using a cradle-to-cradle LCA approach on lithium-ion batteries for electric vehicles in China. J. Clean. Prod. 2022, 369, 133342. [Google Scholar] [CrossRef]

- Rios, F.C.; Grau, D.; Chong, W.K. Reusing exterior wall framing systems: A cradle-to-cradle comparative life cycle assessment. Waste Manag. 2019, 94, 120–135. [Google Scholar] [CrossRef] [PubMed]

- Wiel, A.V.D.; Bossink, B.; Masurel, E. Reverse logistics for waste reduction in cradle-to-cradle-oriented firms: Waste management strategies in the Dutch metal industry. Int. J. Technol. Technol. Manag. 2012, 60, 96–113. [Google Scholar] [CrossRef]

- Baker, T.B.; Smith, S.S.; Bolt, D.M.; Loh, W.Y.; Mermelstein, R.; Fiore, M.C.; Collins, L.M. Implementing clinical research using factorial designs: A primer. Behav. Ther. 2017, 48, 567–580. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Charan Rath, C.; Das, A.P. Marine microfiber pollution: A review on present status and future challenges. Mar. Pollut. Bull. 2019, 140, 188–197. [Google Scholar] [CrossRef] [PubMed]

- Razali, N.M.; Wah, Y.B. Power comparisons of shapiro-wilk, kolmogorov-smirnov, lilliefors and anderson-darling tests. J. Stat. Model. Anal. 2011, 2, 21–33. [Google Scholar]

- Ramasamy, R.; Subramanian, R.B. Synthetic textile and microfiber pollution: A review on mitigation strategies. Environ. Sci. Pollut. Res. 2021, 28, 41596–41611. [Google Scholar] [CrossRef]

- Bishop, D.P. Physical and chemical effects of domestic laundering processes. In Chemistry of the Textiles Industry; Carr, C.M., Ed.; Springer: Dordrecht, The Netherlands, 1995; pp. 125–172. [Google Scholar]

- Ottman, J.A.; Stafford, E.R.; Hartman, C.L. Avoiding green marketing myopia: Ways to improve consumer appeal for environmentally preferable products. Environ. Sci. Policy Sustain. Dev. 2006, 48, 22–36. [Google Scholar] [CrossRef]

- Suki, N.M. Green product purchase intention: Impact of green brands, attitude, and knowledge. Br. Food J. 2016, 118, 2893–2910. [Google Scholar] [CrossRef]

- Paul, J.; Modi, A.; Patel, J. Predicting green product consumption using theory of planned behavior and reasoned action. J. Retail. Consum. Serv. 2016, 29, 123–134. [Google Scholar] [CrossRef]

- Kamalanon, P.; Chen, J.S.; Le, T.T.Y. “Why do we buy green products?” An extended theory of the planned behavior model for green product purchase behavior. Sustainability 2022, 14, 689. [Google Scholar] [CrossRef]

- Jo, M.; Shin, J. Market strategy for promoting green consumption: Consumer preference and policy implications for laundry detergent. Int. J. Consum. Stud. 2017, 41, 283–290. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).