Resilient and Sustainability Analysis of Flexible Supporting Structure of Expansive Soil Slope

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Slope Site

2.2. Geogrid-Based Reinforcement of the Slope

2.3. Monitoring Scheme

2.4. Monitoring Sensors

- (1)

- Water content probes

- (2)

- Earth pressure cells

- (3)

- Flexible displacement meter

- (4)

- Stationary inclinometer

3. Monitoring Results and Analysis

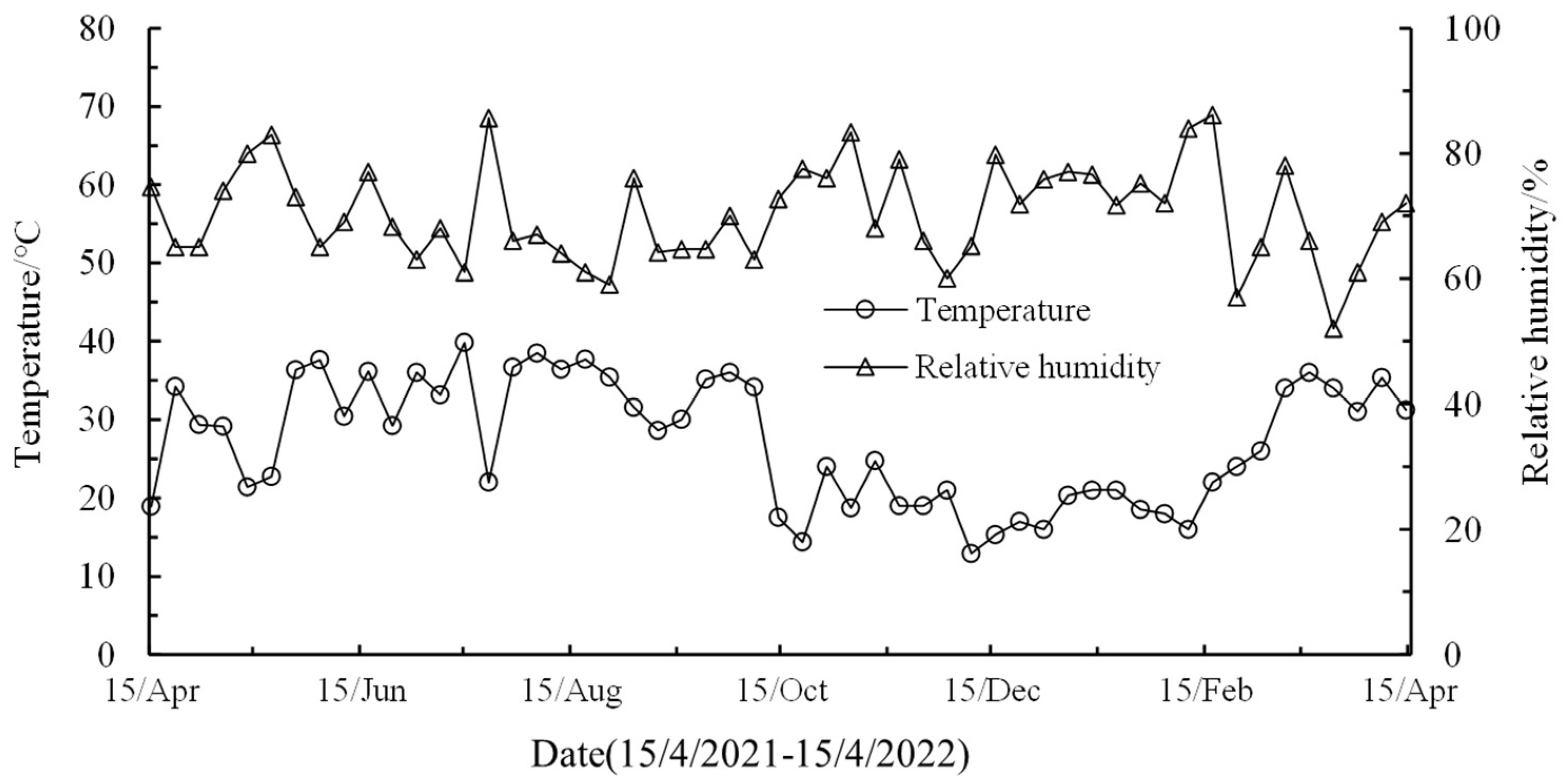

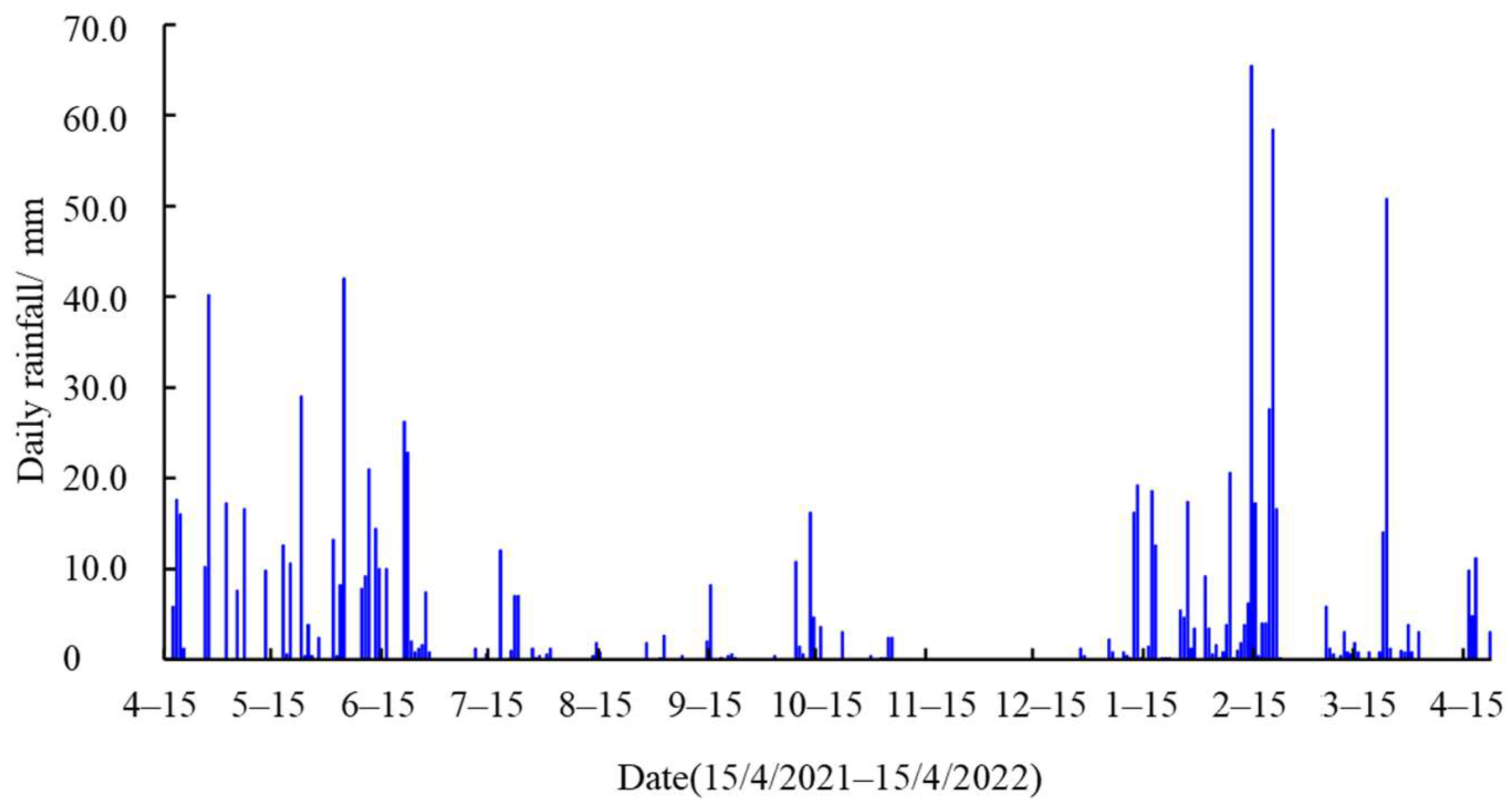

3.1. Meteorological Data of the Reinforced Slope

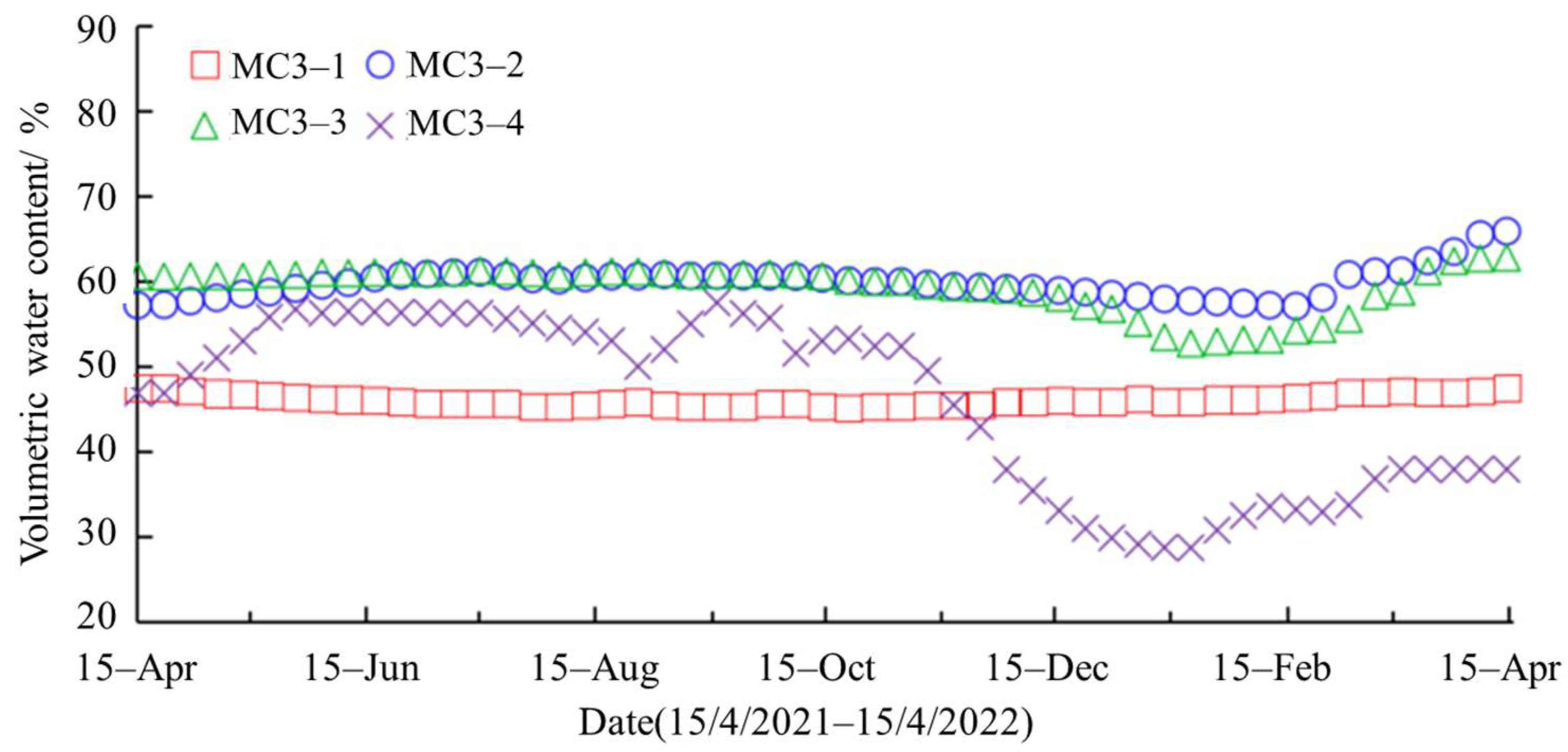

3.2. Water Contents of the Reinforced Slope

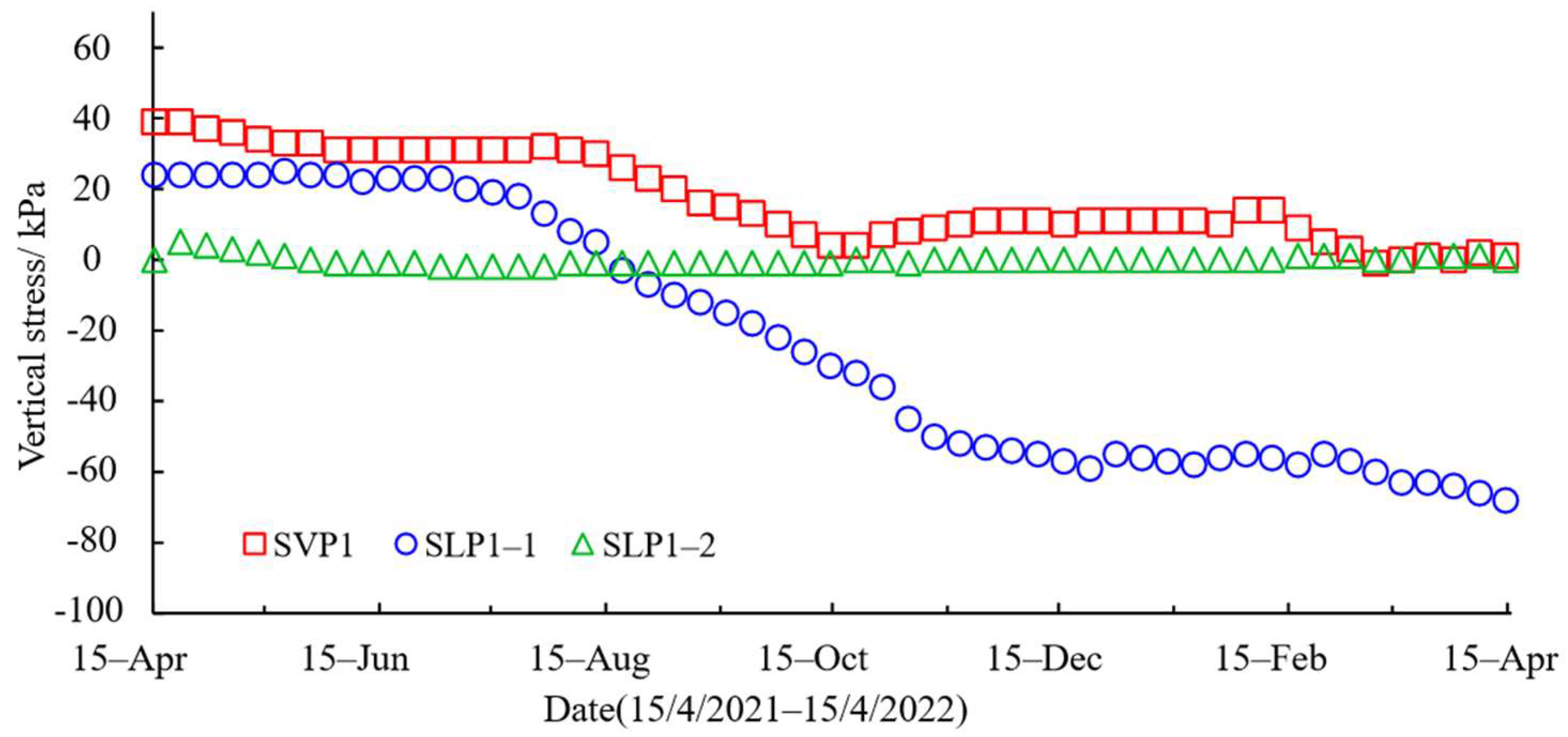

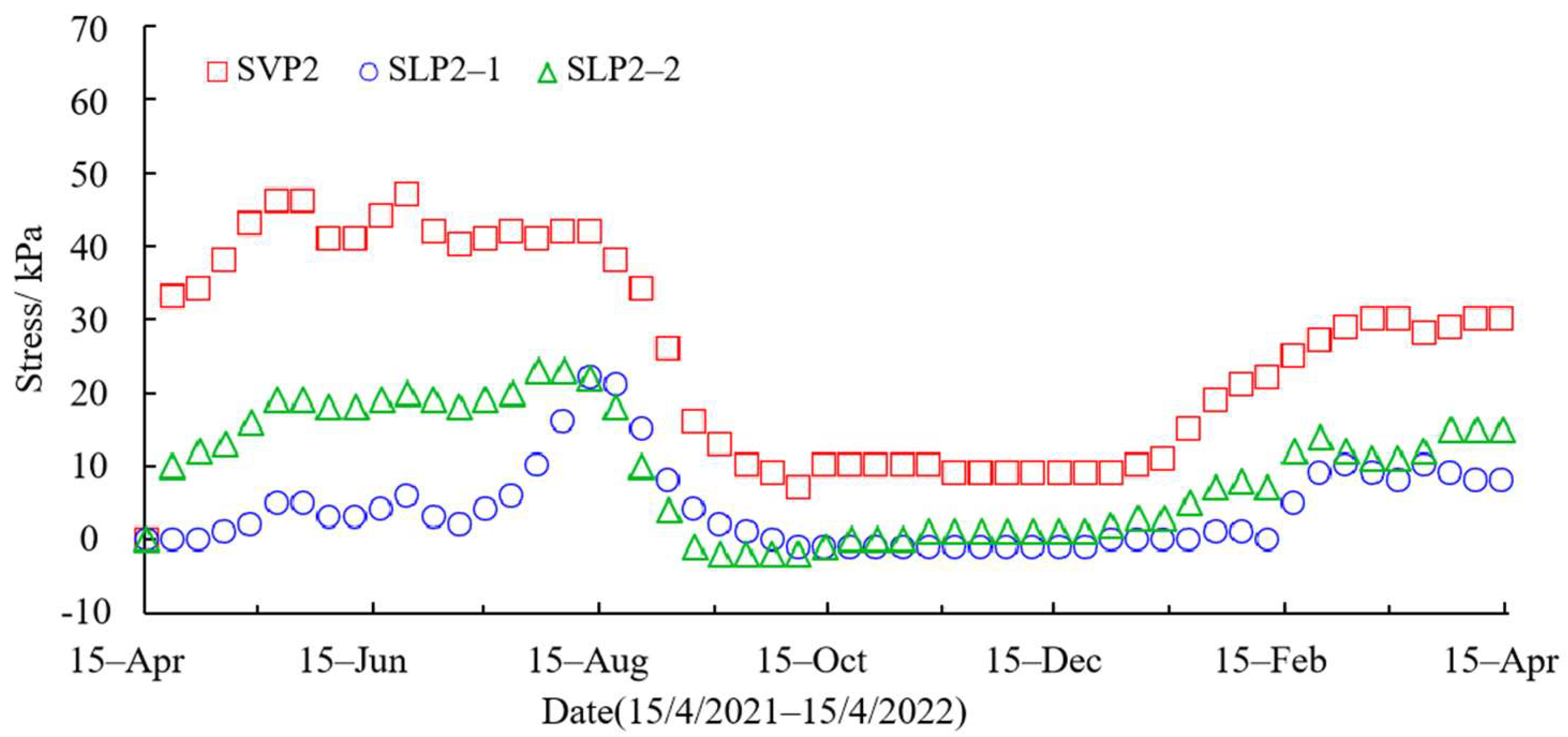

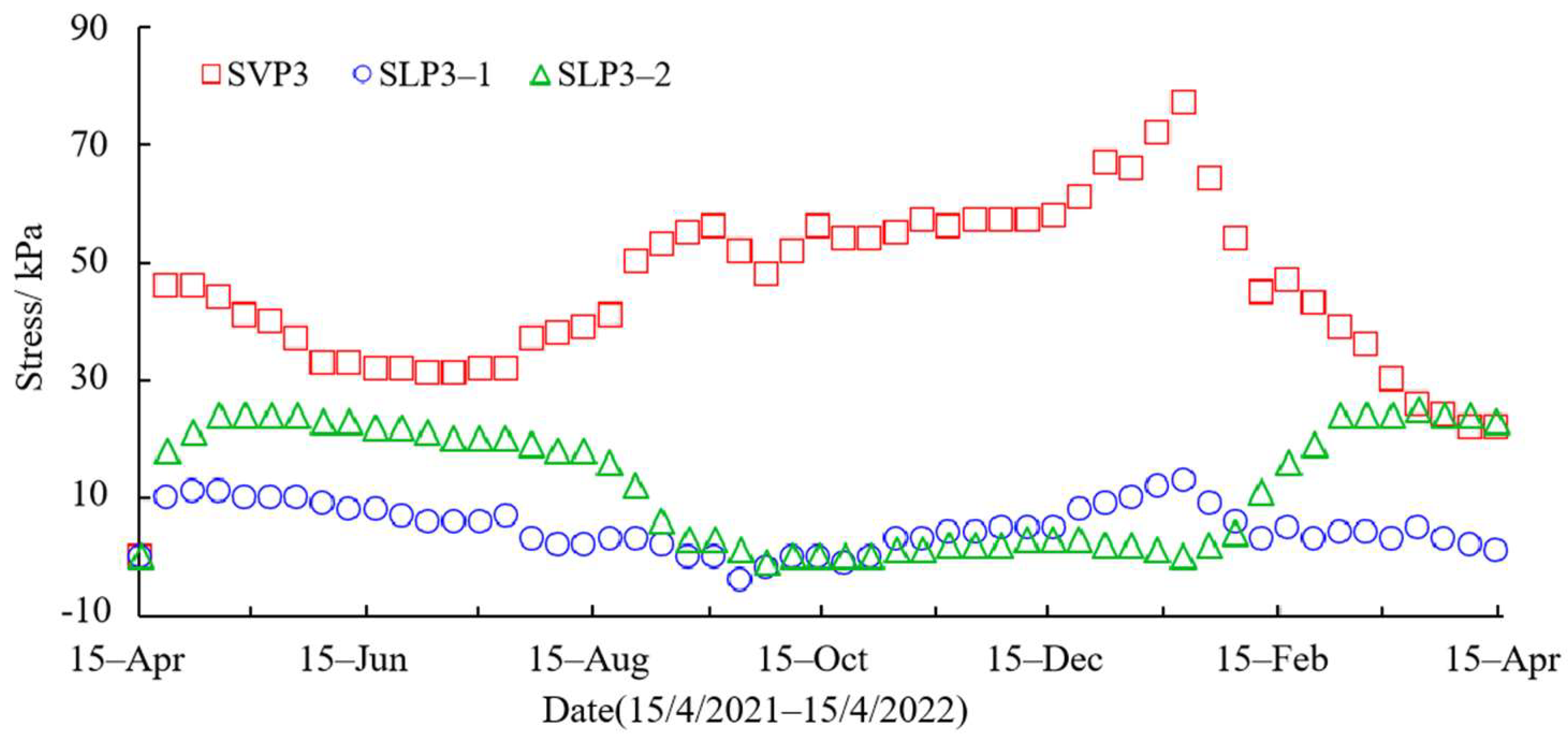

3.3. Stresses of the Reinforced Slope

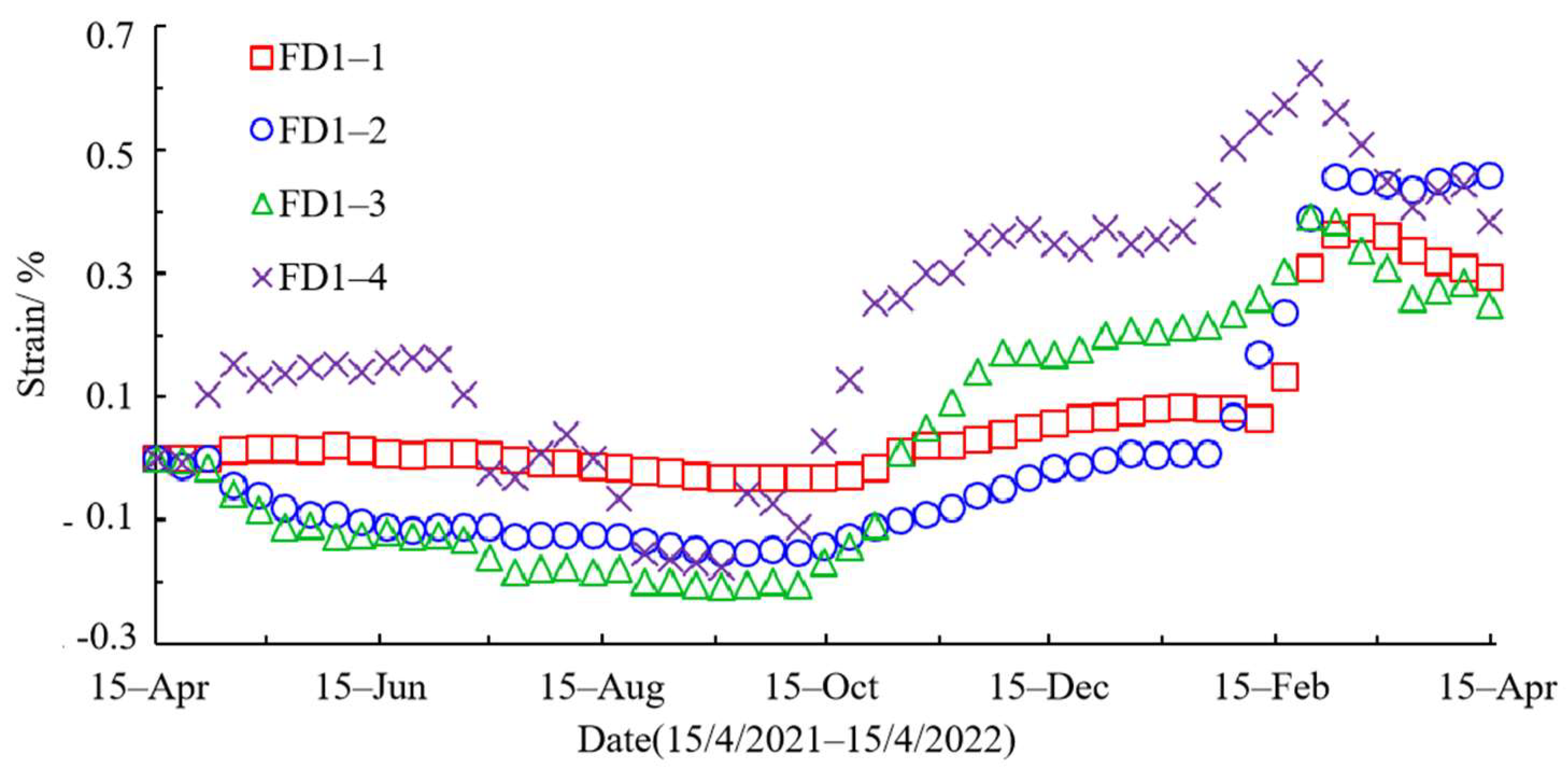

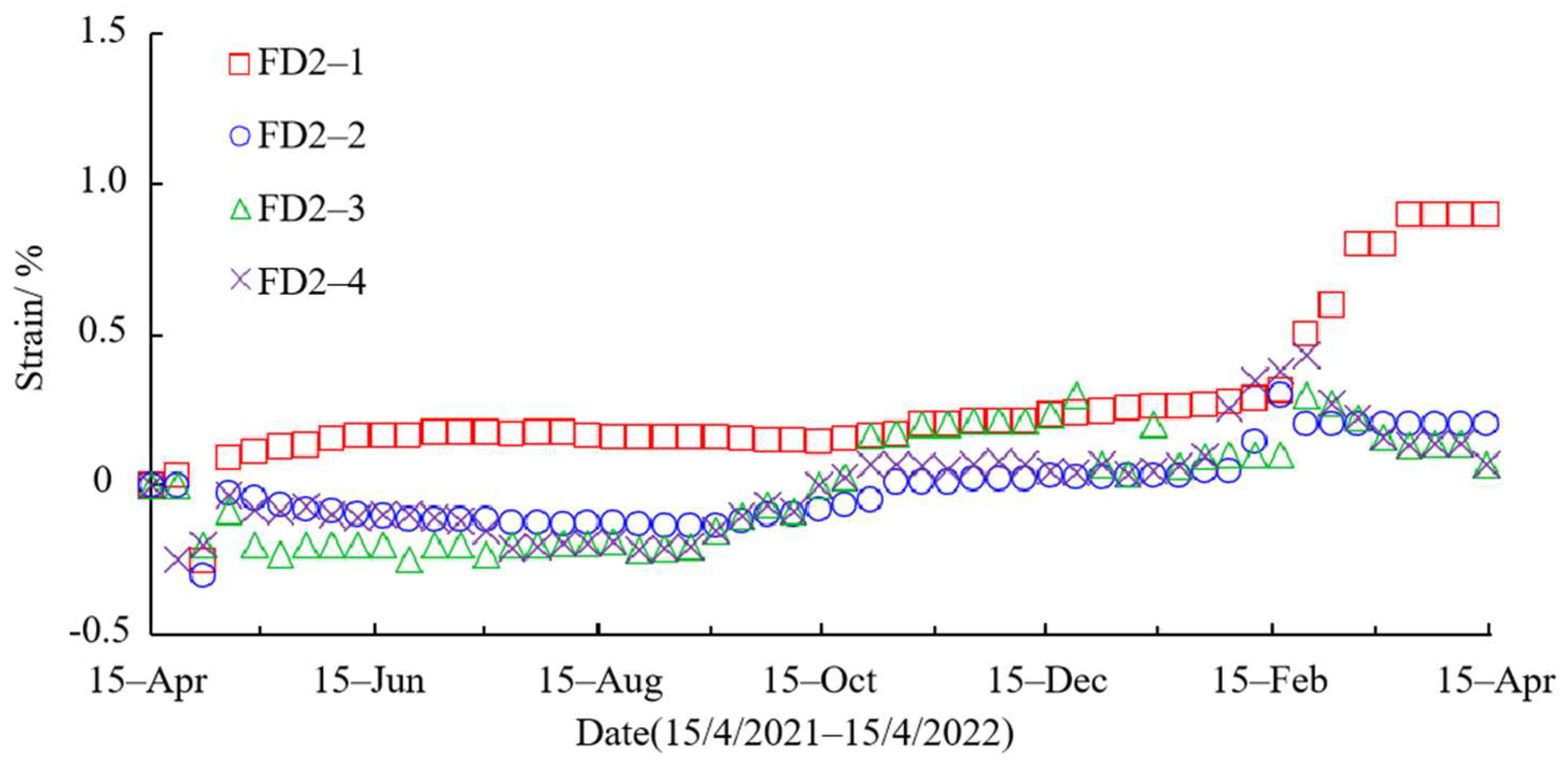

3.4. Strains of Geogrids in the Reinforced Slope

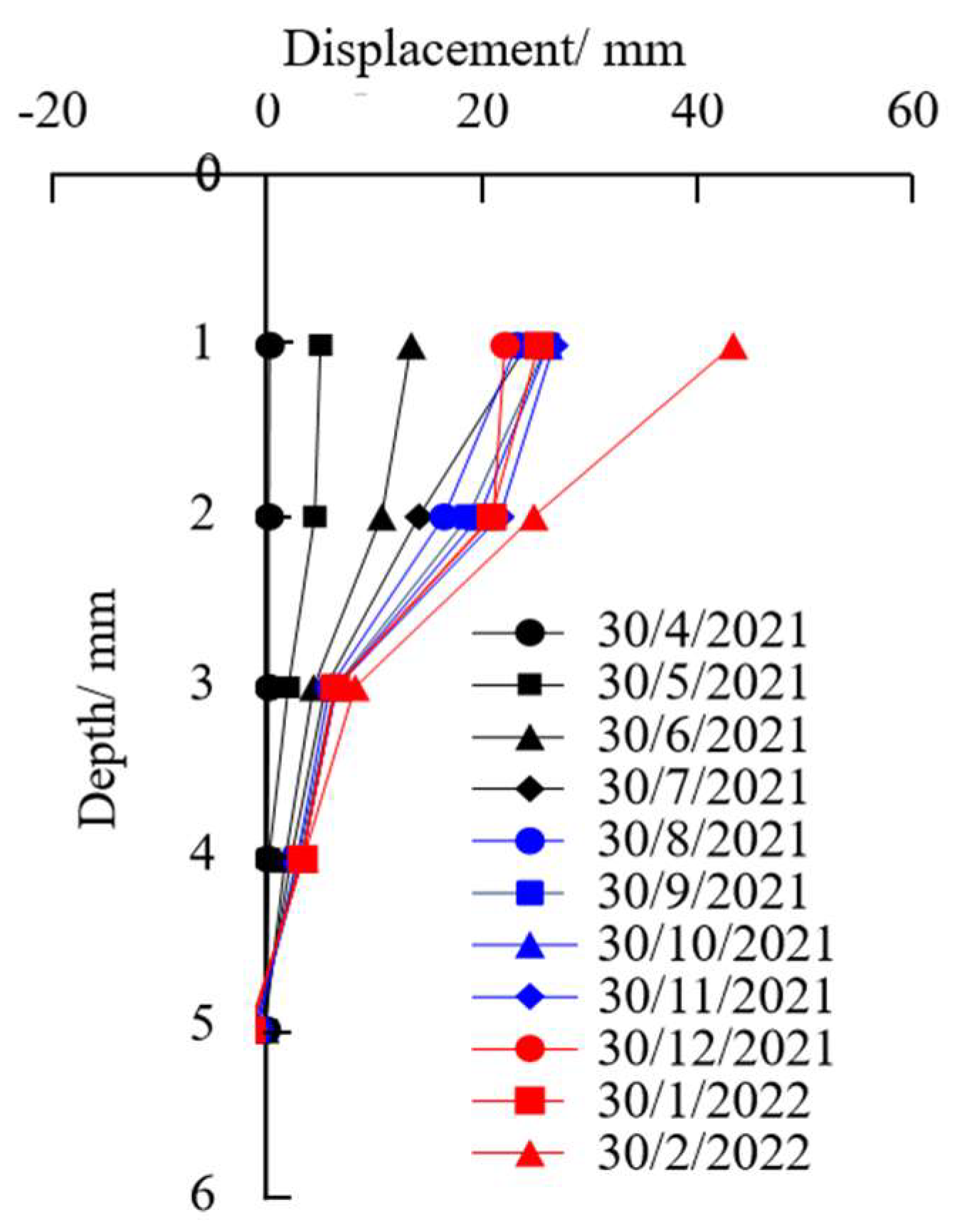

3.5. Horizontal Displacements of the Reinforced Slope

4. Life Cycle Assessment

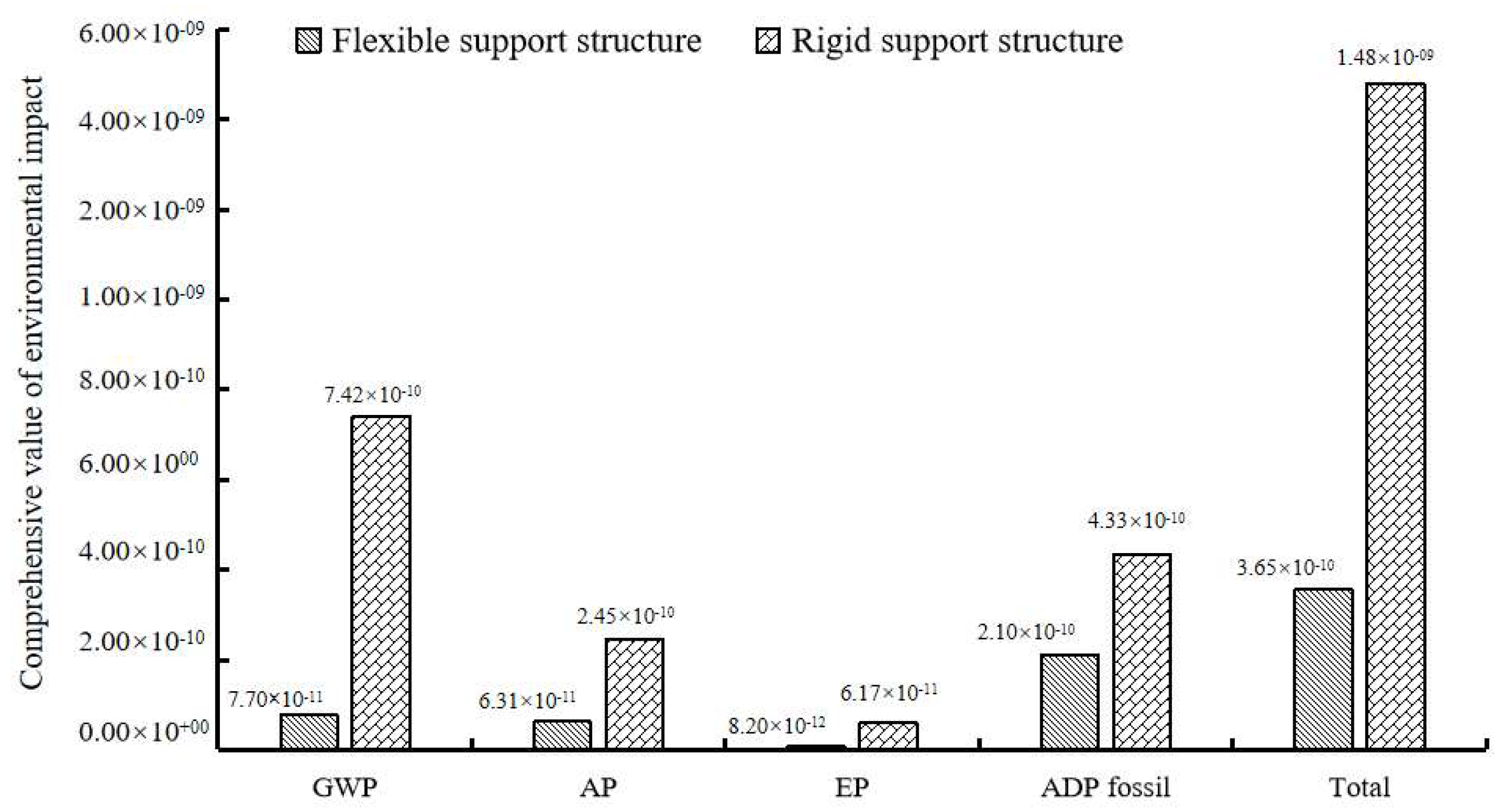

Characterizing Environmental Impacts

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LCA | life cycle assessment |

| LCCA | life cycle cost assessment |

| GWP | global warming potential |

| AP | acidification potential |

| EP | eutrophication potential |

| ADP | fossil abiotic depletion potential fossil |

References

- Ng, C.W.W.; Zhan, L.-T.; Bao, C.-G.; Fredlund, D.G.; Gong, B.-W. Performance of an unsaturated expansive soil slope subjected to artificial rainfall infiltration. Géotechnique 2003, 53, 143–157. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Sharma, M. Micro-mechanical performance evaluation of expansive soil biotreated with indigenous bacteria using MICP method. Sci. Rep. 2021, 11, 10324. [Google Scholar] [CrossRef] [PubMed]

- Puppala, A.; Congress, S.; Banerjee, A. Research advancements in expansive soil characterization, stabilization and geoinfrastructure monitoring. Front. Geotech. Eng. 2019, 15–29. [Google Scholar] [CrossRef]

- Chehade, H.; Dias, D.; Sadek, M.; Jenck, O.; Chehade, F.H. Seismic analysis of geosynthetic-reinforced retaining wall in cohesive soils. Geotext. Geomembr. 2019, 47, 315–326. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Puppala, A.J. Strength and durability assessment of expansive soil stabilized with recycled ash and natural fibers. Transp. Geotech. 2021, 29, 100556. [Google Scholar] [CrossRef]

- Zhang, R.; Long, M.-X.; Lan, T.; Zheng, J.-L.; Geoff, C. Stability analysis method of geogrid reinforced expansive soil slopes and its engineering application. J. Cent. South Univ. 2020, 27, 1965–1980. [Google Scholar] [CrossRef]

- Korini, O.; Bost, M.; Rajot, J.P.; Bennani, Y.; Freitag, N. The influence of geosynthetics design on the behavior of reinforced soil embankments subjected to rockfall impacts. Eng. Geol. 2021, 286, 106054. [Google Scholar] [CrossRef]

- Araújo, G.; Palmeira, E.; Macêdo, í.L. Comparisons between predicted and observed behavior of a geosynthetic reinforced abutment on soft soil. Eng. Geol. 2012, 147–148, 101–113. [Google Scholar] [CrossRef]

- Lei, D.; Chen, L. Study on Runoff and Infiltration for Expansive Soil Slopes in Simulated Rainfall. Water 2020, 12, 222. [Google Scholar] [CrossRef]

- Xiao, J.; Yang, H.-P.; Zhang, J.-H.; Tang, X.-Y. Surficial failure of expansive soil cutting slope and its flexible support treatment technology. Adv. Civ. Eng. 2018, 2018, 1609608. [Google Scholar] [CrossRef]

- Zhan, L.; Chen, R.; Ng, C.W.W. Wetting-induced softening behavior of an unsaturated expansive clay. Landslides 2014, 11, 1051–1061. [Google Scholar] [CrossRef]

- Schulz, W.H.; Smith, J.B.; Wang, G.-H.; Jiang, Y.; Roering, J.J. Clayey Landslide Initiation and Acceleration Strongly Modulated by Soil Swelling. Geophys. Res. Lett. 2018, 45, 1888–1896. [Google Scholar] [CrossRef]

- Liu, Y.; Vanapalli, S.K. Influence of lateral swelling pressure on the geotechnical infrastructure in expansive soils. J. Geotech. Geoenviron. Eng. 2017, 10, 1943–5606. [Google Scholar] [CrossRef]

- Papagiannakis, A.; Bin-Shafique, S.; Lytton, R. Retaining structures in expansive clays. Geotech. Geol. Eng. 2014, 10, 103–124. [Google Scholar] [CrossRef]

- Lade, P.V. The mechanics of surficial failure in soil slopes. Eng. Geol. 2010, 114, 57–64. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, Z.-N.; Zheng, J.-L.; Zhang, J.-L. Experimental Evaluation of Lateral Swelling Pressure of Expansive Soil Fill behind a Retaining Wall. J. Mater. Civ. Eng. 2020, 32, 04019360.1–04019360.11. [Google Scholar] [CrossRef]

- Khan, M.S.; Hossain, S.; Ahmed, A.; Faysal, M. Investigation of a shallow slope failure on expansive clay in Texas. Eng. Geol. 2017, 219, 118–129. [Google Scholar] [CrossRef]

- Qi, S.; Vanapalli, S.K. Influence of swelling behavior on the stability of an infinite unsaturated expansive soil slope. Comput. Geotech. 2016, 76, 154–169. [Google Scholar] [CrossRef]

- Pathak, Y.P.; Alfaro, M.C. Wetting-drying behavior of geogrid reinforced clay under working load conditions. Geosynth. Int. 2010, 17, 144–156. [Google Scholar] [CrossRef]

- Lan, T.; Zhang, R.; Yang, B.-Y.; Meng, X. Influence of Swelling on Shear Strength of Expansive Soil and Slope Stability. Front. Earth Sci. 2022, 10, 849046. [Google Scholar] [CrossRef]

- Murat, K.; Omer, T. Ecologically based hybrid life cycle analysis of continuously reinforced concrete and hot-mix asphalt pavement. Transp. Res. Part D Transp. Environ. 2012, 17, 86–90. [Google Scholar]

- Chinyere, D.; Caroline, H. Evaluation of low-impact modular housing using energy optimization and life cycle analysis. Energy Ecol. Environ. 2019, 4, 286–299. [Google Scholar]

- Nässén, J.; Holmberg, J.; Wadeskog, A.; Nyman, M. Direct and indirect energy use and carbon emissions in the production phase of buildings: An input–output analysis. Energy 2007, 32, 1593–1602. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life cycle analysis in the construction sector: Guiding the optimization of conventional Italian buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Thong, J.; Ho, C.; Noor, Z. Assessment of embodied energy and global warming potential of building construction using life cycle analysis approach: Case studies of residential buildings in Iskandar Malaysia. Energy Build. 2015, 93, 295–302. [Google Scholar]

- Santos, J.; Bryce, J.F.; Lintsch, G. A life cycle assessment of in-place recycling and infrastructure and maintenance practices. Struct. Infrastruct. Eng. 2014, 11, 1199–1217. [Google Scholar] [CrossRef]

- Huang, Y.; Roger, B.; Oliver, H. Development of a life cycle assessment tool for construction and maintenance of asphalt pavements. J. Clean. Prod. 2009, 17, 283–296. [Google Scholar] [CrossRef]

- Chan, A. Economic and Environmental Evaluations of Life Cycle Cost Analysis Practice: A Case Study of Michigan DOT Pavement Projects. Mater’s Thesis, Mater of Science Thesis in Natural Resource and Environment, University of Michigan, Ann Arbor, MI, USA, 2007. [Google Scholar]

- Chang, B.; Kendalla, A. Life Cycle Greenhouse Gas Assessment of Infrastructure for California’s High-speed Rail System. Transp. Res. Part D Transp. Environ. 2011, 16, 429–434. [Google Scholar] [CrossRef]

- Frischknecht, R.; Büsser-Knöpfel, S.; Itten, R. Comparative Life Cycle Assessment of Geosynthetics versus Concrete Retaining Wall. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; pp. 1979–1982. [Google Scholar]

- ISO.14040; Environmental Management—Life Cycle Assessment—Principles and Framework. British Standards Institution: London, UK, 2006.

- Cays, J. An Environmental Life Cycle Approach to Design; Springer Nature Switzerland AG: Cham, Switzerland, 2021. [Google Scholar]

- Chen, Y.-S.; Yang, Y.-P.; Li, X.; Dong, H.-B.; Bai, R.-B. Life Cycle Resource Consumption of Automotive Power Seats. Int. J. Environ. Stud. 2014, 17, 449–462. [Google Scholar] [CrossRef]

| Parameter | Sensor | Quantity | Range | Accuracy |

|---|---|---|---|---|

| Soil moisture | Water content probe | 12 | 0–100% | ±2% |

| Soil stress | Earth pressure cell | 9 | 0–300 kPa | 0.1 kPa |

| Geogrid strain | Flexible displacement meter | 12 | 0–30 mm | 0.01 mm |

| Slope displacement | Inclination probe | 11 | Between −15° and 15° | ±0.05% FS |

| Amount of rainfall | Rain gauge | 1 | ≤4 mm/min | ±4% |

| Temperature | Thermometer | 1 | Between −30 ℃ and 120 ℃ | ±0.5 ℃ |

| Humidity | Hygrometer | 1 | 1–100% | ±1% |

| Types | GWP | AP | EP | ADP Fossil | Total |

|---|---|---|---|---|---|

| Flexible support structure | 7.69 × 10−11 | 6.26 × 10−11 | 8.21 × 10−12 | 2.08 × 10−10 | 3.56 × 10−10 |

| Rigid support structure | 7.42 × 10−10 | 2.45 × 10−10 | 6.17 × 10−11 | 4.33 × 10−10 | 1.48 × 10−9 |

| Projects | Rigid Support Structure | Rigid Support Structure |

|---|---|---|

| HDPE one-way geogrid | 45.92 | \ |

| Gravel filter layer | 21.46 | \ |

| Waterproof geotextile | 4.16 | \ |

| Permeable geomembrane | 14.53 | \ |

| Anchor frame beam | \ | 238.38 |

| Ecological bag | \ | 66.39 |

| slab-pile wall | \ | 433.64 |

| Others (transportation, labor, etc.) | 104.38 | 234.58 |

| Total | 204.46 | 972.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Tang, P.; Lan, T.; Liu, Z.; Ling, S. Resilient and Sustainability Analysis of Flexible Supporting Structure of Expansive Soil Slope. Sustainability 2022, 14, 12813. https://doi.org/10.3390/su141912813

Zhang R, Tang P, Lan T, Liu Z, Ling S. Resilient and Sustainability Analysis of Flexible Supporting Structure of Expansive Soil Slope. Sustainability. 2022; 14(19):12813. https://doi.org/10.3390/su141912813

Chicago/Turabian StyleZhang, Rui, Panxuan Tang, Tian Lan, Zhaojing Liu, and Shiguang Ling. 2022. "Resilient and Sustainability Analysis of Flexible Supporting Structure of Expansive Soil Slope" Sustainability 14, no. 19: 12813. https://doi.org/10.3390/su141912813

APA StyleZhang, R., Tang, P., Lan, T., Liu, Z., & Ling, S. (2022). Resilient and Sustainability Analysis of Flexible Supporting Structure of Expansive Soil Slope. Sustainability, 14(19), 12813. https://doi.org/10.3390/su141912813