Abstract

Overproduction of date fruits with limited industrial utilization leads to huge waste and losses, especially in bisr (the first stage of date maturity). Therefore, this study aimed to investigate the potential of using bisr date powder (BDP), which is rich in dietary fiber, flavonoids, and phenolic and antioxidant compounds, as a replacement for breadcrumbs in the beef burgers. The beef burger samples were produced by replacing breadcrumb powder with different concentration levels of BDP (0.0, 25, 50, 75, and 100%). All the samples were evaluated for their quality characteristics, including chemical composition, cooking properties, texture profile, organoleptic characteristics, and microbial profile. The results revealed that the gradual replacement of breadcrumbs with BDP in beef burgers significantly decreased moisture, protein, and lipid contents and significantly increased ash and carbohydrate contents compared to the control. The substitution of breadcrumbs with BDP at 50, 75, and 100% significantly decreased the cooking yield and increased the cooking loss and shrinking percentage of a beef burger. On the other hand, the textural profile of all beef burger samples showed a significant decrease in burgers’ hardness, gumminess, and chewiness with increasing substitution levels of breadcrumbs by BDP compared to the control. However, the treatment containing 25% BDP was more resilient than the control. In addition, the replacement of breadcrumbs with BDP up to 100% did not significantly affect the organoleptic properties of beef burger products compared to the control. Moreover, the microbiological analysis revealed that all beef burger treatments were safe with acceptable levels of bacterial load according to the Council of the European Communities’ standard specifications. In conclusion, there is a possibility of using BDP as a promising natural replacer of breadcrumbs to produce beef burgers without deteriorating the quality profile and safety of the product.

1. Introduction

Incorporation of plant-based ingredients into meat products is proven to be an effective and consumer-accepted strategy [1]. In fact, meat substitution with plant-based ingredients has opened the way to different approaches toward reformulating better and more sustainable meat products. Using a meat plant extender will not only present an opportunity to reduce the production costs of meat products but also add some healthier ingredients to the product. Meat extenders are non-meat ingredients with high protein and fiber levels that can also enhance the product’s characteristics, including water-holding capacity (WHC), texture, flavor, palatability, and overall appearance [2,3].

The consumers’ demand for beef burgers as fast food has rapidly increased in recent years. Therefore, manufacturers continuously try to improve their products’ sensory and sanitary quality to meet the consumers’ requirements [4]. The reasonable addition of functional fiber sources as meat fillers in some formulations improved their nutritional quality and sensory properties, reduced production costs, and extended their shelf life [5]. The use of agricultural dietary fiber sources could make beef products more affordable and improve their appeal and acceptability [6,7]. Furthermore, the addition of dietary fiber sources in meat products was found to increase their yields, as well as their water and fat retention, and prevent water loss during the cooking process [8] and could have similar sensory characteristics compared to traditional meat products [9].

Additionally, meat in beef sausages was replaced with melon flour made from defatted melon kernels at substitution levels ranging from 10 to 40%. As the substitution levels increased, the sausages’ yield, WHC, and sensory qualities improved [10]. When plum puree (5–15%) was used to substitute low-fat beef patties, the cooking yield and redness were increased, but the WHC, lightness, and yellowness were significantly reduced [11]. Furthermore, with the use of plum puree as an extender in beef patties at substitutions levels of 2.8–6.9%, the cooking yield and sensory attributes remained unaltered with increasing WHC and hardness with the increasing substitution levels [12]. All the previous investigations proved that many fruits are used as meat extenders, but further studies are needed on different meat products with different types of fruits and replacement levels.

Date fruits are one of the main crops in the Middle Eastern countries and several parts of the world. It can be commonly taken at three phases of development: Bisr, Rutab, and Tamar [13]. Currently, minimal amounts of date fruits are consumed at the firm and crunchy bisr stage or the first stage of dates maturity (containing 50% moisture), small amounts at the rutab or ripe stage (containing 30–35% moisture), while the largest portion are consumed as fresh or dried pitted dates at the Tamer stage (containing 10–30% moisture) [14]. Date overproduction causes significant losses due to the current limited processing capacity, especially for dates such as bisr that have a high moisture content. Thus, it is sustainable to utilize the bisr stage as a high fiber-containing date and novel functional ingredient in the food industry [14,15]. Taking the previously mentioned consideration into account, the present study aimed to investigate the effect of bisr date powder inclusion in beef burgers as a partial or total substitution of breadcrumbs on chemical composition, cooking properties, texture profile, microbial analysis, and organoleptic properties.

2. Materials and Methods

2.1. Materials

Minced beef meat, breadcrumbs, salt, fat, sugar, onion, black pepper, garlic, and corn oil were purchased from local markets in the Al-Hasa governorate, the Kingdom of Saudi Arabia, while BDP (Phoenix dactylifera, Shahal cultivar) was obtained from the Date Research Centre, Ministry of Environment, Water and Agriculture, the Kingdom of Saudi Arabia in August 2021.

2.2. Methods

2.2.1. Experimental Approach

In a completely randomized design with three replicates, five burger formulations were compared. The first formulation was a control formulation without additives (Table 1), and the other four formulations contained BDP as a replacement for breadcrumbs at an increasing level (25, 50, 75, and 100% of breadcrumbs and referred to as BDP25, BDP50, BDP75, and BDP100).

Table 1.

Formulation of beef burgers (g) with different concentrations of bisr date powder (BDP) and breadcrumbs.

2.2.2. Proximate Chemical Composition

Moisture, protein, fat, fiber, and ash contents in BDP, fresh beef meat, and cooked beef burgers were evaluated in triplicate using the official methods of the Association of Official Analytical Chemists [16]. While the total carbohydrates are calculated by difference, according to the following equation:

Total carbohydrates (%) = 100 − (moisture % + protein % + fat % + ash % + fiber %)

2.2.3. Beef Burger Preparation

Fresh minced beef meat (moisture 72%, fat 4%) was used for each burger formulation with different food ingredients, as indicated in Table 1. Each burger formulation was well homogenized using a kneading machine (KM400, China) for 10 min at medium speed. Then, dried BDP was used to replace breadcrumbs as a meat filler at 25, 50, 75, and 100% substitution levels. After that, the homogenous mixture of each recipe was pressed into round-shaped pieces of 50 g and a diameter of 9 cm with a thickness of 1 cm by using a commercial burger maker. Finally, the fresh burger products were stored at −18 °C in polyethylene bags until used for further investigations.

2.2.4. Cooking Properties

Burger samples from each formulation were cooked for 10 min on a hot plate (Homemaker 2000-Watt Electric, Model TXG-034C, Guangzhou Jimark Food Machinery Co., Ltd. Guangdong, China) held at 200 °C after warming for 15 min. The samples were continuously turned over every 5 min. on the hot plate to ensure uniform cooking. After that, all the samples were cooled to room temperature (21 °C) before weighting, and the cooking properties of each sample were determined according to [17], using the following equations:

Cooking yield (%) = 100 × (cooked burger weight/raw burger weight)

Cooking loss (%) = 100 × (raw burger weight − cooked burger weight)/raw burger weight

Shrinkage (%) = 100 × (raw burger diameter − cooked burger diameter)/raw burger diameter

2.2.5. Texture Profile Analysis

The different cooked low-fat beef burger samples and the control samples were subjected to texture profile analysis at room temperature using a Texture Analyzer (TA-XT Plus, Godalming, UK), in accordance with Ref. [18]. The different samples were cut into a circular mold with a 2 cm diameter after cooking and cooling at room temperature. The samples were then removed and flattened to 50% of their original height using a cylindrical probe with a diameter of 2.5 cm and a testing rapidity of 1 mm s−1. This process was repeated six times for each sample. The parameters of the texture profile determined in this study were cohesiveness (ratio of active work performed under the second compression curve that under the first compression curve (A2/A1) as dimensionless) and hardness (maximum force required for the initial compression of the sample as N). The total amount of energy needed for the first firmness is A1, and the total amount for the second compression is A2. Springiness is the ability of the sample to recover its original form after the deforming force is removed as mm. At the same time, chewiness is the required work to masticate the sample for swallowing as N mm.

2.2.6. Microbial Analysis

On a 3M Petrifilm® Aerobic Count Plate (3M España S.A., Madrid, Spain), mesophilic aerobic cultures (MAB; 30 °C for 48 h) of cooked low-fat beef burger and control samples were determined. Yeast and molds analysis were performed using potato dextrose agar (PDA) supplemented with Chloramphenicol (Oxoid) and incubated for 5 days at 28 °C (yeasts were counted after 72 h). All analyses were performed in triplicate, and data were presented as log CFU/g as described by [19,20].

2.2.7. Sensory Evaluation

The acceptability test was performed for the different cooked burger samples at the Sensory Analysis Laboratory of the Date Palm Research Centre of Excellence and College of Agriculture and Food, University of King Faisal, Saudi Arabia Kingdom, by using 13 trained panelists. Following a balanced complete block design, each sample was coded with three-digit numbers and presented in a randomized sequential monadic manner. Two sessions of five samples each were used in the sensory test. All the panelists were asked to evaluate the cooked burger samples according to their taste, odor, texture (juiciness and appearance), flavor, color, appearance, and overall quality based on a 5-point hedonic scale, where one represents “like extremely” and five represents “dislike extremely”. The analysis was performed according to [21,22].

2.3. Statistical Analysis

The statistical analyses of the data were performed using the computerized SPSS 20 (IBM SPSS Statistics for Windows, Version 20.0. Armonk, NY, USA: IBM Corp.). The effects of various treatments were analyzed using a one-way Analysis of variance (ANOVA) followed by Duncan’s multiple range tests at probability levels of 0.05 [23].

3. Results and Discussion

In meat products, many fruits and their by-products are used as ingredients to extend their shelf lives or to add fiber and other bioactive compounds [24,25]. The BDP is an agricultural byproduct with a feasible use as a novel food ingredient. The present study investigated the increasing inclusion levels of BDP instead of breadcrumbs as meat extenders or fillers in burger formulation.

3.1. Chemical Composition of Bisr Date Powder (BDP) and Beef Burgers Supplemented with Different Ratios of BDP

Table 2 shows the energy value and different chemical components of BDP. The results indicated a wide variation in date bisr chemical composition. The bisr powder contained low percentages of protein (4.25%) and fat (0.24%) and high percentages of crude fiber (16.00%), total carbohydrates (83.77%), and available carbohydrates (67.77%). In addition, BDP was found to have a high-energy content (290.24 K. Cal/100 g). These results reasonably agree with [26,27,28].

Table 2.

Chemical composition and energy value of bisr date powder (BDP).

According to the literature, fiber in meat products prevents water loss during cooking [29]. In addition to replacing flour, fat, or sugar with less expensive, non-caloric bulking agents, fiber-rich byproducts can also enhance water and oil preservation to improve emulsion or the oxidative stability in food products [30]. Further to their health benefits, dietary fibers have a number of useful properties that are important for food preparation, such as the ability to hold water, the ability to swell, the ability to increase viscosity, and the ability to form gels [31]. Therefore, utilization of date fruits with high fiber content at the bisr stage as a functional ingredient in meat products will be beneficial to improve their cooking properties as well as their sensory characteristics. Dates are usually used as ingredients in food preparations to provide a super taste to the final products [32].

The chemical analysis of beef burgers supplemented with different concentrations of BDP (0,25, 50, 75, and 100% instead of breadcrumbs) is illustrated in Table 3. Due to the increase in dry matter, BDP showed a direct impact on moisture, with a notable drop proportional to increased BDP content. The total replacement of breadcrumbs with BDP in the cooked burgers, reduced moisture to a little over 11%. Ash and carbohydrate contents were found to differ statistically among treatments. The gradual substitution of breadcrumbs with BDP for the production of the beef burger significantly increased ash from 0.71% to 2.02%, and carbohydrate from 2.03% to 15.85% (for control and 100% BDP, respectively). While 100% of additional BDP showed a lower protein and fat content than the control (p < 0.05), this might be a result of non-meat particles being present (BDP). This may be due to the fact that date fruit is usually low in fat and protein content and very rich in total carbohydrates and ash content, as indicated in Table 1.

Table 3.

Chemical composition of beef burger formulated with increasing bisr date powder as a substitute for breadcrumbs.

This resulted in agreement with the findings of Sayas-Barberá, et al. [5], who evaluated the effect of adding different concentrations of date pit (0%, 1.5%, 3%, and 6%) to beef burgers and its effect on the safety and quality throughout 10 days of storage. They found that the addition of 6% date pit powder in the cooked burger reduced the moisture and protein content. Meanwhile, the results disagreed with those of Besbes, et al. [33], who assessed the impact of adding extracted date fiber concentrate (DFC) in beef burger formulations at various levels on quality characteristics (e.g., nutritional value, proximate composition, cook loss, dimensional change, sensorial quality, etc.) and lowering production costs. They found that ash content was lower (p < 0.05) in burgers supplemented with DFC at a level of 1% and 1.5%.

3.2. Beef Burgers Cooking Properties

The cooking properties (cooking yield, cooking loss, and shrinkage) of beef burgers made in this study are indicated in Table 4. These properties are reported to be meat products’ most important quality characteristics [34,35]. In general, the substitution of breadcrumbs with BDP at 50, 75, and 100% significantly decreased the cooking yield. It increased the cooking loss and shrinkage percentage of beef burger samples. The decrement of the cooking yield ranged from 4.74% to 10.51%, while the increments of cooking loss and shrinking as percentages ranged between 89.27–190.81% and 46.56–101.40% in comparison with the control, respectively. When breadcrumbs were substituted with 25% date bisr for the production of the beef burger, the reduction in the cooking yield was only 1.96% compared with the control.

Table 4.

Cooking properties of beef burger formulated with increasing bisr date powder as a substitute for breadcrumbs.

Moreover, the shrinkage percentage of the cooked beef burger diameter was only 6.19% compared to 7.13% for the control. However, the reduction in burger diameter was reported to be due to meat protein denaturation and the loss of water and fat content during cooking [36]. In contrast, the dietary fibers were reported to decrease the cooking loss due to their high ability to keep moisture and fat in their matrix [33]. Anderson and Berry [37] indicated that when pea fiber was added to high-fat ground beef, fat retention in the ground beef significantly increased from 33 percent to values ranging between 85–98%. Likewise, the cooking yield was substantially greater in ground beef containing pea fiber (87–94%) than in control (52%).

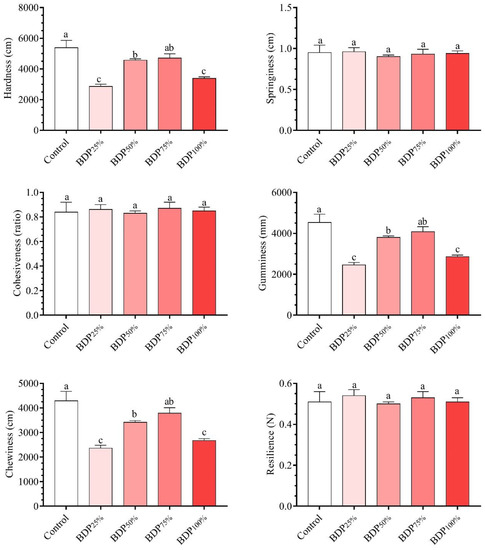

3.3. Texture Profile of the Beef Burger

Figure 1 shows the results of the textural profile of beef burgers made with different concentration levels of BDP and breadcrumbs. From the results, the burger’s hardness, gumminess, and chewiness were significantly (p < 0.05) and gradually decreased with increasing substitution levels of breadcrumbs with BDP in all the formulations. The control treatment was found to be slightly springier and more cohesive than all beef burger formulations with added BDP, but when breadcrumbs were replaced by 25% and 75% BDP, the products were more resilient than the control. The reduction in beef burgers’ hardness values may be related to the moisture retention capabilities of the BDP and its creation of a weaker three-dimensional network with a protein matrix. In addition, some writers indicated that the diluting effect of non-meat elements in meat protein systems mostly accounted for the softer texture [38,39,40].

Figure 1.

Textural profile of beef burgers formulated with increasing bisr date powder levels as a substitute for breadcrumbs. The same symbols in the same column mean no significant difference at the (p ≤ 0.05) level. Control: beef burger with 100% breadcrumbs. BDP25%: burger with 25% replacement of breadcrumbs by BDP; BDP50%: burger with 50% replacement of breadcrumbs by BDP, BDP75%: burger with 75% replacement of breadcrumbs by BDP; BDP100%: burger with 100% BDP.

Moreover, the heat treatment during the cooking process of beef burgers with BDP might have led to some modifications in their structures and, thereby, decreased their texture properties. Nowadays, consumers accept beef burgers that are less gummy, not firm, less springy and cohesive, and easy to chew, as harder, gummier, and chewy burgers require more time wasted in masticating and completing a beef burger meal [39]. Heck, et al. [41] reported that the texture changes in meat products by healthier reformulation are significant challenges, especially for their sensory attributes.

3.4. Beef Burger Microbial Characteristics

According to the literature, the beef burger is considered an ideal medium for the growth of many microorganisms because of its high contents of moisture, protein, and minerals, with some fermentable carbohydrates (glycogen) and favorable pH for most pathogenic microorganisms [42,43]. Therefore, the microbiological characteristics of meat products are a valuable way to determine the quality and safety of human health. However, hygienic conditions during the preparation and processing of meat products will reduce the microbial load of the products. Therefore, the total aerobic bacterial count is usually used to indicate bad hygienic conditions during food processing and storage that can lead to toxin production and pathogen proliferation [44].

According to the Council of the European Communities [45], the limit suggested for the total aerobic bacterial count in beef burgers is 105 microbes/g. The results obtained in Table 5 revealed that the minimum and maximum aerobic plate counts (A.P.C.) in all beef burger samples ranged between 4.6 × 102–6.10 × 102 cfu, which are below the suggested [45] limits. On the other hand, the total count of yeast and fungus in the same samples was found to range between 1.10 × 103–6.30 × 103 cfu. The minimum concentration level was registered for sample B, while the maximum level was recorded in the control (A). In general, the substitution of breadcrumbs with BDP reduced the total counts of yeast and fungus in beef burgers with a slight increment in the total bacterial count.

Table 5.

Microbial characteristics of beef burgers formulated with increasing bisr date powder levels as a substitute for breadcrumbs.

3.5. Sensory Evaluation

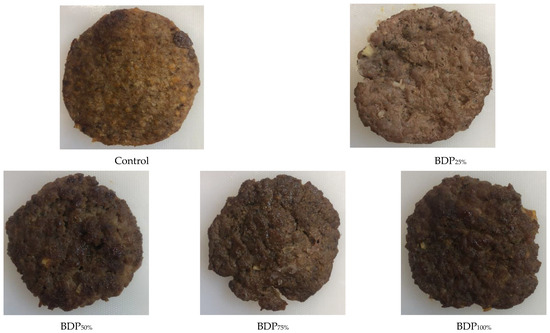

The results of the organoleptic assessment of cooked beef burger samples produced in this study by replacing breadcrumbs with different concentration levels of BDP are shown in Table 6 and Figure 2. The analysis of variance between the different treatments indicated insignificant differences between all beef burger samples that were made with different concentrations of BDP and the control sample concerning their taste, odor, texture, color, appearance, and overall quality. However, the best flavor, odor, texture, and overall quality scores among all the samples recorded for beef burger samples were made with the substitution of 25% breadcrumbs with BDP. However, the substitution of breadcrumbs with up to 100% BDP had no significant negative effects on beef burger products’ organoleptic properties compared with the control.

Table 6.

Sensory evaluation of beef burgers formulated with increasing bisr date powder level as a substitute for breadcrumbs.

Figure 2.

Photomicrograph of cooked beef burgers formulated with increasing bisr date powder level as a substitute for breadcrumbs.

In terms of color, flavor, and juiciness, the sensory evaluation of the acceptability of fat-substituted burger treatments with dry hydrogel enhanced with açai oil revealed no differences (p > 0.05). The control variant has high ratings in the analyses of appearance, color, flavor, taste, juiciness, texture, and overall acceptability, which supports the significance of the type of fat in a burger and highlights how difficult it is to fully satisfy consumer demands by using a fat replacement in place of animal fat [46]. According to Sayas-Barberá, et al. [5], a new substance made from date palm coproducts (pits) was procured and tried as a burger preservative. During the course of 10 days of storage, the impact of adding various amounts of date pit (0%, 1.5%, 3%, and 6%) in beef patties was assessed. Additionally, burgers with 3% BDP had the highest level of product approval among the trained panel, and after cooking, they displayed one of the finest sensory profiles. Recent studies on the creation of novel additives for burgers indicated a concentration of additives that relate to sensory acceptance. According to Pollini, et al. [47], the freeze-dried apple pomace was utilized to fortify beef burgers and contained 40.19% of the daily recommended amount of fiber (4% and 8%). This group of assessors perceived the versions fortified with apple pomace as more uniform, less salty, less acidic, less bitter, and more chewable than assessors who had declared they usually prefer to consume meat.

4. Conclusions

One of the most consumed foods worldwide is the burger. New, superior-quality meat products that are also healthier are in higher demand. A practical, affordable, and healthful component for food fortification, particularly in products of animal origin, is bisr date powder (BDP). In this study, the impact of the gradual replacement of breadcrumbs by BDP as a partial or total substitution on chemical composition, cooking properties, texture profile, microbial analysis, and organoleptic properties of beef burger were investigated. The substitution of breadcrumbs with BDP (as fiber-rich byproducts, low-cost, and non-caloric bulking agents) at 25% to beef burgers was the most advantageous concentration, since the fiber content of BDP was able to preserve the red color of raw burgers, avoid pigment and lipid oxidation, reduce microbial counts, and improve the cooking properties. Furthermore, burgers with 25% BDP led to the highest acceptability of the product to the trained panel, and after cooking, they showed one of the best sensory profiles. BDP could have significant potential as a food improvement agent to eliminate synthetic preservatives and to enrich foods with fiber without losing flavor, color, and texture.

Author Contributions

H.M.M.M., H.A.-M.M., A.R.A. and W.A.A.-S. designed the work and contributed substantially to the study’s concept. H.A.-M.M., H.M.M.M., W.A.A.-S. and S.A.M.A.-A. performed the experimental studies and provided technical support, the literature search, analysis, and interpretation of data. N.K.A., T.M.M.A. and H.M.M.M. were responsible for data reviewing, performance, processing, writing, manuscript revision, supervision, and publishing of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia [Grant No. 908].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available from the corresponding authors upon request.

Conflicts of Interest

The authors declare no potential conflict of interest for this article’s research, authorship, and/or publication.

References

- Lang, M. Consumer acceptance of blending plant-based ingredients into traditional meat-based foods: Evidence from the meat-mushroom blend. Food Qual. Prefer. 2020, 79, 103758. [Google Scholar] [CrossRef]

- Fernandez-Novo, A.; Santos-Lopez, S.; Barrajon-Masa, C.; Mozas, P.; de Mercado, E.; Caceres, E.; Garrafa, A.; Gonzalez-Martin, J.V.; Perez-Villalobos, N.; Oliet, A. Effects of extender type, storage time, and temperature on bull semen parameters. Biology 2021, 10, 630. [Google Scholar] [CrossRef] [PubMed]

- Pintado, T.; Delgado-Pando, G. Towards more sustainable meat products: Extenders as a way of reducing meat content. Foods 2020, 9, 1044. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Pando, G.; Pintado, T. New Strategies for Innovative and Enhanced Meat and Meat Products. Foods 2022, 11, 772. [Google Scholar] [CrossRef] [PubMed]

- Sayas-Barberá, E.; Martín-Sánchez, A.M.; Cherif, S.; Ben-Abda, J.; Pérez-Álvarez, J.Á. Effect of date (Phoenix dactylifera L.) pits on the shelf life of beef burgers. Foods 2020, 9, 102. [Google Scholar] [CrossRef] [PubMed]

- Mehta, N.; Ahlawat, S.; Sharma, D.; Dabur, R. Novel trends in development of dietary fiber rich meat products—A critical review. J. Food Sci. Technol. 2015, 52, 633–647. [Google Scholar] [CrossRef] [PubMed]

- Ursachi, C.Ș.; Perța-Crișan, S.; Munteanu, F.-D. Strategies to improve meat products’ quality. Foods 2020, 9, 1883. [Google Scholar] [CrossRef] [PubMed]

- Shariati-Ievari, S.; Ryland, D.; Edel, A.; Nicholson, T.; Suh, M.; Aliani, M. Sensory and physicochemical studies of thermally micronized chickpea (Cicer arietinum) and green lentil (Lens culinaris) flours as binders in low-fat beef burgers. J. Food Sci. 2016, 81, S1230–S1242. [Google Scholar] [CrossRef]

- Selani, M.M.; Shirado, G.A.; Margiotta, G.B.; Rasera, M.L.; Marabesi, A.C.; Piedade, S.M.; Contreras-Castillo, C.J.; Canniatti-Brazaca, S.G. Pineapple by-product and canola oil as partial fat replacers in low-fat beef burger: Effects on oxidative stability, cholesterol content and fatty acid profile. Meat Sci. 2016, 115, 9–15. [Google Scholar] [CrossRef] [PubMed]

- Igyor, M.; Ankeli, J.; Badifu, G. Effect of defatted melon (Citrullus vulgaris schrad.) kernel flour supplementation on the storage stability and microbiological quality of refrigerated beef-based sausages. J. Food Process. Preserv. 2008, 32, 143–158. [Google Scholar] [CrossRef]

- Yıldız-Turp, G.; Serdaroglu, M. Effects of using plum puree on some properties of low fat beef patties. Meat Sci. 2010, 86, 896–900. [Google Scholar] [CrossRef]

- Serdaroğlu, M.; Kavuşan, H.; İpek, G.; Öztürk, B. Evaluation of the quality of beef patties formulated with dried pumpkin pulp and seed. Korean J. Food Sci. Anim. Resour. 2018, 38, 1–13. [Google Scholar] [PubMed]

- Fernández-López, J.; Viuda-Martos, M.; Sayas-Barberá, E.; Navarro-Rodríguez de Vera, C.; Pérez-Álvarez, J.Á. Biological, Nutritive, Functional and Healthy Potential of Date Palm Fruit (Phoenix dactylifera L.): Current Research and Future Prospects. Agronomy 2022, 12, 876. [Google Scholar] [CrossRef]

- Ghnimi, S.; Umer, S.; Karim, A.; Kamal-Eldin, A. Date fruit (Phoenix dactylifera L.): An underutilized food seeking industrial valorization. NFS J. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Al-Mssallem, M.Q.; Alqurashi, R.M.; Al-Khayri, J.M. Bioactive compounds of date palm (Phoenix dactylifera L.). In Bioactive Compounds in Underutilized Fruits and Nuts; Murthy, H.N., Bapat, V.A., Eds.; Springer: Cham, Switzerland, 2020; pp. 93–105. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 18th ed.; AOAC: Arlington, VA, USA, 2010. [Google Scholar]

- Baioumy, A.A.; Abedelmaksoud, T.G. Quality properties and storage stability of beef burger as influenced by addition of orange peels (albedo). Theory Pract. Meat Process. 2021, 6, 33–38. [Google Scholar] [CrossRef]

- Bourne, M. Food Texture and Viscosity: Concept and Measurement, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- APHA. Compendium of Method for The Microbiological Examination of Food, 5th ed.; Salfinger, Y., TortorelloSpeck, M.L., Eds.; American Public Health Association: Washington, DC, USA, 2015. [Google Scholar] [CrossRef]

- Difco-Manual. Dehydrated Culture Media and Ingredients, 11th ed.; Division of Becton Dickinson and Company: Sparks, MD, USA, 1998. [Google Scholar]

- ISO 6658:1985; Sensory Analysis—Methodology—Flavor Profile Methods. International Organization for Standardization: Geneva, Switzerland, 1985.

- AMSA. Research Guidelines for Cookery, Sensory Evaluation and Instrumental Tenderness Measurements of Meat; American Meat Science Association: Champaign, IL, USA, 2015. [Google Scholar]

- Bradley, E.L.; Blackwood, L.G. Comparing paired data: A simultaneous test for means and variances. Am. Stat. 1989, 43, 234–235. [Google Scholar]

- Peiretti, P.; Gai, F. Fruit and pomace extracts: Applications to improve the safety and quality of meat products. In Fruit and Pomace Extracts; Owen, J.P., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2015; pp. 1–28. [Google Scholar]

- Nardella, S.; Conte, A.; Del Nobile, M.A. State-of-Art on the Recycling of By-Products from Fruits and Vegetables of Mediterranean Countries to Prolong Food Shelf Life. Foods 2022, 11, 665. [Google Scholar] [CrossRef] [PubMed]

- Al-Shahib, W.; Marshall, R.J. The fruit of the date palm: Its possible use as the best food for the future? Int. J. Food Sci. Nutr. 2003, 54, 247–259. [Google Scholar] [CrossRef] [PubMed]

- El-Mergawi, R.A.; AlGeffari, M.A.; Al-Humaid, A. Sugar types, phenolic contents, and antioxidant activities for 17 Saudi Arabian date cultivars and their relations with glycemic indices. Int. J. Fruit Sci. 2019, 19, 315–325. [Google Scholar] [CrossRef]

- Jad Elrab, E.H.; Makki, H.M.M. Determination and comparative evaluation of fruit nutritional value of two Sudanese date palm (Phoenix dactylifera L.) cultivars. Sust. J. Agric. Vet. Sci. 2018, 19, 9. [Google Scholar]

- Schmiele, M.; Mascarenhas, M.C.C.N.; da Silva Barretto, A.C.; Pollonio, M.A.R. Dietary fiber as fat substitute in emulsified and cooked meat model system. LWT Food Sci. Technol. 2015, 61, 105–111. [Google Scholar] [CrossRef]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.C.; Christophe, B.; Attia, H. Dietary fiber and fiber-rich by-products of food processing: Characterization, technological functionality and commercial applications: A review. Food Chem. 2011, 2, 411–421. [Google Scholar] [CrossRef]

- Ajila, C.M.; Aalami, M.; Leelavathi, K.; Prasada Rao, U.J.S. Mango peel powder: A potential source of antioxidant and dietary fiber in macaroni preparations. Innov. Food Sci. Emerg. Technol. 2010, 11, 219–224. [Google Scholar] [CrossRef]

- Al-Yahyai, R.; Manickavasagan, A. An overview of date palm production. In Dates: Production, Processing, Food, and Medicinal Values; Manickavasagan, A., Essa, M.M., Sukumar, E., Eds.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2012; pp. 3–12. [Google Scholar] [CrossRef]

- Besbes, S.; Ghorbel, R.; Salah, R.B.; Masmoudi, M.; Jedidi, F.; Attia, H.; Blecker, C. Date fiber concentrate: Chemical compositions, functional properties and effect on quality characteristics of beef burgers. J. Food Drug Anal. 2010, 18, 8–14. [Google Scholar] [CrossRef]

- Mahmoud, M.H.; Abou-Arab, A.A.; Abu-Salem, F.M. Quality characteristics of beef burger as influenced by different levels of orange peel powder. Am. J. Food Technol. 2017, 12, 262–270. [Google Scholar] [CrossRef]

- Lee, M.; Han, D.; Jeong, J.; Choi, J.; Choi, Y.; Kim, H.; Paik, H.-D.; Kim, C. Effect of kimchi powder level and drying methods on quality characteristics of breakfast sausage. Meat Sci. 2008, 80, 708–714. [Google Scholar] [CrossRef]

- López-Vargas, J.H.; Fernández-López, J.; Pérez-Álvarez, J.Á.; Viuda-Martos, M. Quality characteristics of pork burger added with albedo-fiber powder obtained from yellow passion fruit (Passiflora edulis var. flavicarpa) co-products. Meat Sci. 2014, 97, 270–276. [Google Scholar] [CrossRef]

- Anderson, E.; Berry, B. Effects of inner pea fiber on fat retention and cooking yield in high fat ground beef. Food Res. Int. 2001, 34, 689–694. [Google Scholar] [CrossRef]

- Akwetey, W.; Knipe, C. Sensory attributes and texture profile of beef burgers with gari. Meat Sci. 2012, 92, 745–748. [Google Scholar] [CrossRef]

- Choi, Y.; Choe, J.; Cho, D.; Kim, B. Practical use of surimi-like material made from porcine longissimus dorsi muscle for the production of low-fat pork patties. Meat Sci. 2012, 90, 292–296. [Google Scholar] [CrossRef]

- Kotwaliwale, N.; Bakane, P.; Verma, A. Changes in textural and optical properties of oyster mushroom during hot air drying. J. Food Eng. 2007, 78, 1207–1211. [Google Scholar] [CrossRef]

- Heck, R.T.; Vendruscolo, R.G.; de Araújo Etchepare, M.; Cichoski, A.J.; de Menezes, C.R.; Barin, J.S.; Lorenzo, J.M.; Wagner, R.; Campagnol, P.C.B. Is it possible to produce a low-fat burger with a healthy n−6/n−3 PUFA ratio without affecting the technological and sensory properties? Meat Sci. 2017, 130, 16–25. [Google Scholar] [CrossRef] [PubMed]

- Komba, E.V.; Komba, E.V.; Mkupasi, E.M.; Mbyuzi, A.O.; Mshamu, S.; Mzula, A.; Luwumba, D. Sanitary practices and occurrence of zoonotic conditions in cattle at slaughter in Morogoro Municipality, Tanzania: Implications for public health. Tanzan. J. Health Res. 2012, 14, 14. [Google Scholar] [CrossRef]

- Zafar, A.; Ahmed, E.; Wajiha, H.; Khan, A.B. Microbiological Evaluation of Raw Meat Products Available in Local Markets of Karachi, Pakistan. Proc. Pak. Acad. Sci. B. Life Environ. Sci. 2016, 53, 103–106. [Google Scholar]

- Zweifel, C.; Baltzer, D.; Stephan, R. Microbiological contamination of cattle and pig carcasses at five abattoirs determined by swab sampling in accordance with EU Decision 2001/471/EC. Meat Sci. 2005, 69, 559–566. [Google Scholar] [CrossRef]

- EC. Commission Regulation (EC) No. 2073/2005 on Microbiological Criteria for Foodstuffs; Council of the European Communities: Brussels, Belgium, 2005. [Google Scholar]

- Hanula, M.; Szpicer, A.; Górska-Horczyczak, E.; Khachatryan, G.; Pogorzelska-Nowicka, E.; Poltorak, A. Quality of Beef Burgers Formulated with Fat Substitute in a Form of Freeze-Dried Hydrogel Enriched with Açai Oil. Molecules 2022, 27, 3700. [Google Scholar] [CrossRef]

- Pollini, L.; Blasi, F.; Ianni, F.; Grispoldi, L.; Moretti, S.; Di Veroli, A.; Cossignani, L.; Cenci-Goga, B.T. Ultrasound-Assisted Extraction and Characterization of Polyphenols from Apple Pomace, Functional Ingredients for Beef Burger Fortification. Molecules 2022, 27, 1933. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).