Research on the Preparation and Application of Synthetic Leather from Coffee Grounds for Sustainable Development

Abstract

1. Introduction

2. Material and Methods

2.1. Raw Materials and Composition

2.1.1. Raw Material Composition of the Surface Layer

2.1.2. Raw Material Composition of the Middle Layer

2.1.3. Raw Material Composition of the Base

2.2. Production Processes

2.2.1. Preparation of Surface Layer Slurry

2.2.2. Preparation of Intermediate Layer Slurry

2.2.3. Preparation of Substrate

2.2.4. Coating Combinations

- (1)

- The water-based slag surface slurry obtained in Section 2.2.1 is applied to the release paper and dried. Subsequently, the aqueous slag bonding layer obtained in Section 2.2.2 is coated and laminated to the base fabric or the base fabric obtained in Section 2.2.3, or the water-based residue dry base or the water-based residue wet base, and it is dried to obtain environmentally friendly water-based synthetic leather.

- (2)

- The aqueous slag top layer slurry obtained in Section 2.2.1 is coated on the release paper and dried. Subsequently, the aqueous slag foaming layer slurry obtained in Section 2.2.3 is passed through the foaming machine. Next is to adjust the foaming density to 0.1–1.0 kg/L, apply it to the top layer and dry it. Subsequently, repeat the coating of the aqueous slag foaming layer slurry, then laminate the base fabric or the base fabric obtained in step 5, or the aqueous slag dry base obtained in step 6 or the aqueous slag wet base obtained in Section 2.2.3 and dry to obtain environmentally friendly aqueous synthetic leather.

- (3)

- The aqueous slag top layer stock obtained in Section 2.2.1 is coated on the release paper and dried. The aqueous slag foaming layer obtained in Section 2.2.2 is then fed into the foaming machine. The foaming density is adjusted to 0.1–1.0 kg/L, applied to the top layer and dried. Subsequently, apply the waterborne slag adhesive layer, then laminate the base fabric or the base fabric obtained in 2.2.3 or the waterborne slag dry base or obtain the waterborne slag wet base and dry to obtain the environmentally friendly waterborne synthetic leather.

2.3. Process Advantages and Innovation Points

- By using coffee grounds as a filler in the manufacturing process of water-based synthetic leather, the eco-friendly coffee grounds synthetic leather can effectively reuse the waste materials of daily life. The whole process does not require water and does not use any acidic substances or animal-related ingredients, which fully satisfies sustainable properties.

- The coffee grounds recovered after extraction have a special pore structure with a high-specific surface area. After effective treatment, it is added as a filler and combined with waterborne polyurethane using an aqueous production process to provide a synthetic leather product that is closer to the breathability of leather.

- Waterborne polyurethane emulsion and related water-based additives are used as the main raw materials for synthetic leather manufacturing, and the corresponding products do not contain DMF. The product can completely solve the problem of chemical pollution caused by DMF in solvent-based synthetic leather in the market, and there is no potential chemical hazard to users. At the same time, the DMF recycling process is omitted, and the whole production process is energy-saving and environmentally friendly.

- The natural coffee aroma of coffee and the fillings of coffee grounds produce a certain fragrance on the synthetic leather, giving an added value to the sensory of the synthetic leather product.

3. Analysis of the Application of Sustainable Coffee-Ground Synthetic Leather in Apparel Products

3.1. Analysis of the Types of Products Used

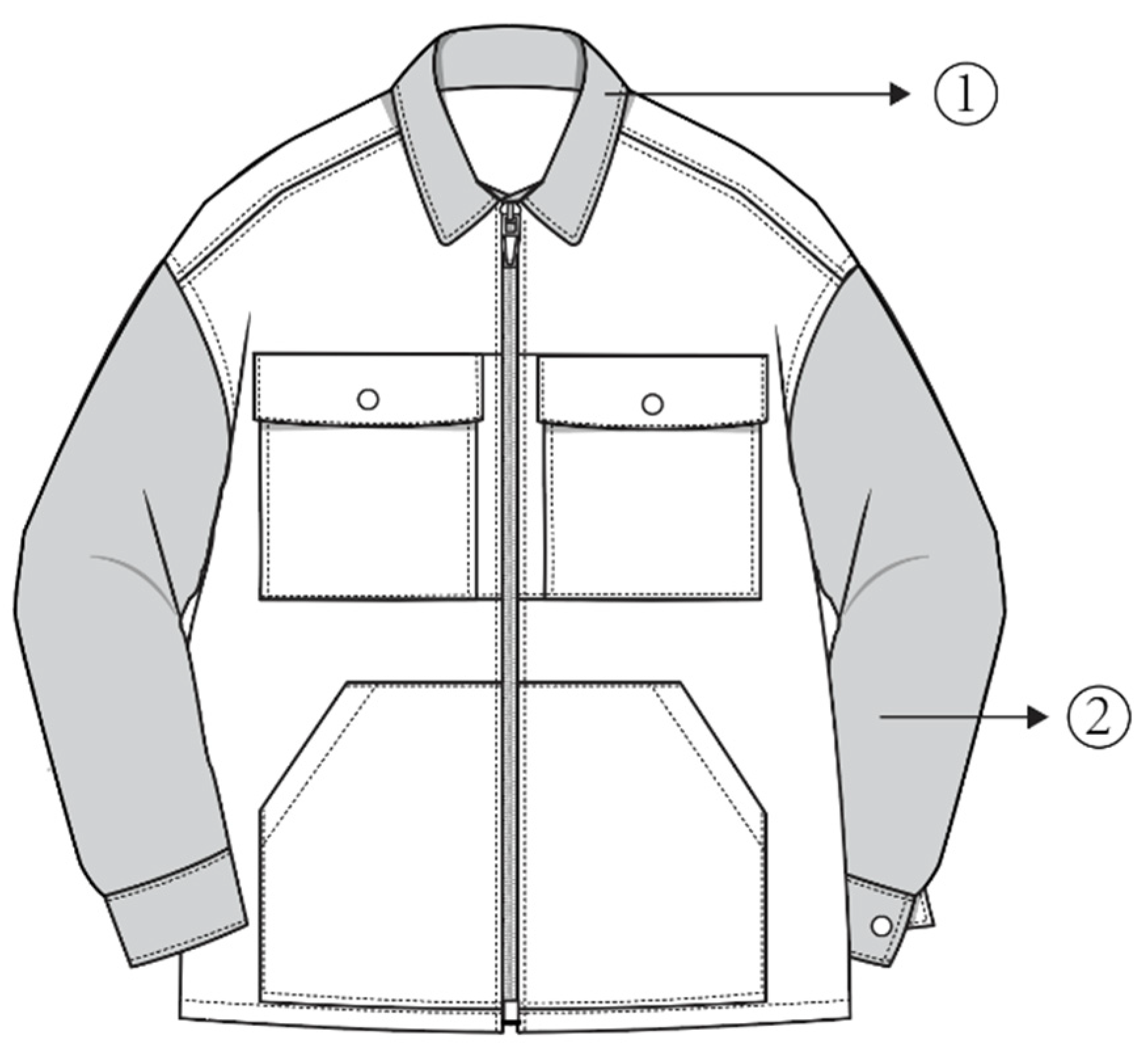

3.1.1. Use in Clothing

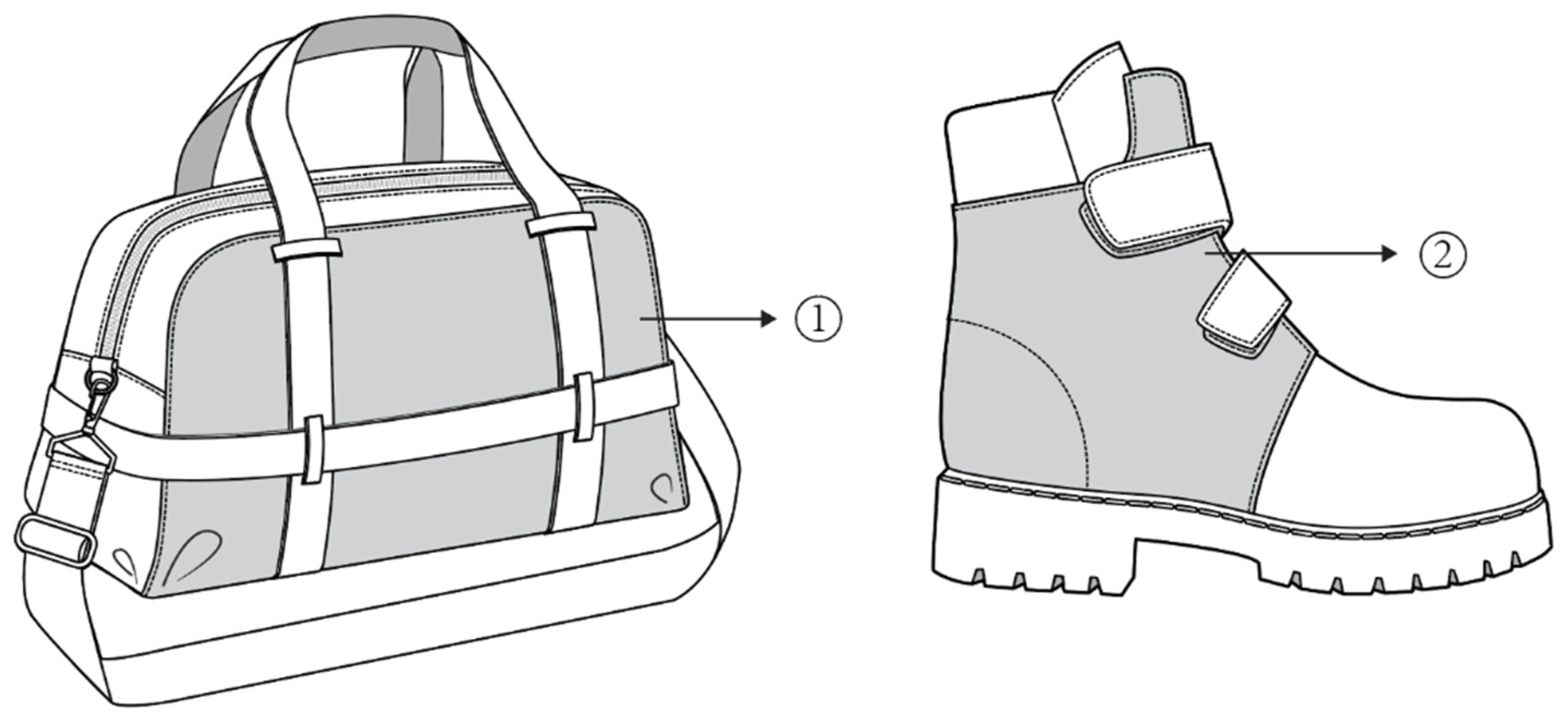

3.1.2. Use in Clothing Accessories

3.2. Specific Process Analysis

3.2.1. Surface Process

3.2.2. Combined Process

4. Material Experiments

4.1. Experimental Procedure and Method

4.1.1. Specimen Preparation

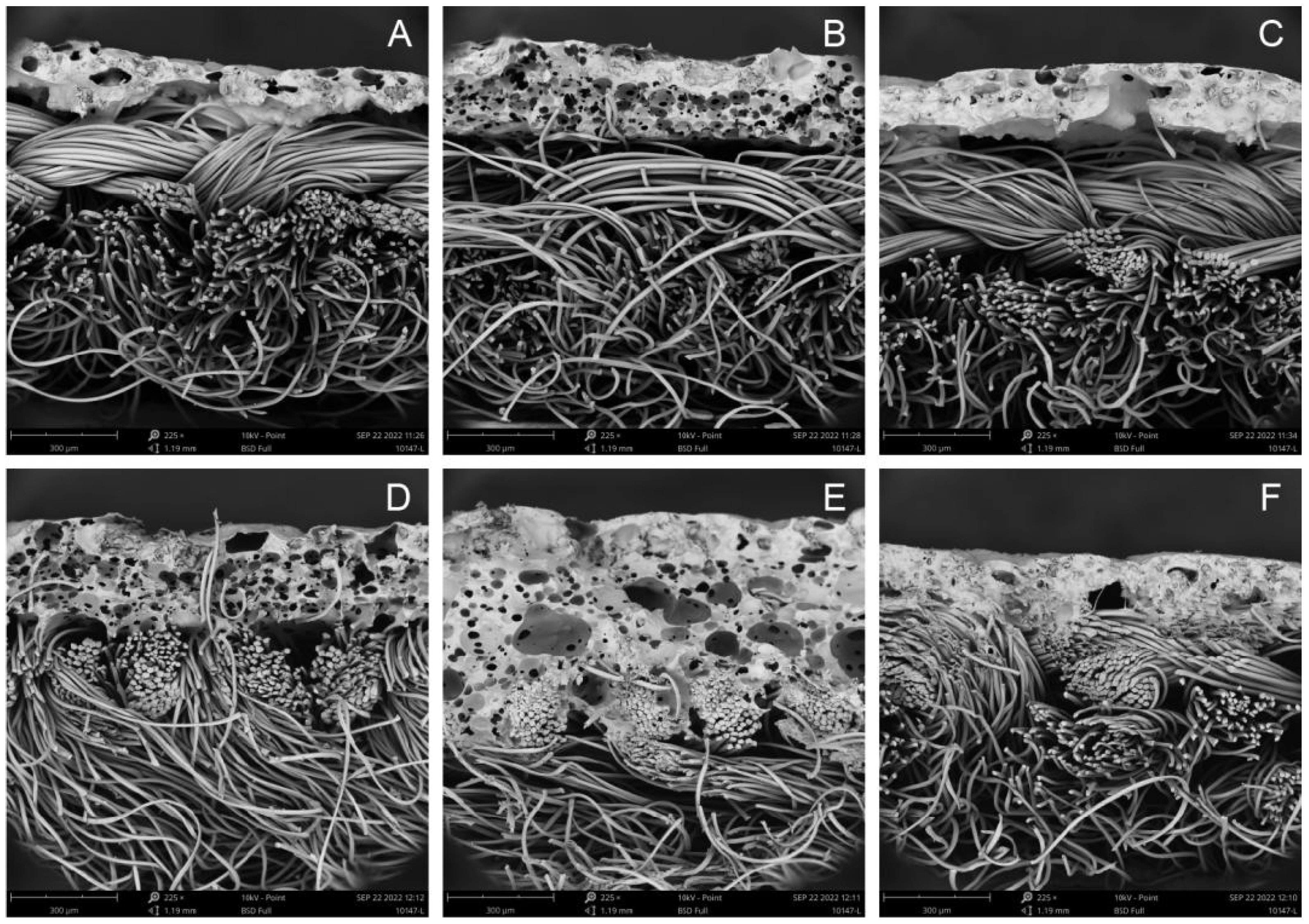

4.1.2. Scanning Electron Micrograph of Samples

4.1.3. Performance Testing

4.2. Experimental Results

4.2.1. Analysis of Wear Resistance Test Results

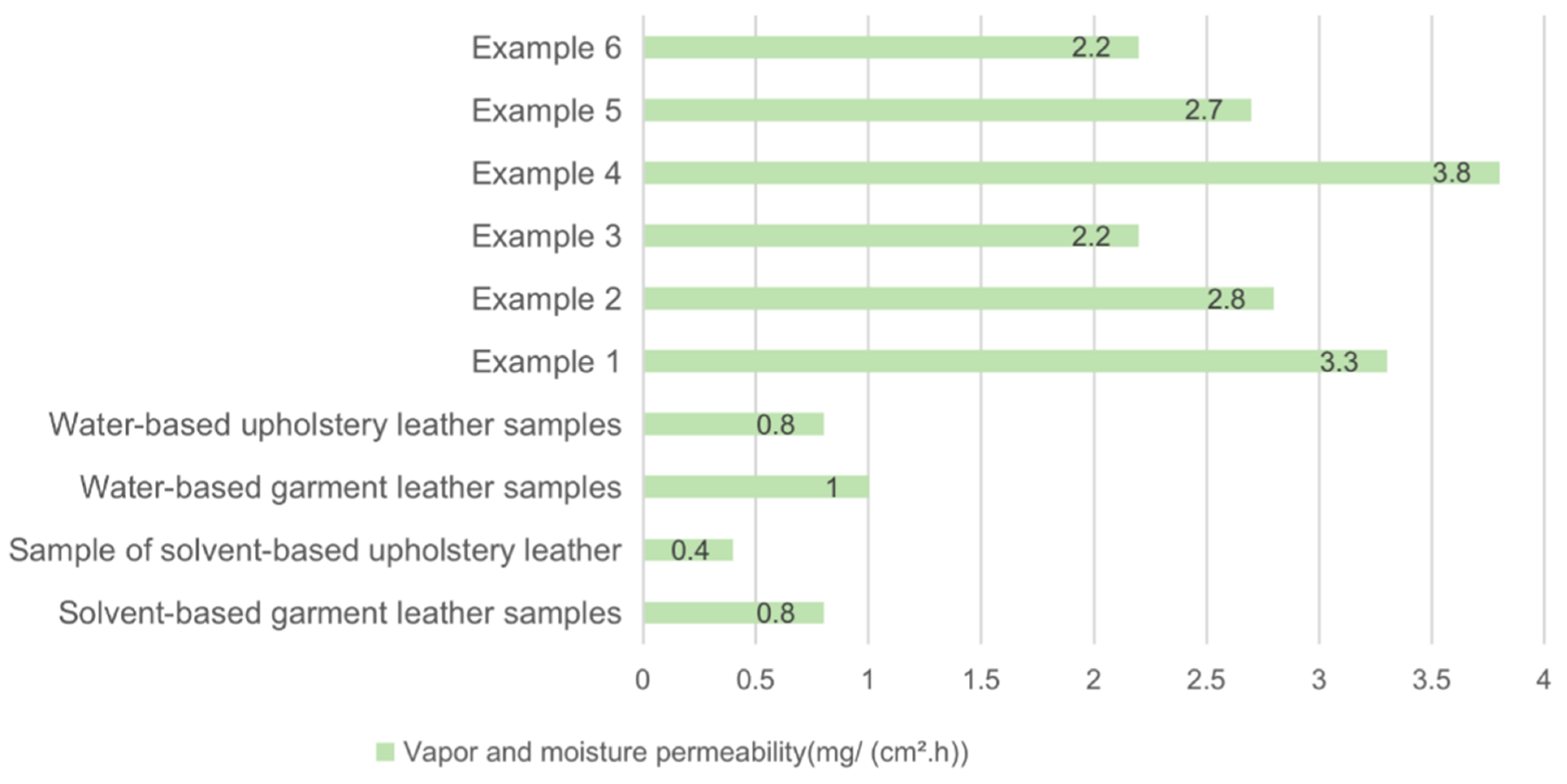

4.2.2. Analysis of Vapor and Moisture Permeability Test Results

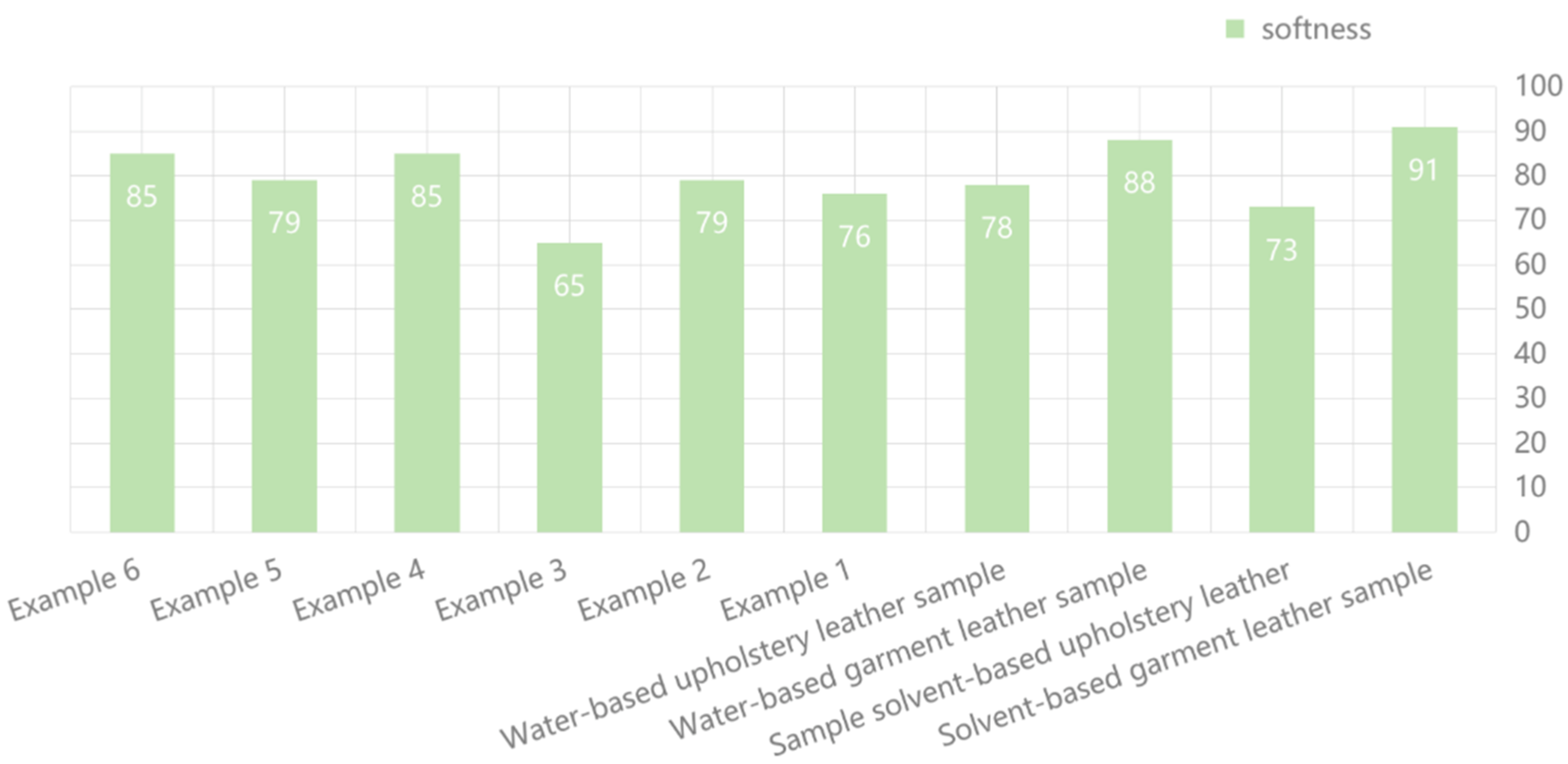

4.2.3. Analysis of Softness Test Results

4.2.4. Analysis of Peel Strength Test Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sudha, T.B.; Thanikaivelan, P.; Aaron, K.P.; Krishnaraj, K.; Chandrasekaran, B. Comfort, chemical, mechanical, and structural properties of natural and synthetic leathers used for apparel. J. Appl. Polym. Sci. 2009, 114, 1761–1767. [Google Scholar] [CrossRef]

- Gurera, D.; Bhushan, B. Fabrication of bioinspired superliquiphobic synthetic leather with self-cleaning and low adhesion. Colloids Surf. A Physicochem. Eng. Asp. 2018, 545, 130–137. [Google Scholar] [CrossRef]

- Hansen, É.; de Aquim, P.M.; Hansen, A.W.; Cardoso, J.K.; Ziulkoski, A.L.; Gutterres, M. Impact of post-tanning chemicals on the pollution load of tannery wastewater. J. Environ. Manag. 2020, 269, 110787. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Huang, C.; Wei, Y.; Zhu, Q.; Tian, W.; Wang, C. Risk assessment of N, N-dimethylformamide on residents living near synthetic leather factories. Environ. Sci. Pollut. Res. 2014, 21, 3534–3539. [Google Scholar] [CrossRef] [PubMed]

- Mariana, M.; Marwan, M.; Mulana, F.; Yunardi, Y.; Ismail, T.A.; Hafdiansyah, M.F. Activation and characterization of waste coffee grounds as bio-sorbent. IOP Conf. Ser. Mater. Sci. Eng. 2018, 334, 012029. [Google Scholar] [CrossRef]

- Ariram, N.; Madhan, B. Development of bio-acceptable leather using bagasse. J. Clean. Prod. 2020, 250, 119441. [Google Scholar] [CrossRef]

- Kim, H. The potential of product design made from coffee waste: Biomaterial for sustainable 3D printing. J. Integr. Des. Res. 2017, 16, 61–70. [Google Scholar]

- Mangindaan, D.; Lin, G.Y.; Kuo, C.J.; Chien, H.W. Biosynthesis of silver nanoparticles as catalyst by spent coffee ground/recycled poly(ethylene terephthalate) composites. Food Bioprod. Process. 2020, 121, 193–201. [Google Scholar] [CrossRef]

- Chen, X.E.; Mangindaan, D.; Chien, H.W. Green sustainable photothermal materials by spent coffee grounds. J. Taiwan Inst. Chem. Eng. 2022, 137, 104259. [Google Scholar] [CrossRef]

- Singaraj, S.P.; Aaron, K.P.; Kaliappa, K.; Kattaiya, K.; Ranganathan, M. Investigations on structural, mechanical and thermal properties of banana fabrics for use in leather goods application. J. Nat. Fibers 2021, 18, 1618–1628. [Google Scholar] [CrossRef]

- Kim, E.J.; Paik, I.K.; Park, J.H. Preparation and adhesion properties of waterborne polyurethane-coated resin for synthetic leather. AIP Conf. Proc. 2019, 2083, 030005. [Google Scholar]

- Tweneboa Kodua, L.; Xiao, Y.; Adjei, N.O.; Asante, D.; Ofosu, B.O.; Amankona, D. Barriers to green human resources management (GHRM) implementation in developing countries. Evidence from Ghana. J. Clean. Prod. 2022, 340, 130671. [Google Scholar] [CrossRef]

- Meyer, M.; Dietrich, S.; Schulz, H.; Mondschein, A. Comparison of the technical performance of leather, artificial leather, and trendy alternatives. Coatings 2021, 11, 226. [Google Scholar] [CrossRef]

- Cai, W.; Xin, W.; Zhang, H.; Luo, Y. Synthesis and application of a low dye absorption waterborne polyurethane for microfiber synthetic leather. Coatings 2022, 12, 728. [Google Scholar] [CrossRef]

- Stepanov, A.; Manninen, M.; Pärnänen, I.; Hirvimäki, M.; Salminen, A. Laser cutting of leather: Tool for industry or designers? Phys. Procedia 2015, 78, 157–162. [Google Scholar] [CrossRef]

- Salom, A.; Adiguzel Zengin, A.C.; Bitlisli, B.O. Temperature sensitive colour changing leathers with thermochromic pigments. J. Soc. Leather Technol. Chem. 2016, 100, 314–320. [Google Scholar]

- Büyükbayraktar, B.R.; Batur, G.E. The comparison of classical weaving and laser technology in denim fabric’s design. Ind. Text. 2021, 72, 418–425. [Google Scholar] [CrossRef]

- Deng, H.T. The researchment of knitted antifouling fabrics and the splicing design on leather garment. In Advanced Materials Research; Wang, R., Liu, H., Eds.; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2011; Volume 331, pp. 543–546. [Google Scholar]

- Braungart, M.; McDonough, W.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions—A strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- Bhushan, B.; Jung, Y.C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 2011, 56, 1–108. [Google Scholar] [CrossRef]

| No. | Ingredients | Content of Ingredients |

|---|---|---|

| 1 | Waterborne polyurethane emulsion | 40–60% |

| 2 | Defoamer | 0.2–1% |

| 3 | Solid waste residue | 10–80% |

| 4 | Fungicide | 0.5–2% |

| 5 | Antimold agent | 0.5–2% |

| 6 | crosslinking agent | 0.2–3% |

| 7 | Wetting agent | 1–2% |

| 8 | Emulsifier | 0.1–3% |

| 9 | Thickening agent | 2–3% |

| Water-Based Slag Foam Layer Slurry | Water-Based Slag Bonding Layer Slurry | ||

|---|---|---|---|

| Ingredients | Component Content | Ingredients | Component Content |

| Waterborne polyurethane emulsion | 40–60% | Waterborne polyurethane emulsion | 40–60% |

| Foaming agent | 3–6% | Solid waste residue | 10–80% |

| Solid waste residue | 10–80% | Fungicide | 0.5–2% |

| Fungicide | 0.5–2% | Antimold agent | 0.5–2% |

| Antimold agent | 0.5–2% | Crosslinker | 0.2–3% |

| crosslinking agent | 0.2–3% | Wetting agent | 1–2% |

| Emulsifier | 0.1–3% | Emulsifier | 0.1–3% |

| Thickening agent | 2–3% | Thickening agent | 2–3% |

| Ingredients | Specific Substances |

|---|---|

| Fungicide | Isothiazolinone fungicide. |

| Waterborne polyurethane emulsion | One or more combinations of anionic aromatic waterborne. Polyurethane emulsions, anionic aliphatic waterborne polyurethane emulsions, cationic aromatic anionic, or cationic aliphatic waterborne polyurethane emulsions. |

| Defoamer | Silicone defoamer or mineral oil defoamer. |

| Foaming agent | One or more of organosilicon modified foaming agent, sodium dodecyl benzene sulfonate foaming agent, and stearate type foaming agent compounded. |

| Fungicide | Isothiazolinone fungicide; antimildew agent is o-phenylphenol sodium antimildew agent |

| Crosslinking agent | One or more of aziridine crosslinking agent, polycarbodiimide crosslinking agent, closed isocyanate crosslinking agent |

| Wetting agent | Silicone wetting agent or acetylene glycol wetting agent |

| Emulsifier | Nonionic emulsifier or anionic emulsifier |

| Thickening agent | One or more compound of polyurethane bonding thickener, acrylate alkali-soluble thickener, cellulose thickener |

| Samples | Friction Color Fastness (Grade) | Martindale Rub Test (Times) | ||

|---|---|---|---|---|

| Dry Grinding | Wet Grinding | Sweat Stains | ||

| Solvent-based garment leather samples | 4.5 | 4.5 | 4.5 | 12,800 Breakage |

| Sample of solvent-based upholstery leather | 4.5 | 4.5 | 4.5 | 25,600 Breakage |

| Water-based garment leather samples | 4.5 | 4.5 | 4.5 | 12,800 without breakage |

| Water-based upholstery leather samples | 4.5 | 4.5 | 4.5 | 25,600 Breakage |

| Example 1 | 4.5 | 4.5 | 4.5 | 25,600 Breakage |

| Example 2 | 4.5 | 4.5 | 4.5 | 25,600 No breakage |

| Example 3 | 4.5 | 4.5 | 4.5 | 25,600 No breakage |

| Example 4 | 4.5 | 4.5 | 4.5 | 25,600 Breakage |

| Example 5 | 4.5 | 4.5 | 4.5 | 25,600 No breakage |

| Example 6 | 5.0 | 5.0 | 5.0 | 25,600 No breakage |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Wang, J.; Zheng, S.; He, X.; Liu, X. Research on the Preparation and Application of Synthetic Leather from Coffee Grounds for Sustainable Development. Sustainability 2022, 14, 13971. https://doi.org/10.3390/su142113971

Tian Y, Wang J, Zheng S, He X, Liu X. Research on the Preparation and Application of Synthetic Leather from Coffee Grounds for Sustainable Development. Sustainability. 2022; 14(21):13971. https://doi.org/10.3390/su142113971

Chicago/Turabian StyleTian, Yujing, Jinyu Wang, Sixian Zheng, Xinyue He, and Xiaogang Liu. 2022. "Research on the Preparation and Application of Synthetic Leather from Coffee Grounds for Sustainable Development" Sustainability 14, no. 21: 13971. https://doi.org/10.3390/su142113971

APA StyleTian, Y., Wang, J., Zheng, S., He, X., & Liu, X. (2022). Research on the Preparation and Application of Synthetic Leather from Coffee Grounds for Sustainable Development. Sustainability, 14(21), 13971. https://doi.org/10.3390/su142113971