Defining Circular Economy Principles for Biobased Products

Abstract

1. Introduction

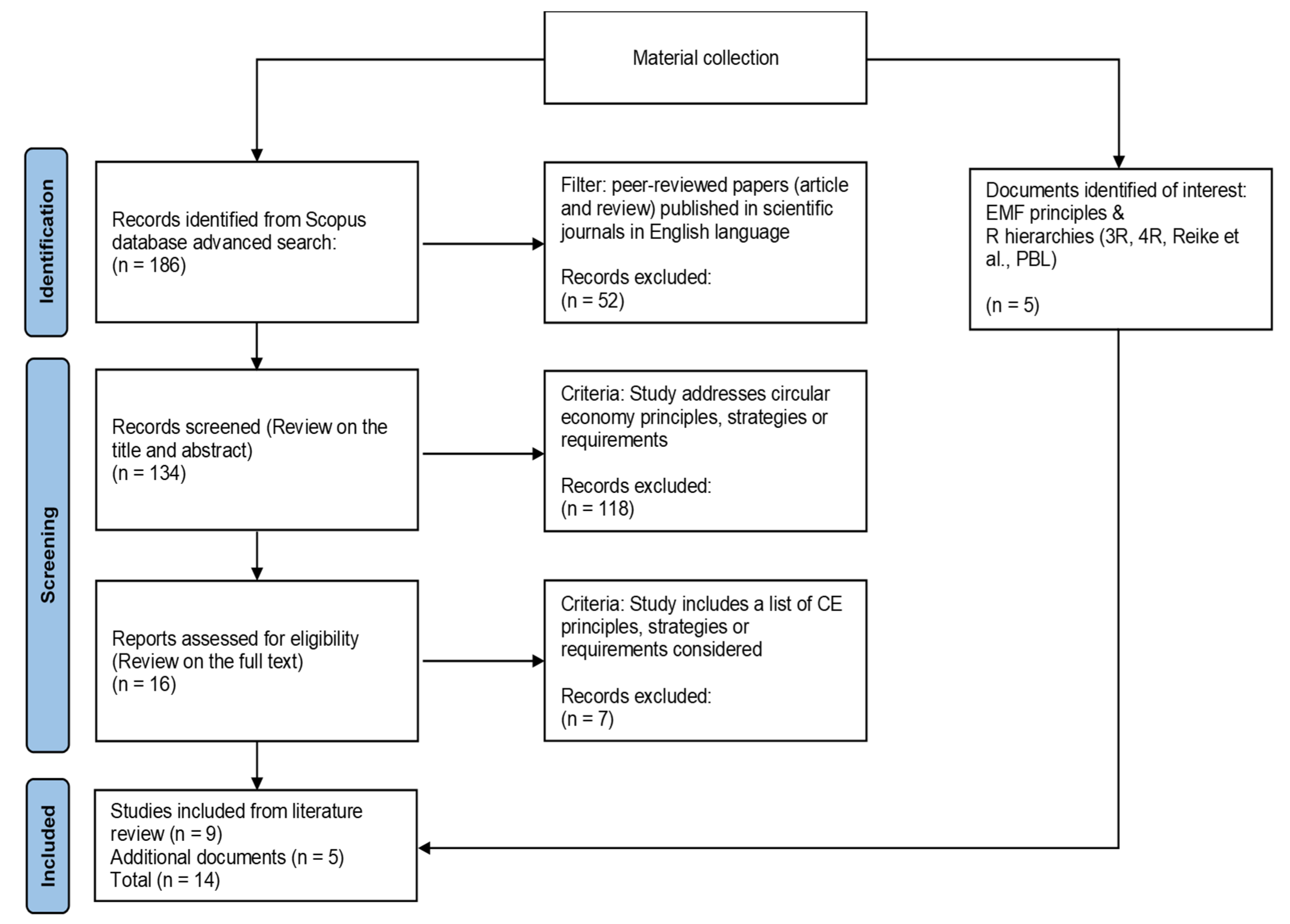

2. Materials and Methods

2.1. Literature Search on General Circular Economy Principles and Strategies

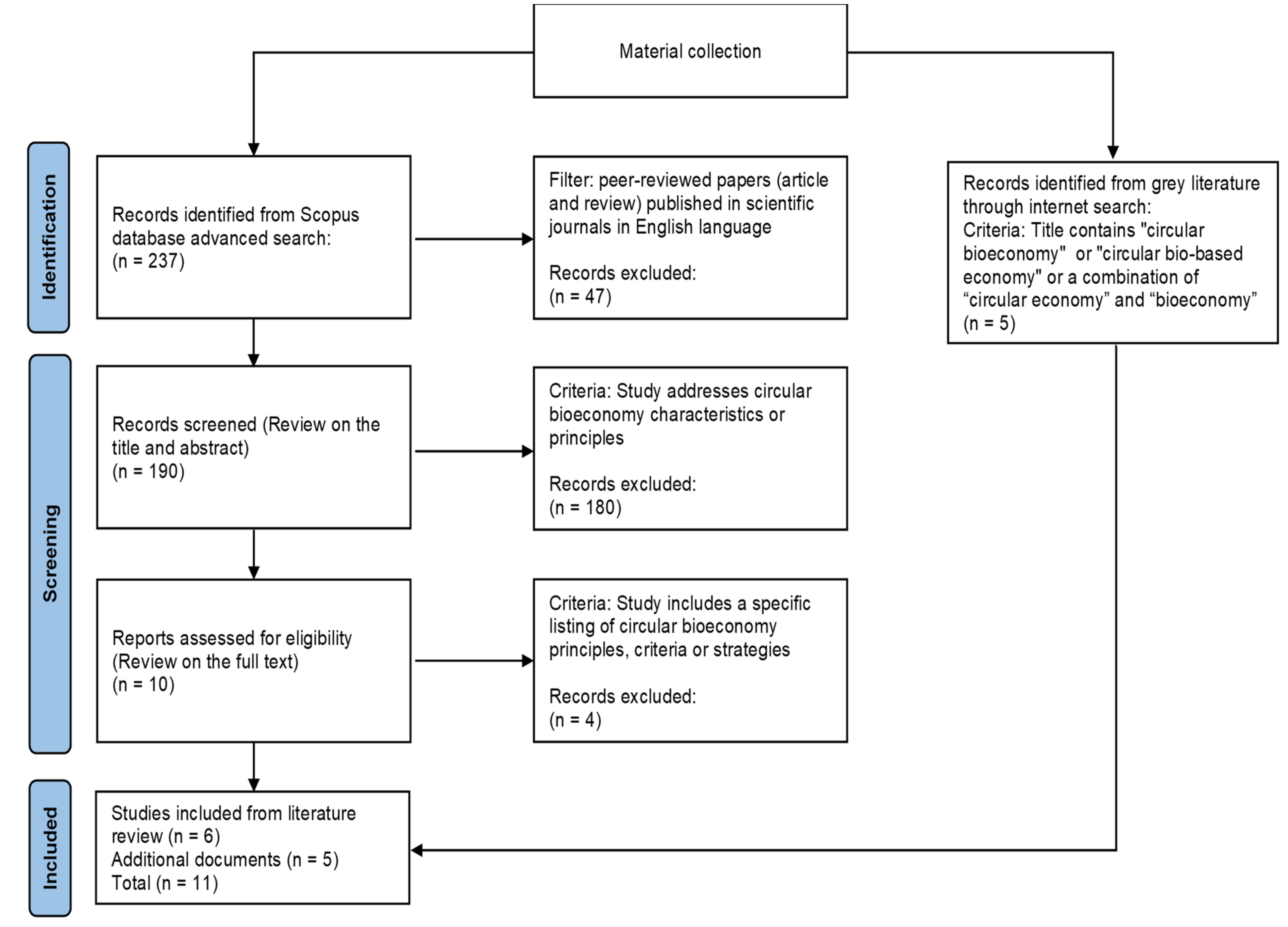

2.2. Identifying Core Characteristics of Circular Bioeconomy and Defining CE Principles for Biobased Products

2.3. Identifying What Needs to Be Measured for Monitoring Circularity of Biobased Products

3. Results

3.1. Circular Economy Principles and Strategies—What to Measure?

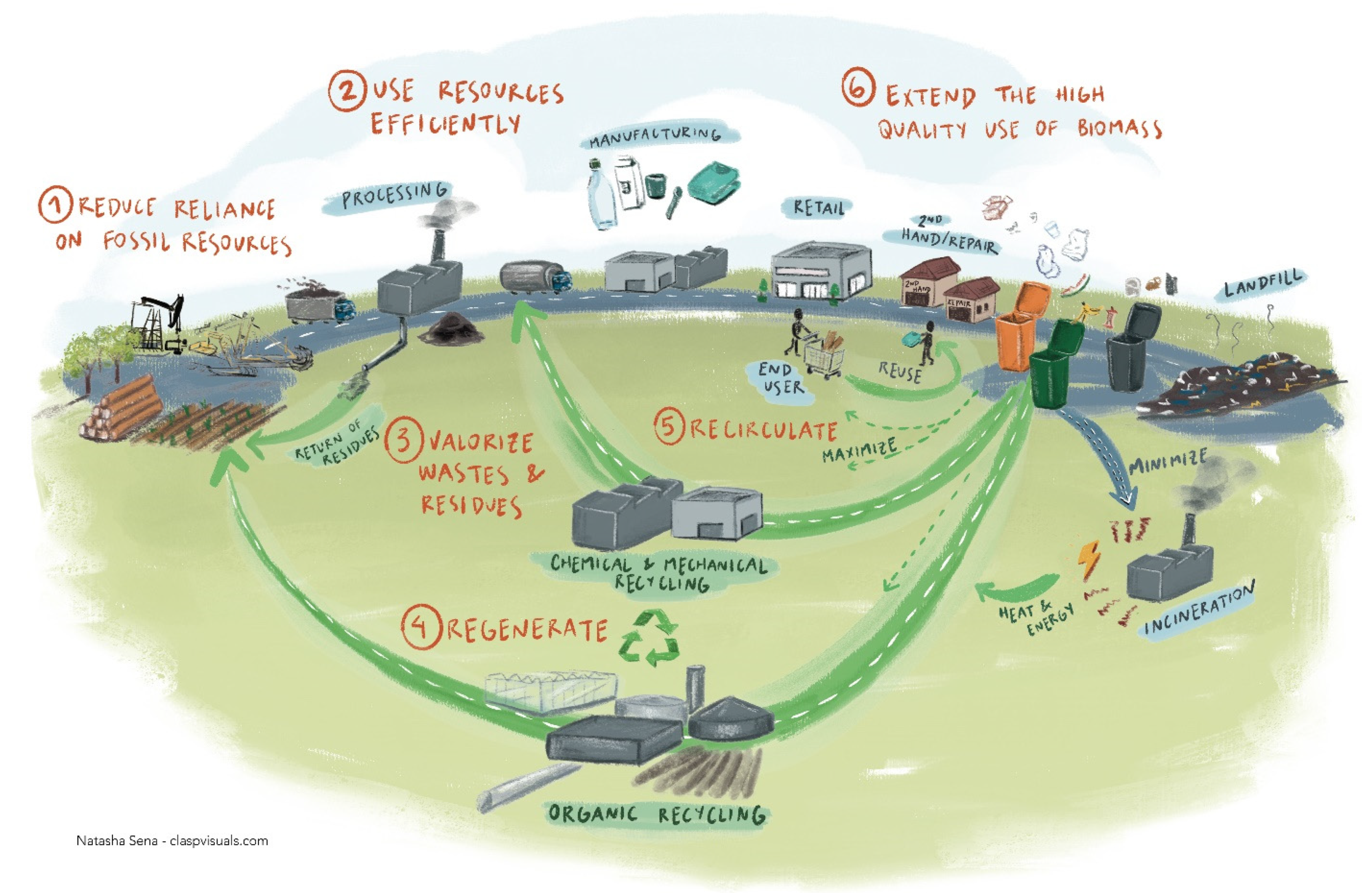

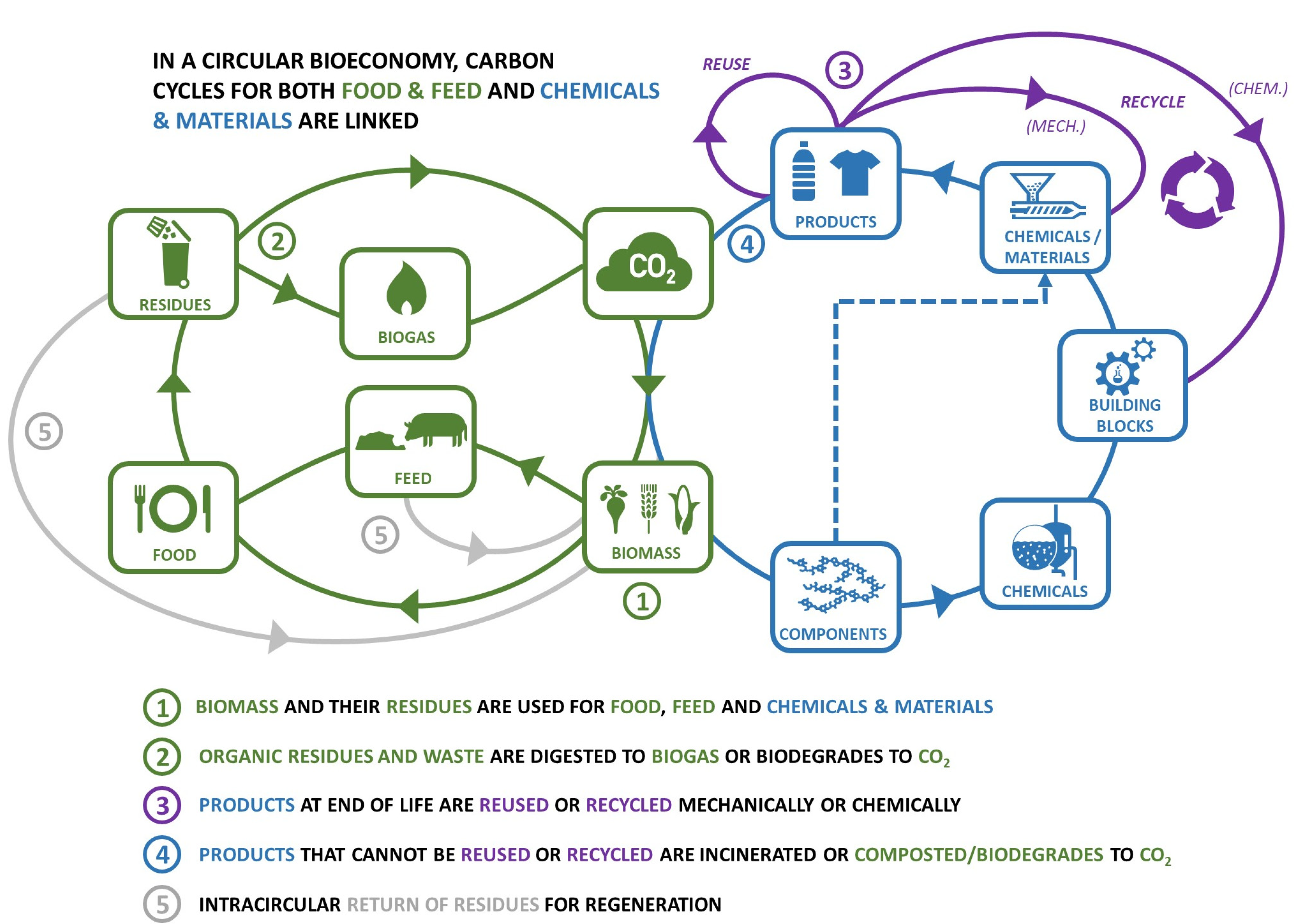

3.2. Biobased Products: Circular Economy Principles and Measurement Needs

3.2.1. Reduce Reliance on Fossil Resources

3.2.2. Use Resources Efficiently (Including Biorefining)

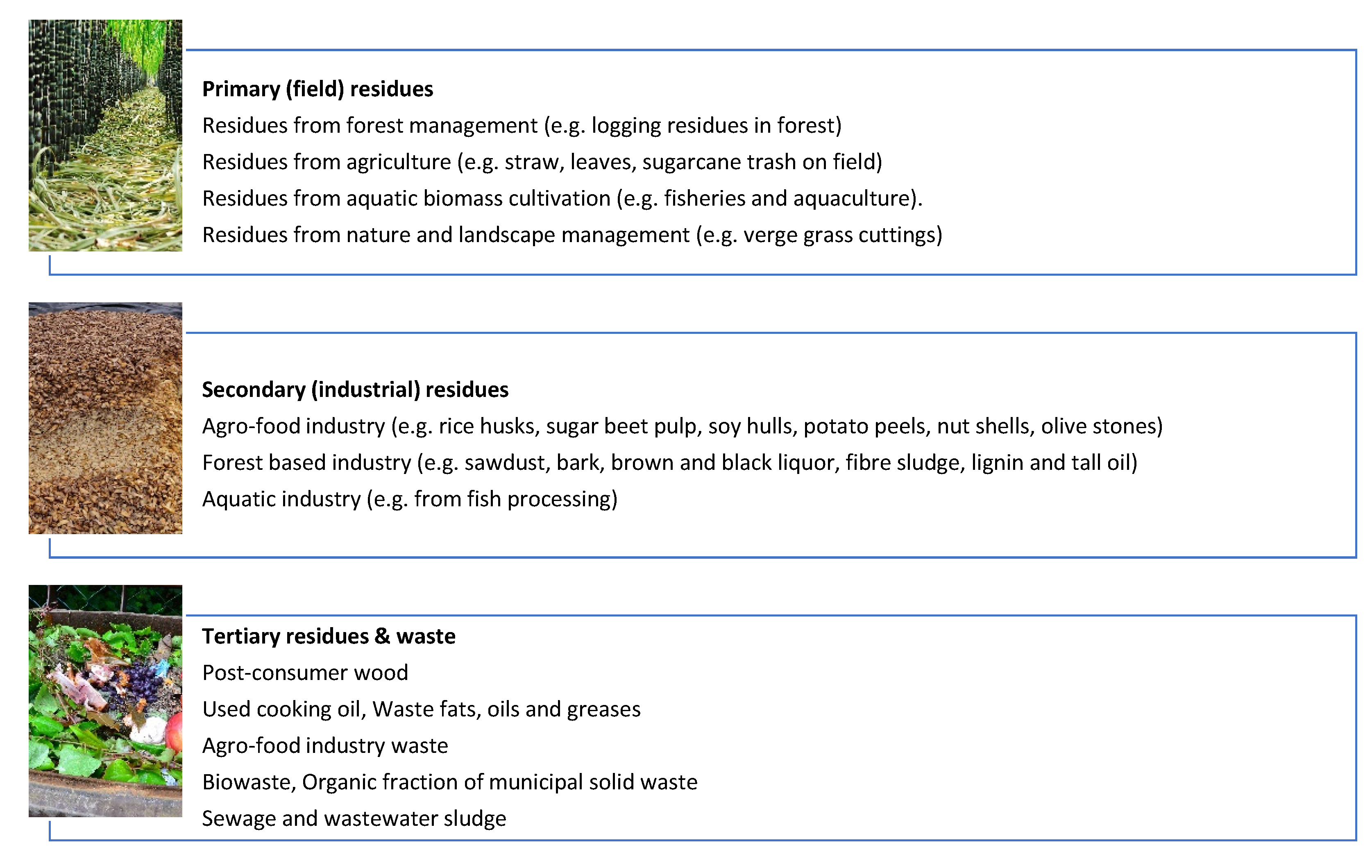

3.2.3. Valorize Wastes and Residues

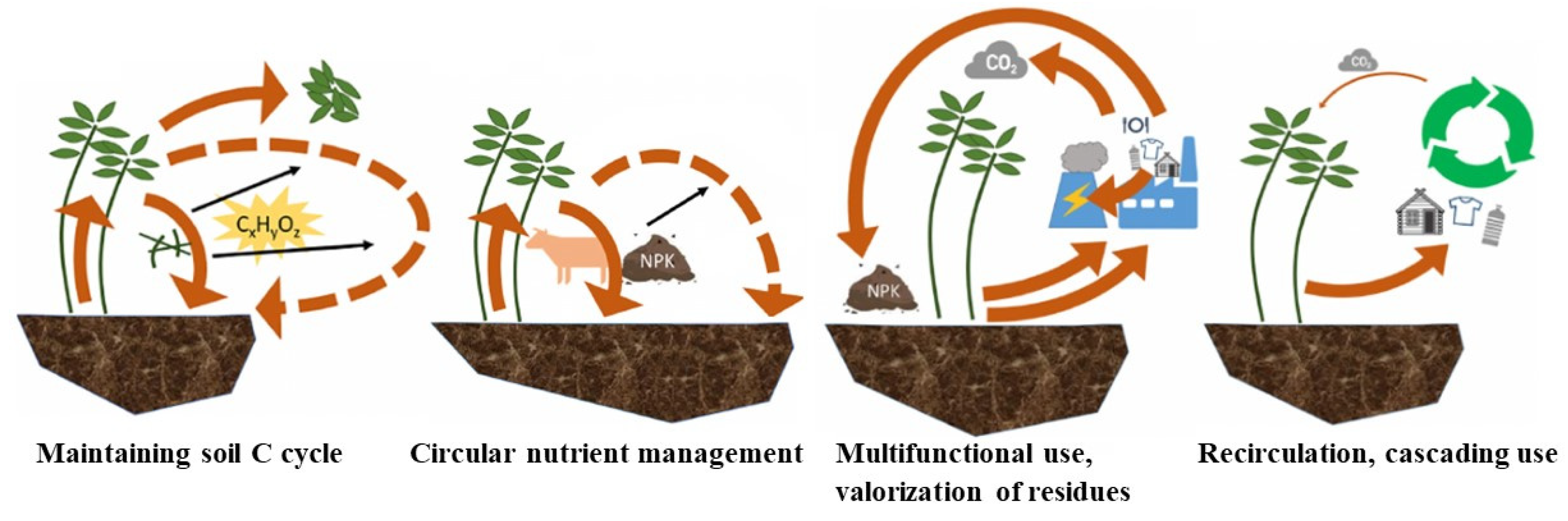

3.2.4. Regenerate (Maintain Carbon and Nutrient Cycles)

3.2.5. Recirculate

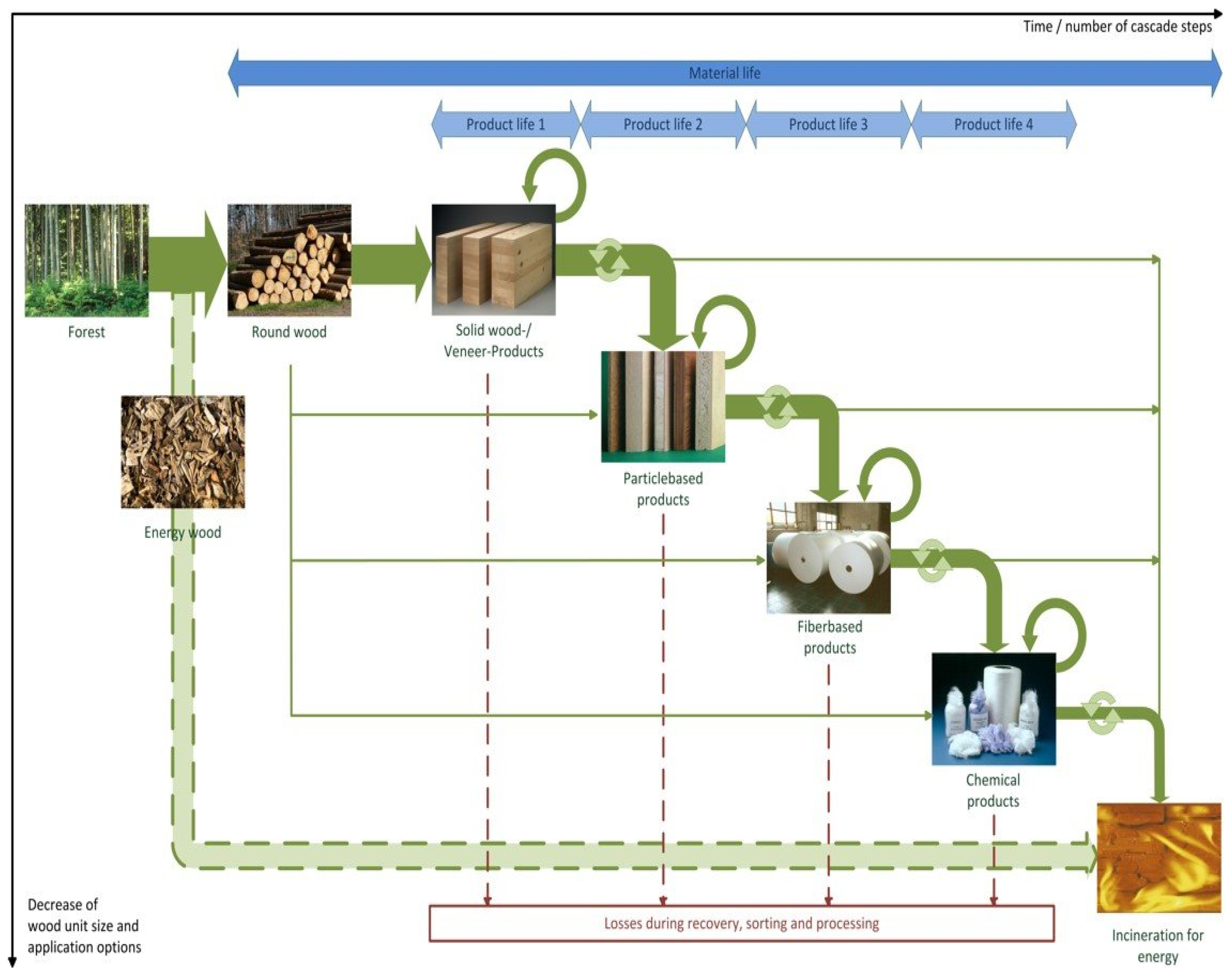

3.2.6. Extend the High-Quality Use of Biomass (Including Cascading Use)

3.2.7. What Needs to Be Measured for Monitoring Circularity of Biobased Products

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- International Resource Panel; United Nations Environmental Programme. Global Resources Outlook 2019: Natural Resources for the Future We Want: A Report of the International Resource Panel; International Resource Panel: Nairobi, Kenya, 2019. [Google Scholar]

- Jurgilevich, A.; Birge, T.; Kentala-Lehtonen, J.; Korhonen-Kurki, K.; Pietikäinen, J.; Saikku, L.; Schösler, H. Transition towards Circular Economy in the Food System. Sustainability 2016, 8, 69. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Circularity Indicators: An Approach to Measure Circularity: Methodology; Ellen MacArthur Foundation: Cowes, UK, 2019. [Google Scholar]

- European Commission. Living Well, within the Limits of Our Planet: 7th EAP—The New General Union Environment Action Programme to 2020; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy; COM(2015) 614 Final; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- European Environmental Agency. The Circular Economy and the Bioeconomy: Partners in Sustainability; European Environmental Agency Report No. 8; European Environmental Agency: Copenhagen, Denmark, 2018. [Google Scholar]

- European Commission. Innovating for Sustainable Growth: A Bioeconomy for Europe; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; Updated Bioeconomy Strategy COM(2018) 673 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. European Green Deal; COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. A New Circular Economy Action Plan: For a Cleaner and More Competitive Europe; COM(2020) 98 Final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. Measuring Progress towards Circular Economy in the European Union—Key Indicators for a Monitoring Framework; SWD(2018) 17 Final; European Commission: Strasbourg, France, 2018. [Google Scholar]

- Carus, M.; Dammer, L. The “Circular Bioeconomy”—Concepts, Opportunities and Limitations; Nova Paper #9 on Bio-Based Economy; Nova-Institut: Hurth, Germany, 2018. [Google Scholar]

- Hetemäki, L.; Hanewinkel, M.; Muys, B.; Ollikainen, M.; Palahí, M.; Trasobares, A. Leading the Way to a European Circular Bioeconomy Strategy; From Science to Policy 5; European Forest Institute: Joensuu, Finland, 2017. [Google Scholar]

- Philp, J.; Winickoff, D. Realising the Circular Bioeconomy. In OECD Science, Technology and Industry Policy Papers, No. 60; OECD Publishing: Paris, France, 2018. [Google Scholar]

- Stegmann, P.; Londo, M.; Junginger, M. The Circular Bioeconomy: Its Elements and Role in European Bioeconomy Clusters. Resour. Conserv. Recycl. X 2020, 6, 100029. [Google Scholar] [CrossRef]

- European Commission. A Clean Planet for All—A European Long-Term Strategic Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; COM/2018/773 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Environmental Agency. Circular Economy in Europe—Developing the Knowledge Base; European Environmental Agency Report No. 2; Publications Office of the European Union: Luxembourg, 2016. [Google Scholar]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Policy Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The Circular Economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- EN 16575:2014; Bio-Based Products—Vocabulary. European Committee for Standardization: Brussels, Belgium, 2014.

- Ellen MacArthur Foundation Circular Economy Systems Diagram. Available online: https://ellenmacarthurfoundation.org/circular-economy-diagram (accessed on 3 December 2021).

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 Explanation and Elaboration: Updated Guidance and Exemplars for Reporting Systematic Reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef]

- G8 Environment Ministers Meeting: Kobe 3R Action Plan; G7 Information Centre: Kobe, Japan, 2008.

- European Commission. Waste Framework Directive: Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring Circular Economy Strategies through Index Methods: A Critical Analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards Sustainable Development through the Circular Economy—A Review and Critical Assessment on Current Circularity Metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular Economy Indicators: What Do They Measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Boyer, R.H.W.; Mellquist, A.C.; Williander, M.; Fallahi, S.; Nyström, T.; Linder, M.; Algurén, P.; Vanacore, E.; Hunka, A.D.; Rex, E.; et al. Three-Dimensional Product Circularity. J. Ind. Ecol. 2021, 25, 824–833. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. How to Assess Product Performance in the Circular Economy? Proposed Requirements for the Design of a Circularity Measurement Framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Kambanou, M.L.; Sakao, T.; Brissaud, D. A Multi-Criteria Evaluation Method of Product-Level Circularity Strategies. Sustainability 2020, 12, 5129. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A Review of Micro Level Indicators for a Circular Economy—Moving Away from the Three Dimensions of Sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Jerome, A.; Helander, H.; Ljunggren, M.; Janssen, M. Mapping and Testing Circular Economy Product-Level Indicators: A Critical Review. Resour. Conserv. Recycl. 2022, 178, 106080. [Google Scholar] [CrossRef]

- Ortiz-de-Montellano, C.G.S.; van der Meer, Y. A Theoretical Framework for Circular Processes and Circular Impacts Through a Comprehensive Review of Indicators. Glob. J. Flex. Syst. Manag. 2022, 23, 291–314. [Google Scholar] [CrossRef]

- The European Bioeconomy Alliance. Bioeconomy—A Motor for the Circular Economy; The European Bioeconomy Alliance: Brussels, Belgium, 2016. [Google Scholar]

- Navare, K.; Muys, B.; Vrancken, K.C.; Van Acker, K. Circular Economy Monitoring—How to Make It Apt for Biological Cycles? Resour. Conserv. Recycl. 2021, 170, 105563. [Google Scholar] [CrossRef]

- Kardung, M.; Cingiz, K.; Costenoble, O.; Delahaye, R.; Heijman, W.; Lovrić, M.; van Leeuwen, M.; M’barek, R.; van Meijl, H.; Piotrowski, S.; et al. Development of the Circular Bioeconomy: Drivers and Indicators. Sustainability 2021, 13, 413. [Google Scholar] [CrossRef]

- Bos, H.L.; Broeze, J. Circular Bio-Based Production Systems in the Context of Current Biomass and Fossil Demand. Biofuels Bioprod. Biorefining 2020, 14, 187–197. [Google Scholar] [CrossRef]

- Muscat, A.; de Olde, E.M.; Ripoll-Bosch, R.; Van Zanten, H.H.E.; Metze, T.A.P.; Termeer, C.J.A.M.; van Ittersum, M.K.; de Boer, I.J.M. Principles, Drivers and Opportunities of a Circular Bioeconomy. Nat. Food 2021, 2, 561–566. [Google Scholar] [CrossRef]

- Brandão, A.S.; Gonçalves, A.; Santos, J.M.R.C.A. Circular Bioeconomy Strategies: From Scientific Research to Commercially Viable Products. J. Clean. Prod. 2021, 295, 126407. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A Taxonomy of Circular Economy Indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

- Van Ree, R.; de Jong, E. Task 42 Biorefining in a Future BioEconomy, IEA Bioenergy ExCo 2019: 08I; IEA Bioenergy: Paris, France, 2019.

- Ellen MacArthur Foundation. Completing the Picture: How the Circular Economy Tackles Climate Change; Ellen MacArthur Foundation: Cowes, UK, 2019. [Google Scholar]

- German Environmental Agency (UBA). Biomass Cascades: Increasing Resource Efficiency by Cascading Use of Biomass—From Theory to Practice; German Environmental Agency: Dessau-Roßlau, Germany, 2017. [Google Scholar]

- Carus, M.; Raschka, A. Renewable Carbon Is Key to a Sustainable and Future-Oriented Chemical Industry; Nova Paper #10 on Bio-Based Economy; Nova-Institut: Hurth, Germany, 2018. [Google Scholar]

- Social Economic Council. Biomass in the Balance: A Sustainability Framework for High-Value Use of Bio-Based Raw Materials; Social Economic Council Advisory Report 20/07; Social Economic Council: The Hague, The Netherlands, 2020. [Google Scholar]

- Dutch Government. A Circular Economy in the Netherlands by 2050 Government-Wide Programme for a Circular Economy; The Ministry of Infrastructure and the Environment and the Ministry of Economic Affairs, also on behalf of the Ministry of Foreign Affairs and the Ministry of the Interior and Kingdom Relations: The Hague, The Netherlands, 2016. [Google Scholar]

- Carus, M.; Skoczinski, P.; Dammer, L.; vom Berg, C.; Raschka, A.; Breitmayer, E. Hitchhiker’s Guide to Carbon Capture and Utilisation (CCU); Nova Paper #11 on Bio-Based Economy; Nova-Institut: Hurth, Germany, 2019. [Google Scholar]

- Muscat, A.; de Olde, E.M.; de Boer, I.J.M.; Ripoll-Bosch, R. The Battle for Biomass: A Systematic Review of Food-Feed-Fuel Competition. Glob. Food Sec. 2020, 25, 100330. [Google Scholar] [CrossRef]

- Van Groenestijn, J.; Harmsen, P.; Bos, H. Biomass for the Circular Economy: Everything You Wanted to Know about Biomass but Were Afraid to Ask; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2019. [Google Scholar]

- De Jong, E.; Higson, A.; Walsh, P.; Wellisch, M. Bio-Based Chemicals: Value Added Products from Biorefineries—Task 42 Biorefinery; IEA Bioenergy Task 42; IEA Bioenergy, 2012.

- Platt, R.; Bauen, A.; Reumerman, P.; Geier, C.; Van Ree, R.; Gursel, I.V.; Garcia, L.; Behrens, M.; von Bothmer, P.; Howes, J.; et al. EU Biorefinery Outlook to 2030—Studies on Support to Research and Innovation Policy in the Area of Bio-Based Products and Services; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- European Commission. Directive (EU) 2018/2001 of the European Parlement and the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast); European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Evangelou, M.W.H.; Papazoglou, E.G.; Robinson, B.H.; Schulin, R. Phytomanagement: Phytoremediation and the Production of Biomass for Economic Revenue on Contaminated Land. In Phytoremediation: Management of Environmental Contaminants; Ansari, A., Gill, S., Gill, R., Lanza, G., Newman, L., Eds.; Springer: Cham, Switzerland, 2015; Volume 1, pp. 115–132. ISBN 9783319103952. [Google Scholar]

- Abhilash, P.C.; Tripathi, V.; Edrisi, S.A.; Dubey, R.K.; Bakshi, M.; Dubey, P.K.; Singh, H.B.; Ebbs, S.D. Sustainability of Crop Production from Polluted Lands. Energy Ecol. Environ. 2016, 1, 54–65. [Google Scholar] [CrossRef]

- Dastyar, W.; Raheem, A.; He, J.; Zhao, M. Biofuel Production Using Thermochemical Conversion of Heavy Metal-Contaminated Biomass (HMCB) Harvested from Phytoextraction Process. Chem. Eng. J. 2019, 358, 759–785. [Google Scholar] [CrossRef]

- Fernando-foncillas, C.; Estevez, M.M.; Uellendahl, H.; Varrone, C. Co-Management of Sewage Sludge and Other Organic Wastes: A Scandinavian Case Study. Energies 2021, 14, 3411. [Google Scholar] [CrossRef]

- Netherlands Enterprise Agency (RVO). Guidance on the Classification of Biomass: Categories and NTA 8003 Codes under the SDE+ Scheme; Netherlands Enterprise Agency: The Hague, The Netherlands, 2019. [Google Scholar]

- Dahiya, S.; Kumar, A.N.; Shanthi Sravan, J.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Food Waste Biorefinery: Sustainable Strategy for Circular Bioeconomy. Bioresour. Technol. 2018, 248, 2–12. [Google Scholar] [CrossRef]

- Bruins, M. Technical Examples on Added Value Generation. Available online: https://power4bio.eu/wp-content/uploads/2020/11/POWER4BIO_WUR_FoodFeed-2-Examples-added-value-generation.pdf (accessed on 13 December 2021).

- POWER4BIO Catalogue of Bioeconomy Solutions. Available online: https://www.bio-based-solutions.eu/#/ (accessed on 13 December 2021).

- Turmel, M.S.; Speratti, A.; Baudron, F.; Verhulst, N.; Govaerts, B. Crop Residue Management and Soil Health: A Systems Analysis. Agric. Syst. 2015, 134, 6–16. [Google Scholar] [CrossRef]

- European Environment Agency. Bio-Waste in Europe—Turning Challenges into Opportunities; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Coppens, J.; Meers, E.; Boon, N.; Buysse, J.; Vlaeminck, S.E. Follow the N and P Road: High-Resolution Nutrient Flow Analysis of the Flanders Region as Precursor for Sustainable Resource Management. Resour. Conserv. Recycl. 2016, 115, 9–21. [Google Scholar] [CrossRef]

- Van den Oever, M.; Molenveld, K.; van der Zee, M.; Bos, H. Bio-Based and Biodegradable Plastics: Facts and Figures; Wageningen Food and Biobased Research: Wageningen, The Netherlands, 2017. [Google Scholar]

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy. Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013; Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 13 December 2021).

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015; Available online: https://ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 13 December 2021).

- Mantau, U. Wood Flow Analysis: Quantification of Resource Potentials, Cascades and Carbon Effects. Biomass Bioenergy 2015, 79, 28–38. [Google Scholar] [CrossRef]

- Spekreijse, J.; Lammens, T.; Parisi, C.; Ronzon, T.; Vis, M. Insights into the European Market of Bio-Based Chemicals: Analysis Based on Ten Key Product Categories; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Odegard, I.; Nusselder, S.; Lindgreen, E.R.; Bergsma, G.; de Graaff, L. Biobased Plastics in a Circular Economy; CE Delft: Delft, The Netherlands, 2017. [Google Scholar]

- Van Es, D.S.; Blaauw, R. Biobased Materials and Chemicals for Relieving and Replacing the Fossil Feedstock System (Project KB34-3B-1); WUR Knowledge Base Program, Circular and Climate Neutral Society: Wageningen, The Netherlands, 2021. [Google Scholar]

- Allwood, J.M. Squaring the Circular Economy: The Role of Recycling within a Hierarchy of Material Management Strategies. In Handbook of Recycling; State-of-the-art for Practitioners, Analysts, and Scientists; Elsevier: Amsterdam, The Netherlands, 2014; pp. 445–477. [Google Scholar] [CrossRef]

- Crippa, M.; De Wilde, B.; Koopmans, R.; Leyssens, J.; Muncke, J.; Ritschkoff, A.-C.; Van Doorsselaer, K.; Velis, C.; Wagner, M. A Circular Economy for Plastics—Insights from Research and Innovation to Inform Policy and Funding Decisions; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- European Environment Agency. Circular by Design: Products in the Circular Economy; European Environmental Agency, Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Kosloski-Oh, S.C.; Wood, Z.A.; Manjarrez, Y.; De Los Rios, J.P.; Fieser, M.E. Catalytic Methods for Chemical Recycling or Upcycling of Commercial Polymers. Mater. Horiz. 2021, 8, 1084–1129. [Google Scholar] [CrossRef] [PubMed]

- Thiounn, T.; Smith, R.C. Advances and Approaches for Chemical Recycling of Plastic Waste. J. Polym. Sci. 2020, 58, 1347–1364. [Google Scholar] [CrossRef]

- Coates, G.W.; Getzler, Y.D.Y.L. Chemical Recycling to Monomer for an Ideal, Circular Polymer Economy. Nat. Rev. Mater. 2020, 5, 501–516. [Google Scholar] [CrossRef]

- Collias, D.I.; James, M.I.; Layman, J.M. Circular Economy of Polymers: Topics in Recycling Technologies; American Chemical Society: Washington, DC, USA, 2021; Volume 1391. [Google Scholar]

- Keegan, D.; Kretschmer, B.; Elbersen, B.; Panoutsou, C. Cascading Use: A Systematic Approach to Biomass beyond the Energy Sector. Biofuels Bioprod. Biorefining 2013, 7, 193–206. [Google Scholar] [CrossRef]

- Campbell-Johnston, K.; Vermeulen, W.J.V.; Reike, D.; Brullot, S. The Circular Economy and Cascading: Towards a Framework. Resour. Conserv. Recycl. X 2020, 7, 100038. [Google Scholar] [CrossRef]

- Höglmeier, K.; Weber-Blaschke, G.; Richter, K. Potentials for Cascading of Recovered Wood from Building Deconstruction—A Case Study for South-East Germany. Resour. Conserv. Recycl. 2013, 78, 81–91. [Google Scholar] [CrossRef]

- Risse, M.; Weber-Blaschke, G.; Richter, K. Resource Efficiency of Multifunctional Wood Cascade Chains Using LCA and Exergy Analysis, Exemplified by a Case Study for Germany. Resour. Conserv. Recycl. 2017, 126, 141–152. [Google Scholar] [CrossRef]

- Vis, M.; Mantau, U.; Allen, B. Study on the Optimised Cascading Use of Wood; No 394/PP/ENT/RCH/14/7689; Publications Office of the European Union: Luxembourg, 2016; ISBN 9789279577253. [Google Scholar]

- Shirvanimoghaddam, K.; Motamed, B.; Ramakrishna, S.; Naebe, M. Death by Waste: Fashion and Textile Circular Economy Case. Sci. Total Environ. 2020, 718, 137317. [Google Scholar] [CrossRef]

- Technical University Munich. Cascading Use of Wood to Ensure Sustainability. 12 December 2017. Phys.org. Available online: https://phys.org/news/2017-12-cascading-wood-sustainability.html (accessed on 13 December 2021).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Schaubroeck, T. Circular Economy Practices May Not Always Lead to Lower Criticality or More Sustainability; Analysis and Guidance Is Needed per Case. Resour. Conserv. Recycl. 2020, 162, 104977. [Google Scholar] [CrossRef]

- Marini, M.; Angouria-Tsorochidou, E.; Caro, D.; Thomsen, M. Daily Intake of Heavy Metals and Minerals in Food—A Case Study of Four Danish Dietary Profiles. J. Clean. Prod. 2021, 280, 124279. [Google Scholar] [CrossRef]

- Thomsen, M.; Faber, J.H.; Sorensen, P.B. Soil Ecosystem Health and Services—Evaluation of Ecological Indicators Susceptible to Chemical Stressors. Ecol. Indic. 2012, 16, 67–75. [Google Scholar] [CrossRef]

- Lange, L.; Connor, K.O.; Arason, S.; Bundgård-Jørgensen, U.; Canalis, A.; Carrez, D.; Gallagher, J.; Gøtke, N.; Huyghe, C.; Jarry, B.; et al. Developing a Sustainable and Circular Bio-Based Economy in EU: By Partnering Across Sectors, Upscaling and Using New Knowledge Faster, and For the Benefit of Climate, Environment & Biodiversity, and People & Business. Front. Bioeng. Biotechnol. 2021, 8, 1456. [Google Scholar] [CrossRef]

- The Circular Bio-Based Europe Joint Undertaking (CBE JU). Available online: https://www.bbi.europa.eu/about/circular-bio-based-europe-joint-undertaking-cbe-ju (accessed on 21 December 2021).

- Ladu, L.; Clavell, J.; Quitzow, R.; Costenoble, O.; Vrins, M.; van den Berg, J.; Babayan, T.; vom Berg, C.; Dammer, L.; Partanen, A.; et al. STAR4BBI D4.4 Regulation Action Plan; Bio-based Industries Consortium: Brussels, Belgium, 2019. [Google Scholar]

- Jarre, M.; Petit-Boix, A.; Priefer, C.; Meyer, R.; Leipold, S. Transforming the Bio-Based Sector towards a Circular Economy—What Can We Learn from Wood Cascading? For. Policy Econ. 2020, 110, 101872. [Google Scholar] [CrossRef]

- Dammer, L.; Bowyer, C.; Breitmayer, E.; Eder, A.; Nanni, S.; Allen, B.; Carus, M.; Essel, R. Mapping Study on the Cascading Use of Wood Products; WWF—World Wide Fund For Nature: Gland, Switzerland, 2016. [Google Scholar]

- Calisto Friant, M.; Vermeulen, W.J.V.; Salomone, R. Analysing European Union Circular Economy Policies: Words versus Actions. Sustain. Prod. Consum. 2021, 27, 337–353. [Google Scholar] [CrossRef]

- Milios, L. Advancing to a Circular Economy: Three Essential Ingredients for a Comprehensive Policy Mix. Sustain. Sci. 2018, 13, 861–878. [Google Scholar] [CrossRef]

- Bais-Moleman, A.L.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.C.; Erb, K.H. Assessing Wood Use Efficiency and Greenhouse Gas Emissions of Wood Product Cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954. [Google Scholar] [CrossRef]

- Höglmeier, K.; Weber-Blaschke, G.; Richter, K. Utilization of Recovered Wood in Cascades versus Utilization of Primary Wood—A Comparison with Life Cycle Assessment Using System Expansion. Int. J. Life Cycle Assess. 2014, 19, 1755–1766. [Google Scholar] [CrossRef]

- Höglmeier, K.; Steubing, B.; Weber-Blaschke, G.; Richter, K. LCA-Based Optimization of Wood Utilization under Special Consideration of a Cascading Use of Wood. J. Environ. Manag. 2015, 152, 158–170. [Google Scholar] [CrossRef]

- Sikkema, R.; Junginger, M.; McFarlane, P.; Faaij, A. The GHG Contribution of the Cascaded Use of Harvested Wood Products in Comparison with the Use of Wood for Energy—A Case Study on Available Forest Resources in Canada. Environ. Sci. Policy 2013, 31, 96–108. [Google Scholar] [CrossRef]

- Thonemann, N.; Schumann, M. Environmental Impacts of Wood-Based Products under Consideration of Cascade Utilization: A Systematic Literature Review. J. Clean. Prod. 2018, 172, 4181–4188. [Google Scholar] [CrossRef]

- Muys, B.; Masiero, M.; Achten, W. Sustainability Issues of Using Forests as a Bioenergy Resource. In Forest Bioenergy for Europe; Pelkonen, P., Mustonen, M., Asikainen, A., Egnell, G., Kant, P., Leduc, S., Pettenella, D., Eds.; European Forest Institute: Joensuu, Finland, 2014; pp. 90–97. ISBN 9789525980103. [Google Scholar]

- Harris, S.; Martin, M.; Diener, D. Circularity for Circularity’s Sake? Scoping Review of Assessment Methods for Environmental Performance in the Circular Economy. Sustain. Prod. Consum. 2021, 26, 172–186. [Google Scholar] [CrossRef]

- Blum, N.U.; Haupt, M.; Bening, C.R. Why “Circular” Doesn’t Always Mean “Sustainable”. Resour. Conserv. Recycl. 2020, 162, 105042. [Google Scholar] [CrossRef]

| Source | Circular Economy Principles/Strategies/Requirements |

|---|---|

| Ellen Mac Arthur Foundation [3] |

|

| Boyer et al. (2021) [29] |

|

| 3R Framework [24] |

|

| 4R [25] |

|

| Saidani et al. (2017) [30] |

|

| Alamerew et al. (2020) [31] |

|

| PBL [18] |

|

| Reike et al. (2018) [19] |

|

| Ortiz-de-Montellano and van der Meer (2022) [34] |

|

| Kristensen and Mosgaard (2020) [32] |

|

| Jerome et al. (2022) [33] |

|

| Moraga et al. (2019) [28] |

|

| Elia et al. (2017) [26] |

|

| Corona et al. (2019) [27] |

|

| Circular Economy Principles: | What Needs to Be Measured: |

|---|---|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vural Gursel, I.; Elbersen, B.; Meesters, K.P.H.; van Leeuwen, M. Defining Circular Economy Principles for Biobased Products. Sustainability 2022, 14, 12780. https://doi.org/10.3390/su141912780

Vural Gursel I, Elbersen B, Meesters KPH, van Leeuwen M. Defining Circular Economy Principles for Biobased Products. Sustainability. 2022; 14(19):12780. https://doi.org/10.3390/su141912780

Chicago/Turabian StyleVural Gursel, Iris, Berien Elbersen, Koen P. H. Meesters, and Myrna van Leeuwen. 2022. "Defining Circular Economy Principles for Biobased Products" Sustainability 14, no. 19: 12780. https://doi.org/10.3390/su141912780

APA StyleVural Gursel, I., Elbersen, B., Meesters, K. P. H., & van Leeuwen, M. (2022). Defining Circular Economy Principles for Biobased Products. Sustainability, 14(19), 12780. https://doi.org/10.3390/su141912780