1. Introduction

Nature-based Solutions (NbS) are implemented actions which are inspired and supported by nature and recently became one key strategy to achieve sustainability under all environmental, economic, and social perspectives. They are designed to address a range of environmental challenges in an efficient and adaptable manner, while providing economic, social, and environmental benefits simultaneously [

1]. NbS is an umbrella term which includes other keywords like Green Infrastructure, Ecosystem-based Adaption, and Ecosystem Services [

2]. Recently, NbS are visible in urban environments. For example, the benefits of Green Infrastructures in cities have been adopted for decades and they are well recognised for reducing the impact of pollutants and noise. However, nowadays, due to fast urban growth, it is a challenge to increase the density of green areas on horizontal surfaces (e.g., open public gardens and parks).

Green roofs and green walls therefore became NbS with high potential for increasing green density. Vertical Green Structures (VGS) are a more recent development compared to green roofs, and they are becoming of high interest in research and commercial areas. In comparison to green roofs, VGS contribute more to the enhancement of social wellbeing by providing stronger visual engagement of people with greenery and as being more easily implemented on existing buildings. The challenges are related to ownership, management, and economic issues, as evidenced by a recent study based on the collection of data from the city administration and specific case studies located in Ljubljana in Slovenia [

3].

Understanding how these systems have developed over the decades is crucial to have better knowledge of the technological innovations dealing with green walls solutions. There are very famous ancestors of VGS in antiquity. The first—the Hanging Gardens of Babylon—dates back to the 7th century BC. Later, the vineyards from Roman times date back to the 3rd century BC, when Romans trained vines by growing them on villa walls and garden trellis [

4,

5]. Therefore, the solution of growing climbing species up on the facades has always existed in human history. Starting the 1920s, the British and North American garden cities movement promoted the integration of house and garden through features like pergolas, trellis structures, and climbing plants. The first patent of a Living Wall (LW) is also traceable back to those decades when Stanley Hart White, a professor from University of Illinois Urbana-Champaign (USA), invented the system named ‘Botanical Brick’ [

6].

In recent decades, VGS was realised by governments to achieve effective, liveable, and sustainable urban planning. In 1984, Biotope Area Factor (BAF) developed and implemented VGSs at urban scale as an ecological enhancement [

7]. Between 2013 and 2016, in London, the Mayor’s Air Quality Fund installed 1012 sq.m. of LW [

8]. In 2013, in Paris, more than 100 VGSs were installed as part of city policy. Between 2014 and 2020, the Mayor of Paris committed a further EUR 2,000,000 budget to the project ‘Des Jardins sur les Murs’ to revegetate the city. In Italy, a law (Law 14 January 2013, n.10) identified the importance of vegetation for the environment, and the need to increase and develop public and private green areas with the use of VGS [

9].

Despite these examples of awareness existing at governmental level, a recent review [

10] conducted on incentive policies to promote the implementation of green roofs and green walls detected 143 different incentives in 113 different cities. Of them, only 22 incentives supported the installation of green walls, together with green roofs. The rest supported green roof installations only, showing the existing gap regarding VGSs. Besides this, no exclusive funds or incentive policies were devoted to the promotion of green walls alone.

VGSs bring different benefits through ecosystem services. Most significantly, they improve the air quality by the plants’ ability to deposit, disperse, and absorb particulate matters, and/or by uptake of gaseous pollutants [

11,

12,

13]. Secondly, they decrease the heat island effect diminishing temperature and improving thermal behaviour of buildings [

14,

15,

16]. They create a microclimate by producing changes in ambient conditions such as temperature and humidity of air layers and airflow in the proximity of the building skin [

17]. Moreover, they enhance biodiversity [

18,

19] both for flora and fauna, decrease noise level [

20], and supply food [

21,

22]. Due to their visual impact, they also contribute to wellbeing and healing physical and mental health [

23,

24]. These benefits are promising; however, there are some crucial question marks about use, maintenance, affordability, environmental impact, and durability of VGS. These create sustainability concerns from the economic and environmental point of view. Apart from their aesthetical value, it is important to evaluate the optimal criteria in the choice of VGSs. Guidelines about maintenance and management of VGSs are currently missing in the literature.

In addition to the above listed benefits, improving Indoor Air Quality (IAQ) has to be mentioned as one of the important motivations for the indoor installation of VGS. Some of them are known as ‘active bio-filters’ having a design with fans that force the air flow. There are recent studies in the literature that, using computational fluid dynamic methods, investigate how to improve the efficiency of the system through novel air flow distribution [

25,

26,

27]. In [

25], the results showed that the capacity of bio filtration is maximised when the percentage of air flow passing through the module decreases. Therefore, volatile organic compounds (VOCs) and particulate matters PMs are both reduced in the environment. In [

26], the authors tested how the air flow distribution is affected from wetting the substrate and from adding a top cover on the module. They found that, when the substrate is saturated with water, the air flow moves through it more easily, becoming cleaner than when dry. In [

27], the effect of the same green wall on the air temperature and humidity is investigated. Regarding temperature, authors found an average temperature decrease of 1 °C and 3 °C in day and night respectively. On the other hand, humidity was higher by approximately 25% during both day and night due to moisture content of the substrate.

There are some reviews in the literature reporting on VGS types [

5,

28,

29,

30]. However comprehensive and homogeneous research to define the products implemented in situ is still very limited. Tamási and Dobszay [

31] conducted a study on 30 LWs in Hungary at country scale with the scope of examining the practical use and requirements of these systems. More comprehensive market reviews are needed that consider the advantages and disadvantages of systems when implemented in real case studies that evaluate the level of environmental and economic sustainability of the existing VGS typologies.

Due to this identified lack of knowledge and growth of VGS market day by day, the present contribution aims to categorise VGSs in the market by proposing a taxonomy and to highlight the direction of emerging trends. By following these trends, different products are evaluated considering economic (e.g., ease of maintenance and cost) and environmental (e.g., recyclability and environmental impact) features.

This paper may be read as a market review for possible interested actors. This paper presents the data collection approach in the

Section 2. In the Results, we highlight existing products’ characteristics in terms of components and materials and underlining their similarities and differences. In the Discussion, the main classes are assessed based on selected criteria with special attention to the sustainability features of products. Finally, in the Conclusion, some suggestions are made to improve sustainability of VGS together with future research needs.

2. Materials and Methods

In this work, 142 products from 58 manufacturers were analysed. The data are web-based. The information was extracted from the producers’ web pages as well as brochures, technical drawings, catalogues, and reports (

Appendix B). To identify producers’ web pages, the Google search engine was used with the following keywords: ‘green wall producers’, ‘companies’, ‘manufacturers’.

The results returned by Google were examined over the first 5 pages. Among the results, companies’ web pages, online architecture, and design marketplaces which connect suppliers and consumers (e.g.,

https://www.archiexpo.com/, accessed on 25 August 2022) were especially analysed. We created a new database from this collected information. This database contains names of manufacturers, the products they produce, and the country of origin of the company (

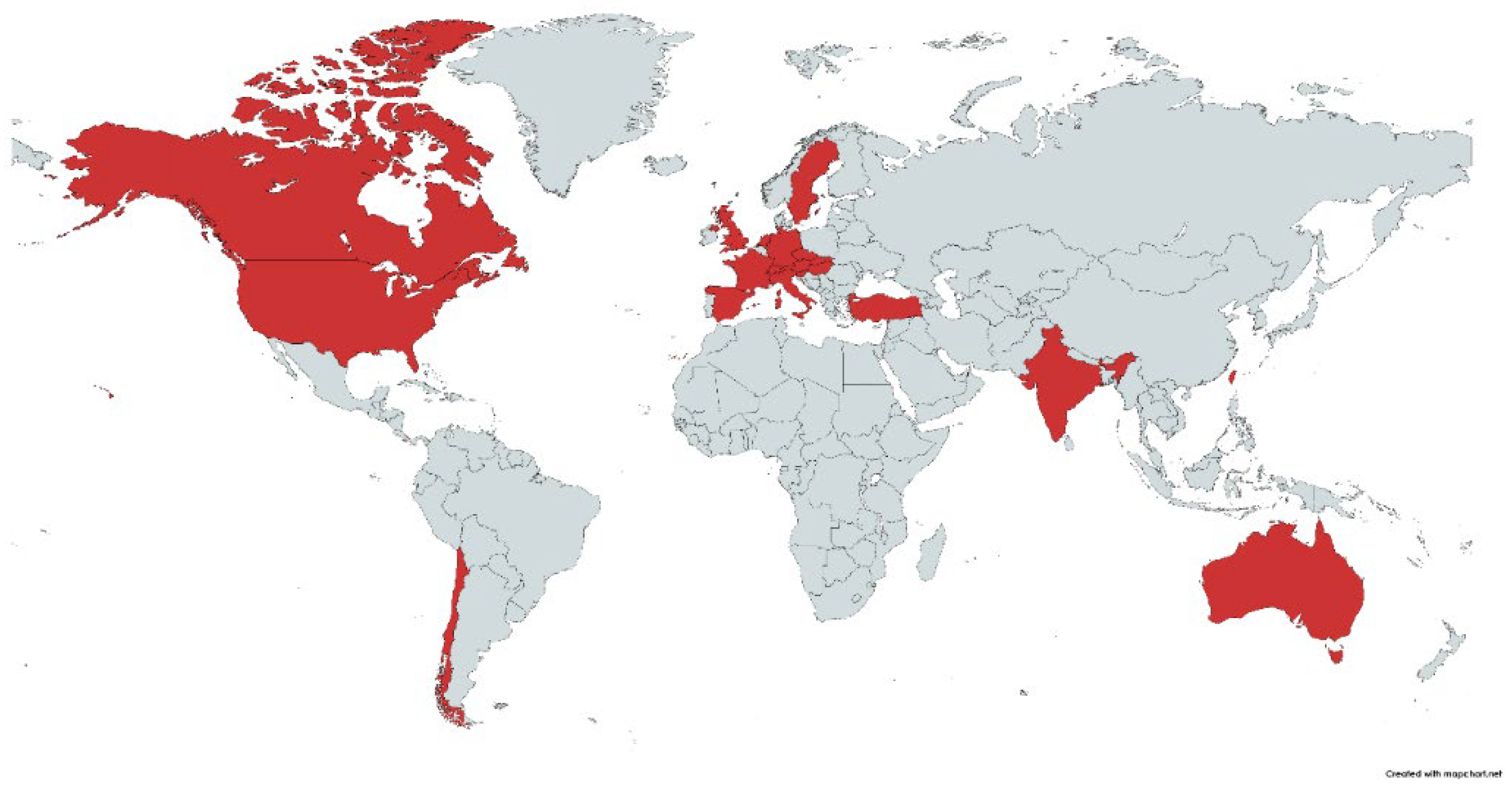

Appendix A). In total, as reported in

Figure 1, we evaluated products from Asia (India, Taiwan, Turkey), America (Canada, USA, Chile), Europe (Austria, Czech Republic, France, Germany, Hungary, Italy, Netherlands, Slovenia, Spain, Sweden, Switzerland, UK), and Australia.

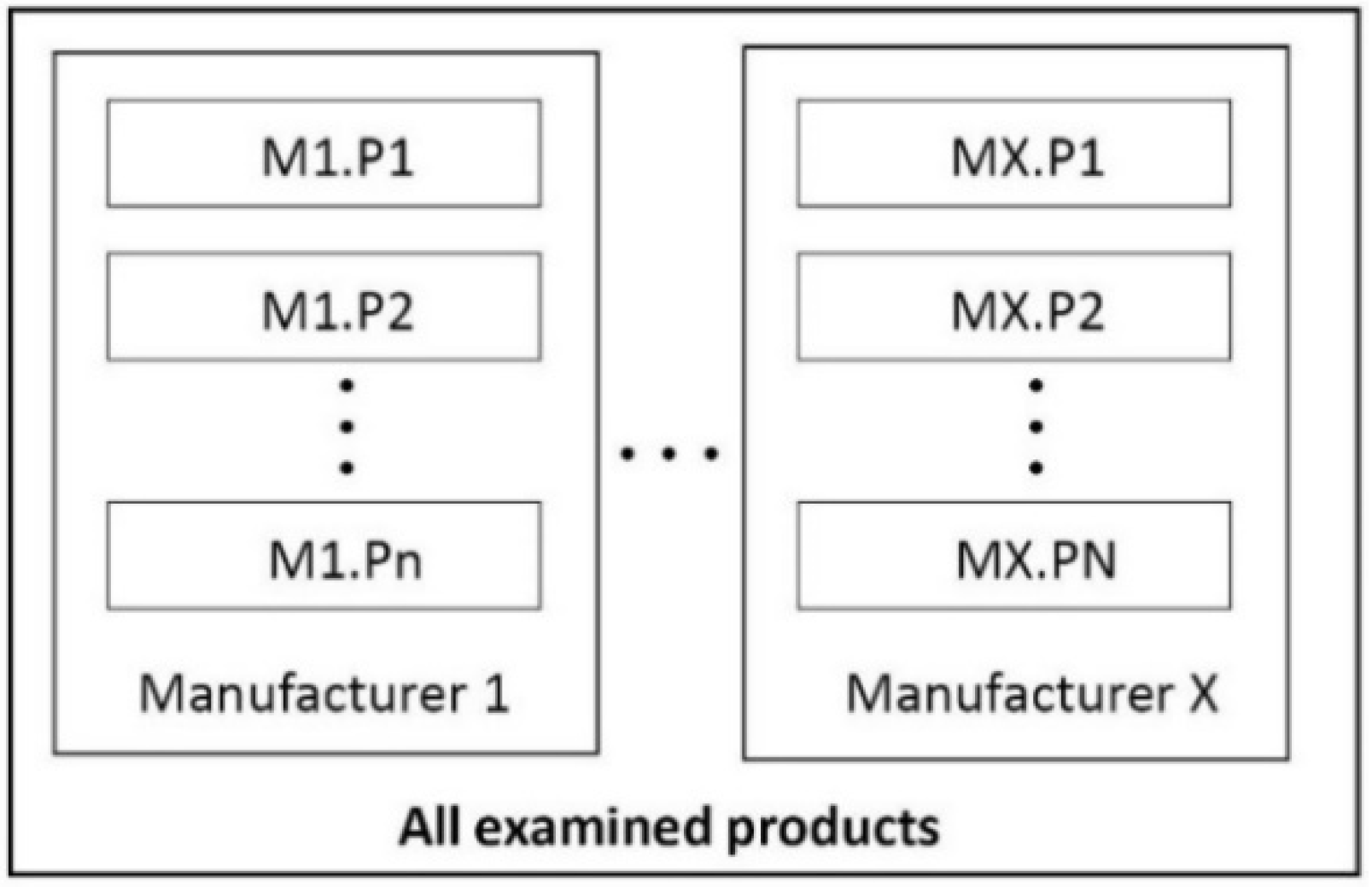

As companies produce more than one product, each product was inserted in the database after being numbered following an alphanumeric order (e.g., M1.P1, …, M1.Pn) being the nth products produced by a single manufacturer (see

Figure 2).

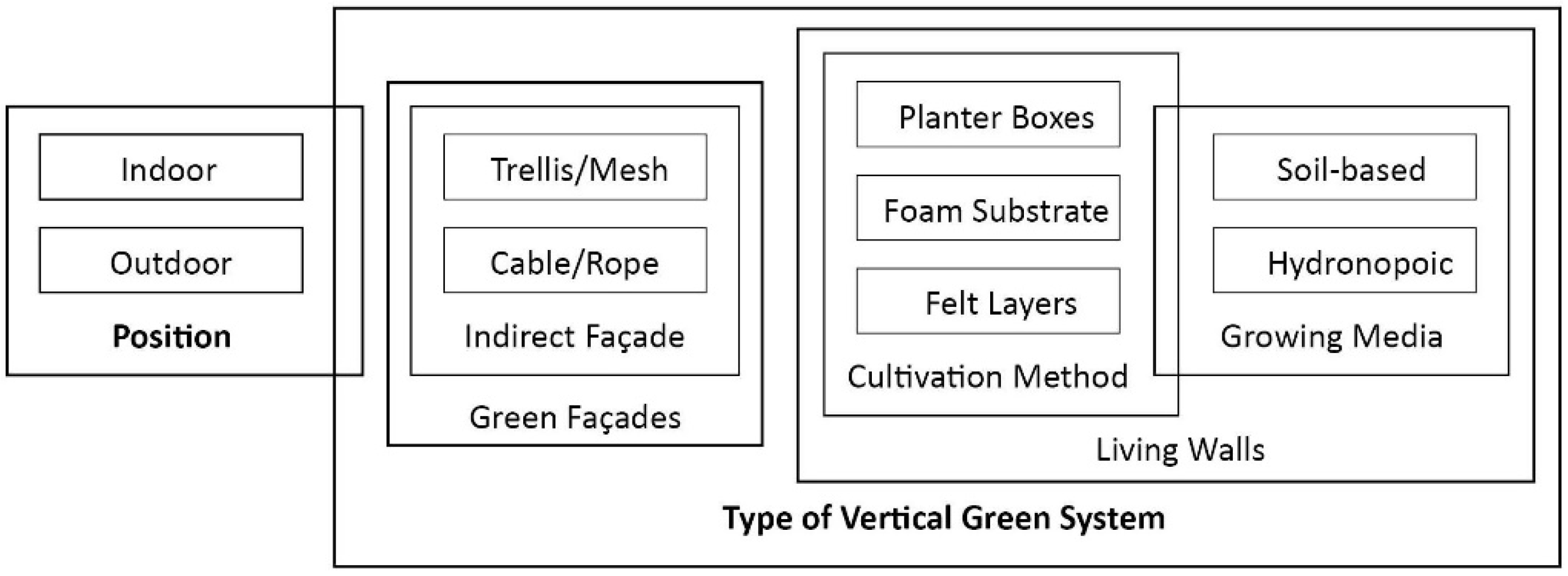

As a further step, products were sorted based on two main classes i.e., position (e.g., indoors or outdoors) and type (i.e., Green Façades (GFs) and Living Walls (LWs)) (see

Figure 3).

Among the 142 products, 24 of them (circa 17%) belong to GFs, whereas the rest are LWs (circa 83%). These products have a suggested place of installation that in 53% of cases is outdoors, in 21% of cases indoors, and in 26% of cases both outdoors and indoors. This principal characterisation is represented as pie charts (first line in

Figure 4).

As all the products are comprised of several components (sometimes different in number), materials, and system construction characteristics, the VGS data was further analysed—in the case of the LW—looking at the cultivation method, and at the growing media (Orange coloured pie charts in

Figure 4). In the case of the GF, instead, we looked at the use of trellis/mesh (IGFT) or cable/rope (IGFC) as supporting structures (blue coloured pie chart in

Figure 4). Among all the studied products, a few samples for each typology were selected critically to cover products that are constructed with different methods and/or materials. Afterward, some sustainability features were assessed by using a three-level scale categorisation (

Table 1).

3. Results

The database regarding classification of analysed products is the first result of this contribution (

Appendix C). It is worth noting that, in the analysis of the percentage (second line of

Figure 4) of products, when a product had several sub-products under the same name but with small differences, these similar sub-products were counted once. The preserved moss walls are also not included in this analysis as they require almost no maintenance since they do not require any soil, substrate, or water. Additionally, some producers named their products as vertical gardens although they do not use real plants. These “fake green walls” were excluded in the present analysis.

In the following sub-section, the analysed taxonomy of VGS is presented by a detailed analysis of the components’ crucial environmental and economic features.

3.1. Available Products’ Components: VGS Taxonomy and Wide Components

Vertical green refers to all forms of vegetated wall surfaces and mainly divided into two groups according to absence or presence of the following components: supporting elements, growing media, vegetation, drainage, and irrigation [

5] as shown by the taxonomy scheme in

Figure 5. GFs require low technology and fewer components in comparison to LWs. GF classification can be based on where plants are rooted. They can be rooted using the soil on the ground or using planting boxes (PB) according to the height of the facade.

LWs can be classified into minor categories by considering several characteristics: type of supporting system, method of cultivation, growing media, and integration potential (see

Figure 5).

The existing elements in all VGS are defined in this paper as VGS-wide components. The VGS-wide components are Vegetation (

Section 3.1.1), Structural Support System (

Section 3.1.2), and Growing Media (

Section 3.1.3). Direct GFs are not included among these typologies since there is no need for any industrial manufacturing.

3.1.1. Vegetation

A great diversity of species can be used for VGS, namely, both deciduous and evergreen. The selection of vegetation is based on climate conditions and available light in the environment.

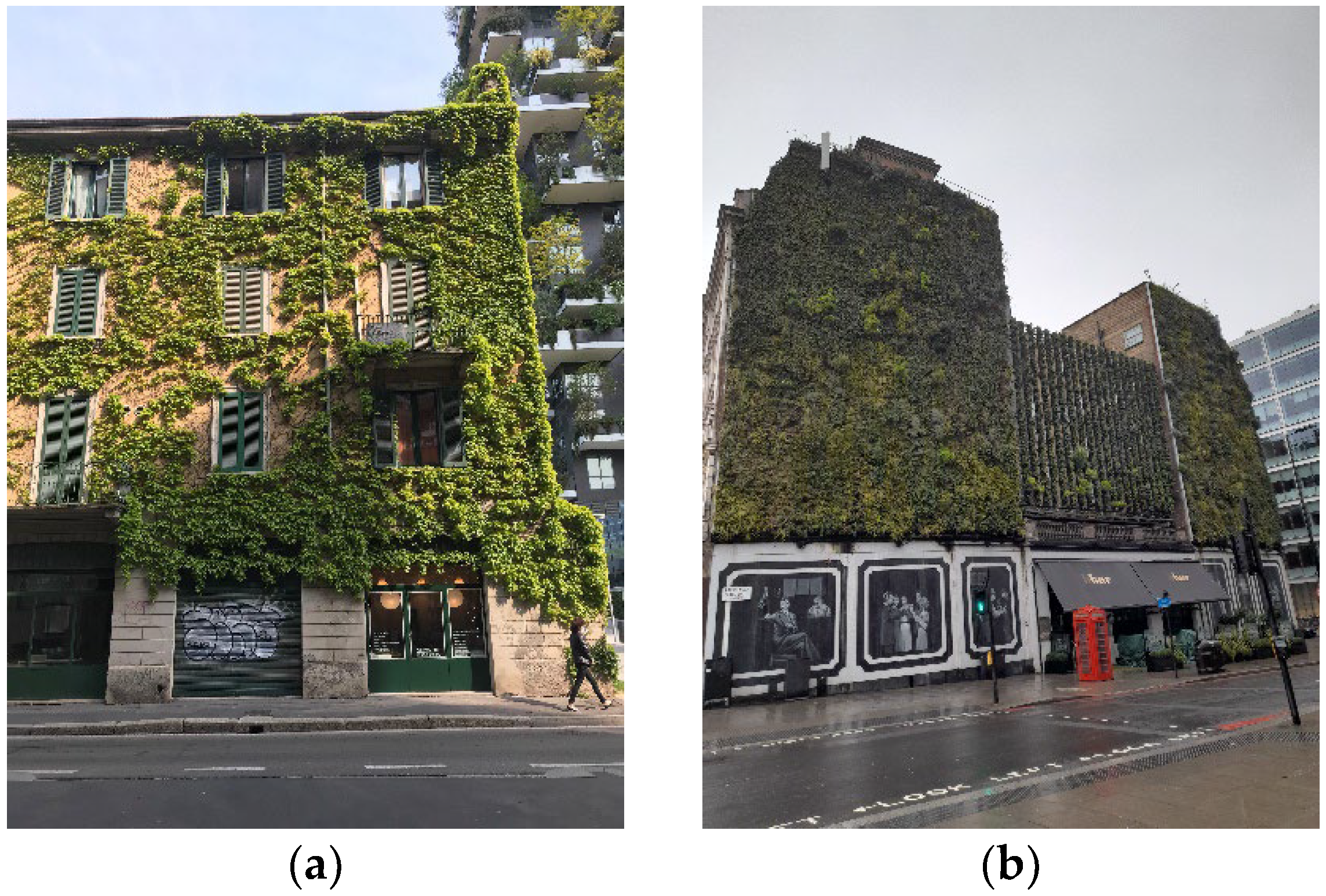

Vegetation in Green Facades (GFs) mainly consists of climbing and self-clinging species (

Figure 6a) such as English ivy (

Hedera Helix), Boston ivy (

Parthenocissus tricuspidata), or cascading groundcover and hedging plants. M17 uses different plant options like Honeysuckle, Jasmine, and Black-eyed Susan, which are main-stem twiners, or twine with their leaf structure. P17.48 is developed according to behaviour of plant growth which gives the possibility to enrich plant species for GFs. Some vine types use thin wiry tendril structures along the stem that can twine or curl around another plant or a component of a facade trellis like Clematis and Passionflower. There are also plants (e.g., runners and scramblers) that use plant attachment like leaf hooking, thorns, and plant strength for hooking partially around a trellis structure until the growth advances to the surrounding support elements.

Vegetation in Living Walls (LWs) is constituted by various plants species (grasses, perennial plants, shrubs, succulents, herbs, and vegetables). Caixa Forum Museum (Madrid) VGS has 15,000–17,000 plants, whose selection of varieties of native plants depends on season. This facade is covered with P39.101. Blanc [

32] selects the species according to their ability to grow in that specific environment under that available light. P46.113 holds up to 49 plants over each sq.m. Their planting strategy is inspired by the location. For example, their project in London shows a patchwork created with 10 species (i.e.,

Fatsia japonica,

Hedera helix,

Polystychum munitum,

Sarcococca confuse,

Cyrtomium falcatum,

Mahonia quifolium,

Pachysandra terminalis,

Soleirolia soleirolii,

Liriope muscari,

Asplenium scolopodrioum).

Another example is London’s largest LW (

Figure 6b) that is designed by Gary Grant. It is 21 m tall and covers a 350 sq.m. facade. It contains 10,000 plants and 16 tons of soil to reduce flooding [

33]. The species include buttercups, crocuses, strawberries, spring bulbs and geraniums.

3.1.2. Structural Support System

Since direct green facades are not included to these analyses, the structural support system is considered as a VGS-wide component. This system provides the strength to VGS and carries and transfers safely all the loads that are caused by each component.

Structural support in Green Facades (GFs) is crucial for the vegetation, especially in tall buildings. In such a case, supporting structures are made of various materials (e.g., coated, stainless steel, galvanized steel, aluminium, or plastic). Each of the constituting materials changes the aesthetical and functional properties of the VGS due to different weight, profile thickness, durability, and cost [

34]. Finally, facades clad (e.g., with glass, steel, or concrete) have to be taken into consideration as additional important parameters [

35]. In literature, except for the freestanding structures that are not in contact with walls, there are two available systems i.e., modular trellis and cable/rope.

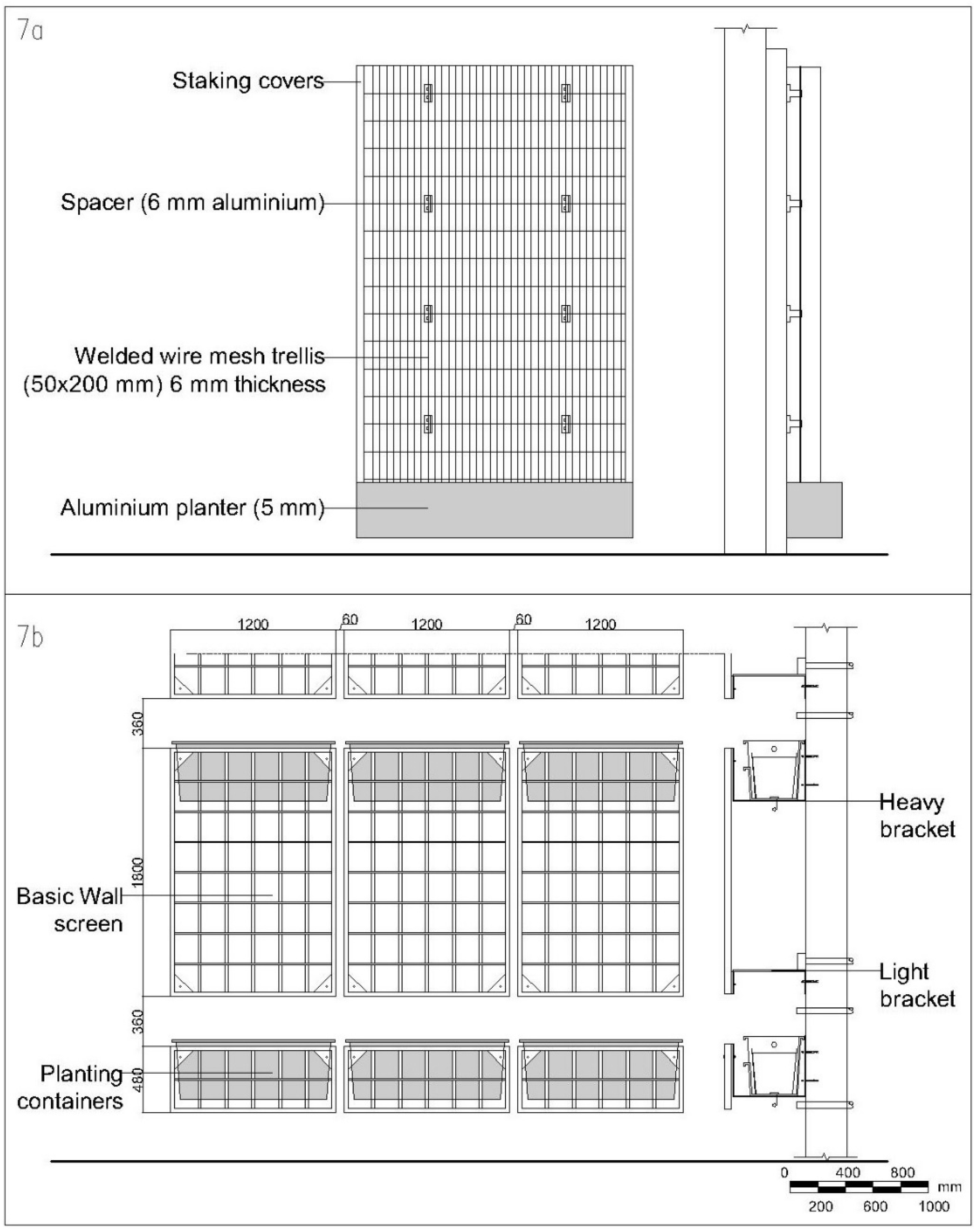

The first system, IGFT, is lightweight and feasible to install in tall facades through conjunction with planters (IGFB) at mid-levels. The M58 manufacturer uses standard dimensions for the P58.142 trellis system (

Figure 7a). It consists of a planter especially made to be placed against the facade, constituted by trellises and spacers (6 mm aluminium). The planters are made of aluminium and differ by dimension. Planting containers may be located at different heights in tall buildings. P20.51 (

Figure 7b) has fiberglass containers which may be directly mounted on the structure or on a built-out sub-structure. A powder coated galvanized steel standard vine screen is attached to these containers. This screen is fastened to the substructure using light brackets.

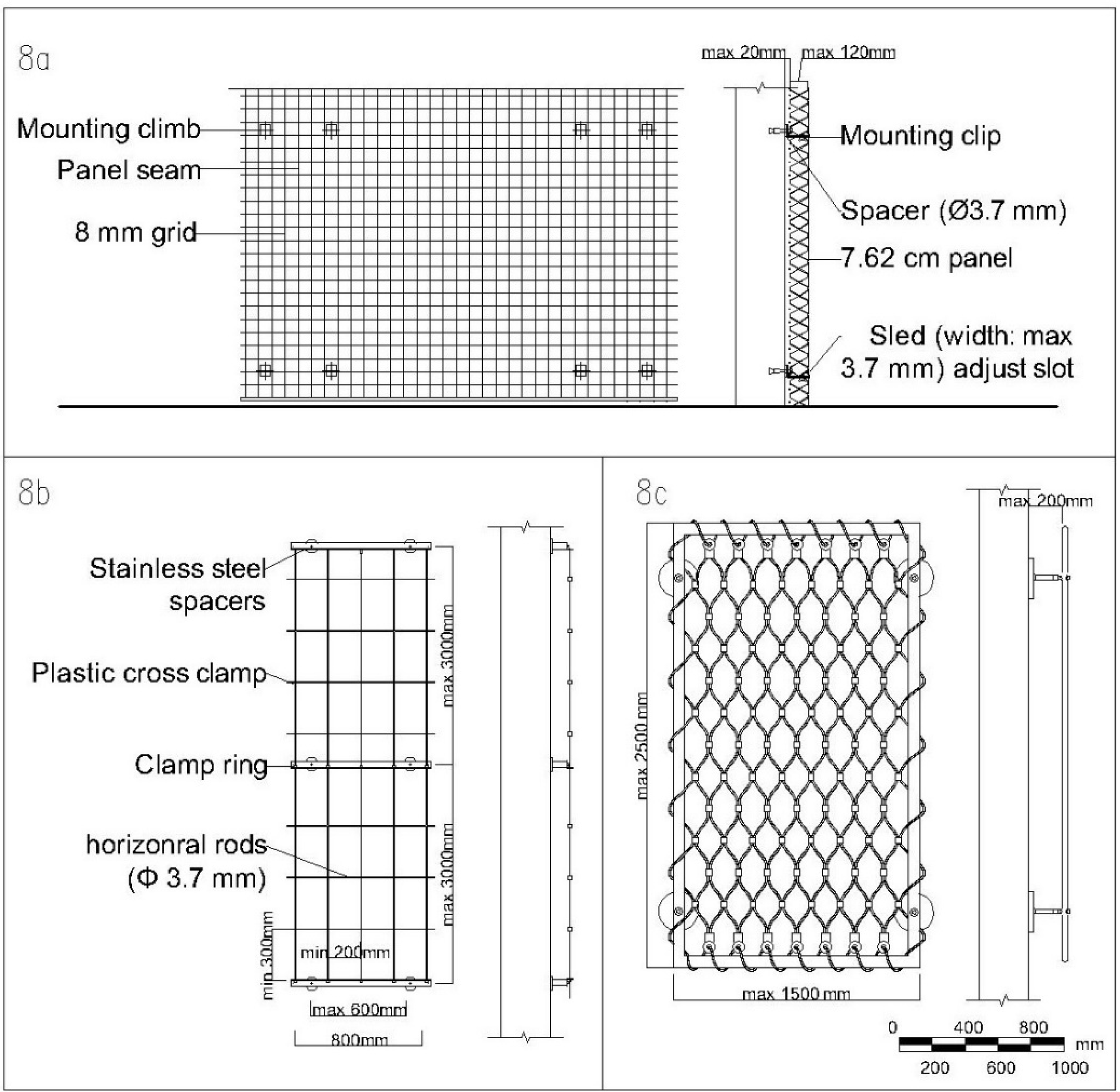

The second system, Indirect GF with Cable/Rope (IGFC), may be constituted by a variety of materials. M17 manufacturer has developed 2D and 3D systems (P17.48, see

Figure 8a). Two-dimensional solutions consist of vertical cables, horizontal cables, rods, grids, or nets. The 3D systems consist of panels with length, width, and depth, created specifically to enhance the growth and to ease maintenance of GF plants.

Other systems may consist of high-tensile steel cables, wire trellises, anchors, spacers, and other elements attached to the construction. Vertical and horizontal wires can be connected through cross clamps to form a flexible trellis system in terms of sizes and patterns. In the case of large facades, to ease the coverage, the system is framed. This can be also a design choice which depends on customer’s demand. M25 produces wire rope structures (P25.66, see

Figure 8b) by using stainless steel (AISI 316) which is suitable to be implemented in all types of facade with sizes up to 150 m height. Besides these ropes, there are also other alternatives called Webnets (P25.67, see

Figure 8c), which are applicable both outdoors and indoors.

Structural support in LWs is more complex in comparison with the GFs due to the heaviness of the system. It depends on which typology (see

Figure 5) may be implemented due to the structural load of each component. The type could be made of a wide range of materials such as metal, wood, or plastic. It can be constructed directly to the wall with uprights and brackets, or indirectly through some auxiliary substructure.

The substructure has several solutions with the most common being the galvanized steel grid. For example, a system made with felt layers, P42.108 (

Figure 9a), has a rail made of galvanized steel with, in the top part of the module, a Rock PEC tissue slot suitable to accommodate and fix this rail to support the system (1800 × 1000 mm).

Apart from systems with felt layers, galvanized steel solutions are common in other modular systems. Peverelli (M40) uses a modular box frame (variable dimensions based on the case) which is made of galvanized steel wire as well. Each of the boxes, called Vegetalis (P40.102, see

Figure 9b), is assembled to anchoring structure (steel grid) by using metal hooks. The hooks are fixed by dowels and screws to the original facade. M8 uses galvanized steel similarly, for all panels (P8.17–20, see

Figure 9c) with external surfaces closed by a mesh. These panels are directly fixed to the wall, without another substructure.

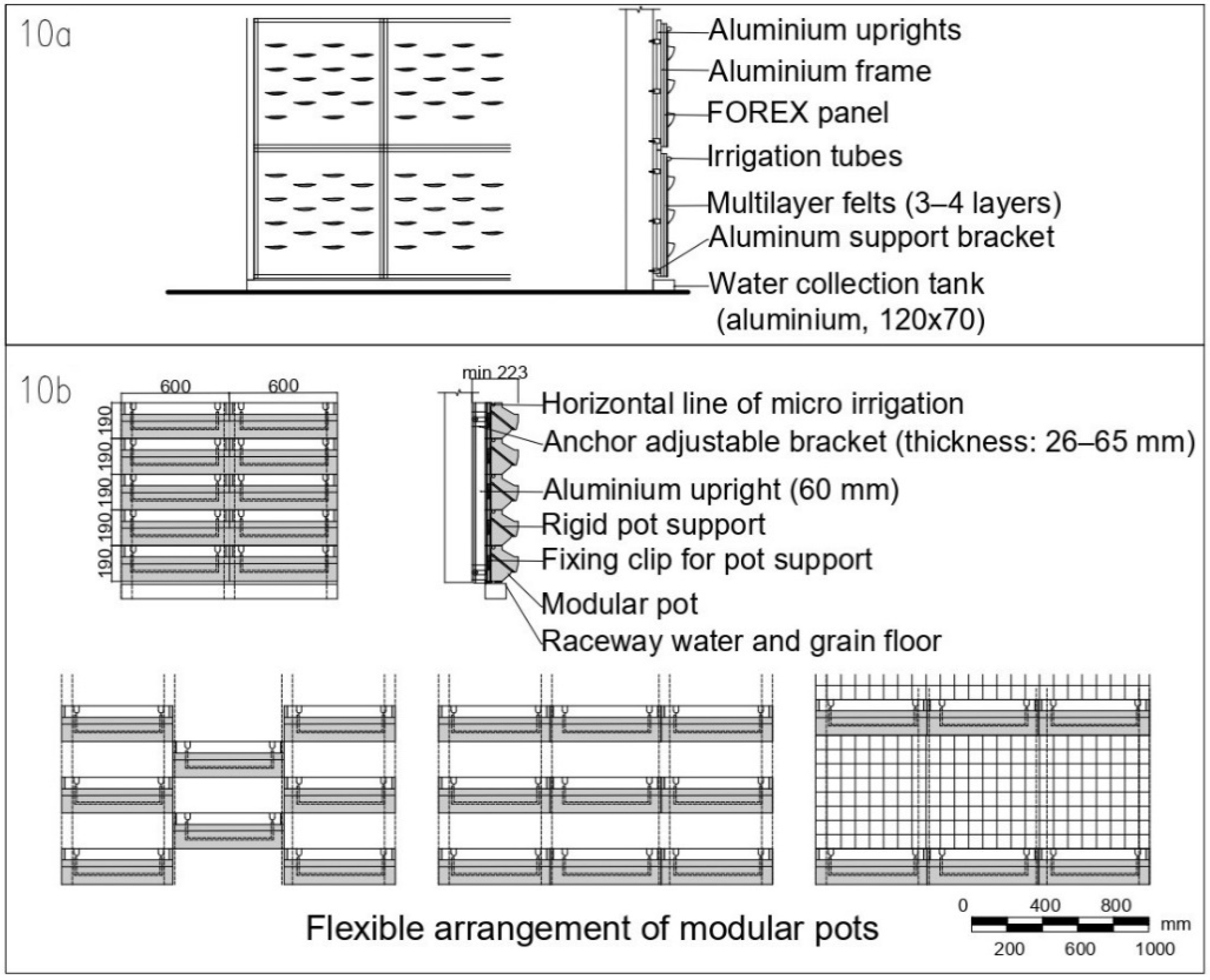

Besides galvanized steel, stainless steel, aluminium, and plastic are other materials used in structural components. A system with felt layers, P48.117 (

Figure 10a) is made of aluminium. All panels hold an aluminium frame and a FOREX plate coated with 3–4 layers of felt, appropriately sculpted for the realisation of planting pockets. The aluminium uprights are fixed to the wall through supporting aluminium brackets fastened with dowels. Systems with plants in containers may consist of aluminium made support system as well. M53 uses aluminium uprights connected to the wall with adjustable brackets fixed to uprights with bolts and screws of VP-Modulo, a typical example of LW with planting containers (P53.130, see

Figure 10b).

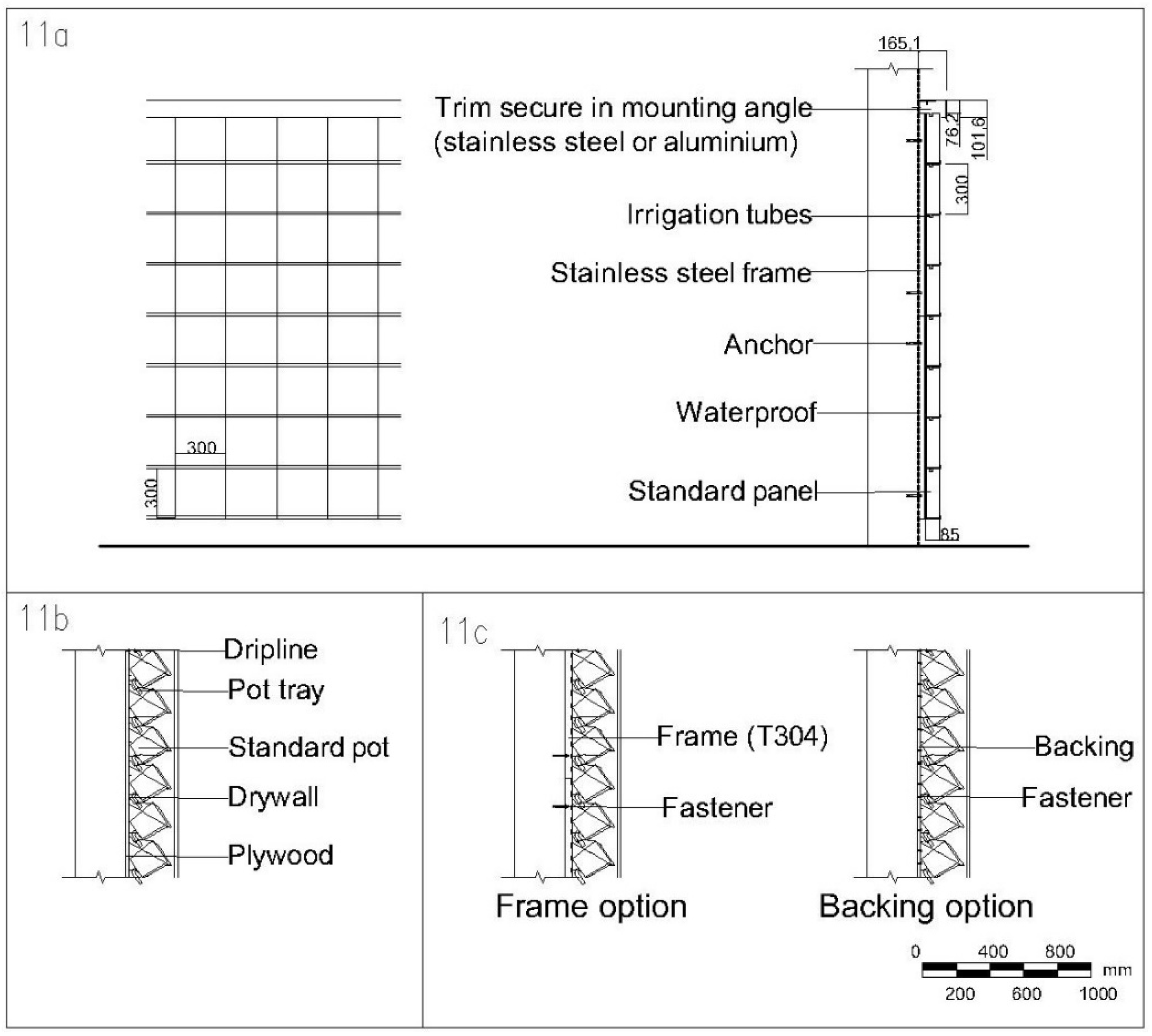

M20 has a variety of products different from structural systems as well as other components for LWs besides indirect GFs. P20.52 (

Figure 11a) consists of modular stainless-steel panels directly hung to a stainless-steel frame (1510 × 9050 × 50 mm). It is mounted to the main structure of the wall as a grid support. M20 also uses plastic in addition to other materials in some products. P20.53 (

Figure 11b) module is made by a plywood (20 mm thickness) that is mounted on the wall structure. Trays are mounted with fasteners on this this plywood panel. The trays are made from recycled polypropylene and they host 2 or 3 potted plants. P20.53 requires plywood backing and waterproofing before trays are installed. P20.54 (

Figure 11c) trays, made of recycled ABS, are directly mounted on concrete and grouted CMU (Concrete Masonry Unit). They require a plywood backing on wood and metal structure and an additional substructure on steel. This stainless-steel frame is mounted on the main structure of the wall. This product uses a combination of grid and surface layers as support.

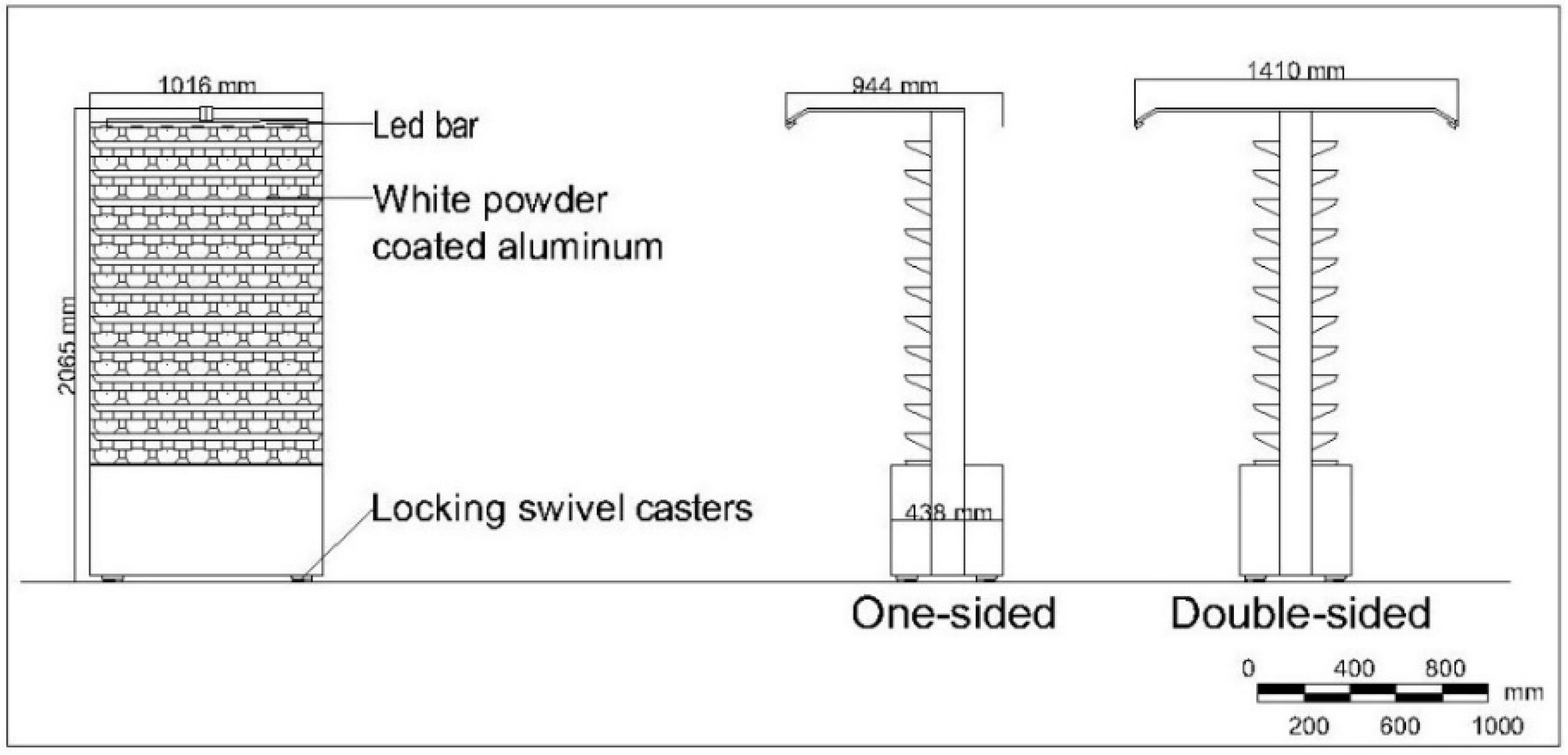

Another class made based on the structural support system is the self-sustaining LWs, such as a free-standing furnishing component, which is used indoors to divide areas in a room like P32.82. Furthermore, many companies launched similar, more versatile products aimed at improving the IAQ, creating privacy, and absorbing sound in interior spaces. P20.55 (

Figure 12) can be single or double side vegetated free standing, furnishing component with a mix of tropical foliage plants, and with a structure made of powder coated aluminium. It can be moved and adjusted in height although it requires electricity to function. These kinds of mobile systems can be used outdoors as well. P29.76 has some models for indoors and outdoors that arrive preassembled and ready to plant. M47 uses the name of Movable Climate Changer (P47.116) since the scope is to improve IAQ.

Besides mounting on the vertical surface, an anchorage system is sometimes required through the ground. Anchorage can be solved in several ways according to the design. The P42.106 (

Figure 13a) panel system applies galvanized iron wire (Ø5 mm) grill each at 100 × 200 mm interval. At the base, the coco fibre vegetation layer spread with latex is installed to help climbing plants to grow. This panel system does not require digging. While P42.105 (

Figure 13b) requires initial digging after that support poles for panels and the panels themselves are placed, the brackets are anchored to the supporting poles and finally the trench is filled up to the plant’s collar. Both systems are similar in terms of area covered, vegetation, and height of growth.

Although this study shows the commonly available product combinations on the market, custom solutions can be implemented for all typologies. Apart from the presented products among LWs, there are others that are quick and easy to install (e.g., P4.12 and P32.81). These products having as their main purpose that of improving IAQ and wellbeing. They come in a wide variety of sizes which help to fit in with a variety of space and plant species requirements. With a similar aesthetical goal, and without the need of a support structure, indoor VGS e.g., P35.93 and P41.104 can be mounted on the wall. These products provide a vegetated wallpaper effect and are made of fully recyclable materials (e.g., P32.84) or natural sustainable bamboo as with P32.86.

3.1.3. Growing Media

The growing media is the place where the roots of plants thrive. In the cases of VGS, material can be conventional i.e., peat-based soil or non-soil based. The non-soil-based principle is called hydroponic (soilless) cultivation to grow plants on an organic fibrous medium (e.g., coconut coir, peat moss, sphagnum moss), or mineral-based fibrous or granular media (e.g., perlite, foam, vermiculite) [

36,

37] (see

Figure 14). The growing media can be constituted by one single material or by a mix of dozens of them. The space for development of roots is generally restricted by the size of the container and by features of growing media [

38]. To have optimal growth conditions plant roots must obtain sufficient water, oxygen, and nutrients.

Figure 14.

Growing media: (

a) Coconut coir [

39]; (

b) Pumice [

40]; (

c) Rice hulls [

41]; (

d) Rockwool [

42]; (

e) Perlite [

43]; (

f) Vermiculite [

44].

Figure 14.

Growing media: (

a) Coconut coir [

39]; (

b) Pumice [

40]; (

c) Rice hulls [

41]; (

d) Rockwool [

42]; (

e) Perlite [

43]; (

f) Vermiculite [

44].

If an exterior wall is a system with soil, it can face problems such as soil loss because of wind or water-driven erosion. Despite these disturbance factors a soil based growing media must be able to retain moisture, allow good aeration, have low salinity, and enable high cation exchange capacity for nutrients. M35 offers a soil-based system with P35.92; so too does M2 and M27 with its products. In detail, P2.2 is an active soil-based system where an air purification unit pumps new air and wicks, fed with water from enclosed troughs, pick up the needed moisture. The moist air is then introduced into the root zone of plants.

Concerning non-soil based growing media, the first commercial example is dated back to the late 1960s when Grodan Rockwool used mineral wool in hydroponics as a planting medium. Since then, several cultivation layers have been introduced into the market. For instance, P42.106 (

Figure 13a) and P42.105 (

Figure 13b) are produced with small differences. In both cases, it is a pre-vegetated panel before installation, inserted on a welded and warm zinc-coated mesh, rooted in a technical substrate, a special mattress that is tightened and stuck to the root apparatus. The vegetation used is climbing plants which grow on stainless-steel made clamps. This module system has two different cultivation layers for each type: in P42.106, the plants grow in a biodegradable container made of coco fibres spread with latex, filled with topsoil, and arranged at the foot of the grid, whereas in P42.105 they grow on a kenaf mattress.

3.2. VGS-Specific Components

The components studied here exist only in the products which belong to LW typology and are defined more in detail as LW-Specific Components. They are constituted by: LW Application System (

Section 3.2.1), LW Irrigation System (

Section 3.2.2).

3.2.1. LW Cultivation System

LWs can be divided into three major groups according to their cultivation methodology i.e., planting boxes (pots/containers), geo-textile layers, and foam substrate.

Planting boxes (examples reported in

Figure 10b and

Figure 11a–c) or planting containers can be made of plastic, metal, or wood if sorted by the frequency of use. The capacity of containers has to be specified by the needs of vegetations’ root zone as it strongly affects the health and growth of vegetation [

31]. This system can consist of single individual pots as in P35.92 with containers of standard size (100 × 100 × 150 mm) made of plastic. The advantage of having these boxes is the ease of removing and replacing dead plants. It also gives the possibility to design different facades thanks to flexibility of shape and size of green surfaces as in the case of P2.2.

In P27.71, pots can be assembled horizontally to become a module constituted by a group of containers. Similarly, the monolithic single piece P32.79 and P54.131 can assemble boxes horizontally only, while P22.59 can be assembled both horizontally and vertically. Another interesting example available in the market is P7.16. It is a panel consisting of PB (608,045 mm). Each panel contains inert growing media and a maximum of 20 plants.

Although plastic remains the main material used in the market to produce boxes, there are currently only a few products made of metal such as Zero Gravity Eden (P24.65) by Italmesh (M24). They develop mesh panels and perforated sheets as architectural solutions. In P24.65, the modular panels are made of aluminium and iron, whereas the holding structure is made of steel (

Figure 15).

Geo-textile layers are a newly emerging material in civil engineering and many other fields. They are ideal materials for infrastructural works and have been used in construction for decades [

45]. With their multifunctional features, their use becomes common in different applications including LW. Both natural and synthetic fibres can be used as geotextiles for various applications. In VGS applications, synthetic fibres (i.e., polyester, polyamide, polyethylene, polypropylene) are the most common on the market. LWs made with geo-textile layers are the second typology, based on application, and are usually made of two or three layers, as reported in

Figure 9a,c and

Figure 10a. This system is the simplest and most basic LWs in terms of ease of construction. The layers consist of planting bags cut at certain intervals and nailed to a wooden or plastic board.

P39.101 was the first example of a geo-textile layer application in this field. This product is constituted by double layers of stapled polyamide felt which support the synthetic fabric with pockets where the roots thrive. Another product, P47.107 is constituted by three layers, going from the outside to the inside: a spun coconut fibre, a Polyfelt Rock PEC, and a polyurethane foam substrate. The coconut fibre is cut in a specific way to create planting pockets. P50.125 has three layers constituted by polyamide, fytotextile, and PVC, going from outside to inside. All the sides are interconnectable with a maximum capacity of 49 plants.

Although these geo-textile layers offer the flexibility of covering all shapes and dimensions of facade, they have many disadvantages. Firstly, the choice of plant species is limited because of the dimension of the pocket cuts in the external layer. Secondly, in frosty weather conditions, the root zone faces the risk of freezing. Most importantly, this system has very high environmental burden based on Life Cycle Assessments (LCA) as reported in the literature. Among the LWs, the CO

2 footprint in the waste class has a major impact due to the impossibility of recycling the geo-textile material [

34]. In addition, LWs with felt layers (LWFL) have disadvantages during usage and maintenance stages as it is difficult to replace dead plants. In this case, the areas with dead plants need to be cut out and the empty spaces filled by attaching new layers of geotextile and planting new plants in between them. The plant species options are limited in comparison with other application methods because large plants can get heavy and cause tearing of the felt layer. This system may create bad smells due to fungus and lichens that form on the felt thanks to the optimal temperature and moisture conditions.

Foam substrate is the third alternative for plant cultivation in LW which helps to reduce the weight of the system. P47.114 offers pre-cultivated panels in nurseries before installation similar to many products. However, foam-based media have the risk of being broken by the roots, so these products typically have a short lifespan. Another example, by the Italian-based company Peverelli (M40) uses a vegetal and natural substratum that consists of an aquatic foam in the product called P40.102 (

Figure 9b). In installations, the VGS is equipped with dispensers that allow adjustment of the moisture in the soil to provide optimal conditions for the sphagnum moss growing medium.

Sphagnum sp. moss is a natural material from the Chile forests and was introduced in the initial phase of cultivation. In this case, carbon emission in the LCA of panels increases due to the transportation from Chile to Italy. Growing media can be composed of a mixture of sphagnum with soil, and coconut chip [

46]. However, moss is beginning to be implemented in VGSs not only in growing media but also as the main component to be installed on panels. A study by Perini et al. [

47] tested the growing ability of mosses on horizontal and vertical surfaces of buildings. They found that mosses can grow in built environments as an affordable solution for both surfaces. This type of greenery composed of a single main layer and low-cost materials hence promises to reduce the costs during the installation and maintenance in comparison to the other available materials in the market. However, these products need to be studied more from an environmental sustainability perspective under different climate conditions and also from the point of view of water distribution and moss mixture adhesion.

3.2.2. LW Irrigation System

Irrigation systems are necessary for LWs to supply water. The amount of water is usually controlled by an automated system with a timer. Irrigation depends on the seasonal conditions of the location where the VGS is installed. P52.129, in a typical location in France, waters the plants 8 min per day in summer, and 5 min per week in winter. Dripper lines exist every 40 cm vertically and every 15 cm horizontally. In systems with geo-textile, the irrigation usually works as a closed circuit through a pipe network. The irrigation process is based on gravity and capillarity. Some systems construct some elements to recycle the water as in the case of a gutter installed at the bottom in P39.101. The gutter serves as an excess water collector. In the case of systems with PB, the water in excess has to be drained from the bottom of each container to avoid root rot. The container can be perforated (on the bottom or better on the side to prevent water dripping onto the plants placed below) or the water can be collected in a gutter and piped to the drainage or recirculation system similar to the system at the Mur Vegetal [

31].

Despite all the benefits of VGS, high water demand is one of the biggest challenges in their implementation. Wrong irrigation construction may cause serious problems for the system. In addition, the demand for maintenance is high as the replacement of pipes is needed every 7.5 years due to the crystallising out of salts [

34].

3.3. Optional Components

Besides the aforementioned components, in some cases VGSs may have optional components i.e., fertigation, monitoring, and lighting [

48].

Fertilisers can be given to supply nutrition. In modular systems, it could be given with the water by drip hoses on the top of each panel (e.g., Flexipanel (P47.114)). Another option is to use a micronutrient solution which is supplied to a storage water container underneath the wall (e.g., Soft Shell (P22.59). LW biofilter (P34.91) is a hydroponic and active system with the main purpose of cleaning the air through a natural processing of contaminants which improve IAQ through the elimination of VOC. Ecologically complex and plant based biofiltration of indoor air, as an alternative to ventilation, is an application of conventional biofiltration implemented since the beginning of this century. In these biofiltration systems, plants can act as a contaminant sink or impart some buffering capacity for fluctuating pollutant concentrations through accumulating airborne contaminants [

49,

50]. Nutrients and microbes are delivered by the circulating water in the form of low concentrations of hydroponic fertilisers although it is difficult to provide the right dose of nutrients in these kinds of hydroponic geo-textile mats.

A monitoring system can be installed with the aims of research or testing the performance of the system during its service life. The 90deGREEN manufacturer (M1) installs an electronic monitoring system by request with the product Fassadenbegrünung (P1.1). This system can also be installed with an alarm to signal when an intervention is needed. For example, Plantwall (P16.44) has moisture and temperature sensors in the plant wall that continuously register the conditions and send a maintenance alarm when action is needed.

The last optional component is the availability of lighting systems used for night illumination; to create diverse aesthetical and ambient light situations; and for plants which may grow optimally indoors. Peverelli (M40) considers it for the outdoor public spaces like squares, sports facilities, or pedestrian areas to create an aesthetic added value for an urban space. Scotscape (M46) advises horticulturists to take in situ light following specific requirements, i.e., to install a source with 1500 lux of illuminance ata 600 mm distance from the LWs as in their product (P49.118). Sempergreen (M47) combines auxiliary lighting for the product LifeMCC (P47.116) with the statement: ‘plants need light in order to grow optimally’. Similarly, Mobilane (M32) developed three different lighting alternatives (i.e., Livespectrum Lumission, Livespectrum Parus, And Livespectrum Mobilight) in the product Livespectrum (P32.89) in order to have sufficient light exposure to allow plants to grow healthily in all the locations. These systems solutions were proposed after simulation and emulation of natural daylight.

Cityscape Inc. (M10) offers lighting in the NatureScreen (P10.22) system as an architectural feature constituted by the trellis system. The lighting elements are composed of energy efficient integrated LEDs to smart cantilevered lights at strategic positions in the VGS. Lights can be wall mounted above the trellis or integrated into each unit, with numerous styles to choose from. Nemec (M35) combines lighting in their product Cascade Garden system (P35.92) for interior gardens installing in every one square meter of wall a 40–50 W metal halogen lamp (or LED equivalent). On the other hand, Terapia Urbana (M50) advises auxiliary lighting both for Fytotextile LW (P50.125) and SlimGreen (P50.126) to ensure enough lighting conditions and surface size in indoor environments when vegetation has not sufficient light.

4. Discussion and Future VGS Sustainable Development

The VGS market has been growing day by day due to both newly introduced materials and innovative technologies. Brand new VGS inventions can be potentially included in smart building technology by utilising innovative technological solutions such as robotic applications or artificial intelligence. These relatively new systems could overcome the barriers associated with continuous monitoring for optimal VGSs maintenance, reducing the costs [

51] and, at the same time, the risk of fire [

52]. After the conducted literature review, it is worth mentioning that VGS prototypes with smart, real-time, and continuous monitoring are rarely available. This gap shows the future direction in which VGS needs to develop. Based on the data collected from available products in the market it is clear that there is an increasing need of VGSs with optimised irrigation that controls in real-time the water requirement thus avoiding a waste of resources. One of the few examples available in the market with control of irrigation is P35.94, as a standing VGS that could be placed anywhere with a rigid surface. This product is designed as a bench for open public spaces. It has an automatic irrigation system powered by solar energy through a rechargeable battery with an inner water reservoir. This reservoir has extra water collectors that provide water for 3–4-month cycles to recuperate. P53.130 has instead a circular irrigation system that is programmable from a smartphone.

A novel smart system with continuous monitoring of the VGS surface temperature, the soil humidity, and other parameters could help to reduce VGS maintenance requirements while enhancing its use in terms of insulation, heatwave reduction effect and air quality improvement capabilities. Finally, these parameters could be useful in discovering in advance, by using robot technologies, if any plant is diseased. This is the case of two different Green Wall Robot concepts: the first concept—developed by Fraunhofer IPA and by the Institute for Energy Efficiency in Production (EEP) of the University of Stuttgart—may dynamically respond to the need demands in relation to the stimuli or stressing factors received by the external environmental conditions.

While the second Green Wall Robot concept exploits the future potentiality of artificial intelligence algorithms used in conjunction with VGS. This concept is constituted by a modular, rail-mounted robot system that was developed specifically for possible applications for urban farming or local food production [

53]. This robot system provides planting, care, and maintenance services. It scans the structure by image processing and removes individual submodules containing diseased or dead plants and replaces them with new ones. It irrigates plants by a pipe system that is integrated into the modules themselves.

Another direction of future research in VGS is to implement the use of smart technology components in VGS to enhance the wall’s ability to improve the IAQ. An example of such an application is provided by Naava that produces a fully automated indoor air purifier and humidifier [

54]. The process starts with the absorption of polluted indoor air through roots and hydroponic growing media. Root microbes purify the air from pollutants, and finally fans return the purified air back to the room. During this procedure, sensors in the system measure the variables, artificial intelligence directs functions automatically, and a remote system transmits information and sends notifications in real time to the user for assessing the IAQ levels and eventually improving the needs of maintenance.

Another study [

55] applied machine learning and IoT (Internet of Things) to VGSs with the aim of detecting anomalies to enhance the automation of maintenance and improve intelligence detection for realising predictive quality assessment of the indoor climate. However, as they highlighted, this machine learning application to VGSs has still many challenges. First, the reliability of the prediction is dependent on the quality of the implemented sensors, their sampling rate, and the size of the collected datasets. Secondly, indoor climate can be more complex to assess depending on the building type, structure, materials and analysed parameters.

The abovementioned examples of technology integrated in the VGS, are used during the operational stage of the system. However, despite the gap in the literature and industry regarding plant selection, a recent study [

56], proposed a methodology to be used at earlier stages e.g., in the design stage, or for concept development in pre-design processes. This methodology is BIM-based and aims to automate the selection of plant species to provide a range of possible variations in VGS. Although this BIM-based procedure considered a major number of parameters necessary in filtering plant alternatives e.g., plant type, leaf type, shape, flowering, water needs, soil type and individual needs; however, it ignored moisture and specific soil properties.

Table 1 presents a critical assessment of different criteria used to compare the typologies of market products. The product assessment criteria are: complexity, ease of maintenance, durability, environmental impact, recyclability, cost, and service area. The assessment method for the overall exemplification discussion and comparison of the market products is based on a three-level scale: 1 being a low score and 3 a high score. As an example, a grade of 1 in complexity means the product is simply assembled, whereas it is not easy to maintain. In durability, it means low ability to last a long time. Regarding environmental impact it means low environmental burden in terms of released gas emissions and used resources; for recyclability, it refers to low potentiality. Finally, a grade of 1 in cost stands for the cheaper product than others. For each criterion, a grade of 2 means the product is at mid-level, and 3 means the maximum level.

For the overall analysis, three products for GFs and four products for LWs are selected. P10.22 is selected to represent IGFT, whereas 19.50 represents IGFC. P58.142 is the last GF constituted by planting boxes (IGFB). In LWs with PB (LWPB), two products are included due to material differences. P24.65 and P53.130 having metal and recyclable expanded polypropylene (EPP), respectively. P42.108 and P47.114 represent LWFL and LW, respectively, with foam substrate (LWFS) as the other main typologies in the market.

In detail, complexity, as the first assessment criterion, is based on the number of components of VGS and their manner of construction. Ease of maintenance follows a similar basis, and it is one of the challenges in the VGS applications. As the complexity increases, ease of maintenance decreases to a low score. Indirect GFs are less complex then LW under all circumstances; therefore, it is easy to supply maintenance. Among IGF, additional components make the system more complex (e.g., P58.124 with PB). On the other hand, if selected LW products are sorted from descending complexity, LWFL takes the first place since it requires a large number of structural support and cultivation layers.

Durability has to be considered during the design phase before installation because of economic and environmental concerns. The durability of VGS depends on shelf life of the components. Some components are needed to be replaced at certain times. The life expectancy for the high-density polyethylene (HDPE) PB and PVC layers on structural support and felt layers themselves are estimated at 50 [

34], 10 [

57], and 3.5 years [

58], respectively. LWFL has the shortest lifespan among LWs. However, each system can stand longer if intense care is carried out continuously including re-planting plants. For example, Italmesh (M24) offers to replace all the plants with a brand-new VGS, to begin a new life cycle for 1/3 of the initial cost.

Regarding environmental impact assessment, all stages of the panels have to be considered from production to disposal. One recent study analysed six different scenarios over two lifespans (i.e., 10 and 25 years) of a LWFL installed in a Mediterranean climate (Genova, Italy). The study found that VGSs has the potential to offer significant benefit from an environmental perspective by reducing greenhouse-gas emissions and energy consumption; however, increased water consumption during the usage period demonstrated a reduction in terms of environmental sustainability when the VGS is applied on a large-scale [

59]. Based on conducted comparative LCA in the literature, LWFL is found to have the highest environmental burden [

34,

58,

60]. The main difference between different LWs is mainly caused by the mass of materials involved in the fixation and structural support systems. After the lifespan of all product types, at the disposal stage, recyclability and reusability of each component become very important factors. In some cases, especially LWFL, it may not be possible to separate multiple layered components for recycling because of their complexity. In LWFS products, similar environmental impact studies are missing so comment is not possible.

Cost remains the most challenging variable to assess for potential customers both in installation and maintenance stages. Range of costs of per sq.m. of VGS should be decided for each level and made available. LWs are always more expensive than GFs due to complexity of components (e.g., structural support system), and high maintenance requirements. A study [

61] analysed the Net Present Value, Internal Rate of Return, and Payback Period of different VGSs and found that LWs cannot be considered as an economically sustainable product due to high costs of installation and maintenance compared with the other analysed greening systems.

On the other hand, Indirect facade without PB is found sustainable depending on the material used for the supporting system. Huang et al. [

62], in their analysis, found that operation and maintenance account for more than 80% of the life-cycle cost. Therefore, the possible economic benefits of reducing energy demand during the VGS operational life have to be considered to decrease the economic load. The same study showed that the payback period by VGS energy savings, in the case of IGFT, is three decades.

Finally, service area is worth discussing due to the fact that performance of VGS is directly connected with the climate conditions at the installation spot. Based on this review, results show that VGS can be implemented in any location with any climate so long as the plants have been selected correctly. To increase durability in the stage of plant selection, the environmental condition and availability of light in respect to orientation need prioritisation over the aesthetics. This selection also plays a role in the overall thermal performance of VGS.

5. Conclusions

As the benefits of VGS are starting to become evident in the framework of sustainability, the demand has increased over the last decades, and correspondingly the market has grown rapidly. The end-users of VGSs are both residential and commercial and include both private and public sectors. In the future, more customers may be interested to purchase these products due to benefits based on their particular needs. For instance, offices and libraries can be mostly attracted by air quality improvement and noise prevention. Places that serve a large number of people like restaurants can be interested due to other benefits such as improved air quality and an enhanced environment leading to psychological and well-being benefits.

However, it should not be forgotten that VGS provide multiple benefits simultaneously. Despite all these potential benefits, future research needs to convince the end-users, property owners, or clients that such technologies are worth the investment, especially in the light of the economic barriers still to be solved. Moreover, as mentioned before, smart technology integration is a research direction which is already taking its first steps in this field, although more research is needed especially for the implementation of tall VGS on already-built systems.

The remaining challenges have to be studied more in detail as VGS have to respond to all requirements of social, environmental, and economical sustainability while in use and in the mid- to long-term. Firstly, this technology requires multidisciplinary knowledge from different fields such as architecture, civil and mechanical engineering, as well as botanic science to maximise the benefit of a VGS. In the current state of knowledge, there is a lack of guidelines for both selection criteria for choosing the optimal VGS typology in a specific location and (or building type and orientation) and also a lack of maintenance and management guidelines. This kind of system requires the consideration of several factors both before the installation (in the design phase), and after the installation during maintenance.

The environmental features of the location are crucial in making appropriate adaptations to climate-specific conditions and in the evaluation of potential wall orientations. In addition, the features of an original wall that will be covered with vegetation have impact on the VGS application. Firstly, if the wall has openings such as doors and/or windows, specific procedures are needed. Secondly, if the VGS is heavy, the original wall has to be strong enough to support this additional weight. For instance, to install P20.51, the wall itself must support almost 1465 kg/sq.m. of system weight. All of these factors, together with VGS typology and planted species, affect the performance and durability of the system. Species selection should be based on their ability to grow in the environment where they are installed in terms of light, temperature, and water conditions, and eventually aesthetics.

In the framework of economic sustainability, the main existing barrier is low affordability (i.e., high installation and maintenance costs). In the case of a tall VGS, users, designers, installers, and maintenance workers need to acquire technical knowledge and/or other skills such as safety measures for accessing high locations during both construction and maintenance.

Then there are concerns about environmental sustainability linked to VGS in many products and installations which remain to be solved. Firstly, there is still a debate concerning VGS long-term efficiency and sustainability since some typologies require soil and water consumption, irrigation system installation, and optionally fertilisation. Besides this, an irrigation system requires a continuous electricity supply and Wi-Fi connection. Secondly, based on the LCA studies conducted in literature [

34,

58,

60], LWFLs are found non-sustainable due to the high amount of resource used and gas emission released.

For the other typologies of LW, the environmental sustainability strictly depends on the material used. The suggested solution is to reduce as much as possible the use of non-sustainable materials in the production of VGS components and replace them with environmentally friendly and recyclable materials. Additionally, each component has to be critically considered based on the waste class they belong to after the end of their lifespan. For instance, the structural support system of indirect GFs should be made of wood-based material rather than the currently most common plastic, coated steel, or stainless steel. Despite these challenges, when everything is taken into account, the VGS have the potential to maximise the benefits from the three pillars of sustainability i.e., social, economic, and environmental. They can also help to earn LEED credits in particular the Sustainable Sites, Energy and Atmosphere, Materials and Resources, and Innovation Credits [

63].

Regarding the position of VGS companies in the industry, instead of a traditional business model, a new planned business model may help in creating eco-innovations. This is thanks to the leveraging effect of rapid and wider diffusion of eco-innovation on environmental, economic, and social improvements [

64].

To contribute to a resilient and sustainable environment, relevant companies should adopt a holistic approach with the aim of creating environmental, economic, and social values at the same time, as well as enabling green technologies and solutions with the help of the eco-innovation concept integrated business model. This statement has to be valid for the long-term. The VGS industry has the potential to meet many goals defined by Vision 2050 [

65] including contributing to healthy and inclusive living spaces, and thriving in harmony with nature. Moreover, VGSs are compatible with the Sustainable Development Goals (SDG) which is a commitment to achieve sustainable development by the year of 2030 [

66]. VGSs contribute specifically to achieving Goal 11 (Sustainable Cities and Communities).

This study contributes to the existing knowledge about VGS. It is a current state-of-the-art market review of available products from both a research and practice point of view.

To achieve this goal, a systematic taxonomy (

Figure 5) was developed by considering the features of components involved in each analysed product. Such a taxonomy can be useful for different stakeholders e.g., on the technical side: designers, architects, landscape architects, environmental engineers, civil engineers, and manufacturers; on the exploitation side: city managers and decision-makers from the public sector; real estate experts and users/owners of buildings.

Finally, a discussion on future research directions is presented to address the efforts of researchers and experts in solving the challenges recognised in the review and to enhance the potential benefits recognised in the VGS e.g., urban air quality improvement. Among the benefits, special focus is needed on the big scale impacts under different climate conditions due to the lack of research on this matter. In rapidly growing cities, the multidisciplinary and interdisciplinary research in plant biology, engineering and architecture provides a more wide-ranging approach to identify the benefits of VGS and contribute to creating a sustainable built environment at district scale.