How Does Manufacturing Intelligentization Influence Innovation in China from a Nonlinear Perspective and Economic Servitization Background?

Abstract

1. Introduction

2. Literature Review

3. Theoretical Background and Research Hypotheses

3.1. Direct Mechanism

3.2. Mediating Mechanism

4. Methods

4.1. Variable Description

4.1.1. Dependent Variable

4.1.2. Independent Variable

4.1.3. Mediating Variable

4.1.4. Control Variables

4.2. Model Design

4.3. Regression Results

4.4. Robustness Tests

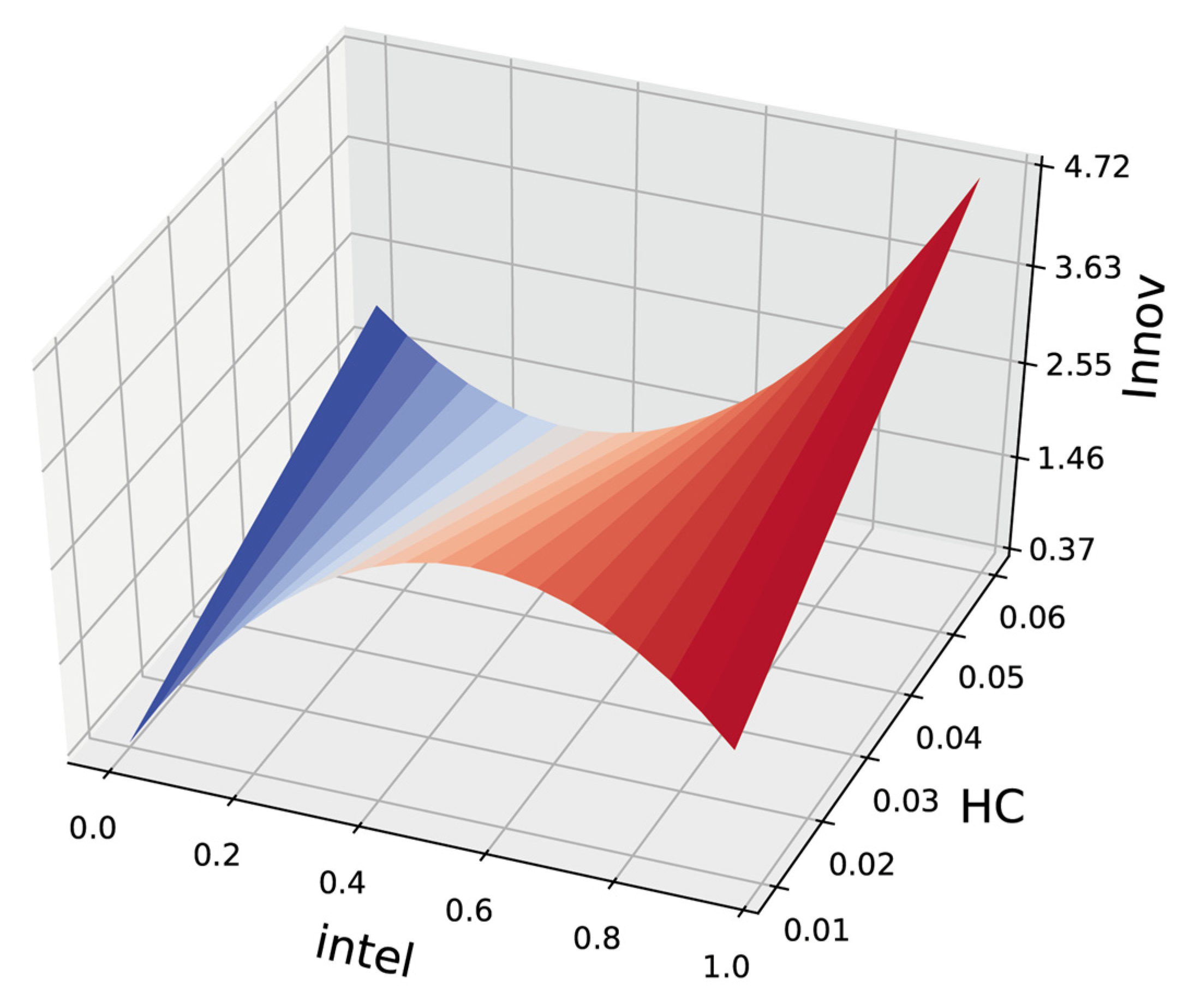

4.5. Test of the Moderating Effect

5. Discussion

5.1. Practical Implications

5.2. Theoretical Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Su, J.; Su, K.; Wang, S. Does the Digital Economy Promote Industrial Structural Upgrading?—A Test of Mediating Effects Based on Heterogeneous Technological Innovation. Sustainability 2021, 13, 10105. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Benedettini, O.; Kay, J.M. The servitization of manufacturing: A review of literature and reflection on future challenges. J. Manuf. Technol. Manag. 2009, 20, 547–567. [Google Scholar] [CrossRef]

- Rabetino, R.; Kohtamäki, M.; Gebauer, H. Strategy map of servitization. Int. J. Prod. Econ. 2017, 192, 144–156. [Google Scholar] [CrossRef]

- Liu, J.; Chang, H.; Forrest, J.Y.; Yang, B. Influence of artificial intelligence on technological innovation: Evidence from the panel data of china’s manufacturing sectors. Technol. Forecast. Soc. 2020, 158, 120142. [Google Scholar] [CrossRef]

- Yang, H.; Li, L.; Liu, Y. The effect of manufacturing intelligence on green innovation performance in China. Technol. Forecast. Soc. 2022, 178, 121569. [Google Scholar] [CrossRef]

- Karhade, P.; Dong, J. Information Technology Investment and Commercialized Innovation Performance: Dynamic Adjustment Costs and Curvilinear Impacts. MIS Q. 2021, 45, 1007–1024. [Google Scholar] [CrossRef]

- Thoben, K.; Wiesner, S.; Wuest, T. “Industrie 4.0” and smart manufacturing-a review of research issues and application examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT driven service-oriented smart manufacturing: Framework and characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 81–91. [Google Scholar] [CrossRef]

- Kleis, L.; Chwelos, P.; Ramirez, R.V.; Cockburn, I. Information technology and intangible output: The impact of IT investment on innovation productivity. Inform. Syst. Res. 2012, 23, 42–59. [Google Scholar] [CrossRef]

- Gómez, J.; Salazar, I.; Vargas, P. Does information technology improve open innovation performance? An examination of manufacturers in Spain. Inform. Syst. Res. 2017, 28, 661–675. [Google Scholar] [CrossRef]

- Wu, S.; Ding, X.; Liu, R.; Gao, H. How does IT capability affect open innovation performance? The mediating effect of absorptive capacity. Eur. J. Innov. Manag. 2019, 24, 43–65. [Google Scholar] [CrossRef]

- Trantopoulos, K.; von Krogh, G.; Wallin, M.W.; Woerter, M. External knowledge and information technology: Implications for process innovation performance. MIS Q. 2017, 41, 287–300. [Google Scholar] [CrossRef]

- Tarafdar, M.; Tanriverdi, H. Impact of the information technology unit on information technology-embedded product innovation. J. Assoc. Inf. Syst. 2018, 19, 2. [Google Scholar]

- Ravichandran, T.; Han, S.; Mithas, S. Mitigating diminishing returns to R&D: The role of information technology in innovation. Inform. Syst. Res. 2017, 28, 812–827. [Google Scholar]

- Haug, A.; Adsbøll Wickstrøm, K.; Stentoft, J.; Philipsen, K. The impact of information technology on product innovation in SMEs: The role of technological orientation. J. Small Bus. Manag. 2020, 1–27. [Google Scholar] [CrossRef]

- Cockburn, I.M.; Henderson, R.; Stern, S. The Impact of Artificial Intelligence on Innovation: An Exploratory Analysis; University of Chicago Press: Chicago, IL, USA, 2019. [Google Scholar]

- Kakatkar, C.; Bilgram, V.; Füller, J. Innovation analytics: Leveraging artificial intelligence in the innovation process. Bus. Horiz. 2020, 63, 171–181. [Google Scholar] [CrossRef]

- Truong, Y.; Papagiannidis, S. Artificial intelligence as an enabler for innovation: A review and future research agenda. Technol. Forecast. Soc. 2022, 183, 121852. [Google Scholar] [CrossRef]

- Grashof, N.; Kopka, A. Artificial intelligence and radical innovation: An opportunity for all companies? Small Bus. Econ. 2022, 1–27. [Google Scholar] [CrossRef]

- Rammer, C.; Fernández, G.P.; Czarnitzki, D. Artificial intelligence and industrial innovation: Evidence from German firm-level data. Res. Policy 2022, 51, 104555. [Google Scholar] [CrossRef]

- Ghasemaghaei, M.; Calic, G. Does big data enhance firm innovation competency? The mediating role of data-driven insights. J. Bus. Res. 2019, 104, 69–84. [Google Scholar] [CrossRef]

- Niebel, T.; Rasel, F.; Viete, S. BIG data-BIG gains? Understanding the link between big data analytics and innovation. Econ. Innov. New Technol. 2019, 28, 296–316. [Google Scholar] [CrossRef]

- Weitzman, M.L. Recombinant Growth. Q. J. Econ. 1998, 113, 331–360. [Google Scholar] [CrossRef]

- Swann, G.M.P. The Economics of Innovation: An Introduction; Edward Elgar Publishing: Cheltenham, UK, 2009. [Google Scholar]

- Wu, L.; Hitt, L.; Lou, B. Data analytics, innovation, and firm productivity. Manag. Sci. 2020, 66, 2017–2039. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward new-generation intelligent manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Wang, B. The future of manufacturing: A new perspective. Engineering 2018, 4, 722–728. [Google Scholar] [CrossRef]

- Karr-Wisniewski, P.; Lu, Y. When more is too much: Operationalizing technology overload and exploring its impact on knowledge worker productivity. Comput. Hum. Behav. 2010, 26, 1061–1072. [Google Scholar] [CrossRef]

- Karamanos, A.G. Leveraging micro- and macro-structures of embeddedness in alliance networks for exploratory innovation in biotechnology. RD Manag. 2012, 42, 71–89. [Google Scholar] [CrossRef]

- Li, X.; Li, K.; Zhou, H. Impact of Inventor’s Cooperation Network on Ambidextrous Innovation in Chinese AI Enterprises. Sustainability 2022, 14, 9996. [Google Scholar] [CrossRef]

- Ahuja, G.; Morris Lampert, C. Entrepreneurship in the large corporation: A longitudinal study of how established firms create breakthrough inventions. Strateg. Manag. J. 2001, 22, 521–543. [Google Scholar] [CrossRef]

- Shipilov, A.V. Firm scope experience, historic multimarket contact with partners, centrality, and the relationship between structural holes and performance. Organ. Sci. 2009, 20, 85–106. [Google Scholar] [CrossRef]

- De Araújo, I.F.; Gonçalves, E.; Taveira, J.G. The role of patent co-inventorship networks in regional inventive performance. Int. Reg. Sci. Rev. 2019, 42, 235–280. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J. Research on a Compound Dual Innovation Capability Model of Intelligent Manufacturing Enterprises. Sustainability 2021, 13, 12521. [Google Scholar] [CrossRef]

- Benedettini, O.; Neely, A.; Swink, M. Why do servitized firms fail? A risk-based explanation. Int. J. Oper. Prod. Manag. 2015, 35, 946–979. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Einola, S.; Rabetino, R. Exploring servitization through the paradox lens: Coping practices in servitization. Int. J. Prod. Econ. 2020, 226, 107619. [Google Scholar] [CrossRef]

- Gebauer, H.; Saul, C.J.; Haldimann, M.; Gustafsson, A. Organizational capabilities for pay-per-use services in product-oriented companies. Int. J. Prod. Econ. 2017, 192, 157–168. [Google Scholar] [CrossRef]

- Krugman, P. Increasing returns and economic geography. J. Polit. Econ. 1991, 99, 483–499. [Google Scholar] [CrossRef]

- Krugman, P.R. Geography and Trade; MIT Press: Cambridge, MA, USA, 1991. [Google Scholar]

- Yu, W.; Chiou, C. Effects of Sustainable Development of the Logistics Industry by Cloud Operational System. Sustainability 2022, 14, 10440. [Google Scholar] [CrossRef]

- Fujita, M.; Krugman, P.R.; Venables, A. The Spatial Economy: Cities, Regions, and International Trade; MIT Press: Cambridge, MA, USA, 1999. [Google Scholar]

- Jiang, C.; Hong, Q.L.; Qiu, L. Service Agglomeration: Characteristics, Mechanism and International Experience; Springer: Singapore, 2019; pp. 89–112. [Google Scholar]

- Camagni, R.; Capello, R. Milieux Innovateurs and Collective Learning: From Concepts to Measurement; Springer: Berlin/Heidelberg, Germany, 2002; pp. 15–45. [Google Scholar]

- Li, J. Research on evaluation benchmark and influencing factors for China’s manufacturing intelligentization. China Soft Sci. 2020, 35, 154–163. [Google Scholar]

- Combes, P.P. Economic structure and local growth: France, 1984–1993. J. Urban Econ. 2000, 47, 329–355. [Google Scholar] [CrossRef]

- Han, F.; Yang, L. How Does the Agglomeration of Producer Services Promote the Upgrading of Manufacturing Structure?: An Integrated Framework of Agglomeration Economies and Schumpeter’s Endogenous Growth Theory. Manag. World 2020, 36, 72–94. [Google Scholar]

- Edwards, J.R.; Lambert, L.S. Methods for integrating moderation and mediation: A general analytical framework using moderated path analysis. Psychol. Methods 2007, 12, 1. [Google Scholar] [PubMed]

- Duranton, G.; Puga, D. Nursery cities: Urban diversity, process innovation, and the life cycle of products. Am. Econ. Rev. 2001, 91, 1454–1477. [Google Scholar]

| Categories | Indicators |

|---|---|

| Intelligent technology | Fixed asset investment in information transmission, computer services, and software industries |

| Intelligent application | Number of patent applications for electronic and communication equipment manufacturing industry |

| Intelligent benefit | Total profit of electronic and communication equipment manufacturing |

| Variable Type | Variable Name | Variable Symbol |

|---|---|---|

| Dependent Variable | Innovation performance | Innov |

| Independent Variable | Manufacturing intelligentization | Intel |

| Mediating Variable | Diversified agglomeration of producer services index | DV |

| Control Variables | Human capital level | HC |

| Fixed capital stock | Fixcap | |

| Government expenditure | Gov | |

| Technology market activity | CTR | |

| Population density | Pdensity | |

| The cost of living | Lifecost |

| Variable | Obs | Mean | Std. Dev. | Min | Max |

|---|---|---|---|---|---|

| Innov | 390 | 7.518 | 1.590 | 2.148 | 10.699 |

| Intel | 390 | 0.065 | 0.109 | 0.004 | 0.972 |

| DV | 390 | 0.219 | 0.051 | 0.077 | 0.348 |

| HC | 390 | 0.026 | 0.009 | 0.010 | 0.068 |

| Fixcap | 390 | 10.758 | 5.792 | 3.819 | 36.749 |

| Gov | 390 | 17.376 | 0.702 | 14.993 | 18.976 |

| CTR | 390 | 13.626 | 1.843 | 8.623 | 17.962 |

| Pdensity | 390 | 0.048 | 0.073 | 0.001 | 0.429 |

| Lifecost | 390 | 0.580 | 0.245 | 0.184 | 1.296 |

| (1) | (2) | (3) | (4) | |

|---|---|---|---|---|

| Innov | Innov | DV | Innov | |

| Intel | 3.182 *** | 3.710 *** | 0.238 *** | 6.918 ** |

| (3.542) | (3.910) | (5.534) | (2.523) | |

| SqIntel | −1.959 ** | −2.439 *** | −0.217 *** | −2.198 ** |

| (−2.471) | (−3.023) | (−5.932) | (−2.368) | |

| DV | 5.183 *** | |||

| (3.981) | ||||

| Intel × DV | −13.513 | |||

| (−1.646) | ||||

| HC | 33.069 *** | 2.616 *** | 23.268 ** | |

| (3.216) | (5.606) | (2.202) | ||

| Fixcap | 0.023 *** | 0.000 | 0.021 *** | |

| (2.894) | (0.721) | (2.715) | ||

| Gov | 0.359 | 0.016 | 0.275 | |

| (1.514) | (1.524) | (1.179) | ||

| CTR | −0.047 | −0.000 | −0.050 | |

| (−1.290) | (−0.030) | (−1.397) | ||

| Pdensity | 1.920 | 0.141 | 0.696 | |

| (0.583) | (0.942) | (0.214) | ||

| Lifecost | −0.276 | 0.021 | −0.389 | |

| (−0.853) | (1.459) | (−1.223) | ||

| _cons | 7.344 *** | 0.703 | −0.166 | 1.455 |

| (148.512) | (0.173) | (−0.901) | (0.365) | |

| Province FE | yes | yes | yes | yes |

| Time FE | yes | yes | yes | yes |

| N | 390 | 390 | 390 | 390 |

| R2 | 0.962 | 0.965 | 0.931 | 0.967 |

| Principal Component | Include R & D | Change DV’s Measure | ||||||

|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | |

| Innov | DV | Innov | Innov | DV | Innov | DV | Innov | |

| Intel | 0.324 *** | 0.023 *** | 0.588 ** | 2.699 *** | 0.244 *** | 5.750 ** | 0.028 *** | 21.565 |

| (3.519) | (5.395) | (2.120) | (2.813) | (5.473) | (2.139) | (5.870) | (0.234) | |

| Sqintel | −0.027 ** | −0.003 *** | −0.021 | −1.533 * | −0.222 *** | −1.227 | −0.022 *** | −2.045 * |

| (−2.330) | (−5.618) | (−1.624) | (−1.873) | (−5.843) | (−1.316) | (−5.433) | (−1.894) | |

| DV | 4.482 *** | 5.294 *** | 25.475 ** | |||||

| (3.806) | (4.169) | (2.054) | ||||||

| Intel × DV | −1.197 | −13.182 | −18.579 | |||||

| (−1.386) | (−1.646) | (−0.201) | ||||||

| HC | 32.595 *** | 2.536 *** | 22.895 ** | 20.172 * | 2.690 *** | 9.714 | 0.288 *** | 26.707 ** |

| (3.147) | (5.402) | (2.155) | (1.916) | (5.496) | (0.902) | (5.601) | (2.399) | |

| Fixcap | 0.021 *** | 0.000 | 0.019 ** | 0.029 *** | 0.000 | 0.027 *** | 0.000 *** | 0.021 ** |

| (2.637) | (0.480) | (2.466) | (3.686) | (0.612) | (3.544) | (2.698) | (2.527) | |

| Gov | 0.350 | 0.015 | 0.264 | −0.077 | 0.019 | −0.171 | 0.001 | 0.335 |

| (1.470) | (1.388) | (1.123) | (−0.301) | (1.594) | (−0.686) | (0.729) | (1.419) | |

| CTR | −0.048 | −0.000 | −0.050 | −0.019 | −0.000 | −0.021 | −0.000 | −0.047 |

| (−1.319) | (−0.164) | (−1.390) | (−0.521) | (−0.124) | (−0.596) | (−0.074) | (−1.300) | |

| Pdensity | 1.870 | 0.126 | 0.909 | 0.565 | 0.149 | −0.691 | −0.078 *** | 3.746 |

| (0.565) | (0.841) | (0.279) | (0.175) | (0.988) | (−0.217) | (−4.744) | (1.101) | |

| Lifecost | −0.291 | 0.021 | −0.405 | −0.290 | 0.021 | −0.406 | 0.004 *** | −0.386 |

| (−0.896) | (1.445) | (−1.265) | (−0.918) | (1.463) | (−1.308) | (2.721) | (−1.184) | |

| RD | 0.398 *** | −0.002 | 0.406 *** | |||||

| (4.116) | (−0.504) | (4.296) | ||||||

| _cons | 1.137 | −0.121 | 2.070 | 2.674 | −0.177 | 3.489 | 0.967 *** | −23.932 * |

| (0.278) | (−0.651) | (0.514) | (0.669) | (−0.954) | (0.892) | (47.634) | (−1.891) | |

| Province FE | yes | yes | yes | yes | yes | yes | yes | yes |

| Time FE | yes | yes | yes | yes | yes | yes | yes | yes |

| N | 390 | 390 | 390 | 390 | 390 | 390 | 390 | 390 |

| R2 | 0.965 | 0.931 | 0.966 | 0.967 | 0.931 | 0.968 | 0.965 | 0.966 |

| (1) | (2) | (3) | (4) | |

|---|---|---|---|---|

| Innov | Innov | DV | Innov | |

| Intel | 14.191 *** | 13.628 *** | 0.069 | 16.241 *** |

| (3.877) | (3.742) | (0.411) | (3.832) | |

| SqIntel | −12.997 *** | −12.919 *** | −0.160 | −13.160 *** |

| (−2.851) | (−2.851) | (−0.773) | (−2.922) | |

| Intel × HC | −374.447 *** | −331.704 *** | 6.117 | −338.093 *** |

| (−3.196) | (−2.819) | (1.137) | (−2.899) | |

| SqIntel × HC | 397.120 *** | 373.824 ** | −2.682 | 394.877 *** |

| (2.593) | (2.450) | (−0.384) | (2.639) | |

| DV | 5.200 *** | |||

| (4.019) | ||||

| Intel × DV | −11.005 | |||

| (−1.276) | ||||

| HC | 31.276 *** | 34.535 *** | 2.561 *** | 23.928 ** |

| (4.173) | (3.379) | (5.477) | (2.286) | |

| Fixcap | 0.020 ** | 0.000 | 0.018 ** | |

| (2.558) | (0.929) | (2.394) | ||

| Gov | 0.335 | 0.018 | 0.253 | |

| (1.423) | (1.633) | (1.092) | ||

| CTR | −0.042 | −0.000 | −0.044 | |

| (−1.154) | (−0.167) | (−1.249) | ||

| Pdensity | 2.081 | 0.126 | 0.911 | |

| (0.636) | (0.843) | (0.281) | ||

| Lifecost | −0.305 | 0.022 | −0.419 | |

| (−0.951) | (1.481) | (−1.330) | ||

| _cons | 6.502 *** | 0.998 | −0.182 | 1.743 |

| (33.233) | (0.248) | (−0.989) | (0.441) | |

| Province FE | yes | yes | yes | yes |

| Time FE | yes | yes | yes | yes |

| N | 390 | 390 | 390 | 390 |

| R2 | 0.965 | 0.966 | 0.932 | 0.967 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, G.; Mai, H. How Does Manufacturing Intelligentization Influence Innovation in China from a Nonlinear Perspective and Economic Servitization Background? Sustainability 2022, 14, 14032. https://doi.org/10.3390/su142114032

Tang G, Mai H. How Does Manufacturing Intelligentization Influence Innovation in China from a Nonlinear Perspective and Economic Servitization Background? Sustainability. 2022; 14(21):14032. https://doi.org/10.3390/su142114032

Chicago/Turabian StyleTang, Genghua, and Hongxun Mai. 2022. "How Does Manufacturing Intelligentization Influence Innovation in China from a Nonlinear Perspective and Economic Servitization Background?" Sustainability 14, no. 21: 14032. https://doi.org/10.3390/su142114032

APA StyleTang, G., & Mai, H. (2022). How Does Manufacturing Intelligentization Influence Innovation in China from a Nonlinear Perspective and Economic Servitization Background? Sustainability, 14(21), 14032. https://doi.org/10.3390/su142114032