Digital Optimization, Green R&D Collaboration, and Green Technological Innovation in Manufacturing Enterprises

Abstract

1. Introduction

2. Literature Review

2.1. Digital Optimization

2.2. Green Technological Innovation

2.3. Green R&D Collaboration

2.4. External Environmental Orientation

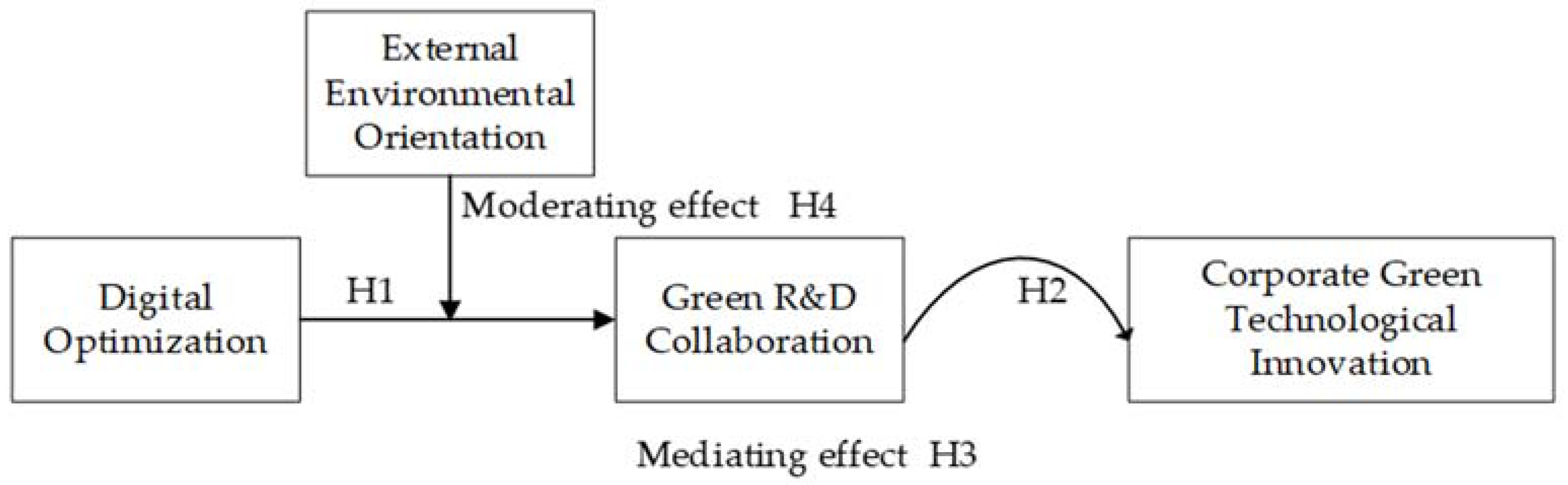

3. Hypotheses

3.1. Digital Optimization and Green R&D Collaboration

3.2. Green R&D Collaboration and Green Technological Innovation

3.3. Mediating Effects of Green R&D Collaboration

3.4. Moderating the Effect of External Environmental Orientation

4. Methods and Data

4.1. Data and Sampling

4.2. Variables

4.2.1. Dependent Variable

4.2.2. Independent Variable

4.2.3. Moderator

4.2.4. Mediator

4.2.5. Controls

4.3. Method of Estimation

EPWi,t + β8Controlsi,t + λt + τj + εi,t

5. Results

5.1. Basic Regression and Mediating Effect

5.2. Moderating Effect

5.3. Advanced Analysis

5.4. Endogeneity

5.5. Robustness

6. Discussion and Conclusions

6.1. Research Conclusions

6.2. Theoretical Implications

6.3. Practical Implications

6.4. Limitations and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, B.; Bega, F. China’s Belt & Road Initiative coal power cooperation: Transitioning toward low-carbon development. Energy Pol. 2021, 156, 112438. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M. Implementation of circular economy business models by small and medium-sized enterprises (SMEs): Barriers and enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Wu, S.; Fan, D.; Su, Y. The co-evolution of global legitimation and technology upgrading: The case of Huawei. Am. Econ. Rev. 2021, 24, 8. [Google Scholar] [CrossRef]

- Numminen, S.; Lund, P.D. Frugal energy innovations for developing countries—A framework. Glob. Chall. 2017, 1, 9–19. [Google Scholar] [CrossRef] [PubMed]

- Hanley, T.; Daecher, A.; Cotteleer, M.; Holdowsky, J. The Industry 4.0 Paradox. Available online: https://www2.deloitte.com/content/dam/Deloitte/mx/Documents/energy-resources/2018/Industry-4dot0-Paradox-Overcoming-disconnects-on-the-path-to-digital-transformation.pdf (accessed on 16 June 2018).

- Xue, L.; Zhang, Q.; Zhang, X.; Li, C. Can digital transformation promote green technology innovation? Sustainability 2022, 14, 7497. [Google Scholar] [CrossRef]

- Moşteanu, N.R.; Faccia, A.; Cavaliere, L.P.L. Digitalization and green economy-changes of business perspectives. In Proceedings of the 2020 4th International Conference on Cloud and Big Data Computing, Virtual, UK, 26–28 August 2020. [Google Scholar]

- Wei, Z.; Sun, L. How to leverage manufacturing digitalization for green process innovation: An information processing perspective. Ind. Manag. Data Syst. 2021, 121, 1026–1044. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Väisänen, J.-M. Digital technologies catalyzing business model innovation for circular economy—Multiple case study. Resour Conserv Recycl 2021, 164, 105155. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Sarkis, J.; Kouhizadeh, M.; Zhu, Q.S. Digitalization and the greening of supply chains. Ind. Manag. Data Syst. 2020, 121, 65–85. [Google Scholar] [CrossRef]

- Trantopoulos, K.; von Krogh, G.; Wallin, M.W.; Woerter, M. External Knowledge and Information Technology: Implications for Process Innovation Performance. MIS Q. 2017, 41, 287. [Google Scholar] [CrossRef]

- Costantini, V.; Crespi, F.; Palma, A. Characterizing the policy mix and its impact on eco-innovation: A patent analysis of energy-efficient technologies. Res. Policy 2017, 46, 799–819. [Google Scholar] [CrossRef]

- Kemp, R.; Oltra, V. Research insights and challenges on eco-innovation dynamics. Ind. Innov. 2011, 18, 249–253. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, X. Can mobile information communication technologies (ICTs) promote the development of renewables?—Evidence from seven countries. Energy Pol. 2021, 149, 112041. [Google Scholar] [CrossRef]

- Zammuto, R.F.; Griffith, T.L.; Majchrzak, A.; Dougherty, D.J.; Faraj, S. Information technology and the changing fabric of organization. Organ Sci. 2007, 18, 749–762. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Siagian, H.; Jie, F. Impact of enhanced Enterprise Resource Planning (ERP) on firm performance through green supply chain management. Sustainability 2021, 13, 4358. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.-A.; Yang, S. Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp 2014, 16, 3–8. [Google Scholar] [CrossRef]

- Lozic, J. Core concept of business transformation: From business digitization to business digital transformation. In Proceedings of the 48th International Scientific Conference on Economic and Social Development—“Managerial Issues in Modern Business”, Warsaw, Poland, 28–29 November 2019. [Google Scholar]

- Lehrer, C.; Wieneke, A.; Vom Brocke, J.; Jung, R.; Seidel, S. How big data analytics enables service innovation: Materiality, affordance, and the individualization of service. J. Manag. Inform. Syst. 2018, 35, 424–460. [Google Scholar] [CrossRef]

- Tallon, P.P.; Ramirez, R.V.; Short, J.E. The Information Artifact in IT Governance: Toward a Theory of Information Governance. J. Manag. Inform. Syst. 2013, 30, 141–177. [Google Scholar] [CrossRef]

- Cardinali, P.G.; De Giovanni, P. Responsible digitalization through digital technologies and green practices. Corp. Soc. Responsib. Environ. Manag. 2022, 29, 984–995. [Google Scholar] [CrossRef]

- De Medeiros, J.F.; Ribeiro, J.L.D.; Cortimiglia, M.N. Success factors for environmentally sustainable product innovation: A systematic literature review. J. Clean. Prod. 2014, 65, 76–86. [Google Scholar] [CrossRef]

- El-Kassar, A.-N.; Singh, S.K. Green innovation and organizational performance: The influence of big data and the moderating role of management commitment and HR practices. Technol. Forecast. Soc. Chang. 2019, 144, 483–498. [Google Scholar] [CrossRef]

- Fussler, C.; James, P. Driving Eco-Innovation: A Breakthrough Discipline for Innovation and Sustainability; Pitman Publishing: Washington, DC, USA, 1996; pp. 23–25. [Google Scholar]

- Oltra, V.; Saint Jean, M. Sectoral systems of environmental innovation: An application to the French automotive industry. Technol. Forecast. Soc. Chang. 2009, 76, 567–583. [Google Scholar] [CrossRef]

- Porter, M.; Van der Linde, C. Green and competitive: Ending the stalemate. In The Dynamics of the Eco-Efficient Economy: Environmental Regulation and Competitive Advantage; Wubben, E.F.M., Ed.; Edward Elgar Publishing: Cheltenham, UK, 1995; pp. 67–79. [Google Scholar]

- Cecere, G.; Corrocher, N.; Mancusi, M.L. Financial constraints and public funding of eco-innovation: Empirical evidence from European SMEs. Small Bus. Econ. 2020, 54, 285–302. [Google Scholar] [CrossRef]

- Waqas, M.; Honggang, X.; Ahmad, N.; Khan, S.A.R.; Iqbal, M. Big data analytics as a roadmap towards green innovation, competitive advantage and environmental performance. J. Clean. Prod. 2021, 323, 128998. [Google Scholar] [CrossRef]

- Cao, S.; Nie, L.; Sun, H.; Sun, W.; Taghizadeh-Hesary, F. Digital finance, green technological innovation and energy-environmental performance: Evidence from China’s regional economies. J. Clean. Prod. 2021, 327, 129458. [Google Scholar] [CrossRef]

- Kobarg, S.; Stumpf-Wollersheim, J.; Welpe, I.M. More is not always better: Effects of collaboration breadth and depth on radical and incremental innovation performance at the project level. Res. Policy 2019, 48, 1–10. [Google Scholar] [CrossRef]

- Scuotto, V.; Santoro, G.; Bresciani, S.; Del Giudice, M. Shifting intra-and inter-organizational innovation processes towards digital business: An empirical analysis of SMEs. Creat. Innov. Manag. 2017, 26, 247–255. [Google Scholar] [CrossRef]

- Un, C.A.; Cuervo-Cazurra, A.; Asakawa, K. R&D collaborations and product innovation. J. Prod. Innov. Manag. 2010, 27, 673–689. [Google Scholar] [CrossRef]

- Maietta, O.W. Determinants of university–firm R&D collaboration and its impact on innovation: A perspective from a low-tech industry. Res. Policy 2015, 44, 1341–1359. [Google Scholar] [CrossRef]

- Banerjee, S.B. Corporate environmentalism: The construct and its measurement. J. Bus. Res. 2002, 55, 177–191. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive advantage, agglomeration economies, and regional policy. Int. Reg. Sci. Rev 1996, 19, 85–90. [Google Scholar] [CrossRef]

- Liu, B.; Yang, B.; Xiao, J.; Zhu, D.; Zhang, B.; Wang, Z.; Dong, M. Review of Optimization Dynamically Applied in the Construction and the Application Potential of ICT. Sustainability 2021, 13, 5478. [Google Scholar] [CrossRef]

- Orellana, S. Digitalizing collaboration. Res. Technol. Manag. 2017, 60, 12–14. [Google Scholar] [CrossRef]

- Adomako, S. Environmental collaboration, sustainable innovation, and small and medium-sized enterprise growth in sub-Saharan Africa: Evidence from Ghana. Sustain. Dev. 2020, 28, 1609–1619. [Google Scholar] [CrossRef]

- Kong, T.; Feng, T.; Ye, C. Advanced manufacturing technologies and green innovation: The role of internal environmental collaboration. Sustainability 2016, 8, 1056. [Google Scholar] [CrossRef]

- Schilling, M.A.; Green, E. Recombinant search and breakthrough idea generation: An analysis of high impact papers in the social sciences. Res. Policy 2011, 40, 1321–1331. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Green project partnership in the supply chain: The case of the package printing industry. J. Clean. Prod. 2006, 14, 661–671. [Google Scholar] [CrossRef]

- Montabon, F.; Sroufe, R.; Narasimhan, R. An examination of corporate reporting, environmental management practices and firm performance. J. Oper. Manag. 2007, 25, 998–1014. [Google Scholar] [CrossRef]

- Günther, W.A.; Rezazade Mehrizi, M.H.; Huysman, M.; Feldberg, F. Debating big data: A literature review on realizing value from big data. J. Strateg. Inf. Syst. 2017, 26, 191–209. [Google Scholar] [CrossRef]

- Yli-Renko, H.; Autio, E.; Sapienza, H.J. Social capital, knowledge acquisition, and knowledge exploitation in young technology-based firms. Strateg. Manag. J. 2001, 22, 587–613. [Google Scholar] [CrossRef]

- Cohen, W.M.; Levinthal, D.A. Absorptive capacity: A new perspective on learning and innovation. Adm. Sci. Q. 1990, 35, 128–152. [Google Scholar] [CrossRef]

- Kaplan, S.; Vakili, K. The double-edged sword of recombination in breakthrough innovation. Strateg. Manag. J. 2015, 36, 1435–1457. [Google Scholar] [CrossRef]

- Fleming, L. Recombinant uncertainty in technological search. Manag. Sci. 2001, 47, 117–132. [Google Scholar] [CrossRef]

- Wuchty, S.; Jones, B.F.; Uzzi, B. The increasing dominance of teams in production of knowledge. Science 2007, 316, 1036–1039. [Google Scholar] [CrossRef]

- Aboelmaged, M. Direct and indirect effects of eco-innovation, environmental orientation and supplier collaboration on hotel performance: An empirical study. J. Clean. Prod. 2018, 184, 537–549. [Google Scholar] [CrossRef]

- Trajtenberg, M.; Henderson, R.; Jaffe, A. University versus corporate patents: A window on the basicness of invention. Econ. Innov. New Technol. 1997, 5, 19–50. [Google Scholar] [CrossRef]

- Pettus, M.L.; Kor, Y.Y.; Mahoney, J.T. Stepping stones to firm growth: Evidence from the deregulated US railroad industry. Acad. Manag. Proc. 2010, 1, 1–6. [Google Scholar] [CrossRef]

- Drover, W.; Wood, M.S.; Corbett, A.C. Toward a cognitive view of signalling theory: Individual attention and signal set interpretation. J. Manag. Stud. 2018, 55, 209–231. [Google Scholar] [CrossRef]

- Puranam, P.; Singh, H.; Zollo, M. Organizing for innovation: Managing the coordination-autonomy dilemma in technology acquisitions. Acad. Manag. J. 2006, 49, 263–280. [Google Scholar] [CrossRef]

- Chaiken, S.; Trope, Y. Dual-Process Theories in Social Psychology; Guilford Press: New York, NY, USA, 1999; pp. 83–86. [Google Scholar]

- Evans, J.S.B. Dual-processing accounts of reasoning, judgment, and social cognition. Annu. Rev. Psychol. 2008, 59, 255–278. [Google Scholar] [CrossRef]

- Appio, F.P.; De Luca, L.M.; Morgan, R.; Martini, A. Patent portfolio diversity and firm profitability: A question of specialization or diversification? J. Bus. Res. 2019, 101, 255–267. [Google Scholar] [CrossRef]

- Aragón-Correa, J.A.; Sharma, S. A Contingent Resource-Based View of Proactive Corporate Environmental Strategy. Acad. Manag. Rev. 2003, 28, 71–88. [Google Scholar] [CrossRef]

- Dechezleprêtre, A.; Glachant, M.; Haščič, I.; Johnstone, N.; Ménière, Y. Invention and Transfer of Climate Change–Mitigation Technologies: A Global Analysis. Rev. Environ. Econ. Policy 2011, 5, 109–130. [Google Scholar] [CrossRef]

- Jaffe, A.B.; Palmer, K. Environmental Regulation and Innovation: A Panel Data Study. Rev. Econ. Stat. 1997, 79, 610–619. [Google Scholar] [CrossRef]

- OECD. Patent Search Strategies for the Identification of Selected Environment-Related Technologies (ENV-TECH). Available online: https://www.oecd.org/environment/consumption-innovation/ENV-tech%20search%20strategies,%20version%20for%20OECDstat%20(2016).pdf (accessed on 29 March 2016).

- Noailly, J.; Batrakova, S. Stimulating energy-efficient innovations in the Dutch building sector: Empirical evidence from patent counts and policy lessons. Energy Pol. 2010, 38, 7803–7817. [Google Scholar] [CrossRef]

- Park, Y.; Mithas, S. Organized Complexity of Digital Business Strategy: A Configurational Perspective. MIS Q. 2020, 44, 85–127. [Google Scholar] [CrossRef]

- Xie, X.M.; Huo, J.G.; Zou, H.L. Green process innovation, green product innovation, and corporate financial performance: A content analysis method. J. Bus. Res. 2019, 101, 697–706. [Google Scholar] [CrossRef]

- North, D.C. A transaction cost theory of politics. J. Theor. Polit. 1990, 2, 355–367. [Google Scholar] [CrossRef]

- Chan, R.Y.; He, H.; Chan, H.K.; Wang, W.Y. Environmental orientation and corporate performance: The mediation mechanism of green supply chain management and moderating effect of competitive intensity. Ind. Mark. Manag. 2012, 41, 621–630. [Google Scholar] [CrossRef]

- Baker, W.E.; Sinkula, J.M. Market orientation and the new product paradox. J. Prod. Innov. Manag. 2005, 22, 483–502. [Google Scholar] [CrossRef]

- Vakili, K.; Kaplan, S. Organizing for innovation: A contingency view on innovative team configuration. Strateg. Manag. J. 2021, 42, 1159–1183. [Google Scholar] [CrossRef]

- Moreira, S.; Markus, A.; Laursen, K. Knowledge diversity and coordination: The effect of intrafirm inventor task networks on absorption speed. Strateg. Manag. J. 2018, 39, 2517–2546. [Google Scholar] [CrossRef]

- Vedula, S.; York, J.G.; Corbett, A.C. Through the Looking-Glass: The Impact of Regional Institutional Logics and Knowledge Pool Characteristics on Opportunity Recognition and Market Entry. J. Manag. Stud. 2019, 56, 1414–1451. [Google Scholar] [CrossRef]

- Nemlioglu, I.; Mallick, S.K. Do Managerial Practices Matter in Innovation and Firm Performance Relations? New Evidence from the UK. Eur. Financ. Manag. 2017, 23, 1016–1061. [Google Scholar] [CrossRef]

- Armstrong, C.S.; Core, J.E.; Guay, W.R. Do independent directors cause improvements in firm transparency? J. Financ. Econ. 2014, 113, 383–403. [Google Scholar] [CrossRef]

- Shaw, D. On-site samples’ regression: Problems of non-negative integers, truncation, and endogenous stratification. J. Econom. 1988, 37, 211–223. [Google Scholar] [CrossRef]

- Silva, J.M.C.S.; Tenreyro, S. The log of gravity. Rev. Econ. Stat. 2006, 88, 641–658. [Google Scholar] [CrossRef]

- Bercovitz, J.; Feldman, M. The mechanisms of collaboration in inventive teams: Composition, social networks, and geography. Res. Policy 2011, 40, 81–93. [Google Scholar] [CrossRef]

- Hanseth, O.; Ciborra, C. Risk, Complexity and ICT.; Edward Elgar Publishing: Northampton, MA, USA, 2007; pp. 44–57. [Google Scholar]

- Myers, I.B.; Myers, P.B. Gifts Differing: Understanding Personality Type, 2nd ed.; Nicholas Brealey: London, UK, 2010; pp. 127–136. [Google Scholar]

- Hansen, B.E. Sample splitting and threshold estimation. Econometrica 2000, 68, 575–603. [Google Scholar] [CrossRef]

- Hwang, I. The effect of collaborative innovation on ICT-based technological convergence: A patent-based analysis. PLoS ONE 2020, 15, e0228616. [Google Scholar] [CrossRef]

- Parrotta, P.; Pozzoli, D.; Pytlikova, M. The nexus between labor diversity and firm’s innovation. J. Popul. Econ. 2014, 27, 303–364. [Google Scholar] [CrossRef]

- Banerjee, R.; Gupta, K. The effects of environmental sustainability and R&D on corporate risk-taking: International evidence. Energy Econ. 2017, 65, 1–15. [Google Scholar] [CrossRef]

- Yun, L.; Yao, X.; Zhu, W.; Zhang, Z. Evaluating the Effect of Redundant Resources on Corporate Entrepreneurial Performance. Sustainability 2022, 14, 7101. [Google Scholar] [CrossRef]

- Hottenrott, H.; Lopes-Bento, C. R&D partnerships and innovation performance: Can there be too much of a good thing? J. Prod. Innov. Manag. 2016, 33, 773–794. [Google Scholar] [CrossRef]

- Sadollah, A.; Nasir, M.; Geem, Z.W. Sustainability and optimization: From conceptual fundamentals to applications. Sustainability 2020, 12, 2027. [Google Scholar] [CrossRef]

- Deephouse, D.L. To be different, or to be the same? It’s a question (and theory) of strategic balance. Strateg. Manag. J. 1999, 20, 147–166. [Google Scholar] [CrossRef]

| Variable names | Measurements | Data sources | Sources |

|---|---|---|---|

| Green technological innovation | OECD Env-Tech categories | Patentics Database | [13] |

| Digital optimization | Context analysis | Firms’ Annual Reports | [19] |

| Green R&D collaboration | IPC-CPC categories with Economic Industry | Patentics Database | [70] |

| External environmental orientation | Context analysis | Firms’ Annual Reports | [66] |

| Firm size | Total assets (billion) | CSMAR Database | [64] |

| Firm leverage ratio | Total Debt divide Total Capital | CSMAR Database | [71] |

| Total assets turnover | The ratio of main business income to total assets | CSMAR Database | [64] |

| Proportion of independent directors | independent directors divide total directors | Resset Database | [72] |

| Firm age | Number of years listed in the Chinese stock market to year 2013 | Resset Database | [64] |

| Firm Pattern | Stated owned or non-Stated owned | Resset Database | [64] |

| Variable Types | Variable Names | Variable Symbols | Observation | Mean | Std | Min | Max |

|---|---|---|---|---|---|---|---|

| Dependent Variable | Green technological innovation | GreenInno | 11,249 | 1.524 | 13.870 | 0.000 | 176.000 |

| Independent Variable | Digital optimization | DIG | 10,027 | 4.540 | 5.141 | 0.000 | 16.000 |

| Controls | Firm size | Size | 11,249 | 21.668 | 1.115 | 16.592 | 26.751 |

| Firm leverage ratio | Lev | 11,249 | 0.321 | 0.238 | −0.006 | 10.878 | |

| Total assets turnover | ROA | 11,249 | 0.043 | 0.090 | −3.911 | 0.863 | |

| Proportion of independent directors | Identi | 11,247 | 0.376 | 0.056 | 0.200 | 0.800 | |

| Firm age | Age | 11,249 | 20.632 | 5.292 | 5.000 | 62.000 | |

| Firm Pattern | Pattern | 11,249 | 0.671 | 0.142 | 0.000 | 1.000 | |

| Mediator | Green R&D collaboration | Co-work | 11,249 | 8.924 | 2.581 | 0.000 | 10.000 |

| Moderator | External environmental orientation | EPW | 11,219 | 4.439 | 2.038 | 1.000 | 11.000 |

| GreenInno | DIG | Size | Lev | ROA | Identi | Age | Pattern | EPW | Co-work | |

|---|---|---|---|---|---|---|---|---|---|---|

| GreenInno | 1 | |||||||||

| DIG | 0.022 ** | 1 | ||||||||

| Size | 0.197 *** | 0.085 *** | 1 | |||||||

| Lev | 0.086 *** | 0.011 | 0.295 *** | 1 | ||||||

| ROA | 0.009 | −0.015 | −0.063 *** | −0.293 *** | 1 | |||||

| Identi | 0.001 | 0.026 *** | −0.011 | −0.003 | −0.005 | 1 | ||||

| Age | 0.024 ** | −0.052 *** | 0.133 *** | 0.097 *** | −0.032 *** | −0.043 *** | 1 | |||

| Pattern | −0.055 *** | 0.005 | −0.314 *** | −0.171 *** | 0.093 *** | 0.017 * | −0.233 ** | 1 | ||

| EPW | 0.031 *** | 0.006 | 0.332 *** | 0.130 *** | −0.021 ** | −0.062 *** | 0.107 *** | −0.120 ** | 1 | |

| Co-work | −0.079 *** | −0.048 *** | −0.105 *** | −0.094 *** | −0.021 ** | 0.034 *** | 0.032 *** | 0.032 *** | −0.068 *** | 1 |

| Variables | Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 |

|---|---|---|---|---|---|---|

| Co-work | Co-work | GreenInno | GreenInno | GreenInno | GreenInno | |

| DIG | 0.013 * | 0.046 * | 0.067 * | 0.071 ** | ||

| (0.008) | (0.023) | (0.035) | (0.034) | |||

| DIG2 | −0.002 | −0.005 ** | −0.007 *** | |||

| (0.002) | (0.002) | (0.002) | ||||

| Co-work | 0.136 *** | 0.672 *** | −0.108 *** | 0.711 *** | ||

| (0.016) | (0.053) | (0.021) | (0.081) | |||

| Co-work2 | −0.076 *** | −0.076 *** | ||||

| (0.005) | (0.006) | |||||

| Size | 0.919 *** | 0.990 *** | 0.978 *** | 0.954 *** | 0.957 *** | 0.962 *** |

| (0.051) | (0.061) | (0.057) | (0.054) | (0.051) | (0.049) | |

| Lev | 1.180 *** | 1.486 *** | 1.482 *** | 1.435 *** | 1.450 *** | 1.138 *** |

| (0.132) | (0.157) | (0.155) | (0.156) | (0.157) | (0.166) | |

| ROA | 4.421 *** | 6.425 *** | 6.459 *** | 6.058 *** | 6.193 *** | 6.154 *** |

| (0.730) | (0.957) | (0.947) | (0.907) | (0.910) | (0.922) | |

| Identi | −1.827 | −3.135 ** | −3.121 ** | −2.894 ** | −2.962 ** | −2.978 ** |

| (1.167) | (1.489) | (1.484) | (1.428) | (1.355) | (1.364) | |

| Age | −0.010 | −0.013 | −0.013 | −0.017 | −0.015 | −0.016 |

| (0.014) | (0.015) | (0.014) | (0.014) | (0.013) | (0.012) | |

| Pattern | 0.027 | 0.021 | 0.030 | −0.001 | 0.006 | 0.009 |

| (0.092) | (0.126) | (0.128) | (0.126) | (0.126) | (0.131) | |

| Constant | −3.882 *** | −3.864 *** | −18.476 *** | −19.381 *** | −19.689 *** | −21.287 *** |

| (0.821) | (0.821) | (1.436) | (1.524) | (1.670) | (1.662) | |

| Year Fixed | Y | Y | Y | Y | Y | Y |

| Industry Fixed | Y | Y | Y | Y | Y | Y |

| Observations | 5875 | 5875 | 11,247 | 11,247 | 5875 | 5875 |

| Log-likelihood | −3041.71 | −3039.97 | −23,597.47 | −19,712.41 | −13,970.54 | −11,709.42 |

| Wald chi2 | 100.44 | 108.83 | 440.18 | 1976.25 | 404.86 | 1252.79 |

| Pseudo R2 | 0.0593 | 0.0599 | 0.5578 | 0.6306 | 0.6107 | 0.6737 |

| Variables | Model 1 | Model 2 | Model 3 | Model 4 | Model 5 |

|---|---|---|---|---|---|

| Co-work | GreenInno | GreenInno | GreenInno | GreenInno | |

| DIG | 0.015 ** | 0.010 ** | 0.069 ** | 0.014 ** | 0.279 *** |

| (0.023) | (0.011) | (0.033) | (0.027) | (0.093) | |

| DIG2 | −0.006 ** | −0.020 *** | |||

| (0.002) | (0.007) | ||||

| EPW | 0.024 * | 0.005 * | 0.063 | ||

| (0.047) | (0.062) | (0.053) | |||

| DIG × EPW | 0.041 ** | −0.006 * | −0.051 ** | ||

| (0.022) | (0.006) | (0.020) | |||

| DIG2 × EPW | 0.003 ** | ||||

| (0.001) | |||||

| Constant | −19.615 *** | −20.815 *** | −20.638 *** | −20.677 *** | −20.648 *** |

| (1.220) | (1.517) | (1.474) | (1.292) | (1.289) | |

| Controls | Y | Y | Y | Y | Y |

| Year Fixed | Y | Y | Y | Y | Y |

| Industry Fixed | Y | Y | Y | Y | Y |

| Observations | 5875 | 5875 | 5875 | 5875 | 5875 |

| Log-likelihood | −15,114.07 | 14,622.97 | −14,537.49 | −14,594.61 | −14,379.58 |

| Wald chi2 | 459.08 | 423.93 | 479.87 | 562.20 | 573.72 |

| Pseudo R2 | 0.5294 | 0.5925 | 0.5949 | 0.5933 | 0.5993 |

| Variable | Thresholds | Thresholds Number | RSS | MES | F | Prob |

|---|---|---|---|---|---|---|

| DIG | Single | 10.167 | 3.26 × 108 | 9.39 × 108 | 37.59 | 0.03 |

| Double | 48.505 | 3.01 × 108 | 9.63 × 108 | 2.81 | 0.78 |

| Variable | Poisson-Regression | |||

|---|---|---|---|---|

| r1 ≤ 10.167 | r1 ≤ 10.167 | r1 > 10.167 | r1 > 10.167 | |

| DIG | 0.006 * | 0.062 * | −0.047 * | −0.030 |

| (0.012) | (0.037) | (0.019) | (0.056) | |

| DIG2 | −0.004 | −0.001 | ||

| (0.003) | (0.003) | |||

| Controls | Y | Y | Y | Y |

| Observations | 4619 | 4619 | 1225 | 1225 |

| Variables | Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 |

|---|---|---|---|---|---|---|

| Co-work | Greeninno | Co-work | Greeninno | Co-work | Greeninno | |

| DIG_IV | 0.169 ** | 0.287 * | 0.275 * | 0.347 ** | 0.065 * | 0.065 * |

| (0.027) | (0.043) | (0.056) | (0.039) | (0.032) | (0.032) | |

| DIG2_IV | −0.035 ** | −0.020 * | −0.006 * | |||

| (0.004) | (0.003) | (0.003) | ||||

| Intellectual property | 3.577 * | 3.462 | ||||

| (0.087) | (0.076) | |||||

| Resource redundancy | 0.283 | 0.336 | ||||

| (0.008) | (0.011) | |||||

| Environmental uncertainty | 1.035 | 1.079 | ||||

| (0.022) | (0.024) | |||||

| Controls | Y | Y | Y | Y | Y | Y |

| Year Fixed | Y | Y | Y | Y | Y | Y |

| Industry Fixed | Y | Y | Y | Y | Y | Y |

| Observations | 10025 | 5875 | 10025 | 5875 | 10025 | 5875 |

| LM | 126.392 | 115.637 | ||||

| [0.000] | [0.000] | |||||

| Log-likelihood | −7179.44 | −5836.81 | −6859.24 | −7669.05 | −19365.73 | −21,447.60 |

| Wald chi2 | 125.67 | 118.29 | 309.45 | 293.59 | 373.54 | 335.86 |

| PseudoR2 | 0.248 | 0.227 | 0.444 | 0.415 | 0.471 | 0.422 |

| Variables | Model 1 | Model 2 | Model 3 | Model 4 | Model 5 |

|---|---|---|---|---|---|

| DIG | 0.041 ** | 0.063 ** | 0.068 * | 0.036 | 0.091 |

| (0.011) | (0.030) | (0.026) | (0.040) | (0.077) | |

| DIG2 | −0.003 ** | −0.005 ** | −0.004 * | −0.002 | −0.010 |

| (0.001) | (0.002) | (0.001) | (0.009) | (0.014) | |

| DIG3 | 0.000 | ||||

| (0.000) | |||||

| Controls | Y | Y | Y | Y | Y |

| Year Fixed | Y | Y | Y | Y | Y |

| Industry Fixed | Y | Y | Y | Y | Y |

| Pseudo R2 | 0.623 | 0.595 | 0.470 | 0.554 | 0.587 |

| Observations | 5427 | 2990 | 5908 | 7728 | 5875 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Wang, S. Digital Optimization, Green R&D Collaboration, and Green Technological Innovation in Manufacturing Enterprises. Sustainability 2022, 14, 12106. https://doi.org/10.3390/su141912106

Li C, Wang S. Digital Optimization, Green R&D Collaboration, and Green Technological Innovation in Manufacturing Enterprises. Sustainability. 2022; 14(19):12106. https://doi.org/10.3390/su141912106

Chicago/Turabian StyleLi, Changchun, and Sen Wang. 2022. "Digital Optimization, Green R&D Collaboration, and Green Technological Innovation in Manufacturing Enterprises" Sustainability 14, no. 19: 12106. https://doi.org/10.3390/su141912106

APA StyleLi, C., & Wang, S. (2022). Digital Optimization, Green R&D Collaboration, and Green Technological Innovation in Manufacturing Enterprises. Sustainability, 14(19), 12106. https://doi.org/10.3390/su141912106