1. Introduction

The textile industry is a pillar of the European economy, and it is expected to grow in the future thanks to the stimulus of fast fashion and the prices of products, which encourage customers to buy and own larger quantities of clothes. Unfortunately, the production of textiles has a strong impact on the environment because of both over-consumption and the practice of production processes requiring the use of substances to manufacture, treat, and dye fabrics. In this context, finding new ways and solutions to transform used textiles into by-products or inputs for production is a trump card for the future of the textile sector. Unluckily, taking up the challenge of a green process providing strict control of the entire design, production, distribution, and end-of-life analysis chain involves costs that make the process difficult to implement by not sufficiently competitive SMEs. This is mainly due to the development of a circular economy policy, which involves large investments with a payoff only from a medium to long-term perspective.

Specifically, in recent years, the relationship between business and sustainability, enucleated in the so-called sustainable business, has seen the most innovation-driven companies consistently start to manage their impact on natural ecosystems and society. On the one hand, the application of sustainability principles for companies entails costs, investments, changes, and innovation efforts that do not always bring immediate economic revenues [

1]. On the other hand, the sustainable approach is a strategic opportunity for growth, allowing both the introduction on the market of products with an extremely reduced impact on the environment, with the same functional and aesthetic characteristics, and a recovery in terms of both energy and materials at the end of the product’s life. In this context, the textile and clothing sector makes no exception. In fact, the most advanced companies are in the process of switching from traditional production processes to a systemic approach that considers the circular economy [

2], i.e., the efficient use of natural resources, the use of renewable energies, reduced or zero waste production, and end-of-life product management.

The initiatives are framed into a logic of Product Lifecycle Thinking, recently recognized as a fundamental strategy for the European Community (Directorate-General for the Environment supported by the European Environment Agency) within the broader framework of actions for sustainable development, developed to promote an integrated system of environmental policy among European states. Not by chance, the European Union developed the “Europe 2020 Strategy” to address environmental issues as well as the current period of economic transition and global difficulties. The strategy intends to achieve economic growth in a smart, sustainable, and equitable manner. The three priorities imply more investment in education, knowledge, research and innovation (smart), a greener, more resource-efficient economic system (sustainable), and greater efforts to increase employment rates, social and territorial cohesion, and tackle poverty (inclusive).

In this complex and dynamic context, only the leaders of the textile industry have the tools, the opportunities, and the vision to carry out a truly green revolution, as demonstrated by related works in literature. In Balanay and Halog [

3], for instance, a review of tools for the Circular Economy (CE) applied in the context of the textile industry is proposed. In detail, such a review recalls a number of concepts related to sustainability and the CE, with reference to the definition of the building blocks of a circular economy. Among others, the following fundamental issues are confronted: sustainable development, ecological transition, green economy, functional economy, and life cycle thinking. Furthermore, a number of limitations to the circular economy concept are stated, including the ones posed by the scale of the considered economy, governance, and management, and of social and cultural definitions. In Jia et al., a comprehensive literature review on the CE applied in the textile and apparel industry is proposed [

4]. When implementing a circular economy in the textile and clothing business, such a study specifically identifies four themes: drivers, barriers, practices, and indicators of sustainable performance. The cited research also suggests a methodology for applying the CE concept and outlines the most important circularity techniques, such as relationship building and dynamic supply chain execution. Finally, a set of performance indicators are suggested. More recently, Ribul et al. offered an updated assessment of strategies in closed-loop mechanical and chemical recycling processes, as well as bio-based technologies that illustrate open-loop textile recycling [

5].

Moreover, some initiatives from large textile and apparel companies, that have promoted recycling initiatives as part of their business strategies, are state of the art. These can be, roughly, divided into “traditional” and “innovative” solutions.

Traditional initiatives carried out in the context of circular economy and green economy are related to processes, with particular reference to the mechanical and thermal recycling of textile products [

6], owing to the typical structure of the organizational system of small and medium-sized enterprises interconnected within industrial and textile districts (e.g., in the Textile District of Prato, Prato, Italy). Mechanical recycling of used textiles includes several process steps and outputs. The first stage is to shred the textiles, resulting in textile fiber pieces, using machines that mechanically shear the fabric. The resultant pieces are carded before being processed in one of two ways: (1) weaving shredded fragments or (2) spinning fibrous materials. In the first case, it is possible to weave together textile fragments without producing yarns, creating “non-woven fabrics” that do not have a precise structure and are bonded through specific treatments, such as mechanical pressure insertion or the insertion of heated plastic filaments. Therefore, the products are composite materials that can be used by manufacturers to make thermal or sound-absorbing insulation panels, such as upholstery, roofing felts, furniture padding, or car insulation, useful in the construction, furniture, or automotive industries [

7]. The second option is ‘textile fiber regeneration’, which yields output yarn, which is then used to produce textiles and new clothing or household items. In particular, the main aim here is to obtain fiber-to-fiber recycling, also referred to by the term “regenerated wool” [

8]. The quality of recycled fabrics is lower than that of the original fabrics, which means less softness and a generally less attractive appearance [

9].

Innovative solutions are mostly based on the wise use of recycled material to obtain fashioned textile products. Just to provide a few examples, Stella McCartney presented a shoe collection composed of biodegradable bio-plastic and recycled plastic, while Gucci introduced 100 percent biodegradable APINAT shoes and began advocating the use of recycled plastic for shoe heels. Bottega Veneta and Gucci both established programs to repurpose discarded leather scraps into shoe production or cuttings into organic fertilizer, and Nike has diverted more than 3 billion plastic bottles from garbage to make products [

10]. Moreover, a paper published in the Waste Management & Research Journal [

11] refers to more than 50 scientific works dealing with the management of textile waste and how it can be an important resource for reuse in new products, with high benefits in terms of design. However, to date, initiatives aimed at integrating an entire production chain in consideration of the circular economy issues are sporadic and unsystematic.

Based on the literature, the subject of CE in the textile industry is increasingly being researched since it has significant effects on the textile industry’s economy. Despite a huge number of methods in the literature, to the best of the authors’ knowledge, a set of rules to be followed by companies willing to perform a transition from traditional linear manufacturing to a circular one is still missing. Accordingly, the main aim of the present work is to propose a set of guidelines to be adopted by textile companies for easily carrying out a CE-based approach. By following the hints provided in this work, based on both the literature review and the huge experience of the Company Manteco SPA, operating in Italy, industries could accomplish the goal of reducing the environmental impact of their production.

In detail:

- –

The method has an impact on the traditional production chain, allowing a transition from linear to circular.

- –

The method brings materials obtained from reuse, eco-friendly product design, yarn and fabric production, quality control, distribution, consumption, and reuse into textile companies.

- –

The method comprises actions to improve human welfare and social equity to significantly reduce environmental risks and ecological deficiencies related to the development of textile products.

2. Materials and Methods

As mentioned above, the main aim of the present work is to provide a set of guidelines to guide textile industries in the transition from traditional production processes to a systemic approach that takes into account the circular economy. This could leverage the efficient use of natural resources, the use of renewable energies, the reduced or lack of waste production, and the management of the end-of-life of the product. By implementing the procedures outlined in the next Section, textile companies could develop an integrated system comprising processes, technologies, products, and control procedures aimed at the production of high-quality textile products in terms of both style and performance that can be obtained through a circular process that includes all phases of production, use, and reuse of materials, with particular reference to wool. This objective involves actions to improve human well-being and social equity, significantly reducing environmental risks and ecological deficiencies linked to the development of textile products.

The processes suggested by the proposed method are applicable to products based on the use of regenerated materials or the combination of reused materials of wool products with certified organic materials. This will allow us to obtain a material “better than the virgin one” with important aesthetic characteristics (so as to be able to make luxury products) and with greater characteristics in terms of the durability of the product.

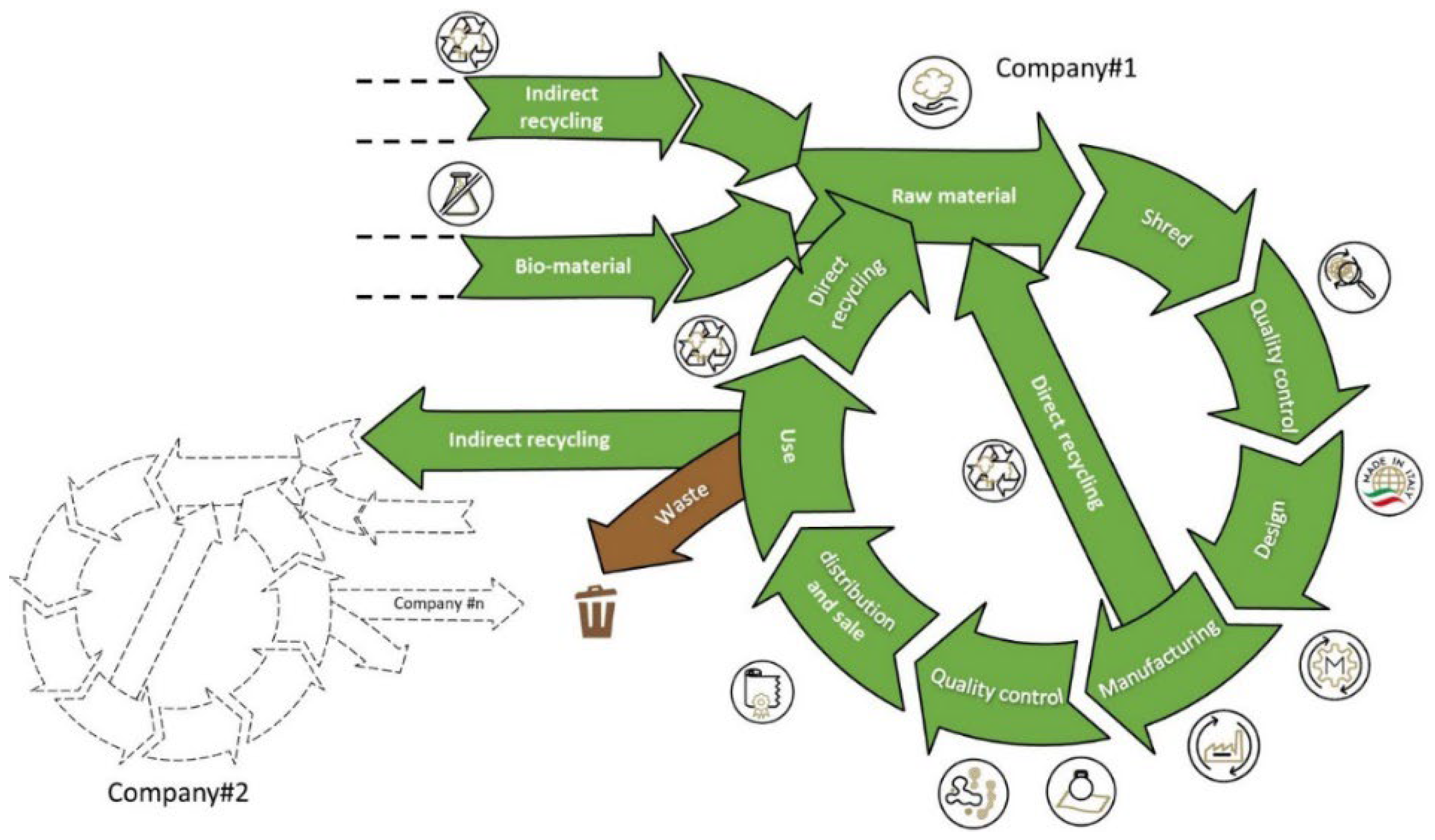

Figure 1 shows the individual stages of the circular process the method proposes.

With reference to such a framework, the guidelines are here proposed to require the company to confront the following challenges:

Definition and drafting of a Sustainability Report;

Optimization of the (raw and recycled) materials conferred;

Eco-Design of textile products, so that they are environmentally friendly as possible;

Implementation of a supply chain traceability, integrating the Block Chain paradigm;

Assessment of products and processes in terms of Life Cycle;

Optimization of the textile products Distribution;

Improvement of the consumption practice by end-users and study of products’ end-of-life;

Reintroduction of most products in the circular process.

Each of the processes is thoroughly explained in this Section and applied in

Section 3 with reference to a case study developed by the Manteco Company.

2.1. Sustainability Report

Adopted by all United Nations Member States in 2015, the 2030 Agenda for Sustainable Development provides a shared roadmap for peace and prosperity for people and the planet today and in the future. Seventeen Sustainable Development Goals (SDGs) are at the heart of it, and they constitute an urgent call to action by all countries—developed and developing—in a global partnership. In this context, a number of initiatives that promote health and education, decrease inequality, and stimulate economic growth should be carried out with the final aim of combating climate change and fighting to protect our oceans and forests. According to the goals of the agenda, companies working in the textile field should be completely aware of the risks and benefits arising from the production of fibers, yarns, fabrics, and cloths, since all production phases can strongly affect the environment. To this end, companies are required to draw up a Sustainability Report with the aim of assessing their economic, environmental, and social performance and defining the company’s improvement objectives for all its stakeholders. This activity, which involves all company functions, represents a very important moment of synthesis that the company should use, through the verification of established indicators, to measure the extent to which sustainability is integrated into their operational logic. Stakeholders to be involved are internal staff and collaborators, regardless of their role, customers, suppliers, and the community, public administration, and credit institutions. There are several well-known sustainability-reporting frameworks and standards available, each supported by trustworthy organizations and persons on their Board of Directors (see

Table 1) [

12].

Each standard deals with a different topic, ranging from narrow (an exclusive focus on greenhouse gas emissions, for example) to broad (encompassing all ESG or the entire range of UN Sustainable Development Goals), and caters to a different set of stakeholders (primarily investors) to broader groups, including customers, employees, and society at large [

12].

Whichever the framework selected by the companies, the Sustainability Report should include at least the following information:

A description of the company profile (e.g., including the business model, structure, and internal infrastructure system).

A description of actions to reduce the environmental impact and stakeholder engagement.

An example of the supply chain accompanied by a series of performance indicators (key indicators).

The Report should be shared with all company stakeholders as well as with the general public. Therefore, it is suggested to share it on the company website.

2.2. Conferring Raw Materials

It is commonly believed that high-quality fabrics can only be obtained starting from virgin materials (e.g., pure virgin wool) suitably treated and dyed with dyes that comply with current regulations in terms of the presence of materials harmful to health, such as heavy metals. In this context, recycled material is intended to produce medium or low-quality products. Therefore, with the aim of making high-quality products with reused material, it is necessary to develop a series of procedures to obtain high-quality raw materials to produce fabrics exclusively obtained from recycled materials. There are three types of raw materials: recycled materials coming from the market, new raw materials coming from the market, and recycled materials coming from the textile company implementing the circular process. Therefore, three different processes are envisaged, depending on the raw material considered for creating the textiles.

2.2.1. Recycled Raw Materials Coming from the Market

The recycled materials supplied (pre- or post-consumer) shall come only from suppliers specifically chosen by the company, with whom it has had a long-standing trusting relationship and who guarantee, even if not certified, the absence of substances that do not comply with harmful substance legislation (e.g., in accordance with Commission Decision 2002/371/EC or with the EcoLabel® initiative).

In addition, companies should be equipped with an internal laboratory. This allows for the characteristics of the incoming material to be checked with particular reference to the identification of the material (fiber percentage composition), the compliance with eco-toxicological requirements (in particular for raw materials that have already been dyed), the possible presence of formaldehyde (mainly due to finishing processes), azo dyes, Pentachlorophenol (PCP), Tetrachlorophenol (TCP), allergenic dyes, and heavy metals. Some reference values are in

Table 2.

Furthermore, the chemical inventory and wastewater must be monitored, and a control strategy that includes a Risk Assessment Plan must be developed. At this stage, it will be necessary for the input materials to be classified not only in terms of fiber content (wool, wool blend, viscose, etc.) but also in terms of color, to avoid further dyeing processes in the production process. In fact, dyeing is known to be one of the production processes with the least sustainability in the supply chain, and its use should be reduced. This means that the quality control should also include colorimetric and spectrophotometric analysis. At the end of this task, only materials that respond positively to the controls (i.e., do not introduce hazardous materials into the cycle) and are categorized in terms of color, will be further processed.

Another strategy to assure the safety of raw materials coming from the market is the Global Recycle Standard (GRS) certification. The GRS label guarantees recycled textiles with additional environmental and social criteria. It is based on a tracking and tracing principle using a certificate-based transaction system to ensure the highest level of integrity. This acts as a monitoring and control mechanism for the whole value chain of certified products. The GRS-certified end-product chain is the only existing certification authority for recycled materials, promoted internationally by the Textile Exchange, a global non-profit organization recognized by major fashion groups. Recycled Claim Standard (RCS) and SCS Recycled Content Certification are other two interesting approaches to comply with ecological requisites. Overall, the cost of materials obtained from recycling (i.e., regenerated wool) is about 80% of the cost of virgin wool, even considering the labor for controlling it in a lab.

2.2.2. New Raw Materials Coming from the Market

The use of virgin wool (or new raw materials in general) may feed the circular process. In fact, the circular supply chain can include non-reused material, even if at a lesser percentage than regenerated wool or items reintroduced into the production cycle but made from recycled resources. In this case, textile companies should ensure that the material provided is in accordance with ecological and social values. To this aim, some preferred solutions are, again, to rely on suppliers’ certification. Some relevant certifications are Organic Content Standard (OCS), Global Organic Textile Standard (GOTS), and Responsible Wool Standard (RWS), a voluntary standard that addresses the welfare of sheep as well as the area on which they graze. The RWS requires all process sites to be certified, beginning with the wool farmers and through to the seller in the final business-to-business transaction. Usually, the last stage to be certified is the garment manufacturer or brand. Concerning wool blend products, artificial fibers such as polyamides (e.g., nylon), polyester, or acrylic can be replaced by environmentally friendly fibers, such as Lyocell or Tencel™, which are mostly made of cellulose [

13]. Natural fibers shall be present in the blend in a proportion varying in the range of 10–30% of the total weight of the blend; regenerated wool shall be present in a proportion higher than 60% of the total weight of the blend.

Regarding the feeding of cotton-based material into the cycle, the use of sustainable cotton from farmers accredited by the Better Company Initiative (BCI) may be a trump card. The BCI is, in fact, an international non-profit organization that has established a recognized Standard System for sustainable cotton production that covers all three pillars of sustainability: environmental, social, and economic. Of course, natural fibers have higher costs when confronted with polyester or other synthetic fibers, which are very cheap. This means that the use of natural fibers would increase the overall cost of the fabrics by 2–3%. This cost can be reduced by using a combination with regenerated wool.

2.2.3. Recycled Materials from the Company

During the traditional production process of making the final yarns, fabrics, or clothes, there is a loss of first-quality material, which causes waste and scrap material. This is a notable waste because these materials, in addition to being of first quality and having a higher economic value than those of previous phases, have already passed through all previous manufacturing phases. Therefore, they are of great environmental value, as they correspond to a certain amount of waste generated during previous supply chain phases. In this regard, companies should recycle at least 80–90% of the waste materials in their internal (or external) production processes. In this case, it is a matter of developing a series of procedures aimed at recovering spinning, winding, weaving (selvedges), and header waste. Companies should ask their external suppliers to follow their recycling strategy for materials left over from manufacturing. The overall cost of the recycled fibers is, in this case, considerably lower (less than 10%) than the virgin wool cost.

2.3. Yarn and Fabric Design and Process

To guarantee the sustainability of the designed product, the principles of eco-design need to be taken into account by developing products in which the end-of-life is actually the beginning of a new process of transformation into raw products. From this point of view, the design of the fabric will have the fundamental objective of considering the typical phases of stylistic conceptualization, the definition of the composition of the fabric, and the definition of the weaves together with the requirements at the end of the product’s life. Particular attention should be given to the possibility of fraying the fabric to obtain raw material ready for subsequent spinning. It is, therefore, necessary for textile companies to leverage the adoption of design methodologies, possibly those that are computer-assisted, which are carried out within a framework of Life Cycle Assessment. In particular, the Design for Recycling (DFR) and Design for Disassembly (DFD) principles are recommended approaches to fulfill the explicit objective of facilitating the recycling of products, their components, and end-of-life materials [

14]. The DFR and DFD initiatives enable the development of guidelines and design checklists aimed at encouraging reuse by creating products that are easy to separate, avoiding permanent fasteners and/or the use of recycled materials, and using pure raw materials (or minimizing fiber blends) to maintain a high resale value. It is important to highlight that the variability of the many types of materials employed, as well as the extensive usage of fiber mixes, is a technical element that delays the success of textile recovery operations. This hinders sorting processes and imposes a requirement of recycling into indistinct blends, driving down cycling that, in turn, affects the commercial value of the recycled material. For this reason, the use of natural fibers (which are easier to be extracted), and the use of unblended and good quality fabrics (which are easier to be disassembled) are strongly recommended in this phase.

Indubitably, the final quality of yarns and fabrics obtained following the aforementioned principles should be at least comparable with the one obtainable with the traditional design approach. Both technical and aesthetic requirements should be satisfied. Concerning technical requirements,

Table 3 lists some suggested values for yarns.

With reference to fabrics, it is possible to identify a number of requisites to be achieved in terms of quality, as depicted in

Table 4.

For both yarns and fabrics, a number of aesthetic and performance parameters should be considered. One of the most important is the color. In effect, modern businesses are usually supplied with databases where spectrophotometric pre-colored fiber information is stored along with suggested percentages to be used to achieve a specified color target. To this aim, textile industries should have “historical” formulas that can be used to produce a final “blend” (using processes such as combing, painting, roving, spinning, or carding [

16]).

Whenever a blend is manufactured, colorists usually perform an instrumental comparison with respect to the color target to determine the color difference. Such a comparison should be tested under a variety of standard illuminants such as D65 or TL84 [

17] using multiple color spaces such as CIELAB or CMC (2:1). D65 corresponds to the average midday light in Western Europe/Northern Europe (comprising both direct sunlight and the light diffused by a clear sky), hence it is also called a daylight illuminant, with 6500 K temperature. TL84 represents a Philips narrow tri-band fluorescent lamp (4000 K temperature). It is important to highlight that when calculated using a spectrophotometer, the color differences between the recipe-based reflectance factors and the spectrophotometric response of the reference in terms of CIELAB and CMC (2:1) distances may be greater than 0.6–0.8 [

18]. Consequently, the original recipe must be modified to meet the required color (see

Figure 2), demanding the creation of numerous samples to decrease the difference in color between the blend formed by mixing the raw components and the desired one. As each trial requires time-consuming manufacturing and measuring procedures, this trial-and-error approach is a bottleneck in the entire fabric manufacturing process.

Consequently, any action to speed up this process is welcomed in the cycle. Not by chance, a number of literature studies address the topic of color matching for textile blends [

11].

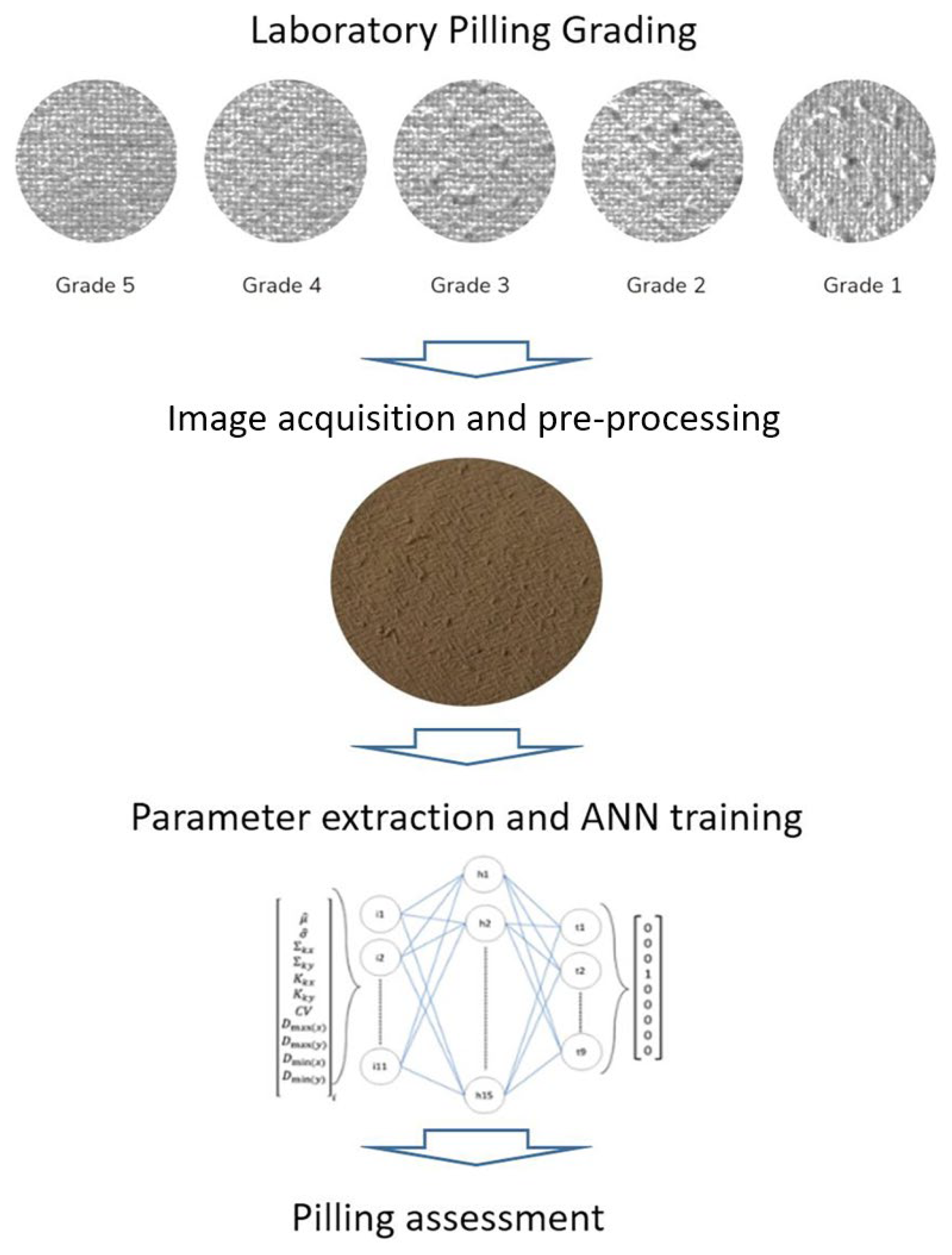

Another important factor to consider as a good performance indicator for the manufactured textile product is the pilling grade. The term “pilling” refers to a surface defect occurring in textile fabrics and consisting of entangled fibers forming the so-called “pills [

18]”. Such pills are caused by the combination of washing and wearing of fabrics; specifically, due to the abrasion of the fabric surface, a number of loose fibers tend to entangle into short fine hairs, thus developing into spherical bundles anchored to the surface of the fabric. According to ISO-12945-2:2000 [

19], the pilling resistance varies in the range of 1–5, where 1 stands for poor pilling resistance and 5 for excellent resistance. Two common pieces of equipment for pilling measurement, used in Europe, are the Martindale pilling tester and the Pilling Box. In both cases, the pilling degree is assessed by skilled operators (experts) comparing the specimens, after a predefined number of cycles performed by the testing equipment, with visual standards (which may be actual fabric samples or photographs). To improve the quality of the pilling control, it is here suggested to carry out a different method for assessing the pilling degree, i.e., to use Machine Vision based systems, as suggested by Furferi et al. [

17] (see

Figure 3).

2.4. Traceability and Block Chain

A relevant aspect to guarantee the circular process is to trace the whole lifecycle of a product from the raw material to the consumer. The problem of traceability in textiles and clothing is a longstanding issue. Because of information asymmetry and a lack of openness, the textile and clothing supply chain is often nearly untraceable. UNI EN ISO 9001:2015 [

20] defines traceability as “the capacity to identify and trace the history, distribution, location, and application of products, parts, materials, and services”. A traceability system tracks and follows the trail as products, components, materials, and services are delivered from suppliers, processed, and eventually distributed as finished goods and services.

Supply chain traceability demands the recording of numerous types of information at various phases of product transformation, from raw material manufacture through reverse logistics. The authors of [

21] stated that traceability information, particularly product traceability, is broadly characterized as product, process, and quality related. Product information should comprise the name, origin, composition, specifications, and facts about all raw materials, intermediates, and finished products given to the end user. Process information should include all the details related to all the processes involved in the manufacturing of the product. Finally, quality information is primarily concerned with the quality of a product and the details linked with it [

22]. All this data should be recorded and maintained using a specific software platform and, if necessary, supplemented with data from other sources currently available in businesses.

In this context, Blockchain (BC) can provide a safe manner of storing information about responsible parties and their actions in a supply chain, including the time and location of supply chain processes, operations, and transactions. In fact, BC proves to be useful to guarantee the following four key capabilities of the textile circular process:

Traceability: the essential idea behind Blockchain traceability is the chronological record of transactions [

23]. Using the block hash and timestamped information, each block in the BC is cryptographically connected to the one that came before it in the ledger, resulting in an immutable historical record of transactions.

Security: cryptographic keys are used to time stamp and identify blocks in the BC ledger. Since data can only be added (not erased or altered), once a block is put into the ledger, it cannot be changed [

24].

Transparency: the decentralized Blockchain network allows scattered parties to connect and exchange data in a secure way [

25].

Autonomous Smart Contracts: smart contracts are automated transaction protocols that carry out a contract’s terms [

26].

Very schematically, the most important traceability points that must be coded to ensure the traceability of the final product are, typically: the identification of the raw material, processing arrangement of the raw or semi-finished material and the spinning, weaving, and finishing arrangement.

Regarding the delivery of incoming materials and the way in which raw materials are processed, data relating to the batch of materials used must be traced and the person responsible for processing must be identified for each batch. For this process, at the least, the following parameters should be assigned: the supplier should be identified by a unique code (e.g., supplier ID), date of delivery, an identification code of the item delivered and the relative quantity, batch number and, if necessary, the supplier’s certification (e.g., certificate number). A unique code should be issued to the digital document containing this information. If the arriving batch of material is sent to the production department (which may also be external to the company), the processing order, followed by the pickup of material from the warehouse, must be managed (e.g., based on a daily list of production orders). The complete history of the product should be monitored using the business’s BC, and the company will be able to identify the product, which phase it is in, and which processes it still needs to go through based on the label affixed to each semi-finished product. The final product code, which could be provided to the customer, should also identify the digital model of the fabric, which will be accompanied by a data sheet (identified by the same code) with the technical parameters specified by the customer.

2.5. Life Cycle Assessment

The term “life cycle” refers to the time span between the raw material phase of a product and its first market introduction until its final withdrawal. Even though the textile business is one of the most consumer-intensive, recycling and reclamation methods receive little attention. To overcome this issue, a life cycle analysis (LCA) is recommended. As is known [

27], a LCA describes in detail the waste potential, energy consumption, and environmental effects of each stage in order to reduce Green House Gas Emissions (GHG). The textile industry must reconsider ways to develop more sustainable materials and technology, as well as ways to improve recycling. The main reasons for performing a LCA are to obtain quantified and reliable information for the emotive debate on the environmental impact of textile products to be used by industry and policymakers and to highlight areas where information on the environmental impact is still unknown or uncertain. Moreover, a LCA allows enabling considerations for the reduction in material and energy flows along the textile life cycle. The LCA of textiles and textile manufacturing presents certain challenges, such as extensive transport distances in life chains, product lifetime evaluation (a major ecological component), and emphasizing synthetic versus natural fiber comparisons. As a methodology, LCA is continually evolving; however, manufacturers and service organizations alike, as a means of opening new viewpoints and broadening the debate over environmentally sound products and processes, are fast adopting the principles behind LCA thinking.

The company’s direct energy consumption mainly consists of electricity for lighting the workplaces and natural gas for heating them. Other consumption could be derived from the company the means of transport, generally calculated from the costs incurred for refueling during the year. Moreover, one of the most adopted impact indicators used for LCA analysis for companies producing yarns and textiles is the water consumption required to produce one square meter of fabric. The environmental and social impact linked to the production of raw materials (cultivation, breeding, synthesis, etc.) is also extremely relevant in the life cycle of the textile product. For this reason, companies should set themselves the objective of constantly increasing the number of raw materials with sustainable characteristics, both in terms of environmental and social impact and animal welfare, as described in

Section 2. By including items with a high sustainability content in the collection, the company must commit to the defense of biodiversity, the protection of natural habitats, and the protection of animal welfare.

2.6. Distribution

The customers of the major textile industries are usually located all over the world. It is therefore unthinkable to have strict control over how goods are transported to the customer. However, it is still possible to maintain a certain level of control, thus minimizing transport emissions. In fact, the practice is to provide fabric samples to customers so that they can “touch” the product. This involves a flow (sometimes significant and quantifiable in the range of 0.25–2%) of the material leaving the company. This material cannot easily be reintroduced into the production cycle and its distribution negatively affects the company’s carbon footprint. To guarantee the same quality to the customer and, at the same time, reduce the movement of material and its exit from the company, companies should implement a strategy of digitization of the fabrics. In fact, by creating a digital model of the fabric and accompanying it with a set of data sheets explaining the product traced through each phase, the buyer will have access to the same information that he would have with the real model (with even more information thanks to the completeness of the information on the datasheet). The substitution of the physical product with a digital file accompanied by technical data sheets is also considered an advantage by virtue of the availability, on the part of the manufacturing company, of already providing a series of technical characteristics of the product that would otherwise be the responsibility of the customer to test.

To minimize arguments in the event of material non-conformity, the explicit criterion for the substitution of physical samples with their digital counterpart is that the production process and the tests performed are all traceable and replicable. If, for example, the product’s colorimetric features do not satisfy the client’s criteria, the textile firm must be able to physically access the samples (available for a predetermined amount of time) and recreate the spectrophotometric assessment in front of the end customer.

A more creative option would be to explore a range of sophisticated audio/video setups to bring customers back into the company’s showroom via live streaming and videoconferencing. The goal is to provide a truly immersive experience, such as by deploying a multi-camera recording system that will make the showroom available to the public via simple and partly autonomous guidance [

28]. In support of this idea, similar systems are adopted today. To cite a few, the luxury brand Louis Vuitton created a virtual showroom where users can access a digital library through an app, which also serves as a marketing tool and enables purchases. Gucci, the Italian fashion label, has advanced its digital strategy in recent years with augmented or virtual reality displays, for example, making their 2018 campaign an immersive one in-store.

2.7. Consumption and End-of-Life

The estimated reuse rate is high in Europe and in Italy in particular (in 2018, according to a report by ASSOSISTEMA Servizi S.r.l. the reuse rate, which includes recycling in other countries with particular reference to North Africa and sub-Saharan Africa, was 68–70%). Moreover, the share of industrially recycled material is in the range of 26–28%. Unfortunately, it is not possible to control the material flow at the end of the first use. In fact, the textile product, while traceable from its origin, exits the company’s “chain of custody” once it is placed on the market, making it impossible to monitor its end-of-life. In other words, the loop’s closure cannot be guaranteed. It should also be noted that textile items are frequently destined for reuse before being discarded (typically by charity and private operators) and are only then collected, repurposed, or thrown away. Finally, because practices addressing the disposal of end-of-life products differ from nation to country, it is impossible to guarantee the continued use of a single norm such as that recommended by the European Community.

Consequently, in this phase, only actions to limit the dispersion of high-quality products can be carried out. Some suggestions are as follows:

- (1)

Leverage the concept of Design for Longevity–The concepts of Design for Longevity attempt to intervene in the original design phase to maximize the usable life of a product, particularly in the fashion industry. The first and most significant barrier is the obsolescence of the items themselves. As a result, the quality of the materials used to make the items should be as high as possible, the design should include considerations for the stress to which the garment is subjected, thus extending its useful life, and colors and styles should be carefully chosen to reduce obsolescence caused by rapid changes in dress sense. Additionally, it is critical to properly express to customers how to handle the textile product and how to recover it in the event of anomalous wear. Increased durability may correspond to a greater willingness on the part of the customer to prolong the use of the good or to bring it to a secondary market for reuse instead of turning it into waste. To check the actual durability of the samples to be placed on the market, severe tests such as resistance to acid and basic chemicals to simulate perspiration and resistance to light to simulate sunshine are required prior to introducing the textile product in the market. This will increase the durability of the product in terms of mechanical and chemical resistance. At this point, special attention should be paid to the behavior of the prototype textiles developed while subjected to vigorous washing cycles, to identify the possibility of unwanted material dispersion in the washing water.

- (2)

Adopt a Distinctive Labeling—The textile company may propose distinctive labeling of the fashion house that iconically demonstrates the quality of the product (at least the quality perceived by the customer and often linked to the brand). By using a product design that is in some way recognizable and iconic, it will be possible to reduce the propensity for wasting, favoring instead a second and third-hand market. The labeling could be accompanied by a reward strategy where the customer who returns the product, once it is no longer considered suitable for its use, gain a voucher for the purchase of another product, possibly from the same company. The returned product is introduced into the manufacturing cycle, with the significant advantage of having a very high percentage of incoming product that already possesses the technical features required for the development of new products.

- (3)

Address Risk Mitigation—The circular process described here is based on the assumption that the fabric is obtained with materials that are subject to strict controls and for which, whether they are virgin or recycled, the absence of substances dangerous to health and the environment will have already been demonstrated (and traced). Consequently, even if the product is wasted, it will not have a significant anthropogenic impact on the environment, and it will presumably be retrieved by other enterprises, fueling an “extended” circular economy at the district level.

2.8. Collection, Recycling, and Re-Introduction into the Circular Production Process

As previously stated, the circular process’s input is material recovered from recycling. Although the great majority of products brought in are not expected to be end-of-life, the eco-design of the products will enable easy reuse by other companies, perhaps initiating a circular economy for other enterprises in the industry. In other words, because the waste material is entirely certified at this moment, what is not circular for the company will become circular for other industrial realities that take the proposed approach in the future. Therefore, a virtuous circle may be created, which may lead to an exponential increase in the utilization of recycled material in the textile chain.

3. Results

The proposed guidelines have been adopted by the company Manteco S.p.A., located in Italy, Manteco is one of the most important companies producing yarns and fabrics for luxury brands such as Armani, Versace, D&G, Prada, Gucci, H&M, and Zara.

To better understand the impact of the proposed procedure on the production of textiles, this Section describes the overall process with reference to a single case study consisting of a fabric composed of regenerated wool (80%) mixed with the biological material TENCEL™ (20%).

Figure 4 shows such a fabric.

Of course, some of the steps proposed by the guidelines are related to the overall company organization and, therefore, are adopted for the production of any new kind of “green” fabric manufactured by the company.

Accordingly,

Table 5 describes which step is related to the company organization rather than to the production of the fabric selected for the case study. Moreover, in the same table, the level of achievement of each step is provided.

3.1. Sustainability Report

The company is committed to a path towards sustainability through the implementation of the 4sustainability

® protocol (

https://www.4sustainability.it/#process-factory (accessed on 1 September 2022)) for managing chemicals in production processes and aimed at eliminating toxic and harmful chemicals through the MRSL ZDHC, in accordance with brand guidelines. Moreover, it adheres to both the Carbon Disclosure Project and Global Reporting Initiative. Specifically, Manteco carried out a protocol named “Sistema Manteco”, which involves the organization of a network of textile companies, artisans, and experienced professionals to create a single, traceable production system. The adhering companies, i.e., 54 realities of the Prato textile district (Italy), constitute the key partners involved in the production of Manteco fabrics. Such companies signed a “Charter of Commitments for a sustainable supply chain”, in which clear objectives and standards were defined in terms of environmental, social, and organizational responsibility. In the devised protocol, several stakeholders are involved: internal staff and collaborators, regardless of their role, customers, suppliers, the community, the public administration, and the credit institutions.

3.2. Conferring Raw Materials

As mentioned above, with reference to the selected case study, the fabric is manufactured by mixing regenerated wool (80%) with virgin lyocell fibers (named TENCEL™). The 95% of regenerated wool is supplied by one of the companies which signed the charter of commitments cited in the previous paragraph, and whose products are certified according to the Global Recycle Standard (GRS). The remaining 5% of regenerated wool is obtained from waste materials in the company’s internal production process. The regenerated wool is subjected to a number of tests in order to verify its compliance with the limits imposed in

Table 2. Since the conferred wool is pre-colored, an important step is to create a blend of the desired color by mixing together differently colored fibers.

In effect, modern businesses are supplied with databases where spectrophotometric pre-colored fiber information is stored along with suggested percentages to be used to achieve a specified color target. In other words, textile industries have “historical” formulas that can be used to produce a final “blend” (using processes such as combing, painting, roving, spinning, or carding). Whenever a blend is made, colorists usually perform an instrumental comparison with respect to the color target to determine the color difference. Such a comparison is tested under a variety of standard illuminants such as D65 or TL84 [

2] using multiple color spaces such as CIELAB or CMC (2:1).

More often than expected, the result achieved by combining the fibers is very different from the reference, even though companies adopt a “consolidated” recipe. In fact, when calculated using a spectrophotometer, the color differences between the recipe-based reflectance factors and the spectrophotometric response of the reference in terms of CIELAB and CMC (2:1) distances may be greater than 0.6–0.8 [

29]. As a result, the original recipe must be modified to meet the required color, demanding the creation of numerous samples in order to decrease the difference in color between the blend formed by mixing the raw components and the desired one. Once the desired color is obtained, the wool fibers are ready to be further processed as described in

Section 3.3.

3.3. Yarn and Fabric Design and Process

Since the input material is not conventional, as described above, the spinning process was readjusted, in terms of processing parameters, to process regenerated wool fibers with organic materials (i.e., Lyocell). These materials, although of organic origin, are processed similarly to viscose in that they are originally obtained in a form of high density and malleability that hardens during the spinning process. The parameters/processes taken into consideration for the production of the yarn are, among others, pre-spinning, drafting, steaming, the number of twists Z (depending on the fineness of the fibers), and the CV of the yarn. At the end of the spinning phase, a number of tests are carried out on a knitted cloth obtained on small hinges in order to carry out a pre-evaluation of the functional, mechanical, and aesthetic characteristics of the yarn obtained;

Table 6 shows the parameters measured for regenerated wool yarns and

Table 7 shows the mechanical properties of lyocell yarns.

Once the yarns are characterized, it is possible to design the fabrics by following the eco-design principles. Different weave solutions were tested using different yarns (e.g., regenerated wool + Lyocell) both as warp and weft.

Additionally, in this case, the technicians were committed to searching for the best setting of weaving parameters to obtain fabrics that complied with the intended design in terms of handling and aesthetics. The overall results obtained for the new fabric prototypes are listed in

Table 8.

3.4. Traceability and Block Chain

The company is now developing a BC-based platform to track all the processes to create new fabrics, together with the development of a number of IT systems, for the real-time quality control of the circular process. However, for the selected case study, this system was not adopted due to its low technological maturity.

3.5. Life Cycle Assessment

An interim life cycle assessment (LCA) of the entire process used to make the new fabric reveals that the new prototype has much lower environmental consequences than virgin wool fibers. The environmental impacts are less than 20% of the virgin counterpart for all lifecycle metrics considered in the assessment, and less than 5% for carbon footprint, particulate matter, acidification, terrestrial and freshwater eutrophication, freshwater ecotoxicity, land usage, and water use. One kilogram of the new fabric is equivalent to 0.07 kg of CO2 equivalent, with transportation accounting for most of this amount. In contrast, the carbon footprint of virgin wool fibers is 75.8 kg CO2 eq./kg

3.6. Distribution

To minimize the impact of distribution, Manteco implemented a strategy of digitization of the fabrics so that the digital model (accompanied by a set of data sheets explaining the product characteristics) is accessible by the stylist without the need for receiving the real model (as already stated, the digital model conveys perhaps even more information thanks to the completeness of the information on the datasheet).

Figure 5 shows some examples of digital models (high resolution images) created by the company.

3.7. Consumption and End-of-Life

This is a particularly crucial aspect to be considered when considering the circular process for the new prototype.

All three strategies described in

Section 2.7 are adopted in this case, some of which are still under investigation:

- -

Design for longevity: the company is creating a new protocol called “Manteco Aging Process”. It is based on the practices already used for the aging of leather materials. Laboratory procedures will be developed to artificially accelerate the aging of the tissues. These, therefore, will be subjected to stricter tests than those substances used in the laboratory (resistance to chemical and basic substances to simulate sweating, resistance to light due to solar radiation, etc.) to verify the effective durability of the samples that will be placed on the market. Particular attention will be paid, in this phase, to the behavior of the prototype fabrics developed when subjected to intensive washing cycles and the possible dispersion of the material in the washing water.

- -

Distinctive Labeling: the fashion house that will receive the new fabric will iconically demonstrate the quality of the product (at least the quality perceived by the customer and often linked to the brand). This is possible given the high brand recognition of the company’s customers.

- -

Risk Mitigation: the circular process carried out by the company is based on fabrics obtained with materials that are subject to strict controls and for which, whether they are virgin or recycled, the absence of substances dangerous to health and the environment will have already been demonstrated (and traced).

3.8. Collection, Recycling, and Re-Introduction into the Circular Production Process

The new fabric is ready to be introduced in the market, but it is too early to have control of its end-of-life. Therefore, this phase was not carried out yet.

Dealing with the overall performance of the proposed method, its effectiveness can be demonstrated by considering the impact of the Circular process in terms of saved energy, water consumption, and produced CO

2, as shown in

Table 9.

4. Conclusions

The present work proposed a set of guidelines for textile industries that aims to perform a transition from traditional production processes to a systemic approach considering the circular economy. Each step involves a strong commitment of the company towards its stakeholders and the implementation of a number of procedures, often accompanied by a certification from third parties. By implementing the outlined procedures, textile companies could develop an integrated system comprising processes, technologies, products, and control procedures aimed at the production of high-quality textile products in terms of both style and performance obtained through a circular process that includes all phases of production, use, and reuse of materials, with particular reference to regenerated wool. The proposed method has been adopted by a major company operating in Italy and is under continuous improvement. The guidelines were tested against a number of case studies, demonstrating their effectiveness in creating brand new products with technical properties similar (or even better) to the ones obtainable using virgin materials.

This work does not pretend to be exhaustive or to completely solve the problem of the transition to a greener process but proposes a series of good practices to improve company performance. The major limitations of this work are related to the fact that the guidelines are applied to a leading company. There is, therefore, no evidence of their application in different contexts such as small and medium-sized enterprises in the textile sector. Future works will be addressed to evaluate a continuous improvement of the proposed methodology, taking into account relevant literature. Dealing with the circular process, more hints will be achieved by implementing similar methods, such as the one proposed by Saha et al. [

30]. With reference to systems for improving the quality of yarns and fabrics, methods based on the approaches proposed in [

31,

32,

33] will be tested and carried out. Furthermore, social aspects are also relevant to the textile companies that aim to implement the CE; accordingly, several approaches, such as the one proposed by Padilla-Rivera et al., will be considered [

34].