1. Introduction

Since power transformers are crucial for the power system’s reliability, the continuity of their operation is essential [

1]. Therefore, a protection system with the features of high dependability (no missing operation), security (no false tripping), and quick speed of operation (short fault clearing time) is required to protect power transformers. According to these requirements, the differential relay is used as the main protection of power transformers [

2,

3,

4].

In [

5], a report on the maloperation of a differential relay in 2017 has been presented. Hence, despite the mentioned features, the differential relay may cause maloperation during transient incidents, including the occurrence of faults (internal/external) that are simultaneous with magnetic inrush current and CT saturation [

6,

7]. Additionally, the CT ratio mismatch and the transformer tap changer operation are other factors that can affect the correct operation of the differential relay [

8]. Hence, studies have presented methods to improve the performance of differential relays, such as [

9,

10,

11]. In addition, in some studies, experimental setups have been proposed to evaluate methods to improve the differential relays’ performance. Accordingly, in [

8], the differential protection methods of the power transformer based on the wavelet analysis have been evaluated using a DS1102 digital signal processor board platform. The authors in [

12] have evaluated the sensitivity and accuracy of differential relays by simulating inrush current and CT saturation. In order to test the performance of the differential relay, the Real Time Digital Simulator (RTDS) was suggested in [

13]. Different faults have been applied in a sample network, and the differential relays operation has been investigated using RTDS. The performance of the differential relays in smart substations during data packet loss has been evaluated in [

14]. The differential relays’ testing method, considering communication links and data synchronization in smart substations, has been presented in [

15]. In [

16], a setup based on the IEC61850 standard was proposed to prevent the maloperation of the differential relay in the face of harmonic currents. In addition, in [

17,

18], the step-by-step test of the numerical differential relay, which is used to protect a power transformer, has been described using a relay tester device.

Although various studies are in the field of performance improvement and differential relay testing, it is still not possible to evaluate the correct/incorrect operation of the differential relay after its operation. Tackling this issue requires an analysis of the behavior of six relay input currents (three-phase currents on each side of the protected transformer) at different sampling times, taking into account the relay setting curve (), where is the biased current (stabilized) and is the difference current (operation) of the differential relay. Indeed, by mapping the relay’s differential trajectory on the curve, the relay’s correct/incorrect performance can be decided. Therefore, the extraction of relay input currents at different sampling times is required.

In general, numerical relays are able to save the input currents and voltages in the form of COMTRADE files under the IEEE C37.111 standard [

19]. When an incident occurs for the transformer, all incoming currents to the relays are recorded in the COMTRADE files. Additionally, to test the relay, using simulation software such as PSCAD, DIgSILENT, and EMTP, the currents and voltages waveforms of various incidents (transient/permanent) can be generated and saved in the COMTRADE file format [

20,

21]. Numerical relays can receive and read COMTRADE files. This method has been utilized in [

22,

23,

24] to evaluate the differential relay performance during inrush current.

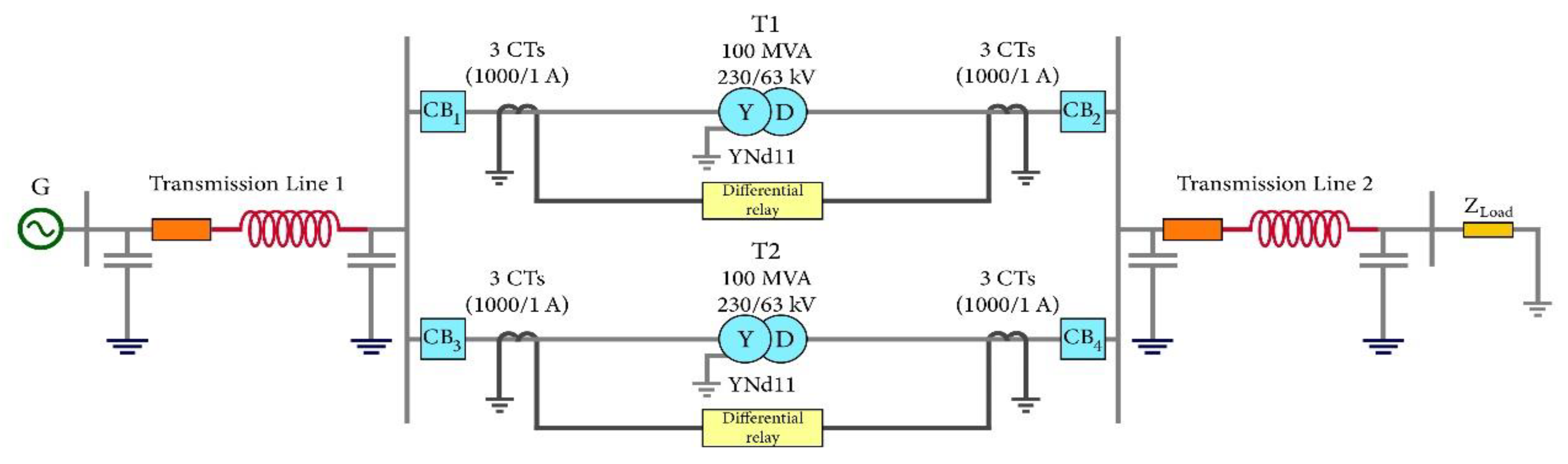

The COMTRADE files extracted from numerical differential relays contain comprehensive information on relay input currents at different sampling times, which can be used to evaluate the correct/incorrect operation of the relay. However, no comprehensive method has been developed for generating a differential trajectory () from these six currents extracted from the COMTRADE files and mapping it on the setting curve (). In this case, only the SIGRA software is specific for producing differential trajectories for Siemens differential relays. Therefore, this paper aims to tackle this important challenge in the field of differential relay studies. The current measurements recorded in the COMTRADE file of the differential relay belong to the secondary currents of the CTs on both sides of the transformer. Hence, they are affected by various factors before entering the differential relay. These factors are mainly associated with the CTs and power transformer connection type. Therefore, in this paper, the role of all these factors on the currents recorded in the COMTRADE file has been determined. Finally, the relay’s differential trajectory on the relay’s setting curve is generated. The proposed method has been evaluated in both simulation and experimental setups. Hence, various incidents are first simulated in the DIgSILENT software for a transformer and saved as a COMTRADE file. The proposed method, implemented in Matlab software, receives these COMTRADE files as the input and generates their differential trajectory. To evaluate the proposed method by experimental setup, this method is implemented on the Vebko-Amirkabir relay tester. Incidents that are created by the DIgSILENT software and stored as the COMTRADE files are applied to a differential relay via this relay tester, and the COMTRADE files produced by the differential relay are given. These COMTRADE files are used as the input to the relay tester. It is proved that the proposed method is able to generate the differential trajectory of the relay on the relay setting curve. The results confirm that the proposed method could generate the differential trajectory of all possible incidents (different faults, inrush currents, and CT saturations) for the differential relay. Therefore, the correct/incorrect operation of the differential relay can be investigated. Additionally, the comparison of the proposed method with the results created in the SIGRA software shows the higher accuracy of the proposed method in generating the differential trajectory of the differential relay.

This paper is structured as follows. In

Section 2, the challenges for differential trajectory generation from COMTRADE files of the differential relays are evaluated.

Section 3 presents the proposed method for generating a differential trajectory from the COMTRADE files. The proposed method is subjected to software and experimental evaluations in

Section 4. Subsequently, in

Section 5, the method proposed in this paper is compared with the method used in SIGRA software in terms of accuracy.

2. Problem Statement

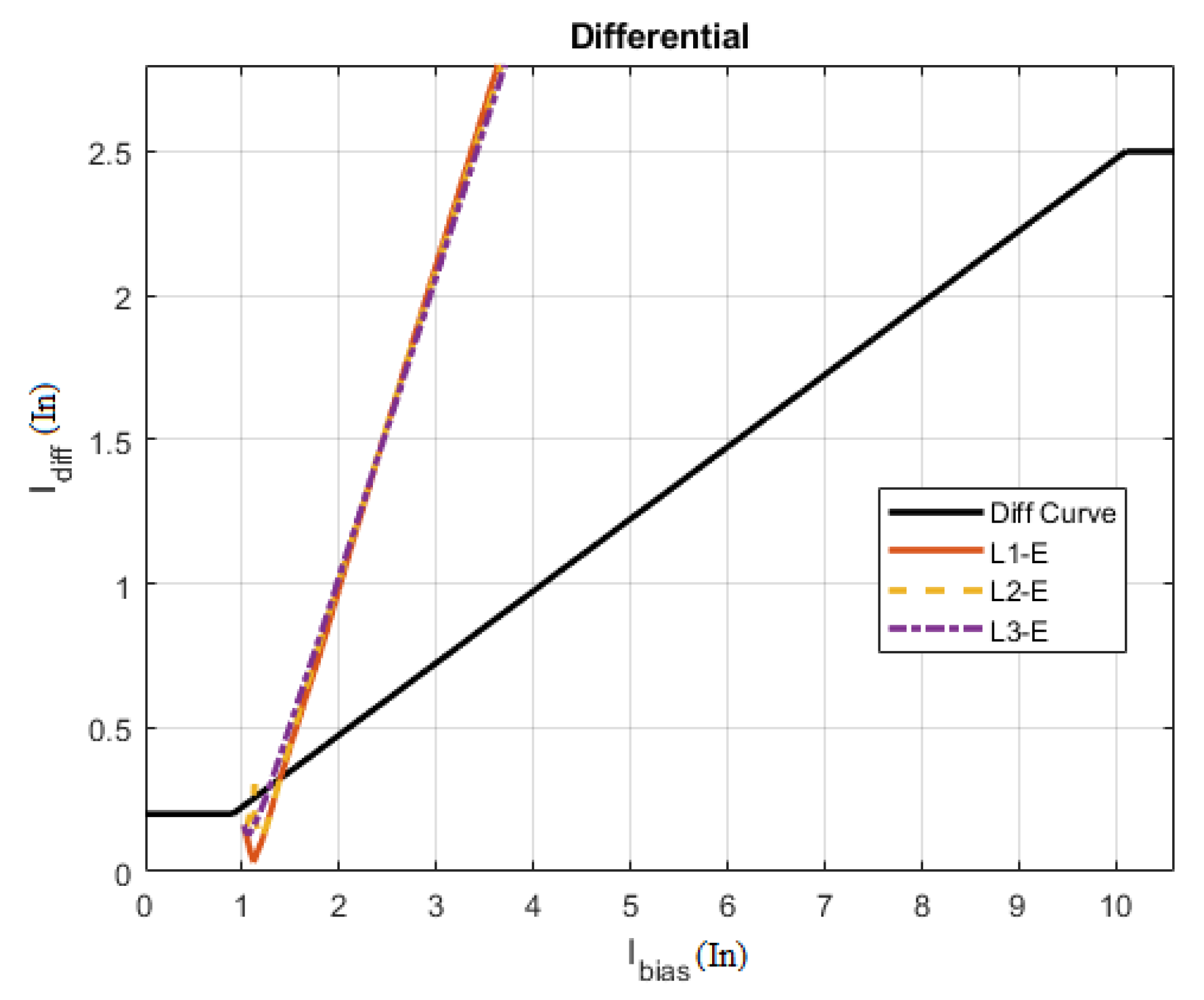

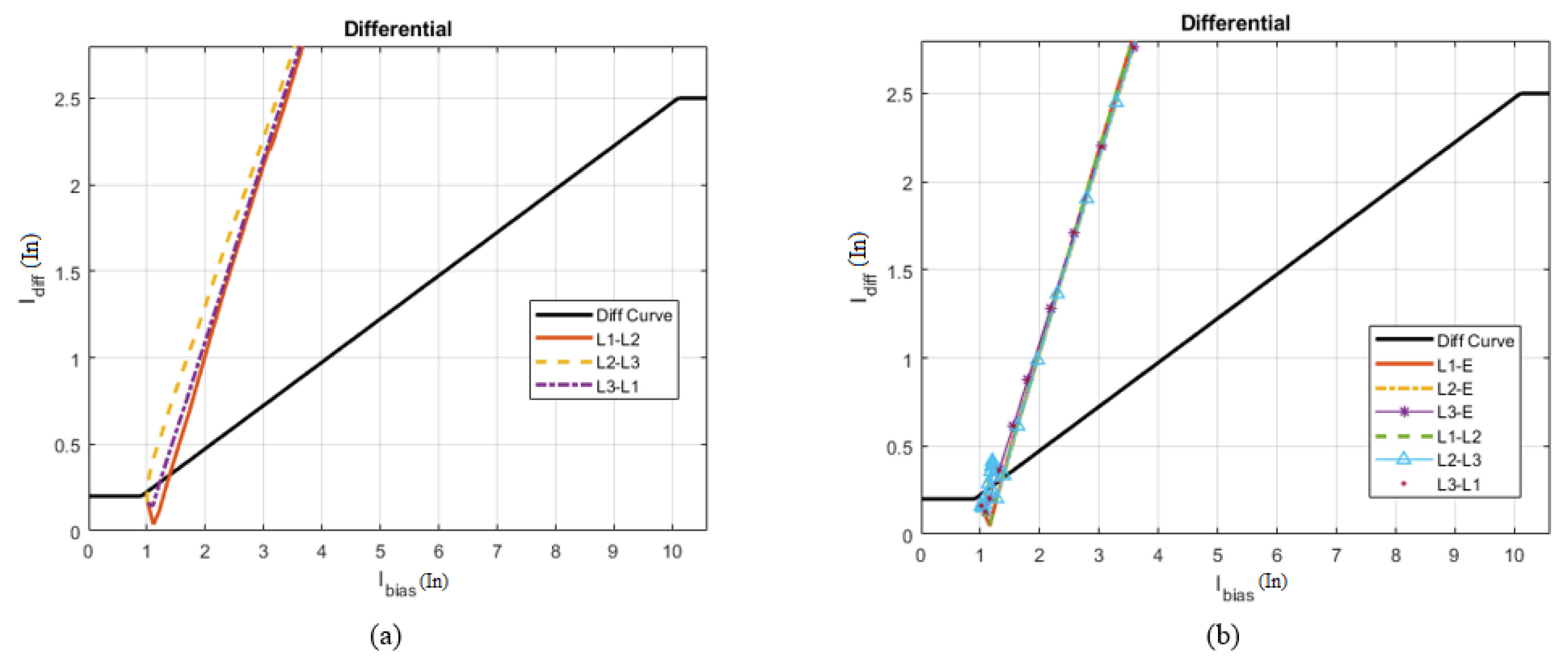

Evaluating the correct operation of differential relays for different events justifies the necessity of generating differential trajectories for these relays.

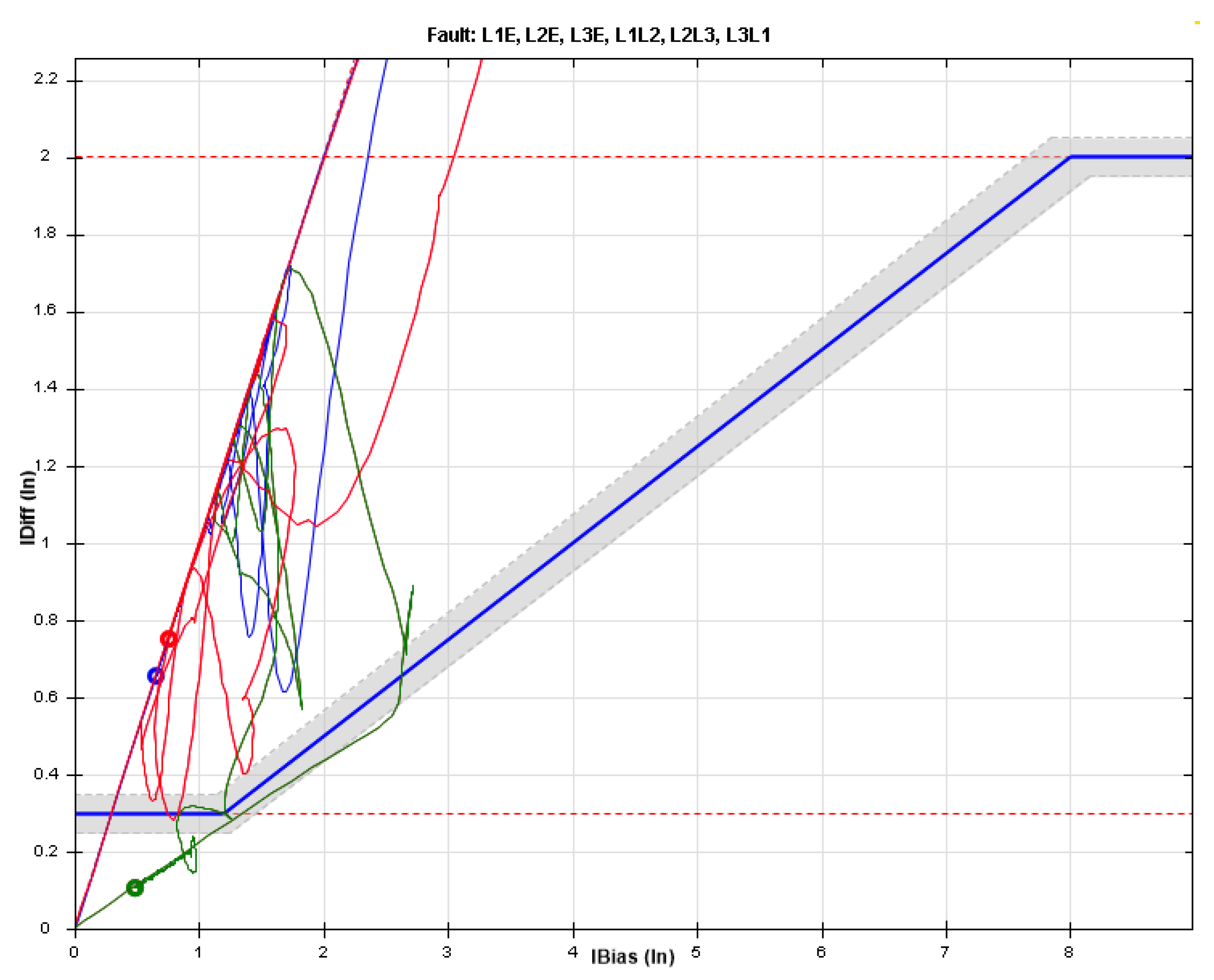

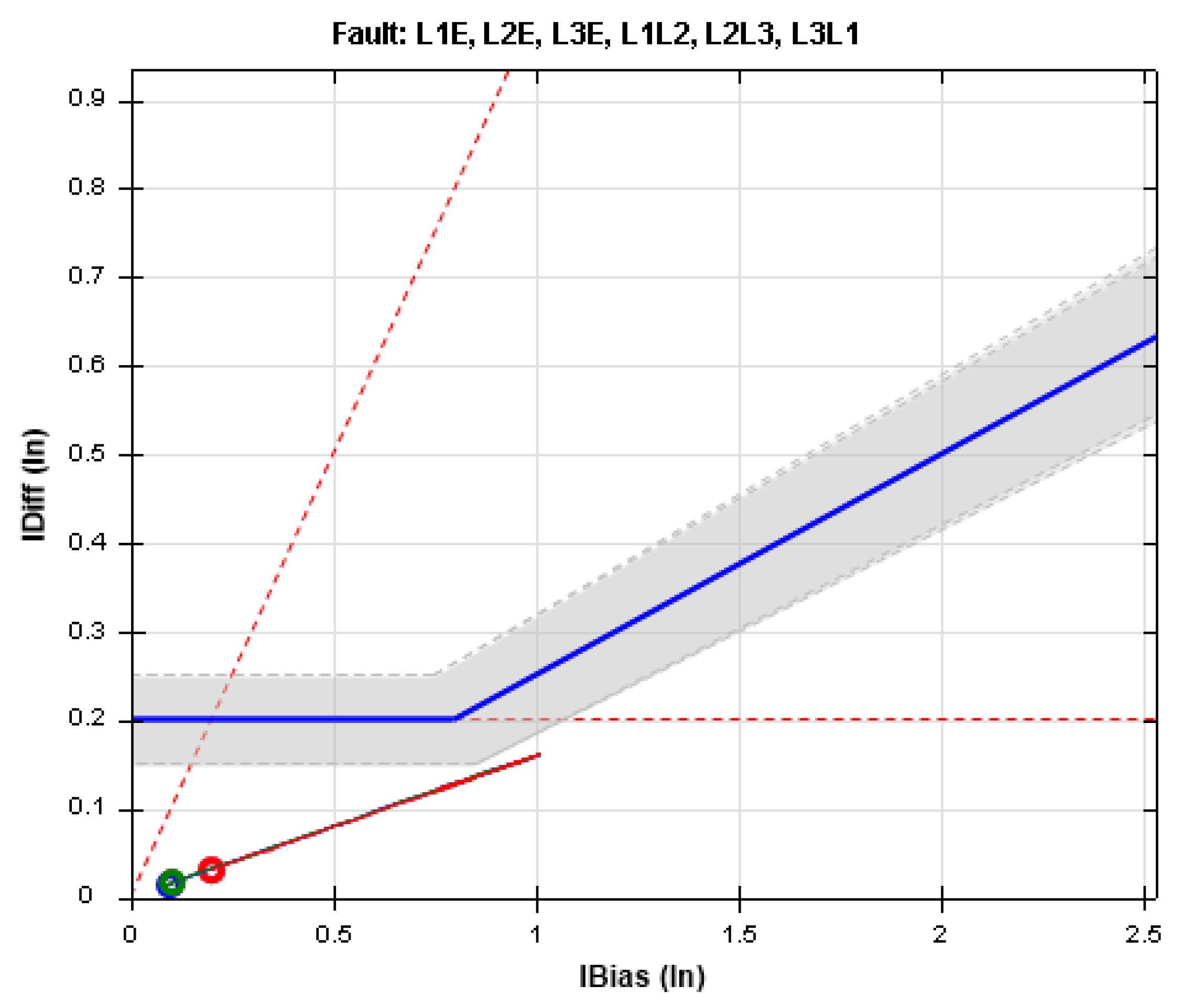

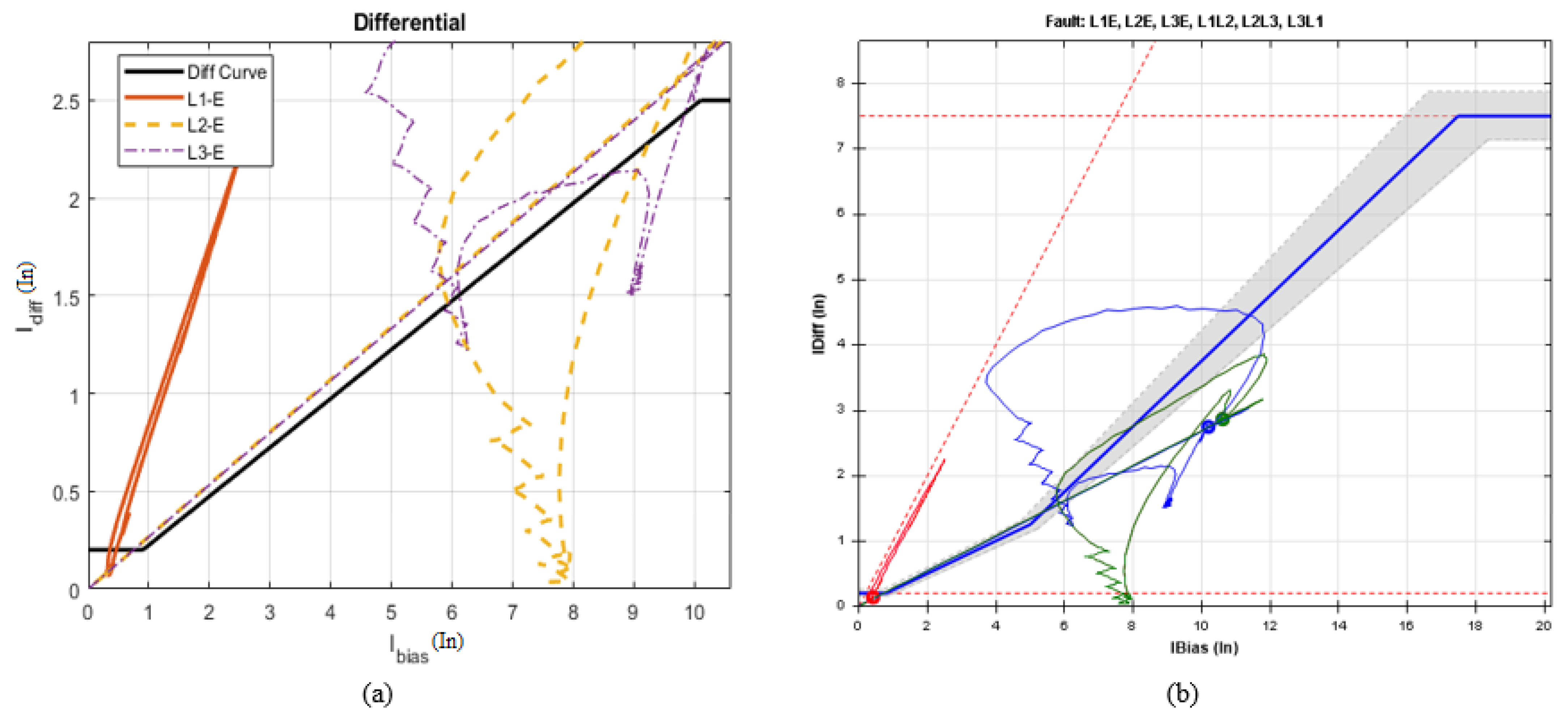

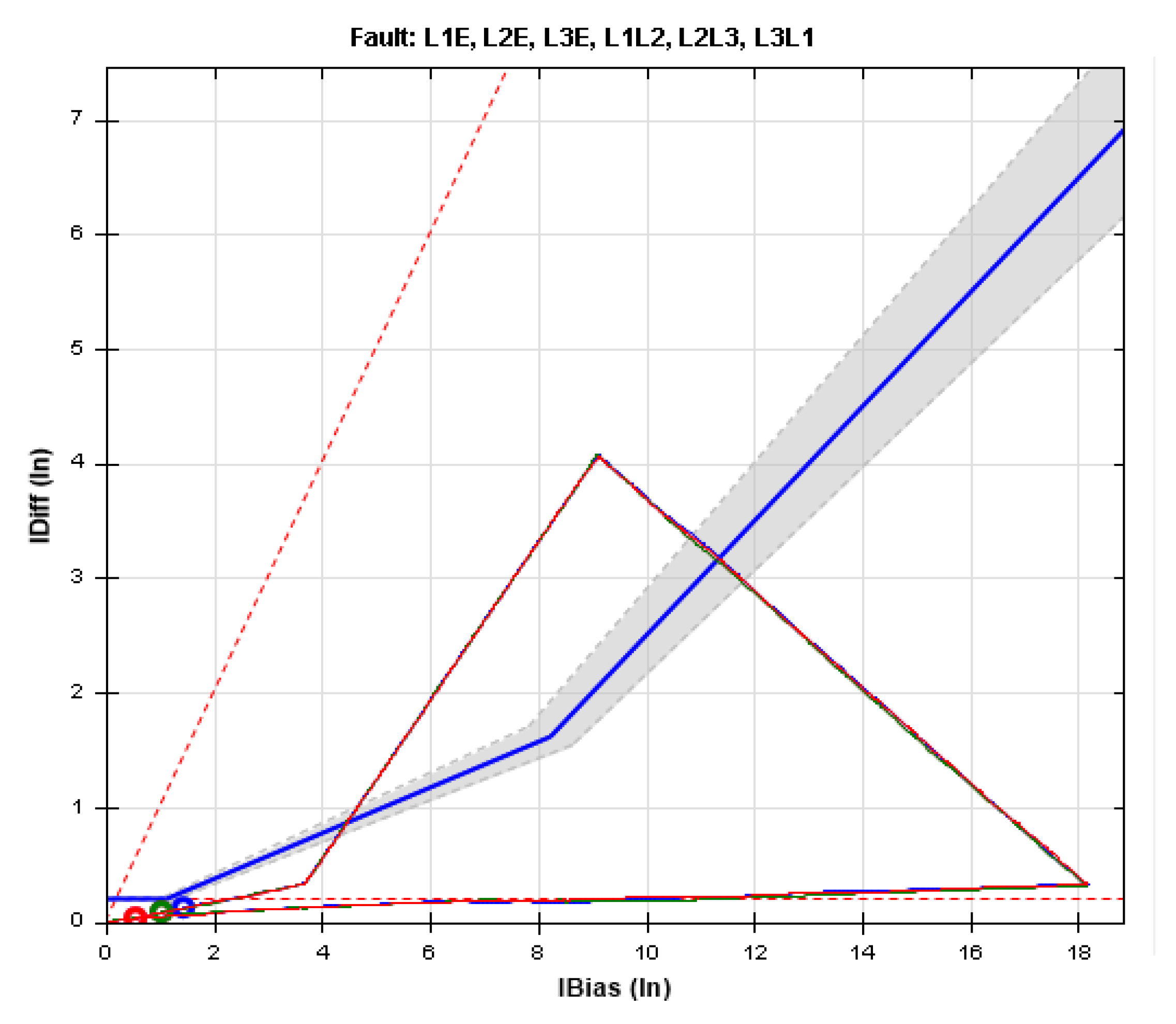

Figure 1 shows an example of this action. As revealed by

Figure 1, the generated differential trajectory is higher than the operational curve of the differential relay, and the relay therefore must operate for the event.

To generate a differential trajectory of the relay, six currents sampled (from both sides of the transformer) at different sampling times of the event must be used. Similar to what is presented in

Table 1, these six currents are recorded in the COMTRADE file of the relay output.

The six currents recorded in

Table 1 (

,

, and

) and (

,

, and

) are the secondary currents of terminals CT1 and CT2 (CTs on both sides of the transformer), respectively, which are recorded at different sampling times.

It is not easy to generate a differential trajectory from stored current samples for different phases (at different times). This is due to the fact that and must be calculated at different times to generate a differential relay trajectory. However, these two parameters are on the secondary sides of CTs on both sides of the protected transformer, and their calculation requires the application of various conditions that affect the input currents of the relay.

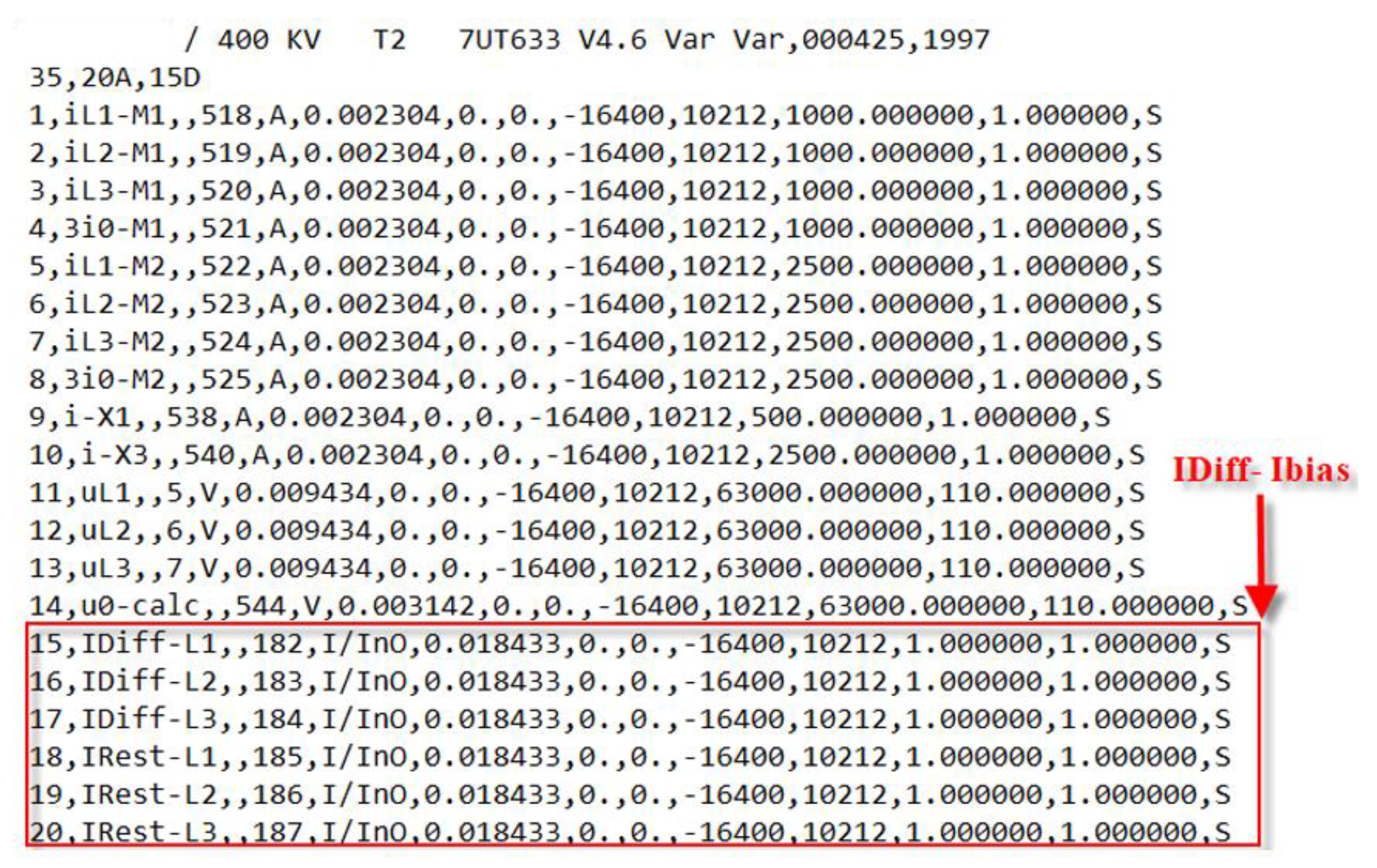

The only exception in this regard is Siemens relays. Similar to

Figure 2, these relays can record

and

values for different sampled moments in addition to six relay input currents in their output COMTRADE file. Therefore, SIGRA software can easily generate the differential trajectory of the relay by reading this COMTRADE file.

Due to the fact that the and values of other brands of differential relays are not registered in their COMTRADE files, therefore, the differential trajectory of these relays cannot be generated easily. Therefore, it is essential to develop a method that is able to create a differential trajectory for all differential protection relays.

3. Proposed Method

In general, the magnitude and phase of the relay input currents are affected by the structure of the protected transformer and the connections of the CTs on both sides [

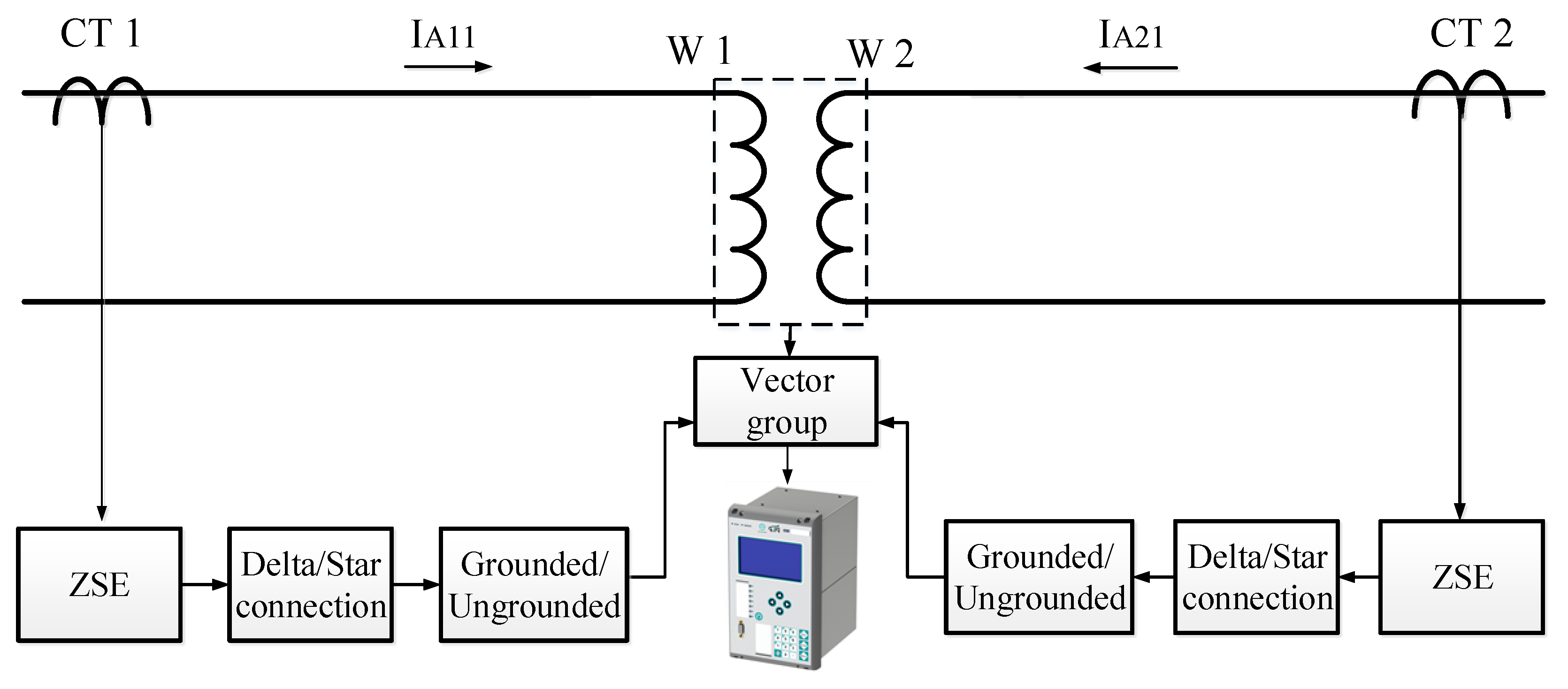

25]. As shown in

Figure 3, the CTs ratio, equipping/not equipping them with a zero sequence elimination (ZSE) unit, the connection type of CTs, and connecting/not connecting the secondary side of CTs to the ground are the factors affecting current inputs. On the other hand, according to

Figure 3, the transformer vector group can also affect the input currents on the differential relay. Therefore, it is necessary to consider the role of all these factors in generating the differential trajectory of the differential relay.

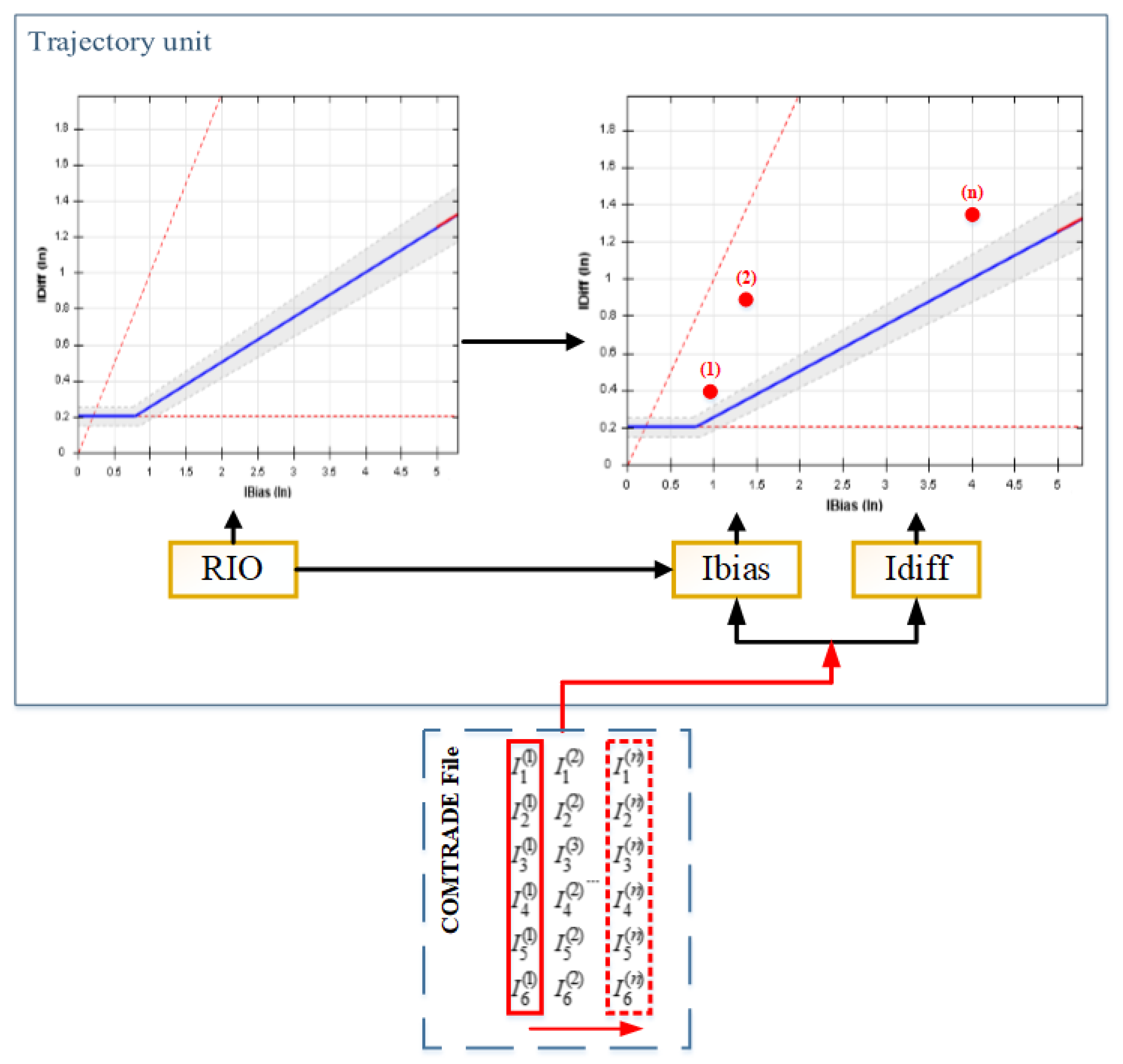

To consider all the factors affecting the input currents of a differential relay and to generate a differential trajectory,

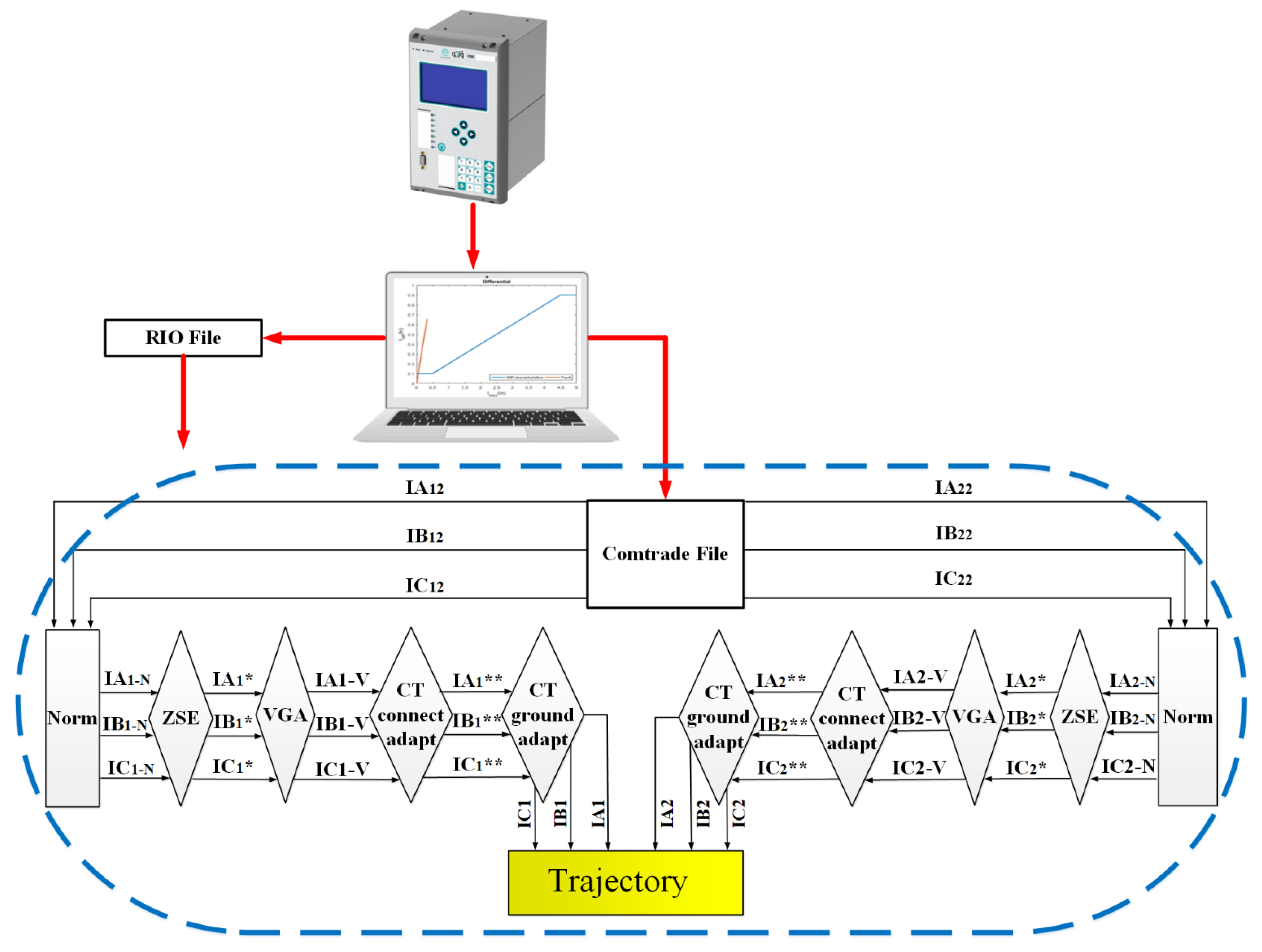

Figure 4 is presented. As seen in

Figure 4, the information stored in the relay can be extracted from two forms, including RIO and COMTRADE files. An RIO file is actually the standard format for reading a protective relay setting or transferring it to a relay tester or other relays.

Table 2 shows the available information in an RIO file of a differential relay which consists of the relay settings, the characteristics of the protected transformer, and CT ratios [

26]. This information is used in the differential trajectory generation process. Additionally, the settings of the differential relay are available in the RIO file. Therefore, the

curve of the differential relay can be acquired in order to analyze the correct/incorrect operation of the differential relay.

According to

Figure 4, six secondary side currents of CT1 (

,

, and

) and CT2 (

,

, and

) are extracted from the COMTRADE file of a differential relay. As revealed in

Figure 4, based on these six currents passing through different processing units, the differential trajectory is generated in the Trajectory unit. It should be noted that the processing units shown in

Figure 4 are the same factors affecting the input currents of the differential relay, which have been presented in

Figure 3. Due to the fact that, depending on the CTs and transformer connections, some of these units may not operate, these units are shown conditionally in

Figure 4.

3.1. Normalizing the Currents

In the first step of generating the differential trajectory, currents extracted from the relay COMTRADE file are normalized. Therefore, according to

Figure 4, the “Norm” processing unit is used to normalize the currents on both sides of the transformer. In this unit, Equations (1) and (2) are used to normalize the currents of the primary and secondary sides of the transformer, respectively [

25].

where

,

, and

are the normalized currents of the CT1 secondary side and

,

and

are the normalized currents of the CT2 secondary side for the

j-th recorded samples in the COMTRADE file. Additionally,

and

are the nominal currents of the CT1 and CT2 primary sides, which are extracted from the RIO file according to

Table 2. It should be noted that the total number of samples stored in the COMTRADE file for each of the six currents is

(

).

In Equations (1) and (2), and are the base currents on the primary and secondary sides of the transformer, respectively. To calculate these base values, two cases are considered.

Case one: If the CT1 and CT2 rated currents have been determined according to the transformer’s primary and secondary side rated currents, the rated currents of the transformer are used to calculate these base values. For this purpose, Equations (3) and (4) are used.

where

and

are the rated voltages of the primary and secondary sides of the transformer, respectively, and

is the rated power of the protected transformer (VA). According to

Table 2, these parameters are obtained from the relay RIO file.

Case two: In some cases, due to the replacement of CTs, the primary rated currents of the CTs are noticeably different from the rated currents of the transformer. In this case, the base current is selected based on the nominal current of CTs on both sides of the transformer and using Equations (5) and (6).

To use these equations, the

value is calculated from Equation (7).

3.2. Zero Sequence Elimination

When the star-point of the transformer winding is grounded (Yn connection), the current can flow to the ground during an earth fault. This issue may cause the maloperation of the differential relay during earth faults that are outside the protection zone of the relay [

27,

28]. To tackle this issue, the ZSE filter is implemented in differential relays [

27]. Indeed, ZSE removes the zero sequence currents flowing from the transformer side when an earth fault occurs.

In order to apply the effect of the ZSE filter on the Yn side of the transformer, the normalized currents of the previous stage are passed through the ZSE processing unit. Therefore, for differential relays that use the ZSE unit, the output currents of this unit are calculated from Equation (8) for the

j-th current samples recorded on the relay COMTRADE file (

,

, and

) [

25].

According to

Figure 4, the ZSE unit is conditional on both sides of the transformer. This means that the normalized currents in each transformer side would be processed in this unit only if the transformer connection of that side is Yn. If processing is not performed in this unit,

,

, and

on that side would be

,

, and

.

3.3. Vector Group Adaptation

In power transformers, a winding (generally the primary winding) is selected as the reference winding for the current phase angle. The current phase angle of this winding is considered zero [

25,

28]. The current phase angle of the secondary winding is identified according to the transformer vector group. This means that the secondary winding current phase angle is shifted according to the transformer vector group. This phase shift can cause differential relay maloperation. For this purpose, the vector group adaptation (VGA) processor is implemented on the secondary winding [

25,

28]. In this unit, the phase shift is corrected using Equation (9).

where,

,

, and

are the output currents of this unit for the

j-th current samples, and

is the vector group number of the transformer. For example, if the transformer vector group is Yd5, then

[

25]. In order to determine the

coefficient, Equation (10) is used.

3.4. CT Connection Adaptation

In this unit, the output currents of the previous units are processed in a case when the transformer winding connection type differs from its CT connection type on each side of the transformer. For example, if the transformer winding is connected in star and its CT at the same side is connected in delta, this unit would process the currents. In this case, the output of this unit (

,

, and

) is determined by Equation (11) for the

j-th current samples.

It should be mentioned that, if this unit is not used on each side of the transformer, the current outputs of this unit would be , , and at that side.

3.5. CT Grounding Adaptation

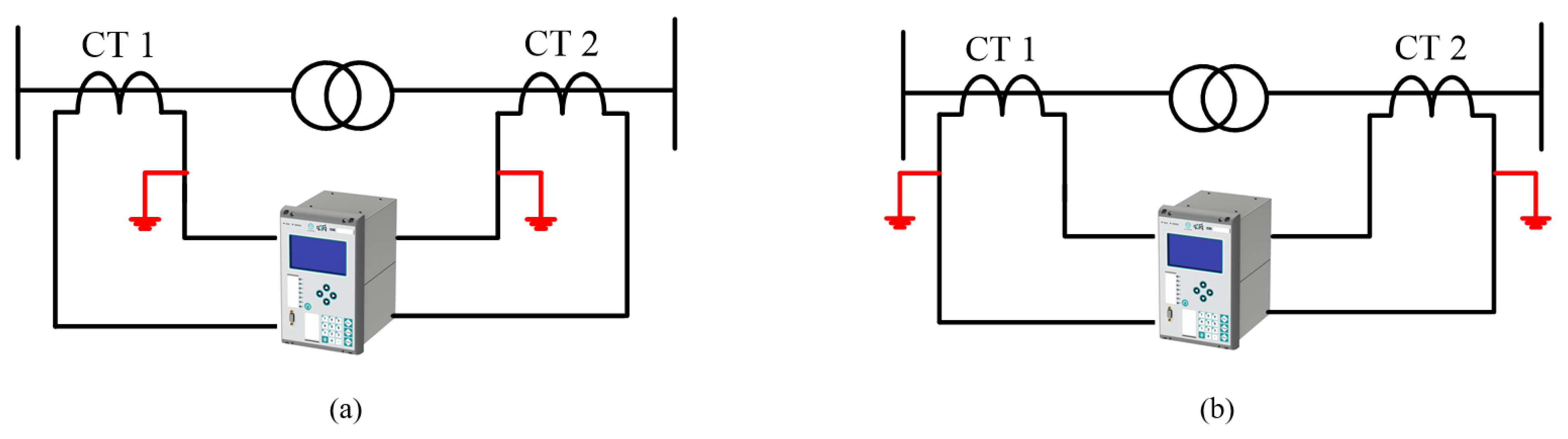

According to

Figure 4, the CT grounding adaptation unit is another processing unit that conditionally analyzes the transformer’s primary and secondary side currents. As shown in

Figure 5a, if the secondary side of the CT is grounded towards the transformer, the currents are not processed in this unit. Otherwise, as shown in

Figure 5b, if the secondary side of the CT is grounded towards the line, the currents are shifted 180 degrees. Therefore, in this case, the output three-phase currents of this unit (

,

, and

) are calculated from Equation (12) for the

j-th current samples.

In

Figure 4, if the currents are not processed in the “CT ground adapt” unit (

Figure 5a), then

,

, and

.

3.6. Generating a Differential Trajectory

After applying the effects of all the affecting factors on the input currents of the relay, the differential trajectory (

) can be generated in the Trajectory unit of

Figure 4 and mapped on the relay setting curve (

). For this purpose, it is necessary to calculate

and

for all sampled currents at different times (

). Equation (13) is used to calculate

[

29].

where,

and

are the

j-th samples of the Trajectory unit input currents for each phase on the primary and secondary sides of the transformer (

and

).

Contrary to

, the calculation of

varies for different brands of the differential relay. Therefore, Equations (14)–(16) present

calculations for different relay manufacturers [

30,

31,

32,

33]. According to

Table 2, the

equation can be extracted from the RIO file of the differential relay.

According to the content provided,

Figure 6 presents the method for generating the differential trajectory from six input currents of the transformer (

). Evidently, at any time, the extracted samples from the six relay input currents (

) that are stored in the COMTRADE file are processed by the proposed method. Additionally, the location of the obtained sample on the

setting curve is determined by calculating

and

for each category of registered samples. The

setting curve is created via the relay settings that are extracted from the RIO file of the relay.

5. Comparison of the Proposed Method with Another Method

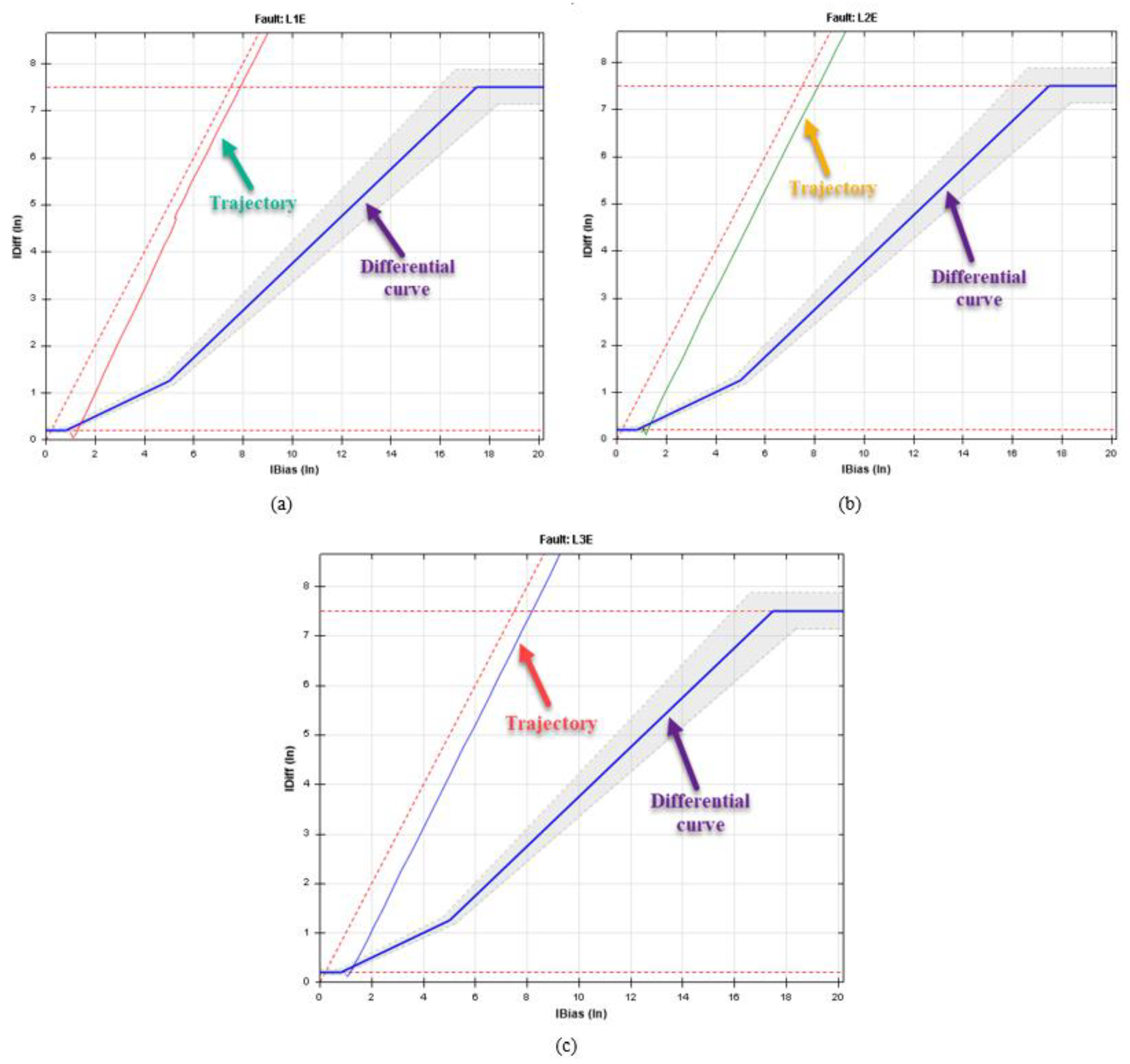

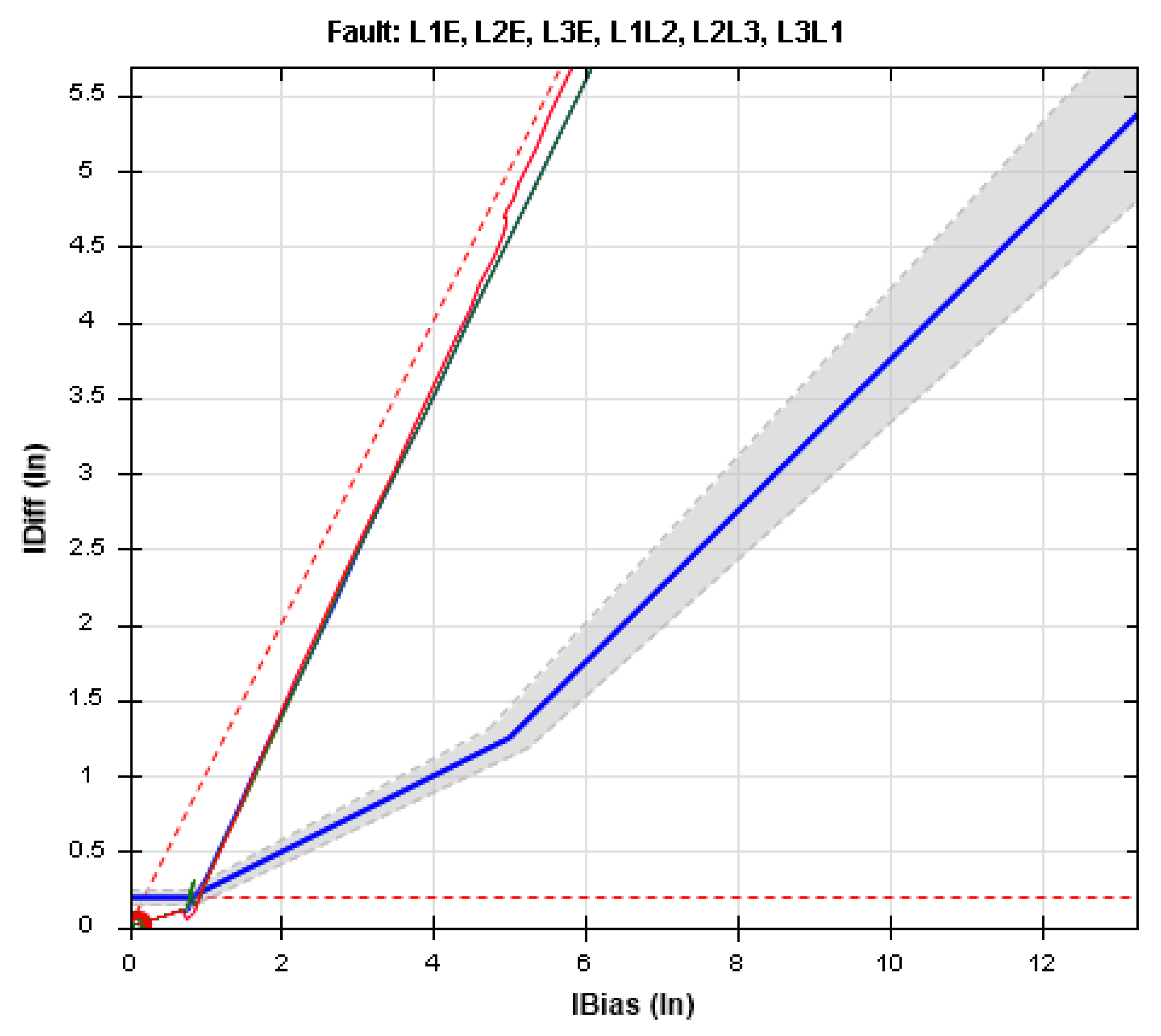

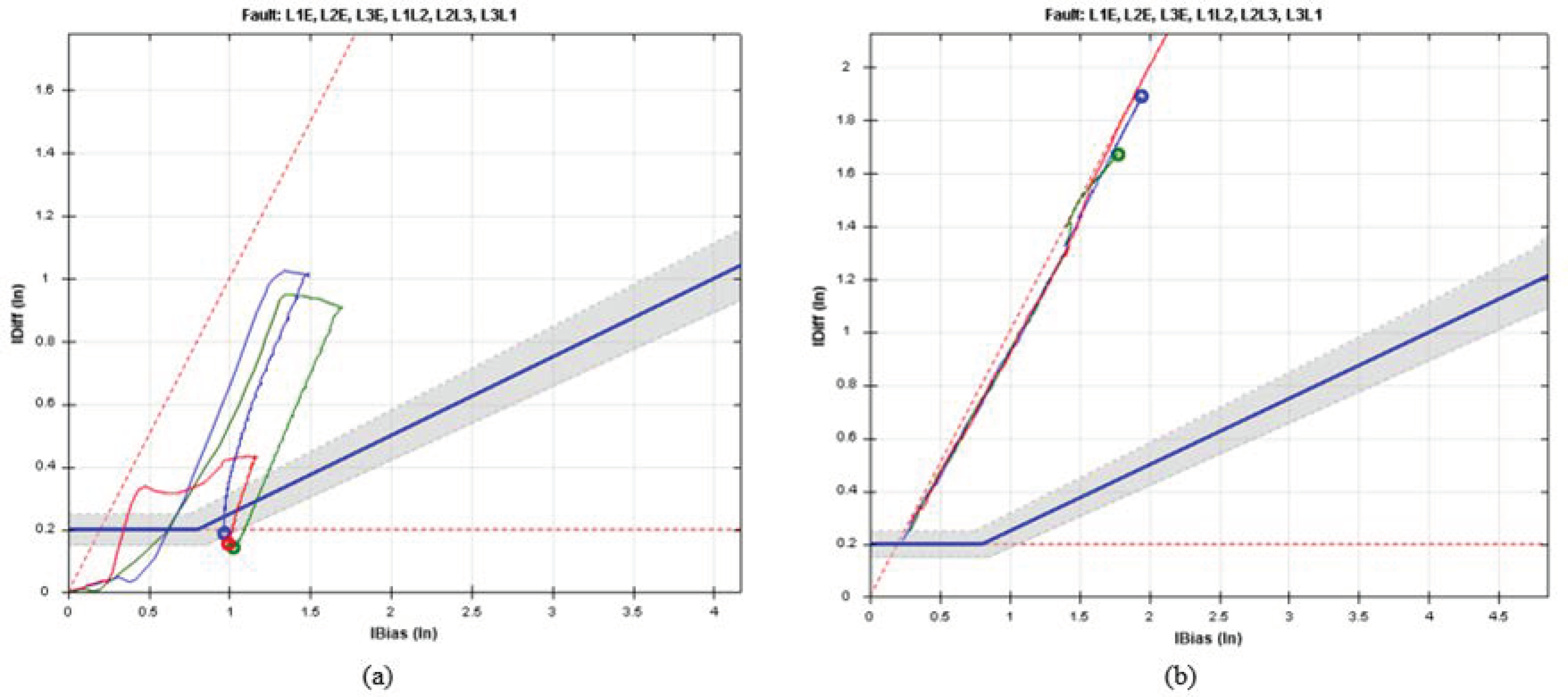

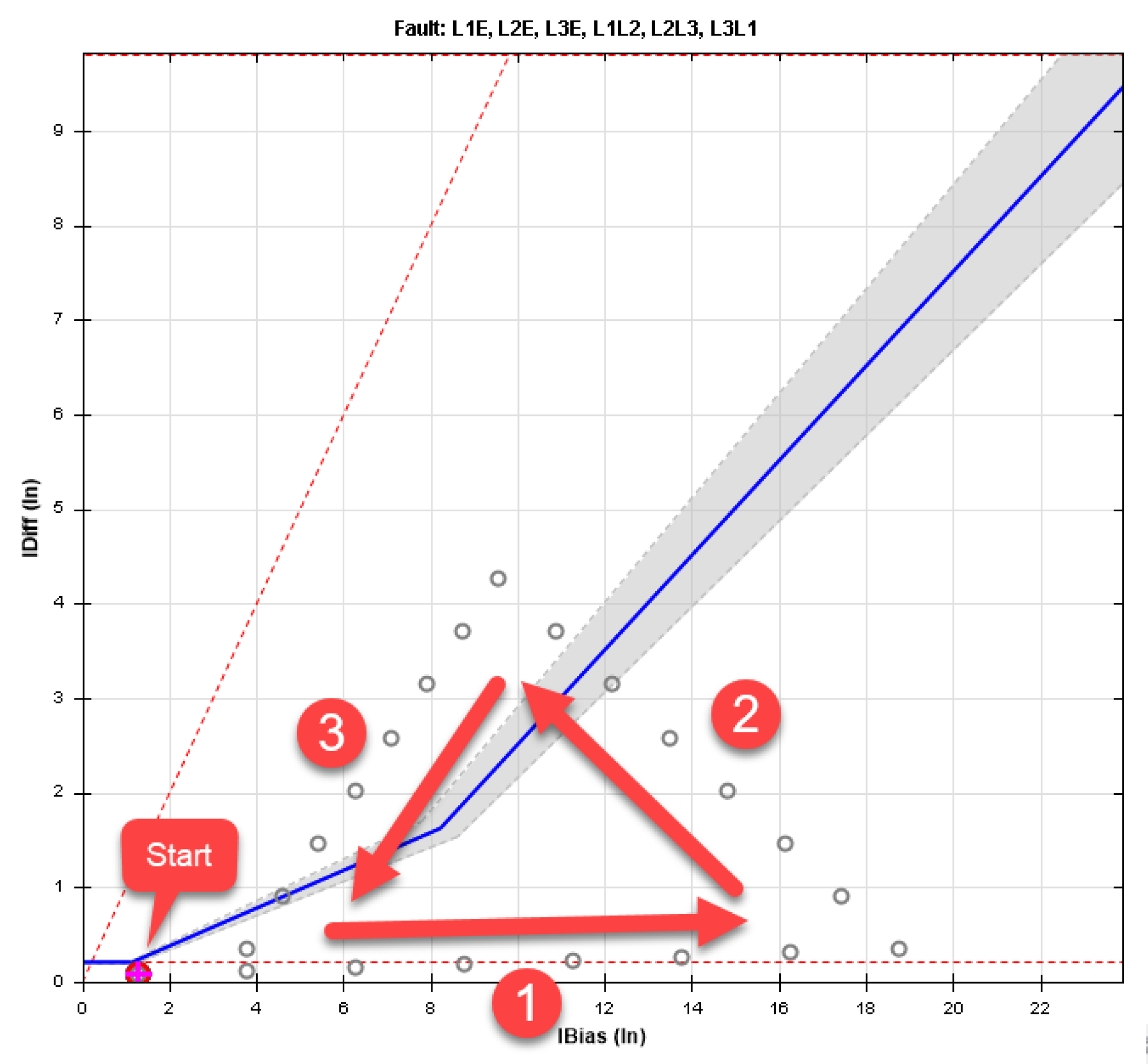

In order to further analyze the proposed method, this method has been compared with the method on SIGRA software. For this analysis, it is necessary to inject a fault current with an identified trajectory to the relay. Hence, the current tracking feature available in relay testing software can be implemented. Therefore, by adding different points on the operational axis of the differential relay, the required fault current can be created, and at the end, these generated currents can be injected into the relay.

Figure 20 shows the differential trajectory created by the current tracking feature for testing the differential relay. As is clear, the start point of this trajectory is outside the operational zone of the differential relay. In the first part, the differential trajectory remains outside the operational zone of the relay. In the second part, the trajectory has entered the operational zone of the differential relay from the third slope. Finally, in the third part, the trajectory exits the operational zone of the differential relay from the second slope and returns to the starting point.

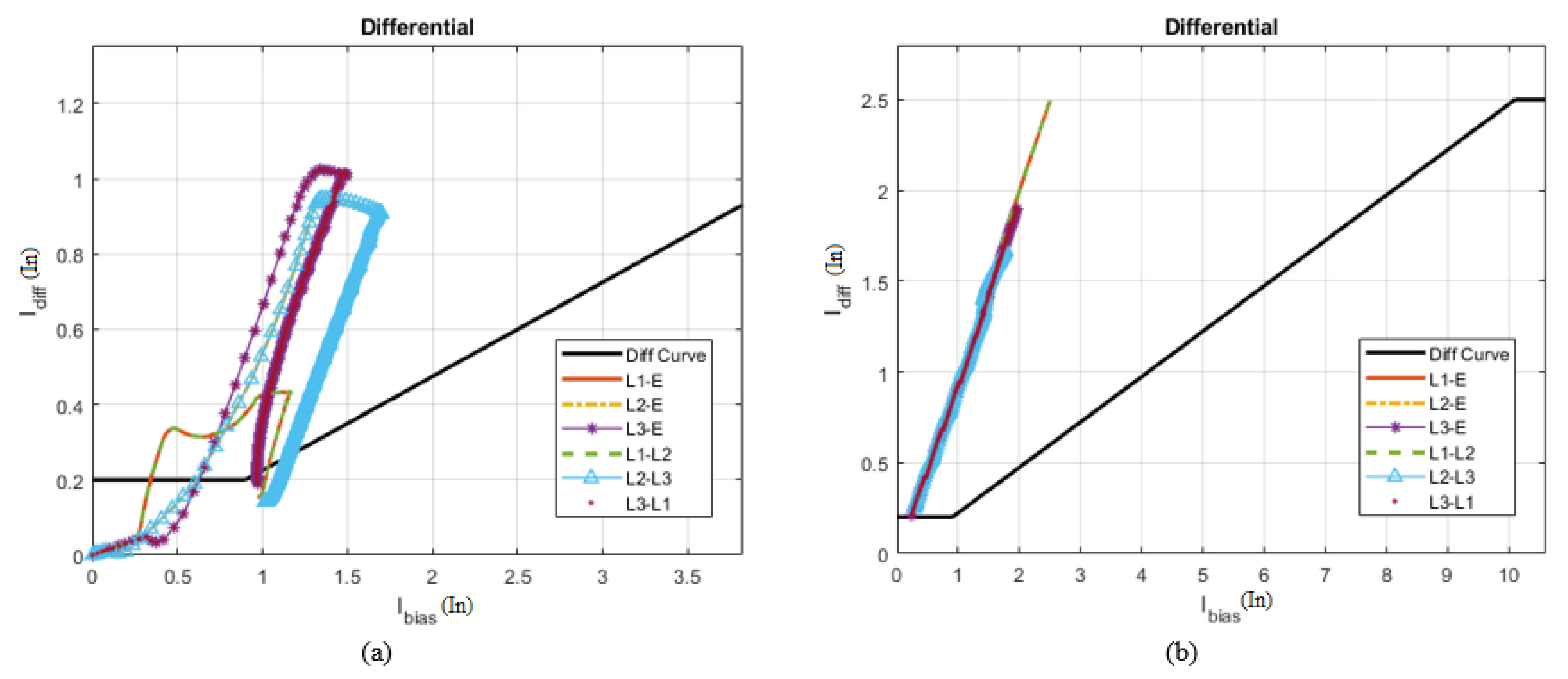

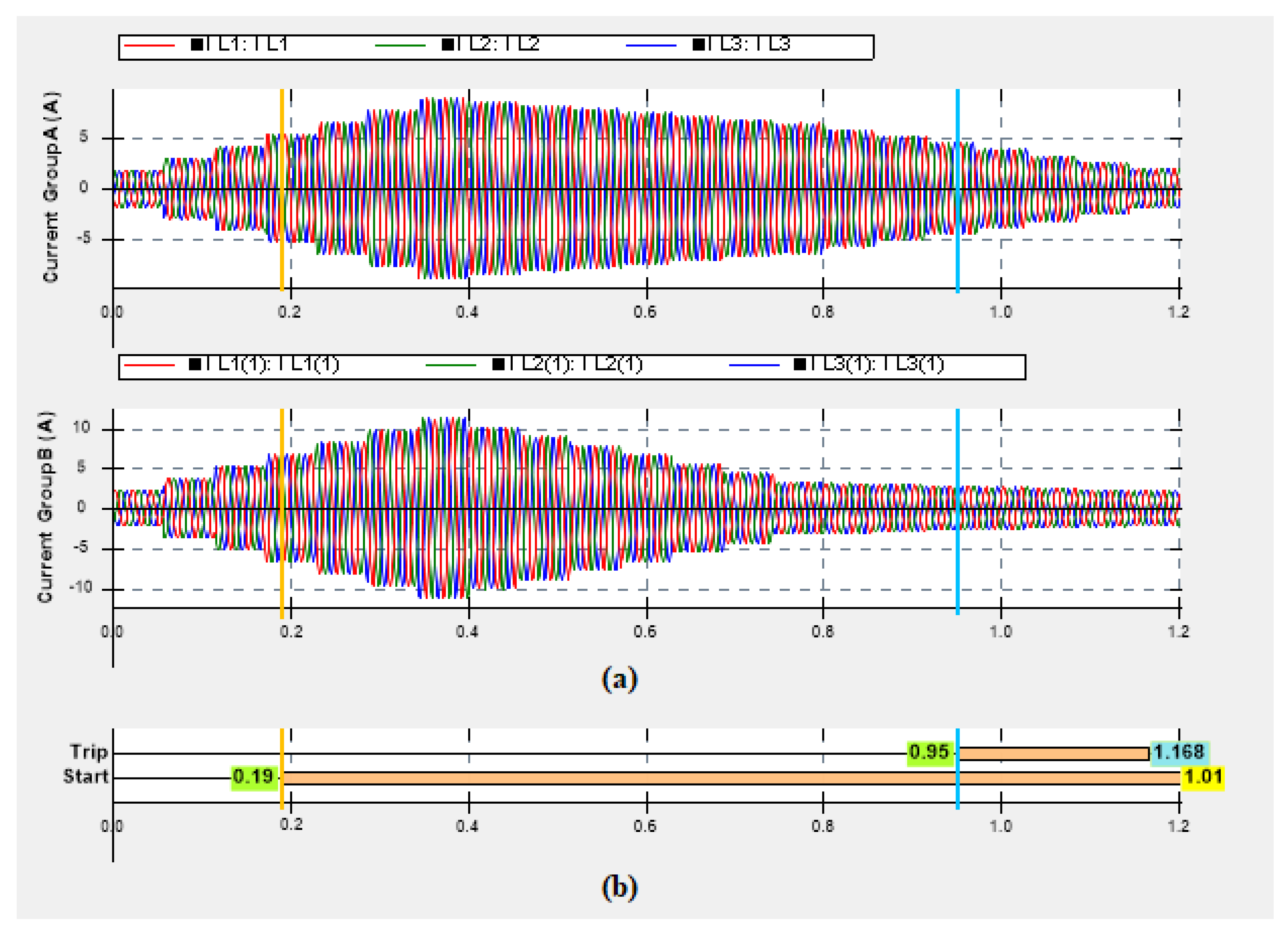

The fault currents generated using the current tracking feature of the tester are shown in

Figure 21a. These fault currents are associated with currents from both sides of the protected transformer. As is clear from

Figure 21b, six fault currents are entered into the relay, and this relay has operated appropriately. After applying this fault to the relay shown in

Figure 9, the COMTRADE file of the relay has been extracted. The differential trajectory of this file is produced and compared by the method proposed in this paper and also by SIGRA software version 4.58 (Develop by Siemens, Munich, Germany).

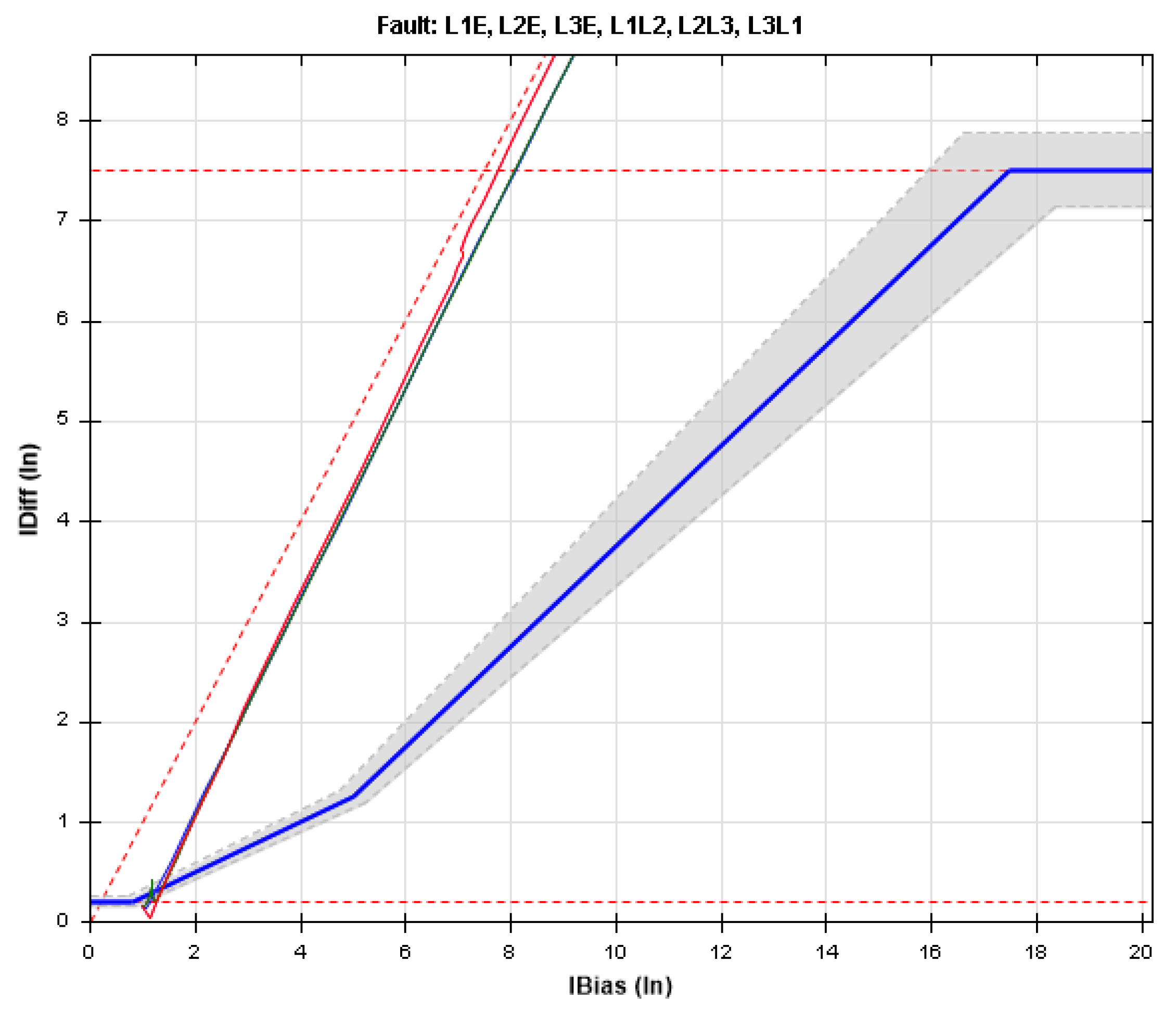

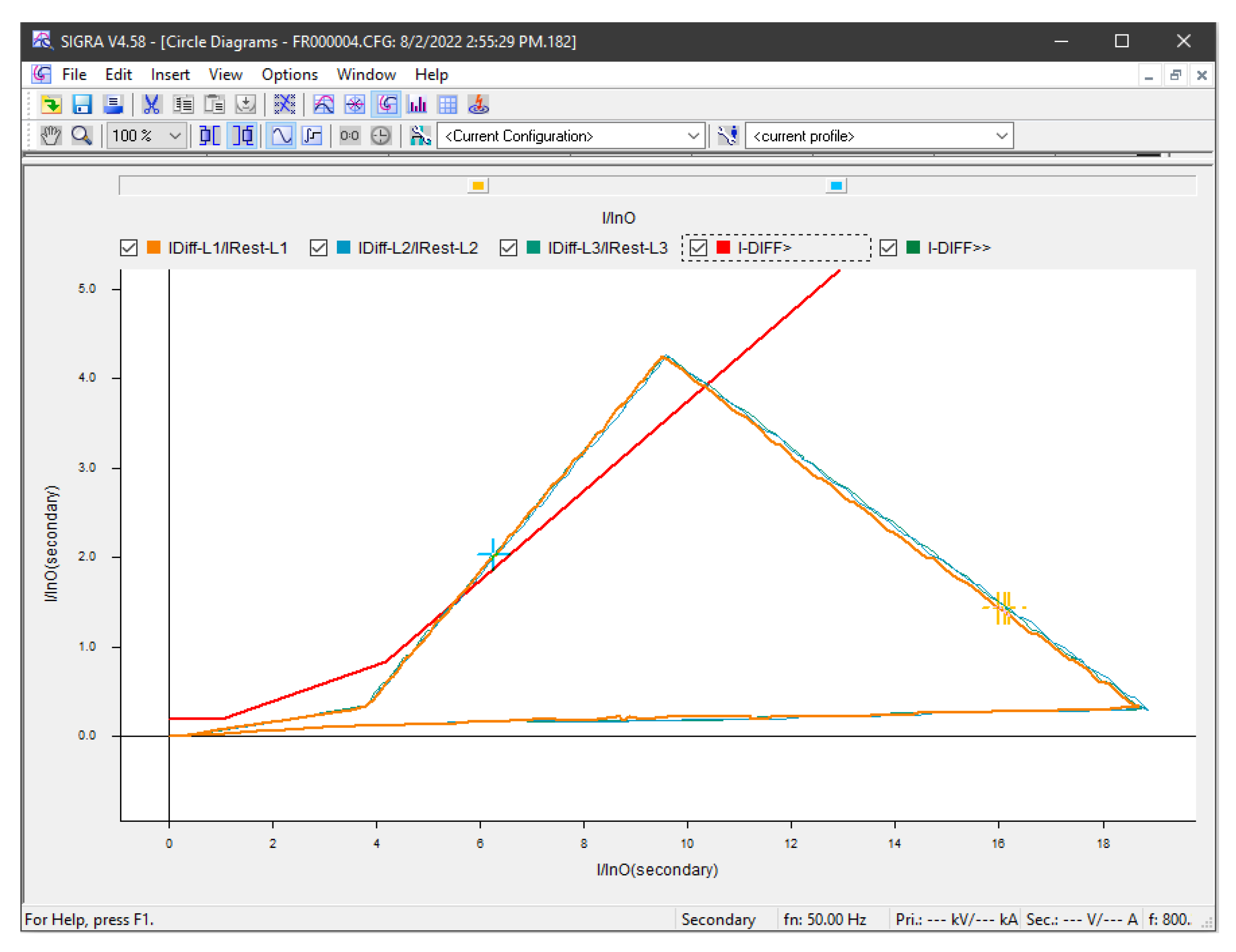

Figure 22 shows the differential trajectory produced by SIGRA software. As is clear from this figure, the starting point of the trajectory shown in

Figure 20 is wrongly determined by SIGRA software. In the following,

Section 1 and

Section 2 (according to

Figure 20) are calculated accurately. However, the trajectory has not exited the operational zone (

Section 3, according to

Figure 20) through the second slope, which was a mistake by SIGRA software, and it has exited the operational zone from the third slope.

Figure 23 shows the trajectory generated by the proposed method in this paper. As is clear from

Figure 23, the starting point of the trajectory has been calculated with high accuracy. Additionally, according to the figure, the trajectory of

Section 1,

Section 2 and

Section 3 (according to

Figure 20) is correctly generated, and in

Section 3, it has exited the operation zone of the relay from the second slope.

6. Conclusions

Despite the many advantages of the differential relay in protecting power transformers, it may be vulnerable to various transient phenomena and cause its maloperation. Although various studies are in the field of performance improvement and differential relay testing, it is still not possible to evaluate the correct/incorrect operation of the differential relay after its operation. This problem requires analyzing the behavior of six input currents of the differential relay at different sampling times, considering the relay setting curve. Hence, a method for generating a differential trajectory from the six currents extracted from the COMTRADE file of the differential relay and mapping them on the setting curve of this relay was presented in this paper. In the proposed method, all the influencing factors on the six currents recorded in the COMTRADE file of the differential relay, including the effects of the CTs connections type and the protected transformer connections type, were considered. The proposed method was evaluated during different incidents (faults, inrush current, and CT saturation) in the simulation and experimental tests. In the experimental tests, the COMTRADE files of simulated incidents were applied to a differential relay through a tester device. Then, the output COMTRADE files of the relay were evaluated by the relay tester in which the proposed method was loaded. The presented results show that the proposed method, using the output COMTRADE files of the relays, is able to generate the differential trajectory of the different incidents in which differential relays may encounter. Therefore, by implementing this method, it is possible to evaluate the correct/incorrect operation of the differential relay for any incident.