1. Introduction

Recent global uncertainties and life-threatening concerns have increased awareness of a healthier and natural lifestyle. Subsequently, it has increased the consumption of eco-friendly products and natural fibers, which demand the management of the declining cotton yield in developing countries to look beyond traditional farming practices [

1,

2]. Managing the constant declining productivity of non-food crops remains a challenge for developing countries [

1]. To handle this challenge, producers in these countries mainly follow traditional practices either by bringing new lands into production (extensification) or increasing the use of crop inputs (intensification) to increase the yield [

3]. This way of raising agricultural productivity in traditional economies makes up a shortage of resources due to a large population base with relatively little arable land and water, as well as the low acceleration of agricultural technological modernization [

4]. Accordingly, the traditional farming model has become more and more unsustainable because of its reliance on the increased use of agricultural factor inputs and land resources [

3], forcing producers in those countries to prefer growing food crops or shifting to other business practices to worsen the situation further. Consequently, some developing countries, which also top producers of non-food crops, have started importing these crops (USDA cotton outlook 2019). Since a significant global portion of global industrial crop produce relies on farmers’ technological expertise from developing countries [

5], this trend would gradually increase the demand for non-food crops at the global level. In addition, these practices, coupled with global crises-driven uncertainties, hint at an upcoming alarming increasing demand for agricultural raw materials such as cotton, natural fiber, and jatropha in coming years, which could shift a typical global crisis into more intense and prolonged consequences [

6]. For instance, since COVID-19, global consumption patterns have shifted towards natural lifestyle and eco-friendly products that significantly depend on industrial crops like cotton and its byproducts [

7]. In this context, most researchers agree that developing countries would have to anticipate the upcoming industrial crop demand within the scarce financial and technological resources for sustainable non-food crop production practices [

8], which is impractical without introducing affordable technology-driven solutions and their extensions [

9].

Debates over the affordable technology-driven solutions continue to heavily focus on doing “more with less” in developing economies [

3,

10]. Subsequently, most researchers believe that a sustainable rise in agricultural output is possible with judicial use of agricultural inputs, i.e., an overall crop yield could proportionally be expanded without altering the input quantities used, or in other words, the crop input quantities could be reduced without changing the total crop production [

11]. This assumption draws on a socio-ecological trade-off along the pathways of extensification or intensification in achieving sustainable crop growth, which demands us to identify favorable combinations of various factors of productivity growth, such as labor, land, capital, and inputs—the total factor productivity (TFP) in agriculture [

3]. Accordingly, the functional scope of such a hypothesis is well exhibited through farming practices of modern economies that have remained the main engine of production growth and the increase in income as a way to modernize their economies and, rather than depending upon intensification or extensification, these systems concentrate on identifying the positive synergies between agriculture inputs [

3]. Therefore, the critical element of crop productivity growth is estimating the technical inefficiency changes of various factors of crop production, which could facilitate the understanding of those factors of production involved in increasing production cost or low yield of non-food crops over the years [

12]. However, understanding crop inputs inefficiencies over time from an empirical perspective is sensitive against agricultural-crop diversity and regions [

13,

14,

15]; this hints to a need for a much closer production growth perspective to track technical efficiency change and technological factors of non-food crop production.

Given the proximity of perspective, cotton production becomes a typical case of the non-food crop for four reasons. First, cotton, also known as white gold, is the world’s most demanding non-food crop as a source of natural fiber for eco-friendly products, byproducts, lint, and edible oil [

1]. It is the most wide-spreading profitable industrial crop for its role with more than 20% of the global share in all fiber use and is the global income to more than 250 million people worldwide [

16]. Even with such a broad global reach, the current cotton production methods are environmentally unsustainable—ultimately undermining the industry’s ability to maintain future demands [

17]. Moreover, various coalitions of international partners promote the sustainable production and use of cotton in multiple ways [

18]. Second, developing countries are among world’s largest cotton producers with a 7% contribution to overall labor employment opportunities [

16]; accordingly, their priorities in bringing cotton production in line with even minimally acceptable environmental standards are significantly challenged despite owning a huge tract of fertile agriculture land [

1]. Third, the main challenge of these developing countries is lower cotton productivity than the rest of the world [

19]. Even the irrigated area of these countries are underperformers for a given yield per unit from the rain-fed cotton-growing regions of the world (World textile information report 2019, USDA annual gain report 2017). Subsequently, farmers in these areas get comparatively less profit when harvesting cotton crops than other food crops, leading to a decrease in cotton crop area. Unfortunately, this situation has been worsening since 2010 in some developing countries and continues to decrease in more than 10 percent of the cropping area. Its reflection is observable because some of the world’s top cotton-producing developing countries have started to import cotton in recent years—an alarming sign of the upcoming increase in demand for raw cotton. Fourth, the low crop productivity of developing countries has a range of contributing socio-ecological factors, and knowing “which factors or their combinations are the main contributors” becomes more critical in identifying the positive integration of these factors for improving crop productivity [

19]. In contrast, very few studies have examined the detailed resources of the productivity and technical efficiency of cotton over time [

1,

19,

20], besides some mentioned limitations. For instance, this feature accommodates the accurate estimation of productivity measures breakdowns when multiple inputs lead to a single output [

19], rather than concentrating on multiple-output and multiple-input technology [

20] and failing to account for multiple input leads to single output technology when analyzing the productivity trend [

12]. Some researchers have attempted a more specific perspective, yet productivity remains a secondary objective in those studies [

1,

21], or they did not account for multifactor analysis [

20]. More importantly, these studies take the theoretical assumption of the accurate estimation of cotton productivity measures’ breakdowns even when accounting for multiple input technology [

21]. This theoretical objective believes in obtaining the maximum output from inputs [

1], which contrasts to the reality where not all inputs can achieve it; consequently, inefficiency may arise. From an implication perspective, scaling the non-constant returns is necessary when considering the overall impact on productivity, and violation of the various situations is one of the required conditions for long-run competitive equilibrium [

22]. To summarize the points mentioned earlier, the situation reveals a significant knowledge gap that demands an implication-oriented multifactor analysis to track which factors of production drive the low crop productivity of cotton, particularly for developing countries. In the long term, such empirical analysis is critical in knowing whether a developing country’s farmers are progressive concerning technical efficiency change, technological change, and speed of knowledge-based learning skills to counter with the existing raw cottons’ supply and demand gap effectively.

Given this background, the study adopts a more specific case using a top-ranked cotton-producing country that has recently started importing raw cotton and struggling to manage the declining cotton yield, i.e., Pakistan’s cotton production represents the non-food crop perspective for developing countries. Accordingly, the main objective of this study is to estimate the production frontier and efficiency relationship of various factors from the implication aspect to identify those factors of production that influence overall cotton production over the years. Accordingly, a stochastic frontier approach was employed to measure the efficiency of the changes by using Pakistan’s cotton production time-series data from a much larger period, 1971–2018. This framework contributed to the existing literature in the following three ways. First, it estimates the indices of crop-wise technical efficiency changes, covering a longer time period using SFA, a parametric procedure for non-food crops. As the main benefit, the parametric approach is capable of accounting for composed error, thereby separating the noise from inefficiencies. This way, it tracks efficiency changes and technological changes in the overall productivity from practical aspects, i.e., scaling non-constant returns of those multiple factors that allow violation of various situations. Second, the SFA allows the functional specific need to accommodate (a) single output from multiple inputs, (b) it can test the hypothesis, and (c) it presents the availability of the maximum likelihood econometric estimates. This crop-specific imperial finding would identify the main drivers of inefficient crop production that might be influencing Pakistan’s self-sufficiency in cotton. Moreover, the study would also estimate the hypothesis of whether subsidies affect cotton crop production. Third, the study puts forward corresponding policy recommendations, specifically for improving cotton production efficiencies. Furthermore, in general, applying such analysis to other developing countries could realize the potential of affordable technology-driven solutions and Agri-Resource efficiencies for sustainable non-food crop production.

Cotton Production and Pakistan Case

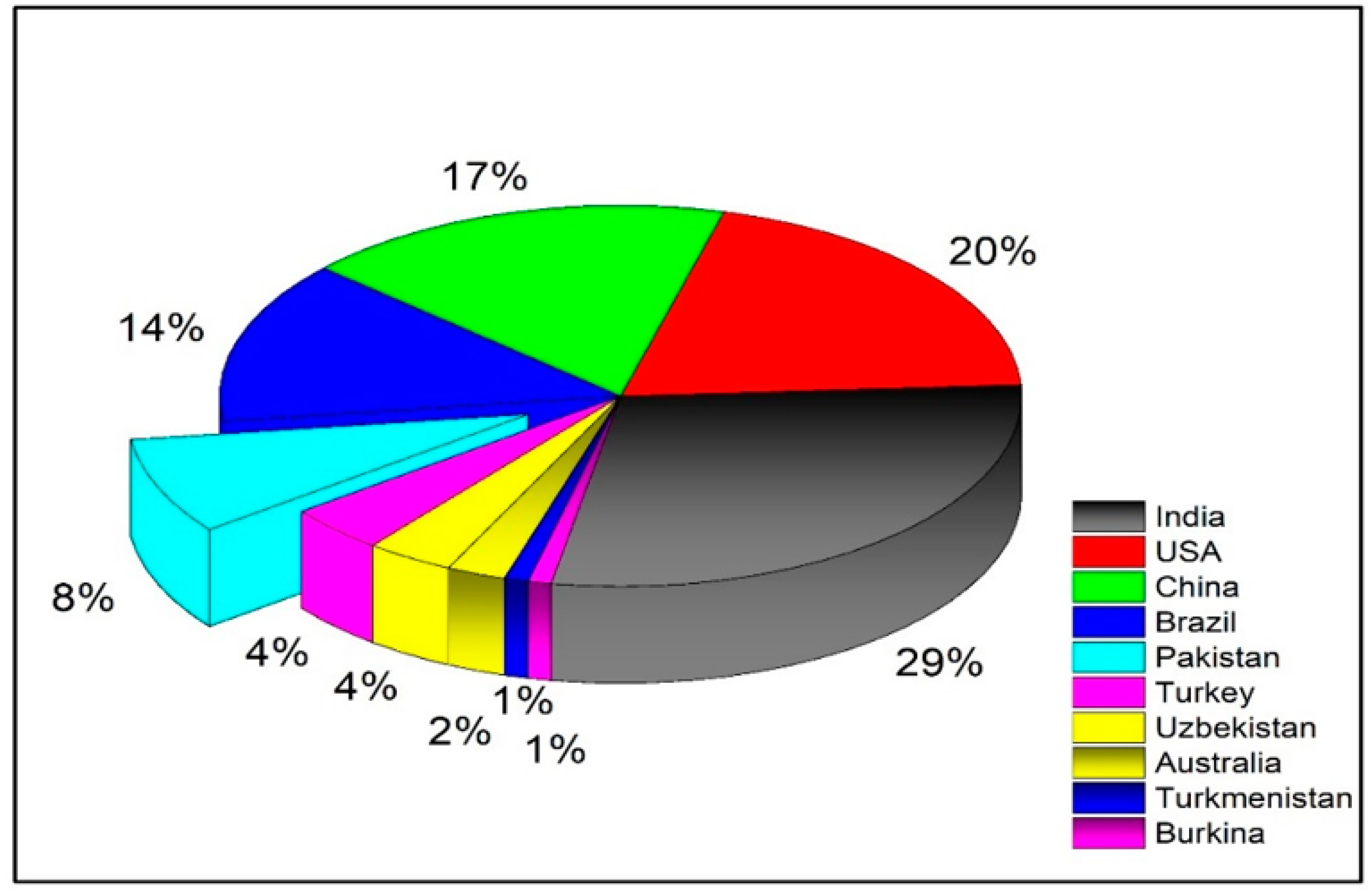

The study uses Pakistan’s cotton production as a typical case to analyze production factors from a much closer input issues and efficiency relationship perspective to represent the non-food crop in a developing country perspective for the following reasons. First, Pakistan is ranked among the top five largest cotton producers (

Figure 1), is the 7th largest cloth producer worldwide, and cotton contributes 10% to the national GDP compared to the overall agriculture sector GDP share of 18.9% [

22]. This sector also contributes to 42.3% of the labor force with employment and provides the raw materials for many value-added sectors [

23], with 55% of the foreign earnings contribution, a share majorly dominated by cotton-based finished products [

24]. Since Pakistan is a developing country, these states apparently favor the export; in contrast, Pakistan has been importing raw cotton for many years. Actually, Pakistan has not been exporting raw cotton since 2010, and it is the fourth country that ends up ending stalk (USDA cotton outlook 2019). Second, the main reason for increasing the import of raw cotton is that Pakistan’s cotton yield per hectare has had a gradually decreasing trend over the years, and the numbers are among the lowest in the world; even the countries that have a much smaller geographic area have a higher yield per hectare than Pakistan [

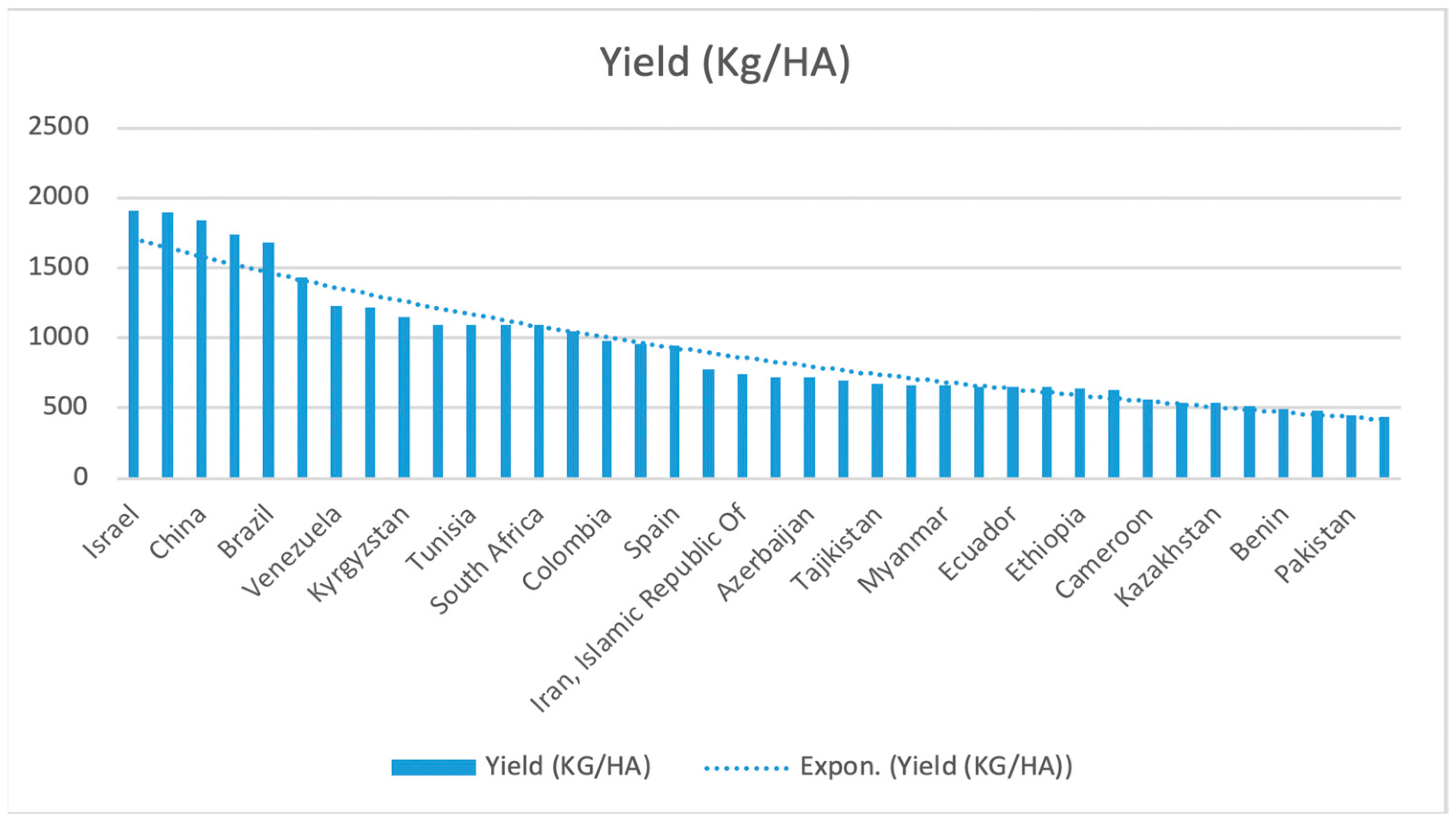

25]. On average, the yield of cotton in Pakistan is 730 kg/ha with 10,671 million bales, which is 1.5–2% lower than to rest of the world, and even irrigated areas of the countries are lagging in terms of lint per hectare from the rain-fed cotton-growing areas of the world (

Figure 2). As a result, cotton cultivation has become less attractive than growing other crops, which leads to the minimizing the area of cotton crops (World textile information report 2017, USDA economic survey of Pakistan (2019–2020)). It is true that the area of cotton crops has been declining in Pakistan since 2004–2005; unfortunately, this situation has been aggravated since 2013–2014, and by the ongoing year, 14.2 percent sowing area of the crop had decreased [

26]. Before 2014–2015, it was 2.902 million hectares, while currently 2.489 million hectares of cotton are being cultivated in Pakistan. Third, this low productivity of Pakistan’s cotton crop mainly results from inefficient use of multiple factors related to irrigation water, plant population, disease protection, plant nutrition, resource management skills, and insufficient technology, resulting in a gap between potential production and actual production (agriculture statistics of Pakistan (2019)). However, as a general trend, Pakistan farmers seek to remedy this low yield per hectare through traditional practices, such as increasing the use of crop inputs (intensification) or bringing new lands into production (extensification), which leads to constantly deteriorating the agricultural ecological environment. Such practices reduce the economic effect of agriculture and destroy the resources and environment on which agriculture depends on for survival and development [

27]. Besides, the scarcity of resources coupled with a large population and lagging agricultural infrastructure is keeping Pakistan’s cotton input and output in a bad state; hence, affordable agricultural technology and its extension become an urgent need to identify the positive balance between the cotton input and output. Fourth, most studies use Pakistan’s agriculture sector to analyze TFP growth in the sector at the national or provincial level. Accordingly, very few studies have analyzed the Pakistan cotton productivity, and efficiency [

1], particularly when “multiple inputs leads to a single output” are involved. Such studies either measure the total factor productivity for multi-crops [

28] or the sub-sector of Pakistan [

26] to analyze the relationship between productivity and agricultural research expenditures or conduct research on the basis of comparative analysis [

1]. As agriculture productivity is expected to be influenced by different factors unique for each crop, a crop-wise analysis at the national level would be more useful [

19]. Moreover, these studies take the theoretical assumption of the accurate estimation of cotton productivity measures’ breakdowns even when accounting for multiple input/output technology [

1]; however, violation of the various crop productivity factors is one of the required conditions for long-run competitive equilibrium. Therefore, this study is being conducted because no prior multifactor analysis is available from an implication perspective that not only scales the non-constant returns when considering the overall impact on cotton production, but also takes a much closer perspective on non-food crops of developing countries like Pakistan concerning the various input and efficiency relationships.

The rest of the paper is arranged as follows:

Section 2 describes the research methods, and

Section 3 represents the results and discussion step-by-step in support of the methodology. Finally,

Section 4 concludes the paper with some recommendations.