Abstract

In parallel with the increase in vehicle sales worldwide, waste tires are becoming an increasing problem. The storage and disposal of these waste tires are critical environmental problems. Re-using these wastes in different areas instead of being disposed of is vital in preventing environmental pollution and creating new low-cost products. From this motivation, this paper investigates the properties of traditional reinforced-concrete beam with recycled steel wires (RSWT) obtained from the waste tires. RSWT were added to reinforced-concrete beam between 1% and 3% by weight with an increment of 1%. In total, 9 cubes, 12 cylinders and 12 reinforced-concrete beams were cast and tested to obtain the compressive, splitting tensile and flexural strengths, respectively. RSWT added to the concrete by 1%, 2% and 3% increased the compressive strength by 17.2%, 30.8% and 46.4%, respectively, compared to the reference concrete. In split tensile strength, 14.4%, 25.1% and 36.7% increases were observed, respectively. This showed that there was an effective increase in the compressive and tensile strength of concrete with the increase of fiber content. Although the effect of fiber content in samples with high stirrup spacing (27 cm) provides significant benefit in improving the beam behavior, the effect of fibers was more limited as the stirrup spacing decreased (20 cm and 16 cm). An approximation of over 91% was obtained between the analytical calculations and the experimental results. This shows that the analytical calculations given in the standards can be used for new experimental studies.

1. Introduction

Sustainability has become a major concern for humankind, especially in recent years. On the basis of this, the world’s resources are constantly decreasing, and the human population continues to increase rapidly. The effective re-use of materials is extremely important in this respect [1,2,3,4,5,6,7,8,9]. There is a sustainability concern in concrete, which is the indispensable material of the construction and building industry. Concrete is the most widely used material in the construction industry; its production consumes a vast amount of natural resources and is responsible for 8–9% of the total global anthropogenic CO2 emissions [10,11,12,13]. Concrete is inevitably affected by external conditions such as temperature and water in practical engineering [14]. Water can affect the mechanical properties of concrete beam, especially the compressive strength [15,16,17]. In this context, it is important to make the concrete mixture with recyclable materials as much as possible, without compromising the expected performance of the concrete (strength for hardened concrete/workability for fresh concrete), thus limiting the amounts of aggregate and cement used [18,19].

There have been efforts to use different waste materials in concrete. One of these is the wastes arising from tires that have expired. The chemical composition and storage problems of car tires pose a problem worldwide. Tires are not biodegradable. Especially in case of the stocking stage, they can cause viral and bacterial diseases to multiply. The environmental problems caused by around 300 million waste tires annually in the USA alone are significant [20]. Similarly, a significant portion (estimated 50%) of the one billion tires that complete their service life in the world every year is addressed through incineration [21]. However, the accumulation of worn-out tires creates health and fire hazards. Therefore, these wastes should be used in a more sustainable way. It is possible to use waste car tires as fuel in cement factories, to be used instead of aggregate in asphalt and concrete, and to use in industry by separating the steel fibers in tires. Steel wire recovered in this way in Europe amounts to over 500,000 tons per year [22].

Composite materials and various types of fibers (glass, steel, carbon, aramid, etc.) are used to improve the mechanical properties of concrete [23,24,25,26,27]. The most common of these is steel fibers (SF). Although the geometry of the fiber depends on the dosage and mechanical properties, SFs significantly improve the weak properties of concrete, which is a brittle material [28,29]. For example, fiber reinforcement improves the mechanical properties (i.e., tensile strain capacity and ductility) and controls crack propagation [30,31] by bridging the cracks and transmitting tensile force across them to enhance the post-cracking tensile behavior. Aiello et al. [32] stated that the main purpose of steel fibers is to prevent and control the crack propagation in concrete. Many studies have proven that using SFs in concrete improves the behavior of reinforced concrete in terms of shear, bending and tensile behaviors [33,34] rate of cracking [35] ductility and stiffness [36,37].

Unlike SF, recycled steel fiber from tire waste (RSWT) is an alternative building material to manufactured steel fibers (SF). In particular, many studies have been conducted to determine the compressive strength, tensile strength, workability and durability of SF-added concrete [38,39]. In these studies, there is no clear consensus on the compressive strength of concrete with RSWT additives. Some researchers say that RSWT decreases compressive strength [40,41]. However, some have mentioned the limited positive effect of RSWT on the compressive strength of concrete [32,42,43,44]. According to Caggiano et al. [45], increasing amounts of fibers (or higher aspect ratios) may enhance the compressive strength of concrete up to a certain threshold; however, a larger amount of steel fibers (beyond that threshold) could have an adverse effect on the resulting compressive strength, thus generating a loss in strength. The researchers found that there was no significant relationship between the increase in the RSWT ratio and the increase in compressive strength [42]. A significant problem is the inability to achieve homogeneity at high dosages of RSWT and the aggregation of RSWT in a certain region. There is a similar lack of information in the change of modulus of elasticity in RWST-reinforced concrete, as pointed out by Bjegovic et al. [46] and Papakonstantinou and Tobolski [40].

From the above comparisons, it is understood that fiber-reinforced concrete has a positive effect on the mechanical performance of the concrete. However, when the issue is limited resources and sustainability, research on recycled materials such as steel wires from waste tires becomes more valuable.

In the literature, the contribution of RSWT to the mechanical properties of concrete in cube, cylindrical or prismatic (Caggiano et al.) [45] concrete elements has been investigated. Experiments on reinforced-concrete members such as beams, columns, slabs, etc., are very limited. To the authors’ best knowledge, only few experimental studies have been carried out so far on reinforced-concrete members containing RSWTs. In particular, in reinforced-concrete elements, bending and tensile damage, which occurs due to the fact that the tensile strength of concrete is quite low and it has a brittle structure, can sometimes occur under service loads and under the influence of loads such as seismic loads. Apart from this, time-dependent creep deformation and shrinkage can cause significant damage to the concrete. After the formation of this damage, repair or strengthening may be required in the load-carrying members. Among this damage, shear damage is a type of damage that is frequently seen and is relatively more difficult to repair than others. It is possible to prevent such damage with additional materials such as fiber to be used in the concrete.

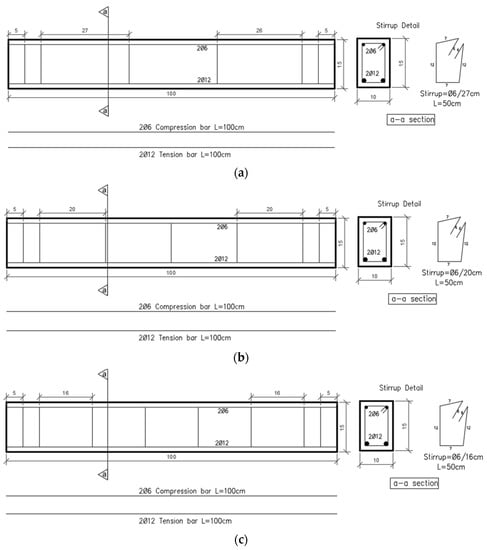

In this study, the main motivation is to determine the shear behavior of small-scale reinforced-concrete beams manufactured with RSWT at various rates. Based on this motivation, an experimental study was planned. The experimental program consisting of 12 shear deficient reinforced-concrete beam specimens was conducted in Necmettin Erbakan University, Konya, Turkey. All rectangular specimens had cross sections of 100 mm × 150 mm and lengths of 1000 mm. The concrete used in the beams was produced with RSWTs in different volumetric ratios (0%, 1%, 2% and 3%). The shear reinforcement (stirrups) was kept very limited as the change in shear capacity of the beams was tested. Beams were manufactured with 6 mm diameter stirrups at 16, 20 and 27 cm spacings. In the beams, 2ϕ12 in the tension zone and 2ϕ6 in the compression zone was used as longitudinal reinforcement. In the four-point bending test, the change in shear capacity of shear beams was examined.

2. Materials and Methods

In this study, recycled steel wires obtained from waste tires were utilized. The used steel wires are shown in Figure 1. The geometry of steel wires was irregular but generally linear. Average length of the steel wires was approximately 30–50 mm. The use of steel wires is higher than 100 mm was avoided to prevent aggregation. For concrete production, CEM I 32.5 type of Portland cement was utilized. The water–cement ratio utilized was 0.6. The cement aggregate ratio was 0.22. Waste lathe scraps were utilized in order to increase the shear performance of the beams.

Figure 1.

The recycled steel wires used in this study.

The experimental program consisting of 12 specimens was conducted in Necmettin Erbakan University. All specimens had cross sections of 100 mm × 150 mm and lengths of 1000 mm. Tensile longitudinal reinforcement of 2ϕ12 and compressive longitudinal reinforcement of 2ϕ6 was utilized for all specimens. The specimens were designed under a balanced reinforcement ratio of 0.0125. Stirrups of ϕ6 with three different spacings were considered. The spacings were 27 cm, 20 cm and 16 cm to obtain shear damage. Moreover, 1%, 2%, and 3% volumetric fiber ratios (Vf) were studied. Using more than 3% volumetric fiber ratio (Vf) was avoided, since it is difficult to work with a 3% Vf fiber ratio. Most probably, aggregation problems would occure if more than 3% Vf fiber ratio was utilized. Due to the possible aggregation problems, the compressive strength and tensile strength would be reduced if more than a 3% fiber ratio was used. Smiliar results were also reported, with steel wires with more than 3% causing workability problems [36,47]. In order to eliminate the aggregation problem, small amounts of steel waste fibers were slowly and continously added in the mixer. The details of the specimens, along with their names, are shown in Table 1. The reinforcement layout utilized in the specimens is demonstrated in Figure 2.

Table 1.

Properties of specimens.

Figure 2.

Reinforcement layout for specimens. (a) Stirrup spacing 27 cm. (b) Stirrup spacing 20 cm. (c) Stirrup spacing 16 cm.

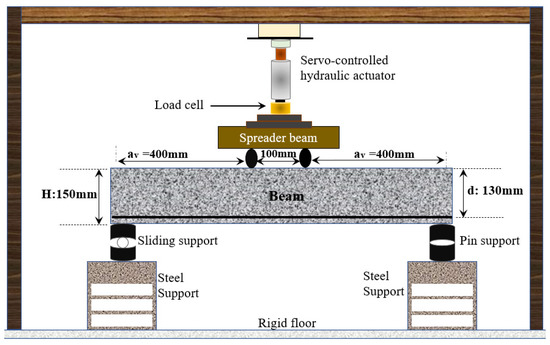

The specimens were loaded under four-point loading. The specimens were placed on two types of supports: pin and roller supports. A shear span to effective depth (av/d) of 3.1 was seen to have shear failure [48,49]. During the experiments, the load and displacements were recorded. The test setup is shown in Figure 3. The volumetric ratio of stirrups (ρw) was calculated using Equation (1). Here, n: number of stirrup arms; Asw: stirrup cross-sectional area; bw: beam width; and s: application range of stirrups.

Figure 3.

Test setup.

In order to produce the beams, the CEM I 32.5 type of Portland cement was utilized. The chemical properties of this cement are given in Table 1. The water–cement ratio utilized was 0.6. The cement aggregate ratio was 0.22. Recycled steel wires from waste tires (RSWT) were utilized to increase the beams’ bending performance. The RSWT used in this study was helical. The recycled lathe scraps were divided into small pieces before being used. For each sample, 10 cm × 20 cm, 15 cm × 15 cm × 15 cm cylindrical and cube samples were used for compressive and splitting tensile tests.

In addition, a slight decrease in the workability of the concrete was observed with the addition of fibers. However, this did not cause a decrease in the compressive strength, as the compression processes were carried out appropriately in cylinder and cube preparation.

3. Experimental Results and Discussion

In the material tests, cylinder (10 cm × 20 cm) and cube (15 cm × 15 cm × 15 cm) compressive strengths were obtained as 25 MPa and 29.5 MPa, respectively, for concrete without any fibers. They were then calculated as 29 MPa and 34.6 MPa for 1% fiber content, 32 MPa and 38.6 MPa for 2% fiber content, and 37 MPa and 43.2 MPa for 3% fiber content. As a result of the cylinder (10 cm × 20 cm) tests used for splitting tensile strengths, 2.83 MPa in the reference sample, 3.24 MPa in the sample containing 1% fiber, 3.54 MPa in the sample containing 2% fiber and 3.87 MPa in the sample containing 3% fiber were obtained. When the conversion coefficients (0.8 and 1.05) are applied for the standard cube (15 cm × 15 cm × 15 cm) and standard cylinder (15 cm × 30 cm), the compressive strength for the reference sample is 23.6 MPa, for the 1% fiber content 27.68 MPa, for the 2% fiber content 30.88 MPa, and for the 3% fiber content 34.56. These were taken into account in the calculations as the MPa.

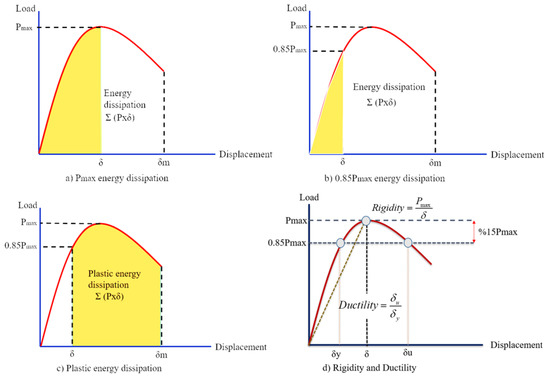

In the experimental study, vertical load midpoint displacement graphs of each sample were drawn. Three different reference samples (SREF-1, SREF-2 and SREF-3) that did not contain any RSWT were considered in the study as well as those with RSWT at different rates (STIRE-1, STIRE-2, STIRE-3, STIRE-4, STIRE-5, STIRE-6, STIRE-7, STIRE-8 and STIRE-9); by comparing a total of 12 different samples, information on the changes in the shear behavior of the beams was attained. The changes in load, displacement, stiffness, ductility and energy dissipation capacities obtained from experimental studies are given in Table 2 and Table 3. Their production is shown in Figure 4.

Table 2.

Experimental results for load and displacement values.

Table 3.

Experimental test results for energy dissipation capacities.

Figure 4.

Energy dissipation capacity, ductility, and rigidity calculation of specimens.

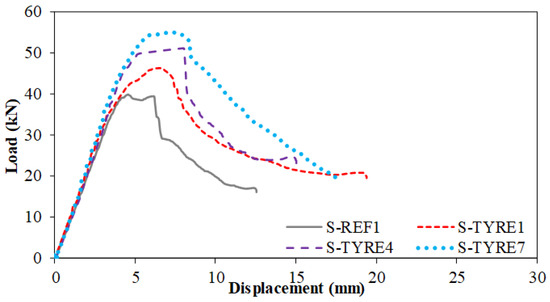

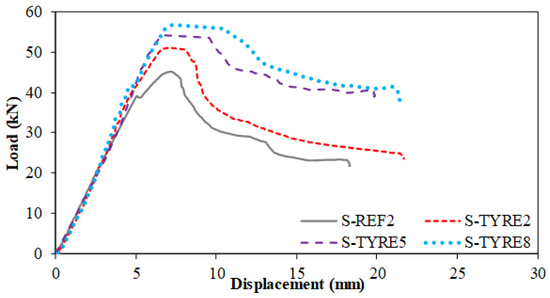

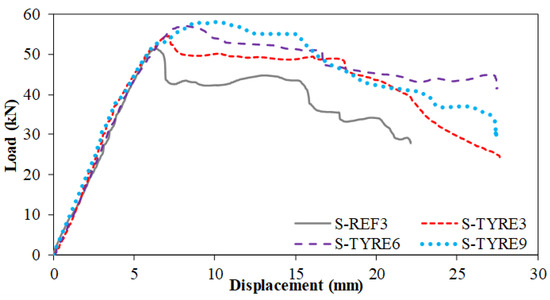

As seen in Table 3, the load carrying capacity of SREF-1, SREF-2 and SREF-3 reference samples without RSWT decreased with the increase in the transverse reinforcement spacing (SREF-1 < SREF-2 < SREF-3). When the transverse reinforcement spacing was reduced from 27 cm in SREF-1 to 20 cm in SREF-2, a 13% increase in load carrying capacity was observed. Similarly, when the transverse reinforcement spacing was reduced to 16 cm in SREF-3, the load carrying capacity increased by 29%. This situation remained valid for the samples in the range of STIRE-1 to STIRE-9 with different ratios of RSWT content, and an increase in load carrying capacity was observed as the transverse reinforcement spacing decreased (Figure 5, Figure 6 and Figure 7). According to SREF-1, with transverse reinforcement spacing of 27 cm and no RSWT, load carrying capacity and displacement value against maximum load are 16–42.6% in STIRE-1 containing 1% RSWT, 28–75.1% in STIRE-4 containing 2% RSWT, and a 38–59.1% increase in STIRE-7 containing 3% RSWT (Figure 5). Compared to the SREF-2 with a stirrup spacing of 20 cm, the STIRE-2 with 1% RSWT had a 13% increase in load carrying capacity and a 2.2% decrease in the maximum load versus displacement value, while the STIRE-5 with 2% RSWT had a 13% increase in load carrying capacity. 19.7% increase in maximum load was detected in STIRE-8 with 3% RSWT (Figure 5). Finally, compared to SREF-3 with a stirrup spacing of 16 cm, STIRE-3 with 1% RSWT increased the load carrying capacity and displacement value against maximum load by 5.9–10.45%, and for STIRE-3 with 2% RSWT 11.03%. There was a 29.79% increase and a 13.2% increase in STIRE-9 containing 3% RSWT. In other words, while an increase was observed in the displacement values under maximum load for the samples with 1%, 2% and 3% RSWT content with a stirrup spacing of 27 cm and 16 cm, a decrease was observed in the samples with a stirrup spacing of 20 cm and a RSWT ratio of 1% and 2%. This naturally led to an increase and decrease in the stiffness values under maximum load. In other words, the highest stiffness value under maximum load occurred in SREF-1 (8.75 kN/mm) with no RSWT and 27 cm transverse reinforcement spacing, while the lowest stiffness value was seen in STIRE-9 with 16 cm transverse reinforcement spacing and 3% RSWT (5.76 kN/mm). Considering the 0.85 Pmax value, where the linear elastic capacity is represented, the yield load carrying capacity increases with the decrease of the transverse reinforcement spacing, as in Pmax, and this value increases as the RSWT ratio increases. In addition, when the displacement values corresponding to 0.85 Pmax were examined, an increase was observed as the RSWT ratio and transverse reinforcement spacing increased. The highest stiffness value corresponding to the yield moment was 10.78 kN/mm for STIRE-7, while the lowest value was 8.36 kN/mm for STIRE-6. The yield (δy) and rupture (δu) displacement values are two important parameters for ductility. According to the literature [50], a sufficient ductility ratio (ductility coefficient) for a sub-balanced ductile design is around 4~5. Although partial ductility was observed in the STIRE-3 sample, sufficient ductility was not observed the other samples. However, as the transverse reinforcement spacing and RSWT ratio increased, δu reached higher values. This is an indication of improvement in ductility. While the ductility rate was highest in STIRE-6 and STIRE-9 samples, the lowest ductility rate was obtained for the sample with 20 cm transverse reinforcement spacing and no waste steel wire.

Figure 5.

Comparison of the samples with 27 cm transverse reinforcement spacing.

Figure 6.

Comparison of the samples with 20 cm transverse reinforcement spacing.

Figure 7.

Comparison of the samples with 16 cm transverse reinforcement spacing.

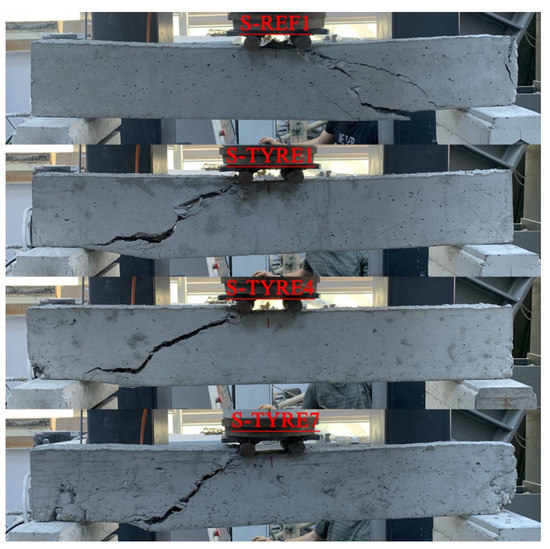

When Figure 5, Figure 6 and Figure 7 are examined, it is understood that the use of RSWT in concrete makes a significant contribution to both displacement and load carrying capacity. For the samples (SREF-1, STIRE-1, STIRE-4 and STIRE-7) with the same transverse reinforcement spacing (27 cm) as shown in Figure 5, the end-of-test damage views are shown in Figure 8.

Figure 8.

Damage views of the reference sample and samples with 27 cm transverse reinforcement spacing and RSWT ratios of 1%, 2% and 3%.

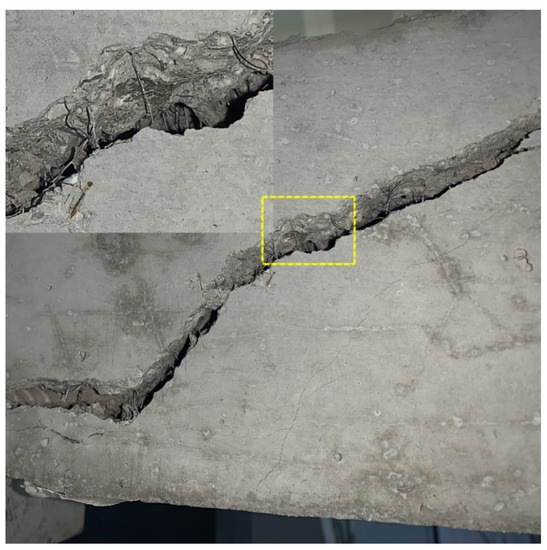

As seen in Figure 8, typical shear damage was observed in all samples. However, when the fracture patterns are examined, it is understood that the fracture direction changes with the increase in the fiber ratio. Especially in STIRE-7, where the fiber ratio is 3%, damage close to 45° occurred, while cracks were observed between 45–60° in other samples. As the stirrup spacing was high and the fiber ratio was the highest, adherence cracks were observed in the samples, except for STIRE-7. The relatively high fiber content in STIRE-7 limited the occurrence of this damage. RSWT appearance after fracture in the STIRE-4 specimen, as shown in Figure 9. In Figure 9, it can be seen that RSWT act as bridges between concrete parts. However, since they have a certain length, they break with the increase of the load in the shear zone. This situation indicates that more load can be carried and fibers can work together with concrete by increasing the fiber ratio to optimum levels.

Figure 9.

Close view of specimen STIRE-4.

The damage views at the end of the test are shown in Figure 10, with the transverse reinforcement spacing reduced to 20 cm (SREF-2, STIRE-2, STIRE-5, STIRE-8). Here, too, typical shear damage occurred, but the shear fracture caused by the reduction of the stirrup spacing extended from the support face to the lower point of the spreader beam to form an angle of 45–60°. Here, while adherence damage was observed towards the support in the SREF-2 sample, this situation was not observed in the other samples. Decreased stirrup spacing and fiber additives limited the occurrence of this damage. In other words, a change was observed in the damage behavior. Thus, the greatest contribution to the change was provided by reducing the stirrup spacing to 20 cm.

Figure 10.

Damage views of the reference sample and samples with 20 cm transverse reinforcement spacing and RSWT ratios of 1%, 2% and 3%.

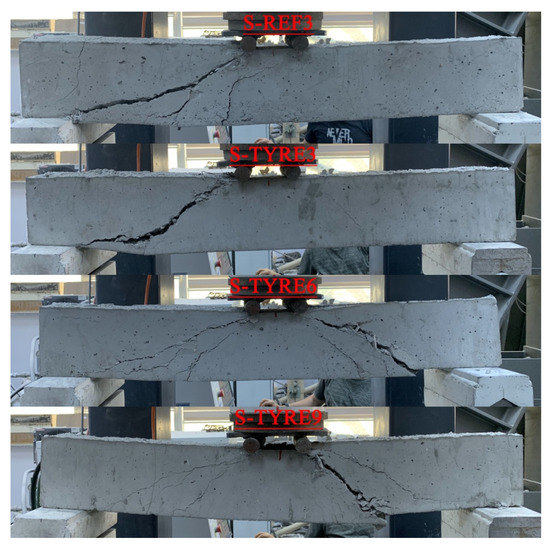

In the experimental study, SREF-3 was obtained by adding different fiber ratios to the samples with the most frequent stirrup spacing (16 cm): STIRE-3 and STIRE-6. At the end of the experiment, STIRE-9 specimens suffered shear damage and collapsed, as shown in Figure 11. Here, the fracture behavior observed in the samples with a fiber ratio of 2% (STIRE-6) and 3% (STIRE-9) was different from all other samples. The bending capacity of the beam is forced, but the bending capacity of the beam is higher than the shear capacity, so the cracks in the bending region are limited. Therefore, shear cracks in both shear openings of the beam became evident. Finally, shear fracture occurred in the right shear opening in both samples. Notice that in STIRE-6, the fracture ended after approximately h in the support flat, and in STIRE-9, after about 2 h due to the support. This indicates that the fibers increase the shear capacity and contribute to the orientation of the damage towards the bending zone.

Figure 11.

Damage views of the reference sample and samples with 16 cm transverse reinforcement spacing and RSWT ratios of 1%, 2% and 3%.

The vertical load values obtained experimentally as a result of the study were supported by analytical work. The analytical study was carried out using the shear capacity formulas given in TS500-2000 [51]. The corresponding formulas are given in Equations (2)–(6):

where Vc is the contribution of concrete to shear capacity, fct is the axial tensile strength, is the split tensile strength, bw is the width of the beam, d is the useful height value, Vw is the contribution of stirrup shear, n is the number of stirrup legs, Asw is the reinforcement area of the stirrup, s is the stirrup spacing, fyw is the stirrup yield strength, P is the vertical breaking load, D is the diameter of the cylinder sample, L is the length of the cylinder sample and Vr is the sum of the contribution of concrete and stirrup to the shear capacity. Analytical calculations were made using the data obtained according to the experimental cylinder and cube sample results. The analytical calculation results obtained to be compared with each test sample are given in Table 4. In Table 4, it is seen that the experimental and analytical calculations are in harmony. This shows that calculations can be made if different fiber ratios are taken into account.

Table 4.

Experimentally and analytically obtained maximum load carrying capacities of the samples.

Three different transverse reinforcement spacings (27 cm, 20 cm and 16 cm) were considered in the study. This study makes an important contribution to the results obtained for samples with different spacing and different sizes. In the study, 6 mm was considered as the transverse reinforcement diameter. The effect of transverse reinforcement diameter change can be taken into account in future studies.

4. Conclusions

At the end of a series of experimental studies, the effect of using a certain ratio (0, 1%, 2% and 3%) of RSWT on reinforced-concrete beam behavior in reinforced-concrete beams produced with different stirrup spacings (27 cm, 20 cm and 16 cm) was observed, and the results are summarized below:

- RSWT added to the concrete by 1%, 2% and 3% increased the compressive strength by 17.2%, 30.8% and 46.4%, respectively, compared to the reference concrete. In split tensile strength, 14.4%, 25.1% and 36.7% increases were observed, respectively. This showed that there was an effective increase in the compressive and tensile strength of concrete with the increase of fiber content. Similar results were obtained in the experiments performed in the literature. For instance, Sahrei et al. [52] used RSWT to improve the mechanical properties of concrete, and it has been observed that fiber’s effect on improving tensile and flexural strengths was much more significant (with 1% RSF enhancement of 11, 90, and 122%, for compressive strength, splitting tensile strength, and flexural strength, respectively, in comparison with the plain mixture. In the literature, similar results have been found by other researchers [53,54,55,56,57,58,59,60].

- With the increase of the RSWT ratio, both the 0.85 Pmax value and the Pmax value of the samples increased. Thus, it was concluded that the beam behavior improved with the increase of the fiber ratio.

- All beams reached failure mode with shear damage. Dominant cracks started at the shear opening and extended to the spreader beam. In addition, no ductile behavior was observed, even at the rate of 3% RSWT. This is due to the high beam bending capacity. The load carrying capacity obtained from STIRE-7 and STIRE-9 with a 3% RSWT ratio increased by 38.14% and 13.2%, respectively, compared to SREF-1 and SREF-3. Since the analytically calculated bending capacity of the reference SREF-1, SREF-2 and SREF-3 was 74.66 kN, the contribution of the fibers to the load bearing capacity was not sufficient to observe the ductile behavior.

- Total energy consumption increased as the transverse reinforcement spacing decreased. In addition, it is understood that there is a linear relationship between the increase in the fiber content and the increase in the total energy consumption capacity.

- Although the effect of fiber content in samples with high stirrup spacing (27 cm) provides significant benefit in improving the beam behavior, the effect of fibers was more limited as the stirrup spacing decreased (20 cm and 16 cm).

- An approximation of over 91% was obtained between the analytical calculations and the experimental results. This shows that the analytical calculations given in the standards can be used for new experimental studies.

- Because as fiber is added the workability of concrete may decrease, it is necessary to increase the water/cement ratio, and a decrease in mechanical properties can be expected as the water–cement ratio increases. In this study, compaction of concrete was carried out fairly regularly under laboratory conditions. However, in real practice, it is difficult to achieve this level of production quality in large-scale manufacturing.

Although there are some studies in the literature on the behavior of concrete produced by using RSWT, it is extremely important for the continuation of these studies in terms of the results obtained, examining the behavior change with the shear beam tests used in this study. In addition, the fact that RSWT mixed into concrete in certain proportions in the study can be produced by recycling methods is also extremely important in terms of the use of alternative waste materials in reinforced-concrete structures.

The competition in the market is ever-increasing; companies are trying to improve their current situation with new products. Especially in the traditional and prefabricated reinforced-concrete construction sector, companies are looking for new materials and approaches that will improve building behaviors in response to earthquakes. With this study, the waste RSWT was recovered in the construction sector. The behavior change of the structure can be examined by adding RSWT at the appropriate rate into the concrete in conventional or prefabricated reinforced-concrete structures, with tests of RSWT at different rates to be carried out in the future.

Author Contributions

Conceptualization, Y.O.Ö., C.A. and E.I.; methodology, Y.O.Ö., M.H.A. and C.A.; formal analysis, Y.O.Ö. and C.A.; investigation, Y.O.Ö.; resources, Y.O.Ö.; data curation, Y.O.Ö.; writing—original draft preparation, C.A., Y.O.Ö., M.H.A., M.H.-N., and E.I.; writing—review and editing, C.A., Y.O.Ö., M.H.A., M.H.-N. and E.I.; visualization, Y.O.Ö. and C.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Most data are included in the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef] [PubMed]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance Assessment of Fiber-Reinforced Concrete Produced with Waste Lathe Fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Deifalla, A.F.; Qureshi, H.J.; Saleem, M.U.; Qaidi, S.M.A.; El-Shorbagy, M.A. Concrete Made with Dune Sand: Overview of Fresh, Mechanical and Durability Properties. Materials 2022, 15, 6152. [Google Scholar] [CrossRef] [PubMed]

- Najm, H.M.; Ahmad, S. The Use of Waste Ceramic Optimal Concrete for A Cleaner and Sustainable Environment—A Case Study of Mechanical Properties. J. Build. Pathol. Rehabil. 2021, 32, 0085–0115. [Google Scholar] [CrossRef]

- Ahmad, J.; Martinez-Garcia, R.; Algarni, S.; de-Prado-Gil, J.; Alqahtani, T.; Irshad, K. Characteristics of Sustainable Concrete with Partial Substitutions of Glass Waste as a Binder Material. Int. J. Concr. Struct. Mater. 2022, 16, 21. [Google Scholar] [CrossRef]

- Qaidi, S.; Al-Kamaki, Y.S.S.; Al-Mahaidi, R.; Mohammed, A.S.; Ahmed, H.U.; Zaid, O.; Althoey, F.; Ahmad, J.; Isleem, H.F.; Bennetts, I. Investigation of the effectiveness of CFRP strengthening of concrete made with recycled waste PET fine plastic aggregate. PLoS ONE 2022, 17, e0269664. [Google Scholar] [CrossRef]

- Martínez-García, R.; Jagadesh, P.; Zaid, O.; Șerbănoiu, A.A.; Fraile-Fernández, F.J.; de Prado-Gil, J.; Qaidi, S.; Grădinaru, C.M. The Present State of the Use of Waste Wood Ash as an Eco-Efficient Construction Material: A Review. Materials 2022, 15, 5349. [Google Scholar] [CrossRef]

- Arbili, M.M.; Alqurashi, M.; Majdi, A.; Ahmad, J.; Deifalla, A.F. Concrete Made with Iron Ore Tailings as a Fine Aggregate: A Step towards Sustainable Concrete. Materials 2022, 15, 6236. [Google Scholar] [CrossRef]

- Hao, D.L.C.; Razak, R.A.; Kheimi, M.; Yahya, Z.; Abdullah, M.M.A.B.; Burduhos Nergis, D.D.; Fansuri, H.; Ediati, R.; Mohamed, R.; Abdullah, A. Artificial Lightweight Aggregates Made from Pozzolanic Material: A Review on the Method, Physical and Mechanical Properties, Thermal and Microstructure. Materials 2022, 15, 3929. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Shahjalal, M.; Islam, K.; Rahman, J.; Ahmed, K.S.; Karim, M.R.; Billah, A.H.M.M. Flexural response of fiber reinforced concrete beams with waste tires rubber and recycled aggregate. J. Clean. Prod. 2021, 278, 123842. [Google Scholar] [CrossRef]

- Arslan, M.; Arslan, H. New Trends on Green Buildings: Investigation of the Feasibility of Using Plastic Members in RC Buildings with SWs. In Proceedings of the IOP Conference Series: Earth and Environmental Science, 2nd International Conference on Green Energy Technology (ICGET 2017), Rome, Italy, 18–20 July 2017; IOP Publishing: Bristol, UK, 2017; p. 012022. [Google Scholar]

- Arslan, M.H.; Arslan, H.D. Use of Plastic Material for Providing Thermal and Acoustics Comforts in Residence Constructed with RC Tunnel form System; CESB (Central Europe Towards Sustainable Building): Quezon City, Philippines, 2013; pp. 301–304. [Google Scholar]

- Farhan Mushtaq, S.; Ali, A.; Khushnood, R.A.; Tufail, R.F.; Majdi, A.; Nawaz, A.; Durdyev, S.; Burduhos Nergis, D.D.; Ahmad, J. Effect of Bentonite as Partial Replacement of Cement on Residual Properties of Concrete Exposed to Elevated Temperatures. Sustainability 2022, 14, 11580. [Google Scholar] [CrossRef]

- Linul, E.; Marşavina, L.; Vălean, C.; Bănică, R. Static and dynamic mode I fracture toughness of rigid PUR foams under room and cryogenic temperatures. Eng. Fract. Mech. 2020, 225, 106274. [Google Scholar] [CrossRef]

- Park, K.-B.; Kim, H.-T.; Her, N.-Y.; Lee, J.-M. Variation of mechanical characteristics of polyurethane foam: Effect of test method. Materials 2019, 12, 2672. [Google Scholar] [CrossRef]

- Liu, K.; Huang, M.; Wang, F.; Zhang, X.; Fu, C.; Xu, P. Interlaminar stability analysis and evaluation of the asphalt pavement with heating cables based on shear fatigue test. Road Mater. Pavement Des. 2022, 1–22. [Google Scholar] [CrossRef]

- Sundaresan, S.; Ramamurthy, V.; Meyappan, N. Improving mechanical and durability properties of hypo sludge concrete with basalt fibres and SBR latex. Adv. Concr. Constr. 2021, 12, 327–337. [Google Scholar]

- Prakash, R.; Raman, S.N.; Subramanian, C.; Divyah, N. Eco-friendly fiber-reinforced concretes. In Handbook of Sustainable Concrete and Industrial Waste Management; Elsevier: Amsterdam, The Netherlands, 2022; pp. 109–145. [Google Scholar]

- Wang, J.; Dai, Q.; Guo, S.; Si, R. Study on Rubberized Concrete Reinforced with Different Fibers. ACI Mater. J. 2019, 116, 21–31. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of tyre steel fibres as concrete reinforcement. Proc. Inst. Civ. Eng.-Eng. Sustain. 2004, 157, 131–138. [Google Scholar] [CrossRef]

- Arslan, M.H.; Yazman, Ş.; Hamad, A.A.; Aksoylu, C.; Özkılıç, Y.O.; Gemi, L. Shear strengthening of reinforced concrete T-beams with anchored and non-anchored CFRP fabrics. Structures 2022, 39, 527–542. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Yazman, Ş.; Aksoylu, C.; Arslan, M.H.; Gemi, L. Numerical investigation of the parameters influencing the behavior of dapped end prefabricated concrete purlins with and without CFRP strengthening. Constr. Build. Mater. 2021, 275, 122173. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Aksoylu, C.; yazman, Ş.; Gemi, L.; Arslan, M.H. Behavior of CFRP-strengthened RC beams with circular web openings in shear zones: Numerical study. Structures 2022, 41, 1369–1389. [Google Scholar] [CrossRef]

- Baraghith, A.T.; Mansour, W.; Behiry, R.N.; Fayed, S. Effectiveness of SHCC strips reinforced with glass fiber textile mesh layers for shear strengthening of RC beams: Experimental and numerical assessments. Constr. Build. Mater. 2022, 327, 127036. [Google Scholar] [CrossRef]

- Mansour, W.; Fayed, S. Flexural rigidity and ductility of RC beams reinforced with steel and recycled plastic fibers. Steel Compos. Struct. 2021, 41, 317–334. [Google Scholar]

- ACI Committee. 544, 544.1 R-96: Report on Fiber Reinforced Concrete (Reapproved 2009). American Concrete Institute. Available online: http://indiafiber.com/Files/ACI%20report.pdf (accessed on 8 September 2022).

- Conforti, A.; Minelli, F.; Tinini, A.; Plizzari, G.A. Influence of polypropylene fibre reinforcement and width-to-effective depth ratio in wide-shallow beams. Eng. Struct. 2015, 88, 12–21. [Google Scholar] [CrossRef]

- fibBulletin. International Feder-ation for Structural Concrete (fib65). In Final Draft. Vol 1.; fibBulletin: Lausanne, Switzerland, 2010. [Google Scholar]

- fibBulletin. International Feder-ation for Structural Concrete (fib66). In Final Draft. Vol 2.; fibBulletin: Lausanne, Switzerland, 2012. [Google Scholar]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef]

- Yang, L.; Lin, X.; Gravina, R.J. Evaluation of dynamic increase factor models for steel fibre reinforced concrete. Constr. Build. Mater. 2018, 190, 632–644. [Google Scholar] [CrossRef]

- Amin, A.; Foster, S.J.; Muttoni, A. Derivation of the σ-w relationship for SFRC from prism bending tests. Struct. Concr. 2015, 16, 93–105. [Google Scholar] [CrossRef]

- Gali, S.; Subramaniam, K.V.L. Multi-linear stress-crack separation relationship for steel fiber reinforced concrete: Analytical framework and experimental evaluation. Theor. Appl. Fract. Mech. 2018, 93, 33–43. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Aksoylu, C.; Arslan, M.H. Experimental and numerical investigations of steel fiber reinforced concrete dapped-end purlins. J. Build. Eng. 2021, 36, 102119. [Google Scholar] [CrossRef]

- Chiranjeevi Reddy, K.; Subramaniam, K.V. Experimental investigation of crack propagation and post-cracking behaviour in macrosynthetic fibre reinforced concrete. Mag. Concr. Res. 2017, 69, 467–478. [Google Scholar] [CrossRef]

- Bethoft, K.; Samarakoon, S.; Evangelista, L.; Mikalsen, B. Performance of recycled and commercial fiber reinforced concrete beams in combined action with conventional reinforcement. In Proceedings of the SynerCrete’18: Interdisciplinary Approaches for Cement-Based Materials and Structural Concrete: Synergizing Expertise and Bridging Scales of Space and Time, Funchal, Portugal, 24–26 October 2018. [Google Scholar]

- Samarakoon, S.S.M.; Ruben, P.; Pedersen, J.W.; Evangelista, L. Mechanical performance of concrete made of steel fibers from tire waste. Case Stud. Constr. Mater. 2019, 11, e00259. [Google Scholar] [CrossRef]

- Papakonstantinou, C.G.; Tobolski, M.J. Use of waste tire steel beads in Portland cement concrete. Cem. Concr. Res. 2006, 36, 1686–1691. [Google Scholar] [CrossRef]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Fiber-reinforced concrete with low content of recycled steel fiber: Shear behaviour. Constr. Build. Mater. 2018, 161, 141–155. [Google Scholar] [CrossRef]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Flexural performance of steel fibre reinforced concrete with manufactured and recycled tyre steel fibres. In Construction Materials for Sustainable Future; University of Zagreb: Zagreb, Croatia, 2017; pp. 904–911. Available online: https://pure.qub.ac.uk/en/activities/first-international-conference-construction-materials-for-sustain-2 (accessed on 8 September 2022).

- Yazıcı, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Atiş, C.D.; Karahan, O. Properties of steel fiber reinforced fly ash concrete. Constr. Build. Mater. 2009, 23, 392–399. [Google Scholar] [CrossRef]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Bjegovic, D.; Baricevic, A.; Lakusic, S.; Damjanovic, D.; Duvnjak, I. Positive interaction of industrial and recycled steel fibres in fibre reinforced concrete. J. Civ. Eng. Manag. 2013, 19, S50–S60. [Google Scholar] [CrossRef]

- Köroglu, M.A.; Ashour, A. Mechanical properties of self-compacting concrete with recycled bead wires. Rev. Construcción 2019, 18, 501–512. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Aksoylu, C.; Arslan, M.H. Numerical evaluation of effects of shear span, stirrup spacing and angle of stirrup on reinforced concrete beam behaviour. Struct. Eng. Mech. Int’l J. 2021, 79, 309–326. [Google Scholar]

- Aksoylu, C.; Özkılıç, Y.O.; Arslan, M.H. Mechanical Steel Stitches: An Innovative Approach for Strengthening Shear Deficiency in Undamaged Reinforced Concrete Beams. Buildings 2022, 12, 1501. [Google Scholar] [CrossRef]

- Aykac, S.; Yilmaz, M. Behaviour and strength of RC beams with regular triangular or circular web openings. J. Fac. Eng. Archit. Gazi Univ. 2011, 26, 711–718. [Google Scholar]

- Institutaion, T.S. TS 500 Design and Construction Rules of Reinforced Concrete Structures. Ank. Turk. 2000. Available online: https://staff.emu.edu.tr/cemalgenes/Documents/courses/Civl471_2019_20_Spring/330321606-TS-500-English-Version.pdf. (accessed on 8 September 2022).

- Moghadam, A.S.; Omidinasab, F.; Abdalikia, M. The effect of initial strength of concrete wastes on the fresh and hardened properties of recycled concrete reinforced with recycled steel fibers. Constr. Build. Mater. 2021, 300, 124284. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Prasad, M.; Kumar, P.R. Mechanical properties of fiber reinforced concretes produced from building demolished waste. Environ. Researh Dev. 2007, 2, 180–187. [Google Scholar]

- Chaboki, H.R.; Ghalehnovi, M.; Karimipour, A.; De Brito, J. Experimental study on the flexural behaviour and ductility ratio of steel fibres coarse recycled aggregate concrete beams. Constr. Build. Mater. 2018, 186, 400–422. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R.; Abdollahnejad, Z.; Nematollahi, B.; Sanjayan, J.G.; Illikainen, M. A comparison of the effects of pozzolanic binders on the hardened-state properties of high-strength cementitious composites reinforced with waste tire fibers. Compos. Part B Eng. 2019, 162, 134–153. [Google Scholar] [CrossRef]

- Simalti, A.; Singh, A.P. Comparative study on performance of manufactured steel fiber and shredded tire recycled steel fiber reinforced self-consolidating concrete. Constr. Build. Mater. 2021, 266, 121102. [Google Scholar] [CrossRef]

- Martinelli, E.; Caggiano, A.; Xargay, H. An experimental study on the post-cracking behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298. [Google Scholar] [CrossRef]

- Sengul, O. Mechanical behavior of concretes containing waste steel fibers recovered from scrap tires. Constr. Build. Mater. 2016, 122, 649–658. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).