The First 3D-Printed Building in Spain: A Study on Its Acoustic, Thermal and Environmental Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Building Description and Comparative Study

2.2. Thermal Behavior

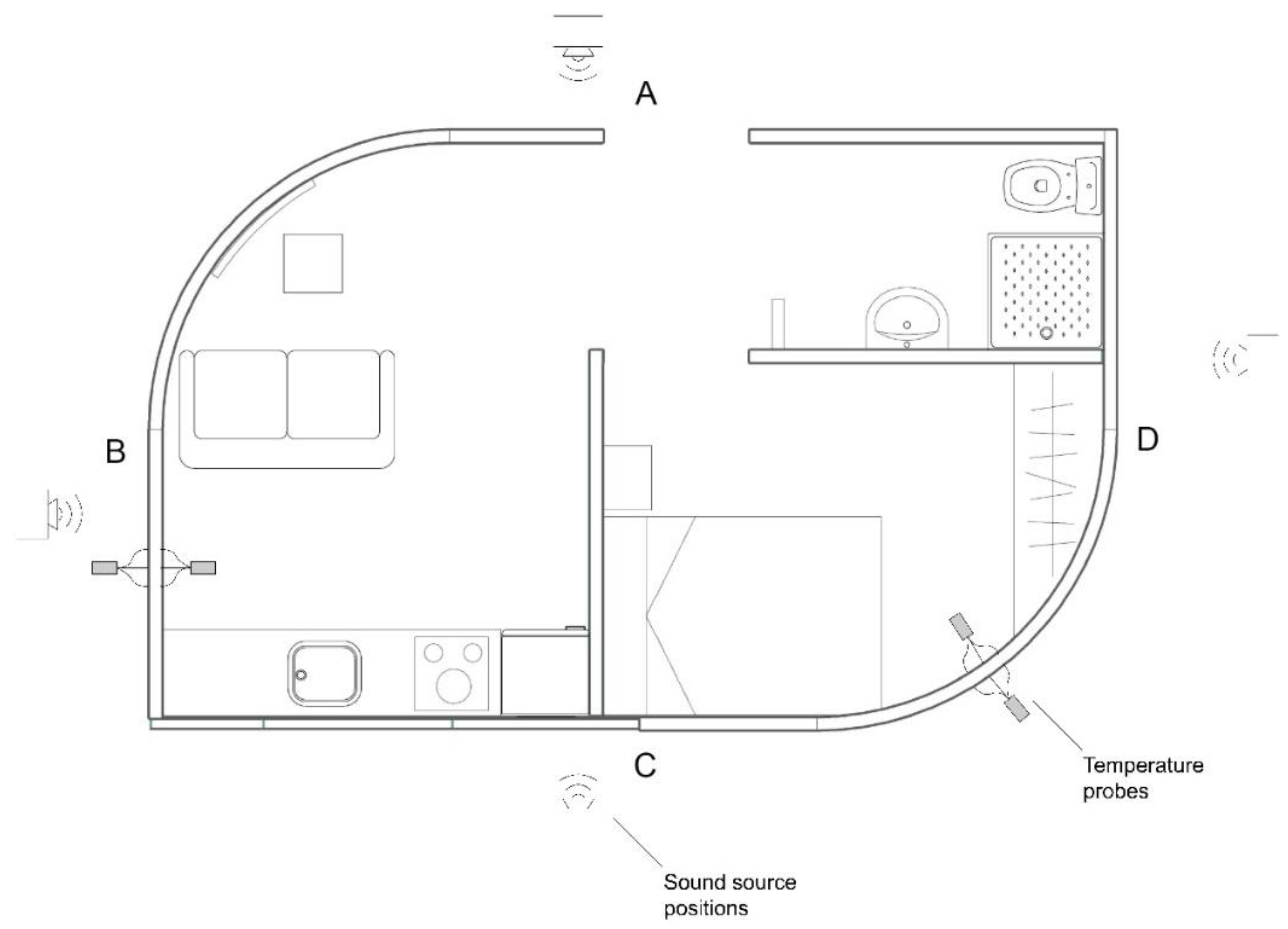

2.3. Airborne Acoustic Insulation

2.4. Life Cycle Assessment Methodology

3. Results and Discussion

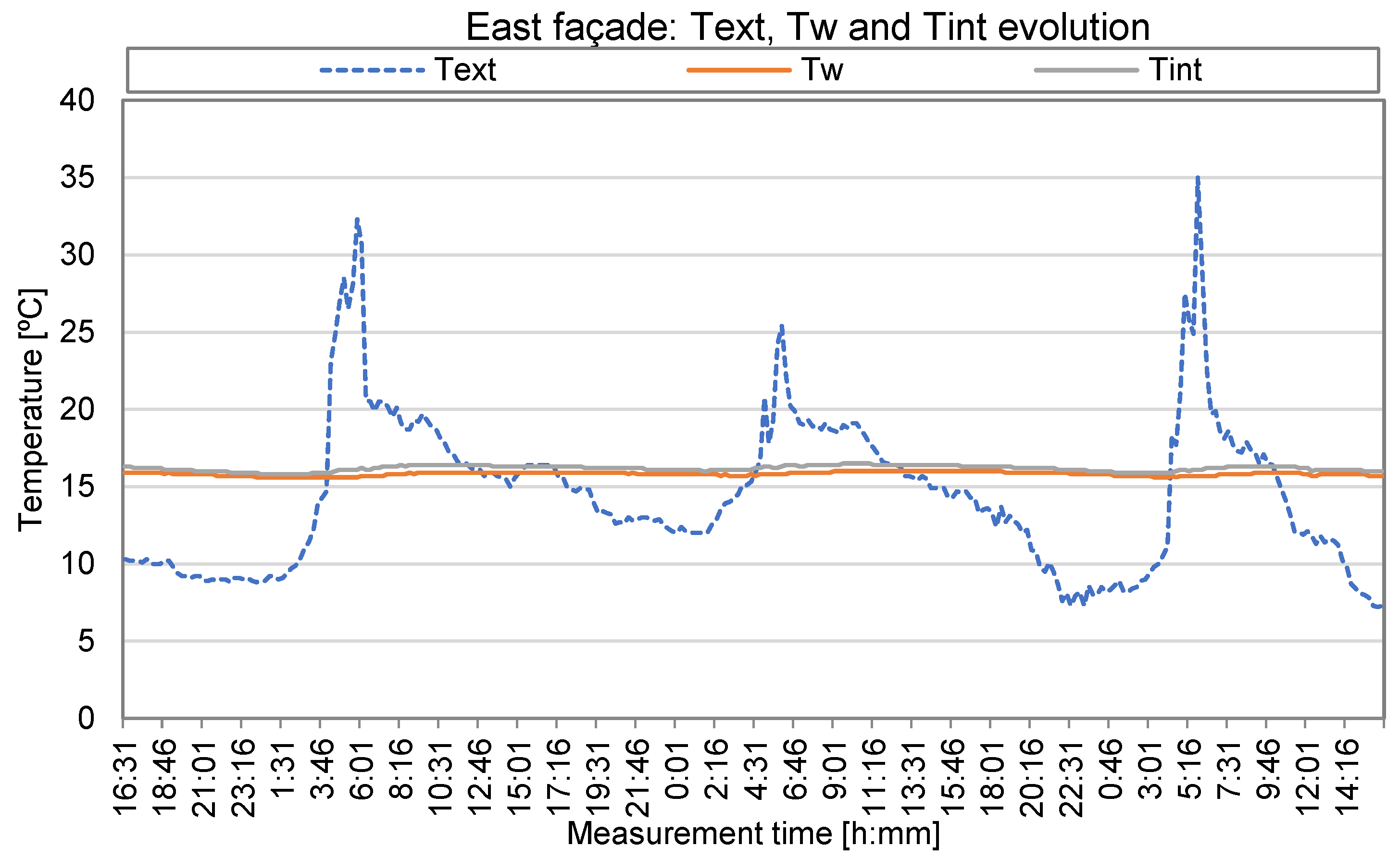

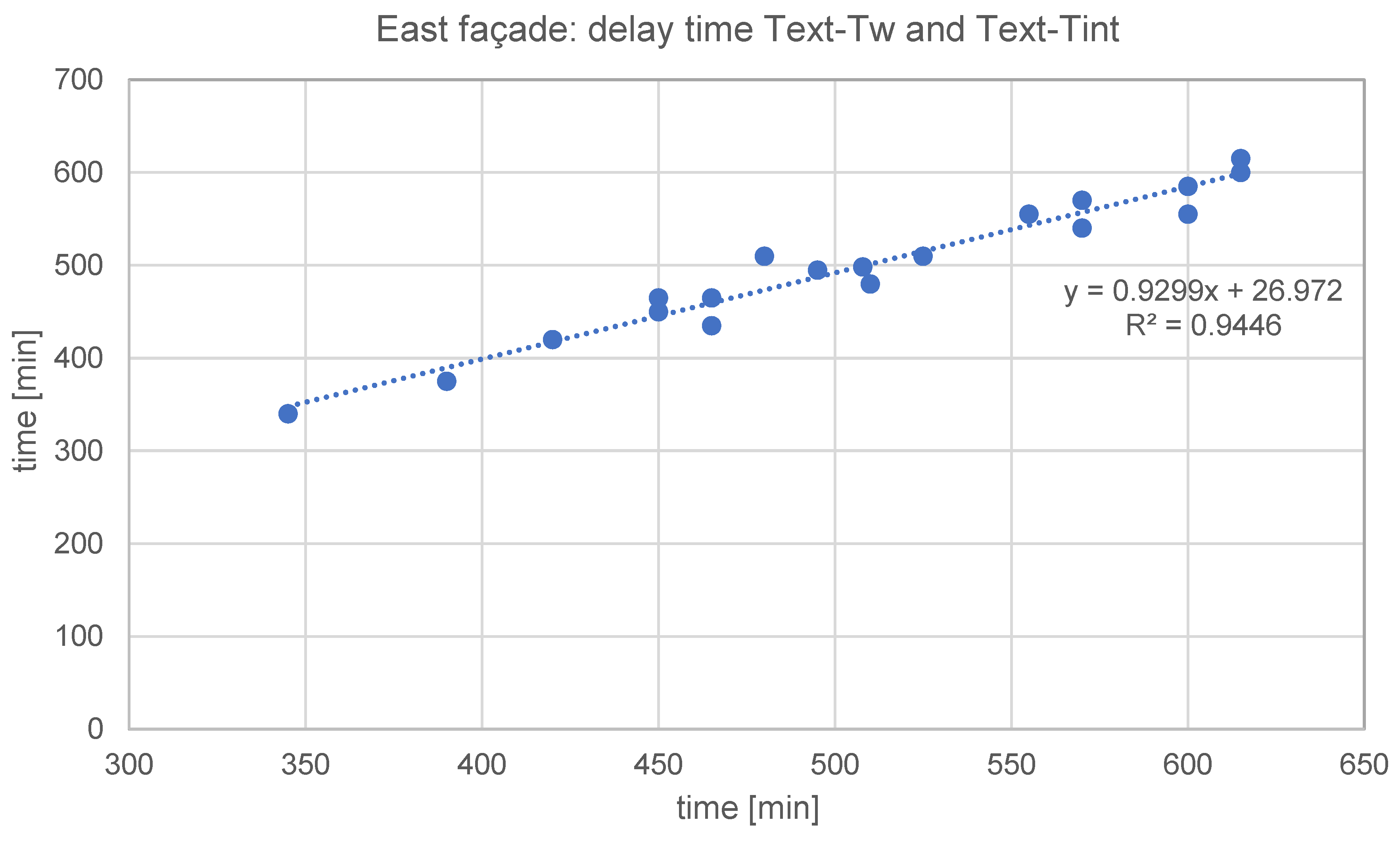

3.1. Thermal Results

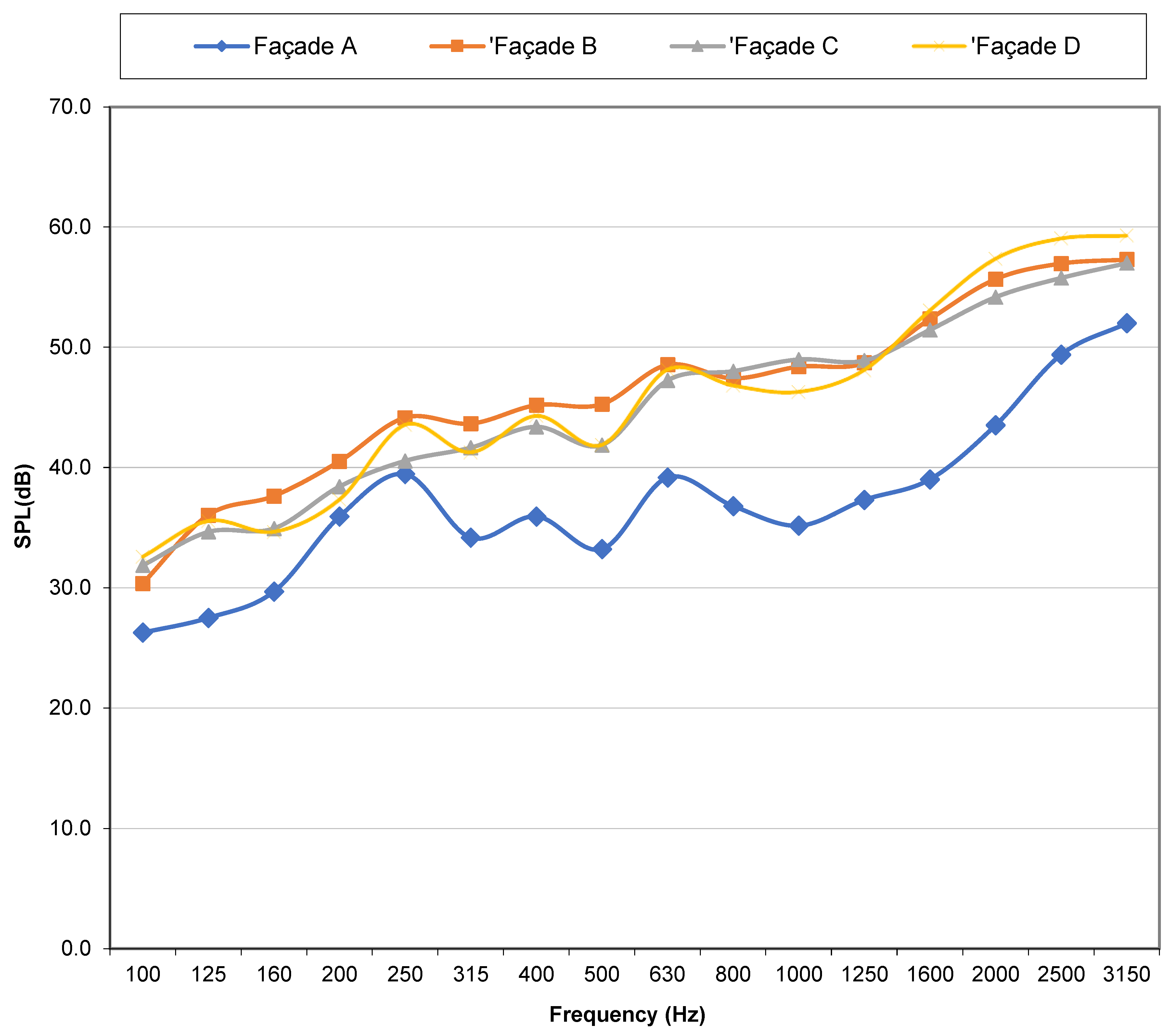

3.2. Acoustic Results

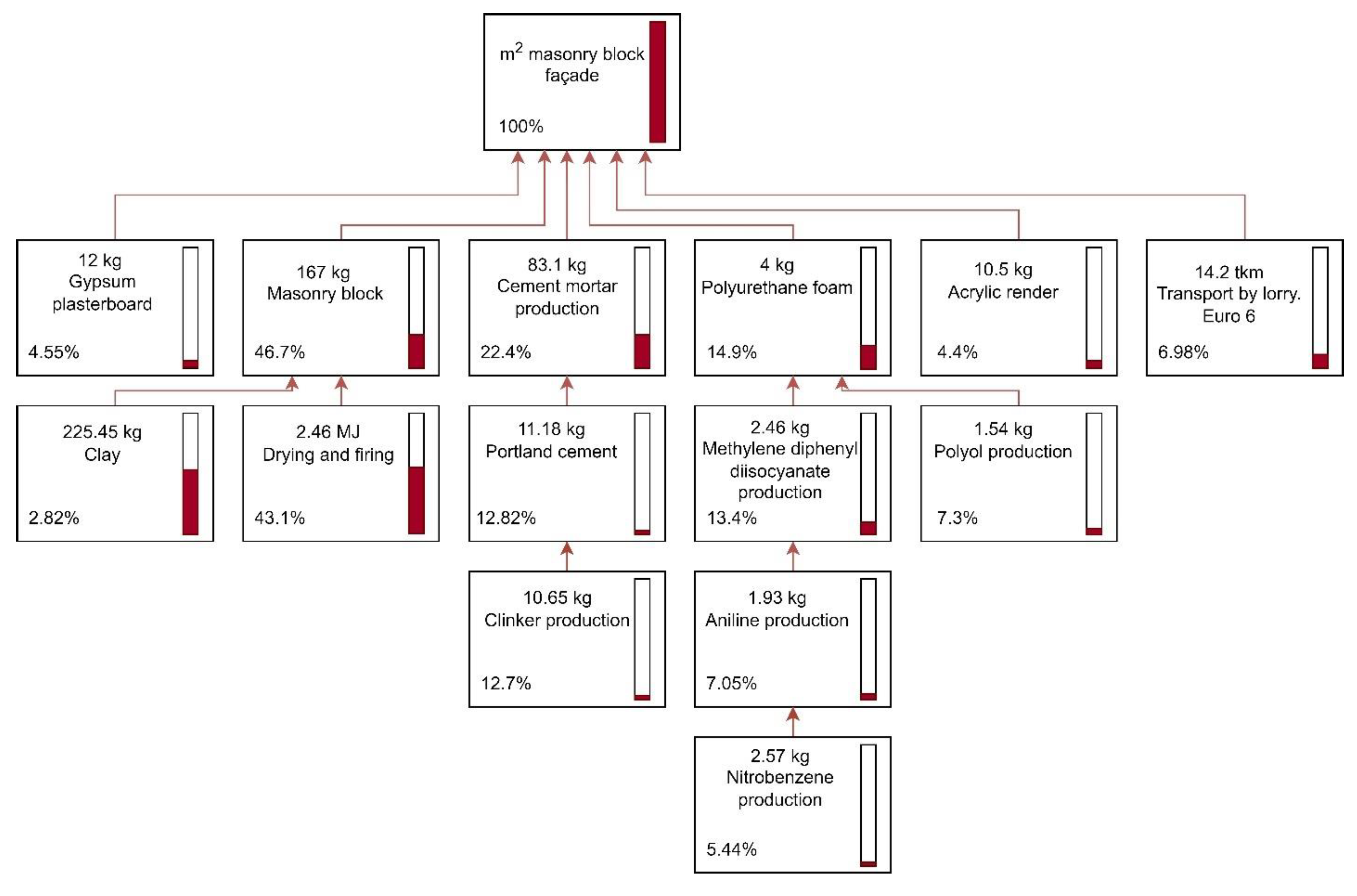

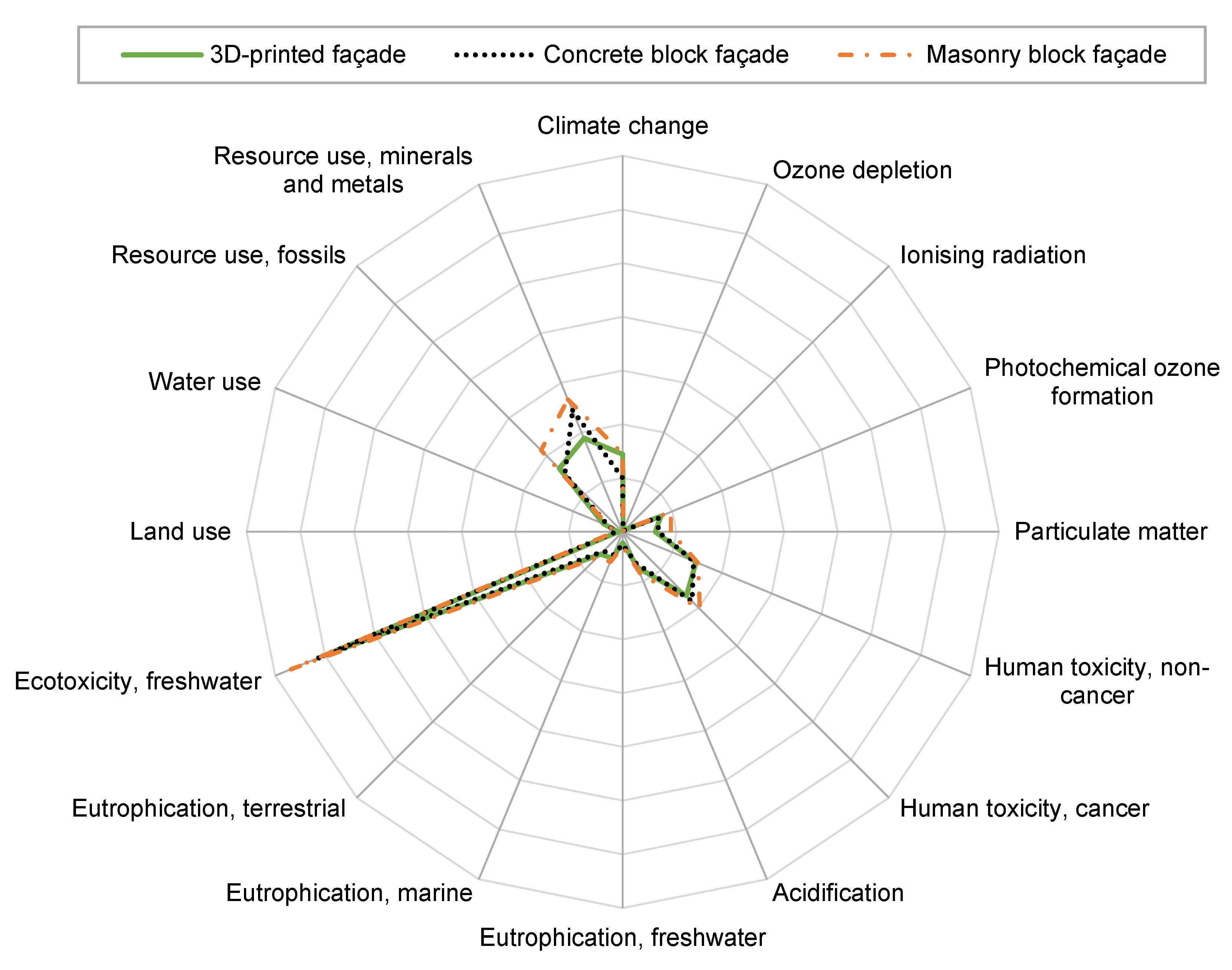

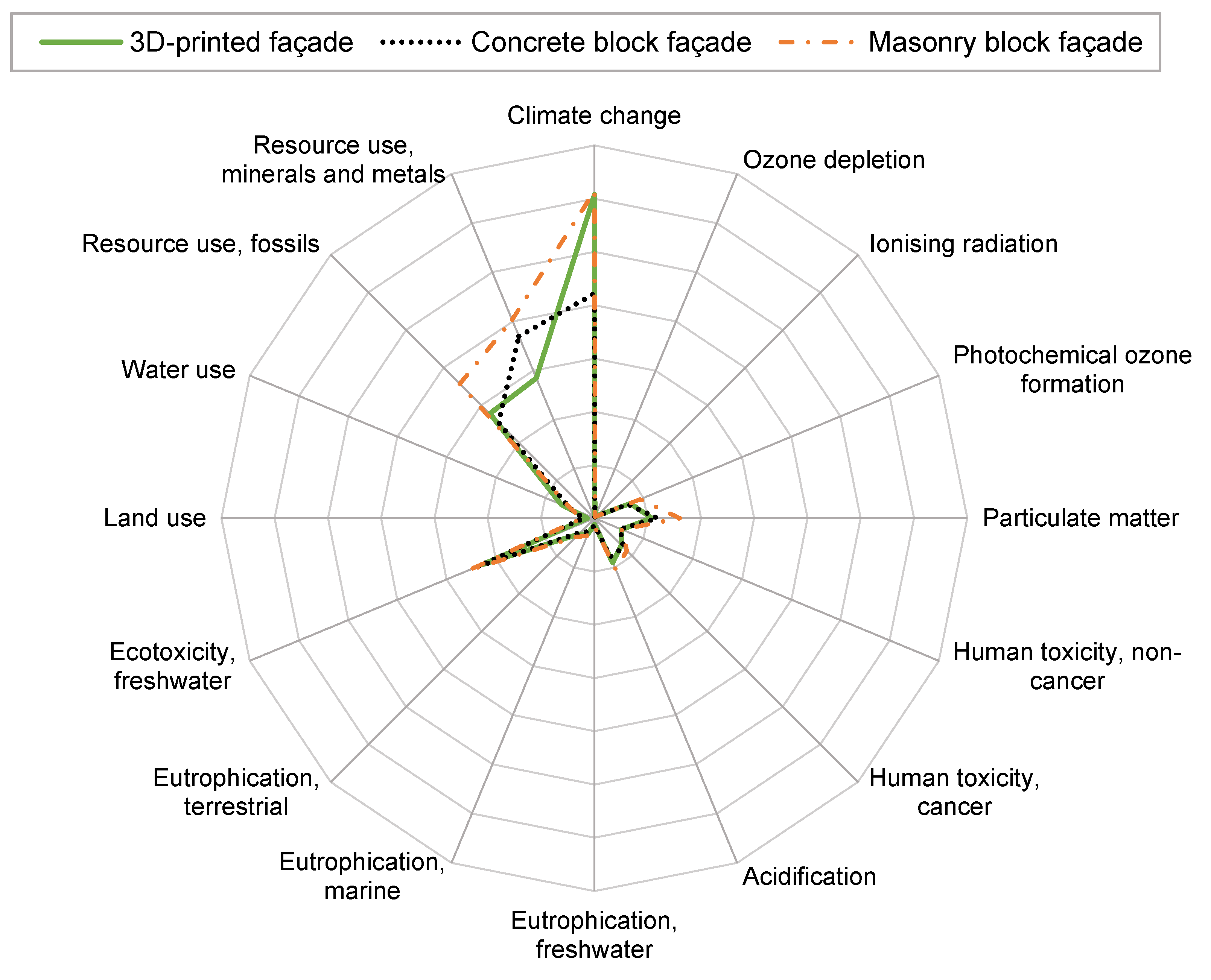

3.3. LCA Results

4. Conclusions and Outlook

- The 3D-printed façade shows excellent thermal insulation abilities. The measured thermal transmittance ranges from 0.241 Wm−2K−1 in the south façade to 0.237 Wm−2K−1 in the east façade.

- This thermal transmittance is adequate for any Spanish climate zone described in the Spanish Technical Building Code. However, it is not adequate for some countries in Europe, such as Germany, where thermal insulation needs to be lower than 0.2 W/m2K. It complies with the regulations in countries such as Slovenia (0.28 W/m2K) and Italy, in some of their climate zones (0.29 W/m2K in zone D) [51,52].

- The dynamic behavior of the façade is adequate for the needs of the Spanish climate, with a thermal lag of 7 h and 47 min. There is also a favorable correspondence between the calculated and estimated time lags of the east façade. In the case of the south façade, the higher percentage of the transparent area interferes with the critical radiation effect.

- Acoustic performance:

- The airborne acoustic insulation of the building envelope meets the Spanish Technical Building Code (CTE) requirements. The in situ measurements of the sound reduction index reached up to 45 dB.

- This result is adequate for areas with a noise level of up to 75 dB. The sound reduction indexes (SRI) of the four façades were measured and compared to the theoretical model results.

- The comparison of both the theoretical and measured values of the transmittance and standard SRI shows a good level of concordance. The results show a maximum difference of 2 dB, with an uncertainty index of 3 dB. The acoustic behavior of the entrance door influenced the results for façade A, which explains the difference of 8 dB compared to the others.

- Environmental impacts:

- The environmental impacts of the 3D-printed façade are comparable to those of conventional constructions.

- The comparative life cycle assessment indicates that using this 3D-printing system does not imply a significant increase in carbon dioxide emissions compared to more conventional alternatives, such as concrete blocks.

- Although the difference is only slight, the 3D-printing façade emits a lower amount of CO2 than a façade built using masonry blocks. This pattern repeats itself in most of the impact categories obtained using the environmental footprint methodology.

- After summing the normalized and weighted impacts, the single-score result obtained shows that the overall environmental impact of the 3D-printed façade is similar to that of the concrete block façade. The difference is mainly due to the higher amount of concrete per square meter needed to build the printed one. This could be improved either by reducing the cement content in the concrete or by creating a concrete pattern that leaves voids of holes. These solutions would affect the acoustic and thermal performance, which require further analysis.

- Summary and general recommendations:

- Overall, the study proves that the house complies with the Spanish acoustic and thermal regulations. However, the LCA results show that it cannot be considered a sustainable alternative to conventional constructions.

- The time needed to build the 3D-printed façade is significantly shorter than that required to build the other two typologies. This implies a reduction in both the cost and the environmental impact of the construction works.

- Working with lighter concretes or alternative shapes should be the objective of future studies. As long as the new solutions imply a reduced amount of cement, the resulting façade will have lower environmental impacts. This will also have consequences for the thermal and acoustic performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete–a new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.; Le, T.; Austin, S.; Gibb, A.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- 3D Systems Our Story. 3D System Website. 2021. Available online: https://www.3dsystems.com/our-story (accessed on 19 March 2021).

- Sachs, E.M.; Haggerty, J.S.; Cima, M.J.; Williams, P.A. Three-Dimensional Printing Techniques. U.S. Patent 5,340,656A, 23 August 1994. [Google Scholar]

- Strauss, H. AM Envelope: The Potential of Additive Manufacturing for Facade Constructions; TU Delft: Delft, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Strauss, H.; Knaack, U. Additive Manufacturing for Future Facades. J. Facade Des. Eng. 2016, 3, 225–235. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia. Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China Technol. Sci. 2017, 61, 475–495. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Corcione, C.E.; Palumbo, E.; Masciullo, A.; Montagna, F.; Torricelli, M.C. Fused Deposition Modeling (FDM): An innovative technique aimed at reusing Lecce stone waste for industrial design and building applications. Constr. Build. Mater. 2018, 158, 276–284. [Google Scholar] [CrossRef]

- Facade of Dutch EU Building Uses 3D-Printed Bioplastic. Available online: https://www.dezeen.com/2016/01/12/european-union-3d-printed-facade-dus-architects-holland/ (accessed on 14 December 2021).

- Poullain, P.; Paquet, E.; Garnier, S.; Furet, B. On site deployment of 3D printing for the building construction–The case of YhnovaTM. MATEC Web Conf. 2018, 163, 01001. [Google Scholar] [CrossRef]

- Germany’s First Printed House Officially Openend. Available online: https://www.peri.com/en/media/press-releases/germanys-first-printed-house-officially-openend.html (accessed on 10 January 2022).

- Souza, M.T.; Ferreira, I.M.; de Moraes, E.G.; Senff, L.; de Oliveira, A.P.N. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects. J. Build. Eng. 2020, 32, 101833. [Google Scholar] [CrossRef]

- Alfaify, A.; Saleh, M.; Abdullah, F.; Al-Ahmari, A. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Haghighi, A. Large-Scale Automated Additive Construction: Overview, Robotic Solutions, Sustainability, and Future Prospect. Sustainability 2022, 14, 9782. [Google Scholar] [CrossRef]

- Buswell, R.A.; De Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Chau, C.-K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- UNE EN 15804:2012+A2:2020; Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Products-European Standards. European Committee for Standardization: Brussels, Belgium, 2020.

- Bemore3D Viviendas, Dispositivos Y Construcción 3D. Available online: https://bemore3d.com/language/en/home/ (accessed on 10 January 2022).

- Spanish Ministry of Transportation, Movility and Urban Agenda. EHE 08, Act on Structural Concrete. 2008. Available online: https://www.mitma.gob.es/organos-colegiados/mas-organos-colegiados/comision-permanente-del-hormigon/cph/instrucciones/ehe-08-version-en-ingles (accessed on 10 January 2022).

- Santoni, A.; Bonfiglio, P.; Fausti, P.; Marescotti, C.; Mazzanti, V.; Mollica, F.; Pompoli, F. Improving the sound absorption performance of sustainable thermal insulation materials: Natural hemp fibres. Appl. Acoust. 2019, 150, 279–289. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’alessandro,, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Soler, D.; Salandin, A.; Micó, J.C. Lowest thermal transmittance of an external wall under budget, material and thickness restrictions: An integer linear programming approach. Energy Build. 2018, 158, 222–233. [Google Scholar] [CrossRef]

- Li, F.G.N.; Smith, A.; Biddulph, P.; Hamilton, I.G.; Lowe, R.; Mavrogianni, A.; Oikonomou, E.; Raslan, R.; Stamp, S.; Stone, A.; et al. Solid-wall U-values: Heat flux measurements compared with standard assumptions. Build. Res. Inf. 2014, 43, 238–252. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cid-Falceto, J.; Cañas, I. Ground Thermal Inertia for Energy Efficient Building Design: A Case Study on Food Industry. Energies 2012, 5, 227–242. [Google Scholar] [CrossRef]

- Nocera, F.; Caponetto, R.; Giuffrida, G.; Detommaso, M. Energetic Retrofit Strategies for Traditional Sicilian Wine Cellars: A Case Study. Energies 2020, 13, 3237. [Google Scholar] [CrossRef]

- ISO 6946; Building Components and Building Elements. Thermal Resistance and Thermal Transmittance. Calculation Methods. International Organization for Standardization: London, UK, 2018.

- ISO 7345; Thermal Performance of Buildings and Building Components. Physical Quantities and Definitions. International Organization for Standardization: London, UK, 2018.

- McMullan, R. Environmental Science in Building; Red Globe Press: London, UK, 2018. [Google Scholar]

- Ministerio de Fomento. Gobierno de España DB-HE. Código Técnico La Edif. 2020, 1–129. [Google Scholar]

- ISO 9869-1; Thermal Insulation. Building Elements. In-Situ Measurement of Thermal Resistance and Thermal Transmittance. Part 1: Heat Flow Meter Method. International Organization for Standardization: London, UK, 2014.

- Rasooli, A.; Itard, L. In-situ characterization of walls’ thermal resistance: An extension to the ISO 9869 standard method. Energy Build. 2018, 179, 374–383. [Google Scholar] [CrossRef]

- Choi, D.S.; Ko, M.J. Analysis of Convergence Characteristics of Average Method Regulated by ISO 9869-1 for Evaluating In Situ Thermal Resistance and Thermal Transmittance of Opaque Exterior Walls. Energies 2019, 12, 1989. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Rodríguez-Álvaro, R.; Moyano, J.J.; Rico, F.; Marín, D. Determining the U-Value of Façades Using the Thermometric Method: Potentials and Limitations. Energies 2018, 11, 360. [Google Scholar] [CrossRef]

- ISO 13786; Thermal Performance of Building Components. Dynamic Thermal Characteristics. Calculation Methods. International Organization for Standardization: London, UK, 2017.

- Bragança, L.; Almeida, M.; Silva, S.; Mendonça, P. Acoustic Evaluation of Some Non-Conventional Solutions in Construction. Proc. Acústica; Guimarães-Port. 2004, 178, p1. Available online: https://1library.co/document/wq201pjz-acoustic-evaluation-of-some-non-conventional-solutions-construction.html (accessed on 10 January 2022).

- Aksoylu, C.; Mendi, E.; Söylev, A.; Üniversitesi, S.; Fakültesi, M.; Mühendisliği Bölümü, İ.; Karatay Üniversitesi, K.; Mühendisliği Bölümü, B.; Erbakan Üniversitesi, N.; Fakültesi, M.-M. Ses yalıtımında ses azaltım indisi modellerinin karşılaştırmalı olarak incelenmesi. J. Fac. Eng. Archit. Gazi Univ. 2016, 31, 961–970. [Google Scholar] [CrossRef][Green Version]

- Ministerio de Fomento; Gobierno de España CTE; DB-HR. Protección Frente al Ruido; Ministerio de Fomento: Madrid, Spain, 2006. [Google Scholar]

- ISO 14040; Environmental Management. Life Cycle Assessment. Principles and Framework. International Organization for Standardization: London, UK, 2006.

- Mesa, J.A.; Fúquene-Retamoso, C.; Maury-Ramírez, A. Life Cycle Assessment on Construction and Demolition Waste: A Systematic Literature Review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- European Commission. Recommendation 2013/179/EU on the use of common methods to measure and communicate the life cycle environmental performance of products and organisations. Off. J. Eur. Union 2013, 124, 210. [Google Scholar]

- Quintana-Gallardo, A.; Clausell, J.R.; Guillén-Guillamón, I.; Mendiguchia, F.A. Waste valorization of rice straw as a building material in Valencia and its implications for local and global ecosystems. J. Clean. Prod. 2021, 318, 128507. [Google Scholar] [CrossRef]

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M. Design method of high performance precast external walls for warm climate by multi-objective optimization analysis. Energy 2015, 90, 1645–1661. [Google Scholar] [CrossRef]

- Keränen, J.; Hakala, J.; Hongisto, V. The sound insulation of façades at frequencies 5–5000 Hz. Build. Environ. 2019, 156, 12–20. [Google Scholar] [CrossRef]

- ISO 717-1; Acoustics. Rating of Sound Insulation in Buildings and of Building Elements. Part 1: Airborne Sound Insulation. International Organization for Standardization: London, UK, 2013.

- Mak, C.M.; Wang, Z. Recent advances in building acoustics: An overview of prediction methods and their applications. Build. Environ. 2015, 91, 118–126. [Google Scholar] [CrossRef]

- Ahmed, K.; Carlier, M.; Feldmann, C.; Kurnitski, J. A New Method for Contrasting Energy Performance and Near-Zero Energy Building Requirements in Different Climates and Countries. Energies 2018, 11, 1334. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; Schau, E.M.; Niemelä, E.P.; Burnard, M.D. Comparing the environmental impacts of wooden buildings in Spain, Slovenia, and Germany. J. Clean. Prod. 2021, 329, 129587. [Google Scholar] [CrossRef]

| Materials | Mass (Kg) |

|---|---|

| Water | 180.00 |

| Portland cement | 500.00 |

| Sand 0/2, grinded | 1400.00 |

| MasterGlenium ACE425 (polycarboxylate) | 0.36 |

| Mass cohesive (REOMIX 175) | 0.09 |

| Total mass | 2080.45 |

| Concrete Specifications | |

|---|---|

| Minimum content of cement | 500 Kg/m3 |

| Maximal dimension of aggregates | 2 mm |

| Water for soft consistence | 15 ± 1% based on weight of cement |

| Fresh bulk density | 2100 ± 50 Kgm3 |

| Hardened bulk density | 2300 ± 50 Kgm3 |

| Minimum consistency (UNE EN 1015-3) | 12 ± 1 cm |

| Working time at 21 °C | 45 min |

| Setting time 1 | 120 min |

| Resistance to compression (UNE EN 12390-1,2,3) | >25 MPa |

| Material | Thickness [m] | Thermal Conductivity [WK−1m−1] | Density [kg/m3] | Specific Heat [Jkg−1K−1] |

|---|---|---|---|---|

| Inner gypsum layer | 0.015 | 0.25 | 825 | 1000 |

| Micro-concrete | 0.15 | 1.65 | 2000 | 1000 |

| Inner cement render | 0.03 | 0.80 | 1050 | 1000 |

| EPS | 0.10 | 0.038 | 30 | 1000 |

| Exterior acrylic render | 0.01 | 0.20 | 1050 | 1500 |

| Façade Type | U-Value (W/m2K) | Thermal Lag (h) |

|---|---|---|

| 3D-printed | 0.2684 | 7.71 |

| Masonry blocks | 0.2662 | 9.45 |

| Concrete blocks | 0.2623 | 8.25 |

| Façade | Dn,Tw(C,Ctr) | Dn,Tw,Ctr |

|---|---|---|

| A | 39(−1, −3) | 36 dB |

| B | 50(−2, −5) | 45 dB |

| C | 49(−2, −5) | 45 dB |

| D | 48(−1, −4) | 44 dB |

| Façade | Theoretical Model | In Situ Results |

|---|---|---|

| A | 38 dB | 36 dB |

| B | 46 dB | 45 dB |

| C | 46 dB | 45 dB |

| D | 46 dB | 44 dB |

| Impact Category | Unit | 3D-Printed Façade | Concrete Block Façade | Masonry Block Façade |

|---|---|---|---|---|

| Climate change | kg CO2 eq | 116.56 | 81.02 | 118.39 |

| Ozone depletion | kg CFC11 eq | 1.00 × 10−5 | 8.94 × 10−6 | 1.29 × 10−5 |

| Ionizing radiation | kBq U-235 eq | 2.54 | 1.61 | 2.34 |

| Photochemical ozone formation | kg NMVOC eq | 0.31 | 0.28 | 0.39 |

| Particulate matter | disease inc. | 4.15 × 10−5 | 4.53 × 10−5 | 6.08 × 10−5 |

| Human toxicity, non-cancer | CTUh | 3.53 × 10−6 | 3.42 × 10−6 | 3.64 × 10−6 |

| Human toxicity, cancer | CTUh | 2.84 × 10−7 | 3.10 × 10−7 | 3.45 × 10−7 |

| Acidification | mol H+ eq | 0.4181 | 0.3658 | 0.4849 |

| Eutrophication, freshwater | kg P eq | 3.19 × 10−3 | 3.44 × 10−3 | 4.11 × 10−3 |

| Eutrophication, marine | kg N eq | 0.10 | 0.09 | 0.12 |

| Eutrophication, terrestrial | mol N eq | 1.02 | 0.87 | 1.19 |

| Ecotoxicity, freshwater | CTUe | 2532.33 | 2637.68 | 2872.01 |

| Land use | Pt | 688.71 | 1049.72 | 1202.74 |

| Water use | m3 depriv. | 45.21 | 33.52 | 32.76 |

| Resource use, fossils | MJ | 1075.90 | 982.52 | 1391.15 |

| Resource use, minerals and metals | kg Sb eq | 1.13 × 10−3 | 1.39 × 10−3 | 1.51 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salandin, A.; Quintana-Gallardo, A.; Gómez-Lozano, V.; Guillén-Guillamón, I. The First 3D-Printed Building in Spain: A Study on Its Acoustic, Thermal and Environmental Performance. Sustainability 2022, 14, 13204. https://doi.org/10.3390/su142013204

Salandin A, Quintana-Gallardo A, Gómez-Lozano V, Guillén-Guillamón I. The First 3D-Printed Building in Spain: A Study on Its Acoustic, Thermal and Environmental Performance. Sustainability. 2022; 14(20):13204. https://doi.org/10.3390/su142013204

Chicago/Turabian StyleSalandin, Andrea, Alberto Quintana-Gallardo, Vicente Gómez-Lozano, and Ignacio Guillén-Guillamón. 2022. "The First 3D-Printed Building in Spain: A Study on Its Acoustic, Thermal and Environmental Performance" Sustainability 14, no. 20: 13204. https://doi.org/10.3390/su142013204

APA StyleSalandin, A., Quintana-Gallardo, A., Gómez-Lozano, V., & Guillén-Guillamón, I. (2022). The First 3D-Printed Building in Spain: A Study on Its Acoustic, Thermal and Environmental Performance. Sustainability, 14(20), 13204. https://doi.org/10.3390/su142013204