Evaluation of Melting Mechanism and Natural Convection Effect in a Triplex Tube Heat Storage System with a Novel Fin Arrangement

Abstract

:1. Introduction

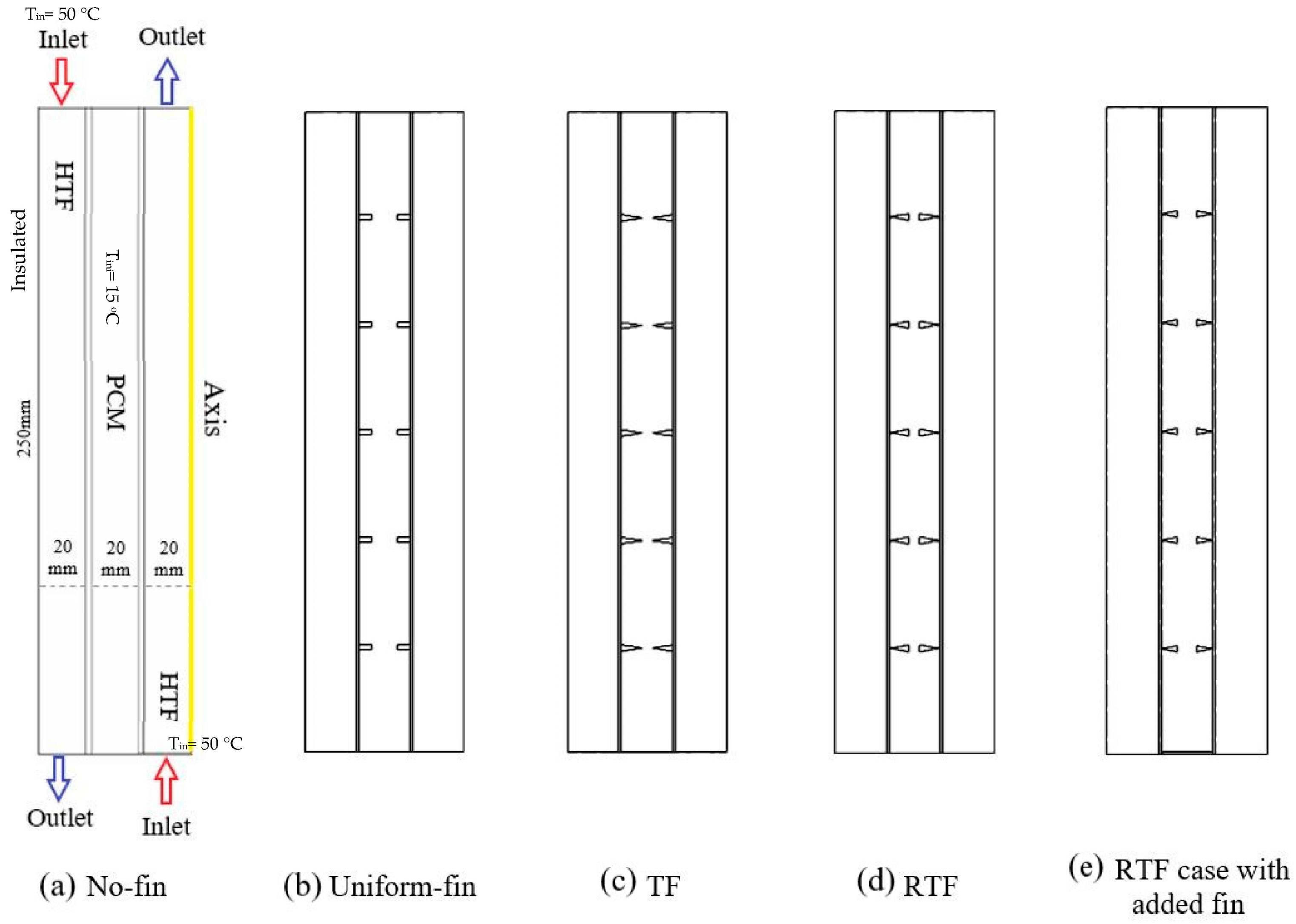

2. System Description

3. Mathematical Modeling

- Consider incompressible and Newtonian fluid molten PCM.

- Consider ignorable viscous dissipation.

- Consider variable density while the other physical properties of PCM are constant.

- Apply Boussinesq approximation for density variation in the liquid PCM.

4. Numerical Analysis

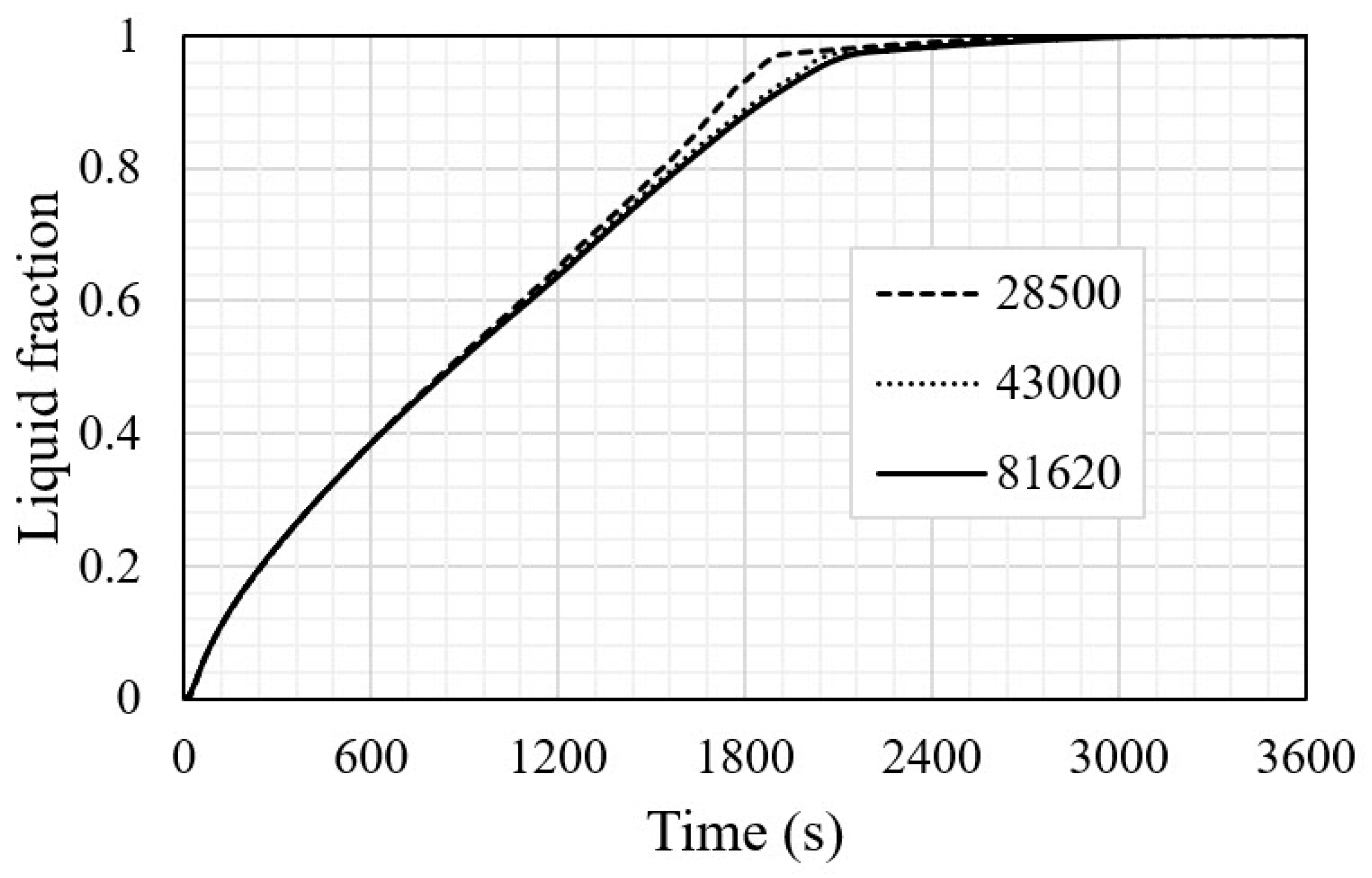

4.1. Spatial and Temporal Discretization

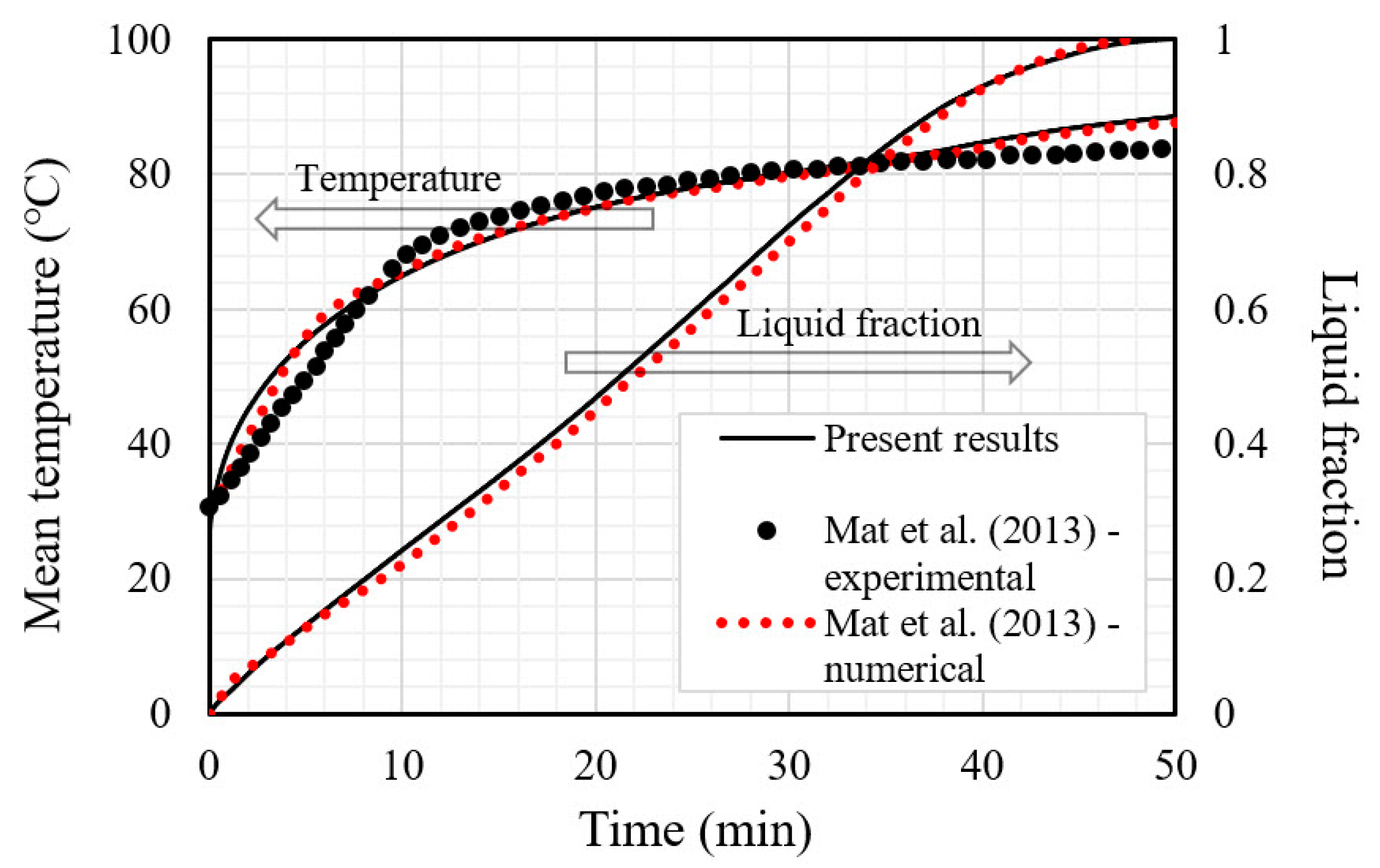

4.2. Model Validation

5. Results and Discussion

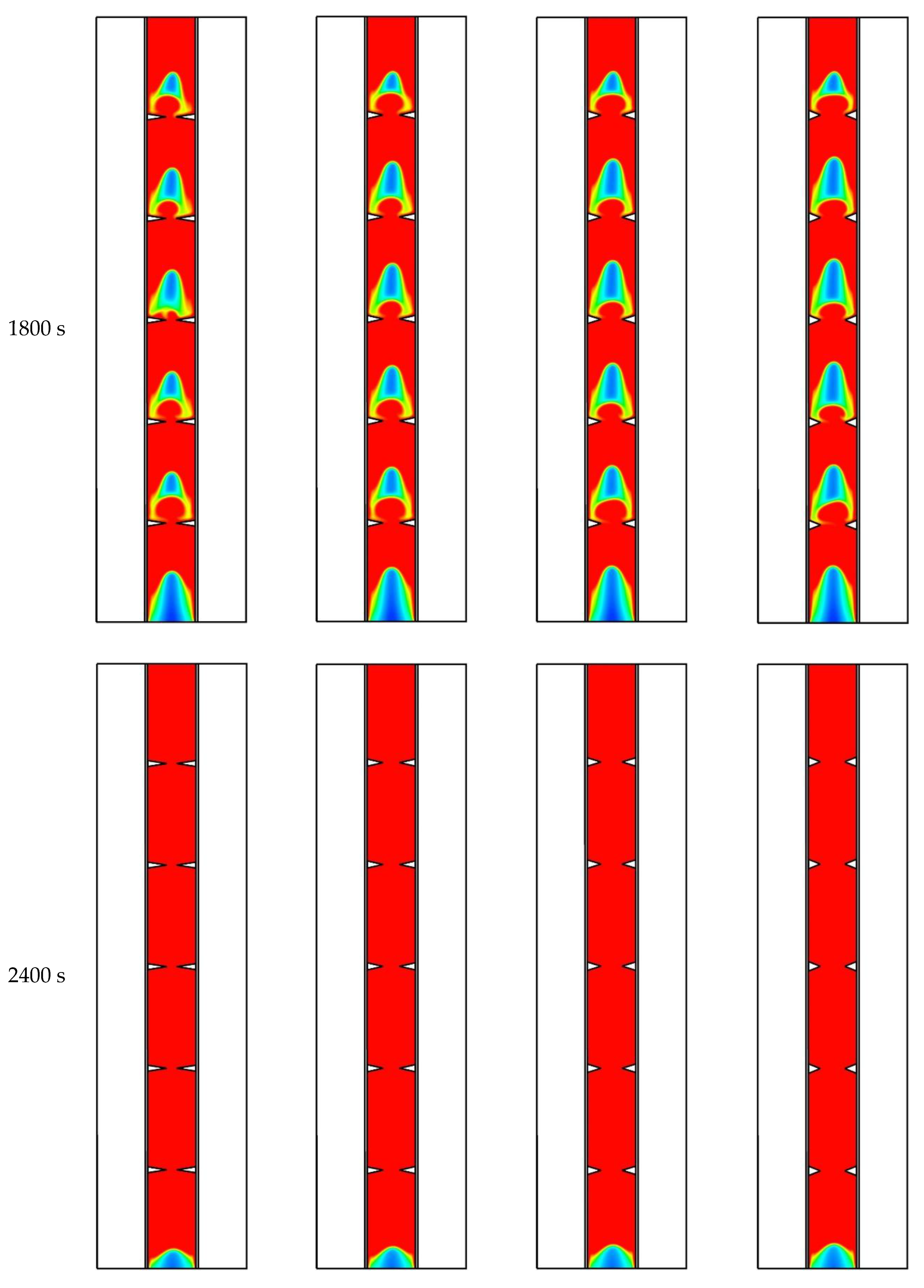

5.1. Effects of Using Triangular Fins on the Charging Phenomenon

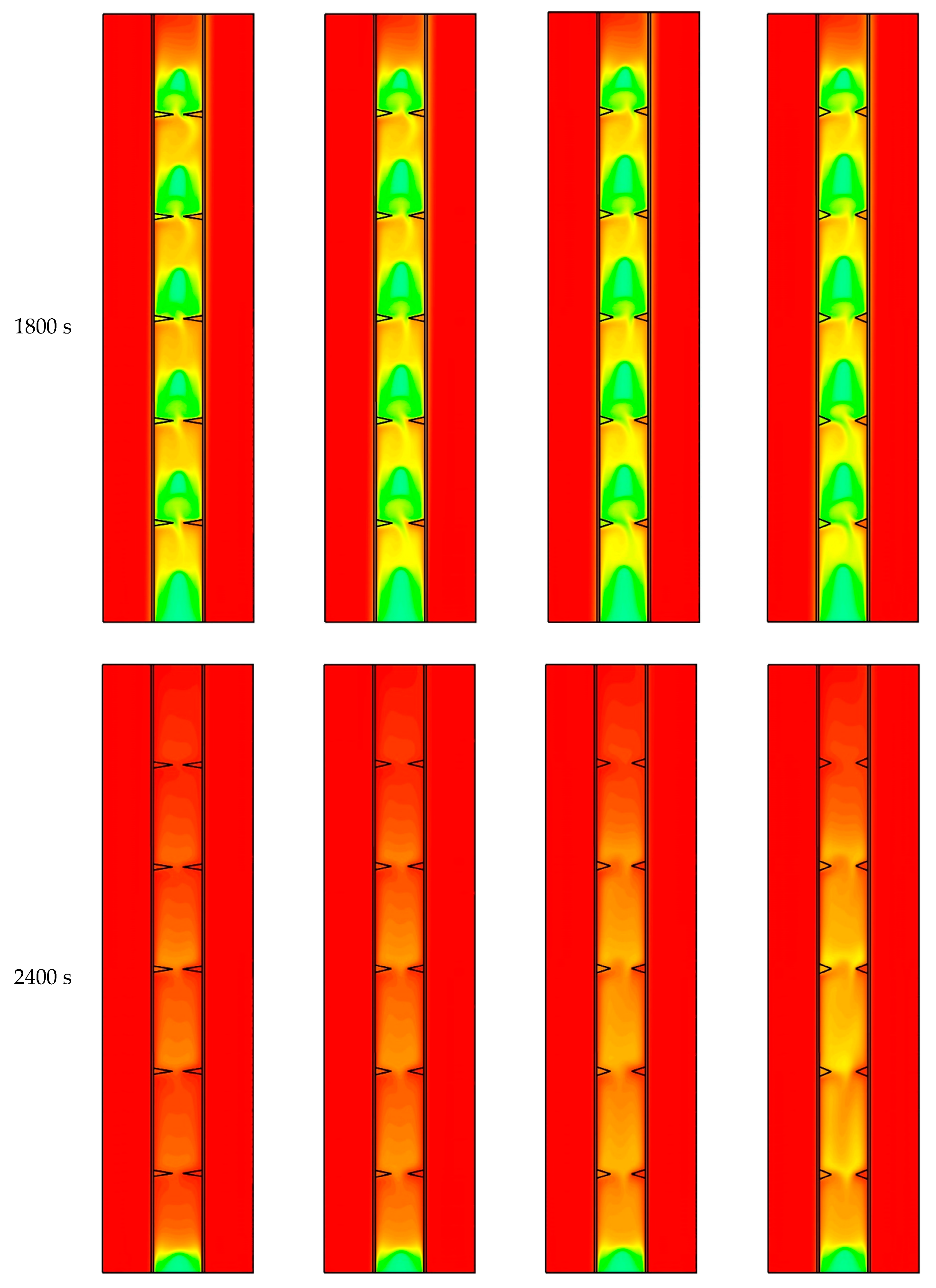

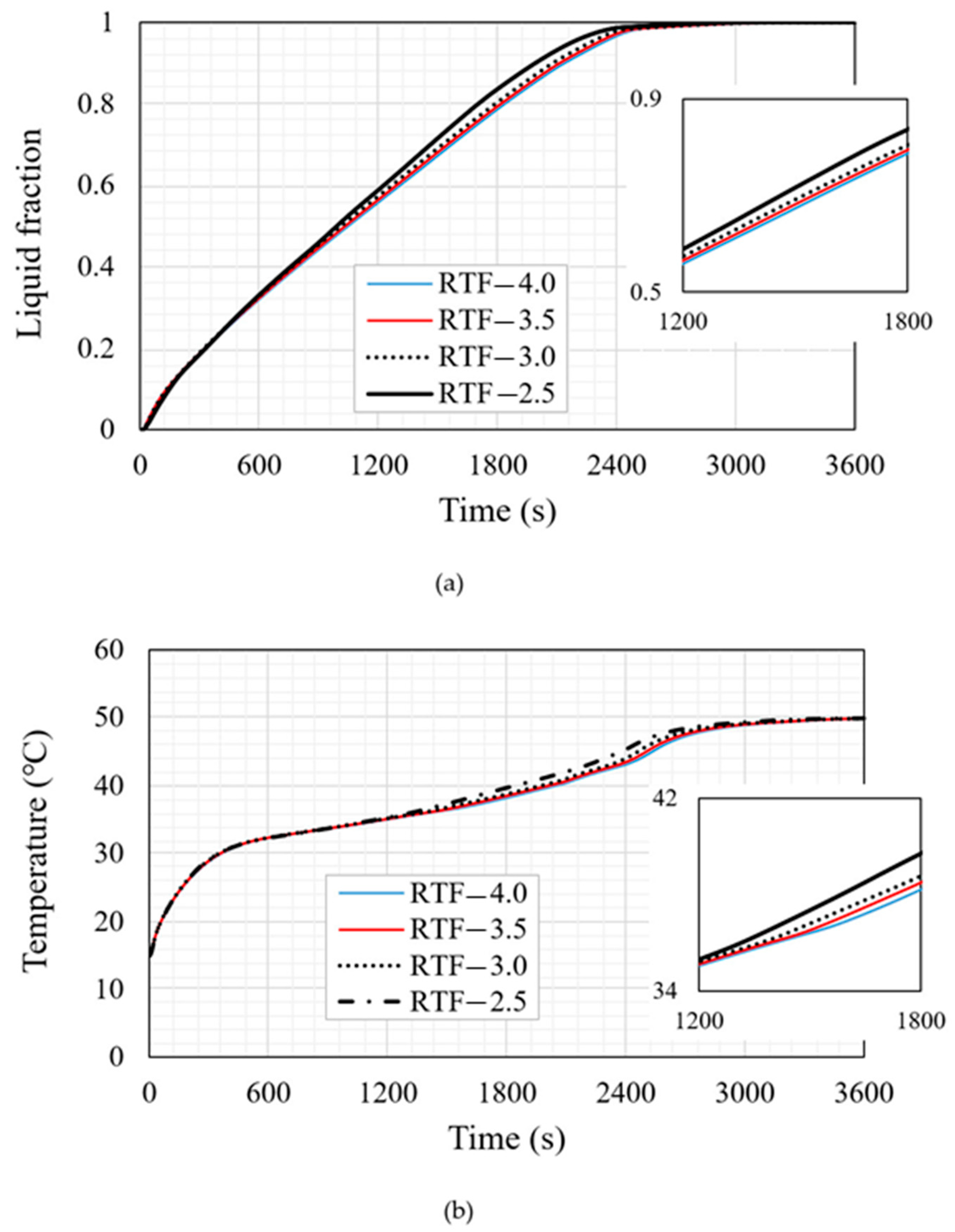

5.2. Effects of Using Reverse Triangular Fins on the Charging Process

5.3. Summary of Selecting the Best Configuration

5.4. Comparing the Thermal Performance of Reverse Triangular Fins with That of No-Fin and Uniform-Fin Cases

5.5. Investigating the Effects of the Fin Added at the Bottom of the Heat Exchanger on the Charging Process of the PCM

6. Conclusions

- The slope of the sides of the triangular fins has a determinant role in the circulation of the PCM inside the heat storage unit.

- The case with the lowest slope (case with the highest fins height) provided a better barrier to keep the PCM inside the zone between two pairs of neighbor fins, while the case with the shortest fin height accelerated the PCM circulation through the zones.

- The case with the highest height of the fins, and thus the lowest base, experienced the fastest phase change process due to having the largest surface area of the fin.

- The reverse triangular fin provided a strong barrier against transferring the molten PCM through the zone, which slightly accelerated the melting process and improved the thermal storage rate.

- The case with reverse triangular fins and the highest height showed higher performance compared with the other cases, since 98.8% of the entire zone was melted, except the region at the bottom of the unit.

- Adding a rectangular fin to the bottom of the heat exchange with reverse triangular fins and the highest height was selected as the best model, resulting in the lowest melting time (1978 s) and the highest heat storage rate (81.5 W).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Mushy zone constant | Greek symbols | ||

| (J kg−1 K−1) | Specific heat | Liquid fraction | |

| E (J) | Heat storage | (K−1) | Thermal expansion |

| (m s−2) | Gravity | (kg m−3) | PCM Density |

| (W m−1 K−1) | Effective thermal conductivity | (J kg−1) | PCM Latent heat |

| (J kg−1) | Latent heat of fusion | (m2·s−1) | Viscosity |

| P (kg m−1 s−2) | Pressure | Abbreviation | |

| (kg m−1 s−2) | Source term | TES | Thermal energy storage |

| (s) | Time | PCM | Phase change materials |

| (°C) | Temperature | LHS | Latent heat storage |

| (°C) | Air temperature | HTF | Heat transfer fluid |

| (°C) | Solid temperature | LHTES | Latent heat thermal energy storage |

| (°C) | Liquidus temperature | TTHX | Triple tube heat exchanger |

| (°C) | Solidus temperature | ||

| (m/s) | Velocity | ||

References

- Yang, Y.; Wang, Y.; Zheng, C.; Lin, H.; Xu, R.; Zhu, H.; Bao, L.; Xu, X. Lanthanum carbonate grafted ZSM-5 for superior phosphate uptake: Investigation of the growth and adsorption mechanism. Chem. Eng. J. 2022, 430, 133166. [Google Scholar] [CrossRef]

- Jiang, C.; Zheng, Y.; Wang, D.; Zheng, Y.; Xie, C.; Shi, L.; Liu, Z.; Tang, Y. Unusual Size Effect in Ion and Charge Transport in Micron-sized Particulate Aluminum Anodes of Lithium-ion Batteries. Angew. Chem. Int. Ed. 2022, e202208370. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Zhang, Y.; Jia, D.; Zhang, X.; Hou, Y.; Li, R.; Wang, J. Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions. Int. J. Mach. Tools Manuf. 2017, 122, 55–65. [Google Scholar] [CrossRef]

- Bai, B.; Zhou, R.; Cai, G.; Hu, W.; Yang, G. Coupled thermo-hydro-mechanical mechanism in view of the soil particle rearrangement of granular thermodynamics. Comput. Geotech. 2021, 137, 104272. [Google Scholar] [CrossRef]

- Hassan, F.; Jamil, F.; Hussain, A.; Ali, H.M.; Janjua, M.M.; Khushnood, S.; Farhan, M.; Altaf, K.; Said, Z.; Li, C. Recent advancements in latent heat phase change materials and their applications for thermal energy storage and buildings: A state of the art review. Sustain. Energy Technol. Assess. 2022, 49, 101646. [Google Scholar] [CrossRef]

- Romdhane, S.B.; Amamou, A.; Khalifa, R.B.; Said, N.M.; Younsi, Z.; Jemni, A. A review on thermal energy storage using phase change materials in passive building applications. J. Build. Eng. 2020, 32, 101563. [Google Scholar] [CrossRef]

- Jarvinen, J.; Goldsworthy, M.; White, S.; Pudney, P.; Belusko, M.; Bruno, F. Evaluating the utility of passive thermal storage as an energy storage system on the Australian energy market. Renew. Sustain. Energy Rev. 2021, 137, 110615. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Jia, D.; Yang, M. Grinding temperature and energy ratio coefficient in MQL grinding of high-temperature nickel-base alloy by using different vegetable oils as base oil. Chin. J. Aeronaut. 2016, 29, 1084–1095. [Google Scholar] [CrossRef]

- Gong, S.; Sheng, X.; Li, X.; Sheng, M.; Wu, H.; Lu, X.; Qu, J. A Multifunctional Flexible Composite Film with Excellent Multi-Source Driven Thermal Management, Electromagnetic Interference Shielding, and Fire Safety Performance, Inspired by a “Brick–Mortar” Sandwich Structure. Adv. Funct. Mater. 2022, 32, 2200570. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, Y.; Zhang, F.; Lee, C.S. A novel aluminum–graphite dual-ion battery. Adv. Energy Mater. 2016, 6, 1502588. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, J.; Zhang, Z.; Sun, M.; Yu, Y.; Wang, J.; Cai, S. Analysis of magnetorheological clutch with double cup-shaped gap excited by Halbach array based on finite element method and experiment. Smart Mater. Struct. 2022, 31, 075008. [Google Scholar] [CrossRef]

- Wu, X.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Zhang, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z. Circulating purification of cutting fluid: An overview. Int. J. Adv. Manuf. Technol. 2021, 117, 2565–2600. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Li, H.; Li, L.; Bu, L.; Wang, T. Numerical investigation on the melting of nanoparticle-enhanced phase change materials (NEPCM) in a bottom-heated rectangular cavity using lattice Boltzmann method. Int. J. Heat Mass Transf. 2015, 81, 415–425. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Z.; Sun, M.; Yu, Y.; Wang, J.; Cai, S. The influence of the temperature on the dynamic behaviors of magnetorheological gel. Adv. Eng. Mater. 2022, 2101680. [Google Scholar] [CrossRef]

- Ajarostaghi, S.S.M.; Delavar, M.A.; Dolati, A. Numerical investigation of melting process in horizontal shell-and-tube phase change material storage considering different HTF channel geometries. Heat Transf. Res. 2017, 48, 1515–1529. [Google Scholar] [CrossRef]

- Jegadheeswaran, S.; Pohekar, S.D. Performance enhancement in latent heat thermal storage system: A review. Renew. Sustain. Energy Rev. 2009, 13, 2225–2244. [Google Scholar]

- Rahimi, M.; Ranjbar, A.; Ganji, D.; Sedighi, K.; Hosseini, M. Experimental investigation of phase change inside a finned-tube heat exchanger. J. Eng. 2014, 2014, 641954. [Google Scholar] [CrossRef]

- Hosseini, M.; Rahimi, M.; Bahrampoury, R. Thermal analysis of PCM containing heat exchanger enhanced with normal annular fines. Mech. Sci. 2015, 6, 221–234. [Google Scholar] [CrossRef]

- Jayaprakash, M.; Alzahrani, H.A.; Sowmya, G.; Kumar, R.V.; Malik, M.; Alsaiari, A.; Prasannakumara, B. Thermal distribution through a moving longitudinal trapezoidal fin with variable temperature-dependent thermal properties using DTM-Pade approximant. Case Stud. Therm. Eng. 2021, 28, 101697. [Google Scholar] [CrossRef]

- Wang, F.; Kumar, R.V.; Sowmya, G.; El-Zahar, E.R.; Prasannakumara, B.; Khan, M.I.; Khan, S.U.; Malik, M.; Xia, W.-F. LSM and DTM-Pade approximation for the combined impacts of convective and radiative heat transfer on an inclined porous longitudinal fin. Case Stud. Therm. Eng. 2022, 35, 101846. [Google Scholar] [CrossRef]

- Algarni, M.; Alazwari, M.A.; Safaei, M.R. Optimization of Nano-Additive Characteristics to Improve the Efficiency of a Shell and Tube Thermal Energy Storage System Using a Hybrid Procedure: DOE, ANN, MCDM, MOO, and CFD Modeling. Mathematics 2021, 9, 3235. [Google Scholar]

- Ju, Y.; Zhu, T.; Mashayekhi, R.; Mohammed, H.I.; Khan, A.; Talebizadehsardari, P.; Yaïci, W. Evaluation of Multiple Semi-Twisted Tape Inserts in a Heat Exchanger Pipe Using Al2O3 Nanofluid. Nanomaterials 2021, 11, 1570. [Google Scholar] [CrossRef] [PubMed]

- Chu, Y.-M.; Nazir, U.; Sohail, M.; Selim, M.M.; Lee, J.-R. Enhancement in thermal energy and solute particles using hybrid nanoparticles by engaging activation energy and chemical reaction over a parabolic surface via finite element approach. Fractal Fract. 2021, 5, 119. [Google Scholar] [CrossRef]

- Gao, T.; Zhang, Y.; Li, C.; Wang, Y.; An, Q.; Liu, B.; Said, Z.; Sharma, S. Grindability of carbon fiber reinforced polymer using CNT biological lubricant. Sci. Rep. 2021, 11, 22535. [Google Scholar] [PubMed]

- El Hasadi, Y.M.; Khodadadi, J. Numerical simulation of the effect of the size of suspensions on the solidification process of nanoparticle-enhanced phase change materials. J. Heat Transf. 2013, 135, 052901. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Zhang, Y.; Yang, M.; Jia, D.; Liu, G.; Hou, Y.; Li, R.; Zhang, N.; Wu, Q. Experimental assessment of an environmentally friendly grinding process using nanofluid minimum quantity lubrication with cryogenic air. J. Clean. Prod. 2018, 193, 236–248. [Google Scholar] [CrossRef]

- Ghalambaz, M.; Mehryan, S.; Hajjar, A.; Veismoradi, A. Unsteady natural convection flow of a suspension comprising Nano-Encapsulated Phase Change Materials (NEPCMs) in a porous medium. Adv. Powder Technol. 2020, 31, 954–966. [Google Scholar]

- Ho, C.; Liu, Y.-C.; Ghalambaz, M.; Yan, W.-M. Forced convection heat transfer of Nano-Encapsulated Phase Change Material (NEPCM) suspension in a mini-channel heatsink. Int. J. Heat Mass Transf. 2020, 155, 119858. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, Z.; Yang, J.; Chen, J.; Chen, K.; Yan, K.; Meng, X.; Zhang, X.; He, M. Study on the suppression mechanism of (NH4)2CO3 and SiC for polyethylene deflagration based on flame propagation and experimental analysis. Powder Technol. 2022, 399, 117193. [Google Scholar]

- Wang, Y.; Li, C.; Zhang, Y.; Yang, M.; Li, B.; Dong, L.; Wang, J. Processing characteristics of vegetable oil-based nanofluid MQL for grinding different workpiece materials. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 327–339. [Google Scholar]

- Zhou, S.-S.; Almarashi, A.; Talabany, Z.J.; Selim, M.M.; Issakhov, A.; Li, Y.-M.; Yao, S.-W.; Li, Z. Augmentation of performance of system with dispersion of nanoparticles inside PCM. J. Mol. Liq. 2021, 333, 115921. [Google Scholar]

- Guo, J.; Du, Z.; Liu, G.; Yang, X.; Li, M.-J. omprCession effect of metal foam on melting phase change in a shell-and-tube unit. Appl. Therm. Eng. 2022, 206, 118124. [Google Scholar] [CrossRef]

- Sardari, P.T.; Grant, D.; Giddings, D.; Walker, G.S.; Gillott, M. Composite metal foam/PCM energy store design for dwelling space air heating. Energy Convers. Manag. 2019, 201, 112151. [Google Scholar]

- Cheng, Z.; Guo, Z.; Fu, P.; Yang, J.; Wang, Q. New insights into the effects of methane and oxygen on heat/mass transfer in reactive porous media. Int. Commun. Heat Mass Transf. 2021, 129, 105652. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, Y.; Li, C.; Yang, M.; Gao, T.; Said, Z.; Sharma, S. Lubrication-enhanced mechanisms of titanium alloy grinding using lecithin biolubricant. Tribol. Int. 2022, 169, 107461. [Google Scholar] [CrossRef]

- Chu, Y.M.; Bashir, S.; Ramzan, M.; Malik, M.Y. Model-based comparative study of magnetohydrodynamics unsteady hybrid nanofluid flow between two infinite parallel plates with particle shape effects. Math. Methods Appl. Sci. 2022, 1–15. [Google Scholar] [CrossRef]

- Sowmya, G.; Varun Kumar, R.S.; Alsulami, M.D.; Prasannakumara, B.C. Thermal stress and temperature distribution of an annular fin with variable temperature-dependent thermal properties and magnetic field using DTM-Pade approximant. Waves Random Complex Media 2022, 1–29. [Google Scholar] [CrossRef]

- Baslem, A.; Sowmya, G.; Gireesha, B.J.; Prasannakumara, B.C.; Rahimi-Gorji, M.; Hoang, N.M. Analysis of thermal behavior of a porous fin fully wetted with nanofluids: Convection and radiation. J. Mol. Liq. 2020, 307, 112920. [Google Scholar] [CrossRef]

- Sowmya, G.; Gireesha, B.J.; Sindhu, S.; Prasannakumara, B.C. Investigation of Ti6Al4V and AA7075 alloy embedded nanofluid flow over longitudinal porous fin in the presence of internal heat generation and convective condition. Commun. Theor. Phys. 2020, 72, 025004. [Google Scholar] [CrossRef]

- Yang, X.; Guo, J.; Yang, B.; Cheng, H.; Wei, P.; He, Y.-L. Design of non-uniformly distributed annular fins for a shell-and-tube thermal energy storage unit. Appl. Energy 2020, 279, 115772. [Google Scholar] [CrossRef]

- Guo, J.; Wang, X.; Yang, B.; Yang, X.; Li, M.-J. Thermal assessment on solid-liquid energy storage tube packed with non-uniform angled fins. Sol. Energy Mater. Sol. Cells 2022, 236, 111526. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.; Liu, Z.; Luo, X.; Yan, J. Effect of fin number on the melting phase change in a horizontal finned shell-and-tube thermal energy storage unit. Sol. Energy Mater. Sol. Cells 2022, 236, 111527. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Said, Z.; Zhang, Y.; Li, R.; Debnath, S.; Ali, H.M.; Gao, T.; Long, Y. Semiempirical heat flux model of hard-brittle bone material in ductile microgrinding. J. Manuf. Processes 2021, 71, 501–514. [Google Scholar]

- Al-Abidi, A.A.; Mat, S.; Sopian, K.; Sulaiman, M.; Mohammad, A.T. Numerical study of PCM solidification in a triplex tube heat exchanger with internal and external fins. Int. J. Heat Mass Transf. 2013, 61, 684–695. [Google Scholar] [CrossRef]

- Abdulateef, A.M.; Mat, S.; Sopian, K.; Abdulateef, J.; Gitan, A.A. Experimental and computational study of melting phase-change material in a triplex tube heat exchanger with longitudinal/triangular fins. Sol. Energy 2017, 155, 142–153. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Z.; Yang, B.; Yang, X.; Yan, J. Melting assessment on the angled fin design for a novel latent heat thermal energy storage tube. Renew. Energy 2022, 183, 406–422. [Google Scholar] [CrossRef]

- Senthil, R.; Patel, A.; Rao, R.; Ganeriwal, S. Melting Behavior of Phase Change Material in a Solar Vertical Thermal Energy Storage with Variable Length Fins added on the Heat Transfer Tube Surfaces. Int. J. Renew. Energy Dev. 2020, 9, 361–367. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Lohrasbi, S.; Ganji, D.D.; Nsofor, E.C. Accelerated melting of PCM in energy storage systems via novel configuration of fins in the triplex-tube heat exchanger. Int. J. Heat Mass Transf. 2018, 124, 663–676. [Google Scholar]

- Abdulateef, A.M.; Abdulateef, J.; Sopian, K.; Mat, S.; Ibrahim, A. Optimal fin parameters used for enhancing the melting and solidification of phase-change material in a heat exchanger unite. Case Stud. Therm. Eng. 2019, 14, 100487. [Google Scholar] [CrossRef]

- Chu, Y.-M.; Shankaralingappa, B.; Gireesha, B.; Alzahrani, F.; Khan, M.I.; Khan, S.U. Combined impact of Cattaneo-Christov double diffusion and radiative heat flux on bio-convective flow of Maxwell liquid configured by a stretched nano-material surface. Appl. Math. Comput. 2022, 419, 126883. [Google Scholar]

- Sun, X.; Mohammed, H.I.; Tiji, M.E.; Mahdi, J.M.; Majdi, H.S.; Wang, Z.; Talebizadehsardari, P.; Yaïci, W. Investigation of Heat Transfer Enhancement in a Triple TUBE Latent Heat Storage System Using Circular Fins with Inline and Staggered Arrangements. Nanomaterials 2021, 11, 2647. [Google Scholar] [CrossRef] [PubMed]

- Sivalakshmi, S.; Raja, M.; Gowtham, G. Effect of helical fins on the performance of a double pipe heat exchanger. Mater. Today Proc. 2021, 43, 1128–1131. [Google Scholar] [CrossRef]

- Abdulateef, A.M.; Jaszczur, M.; Hassan, Q.; Anish, R.; Niyas, H.; Sopian, K.; Abdulateef, J. Enhancing the melting of phase change material using a fins–nanoparticle combination in a triplex tube heat exchanger. J. Energy Storage 2021, 35, 102227. [Google Scholar] [CrossRef]

- Safari, V.; Abolghasemi, H.; Kamkari, B. Experimental and numerical investigations of thermal performance enhancement in a latent heat storage heat exchanger using bifurcated and straight fins. Renew. Energy 2021, 174, 102–121. [Google Scholar]

- Masoumpour-Samakoush, M.; Miansari, M.; Ajarostaghi, S.S.M.; Arıcı, M. Impact of innovative fin combination of triangular and rectangular fins on melting process of phase change material in a cavity. J. Energy Storage 2022, 45, 103545. [Google Scholar]

- Ghalambaz, M.; Mehryan, S.; Mahdavi, M.; Younis, O.; Alim, M.A. Evaluation of the melting performance in a conical latent heat thermal unit having variable length fins. Sustainability 2021, 13, 2667. [Google Scholar]

- Najim, F.T.; Mohammed, H.I.; Al-Najjar, H.M.T.; Thangavelu, L.; Mahmoud, M.Z.; Mahdi, J.M.; Tiji, M.E.; Yaïci, W.; Talebizadehsardari, P. Improved Melting of Latent Heat Storage Using Fin Arrays with Non-Uniform Dimensions and Distinct Patterns. Nanomaterials 2022, 12, 403. [Google Scholar] [CrossRef]

- Punniakodi, B.M.S.; Senthil, R. A review on container geometry and orientations of phase change materials for solar thermal systems. J. Energy Storage 2021, 36, 102452. [Google Scholar] [CrossRef]

- Li, Z.; Shahsavar, A.; Al-Rashed, A.A.; Talebizadehsardari, P. Effect of porous medium and nanoparticles presences in a counter-current triple-tube composite porous/nano-PCM system. Appl. Therm. Eng. 2020, 167, 114777. [Google Scholar] [CrossRef]

- Wang, P.; Wang, X.; Huang, Y.; Li, C.; Peng, Z.; Ding, Y. Thermal energy charging behaviour of a heat exchange device with a zigzag plate configuration containing multi-phase-change-materials (m-PCMs). Appl. Energy 2015, 142, 328–336. [Google Scholar] [CrossRef]

- Esapour, M.; Hosseini, M.; Ranjbar, A.; Pahamli, Y.; Bahrampoury, R. Phase change in multi-tube heat exchangers. Renew. Energy 2016, 85, 1017–1025. [Google Scholar] [CrossRef]

- Mat, S.; Al-Abidi, A.A.; Sopian, K.; Sulaiman, M.; Mohammad, A.T. Enhance heat transfer for PCM melting in triplex tube with internal–external fins. Energy Convers. Manag. 2013, 74, 223–236. [Google Scholar] [CrossRef]

| Cases | Description | Triangle Base/Uniform Fins Width (mm) | Triangle Height/Uniform Fins Height (mm) | Added Fin Dimensions (mm) |

|---|---|---|---|---|

| 1 | no-fin | - | - | - |

| 2 | uniform-fin | 2 | 5 | - |

| 3 | uniform-fin + added fin | 1.6 | 5 | 1 × 20 |

| 4 | TF-base 2.5 | 2.5 | 8 | - |

| 5 | TF-base 3.0 | 3.0 | 6.65 | - |

| 6 | TF-base 3.5 | 3.5 | 5.7 | - |

| 7 | TF-base 4.0 | 4.0 | 5 | - |

| 8 | RTF-base 2.5 | 2.5 | 8 | - |

| 9 | RTF-base 3.0 | 3.0 | 6.65 | - |

| 10 | RTF-base 3.5 | 3.5 | 5.7 | - |

| 11 | RTF-base 4.0 | 4.0 | 5 | - |

| 12 | RTF-base 2.5 + added fin (constant base) | 2.5 | 6.4 | 1 × 20 |

| 13 | RTF-base 2.5 + added fin (constant height) | 2 | 8 | 1 × 20 |

| Properties | [kg/m3] | [kg/m3] | Lf [kJ/kg] | Cp [kJ/kg·K] | K [W/m·K] | µ [N·s/m2] | TL [°C] | TS [°C] | β [J/K] |

|---|---|---|---|---|---|---|---|---|---|

| Values | 770 | 860 | 170 | 2 | 0.2 | 0.023 | 36 | 29 | 0.0006 |

| Number of cells | 43,000 | ||

| Value of Time step size (s) | 0.1 | 0.2 | 0.4 |

| Melting duration | 4733 | 4727 | 4701 |

| Case | Case 4 | Case 5 | Case 6 | Case 7 | Case 8 | Case 9 | Case 10 | Case 11 |

|---|---|---|---|---|---|---|---|---|

| TF-base 2.5 | TF-base 3.0 | TF-base 3.5 | TF-base 4.0 | RTF-base 2.5 | RTF-base 3.0 | RTF-base 3.5 | RTF-base 4.0 | |

| Melting time (s) | 3060 | 3118 | 3176 | 3212 | 2997 | 3149 | 3180 | 3209 |

| Heat storage rate (W) | 55.01 | 53.9 | 52.99 | 52.39 | 56.05 | 53.38 | 52.85 | 52.36 |

| Case | Case 1 (No-Fin) | Case 2 (Uniform-Fin) | Case 8 (RTF-Base 2.5) |

|---|---|---|---|

| Melting time (s) | 4654 | 3056 | 2997 |

| Heat storage rate (W) | 36.2 | 55.1 | 56.1 |

| Case | Case 3 (Uniform-Fin + Added Fin) | Case 12 (RTF-Base 2.5 + Added Fin (Base Constant)) | Case 13 (RTF-Base 2.5 + Added Fin (Height Constant)) |

|---|---|---|---|

| Melting time (s) | 2057 | 2178 | 1978 |

| Heat storage rate (W) | 77.9 | 74.5 | 81.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Najim, F.T.; Kaplan, S.; Mohammed, H.I.; Dulaimi, A.; Abed, A.M.; Ibrahem, R.K.; Al-Qrimli, F.A.; Mahmoud, M.Z.; Awrejcewicz, J.; Pawłowski, W. Evaluation of Melting Mechanism and Natural Convection Effect in a Triplex Tube Heat Storage System with a Novel Fin Arrangement. Sustainability 2022, 14, 10982. https://doi.org/10.3390/su141710982

Najim FT, Kaplan S, Mohammed HI, Dulaimi A, Abed AM, Ibrahem RK, Al-Qrimli FA, Mahmoud MZ, Awrejcewicz J, Pawłowski W. Evaluation of Melting Mechanism and Natural Convection Effect in a Triplex Tube Heat Storage System with a Novel Fin Arrangement. Sustainability. 2022; 14(17):10982. https://doi.org/10.3390/su141710982

Chicago/Turabian StyleNajim, Farqad T., Sami Kaplan, Hayder I. Mohammed, Anmar Dulaimi, Azher M. Abed, Raed Khalid Ibrahem, Fadhil Abbas Al-Qrimli, Mustafa Z. Mahmoud, Jan Awrejcewicz, and Witold Pawłowski. 2022. "Evaluation of Melting Mechanism and Natural Convection Effect in a Triplex Tube Heat Storage System with a Novel Fin Arrangement" Sustainability 14, no. 17: 10982. https://doi.org/10.3390/su141710982

APA StyleNajim, F. T., Kaplan, S., Mohammed, H. I., Dulaimi, A., Abed, A. M., Ibrahem, R. K., Al-Qrimli, F. A., Mahmoud, M. Z., Awrejcewicz, J., & Pawłowski, W. (2022). Evaluation of Melting Mechanism and Natural Convection Effect in a Triplex Tube Heat Storage System with a Novel Fin Arrangement. Sustainability, 14(17), 10982. https://doi.org/10.3390/su141710982