Absorptive Capacity and Its Dual Effect on Technological Innovation: A Structural Equations Model Approach

Abstract

1. Introduction

2. Literature Review

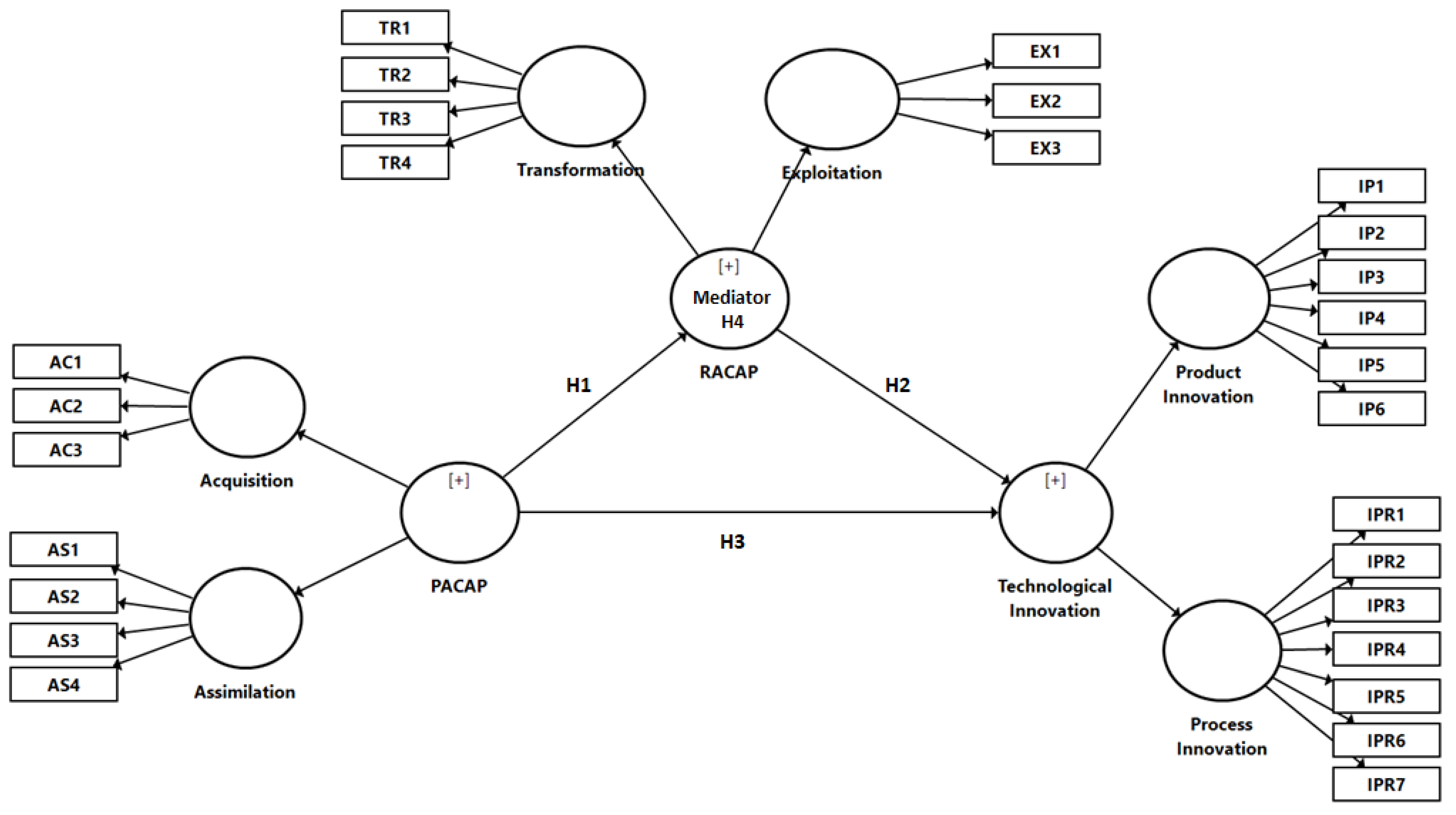

3. Materials and Methods

3.1. Sample Design and Data Gathering

3.2. Measurement of Variables

3.3. Common Method Variance

3.4. Reliability, Convergent, and Discriminant Validity

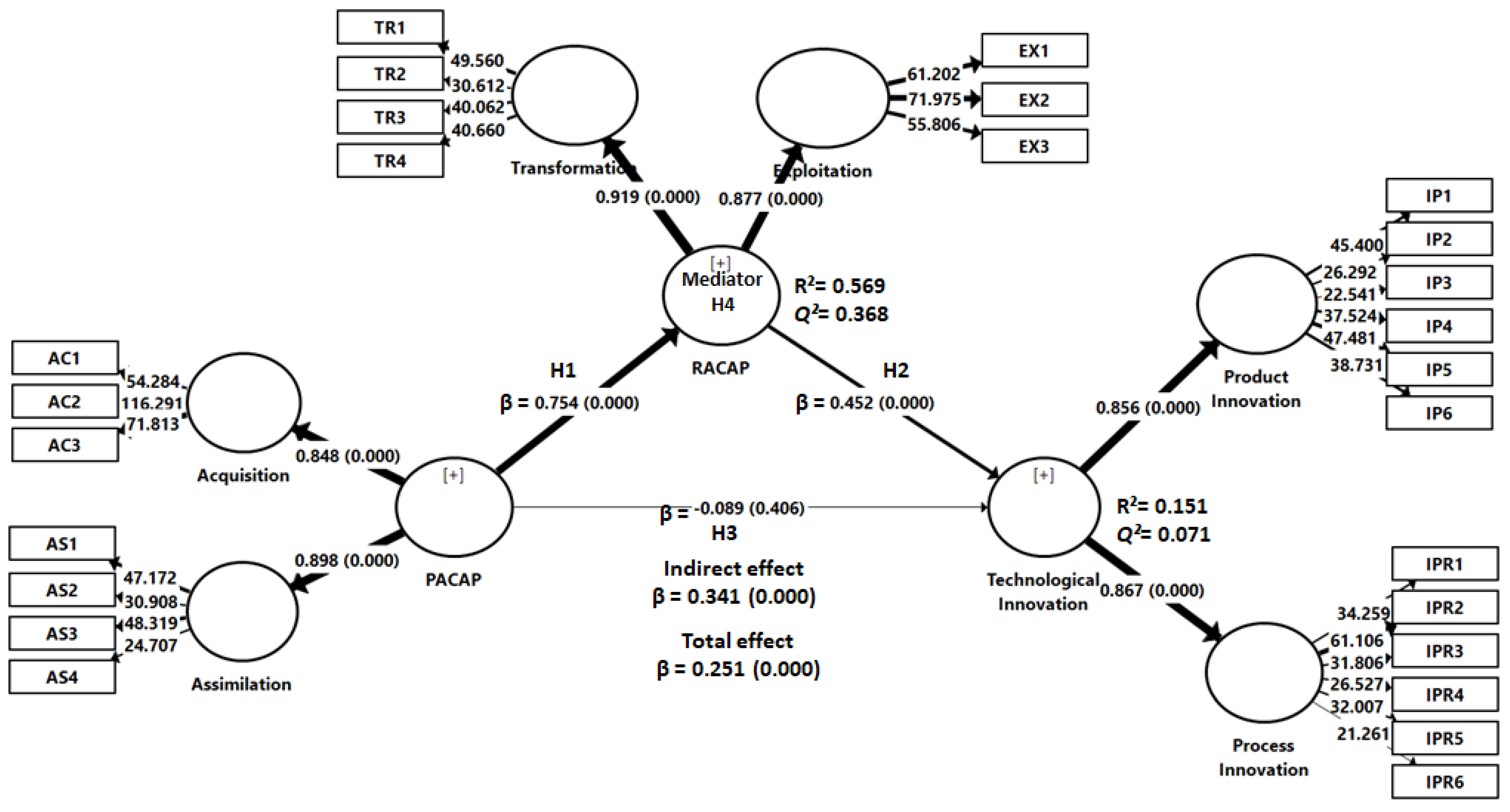

4. Results

5. Discussion

5.1. Managerial Implications

5.2. Theoretical Implications

6. Conclusions

Limitations and Future Research Avenues

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Limaj, E.; Bernroider, E.W.N. The Roles of Absorptive Capacity and Cultural Balance for Exploratory and Exploitative Innovation in SMEs. J. Bus. Res. 2019, 94, 137–153. [Google Scholar] [CrossRef]

- Taran, Y.; Boer, H.; Lindgren, P. A Business Model Innovation Typology. Decis. Sci. 2015, 46, 301–331. [Google Scholar] [CrossRef]

- Distel, A.P. Unveiling the Microfoundations of Absorptive Capacity: A Study of Coleman’s Bathtub Model. J. Manag. 2019, 45, 2014–2044. [Google Scholar] [CrossRef]

- Engelman, R.M.; Fracasso, E.M.; Schmidt, S.; Zen, A.C. Intellectual Capital, Absorptive Capacity and Product Innovation. Manag. Decis. 2017, 55, 474–490. [Google Scholar] [CrossRef]

- Flatten, T.C.; Engelen, A.; Zahra, S.A.; Brettel, M. A Measure of Absorptive Capacity: Scale Development and Validation. Eur. Manag. J. 2011, 29, 98–116. [Google Scholar] [CrossRef]

- Volberda, H.W.; Foss, N.J.; Lyles, M.A. Absorbing the Concept of Absorptive Capacity: How to Realize Its Potential in the Organization Field. Organ. Sci. 2010, 21, 931–951. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Cawley Vergara, A.M.; Garza-Reyes, J.A.; Sawhney, R. Organizational Learning Paths Based upon Industry 4.0 Adoption: An Empirical Study with Brazilian Manufacturers. Int. J. Prod. Econ. 2020, 219, 284–294. [Google Scholar] [CrossRef]

- Alvarenga, A.; Matos, F.; Godina, R.; Matias, J.C.O. Digital Transformation and Knowledge Management in the Public Sector. Sustainability 2020, 12, 5824. [Google Scholar] [CrossRef]

- Machado, D.A.d.S.; Barcelos, E.J.B.V.; Maccari, E.A.; Mazieri, M.R. Absorptive Capacity as a Strategy for Innovation in Service Microenterprises under Crisis Environment. Rev. Gestão Tecnol. 2020, 20, 28–50. [Google Scholar] [CrossRef]

- Kumar, N.; Rose, R.C.; Muien, N.F.A. The Influences of Absorptive Capacity and Social Capital on Knowledge Transfer. J. Appl. Bus. Res. 2009, 25, 99–108. [Google Scholar] [CrossRef]

- Cohen, W.M.; Levinthal, D.A. Absorptive Capacity: A New Perspective on Learning and Innovation. Adm. Sci. Q. 1990, 35, 128–152. [Google Scholar] [CrossRef]

- Bacon, E.; Williams, M.D.; Davies, G.H. Recipes for Success: Conditions for Knowledge Transfer across Open Innovation Ecosystems. Int. J. Inf. Manag. 2019, 49, 377–387. [Google Scholar] [CrossRef]

- Adams, D.R.; Flatten, T.C.; Brinkmann, H.; Brettel, M. Consequences and Antecedents of Absorptive Capacity in a Cross-Cultural Context. Int. J. Innov. Manag. 2016, 20, 1650003. [Google Scholar] [CrossRef]

- Petti, C.; Tang, Y.; Margherita, A. Technological Innovation vs Technological Backwardness Patterns in Latecomer Firms: An Absorptive Capacity Perspective. J. Eng. Technol. Manag. 2019, 51, 10–20. [Google Scholar] [CrossRef]

- Flor, M.L.; Cooper, S.Y.; Oltra, M.J. External Knowledge Search, Absorptive Capacity and Radical Innovation in High-Technology Firms. Eur. Manag. J. 2018, 36, 183–194. [Google Scholar] [CrossRef]

- Ali, M.; Ali, I.; Al-Maimani, K.A.; Park, K. The Effect of Organizational Structure on Absorptive Capacity in Single and Dual Learning Modes. J. Innov. Knowl. 2018, 3, 108–114. [Google Scholar] [CrossRef]

- Gao, S.; Yeoh, W.; Wong, S.F.; Scheepers, R. A Literature Analysis of the Use of Absorptive Capacity Construct in IS Research. Int. J. Inf. Manag. 2017, 37, 36–42. [Google Scholar] [CrossRef]

- Apriliyanti, I.D.; Alon, I. Bibliometric Analysis of Absorptive Capacity. Int. Bus. Rev. 2017, 26, 896–907. [Google Scholar] [CrossRef]

- Cuevas-Vargas, H.; Aguirre, J.; Parga-Montoya, N. Impact of ICT Adoption on Absorptive Capacity and Open Innovation for Greater Firm Performance. The Mediating Role of ACAP. J. Bus. Res. 2022, 140, 11–24. [Google Scholar] [CrossRef]

- Tsai, W. Knowledge Transfer in Intraorganizational Networks: Effects of Network Position and Absorptive Capacity on Business Unit Innovation and Performance. Acad. Manag. J. 2001, 44, 996–1004. [Google Scholar] [CrossRef]

- Zahra, S.A.; George, G. Absorptive Capacity: A Review, Reconceptualization, and Extension. Acad. Manag. Rev. 2002, 27, 185–203. [Google Scholar] [CrossRef]

- Camisón, C.; Forés, B. Knowledge Absorptive Capacity: New Insights for Its Conceptualization and Measurement. J. Bus. Res. 2010, 63, 707–715. [Google Scholar] [CrossRef]

- Ali, M.; Park, K. The Mediating Role of an Innovative Culture in the Relationship between Absorptive Capacity and Technical and Non-Technical Innovation. J. Bus. Res. 2016, 69, 1669–1675. [Google Scholar] [CrossRef]

- Cockburn, I.M.; Henderson, R.M. Absorptive Capacity, Coauthoring Behavior, and the Organization of Research in Drug Discovery. J. Ind. Econ. 2003, 46, 157–182. [Google Scholar] [CrossRef]

- Gölgeci, I.; Swiatowiec-Szczepanska, J.; Raczkowski, K. How Does Cultural Intelligence Influence the Relationships between Potential and Realised Absorptive Capacity and Innovativeness? Evidence from Poland. Technol. Anal. Strateg. Manag. 2017, 29, 857–871. [Google Scholar] [CrossRef]

- Cassol, A.; Gonçalo, C.R.; Ruas, R.L. Redefining the Relationship between Intellectual Capital and Innovation: The Mediating Role of Absorptive Capacity. Braz. Adm. Rev. 2016, 13, 1–25. [Google Scholar] [CrossRef]

- Leal-Rodríguez, A.L.; Roldán, J.L.; Ariza-Montes, J.A.; Leal-Millán, A. From Potential Absorptive Capacity to Innovation Outcomes in Project Teams: The Conditional Mediating Role of the Realized Absorptive Capacity in a Relational Learning Context. Int. J. Proj. Manag. 2014, 32, 894–907. [Google Scholar] [CrossRef]

- Yuwono, W. Empirical Analysis of Intellectual Capital, Potential Absorptive Capacity, Realized Absorptive Capacity and Cultural Intelligence on Innovation. Manag. Sci. Lett. 2021, 11, 1399–1406. [Google Scholar] [CrossRef]

- Duan, Y.; Huang, L.; Luo, X.; Cheng, T.C.E.; Liu, H. The Moderating Effect of Absorptive Capacity on the Technology Search and Innovation Quality Relationship in High-Tech Manufacturing Firms. J. Eng. Technol. Manag. 2021, 62, 101656. [Google Scholar] [CrossRef]

- Van De Ven, A.H.; Rogers, E.M. Innovations and Organizations: Critical Perspectives. Communic. Res. 1988, 15, 632–651. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Martin, J.A. Dynamic Capabilities: What Are They? Strateg. Manag. J. 2000, 21, 1105–1121. [Google Scholar] [CrossRef]

- Mir, M.; Casadesús, M.; Petnji, L.H. The Impact of Standardized Innovation Management Systems on Innovation Capability and Business Performance: An Empirical Study. J. Eng. Technol. Manag. 2016, 41, 26–44. [Google Scholar] [CrossRef]

- Lane, P.J.; Koka, B.R.; Pathak, S. The Reification of Absorptive Capacity: A Critical Review and Rejuvenation of the Construct. Acad. Manag. Rev. 2006, 31, 833–863. [Google Scholar] [CrossRef]

- Kanter, R.M. When a Thousand Flowers Bloom: Structural, Collective, and Social Conditions for Innovation in Organizations. In Knowledge Management and Organisational Design; Myers, P.S., Ed.; Butterworth-Heinemann: Newton, MA, USA, 1996; pp. 93–131. [Google Scholar]

- Annala, L.; Sarin, A.; Green, J.L. Co-Production of Frugal Innovation: Case of Low Cost Reverse Osmosis Water Filters in India. J. Clean. Prod. 2018, 171, S110–S118. [Google Scholar] [CrossRef]

- Stott, N.; Tracey, P. Organizing and Innovating in Poor Places. Innov. Organ. Manag. 2018, 20, 1–17. [Google Scholar] [CrossRef]

- von Janda, S.; Kuester, S.; Schuhmacher, M.C.; Shainesh, G. What Frugal Products Are and Why They Matter: A Cross-National Multi-Method Study. J. Clean. Prod. 2020, 246, 118977. [Google Scholar] [CrossRef]

- Agramunt, L.F.; Berbel-Pineda, J.M. The Positive Moderating Effect of Absorptive Capacity on R&investment: The Case of Argentina’s Ict Firms. An. Acad. Bras. Cienc. 2018, 90, 3207–3221. [Google Scholar] [CrossRef]

- Rangus, K.; Slavec, A. The Interplay of Decentralization, Employee Involvement and Absorptive Capacity on Firms’ Innovation and Business Performance. Technol. Forecast. Soc. Change 2017, 120, 195–203. [Google Scholar] [CrossRef]

- Kedia, B.L.; Bhagat, R.S. Cultural Constraints on Transfer Technology across Nations: Implications for Research in International and Comparative Management. Acad. Manag. Rev. 1998, 13, 559–571. [Google Scholar] [CrossRef]

- Todorova, G.; Durisin, B. Absorptive Capacity: Valuing a Reconceptualization. Acad. Manag. Rev. 2007, 32, 774–786. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- García-Sánchez, E.; García-Morales, V.J.; Martín-Rojas, R. Influence of Technological Assets on Organizational Performance through Absorptive Capacity, Organizational Innovation and Internal Labour Flexibility. Sustainability 2018, 10, 770. [Google Scholar] [CrossRef]

- Damanpour, F.; Schneider, M. Phases of the Adoption of Innovation in Organizations: Effects of Environment, Organization and Top Managers. Br. J. Manag. 2006, 17, 215–236. [Google Scholar] [CrossRef]

- Zheng, W.; Yang, B.; McLean, G.N. Linking Organizational Culture, Structure, Strategy, and Organizational Effectiveness: Mediating Role of Knowledge Management. J. Bus. Res. 2010, 63, 763–771. [Google Scholar] [CrossRef]

- Fosfuri, A.; Tribó, J.A. Exploring the Antecedents of Potential Absorptive Capacity and Its Impact on Innovation Performance. Omega Int. J. Manag. Sci. 2008, 36, 173–187. [Google Scholar] [CrossRef]

- Kamal, E.M.; Flanagan, R. Understanding Absorptive Capacity in Malaysian Small and Medium Sized (SME) Construction Companies. J. Eng. Des. Technol. 2012, 10, 180–198. [Google Scholar] [CrossRef]

- Denford, J.S. Building Knowledge: Developing a Knowledge-Based Dynamic Capabilities Typology. J. Knowl. Manag. 2013, 17, 175–194. [Google Scholar] [CrossRef]

- Kim, D.J.; Kogut, B. Technological Platforms and Diversification. Organ. Sci. 1996, 7, 283–301. [Google Scholar] [CrossRef]

- Davila, G.A.; Durst, S.; Varvakis, G. Knowledge Absorptive Capacity, Innovation, and Firm’s Performance: Insights from the South of Brazil. Int. J. Innov. Manag. 2018, 22, 1850013. [Google Scholar] [CrossRef]

- Mennens, K.; Van Gils, A.; Odekerken-Schröder, G.; Letterie, W. Exploring Antecedents of Service Innovation Performance in Manufacturing SMEs. Int. Small Bus. J. Res. Entrep. 2018, 36, 500–520. [Google Scholar] [CrossRef]

- Albort-Morant, G.; Henseler, J.; Cepeda-Carrión, G.; Leal-Rodríguez, A.L. Potential and Realized Absorptive Capacity as Complementary Drivers of Green Product and Process Innovation Performance. Sustainability 2018, 10, 381. [Google Scholar] [CrossRef]

- Cassol, A.; Zanesco, D.; Barsalini Martins, C.; Marietto, M.L. Capacidade Absortiva Como Moderadora Da Relação Entre Inovatividade Organizacional E Desempenho Inovador De Pequenas E Médias Empresas Brasileiras. Interciencia 2019, 44, 15–22. [Google Scholar]

- Yuwono, W.; Daihani, D.U.; Arafah, W. Empirical Testing of the Mediating Effect of Absorptive Capacity and Moderation of Cultural Intelligence on Intellectual Capital and Innovation Analysis on the Tourism Industry. In Proceedings of the International Conference on Management, Accounting, and Economy (ICMAE 2020); Atlantis Press SARL, 2020; Volume 151, pp. 243–247. [Google Scholar]

- Laviniki, J.; Laimer, C.G.; Rodrigues, C.; Marques, J.L. The Effect of Absorptive Capacity on the Financial Performance of Brazilian and Portuguese Companies in a Low Technological Intensity Sector. Braz. Bus. Rev. 2021, 18, 537–560. [Google Scholar] [CrossRef]

- Del Carpio Gallegos, J.F.; Miralles, F. Analyzing Technological Innovation in Low and Medium-Low Tech Peruvian Manufacturing Companies | Análisis de La Innovación Tecnológica En Las Empresas Peruanas de Manufactura de Baja y Media Baja Intensidad Tecnológica. Contad. Adm. 2019, 64, 1–22. [Google Scholar]

- Pateli, A.G.; Giaglis, G.M. Technology Innovation-Induced Business Model Change: A Contingency Approach. J. Organ. Chang. Manag. 2005, 18, 167–183. [Google Scholar] [CrossRef]

- Damanpour, F.; Gopalakrishnan, S. Theories of Organizational Structure and Innovation Adoption: The Role of Environmental Change. J. Eng. Technol. Manag. 1998, 15, 1–24. [Google Scholar] [CrossRef]

- Ince, H.; Imamoglu, S.Z.; Turkcan, H. The Effect of Technological Innovation Capabilities and Absorptive Capacity on Firm Innovativeness: A Conceptual Framework. Procedia-Soc. Behav. Sci. 2016, 235, 764–770. [Google Scholar] [CrossRef]

- Ringle, C.M.; Wende, S.; Becker, J.-M. SmartPLS 3 2015.

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Becker, J.-M.; Klein, K.; Wetzels, M. Hierarchical Latent Variable Models in PLS-SEM: Guidelines for Using Reflective-Formative Type Models. Long Range Plan. 2012, 45, 359–394. [Google Scholar] [CrossRef]

- Lohmöller, J.-B. Latent Variable Path Modeling with Partial Least Squares; Physica: Heidelberg, Germany, 1989. [Google Scholar]

- Ringle, C.M.; Sarstedt, M.; Straub, D.W. Editor’s Comments: A Critical Look at the Use of PLS-SEM in MIS Quarterly. MIS Q. 2012, 36, iii–xiv. [Google Scholar] [CrossRef]

- Wetzels, M.; Odekerken-Schröder, G.; van Oppen, C. Using PLS Path Modeling for Assessing Hierarchical Construct Models: Guidelines and Empirical Illustration. MIS Q. 2009, 33, 177–195. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS_SEM), 3rd ed.; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2022. [Google Scholar]

- INEGI National Economic Units’ Statistical Directory. Available online: https://bit.ly/3r79yx1 (accessed on 7 August 2019).

- Cohen, J. A Power Primer. Psychol. Bull. 1992, 112, 155–159. [Google Scholar] [CrossRef] [PubMed]

- Roldán, J.L.; Sánchez-Franco, M.J. Variance-Based Structural Equation Modeling: Guidelines for Using Partial Least Squares in Information Systems Research. In Research Methodologies, Innovations and Philosophies in Software Systems Research; Mora, M., Gelman, O., Steenkamp, A.L., Raisinghani, M., Eds.; IGI Global: Hershey, PA, USA, 2012; pp. 193–221. ISBN 9781466601796. [Google Scholar]

- Hair, J.F.; Sarstedt, M.; Ringle, C.M.; Mena, J.A. An Assessment of the Use of Partial Least Squares Structural Equation Modeling in Marketing Research. J. Acad. Mark. Sci. 2012, 40, 414–433. [Google Scholar] [CrossRef]

- Cuevas-Vargas, H. La Influencia de La Innovación y La Tecnología En La Competitividad de Las Pymes Manufactureras Del Estado de Aguascalientes. Ph.D. Thesis, Universidad Autónoma de Aguascalientes, Aguascalientes, Mexico, 2016. [Google Scholar]

- OECD; Eurostat. Oslo Manual 2018: Guidelines for Collecting, Reporting and Using Data on Innovation, 4th ed.; OECD Publishing: Paris, France; Eurostat: Luxembourg, 2018; ISBN 9789264304550. [Google Scholar]

- Rodríguez-Ardura, I.; Meseguer-Artola, A. Editorial: How to Prevent, Detect and Control Common Method Variance in Electronic Commerce Research. J. Theor. Appl. Electron. Commer. Res. 2020, 15, I–V. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Organ, D.W. Self-Reports in Organizational Research: Problems and Prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Kock, N. Common Method Bias in PLS-SEM: A Full Collinearity Assessment Approach. Int. J. e-Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Nunnally, J.C.; Bernstein, I.H. Psychometric Theory, 3rd ed.; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A New Criterion for Assessing Discriminant Validity in Variance-Based Structural Equation Modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Clark, L.A.; Watson, D. Constructing Validity: Basic Issues in Objective Scale Development. Psychol. Assess. 1995, 7, 309–319. [Google Scholar] [CrossRef]

- Chin, W.W. The Partial Least Squares Approach to Structural Equation Modeling. In Modern Methods for Business Research; Marcoulides, G.A., Ed.; Lawrence Erlbaum Associates Publishers: Mahwah, NJ, USA, 1998; pp. 295–358. [Google Scholar]

- Falk, R.F.; Miller, N.B. A Primer for Soft Modeling; University of Akron Press: Akron, OH, USA, 1992. [Google Scholar]

- Stone, M. Cross-Validatory Choice and Assessment of Statistical Predictions. J. R. Stat. Soc. Ser. B 1974, 36, 111–147. [Google Scholar] [CrossRef]

- Geisser, S. A Predictive Approach to the Random Effect Model. Biometrika 1974, 61, 101–107. [Google Scholar] [CrossRef]

- Faul, F.; Erdfelder, E.; Buchner, A.; Lang, A.G. Statistical Power Analyses Using G*Power 3.1: Tests for Correlation and Regression Analyses. Behav. Res. Methods 2009, 41, 1149–1160. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Lynch, J.G.J.; Chen, Q. Reconsidering Baron and Kenny: Myths and Truths about Mediation Analysis. J. Consum. Res. 2010, 37, 197–206. [Google Scholar] [CrossRef]

- Carvalho, E.G.; Sugano, J.Y. Entrepreneurial Orientation and Open Innovation in Brazilian Startups: A Multicase Study. Interações 2016, 17, 448–462. [Google Scholar] [CrossRef]

- Xin, K.; Sun, Y.; Zhang, R.; Liu, X. Debt Financing and Technological Innovation: Evidence from China. J. Bus. Econ. Manag. 2019, 20, 841–859. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. The Role of Absorptive Capacity and Innovation Strategy in the Design of Industry 4.0 Business Models-A Comparison between SMEs and Large Enterprises. Eur. Manag. J. 2021, 39, 333–343. [Google Scholar] [CrossRef]

- Moeller, K.; Steinman, J.-C.; Calabretta, G. Implications from Innovativeness Typology on Innovation Performance Measurement: A Bibliometric Analysis. In Proceedings of the 2014 European Academy of Management Conference (EURAM), Valencia, Spain, 4–7 June 2014; pp. 1–38. [Google Scholar]

- Jackson, P.; Richter, N. Situational Logic: An Analysis of Open Innovation Using Corporate Accelerators. Int. J. Innov. Manag. 2017, 21, 1750062. [Google Scholar] [CrossRef]

- Weiblen, T.; Chesbrough, H.W. Engaging with Startups to Enhance Corporate Innovation. Calif. Manag. Rev. 2015, 57, 66–90. [Google Scholar] [CrossRef]

- Schueffel, P. The Effects of Entrepreneurial Orientation on Innovation Performance, Open Innovation Proclivity, and Openness. In Proceedings of the 2014 Annual Meeting of the Academy of Management, Philadelphia, PA, USA, 1–5 August 2014. [Google Scholar]

- Zhai, Y.M.; Sun, W.Q.; Tsai, S.B.; Wang, Z.; Zhao, Y.; Chen, Q. An Empirical Study on Entrepreneurial Orientation, Absorptive Capacity, and SMEs’ Innovation Performance: A Sustainable Perspective. Sustainability 2018, 10, 314. [Google Scholar] [CrossRef]

| Constructs | Indicators (Manifest Variables) | Convergent Validity | Reliability | |||

|---|---|---|---|---|---|---|

| Factor Loading >0.7 | t-Value >2.57 | AVE | CR | Cronbach’s Alpha | ||

| >0.5 | >0.7 | >0.7 | ||||

| Acquisition | AC1-Information about our industry | 0.903 *** | 54.284 | 0.860 | 0.949 | 0.918 |

| AC2-Motivation to use information from our industry | 0.956 *** | 116.291 | ||||

| AC3-Our management encourages workers to use information outside of the industry | 0.922 *** | 71.813 | ||||

| Assimilation | AS1-Communication between departments | 0.880 *** | 47.172 | 0.750 | 0.923 | 0.889 |

| AS2-Support between departments to solve problems | 0.875 *** | 30.908 | ||||

| AS3-There is information flow | 0.882 *** | 48.319 | ||||

| AS4-There are departmental meetings and take advantage of the flow of information | 0.827 *** | 24.707 | ||||

| Transformation | TR1-The flow of information is structured | 0.881 *** | 49.560 | 0.782 | 0.935 | 0.907 |

| TR2-Our employees are willing to absorb knowledge | 0.892 *** | 30.612 | ||||

| TR3-Employees standardize the knowledge acquired | 0.879 *** | 40.062 | ||||

| TR4-Employees apply new knowledge | 0.885 *** | 40.660 | ||||

| Exploitation | EX1-New prototypes are developed | 0.918 *** | 61.202 | 0.854 | 0.946 | 0.915 |

| EX2-New technologies are freadapted | 0.941 *** | 71.975 | ||||

| EX3-The company adapts to the adoption of technologies | 0.914 *** | 55.806 | ||||

| Product innovation | IP1-New products/services are accepted by the market | 0.864 *** | 45.400 | 0.721 | 0.939 | 0.923 |

| IP2-Our new products are environmentally friendly | 0.830 *** | 26.292 | ||||

| IP3-Our new or improved products/services are imitated by our competitors | 0.810 *** | 22.541 | ||||

| IP4-Our new or improved products/services are brought to market faster than the competition | 0.864 *** | 37.524 | ||||

| IP5-We have better R&D capability than our competitors | 0.865 *** | 47.481 | ||||

| IP6-We make new products with the existing ones | 0.861 *** | 38.731 | ||||

| Process innovation | IPR1-Process technology is systematized in real-time | 0.815 *** | 34.259 | 0.675 | 0.925 | 0.903 |

| IPR2-New equipment available to improve product quality | 0.897 *** | 61.106 | ||||

| IPR3-Our new processes increase production capacity | 0.847 *** | 31.806 | ||||

| IPR4-Efficient manufacturing processes are developed | 0.804 *** | 26.527 | ||||

| IPR5-We have equipment that makes materials and energy efficient | 0.793 *** | 32.007 | ||||

| IPR6-Equipment can be flexible to meet customer requirements | 0.767 *** | 21.261 | ||||

| HOCs | Latent variables | Path coefficient | AVE | CR | Cronbach’s Alpha | |

| PACAP | Acquisition of knowledge | 0.848 | 0.611 | 0.916 | 0.893 | |

| Assimilation of knowledge | 0.898 | |||||

| RACAP | Transformation of knowledge | 0.919 | 0.659 | 0.931 | 0.914 | |

| Exploitation of knowledge | 0.877 | |||||

| TI | Product innovation | 0.856 | 0.516 | 0.927 | 0.914 | |

| Process innovation | 0.867 | |||||

| Constructs | Acquisition | Assimilation | Transformation | Exploitation | Product inn. | Process inn. |

|---|---|---|---|---|---|---|

| AVE = 0.860 | AVE = 0.750 | AVE = 0.782 | AVE = 0.854 | AVE = 0.721 | AVE = 0.675 | |

| Acquisition | 0.927 | [0.583] | [0.561] | [0.596] | [0.204] | [0.433] |

| Assimilation | 0.529 | 0.866 | [0.759] | [0.670] | [0.138] | [0.357] |

| Transformation | 0.513 | 0.683 | 0.884 | [0.676] | [0.098] | [0.478] |

| Exploitation | 0.547 | 0.605 | 0.616 | 0.924 | [0.188] | [0.545] |

| Product inn. | 0.186 | −0.114 | 0.091 | 0.176 | 0.849 | [0.521] |

| Process inn. | 0.392 | 0.316 | 0.430 | 0.494 | 0.485 | 0.821 |

| HOCs | PACAP | RACAP | Technological Innovation |

|---|---|---|---|

| AVE = 0.611 | AVE = 0.659 | AVE = 0.516 | |

| PACAP | 0.781 | [0.834] | [0.370] |

| RACAP | 0.754 | 0.812 | [0.411] |

| Technological Innovation | 0.251 | 0.384 | 0.719 |

| Hypotheses | Path | Standardized Coefficient β | t-Value | Decision | R² |

|---|---|---|---|---|---|

| H1 | PACAP → RACAP | 0.754 *** | 24.575 | Supported | 0.569 |

| H2 | RACAP → Technological innovation | 0.452 *** | 4.534 | Supported | 0.151 |

| H3 | PACAP → Technological innovation | −0.089 N.S. | 0.832 | Not supported | |

| H4 | PACAP → RACAP → Technological innovation | 0.341 *** | 4.360 | Supported |

| Path Mediation Relationships | Direct Effect p3 | 95% CI Bias-Corrected | Indirect Effect 1 p1 * p2 | 95% CI Bias-Corrected |

|---|---|---|---|---|

| PACAP → RACAP→ Technological innovation | −0.089 | [−0.299, 0.121] | 0.341 | [0.188, 0.493] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cuevas-Vargas, H.; Cortés-Palacios, H.A.; Leana-Morales, C.; Huerta-Mascotte, E. Absorptive Capacity and Its Dual Effect on Technological Innovation: A Structural Equations Model Approach. Sustainability 2022, 14, 12740. https://doi.org/10.3390/su141912740

Cuevas-Vargas H, Cortés-Palacios HA, Leana-Morales C, Huerta-Mascotte E. Absorptive Capacity and Its Dual Effect on Technological Innovation: A Structural Equations Model Approach. Sustainability. 2022; 14(19):12740. https://doi.org/10.3390/su141912740

Chicago/Turabian StyleCuevas-Vargas, Héctor, Héctor Abraham Cortés-Palacios, Cid Leana-Morales, and Eduardo Huerta-Mascotte. 2022. "Absorptive Capacity and Its Dual Effect on Technological Innovation: A Structural Equations Model Approach" Sustainability 14, no. 19: 12740. https://doi.org/10.3390/su141912740

APA StyleCuevas-Vargas, H., Cortés-Palacios, H. A., Leana-Morales, C., & Huerta-Mascotte, E. (2022). Absorptive Capacity and Its Dual Effect on Technological Innovation: A Structural Equations Model Approach. Sustainability, 14(19), 12740. https://doi.org/10.3390/su141912740