Abstract

Food loss and waste are two of the many problems that modern society is facing. To date, among many solutions, the circular economy is the one prevailing. A successful transition toward a circular economy (CE) requires the food sector to overcome the challenges of today’s complex food supply chains such as information asymmetry, poor cooperation among stakeholders, and concerns about food safety. Blockchain, a form of distributed ledger technology, has been progressively gaining traction in supply chains in areas like data management, certifying product provenance and tracking products. Despite its importance, knowledge around the potential of the blockchain technology in facilitating the transition towards a circular economy in the agri-food sector is fragmented. This review provides evidence-based insights into the blockchain implementations in the food supply chains and the implications for CE. Our findings indicated four major areas that blockchain could accelerate CE in the agri-food sector: improving data utility; supply chain management efficacy; enhanced eco-efficiency; and superior traceability.

1. Introduction

One of the most pressing challenges of our modern society is food waste. It is estimated that one third of the food produced globally is wasted every year [1]. In addition, global population growth and unsustainable production–consumption patterns put pressure on the agri-food system. It is estimated that by 2050 the demand for food in the world will increase by 50% (FAO 2016), which might subsequently cause a significant increase in food waste [2]. Part of the problem is related to the current linear economy with the ‘take-make-dispose’ pattern. This method of production does not use renewable resources and usually prioritizes sales but not collaboration or innovation [3]. Thus, this linear method of production is maximizing the extraction of collected resources, processing them into products that are consumed until discarded as waste [4]. Eventually this linear model of production, with its inefficient use of raw materials, will result in higher resource prices and supply disruptions [5,6].

Recently, the notion of a ‘Circular Economy’ (CE) has gained traction as an alternative to the currently prevailing linear economic system, though it is far from clearly defined [7,8]. Broadly, CE refers to “an economy where waste in principle is not generated, […] and the value of products, materials and resources is retained in the economy as long as possible” [9] (p. 78). CE in the agri-food sector is based on the principles of reducing demands on external inputs, recirculating nutrients, and minimizing the environmental impact of discharges and runoff [2,10,11,12].

To date, research has found some strategies for limiting and/or improving the usage of resources and advancing in the adoption of CE. Advances in the technology of the reduction in raw materials for output by increasing the recycling of the waste enable: utilizing by-products that can be converted to new inputs or bioenergy for agriculture; improving storage methods with technology that reduces the risk of destruction of perishable goods; and new distribution methods to prevent postharvest losses. These are examples of strategies in shifting toward CE [13]. Regenerative practices, such as local and organic produce, are also helping the shift toward CE by reducing emissions and maintaining natural resources (see e.g., [14,15,16,17]). However, in the transition toward CE, food value chains are facing obstacles such as lack of data and information asymmetry [18], complexities of the food supply chains, and lack of technical competencies [19,20,21]. In addition, safety concerns (e.g., microbial or mycotoxin contamination, antibiotic and pesticide residues, and zoonotic disease spread) may arise from the use of recycled materials for food production [22,23,24]. Therefore, a successful transition towards the CE requires monitoring the food safety of recycled materials and environmental impacts as well as improving eco-efficiency in production [17]. This transition also requires effective communication and cooperation across actors within the supply chain [20].

Blockchain is increasingly viewed as a collaborative platform that helps achieve sustainable agriculture [25]. Currently, most of the blockchain use cases in the agriculture and food sectors are developed concerning food traceability (e.g., [26,27,28,29,30,31,32]), however, it seems that this technology has the potential to also facilitate transparent information exchange and empower food supply chains [33]. A blockchain is a distributed ledger of transactions that are maintained across several nodes that are linked to, and managed collectively by, all participants in a peer-to-peer network [34]. A new block of information (a record) must be verified by the network (known as consensus mechanisms) before adding it to the blockchain [21]. Any modification to the recorded data should also adhere to the consensus protocol (e.g., Proof-of-Work (PoW), Proof-of-Stake (PoS), and Delegated PoS (DPoS)), meaning the majority of the members of the network should agree [35]. Besides, a change to any single record (value) will bring about the alteration of all its subsequent records. It is therefore very difficult to alter data documented in a blockchain (although there are still security issues due to faulty technology implementation that needs to be fixed [36,37]. Therefore, blockchain is viewed as an immutable distributed decentralized data management system that has the potential to revolutionize data use in agriculture [38].

Previous reviews have indicated that a successful application of CE should be preceded by an adequate policy and regulatory framework, and blockchain can be an important tool for establishing these frameworks [20,39]. In addition, it has been advocated that the usage of blockchain contributes to the development of new sustainable food systems [40]. While other reviews have reported on the applications of blockchain this far in food supply chain [41,42,43,44], to the best of our knowledge and from what was reported above, none of these reviews have explored how elements of blockchain can be used for addressing the challenges that CE is currently facing in the food supply chain. Therefore, this review will firstly introduce the current state of art of CE and its barriers and then report on the ways blockchain can improve the issues of CE in the food sector. In contrast to the existing reviews, this paper gives a focused overview on the intersection of blockchain agri-food use cases and CE.

The remaining part of the paper proceeds as follows. The second section concerns the method for data collection and analysis. The third section provides an overview of barriers in transition towards CE in the agri-food sector followed by analysis on the reported blockchain applications with implications for the CE in the food system. Fourth section discusses the theoretical significance, practical implications, limitations, and future research. The last section briefly concludes the review.

2. Materials and Methods

We have conducted a narrative review [45] to synthesize the literature on the application of blockchain technology in the agri-food sector and explore the evidence level supporting insights for the transition towards CE in this sector. Following the Green et al. [46] approach to narrative review (overview) writing, this review was performed through reporting sources, search terms, inclusion and exclusion criteria, and synthesis results. A narrative review offers a breadth of literature coverage and presents a broad perspective on a topic [47]. It is particularly useful for providing insights and interpretations repeatedly used in the review studies of the sustainability concerns [48,49]. We selected this methodology as our aim was not to thoroughly examine the characteristics of different blockchain frameworks and technical implications, but rather to explore insights that this technology offers for a transition towards CE in the agri-food sector [50].

In August 2021, we searched within the common electronic databases ScienceDirect, Web of Science, and Scopus. in our search, we did not include additional literature sources such as Google Scholar, AgEconSearch and various databases of grey literature, online resources, technical magazines, and non-peer-reviewed articles that could be helpful to deliver a more inclusive representation of such a new subject. Through the literature databases we explored high-quality, peer-reviewed publications and this decision allowed us to concentrate on the content rather than on the scientific credibility of the research under consideration

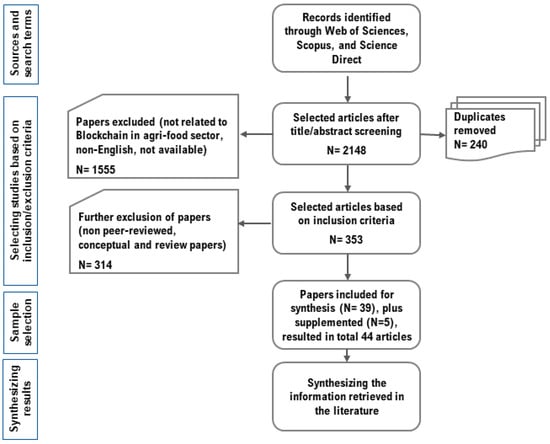

The search strategy included three main concepts of ‘blockchain technology’, ‘agricultural sector’ and ‘circular economy’ keywords. The search query starting for the mentioned databases was ((Blockchain) AND (Agriculture* OR Agribusiness* OR Farm* OR Food*) AND (Valorize* OR Recycle* OR Circular*)). We used this query for searching the title, abstract and keywords through each database. Our search was limited to peer-reviewed articles published in English between 2017–2021, as literature prior to 2017 was considered unlikely to reflect blockchain technology’s contemporary research developments. This search initially yielded 2148 articles, which were independently reviewed by two of the authors to exclude those irrelevant to the link between blockchain implementations in the agri-food sector and circular economy. We excluded commentaries, reviews, and grey literature (e.g., conference proceedings, book chapters, unpublished theses, reports, and white papers). Our focus was only to include papers presenting original empirical research results on the application of blockchain-enabled solutions in the agriculture and food supply chains. We also did not consider articles that focused on other aspects of precision agriculture (such as Industry 4.0 and the Internet of Things). Ultimately, 39 articles were assessed as being eligible for full-text review. The reference lists of included papers were searched, and relevant articles not retrieved in our search are added to our final sample. The final set included 44 articles. The key steps of our narrative literature search are presented in Figure 1.

Figure 1.

The overall flow of literature search and selection.

3. Results

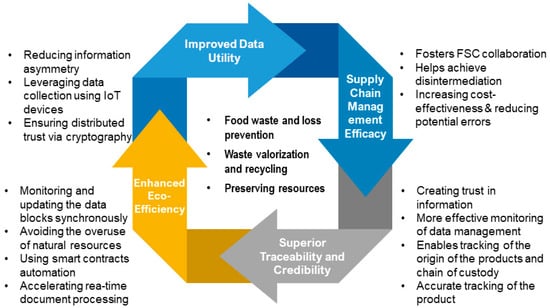

In this section, we present the outcomes of our review on the role of blockchain technology in facilitating a transition toward a circular agri-food system. We start by reviewing the main challenges in shifting to the agri-food CE across the retrieved articles followed by the outcome of our review by depicting areas where blockchain contributed to a circular food supply chain (see Figure 2).

Figure 2.

How blockchain technology facilitates transition towards a circular economy in the food supply chain (own elaboration).

This study was a narrative review built on three major scientific databases covering the period 2017–2021. I. Since the aim of this review was not to provide a critical assessment of drivers and challenges of incorporating blockchain-enabled systems, details on the theoretical framework of the studies and the relationship between variables are not present in the description of the results. Recent reviews authored by Pandey and Singal [51], Sanka and Cheung [52] and Li et al. [53] can be regarded as a supplement to this review.

3.1. Challenges of Circular Economy in the Food Sector

Despite its advantages, the transition to a CE in the food supply chain (FSC) remains limited [54].

CE transition requires significant changes in the supply chain ranging from the design of products that are more resource-efficient to the waste management and recycling of biomass [55]. Reviewing the literature indicated that one of the major obstacles is the lack of information on product design and production [56]. This would require advanced data processing and forecasting techniques [57], as well as a reliable and transparent platform for communicating across actors in the supply chain [21]. Given the complex and interconnected nature of food supply chains, transition toward CE demands mechanisms that facilitate chain management and reduce the unnecessary intermediaries [35]. The findings in this review also indicate that another factor hindering CE in the agri-food sector is the lack of technological infrastructure [19]. In addition, due to the perishable and short shelf life nature of the products, food safety is one of the major concerns [21]. These obstacles are summarized in Table 1 and further elaborated below.

Table 1.

Barriers to implementing CE in the agri-food sector.

3.1.1. Lack of Information on Product and Processes

Reviewing the literature indicates that the current food supply chain system suffers from a lack of transparency and information asymmetry [81,82] that increases transaction costs, and ultimately leads to market failure [58]. Information asymmetry occurs when all parties involved in the process are not equally informed about the transaction; this problem arises in part due to the centralized food supply chain systems that are prone to erroneous data and even data tampering [83,84,85]. In addition, different stakeholders within the supply chain may use different information management platforms that make it difficult to connect them [18].

One of the major principles in the transition towards CE is the design of products that are eco-efficient, which often requires processing large data acquired from various life cycle analyses [86]. Establishing these eco-efficient products entails transparent communication and verification of transactions across the food value chain. As indicated by Eijk [60], FSC is currently facing the problem of obscure cross-cycle and cross-sector operations. The absence of an efficient mechanism for recording, processing and retrieving information will lead to long periods of delay in data processing, disruption to the food system, and hence food waste [87].

Moreover, in the realm of the CE, the concept of waste valorization has emerged to reduce the consumption of raw materials and reduce waste. Successful valorization (and industrial symbiosis) depends on good knowledge of resources and energy flows across industrial sectors and geographical regions [60]. A number of authors have recognized that the lack of reliable information on the composition and origin of materials runs the risk of choosing low-quality or even unsafe material among FSC actors [85,86]. Furthermore, in the absence of valid data, food fraud occurs which adds to the crisis regarding lack of trust in food systems [86]. As indicated in Table 1, the issue of trust in the food system and concerns for food fraud have been discussed by a great number of authors in the literature [62,63,64,65,66]. Food fraud poses a serious threat to the food system but can take different forms (from the dilution of alcoholic beverages to the intentional mislabelling of allergens) and hence information is often difficult to detect. All of these concerns indicate that waste valorization requires a platform for transparent information exchange concerning inputs and outputs to optimize the processes drawn [56].

3.1.2. Complex Supply Chains

Global FSCs are labor-intensive and spread across diverse locations (often across international borders) with a broad range of stakeholders. There exists a considerable body of literature on complexities in the food supply chain and different kinds of risks due to these complexities [63,64,65,66,68]. The risks that supply chains are exposed to consist of demand-side, supply-side and catastrophic risks [88]. Supply-side risks include suppliers’ risks in terms of capacity limitation (e.g., poor logistics performance, and telecommunication) and technology incompatibilities (e.g., due to changes in intellectual properties, and skills) [89]. Demand-side risks refer to the disruptions evolving from downstream supply chain operations. Demand disruptions are mainly induced by the mismatch between the forecast and real demands or from improper supply chain coordination [88]. The bullwhip effect is a well-known demand-side risk which denotes the amplification of demand fluctuations as it moves upstream in the supply chain [90]. Catastrophic risks encompass natural disasters (e.g., droughts and floods), social-political disturbances (e.g., political and regulatory instabilities), and economic crises [88]. The possible negative consequences of these disruptions are obsolescence and inefficient capacity utilization [88], which eventually result in food waste and loss [20]. As discussed by Avraamidou, Baratsas, Tian and Pistikopoulos [54], the transition towards CE presents a multitude of benefits yet entails substantial transformation and investment costs, which may cause additional disturbances in the food supply chain. Nowadays, the robustness of supply chains (i.e., the ability to maintain their operations and cope with external and internal disturbances) is becoming increasingly important [91].

Since food production and consumption often occur in different geographical locations, supply chains may need to be restructured to promote the re-purposing and recycling of waste material. Incentives are desired for entities throughout the supply chain to enthusiastically consider sustainable resources, as well as valorization and recycling options [56]. Extant literature emphasizes that in transition towards CE, active cooperation between stakeholders in the supply chain is essential to achieve superior supply chain management and minimize environmental adverse effects [20,92,93,94]. Poor cooperation among participants and stakeholders will result in low integration in supply chains and distortions in demand (e.g., the bullwhip effect) [68]. Supply chain integration principally refers to the ability of stakeholders to effectively communicate and seamlessly exchange information. Continuous, cross-organizational integration of the supply chain is an inevitable need for the food supply chain in a time of increased disturbances. Supply chain integration necessitates enhanced ‘visibility’ through the value chain, i.e., logistics and operational systems must be integrated through efficient information-sharing mechanisms. Supply chain visibility concerns capturing and analyzing timely and accurate supply chain data that informs decision-making, mitigates risk, and improves processes [95]. Supply chain visibility demands trust and cooperation among trading partners [68]. Hence, when the level of trust is high among stakeholders, they will most likely adopt a cooperative/collaborative approach [68,96] and in long run this leads to enhanced supply chain efficiency [97].

A series of recent studies has indicated that a fundamental way to improve the visibility and robustness of the food supply chain is to employ distributed, decentralized control solutions [20,90]. Cyber–Physical Systems (CPS) are considered a solution to increase supply chain robustness. CPS are mechanisms of joint computational entities that are in intensive connection with the adjacent physical world and its processes, providing and using seamless data-processing services available on the internet [90,98]. CPS relies on autonomous and cooperative subsystems (such as the Internet of Things (IoT) and sensor networks, Big Data and data mining) that are connected on a contextual basis within and across all levels of the supply chain [90]. The cyber–physical solutions through the quicker and more reliable detection of potential disturbances facilitate the transparent and robust functioning of supply chains [90]. Yet, CPS mechanisms and IoT based solutions are increasingly facing the problems of handling Big Data (i.e., scalability), and maintaining both transparency and privacy [99].

3.1.3. Lack of Technological Competencies

As emphasized in Table 1, the loss of resources is another important concern in agri-food circularity [19,74]. Literature on agri-food CE dwells on the lack of infrastructure and technical competency in eco-efficient food production [19,74]. Technology and infrastructure examples comprise inadequate storage/packaging for harvested produce, poor harvesting technology, deficiency in temperature management of produce at harvest, unsuitable fishing gear and shortage of cold storage of landed catch. Effective measures are required to reduce food loss and waste [74]. Digital technologies are playing an increasing role in managing resources and eco-efficiency in the food supply chain [100].

Furthermore, food waste valorization is one of the research fields that has received a lot of interest in recent years as a possible alternative to the disposal of a variety of wastes [75]. Food waste constitutes a largely under-utilized residue from which a range of valuable components (e.g., proteins, lipids, antioxidants and other valuable compounds) can be derived [101]. Advanced valorization strategies embrace, but are not restricted to, microwave-assisted extraction of beneficial ingredients, biological (e.g., fermentation) and combined chemo-enzymatic methods for the development of functional bio-derived products, and flow technologies to enable cascade-type separation/isolation of valuable chemical components, etc. [102,103].

There has been a surge of innovation in food waste valorization over the last few years and the concept of upcycling is gaining interest [104]. Upcycling is defined as the “reuse of discarded materials which results in an increase in value” [104] (p. 146). However, technological inefficiencies and communication mechanisms limit the ability to fully exploit the potential prospects given by valorization and upcycling [75]. Previous studies have shown that integration with IoT sensors and Artificial Intelligence (AI) technology can foster efficiency in retrieving useful components from recycling processes [76,77,105]. However, even with these technologies the problem of data security and handling big data remain to be addressed.

3.1.4. Quality Assurance and Food Safety Concerns

Due to the heightened importance of resource efficiency and sustainable development, there is greater interest in the valorization of waste and waste-derived materials [75]. Valorization entails redirecting former food waste materials by extracting or converting ingredients for food or feed while taking into account economic viability and legislative compliance [75]. As the interest in recycling upsurges, the concern for monitoring food safety risks associated with the use of waste-derived materials is escalating. Previous studies have emphasized a growing concern for hurdles in establishing a circular economy less via technical aspects, and rather more through food safety and consumer concerns [94,106].

As depicted in Table 1, ensuring healthy, safe, and high-quality food is one of the concerns of actors within the food supply chain. Food properties for safety and quality assessment include contamination (e.g., microbial defilement, pesticide residuals, artificial colorant, food pathogen contamination, allergen ingredients, toxins, infected animals, heavy metal contamination, food additives and chemicals abuse, etc.), spoilage (associated with temperature, relative humidity, sanitation procedure, expiration, etc.), and compromise (refers to tampering, misrepresentation, and substitution) [21,107]. Food safety monitoring is the system of routinely controlling safety hazards, assuring compliance adherence, and ensuring that safety procedures are being correctly implemented during food production.

Food regulatory compliance requires controlling safety risks from the background environment (e.g., quality of the soil, water, air, and sunlight), monitoring excess residues of applied treatments (e.g., fertilizers, pesticides, hormones, etc.), and safety risks associated with processing environment (e.g., temperature and microbial control) [30]. At the early stages of production the background environment, such as soil quality and climate, should be evaluated. Assuring the quality of the food also depends on monitoring the treatments such as fertilizers, pesticides, and hormones applied in farming practices. The measures include controlling the credibility of the suppliers (i.e., whether purchased from trusted suppliers) and the risk of treatment residues. Moreover, there is a need for documentation of postharvest conditions such as storage (refrigeration environment, storage time), processing methods (e.g., ultrasounds, pasteurization, etc.), and distribution infrastructure (e.g., packaging) [30]. To impede hazardous materials from entering the food supply chain, recycled biomass will need to be carefully assessed [79]. Hence, food supply chains need to be able to monitor the origin of recycled materials and the food quality at different stages of production [30].

3.2. The Role of Blockchain in Circular Food Systems

Based on our literature review, we identified four major areas where blockchain could affect CE transition: (1) improving data utility; (2) supply chain management efficacy; (3) enhanced eco-efficiency; and (4) superior traceability and credibility (see Figure 2). Table 2 presents the potential for blockchain technology in achieving CE strategies in the agri-food sector, and detailed discussion is provided in the following sections.

Table 2.

The role of blockchain technology in shifting towards a Circular Economy (CE) in the agri-food sector.

3.2.1. Improved Data Utility

Improving data accuracy is important for the transactions that occur throughout the food supply chains [108], s it offers opportunities for the members of the food supply chain to address emerging risks and operational challenges. In addition, moving towards CE entails an increase in sharing data and monitoring transactions [86]. Blockchain allows data to be accessed by multiple actors simultaneously, and its automation feature provides a secure platform for sharing information across different entities. Improving the speed of transactions and transparent information will help in reducing waste.

Mechanisms underlying blockchain technology, such as distributed peer-to-peer (P2P) networks, public-key cryptography, and hash algorithms, improve transparency, traceability and security [107]. These mechanisms play an important role in ensuring distributed trust that is consensually shared, replicated, and synchronized among participants in a distributed ledger [107]. Garaus and Treiblmaier [109] investigated how a blockchain-enabled food traceability system affects consumers’ trust, and eventually, their food choice. Results of experiments indicated that informing consumers about blockchain system traceability and building trust had a positive effect on their food choices. The results of this study also confirmed that in comparison with traditional traceability systems, blockchain-enabled traceability mediates trust in the retailer. This system enabled consumers to easily verify the origin of the products [107].

Research has demonstrated that blockchain technology can reduce information asymmetry by providing accurate, timely and trusted information in the supply chain [110,111]. The blockchain allows for tracking food authenticity and storing and verifying digital identities through securely encoded legal documents, and reducing fraud and transaction costs through smart contracts [85]. In addition, the diffusion of IoT and Big Data into blockchain networks improves the accuracy and system reliability [111].

3.2.2. Supply Chain Management Efficacy

The decentralized architecture of blockchain makes the use of blockchain traceability in the supply chain obvious. The distributed ledger mechanisms imply that blockchain could empower global trading partners to engage in secure transactions, as well as an agreement concerning the shared procedures for increasing transparency, visibility, and productivity [70,110,131].

Blockchain can improve the efficacy of business processes alongside lowering the costs of the supply chain by enhancing logistical performance [110,131]. Casino, Kanakaris, Dasaklis, Moschuris, Stachtiaris, Pagoni and Rachaniotis [131] examined the ability of blockchain to improve FSC efficiency. The authors concluded that the proposed model had advantages such as increased reliability, efficiency, quality, and resilience. Hence, the relevant traceability-related operating costs, as well as the costs of the food supply chain traceability process, were also reduced. Dobrovnik, Herold, Fürst and Kummer [119] also noted that blockchain technology helps FSC with increasing cost-effectiveness, reducing potential errors, and assuring instant availability of accurate and reliable FSC information.

Food supply chains commonly have a complex interconnected network of farmers, suppliers, manufacturers, retailers, distributors, auditors, and customers [35]. In the transition to the CE, all supply chain actors should be involved, and collaboration is a crucial element. Low coordination among stakeholders due to the supply chain complexities leads to inefficiency and hence food waste [20]. The shared ledger structure of blockchain supports streamlining the workflow across all the network’s participants [116,133]. Furthermore, the shared structure warrants visibility for auditors about the participants’ activities in the value chain. Rejeb, Keogh, Zailani, Treiblmaier and Rejeb [110] conducted a review on the potential benefits of blockchain technology in the food industry, and the review results highlighted the benefits of blockchain technology for food supply chain collaboration. They noted that this technology creates opportunities for stakeholders in the food supply chain to work together more effectively, because this technology provides the necessary ground for collaborative arrangements by creating trust and sharing information; sharing information and synchronizing stakeholder decisions in the food supply chain can strengthen collaboration between different layers of the food chain [110]. In addition, reviewing blockchain implementations in supply chain management suggests blockchain technology’s potential in alleviating the problem of intermediaries [110]. The increased transparency because of creating a copy of data blocks at each node of the network facilitates real-time communication among stakeholders throughout the entire supply chain and renders the need for trusted intermediaries [70,118].

However, in order to achieve the highest benefits from blockchain, some technical issues need to be addressed. It is argued that blockchain-enabled FSC systems need to become more autonomous to improve the resilience of the food network by lowering the limitations for participants to join, execute operations, and retrieve source codes of smart contracts [134]. Encryption errors and security threats (e.g., the vulnerability of blockchain endpoints, routing attacks, Sybils attacks, etc.) may bring considerable financial losses for network participants. Wu et al. [135] highlight that blockchain might be subject to several security risks such as a mining attack, which can put supply chain participants at risk of data and financial loss. Zhao et al. [136] contended that the blockchain decentralized feature and its integration with a wide-ranging peer-to-peer wireless sensor network might give rise to several security and confidentiality concerns in the agri-food value chain. Zhao, Liu, Lopez, Lu, Elgueta, Chen and Boshkoska [136] claim that using a blockchain may involve an unprecedented degree of transparency and exposure of participants’ operations, thereby jeopardizing confidentiality. Blockchains (especially public blockchains) may not guarantee confidentiality for FSC actors as information will be exposed to all network participants [21]. If information is considered strategic, sensitive, or confidential, business entities may be unwilling to participate in blockchain-based FSCs until the risk is mitigated [135].

3.2.3. Enhanced Eco-Efficiency

Today, the food supply chain is facing losses of resources, especially due to the lack of efficiency in production and the lack of technologies, which leads to food waste [19]. The use of data and information is becoming increasingly important in the agriculture industry to achieve a higher level of productivity and sustainability [137]. Smart agriculture has been empowered by ICT (Information and Communication Technology) and the application of various digital data collection and analysis technologies including the IoT, Unmanned Aerial Vehicles (UAV), and Machine Learning [35]. For example, satellite remote sensing data on soil conditions can help farmers manage their crops [138], using mobile apps reduces information costs and allow farmers access to local markets [139], and the utilization of the Global Positioning System (GPS) devices enables accurate field mapping and effective crop scouting [140].

Yet, a key concern in establishing smart agriculture is the development of a comprehensive security system that supports the usage and administration of data [35]. Blockchain has the potential to improve eco-efficiency in the agri-food sector through smart contracts and the fusion with IoT [25,35]. Salah, Nizamuddin, Jayaraman and Omar [71] examined the potential of a blockchain-based traceability framework for soybean transactions across the supply chain. Using smart contracts and an immutable ledger of transactions mechanisms, their model enabled secure monitoring of data points and increased the efficiency of soybean-related transactions. Automation (due to smart contracts) and enhanced efficiency have been reported in the fruit and vegetable supply chains [34], as well as those for grain [141].

A broad range of smart farming solutions is developed based on the joint application of blockchain, IoT, and technology [137,142]. For instance, Patil et al. [143] proposed self-organized blockchain-based smart greenhouse farm architecture for ecological food traceability and monitoring food quality. The use of IoT sensors replaces manual detection and verification of data which can reduce significantly human errors and interventions in the system. The authors indicated the possibility of using smart contract scripts to execute a set of automated warning codes to help the regulatory bodies to detect problems and process them in due time [143].

In addition, blockchain enables the monitoring of the source of raw materials to prevent the extraction and overuse of natural resources [74]. For example, farmland irrigation associations in Taiwan employed a blockchain-based system to collect and archive irrigation data [144]. Farmland irrigation has direct and indirect impacts on agricultural production, rural well-being, and the environment, and associations collectively operate and publish their data about irrigation management on a blockchain network. Data from each of these associations are integrated, and over time the longitudinal database can be employed to inform decision-making on capacity-building and maintenance of irrigation canals [144]. The blockchain’s data immutability and transparency further facilitated public engagement in irrigation management and improved water resource use [144]. Park and Li (2021) conducted a literature review and case studies on the ability of blockchain in transforming supply chains toward sustainable food production. Park and Li [74] also contended that blockchain technology can facilitate monitoring of the production process in order to update information synchronously for all the participants in real-time. This information can also include the location and amount of emissions, especially carbon emissions, waste water, or toxic pollutants from each step. Therefore, managers can use this information to make informed decisions to fulfil environmental policies, as well as to improve supply chain eco-efficiency. The authors concluded that this technology has the potential to provide a sustainable resource-use rate and increases eco-efficiency within the supply chain. It should be noted that blockchain technology is not inherently sustainable or unsustainable, but can be seen as a tool that contributes on a technological level to improve supply chain efficiency and food sustainability [137]. Despite the blockchain’s ability to maintain sustainable resource use and monitor emissions, the technology is in its infancy in this area and further evidence is needed.

3.2.4. Superior Traceability and Credibility

A circular system requires technology that enables monitoring food safety and tracking the source of recycled materials or by-products. Food security monitoring is crucial in food supply chains to prevent cross-contamination and foodborne disease outbreaks [21]. Other food safety issues include improper sanitation processes, failure of practices to eradicate pathogens, inappropriate storage conditions, etc. [145,146,147].

There are different forms of blockchain technologies (i.e., public, private, and hybrid blockchain) that can be used to introduce traceability, transparency, and accountability in the food supply chain [148]. Extant blockchain-based traceability use cases in the agri-food sector provided ample evidence of its ability to improve food quality traceability [26,27,28,29,30,31,32]. Recent examples include a collaboration between IBM (International Business Machines Corporation) and the Brooklyn Roasting Company, to use blockchain in tracking coffee bags, as well as the development of a blockchain-based platform that tracks “grass-fed” beef in Wyoming to ensure quality [149].

Blockchain technology, when combined with programming algorithms, through leveraging smart contracts could offer superior traceability in comparison with traditional traceability [26,27,28,29,30,31,32]. Blockchain ensures enhanced transparency into the details of the provenance of the food (origin), the chain of custody of a product (documenting the changes in product ownership throughout its journey in the supply chain), and the processes. Blockchain-based traceability allows all participants in the network to access information regarding the chain of custody and the path of a product through the supply chain in real time [122,129]. As a result, monitoring and control of food quality for the regulatory authorities can be accelerated [150]. For instance, Wang, Chen, Hao and Yang [130] showed how the blockchain-based dairy traceability model assisted authorities to track the accuracy of the information in the milk supply chain. In the proposed model, information related to milk production and processing is collected using Radio Frequency Identification (RFID) and smart-tagged bar codes, then transmitted to a peer-to-peer decentralized network. Transmitted information includes the origin of dairy cows, feed, vaccine status, health environment, nutritional content of milk, production date, shelf life, storage environment and conditions, logistics information and sales information. This blockchain traceability system is configured to prevent tampering with recorded data arbitrarily to ensure the authenticity and reliability of the information [130]. However, to ensure food safety, food industry stakeholders must comply with diverse regional, national, and international policies and regulations. Safety regulations are different across local and/or international governments, which makes it challenging to synchronize data integrity in the global supply chains due to the decentralized nature of blockchain technology [21,151]. The lack of industry standards governing blockchain use cases also makes it difficult to integrate all stakeholders into a unified regulatory framework [110]. Moreover, regulatory bodies might need access to the pre-existing data of the local members of the supply chain, which is not included in the blockchain network [21]. It seems that the application programming interface [152] should be configured in the blockchain framework to connect the pre-existing data from suppliers and should be designed to connect or report all the data to the regulatory systems [21]. In this case, once the integrated data storage system has been built by the food providers, the API can relate to various local regulatory systems.

Traceability in blockchain also depends significantly on the convenience of obtaining crucial data such as credence claims (e.g., organic, halal, kosher, and animal welfare) and certificates [110]. After data blocks have been recorded on the blockchain, the authenticity of data blocks is validated in real-time by third-party attesters [30,132]. As a result, blockchain allows open access to data followed by strengthening trust [34].

4. Discussion

This review considered the literature on blockchain technology implementations in agri-food supply chain management, exploring its functionality with respect to four key challenges in a transition towards CE. Our review identified two major themes across retrieved articles discussing blockchain technology’s potential in: (a) preventing food loss and waste through improved data utility in designing eco-efficient products and supply chain efficacy; and (b) creating trust due to enhanced quality monitoring and traceability. We next highlight the key implications of these outcomes in more detail below, followed by suggestions for future research.

4.1. Preventing Food Loss and Waste through Improved Data Utility, Eco-Efficiency, and Supply Chain Efficacy

The main drivers of food loss and waste are attributed to the lack of information in production and processes (including the problem of asymmetric information, lack of data processing capacity, and lack of data transparency), complex supply chains and lack of technological competencies [62,68]. This review confirms that blockchain can improve data utility, enhance the design of eco-efficient products, and improve food supply chain management which all help in lowering food loss and waste [117]. This finding broadly agrees with those obtained by other reviews [25,42,53] in this area confirming the blockchain’s ability in improving transparency and production efficiency.

Information asymmetry exists when stakeholders in the food supply chain are not equally informed about the transactions [81,82]. This problem occurs, to some extent, because of the centralized food supply chains which are prone to flawed data and even data manipulation [83,84,85]. By leveraging a shared and trusted database of ledgers stored in a decentralized system, blockchain seeks to restructure information ecosystems in a more transparent, secure, and efficient manner [67,111,112]. This secure ledger of transactions from various steps in supply chains, (and other logistics chains), reduces transactional inefficiencies resulting from information asymmetries [128]. At a field level, loss occurs often due to weather conditions or disease but also due to poor supply chain management practices or poor communication; for example, on whether the harvest time is ahead of or behind schedule. Farmers could load the data about farm conditions on the blockchain network, communicating well in advance to market, early harvest, or a lower-than-expected yield well in advance [117,121]. They can also be informed about market prices and fluctuations in demand. While retail losses are often minor, they might arise owing to overstocking of products or poor demand forecasts. Optimal storage temperatures could also be regulated (through smart contracts and sensors) and documented on the blockchain system, allowing distributors to store the products most efficiently to maximize shelf life, potentially decreasing food waste [77].

Our findings indicate that blockchain can also leverage supply chain management through optimized operations, mapping, and visualization [153]. Significant waste of resources occurs during the logistical processes throughout the food supply chain; hence, digitalization and improvements in the logistic management systems play an important role in the reduction in food loss. This corroborates the findings of Ouyang et al. [154] and Yetis et al. [155] who investigated optimized production management using blockchain-based customization frameworks. There is a growing interest among researchers to examine the efficiency of blockchain-based supply chain management implementations and smart farming [29,32]. In addition, our findings suggest that the blockchain can enhance eco-efficiency owing to digitalization and using smart contracts, mainly in the early phases of the food supply chain [84,113,114,156]. Blockchain provides a platform for automation in the agricultural sector and acts as a bridge between digital and traditional agri-food production. Digitalization, and acquiring real-time data across IoT sensors, improve resource utilization at the farm level [153]. Smart contracts can execute automatic operations, data collection from sensors, and secure financial transactions, reducing the need for trusted intermediaries. Blockchain integration with other IoT solutions can also facilitate monitoring the source of raw materials to prevent the over-extraction of natural resources [80,124]. However, the current status of high computing costs and delays hinders the amalgamation of blockchain with IoT that has limited power and storage potential [25,125]. Further studies, which take these properties into account, will need to be undertaken. In addition to contributions such as facilitated eco-efficiency and reliable data, energy saving in production is increased with the blockchain-based frameworks [155].

Moreover, creating a real-time reliable information exchange system will help to effectively manage surplus food, once it is generated, for instance through transformation processes in order to be used as animal feeding, fertilizers, and energy [30]. Blockchain seems to play an important role in facilitating food waste recycling and valorization, yet our review did not provide empirical evidence of current blockchain use cases for food waste valorization.

4.2. Creating Trust Due to Enhanced Traceability and Monitoring

The current review found that blockchain leverages the use of smart contracts and IoT devices for employing traceability in the agri-food supply chain [26,132]. Blockchain technology allows access to end-to-end traceability data revealing the provenance, real-time location, and status of production practices, which improves trust in transactions across the supply chain and enables effective monitoring [64]. These properties enable blockchain to quickly pinpoint potential sources of contamination to effectively prevent or rectify outbreaks [122]. In accordance with the present results, previous reviews (see for example Xiong, Dalhaus, Wang and Huang [25]) have demonstrated that blockchain facilitates monitoring of the production process in order to update information synchronously for all the participants in real-time. This information can also incorporate the location and degree of emissions, especially carbon emissions, wastewater, or toxic pollutants from each phase of the supply chain [59,69]. After data transactions have been recorded on the blockchain system, the authenticity of data can be confirmed in real-time by third-party attesters. This also facilitates the traceability and credibility of certificates such as organic and animal welfare [110].

Given the variety of food processing industries and the substantial amount of waste streams engendered, it is crucial to improve the supply chain valorization efficiency [19]. Our findings suggest that blockchain has a great potential for monitoring and verifying food developed from recycled biomass [74]. While extant research has provided ample evidence on the blockchain’s potential in facilitating food traceability [121,122,125], its application in monitoring the food quality of recycled food is scant. Different justifications can be offered for the paucity of traceability solutions for recycled food (e.g., upcycled food). For example, the blockchain is still in its infancy and most of the use cases developed in the agri-food sector did not move beyond the proof-of-concept with little empirical implications [25,157,158]. In addition, technical challenges and lack of adequate legislation were identified as possible reasons for delay in using blockchain-based traceability solutions for recycled food [43,44,53].

5. Perspectives

This study offers insights from the literature on the potential of blockchain use cases for CE in the food system, which enables us to identify research gaps and propose an agenda for future research directions.

First, our review found that blockchain implementations help to prevent food waste and loss through improved data utility, facilitating eco-efficiency, and supply chain management. It also enables efficient food traceability, which contributes to better resource management and reduces food waste at different stages of the supply chain. For the CE transition, active cooperation between members of the supply chain is vital to achieve superior supply chain efficiency and minimize environmental impacts [20,92,93,94]. Current literature provides evidence on the potential of blockchain to improve trust in the food supply chain [65,125], yet most of these findings are at the conceptual level or implemented at a limited scale [26,34,117,125]. Moreover, current blockchain use cases did not develop with the CE in focus, hence more research is needed in this area.

Second, the existing related papers focused on supply chains with few actors. Future research must consider global logistic chains with a wider range of actors across dispersed geographical regions [73,159]. In addition, further research is required on the participation of smallholder farming versus larger farms [25]. On-farm data generated and collected throughout the farming process is dispersed and held by individual farmers, and it seems that the size of the farm can affect the willingness to participate in the blockchain network and integrate this data [25].

Third, the hype surrounding digital technologies and the development of blockchain-based solutions suggest that industrial-scale adoption of this technology will surge in the next few years [52,160]. Despite all of its promising opportunities and strength, there are still technical challenges that need to be resolved for its wide industrial-scale adoption [25]. Issues such as cost of the implementation, legacy systems (e.g., integrating blockchain with already established information management infrastructures), scalability, and lack of adequate legislation were identified as future research directions [43,44,53]. Currently, scalability is the key issue that hinders the full implementation of blockchain in some areas [52,161]. Scalability of blockchain networks refers to the system’s capacity to sustain increased transaction loads while also expanding the number of nodes in the network [162]. To develop an optimum blockchain solution, optimal levels of network security, decentralization, and scalability (known as blockchain trilemma trade-off) need to be determined [163]. Scalability performances of blockchains depend on the transaction throughput/latency (data read and write performance on the network), and data storage volume (storage performance) [161]. In addition, there is always a trade-off between network security, decentralization, and the level of scalability in blockchain, since these properties cannot perfectly coexist at the same time without jeopardizing one of them [163]. It is very challenging to achieve a high level of these properties simultaneously in the current blockchain designs [164]. This is particularly important in the food supply chain network, which is characterized as complex, globally dispersed, and continuously evolving.

6. Conclusions

Technology is a critical component of the circular economy (CE) framework, which advocates for fundamental and radical technological solutions to develop successful circular patterns. This is particularly relevant for implementing the CE framework in the food sector, which requires technological support for preventing food surplus and waste management.

Although it is still in its early phases, blockchain technology is rapidly developing and providing evidence of the sustainability and CE implications. A transition towards CE requires a trusted mechanism for the transparent processing of data and communication. Blockchain is intended to store and update data in a secure, tamper-proof, and irreversible digital ledger. Blockchain technology is a revolutionary new ledger framework for exchanging and updating information by connecting databases in a decentralized, peer-to-peer, open-access network. Thus, blockchain has the potential to improve data utility through increasing trust among the actors in the food value chain, while reducing information asymmetry. This in turn reduces the supply–demand imbalances and hence helps to prevent food surplus (loss). In addition, establishing a real-time reliable information exchange system will help to effectively manage surplus food, once it is generated, for instance through transformation processes in order to be used as animal feed, fertilizers, and energy.

Moreover, the food supply chain is complex and challenging to manage due to a variety of intermediaries and the perishable nature of the products. Blockchain strengthens participatory practices and trust among actors in the supply chain, and can leverage supply chain management through optimized operations, mapping, and visualization. Significant waste of resources occurs during the logistical processes throughout the food supply chain, and therefore digitalization and improvements in the logistic management systems play an important role in the reduction in food loss. Blockchain provides a platform for automation in the agricultural sector and acts as a bridge between digital and traditional agri-food production to foster eco-innovation.

Most important of all, blockchain can also extend the advantage of real-time visibility to enable effective traceability. A CE entails waste valorization and recycling biomaterials that will raise quality assurance and food safety concerns. Waste valorization is industrial processing of increasing popularity, which presents a range of potentially valuable options for dealing with residues other than landfilling and/or incineration. Due to the perishable nature of the food supply chain, a successful transition toward CE requires the monitoring of food safety and tracking the sources of recycled materials. Yet, most of the extant industrial-scale blockchain circular economy applications have been related to monitoring non-biological materials. Integration with the IoT sensors and Global Positioning Systems (GPS) facilitates the track of products’ movement and storage conditions and provides a trail of dynamically updated information stored on a blockchain that enables the value chain actors to make more informed decisions.

Overall, evidence suggests that blockchain offers an effective and robust framework for boosting food traceability and a reliable mechanism to confirm the quality, safety, and sustainability of agri-foods. Despite the great gains (such as visibility, tamper-resistance, and automation), this technology has to overcome technical obstacles such as energy consumption and scalability. In addition, explicit intentions of blockchain implementation to make agri-food supply chains suited for a circular economy are still scarce. This is partly because successful blockchain-based implementation for CE necessitates a high level of collaboration across the entire supply chain, often making substantial adjustments to many parts of their operations. The agri-food supply chains are complex and often dispersed across continents, which makes it difficult to achieve such a collaborative culture and necessary fundamental changes.

Author Contributions

Conceptualization, A.P. and S.A.K.; methodology, S.A.K. and A.P.; formal analysis, A.P. and S.A.K.; resources, A.P. and S.A.K.; data curation, S.A.K.; writing—original draft preparation, A.P. and V.X.; writing—review and editing, A.P., S.A.K. and V.X.; visualization, A.P.; supervision, A.P.; project administration, A.P.; funding acquisition, A.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Thanks to Tina Pienkuukka for proofreading the article.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Agri-food | Farming and food processing, food delivery and consumption |

| CE | Circular Economy |

| CPS | Cyber–Physical Systems |

| DPoS | Delegated PoS (Proof-of-Stake) |

| FAO | The Food and Agriculture Organization |

| FSC | Food Supply Chain |

| GPS | Global Positioning System |

| IBM | International Business Machines Corporation |

| ICT | Information and Communication Technology |

| IoT | Internet of Things |

| PoC | Proof-of-Concept |

| PoS | Proof-of-Stake |

| PoW | Proof-of-Work |

| P2P | Peer-to-Peer |

| RFID | Radio-Frequency Identification |

| UAV | Unmanned Aerial Vehicles |

References

- FAO. The State of Food and Agriculture 2019. Moving Forward on Food Loss and Waste Reduction; Food and Agriculture Organization of the United Nations: Rome, Italy, 2019; ISBN 978-92-5-131789-1. Available online: https://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 29 November 2021).

- Farooque, M.; Zhang, A.; Liu, Y. Barriers to circular food supply chains in China. Supply Chain. Manag.: An. Int. J. 2019, 24, 677–696. [Google Scholar] [CrossRef]

- Gubeladze, D.; Pavliashvili, S. Linear economy and circular economy-current state assessment and future vision. Int. J. Innov. Technol. Econ. 2020, 5, 1–4. [Google Scholar] [CrossRef]

- Nižetić, S.; Šolić, P.; López-de-Ipiña González-de-Artaza, D.; Patrono, L. Internet of Things (IoT): Opportunities, issues and challenges towards a smart and sustainable future. J. Clean Prod. 2020, 274, 122877. [Google Scholar] [CrossRef] [PubMed]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Foundation, E.M. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2019; pp. 21–34. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf (accessed on 14 June 2020).

- Oliveira, M.M.; Lago, A.; Dal’ Magro, G.P. Food loss and waste in the context of the circular economy: A systematic review. J. Clean. Prod. 2021, 294, 126284. [Google Scholar] [CrossRef]

- Ojha, S.; Bußler, S.; Schlüter, O.K. Food waste valorisation and circular economy concepts in insect production and processing. Waste Manag. 2020, 118, 600–609. [Google Scholar] [CrossRef]

- Alterå, O. Från värdekedja till värdecykel—Såfår Sverige en mer cirkulär ekonomi (From a value chain to a value circle—How Sweden will reach a more circular economy); Länsstyrelsen Västra Götalands län: Stockholm, Sweden, 2017; p. 22. [Google Scholar]

- FAO (Food and Agriculture Organization of the United Nations). Circular Economy: Waste-to-Resource & COVID-19; Food and Agriculture Organization of the United Nations: Rome, Italy; Available online: http://www.fao.org/land-water/overview/covid19/circular/en/ (accessed on 21 August 2021).

- EMF. Towards the Circular Economy: Accelerating the Scale-up Across Global Supply Chains. Available online: https://reports.weforum.org/toward-the-circular-economy-accelerating-the-scale-up-across-global-supply-chains/ (accessed on 13 February 2018).

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Despoudi, S.; Dora, M. Circular food supply chains. Inst. Food Sci. Technol. 2020, 34, 48–51. [Google Scholar] [CrossRef]

- LaCanne, C.E.; Lundgren, J.G. Regenerative agriculture: Merging farming and natural resource conservation profitably. PeerJ 2018, 6, e4428. [Google Scholar] [CrossRef]

- Grant, S. Organizing alternative food futures in the peripheries of the industrial food system. J. Sustain. Educ. 2017, 14, 1–14. [Google Scholar]

- Duarte, L.O.; Kohan, L.; Pinheiro, L.; Fonseca Filho, H.; Baruque-Ramos, J. Textile natural fibers production regarding the agroforestry approach. SN Appl. Sci. 2019, 1, 914. [Google Scholar] [CrossRef]

- Newton, P.; Civita, N.; Frankel-Goldwater, L.; Bartel, K.; Johns, C. What is regenerative agriculture? A review of scholar and practitioner definitions based on processes and outcomes. Front. Sustain. Food Syst. 2020, 4, 194. [Google Scholar] [CrossRef]

- Hua, J.; Wang, X.; Kang, M.; Wang, H.; Wang, F.Y. Blockchain based provenance for agricultural products: A distributed platform with duplicated and shared bookkeeping. In Proceedings of the 2018 IEEE Intelligent Vehicles Symposium (IV), Changshu, China, 26–30 June 2018; pp. 97–101. [Google Scholar]

- Banasik, A.; Kanellopoulos, A.; Claassen, G.D.H.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G.A.J. Assessing alternative production options for eco-efficient food supply chains using multi-objective optimization. Ann. Oper. Res. 2017, 250, 341–362. [Google Scholar] [CrossRef]

- Ada, N.; Kazancoglu, Y.; Sezer, M.D.; Ede-Senturk, C.; Ozer, I.; Ram, M. Analyzing barriers of circular food supply chains and proposing industry 4.0 solutions. Sustainability 2021, 13, 6812. [Google Scholar] [CrossRef]

- Xu, J.; Guo, S.; Xie, D.; Yan, Y. Blockchain: A new safeguard for agri-foods. Artif. Intell. Agric. 2020, 4, 153–161. [Google Scholar] [CrossRef]

- Alamri, M.; Qasem, A.A.; Mohamed, A.A.; Hussain, S.; Ibraheem, M.A.; Shamlan, G.; Alqah, H.A.; Qasha, A.S. Food packaging’s materials: A food safety perspective. Saudi J. Biol. Sci. 2021, 28, 4490–4499. [Google Scholar] [CrossRef]

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Toma, L.; Revoredo-Giha, C.; Costa-Font, M.; Thompson, B. Food Waste and Food Safety Linkagesalong the Supply Chain. EuroChoices 2020, 19, 24–29. [Google Scholar] [CrossRef]

- Van Wassenaer, L.; Verdouw, C.; Wolfert, S. What blockchain are we talking about? An analytical framework for understanding blockchain applications in agriculture and food. Front. Blockchain 2021, 4, 653128. [Google Scholar] [CrossRef]

- Garrard, R.; Fielke, S. Blockchain for trustworthy provenances: A case study in the Australian aquaculture industry. Technol. Soc. 2020, 62, 101298. [Google Scholar] [CrossRef]

- Wamba, S.F.; Queiroz, M.M. Blockchain in the operations and supply chain management: Benefits, challenges and future research opportunities. Int. J. Inf. Manag. 2020, 52, 102064. [Google Scholar] [CrossRef]

- Bettín-Díaz, R.; Rojas, A.E.; Mejía-Moncayo, C. Methodological approach to the definition of a Blockchain system for the food Industry supply chain traceability. In Proceedings of the International Conference on Computational Science and Its Applications ICCSA, Melbourne, VIC, Australia, 2–5 July 2018; Gervasi, O., Murgante, B., Misra, S., Stankova, E., Torre, C.M., Rocha, A.M.A.C., Taniar, D., Apduhan, B.O., Tarantino, E., Ryu, Y., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 19–33. [Google Scholar]

- Tian, F.J. An Agri-Food Supply Chain Traceability System For China Based On RFID & Blockchain Technology. In Proceedings of the 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–6. [Google Scholar]

- Feng, T. A Supply Chain Traceability System for food safety based on HACCP, Blockchain & Internet Of Things. In Proceedings of the International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; pp. 1–6. [Google Scholar]

- Galvez, J.F.; Mejuto, J.C.; Simal-Gandara, J. Future challenges on the use of blockchain for food traceability analysis. TrAC Trends Anal. Chem. 2018, 107, 222–232. [Google Scholar] [CrossRef]

- Caro, M.P.; Ali, M.S.; Vecchio, M.; Giaffreda, R. Blockchain-based traceability in Agri-Food supply chain management: A practical implementation. In Proceedings of the IoT Vertical and Topical Summit on Agriculture, Tuscany, Italy, 8–9 May 2018; pp. 1–4. [Google Scholar]

- Nandi, S.; Sarkis, J.; Hervani, A.A.; Helms, M.M. Redesigning Supply Chains using Blockchain-Enabled Circular Economy and COVID-19 Experiences. Sustain. Prod. Consum. 2021, 27, 10–22. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Li, M.; Yu, H.; Wang, M.; Xu, D.; Sun, C. A Trusted Blockchain-Based Traceability System for Fruit and Vegetable Agricultural Products. IEEE Access 2021, 9, 36282–36293. [Google Scholar] [CrossRef]

- Xiong, H.; Dalhaus, T.; Wang, P.; Huang, J. Blockchain Technology for Agriculture. Appl. Ration. 2020, 3. [Google Scholar] [CrossRef]

- Chen, H.; Pendleton, M.; Njilla, L.; Xu, S. A Survey on Ethereum Systems Security: Vulnerabilities, Attacks, and Defenses. ACM Comput. Surv. 2021, 53, 1–43. [Google Scholar] [CrossRef]

- Li, X.; Jiang, P.; Chen, T.; Luo, X.; Wen, Q. A survey on the security of blockchain systems. Future Gener. Comput. Syst. 2020, 107, 841–853. [Google Scholar] [CrossRef]

- Iansiti, M.; Lakhani, K.R. The Truth About Blockchain. Harv. Bus. Rev. 2017, 95, 118–127. [Google Scholar]

- Adams, D.; Donovan, J.; Topple, C. Achieving sustainability in food manufacturing operations and their supply chains: Key insights from a systematic literature review. Sustain. Prod. Consum. 2021, 28, 1491–1499. [Google Scholar] [CrossRef]

- Valoppi, F.; Agustin, M.; Abik, F.; Morais de Carvalho, D.; Sithole, J.; Bhattarai, M.; Varis, J.J.; Arzami, A.; Pulkkinen, E.E.; Mikkonen, K.S. Insight on current advances in food science and technology for feeding the world population. Front. Sustain. Food Syst. 2021, 5, 626227. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Abdollahi, A.; Zailani, S.; Iranmanesh, M.; Ghobakhloo, M. Digitalization in food supply chains: A bibliometric review and key-route main path analysis. Sustainability 2021, 14, 83. [Google Scholar] [CrossRef]

- Duan, J.; Zhang, C.; Gong, Y.; Brown, S.; Li, Z. A content-analysis based literature review in blockchain adoption within food supply chain. Int. J. Environ. Res. Public Health 2020, 17, 1784. [Google Scholar] [CrossRef]

- Pandey, V.; Pant, M.; Snasel, V. Blockchain technology in food supply chains: Review and bibliometric analysis. Technol. Soc. 2022, 69, 101954. [Google Scholar] [CrossRef]

- Vu, N.; Ghadge, A.; Bourlakis, M. Blockchain adoption in food supply chains: A review and implementation framework. Prod. Plan. Control 2021, 1–18. [Google Scholar] [CrossRef]

- Grant, M.J.; Booth, A. A typology of reviews: An analysis of 14 review types and associated methodologies. Health Inf. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef]

- Green, B.N.; Johnson, C.D.; Adams, A. Writing narrative literature reviews for peer-reviewed journals: Secrets of the trade. J. Chiropr. Med. 2006, 5, 101–117. [Google Scholar] [CrossRef]

- Baker, J.D. The purpose, process and methods of writing a literature review: Editorial. Assoc. Oper. Room Nurses AORN J. 2016, 103, 265–269. [Google Scholar] [CrossRef]

- Rajput, S.P.; Datta, S. Sustainable and green manufacturing—A narrative literature review. Mater. Today: Proc. 2020, 26, 2515–2520. [Google Scholar] [CrossRef]

- Clemente-Suárez, V.J.; Rodriguez-Besteiro, S.; Cabello-Eras, J.J.; Bustamante-Sanchez, A.; Navarro-Jiménez, E.; Donoso-Gonzalez, M.; Beltrán-Velasco, A.I.; Tornero-Aguilera, J.F. Sustainable Development Goals in the COVID-19 Pandemic: A Narrative Review. Sustainability 2022, 14, 7726. [Google Scholar] [CrossRef]

- Acai, A.; Sonnadara, R.R.; O’Neill, T.A. Getting with the times: A narrative review of the literature on group decision making in virtual environments and implications for promotions committees. Perspect. Med. Educ. 2018, 7, 147–155. [Google Scholar] [CrossRef]

- Pandey, M.; Singal, B. Blockchain technology in biomanufacturing: Current perspective and future challenges. In Blockchain Technology for Emerging Applications: A Comprehensive Approach; Islam, H., Pal, A.K., Samanta, D., Bhattacharyya, S., Eds.; Academic Press: London, UK, 2022; pp. 207–237. [Google Scholar]

- Sanka, A.I.; Cheung, R.C. A systematic review of blockchain scalability: Issues, solutions, analysis and future research. J. Netw. Comput. Appl. 2021, 195, 103232. [Google Scholar] [CrossRef]

- Li, K.; Lee, J.-Y.; Gharehgozli, A. Blockchain in food supply chains: A literature review and synthesis analysis of platforms, benefits and challenges. Int. J. Prod. Res. 2021, 1–20. [Google Scholar] [CrossRef]

- Avraamidou, S.; Baratsas, S.G.; Tian, Y.; Pistikopoulos, E.N. Circular Economy—A challenge and an opportunity for Process Systems Engineering. Comput. Chem. Eng. 2020, 133, 106629. [Google Scholar] [CrossRef]

- Hobson, K. Closing the loop or squaring the circle? Locating generative spaces for the circular economy. Prog. Hum. Geogr. 2015, 40, 88–104. [Google Scholar] [CrossRef]

- Jaeger, B.; Upadhyay, A. Understanding barriers to circular economy: Cases from the manufacturing industry. J. Enterp. Inf. Manag. 2020, 33, 729–745. [Google Scholar] [CrossRef]

- Modgil, S.; Gupta, S.; Sivarajah, U.; Bhushan, B. Big data-enabled large-scale group decision making for circular economy: An emerging market context. Technol. Forecast. Soc. Change 2021, 166, 120607. [Google Scholar] [CrossRef]

- Bogetoft, P.; Olesen, H.B. Design of Production Contracts: Lessons from Theory and Agriculture; Copenhagen Business School Press DK: Copenhagen, Denmark, 2004; p. 208. [Google Scholar]

- Chen, Y.; Li, Y.; Li, C. Electronic agriculture, blockchain and digital agricultural democratization: Origin, theory and application. J. Clean. Prod. 2020, 268, 122071. [Google Scholar] [CrossRef]

- Eijk, F.V. Barriers and Drivers towards a Circular Economy. Literature Review; Acceleratio B.V.: Naarden, The Netherlands, 2015. [Google Scholar]

- Zhang, Q.; Han, Y.-Y.; Su, Z.-B.; Fang, J.-L.; Liu, Z.-Q.; Wang, K.-Y. A storage architecture for high-throughput crop breeding data based on improved blockchain technology. Comput. Electron. Agric. 2020, 173, 105395. [Google Scholar] [CrossRef]

- Yang, Y.; Huisman, W.; Hettinga, K.A.; Liu, N.; Heck, J.; Schrijver, G.H.; Gaiardoni, L.; van Ruth, S.M. Fraud vulnerability in the Dutch milk supply chain: Assessments of farmers, processors and retailers. Food Control. 2019, 95, 308–317. [Google Scholar] [CrossRef]

- Ferdousi, T.; Gruenbacher, D.; Scoglio, C.M. A Permissioned Distributed Ledger for the US Beef Cattle Supply Chain. IEEE Access 2020, 8, 154833–154847. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Estimating the Impact of Blockchain Adoption in the Food Processing Industry and Supply Chain. Int. J. Food Eng. 2020, 16, 20190109. [Google Scholar] [CrossRef]

- Violino, S.; Pallottino, F.; Sperandio, G.; Figorilli, S.; Ortenzi, L.; Tocci, F.; Vasta, S.; Imperi, G.; Costa, C. A full technological traceability system for extra virgin olive oil. Foods 2020, 9, 624. [Google Scholar] [CrossRef]

- Tan, A.; Gligor, D.; Ngah, A. Applying Blockchain for Halal food traceability. Int. J. Logist. Res. Appl. 2020, 25, 947–964. [Google Scholar] [CrossRef]

- Leng, K.; Bi, Y.; Jing, L.; Fu, H.-C.; Van Nieuwenhuyse, I. Research on agricultural supply chain system with double chain architecture based on blockchain technology. Future Gener. Comput. Syst. 2018, 86, 641–649. [Google Scholar] [CrossRef]

- Co, H.C.; Barro, F. Stakeholder theory and dynamics in supply chain collaboration. Int. J. Oper. Prod. Manag. 2009, 29, 591–611. [Google Scholar] [CrossRef]

- Köhler, S.; Pizzol, M. Technology assessment of blockchain-based technologies in the food supply chain. J. Clean. Prod. 2020, 269, 122193. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. Int. J. Inf. Manag. 2020, 52, 101967. [Google Scholar] [CrossRef]

- Salah, K.; Nizamuddin, N.; Jayaraman, R.; Omar, M. Blockchain-based soybean traceability in agricultural supply chain. IEEE Access 2019, 7, 73295–73305. [Google Scholar] [CrossRef]

- Syromyatnikov, D.; Geiko, A.; Kuashbay, S.; Sadikbekova, A. Agile supply chain management in agricultural business. Int. J. Supply Chain. Manag. 2020, 9, 377–383. [Google Scholar]

- Tönnissen, S.; Teuteberg, F. Analysing the impact of blockchain-technology for operations and supply chain management: An explanatory model drawn from multiple case studies. Int. J. Inf. Manag. 2020, 52, 101953. [Google Scholar] [CrossRef]

- Park, A.; Li, H. The Effect of Blockchain Technology on Supply Chain Sustainability Performances. Sustainability 2021, 13, 1726. [Google Scholar] [CrossRef]

- Luque, R.; Clark, J.H. Valorisation of food residues: Waste to wealth using green chemical technologies. Sustain. Chem. Processes 2013, 1, 10. [Google Scholar] [CrossRef]

- Xu, J.; Gu, B.; Tian, G. Review of agricultural IoT technology. Artif. Intell. Agric. 2022, 2, 10–22. [Google Scholar] [CrossRef]

- Feng, H.; Wang, W.; Chen, B.; Zhang, X. Evaluation on Frozen Shellfish Quality by Blockchain Based Multi-Sensors Monitoring and SVM Algorithm during Cold Storage. IEEE Access 2020, 8, 54361–54370. [Google Scholar] [CrossRef]

- George, R.V.; Harsh, H.O.; Ray, P.; Babu, A.K. Food quality traceability prototype for restaurants using blockchain and food quality data index. J. Clean. Prod. 2019, 240, 118021. [Google Scholar] [CrossRef]

- Berchicci, L.; Bodewes, W. Bridging environmental issues with new product development. Bus. Strategy Environ. 2005, 14, 272–285. [Google Scholar] [CrossRef]

- Iqbal, R.; Butt, T.A. Safe farming as a service of blockchain-based supply chain management for improved transparency. Clust. Comput. 2020, 23, 2139–2150. [Google Scholar] [CrossRef]

- Antle, J.M. Economic analysis of food safety. Handb. Agric. Econ. 2001, 1, 1083–1136. [Google Scholar]

- Starbird, S.A.; Amanor-Boadu, V. Contract selectivity, food safety, and traceability. J. Agric. Food Ind. Organ. 2007, 5. [Google Scholar] [CrossRef]

- Ronaghi, M.H. A blockchain maturity model in agricultural supply chain. Inf. Processing Agric. 2021, 8, 398–408. [Google Scholar] [CrossRef]

- Mao, D.; Hao, Z.; Wang, F.; Li, H. Innovative Blockchain-Based Approach for Sustainable and Credible Environment in Food Trade: A Case Study in Shandong Province, China. Sustainability 2018, 10, 3149. [Google Scholar] [CrossRef]

- Qlikchain Role of Blockchain to Prevent Information Asymmetry in Food Value Chains. Available online: https://www.qlikchain.com/qlikblogs/2019/10/24/role-of-blockchain-to-prevent-information-asymmetry-in-food-value-chains (accessed on 24 October 2019).

- Maaß, O.; Grundmann, P. Governing transactions and interdependences between linked value chains in a circular economy: The case of wastewater reuse in Braunschweig (Germany). Sustainability 2018, 10, 1125. [Google Scholar] [CrossRef]

- Amin, M.R.; Zuhairi, M.F.; Saadat, M.N. Enhanced Blockchain Transaction: A Case of Food Supply Chain Management. J. Eng. Appl. Sci. 2020, 15, 99–106. [Google Scholar] [CrossRef]

- Wagner, S.M.; Bode, C. An empirical investigation into supply chain vulnerability. J. Purch. Supply Manag. 2006, 12, 301–312. [Google Scholar] [CrossRef]

- Zeng, A.Z.; Berger, P.D.; Gerstenfeld, A. Managing the supply-side risks in supply chains: Taxonomies, processes, and examples of decision-making modeling. In Applications of Supply Chain Management and E-Commerce Research; Geunes, J., Akçali, E., Pardalos, P.M., Romeijn, H.E., Shen, Z.-J.M., Eds.; Springer: Boston, MA, USA, 2005; pp. 141–160. [Google Scholar]

- Monostori, J. Supply chains robustness: Challenges and opportunities. Procedia CIRP 2018, 67, 110–115. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness. J. Supply Chain. Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Gupta, S.; Chen, H.; Hazen, B.T.; Kaur, S.; Santibañez Gonzalez, E.D.R. Circular economy and big data analytics: A stakeholder perspective. Technol. Forecast. Soc. Change 2019, 144, 466–474. [Google Scholar] [CrossRef]

- Cillo, V.; Petruzzelli, A.M.; Ardito, L.; Del Giudice, M. Understanding sustainable innovation: A systematic literature review. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 1012–1025. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; Stangherlin, I.D.C. Upcycled by-product use in agri-food systems from a consumer perspective: A review of what we know, and what is missing. Technol. Forecast. Soc. Change 2021, 168, 120749. [Google Scholar] [CrossRef]

- Dharmapalan, V.; O’Brien, W.J.; Morrice, D. Defining supply chain visibility for industrial construction projects. Front. Built Environ. 2021, 127, 1–16. [Google Scholar] [CrossRef]

- Johnston, D.A.; McCutcheon, D.M.; Stuart, F.I.; Kerwood, H. Effects of supplier trust on performance of cooperative supplier relationships. J. Oper. Manag. 2004, 22, 23–38. [Google Scholar] [CrossRef]

- Liu, G. The Impact of Supply Chain Relationship on Food Quality. Procedia Comput. Sci. 2018, 131, 860–865. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Uddin, M.A.; Stranieri, A.; Gondal, I.; Balasubramanian, V. A survey on the adoption of blockchain in iot: Challenges and solutions. Blockchain: Res. Appl. 2021, 2, 100006. [Google Scholar] [CrossRef]