Aggregate Evaluation and Geochemical Investigation of Limestone for Construction Industries in Pakistan: An Approach for Sustainable Economic Development

Abstract

1. Introduction

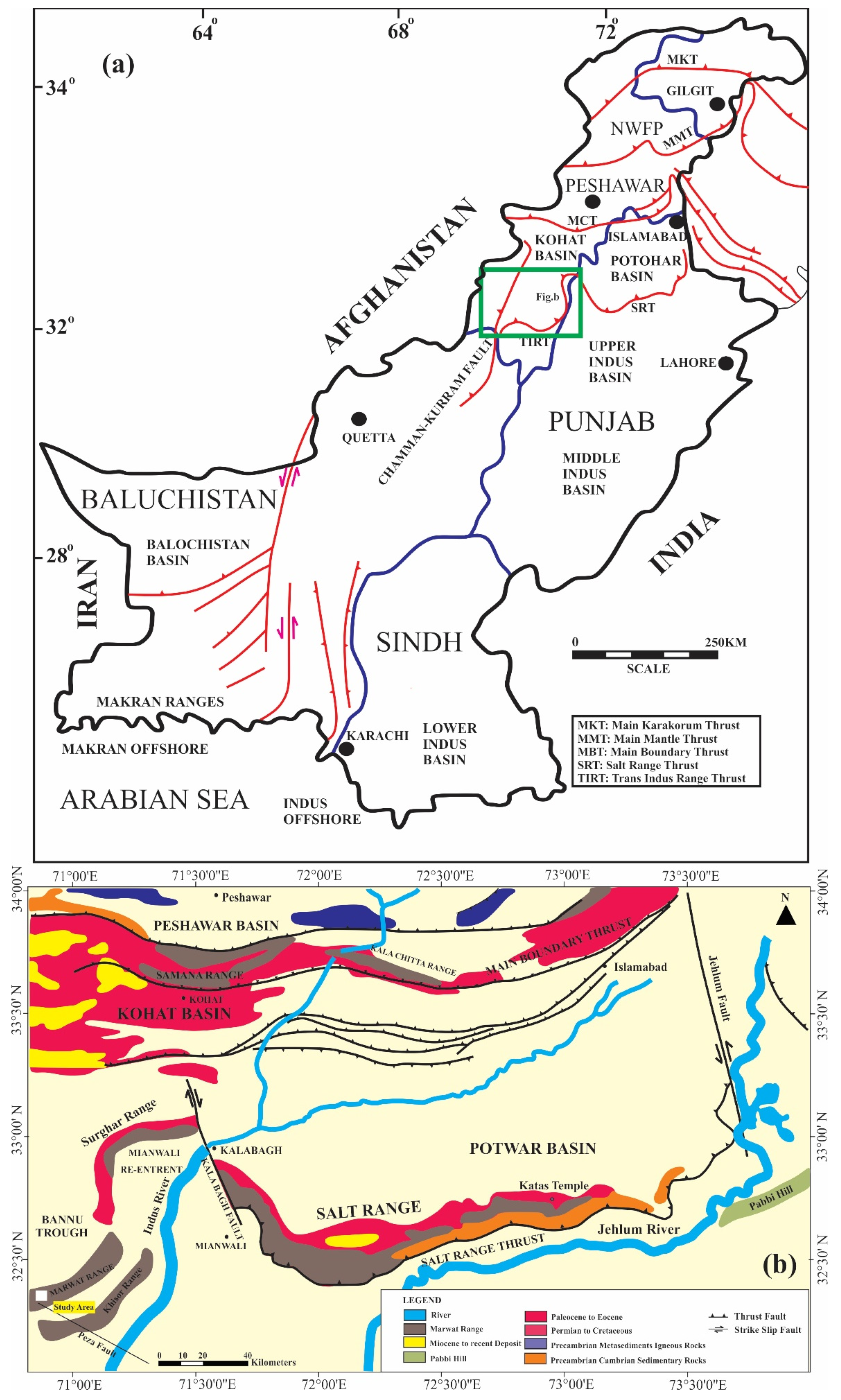

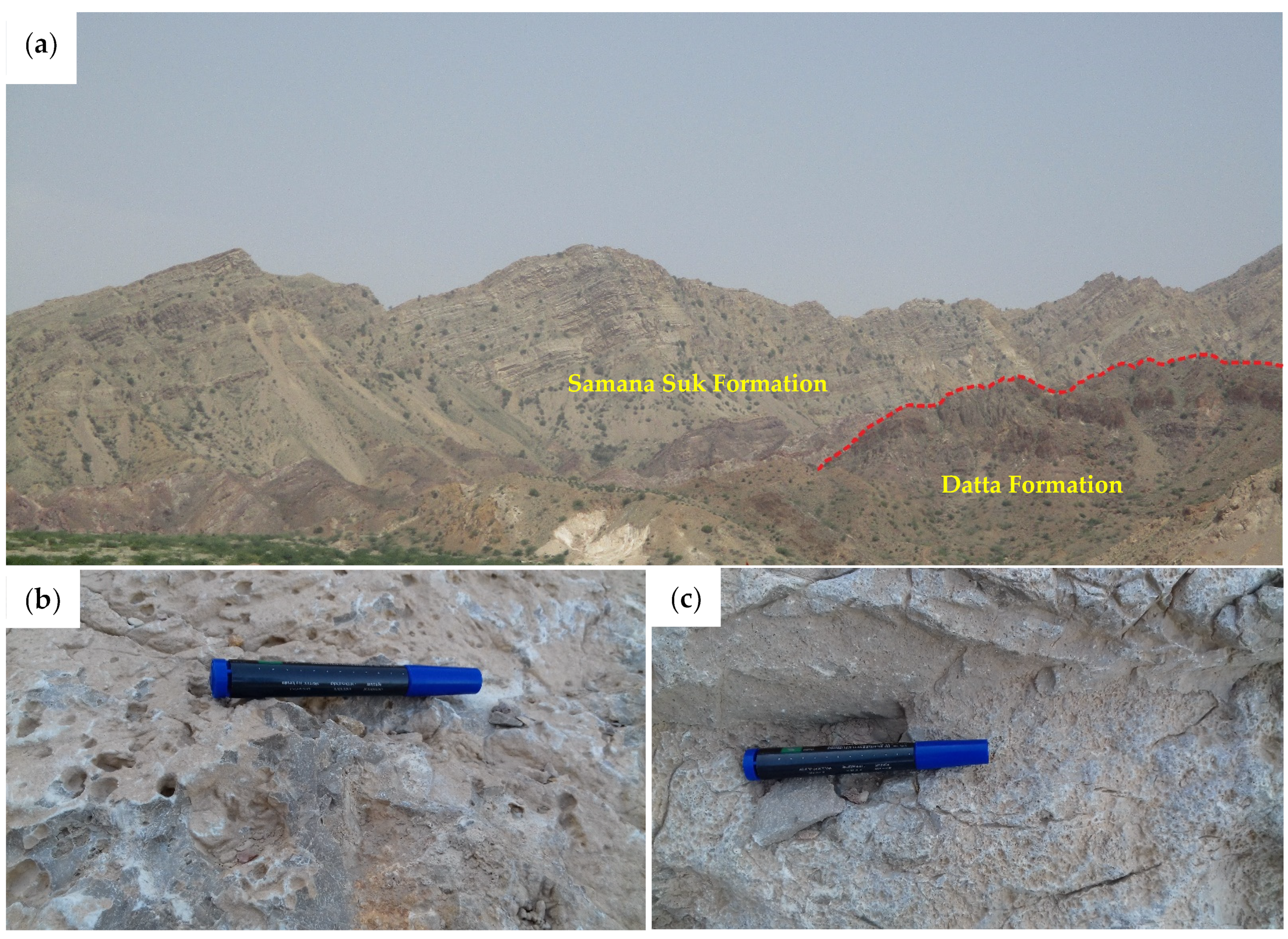

2. Geological Setting

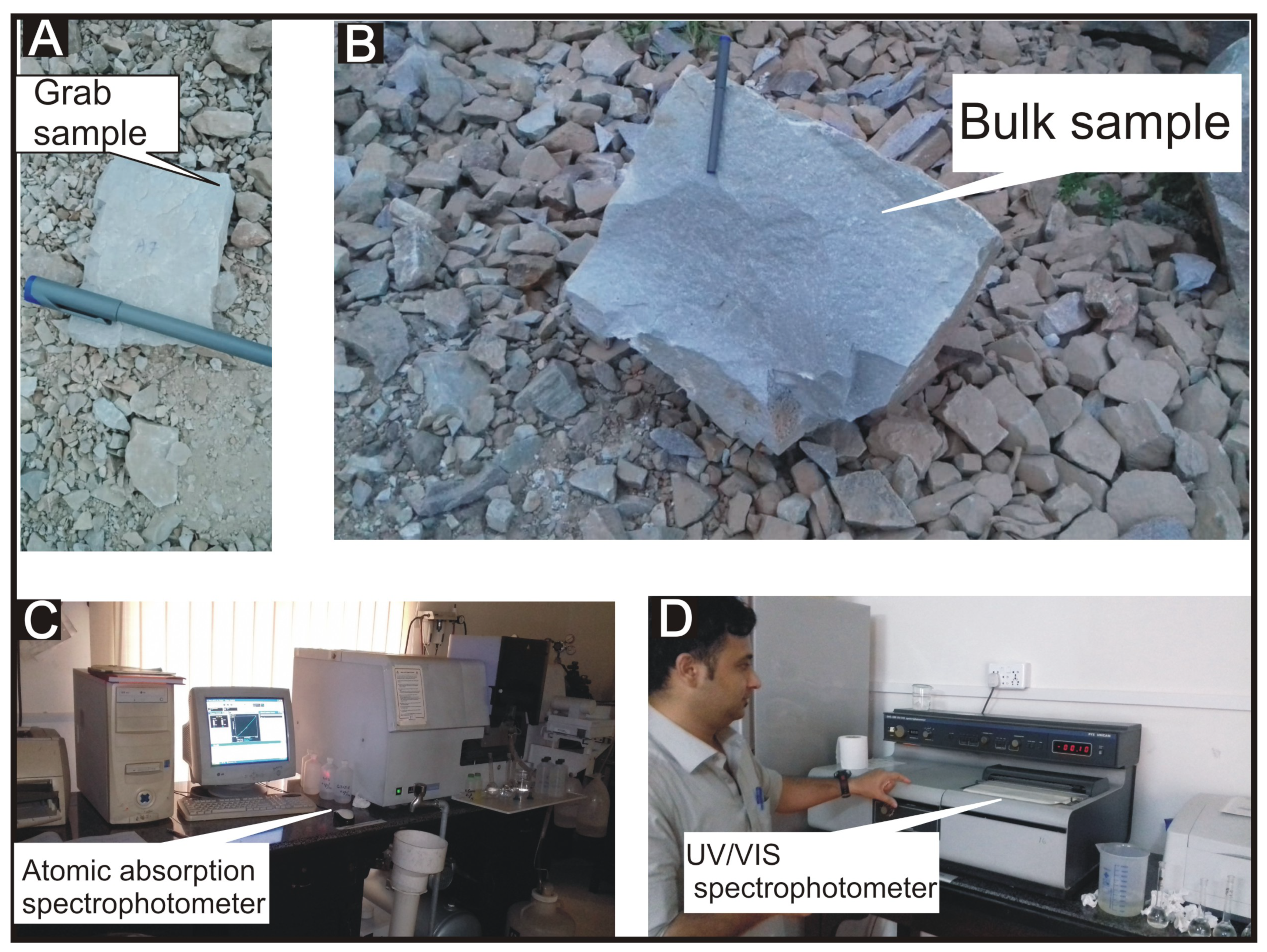

3. Materials and Methods

3.1. Study Area

3.2. Samples Collection and Testing Procedure

3.3. Petrography

3.4. Statistical Analysis

4. Results and Discussion

4.1. Engineering Properties

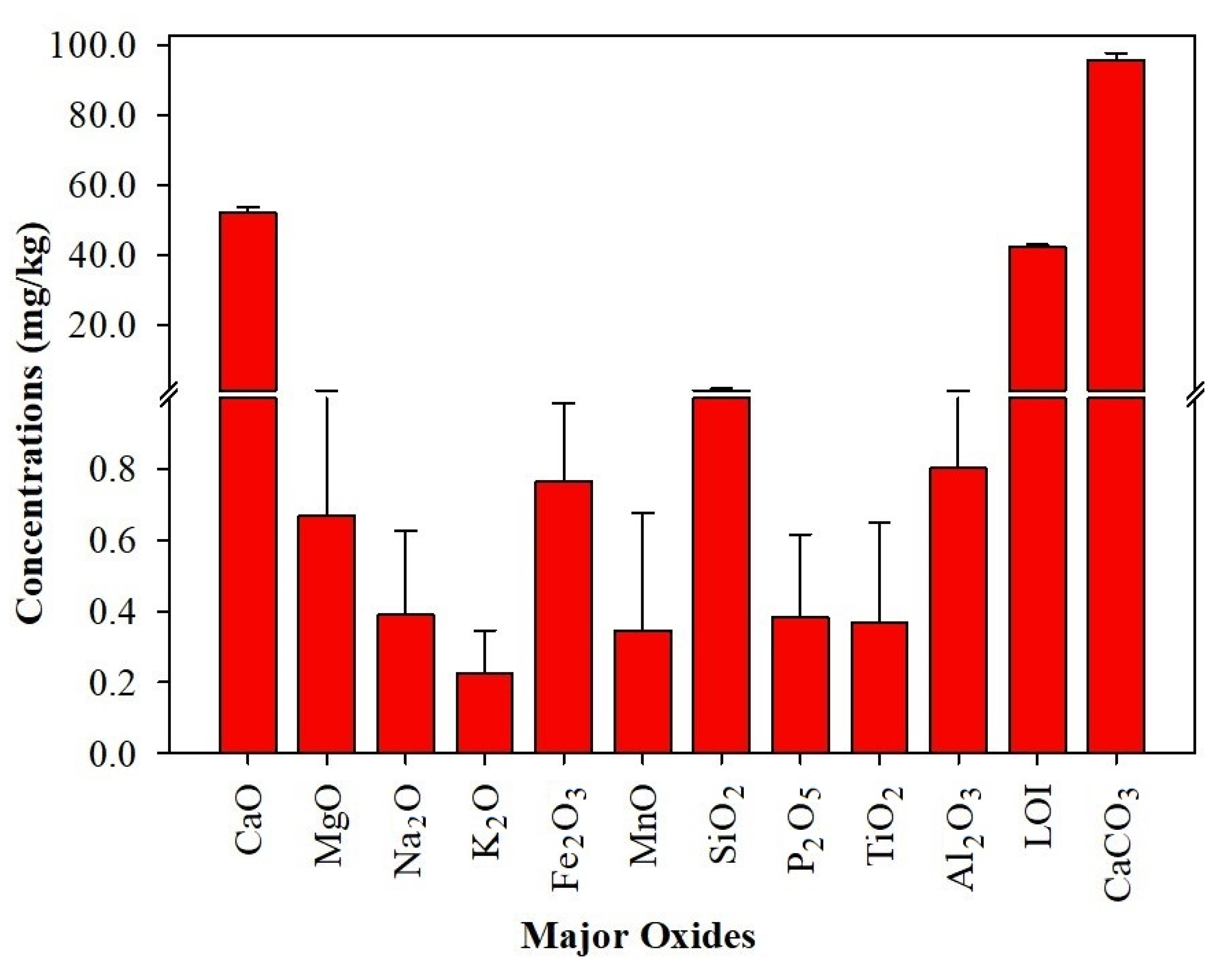

4.2. Mineralogical and Chemical Evaluation

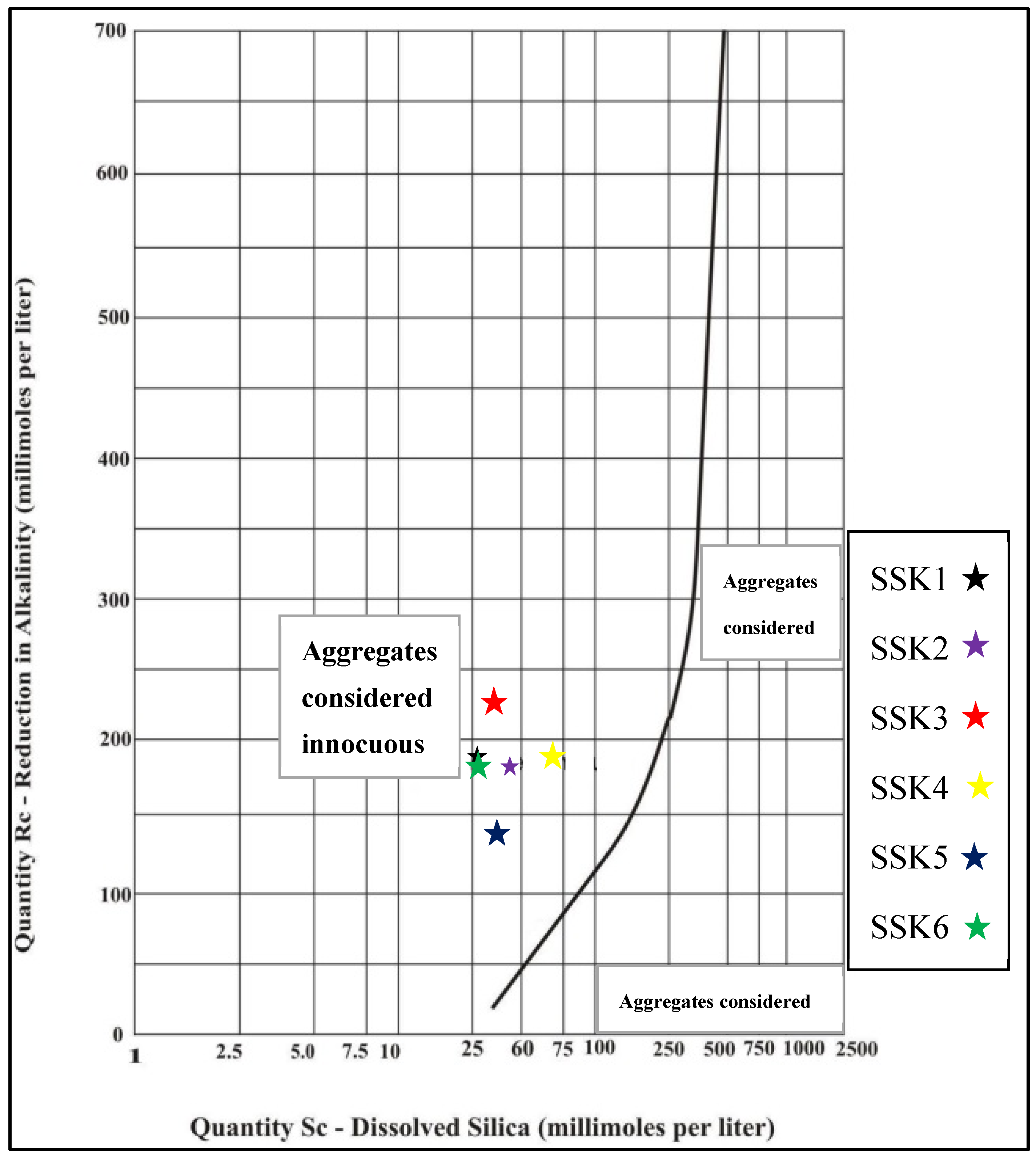

4.3. Petrographic Evaluation

4.4. Aggregate Suitability of Limestone for the Construction Industry

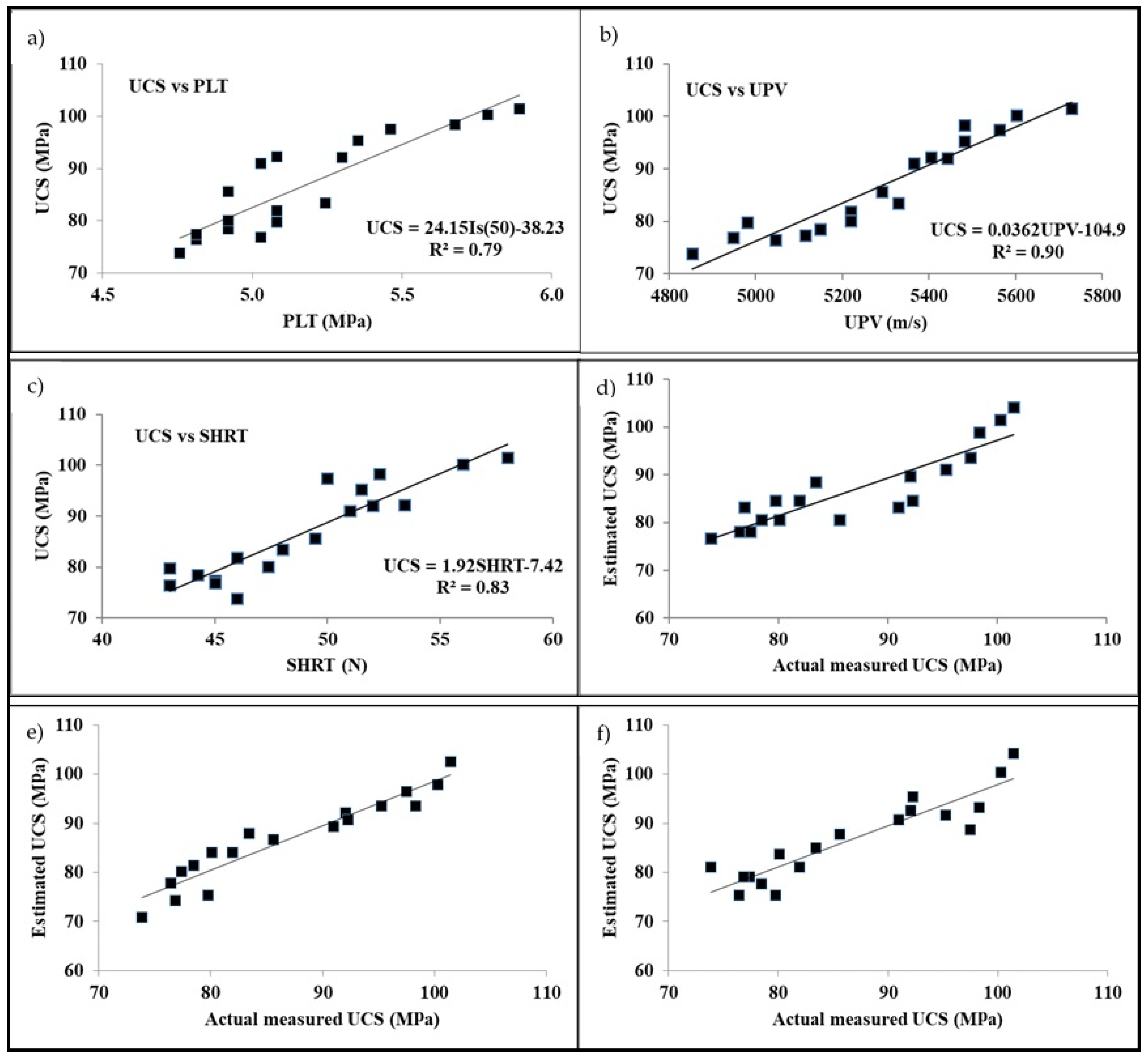

4.5. Estimation of UCS from PLT, UPV, and SHRT

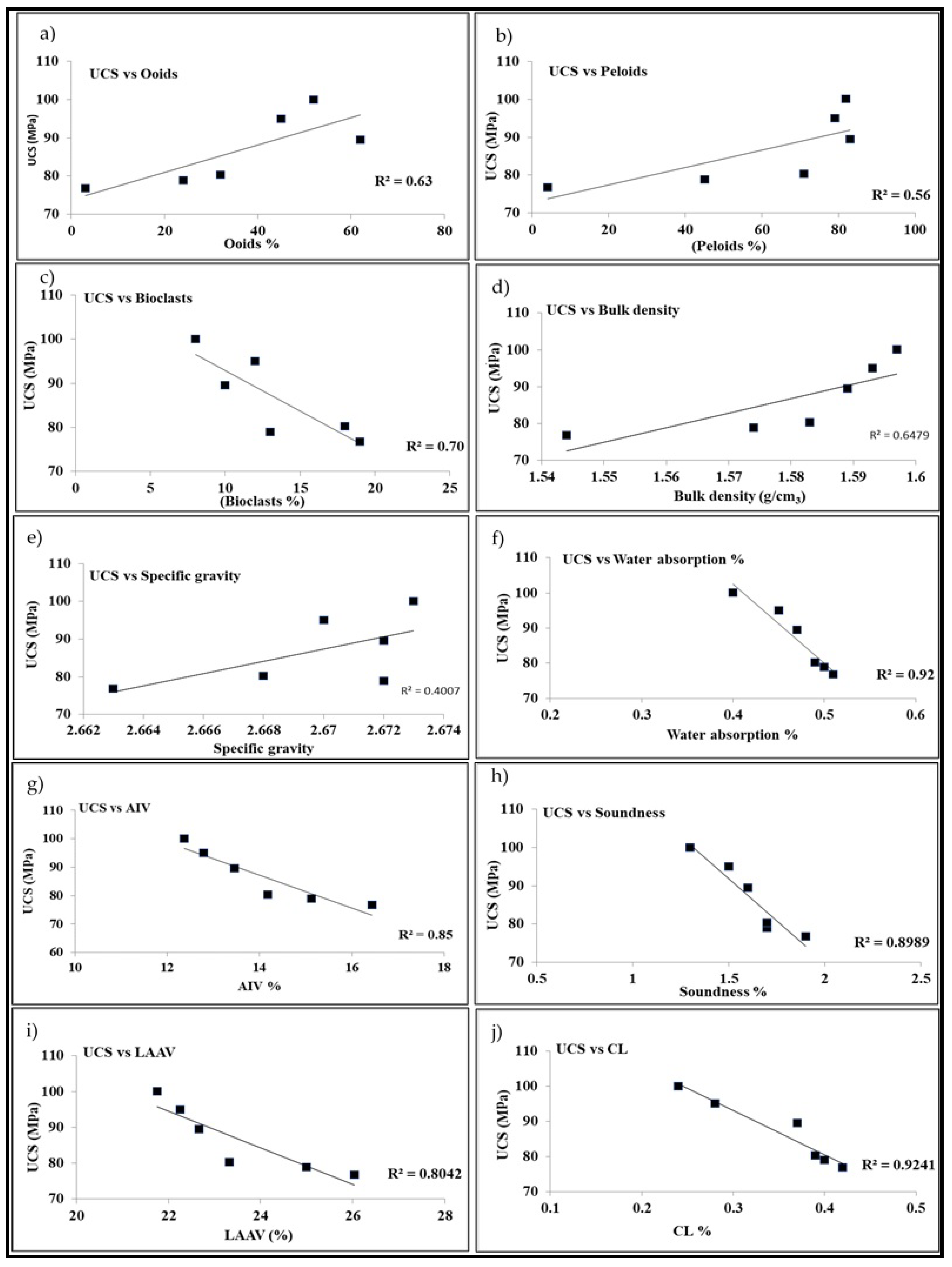

4.6. Relationship between Geo-Mechanical and Petrographic Properties

5. Conclusions

- I.

- This research study was performed to examine the aggregate suitability and geochemical properties of limestone from the Sheikh Budin Hills, north-western Pakistan.

- II.

- All the results of the aggregate parameters (SG = 2.6, WA = 0.47%, BD = 1.58 g/cm3, FI = 16.8%, EI = 16.39%, S = 1.6%, AIV = 14%, LAAV = 23.51%, CL = 0.35%, UCS = 86.7 MPa, PLT = 5.18 MPa, UPV = 5290 m/s, SHRT = 49 N) are well within the range of the values permissible for its exploitation as an engineering material in the construction industry.

- III.

- The mineralogical and geochemical evaluation of limestone indicates that it is mainly made of the mineral calcite (95.81%), and it qualifies the international standard that is required for cement manufacturing. Pearson’s correlation analysis resulted in establishing a strong positive correlation among CaCO3, CaO, and LOI. Moreover, the ASR test also proved it to be suitable for its usage as an aggregate material.

- IV.

- The petrographic studies suggest that the limestone is free of any deleterious or harmful materials that can lead to alkali–silica reactivity. These studies also show that the diagenetic fabric of the limestone is well compacted, thus, resulting in the high strength of these rocks.

- V.

- This research study developed empirical correlation equations for the estimation of UCs from PLT, UPV, and SHRT. These correlation equations will be quite helpful for practicing engineers, geologists and researchers. It will also motivate and encourage more researchers to carry out these sorts of studies for the development of more correlation models, in order to check the validity of these equations. Furthermore, the regression analysis exhibited that the empirical correlation equation for estimating uniaxial compressive strength with ultrasonic pulse velocity is more reliable than the Schmidt hammer rebound test and the point load test. Therefore, this study recommends the use of the UPV test for the estimation of UCs on the basis of its higher level of accuracy.

- VI.

- Moreover, this research study also revealed that the strength of rocks is directly proportional with ooids and peloids, while inversely proportional to bioclasts. Specific gravity and bulk density had a positive influence on the UCS values of limestone; however, the aggregate impact value, Los Angeles abrasion value, water absorption, and soundness adversely affected the UCS and other mechanical properties.

- VII.

- It can be concluded from the above discussion that the studied limestone has great potential for use as a raw material in the construction industries. Therefore, the limestone of the studied area can be used as a raw material in various ongoing and future projects under CPEC. Consequently, it will play a pivotal role in the economic development of the country.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Janjuhah, H.T.; Kontakiotis, G.; Wahid, A.; Khan, D.M.; Zarkogiannis, S.D.; Antonarakou, A. Integrated Porosity Classification and Quantification Scheme for Enhanced Carbonate Reservoir Quality: Implications from the Miocene Malaysian Carbonates. J. Mar. Sci. Eng. 2021, 9, 1410. [Google Scholar] [CrossRef]

- Janjuhah, H.T.; Alansari, A.; Vintaned, J.A.G. Quantification of microporosity and its effect on permeability and acoustic velocity in Miocene carbonates, Central Luconia, offshore Sarawak, Malaysia. J. Pet. Sci. Eng. 2019, 175, 108–119. [Google Scholar] [CrossRef]

- Bensted, J. δ-dicalcium silicate and its hydraulicity. Cem. Concr. Res. 1978, 8, 73–76. [Google Scholar] [CrossRef]

- Galetakis, M.; Alevizos, G.; Leventakis, K. Evaluation of fine limestone quarry by-products, for the production of building elements—An experimental approach. Constr. Build. Mater. 2012, 26, 122–130. [Google Scholar] [CrossRef]

- Khanlari, G.; Naseri, F. Prediction of aggregate modified index (AMI) using geomechanical properties of limestones. Bull. Eng. Geol. Environ. 2018, 77, 803–814. [Google Scholar] [CrossRef]

- Ioannou, I.; Petrou, M.F.; Fournari, R.; Andreou, A.; Hadjigeorgiou, C.; Tsikouras, B.; Hatzipanagiotou, K.J.G.S. London, Special Publications. Crushed limestone as an aggregate in concrete production: The Cyprus case. Geol. Soc. London Spéc. Publ. 2010, 331, 127–135. [Google Scholar] [CrossRef]

- Ahsan, N.; Gondal, M.J.I.J.o.A. Aggregate suitability studies of limestone outcrops in Dhak pass, western Salt range, Pakistan. Int. J. Agric. Appl. Sci. 2016, 4, 69–75. [Google Scholar]

- Zarif, I.; Tuğrul, A. Aggregate properties of Devonian limestones for use in concrete in Istanbul, Turkey. Bull. Eng. Geol. 2003, 62, 379–388. [Google Scholar] [CrossRef]

- Ben Salah, I.; Ben M’Barek, M.; Mezza, S.; Boughdiri, M. Geotechnical study of the Aptian limestone of the kef region. Open J. Geol. 2018, 8, 1084–1101. [Google Scholar] [CrossRef][Green Version]

- Kayabaşı, A.; Soypak, R.; Göz, E. Evaluation of limestone quarries for concrete and asphalt production: A case study from Ankara, Turkey. Arab. J. Geosci. 2018, 11, 1–22. [Google Scholar] [CrossRef]

- Kamani, M.; Ajalloeian, R. Evaluation of the mechanical degradation of carbonate aggregate by rock strength tests. J. Rock Mech. Geotech. Eng. 2019, 11, 121–134. [Google Scholar] [CrossRef]

- Shinawi, A.E.; Mésároš, P.; Zeleňáková, M.J.S. The Implication of Petrographic Characteristics on the Mechanical Behavior of Middle Eocene Limestone, 15th May City, Egypt. Sustainability 2020, 12, 9710. [Google Scholar] [CrossRef]

- Qaid, A.M.; Alqubati, N.; Al-Hawbani, A.M. Physical and Geochemical Assessment of Limestone of Amran Group in Arhab Area-North Sana’a for Industrial Uses. Tech. BioChemMed 2021, 2, 28–38. [Google Scholar]

- Hussain, V.; Bilqees, R.; Nasreen, S. Petrology and industrial application of Nizampur Limestones, NWFP, Pakistan. Pak. J. Sci. Ind. Res. 1989, 32, 775–779. [Google Scholar]

- Bilqees, R.; Shah, T. Industrial applications of limestone deposits of Kohat, NWFP: A research towards the sustainability of the deposits. Biol. Sci. PJSIR 2007, 50, 293–298. [Google Scholar]

- Jan, N.; Bilqees, R.; Riaz, M.; Noor, S.; Younas, M. Study of limestone from Nizampur area for industrial utilization. J. Chem. Soc. Pak. 2009, 31, 16–20. [Google Scholar]

- Bilqees, R.; Tahirkheli, T.; Pirzada, N.; Abbas, S.M. Industrial applications of Abbottabad limestone; utilizing its chemical and engineering properties. J. Himal. Earth Sci. 2012, 45, 91. [Google Scholar]

- Bilqees, R.; Sarwar, M.R.; Haneef, M.; Khan, T. Source of cement raw material for the construction of Bhasha Dam in Gilgit Diamir District, Pakistan. J. Himal. Earth Sci. 2015, 48, 1–8. [Google Scholar]

- Naeem, M.; Khalid, P.; Sanaullah, M.; ud Din, Z. Physio-mechanical and aggregate properties of limestones from Pakistan. Acta Geod. Geophys. 2014, 49, 369–380. [Google Scholar] [CrossRef]

- Malahat, F.; Naseer, A.; Bilqees, R. Engineering and Mineralogical Assessment of Coarse Aggregates used in District Mardan. J. Himal. Earth Sci. 2018, 51, 34–43. [Google Scholar]

- Rehman, S.U.; Ahmed, M.; Hasan, F.; Hassan, S.; Rehman, F.; Ullah, M.F. Aggregate suitability studies of Middle Jurassic Samana Suk Formation exposed at Sheikh Budin Hill, Marwat Range, Pakistan. J. Biodivers. Environ. Sci. 2018, 12, 159–168. [Google Scholar]

- Hassan, E.; Hannan, A.; Rashid, M.; Ahmed, W.; Zeb, M.; Khan, S.; Ahmad, A. Resource assessment of Sakesar limestone as aggregate from salt range Pakistan based on geotechnical properties. Int. J. Hydrol. 2020, 4, 24–29. [Google Scholar] [CrossRef]

- Rehman, G.; Zhang, G.; Rahman, M.U.; Rahman, N.U.; Usman, T.; Imraz, M.J.A.G.e.G. The engineering assessments and potential aggregate analysis of mesozoic carbonates of Kohat Hills Range, KP, Pakistan. Acta Geod. Geophys. 2020, 55, 477–493. [Google Scholar] [CrossRef]

- Asif, A.R.; Islam, I.; Ahmed, W.; Sajid, M.; Qadir, A.; Ditta, A. Exploring the potential of Eocene carbonates through petrographic, geochemical, and geotechnical analyses for their utilization as aggregates for engineering structures. Arab. J. Geosci. 2022, 15, 1–19. [Google Scholar] [CrossRef]

- Broch, E.; Franklin, J. The point-load strength test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 669–676. [Google Scholar] [CrossRef]

- Bieniawski, Z. The point-load test in geotechnical practice. Eng. Geol. 1975, 9, 1–11. [Google Scholar] [CrossRef]

- Cargill, J.S.; Shakoor, A. Evaluation of empirical methods for measuring the uniaxial compressive strength of rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1990, 27, 495–503. [Google Scholar] [CrossRef]

- Akram, M.; Bakar, M.A. Correlation between uniaxial compressive strength and point load index for salt-range rocks. Pak. J. Eng. Appl. Sci. 2016, 1, 1–8. [Google Scholar]

- Salah, H.; Omar, M.; Shanableh, A. Estimating unconfined compressive strength of sedimentary rocks in United Arab Emirates from point load strength index. J. Appl. Math. Phys. 2014, 2, 296–303. [Google Scholar] [CrossRef]

- Sharma, P.; Singh, T. A correlation between P-wave velocity, impact strength index, slake durability index and uniaxial compressive strength. Bull. Eng. Geol. Environ. 2008, 67, 17–22. [Google Scholar] [CrossRef]

- Kurtuluş, C.; Irmak, T.S.; Sertçelik, I. Physical and mechanical properties of Gokceada: Imbros (NE Aegean Sea) island andesites. Bull. Eng. Geol. Environ. 2010, 69, 321–324. [Google Scholar] [CrossRef]

- Yagiz, S. P-wave velocity test for assessment of geotechnical properties of some rock materials. Bull. Mater. Sci. 2011, 34, 947. [Google Scholar] [CrossRef]

- Sarkar, K.; Vishal, V.; Singh, T. An empirical correlation of index geomechanical parameters with the compressional wave velocity. Geotech. Geol. Eng. 2012, 30, 469–479. [Google Scholar] [CrossRef]

- Singh, R.; Hassani, F.; Elkington, P. The application of strength and deformation index testing to the stability assessment of coal measures excavations. In Proceedings of the 24th US Symposium on Rock Mechanics (USRMS), College Station, TX, USA, 20 June 1983. [Google Scholar]

- Sheorey, P. Schmidt hammer rebound data for estimation of large scale in situ coal strength. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1984, 21, 39–42. [Google Scholar] [CrossRef]

- Haramy, K.; DeMarco, M. Use of the Schmidt hammer for rock and coal testing. In Proceedings of the 26th US Symposium on Rock Mechanics (USRMS), Rapid City, SD, USA, 26 June 1985. [Google Scholar]

- O’Rourke, J. Rock index properties for geoengineering in underground development. Min. Eng. 1989, 41, 106–109. [Google Scholar]

- Shalabi, F.I.; Cording, E.J.; Al-Hattamleh, O.H. Estimation of rock engineering properties using hardness tests. Eng. Geol. 2007, 90, 138–147. [Google Scholar] [CrossRef]

- Nizami, A.; Sheikh, R. Sedimentology of the Middle Jurassic Samana Suk Formation, Makarwal Section, Surghar Range, Trans Indus Ranges, Pakistan. Geol. Bull. Punjab Univ. 2009, 44, 11–25. [Google Scholar]

- Blisniuk, P.M.; Sonder, L.J.; Lillie, R.J. Foreland normal fault control on northwest Himalayan thrust front development. Tectonics 1998, 17, 766–779. [Google Scholar] [CrossRef]

- Bilal, A.; Mughal, M.S.; Janjuhah, H.T.; Ali, J.; Niaz, A.; Kontakiotis, G.; Antonarakou, A.; Usman, M.; Hussain, S.A.; Yang, R. Petrography and Provenance of the Sub-Himalayan Kuldana Formation: Implications for Tectonic Setting and Palaeoclimatic Conditions. Minerals 2022, 12, 794. [Google Scholar] [CrossRef]

- Ali, A. Structural Analysis of the Trans-Indus Ranges: Implications for the Hydrocarbon Potential of the NW Himalayas, Pakistan. Ph.D. Thesis, National Centre of Excellence in Geology, University of Peshawar, Peshawar, Pakistan, 2010. [Google Scholar]

- Ali, S.K.; Janjuhah, H.T.; Shahzad, S.M.; Kontakiotis, G.; Saleem, M.H.; Khan, U.; Zarkogiannis, S.D.; Makri, P.; Antonarakou, A. Depositional Sedimentary Facies, Stratigraphic Control, Paleoecological Constraints, and Paleogeographic Reconstruction of Late Permian Chhidru Formation (Western Salt Range, Pakistan). J. Mar. Sci. Eng. 2021, 9, 1372. [Google Scholar] [CrossRef]

- Nizami, A.R. Microfacies analysis and diagenetic settings of the middle Jurassic Samana Suk Formation, Sheikh Budin Hill section, trans Indus ranges-Pakistan. Geol. Bull. Punjab Univ. 2009, 44, 69–84. [Google Scholar]

- ASTM C29; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. American Society for Testing and Materials, Annual Book: West Conshohocken, PA, USA, 2009.

- BS 812-112; Methods of Determination of Aggregate Impact Value (AIV). British Standard Institution: London, UK, 1990.

- ASTM C127-07; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D4791; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM C88-05; Standard Test Method for Soundness of Aggregate by Use of Sodium Sulfate or Magnesium Sulfate. ASTM International: West Conshohocken, PA, USA, 2005; Volume 4.2, pp. 37–42.

- BS 812-112; Testing Aggregates. Method for Determination of Aggregate Impact Value (AIV). British Standarts Institution: London, UK, 1990.

- ASTM C142/C142M-10; Standard Test Method for Clay Lumps and Friable Particles in Aggregates. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM C131; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C170-16; Standard Test Method for Compressive Strength of Dimension Stone. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D 5731-95; Standart Test Method for Determination of the Point Load Strength Index of Rock. ASTM International: West Conshohocken, PA, USA, 1995.

- ASTM D 2845-00; Standard Test Method for Laboratory Determination of Pulse Velocities and Ultrasonic Elastic Constants of Rock. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM D5873-00; Standard Test Method for Determination of Rock Hardness by Rebound Hammer Method. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM C289-07; Standard Test Method for Potential Alkali-Silica Reactivity of Aggregates (Chemical Method). ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM C295; Standard Guide for Petrographic Examination of Aggregrates for Concret. ASTM International: West Conshohoken, PA, USA, 2012.

- BS 105.1; Testing Aggregates. Methods for Determination of Particle Shape. Flakiness Index. British Standard Institution: London, UK, 1989.

- BS 812-105-2; Testing Aggregates. Methods for Determination of Particle Shape. Elongation Index. British Standard Institution: London, UK, 1990.

- Khan, J.; Ahmed, W.; Yasir, M.; Islam, I.; Janjuhah, H.T.; Kontakiotis, G. Pollutants Concentration during the Construction and Operation Stages of a Long Tunnel: A Case Study of Lowari Tunnel,(Dir–Chitral), Khyber Pakhtunkhwa, Pakistan. Appl. Sci. 2022, 12, 6170. [Google Scholar] [CrossRef]

- Smith MR, C.L. Aggregates: Sand, Gravel and Crushed Rock Aggregates for Construction Purposes; Geological Society: London, UK, 2001; Volume 17. [Google Scholar]

- ISRM. ISRM suggested method for determination of the Schmidt hammer rebound hardness: Revised version. In The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007-2014; Springer: Berlin/Heidelberg, Germany, 2008; pp. 25–33. [Google Scholar]

- Selby, M. A rock mass strength classification for geomorphic purposes: With tests from Antarctica and New Zealand. Z. Geomorphol. Stuttg. 1980, 24, 31–51. [Google Scholar] [CrossRef]

- Hatheway, A.W. The complete ISRM suggested methods for rock characterization, testing and monitoring; 1974–2006. Environ. Eng. Geosci. 2009, 15, 47–48. [Google Scholar] [CrossRef]

- Malhotra, V. Testing Hardened Concrete: Non-Destructive Methods, ACI Monograph No. 9, ACI; Iowa State University Press: Ames, IA, USA, 1976. [Google Scholar]

- Akram, M.; Farooq, S.; Naeem, M.; Ghazi, S. Prediction of mechanical behaviour from mineralogical composition of Sakesar limestone, Central Salt Range, Pakistan. Bull. Eng. Geol. Environ. 2017, 76, 601–615. [Google Scholar] [CrossRef]

- Lea, F. The Chemistry of Cement and Concrete; Arnold: London, UK, 1970; Volume 243, p. 727. [Google Scholar]

- Boynton, R.S. Chemistry and Technology of Lime and Limestone; John Wiley&Sons. Inc.: New York, NY, USA, 1980. [Google Scholar]

- Grattan-Bellew, P.; Chan, G. Comparison of the morphology of alkali–silica gel formed in limestones in concrete affected by the so-called alkali–carbonate reaction (ACR) and alkali–silica reaction (ASR). Cem. Concr. Res. 2013, 47, 51–54. [Google Scholar] [CrossRef]

- Irfan, T. Mineralogy, fabric properties and classification of weathered granites in Hong Kong. Q. J. Eng. Geol. Hydrogeol. 1996, 29, 5–35. [Google Scholar] [CrossRef]

- Yasir, M.; Ahmed, W.; Islam, I.; Sajid, M.; Janjuhah, H.T.; Kontakiotis, G. Composition, Texture, and Weathering Controls on the Physical and Strength Properties of Selected Intrusive Igneous Rocks from Northern Pakistan. Geosciences 2022, 12, 273. [Google Scholar] [CrossRef]

- French, W. Concrete petrography: A review. Q. J. Eng. Geol. Hydrogeol. 1991, 24, 17–48. [Google Scholar] [CrossRef]

- López-Buendía, A.; Climent, V.; Verdú, P. Lithological influence of aggregate in the alkali-carbonate reaction. Cem. Concr. Res. 2006, 36, 1490–1500. [Google Scholar] [CrossRef]

- Ferraris, C.F.; Ferraris, C.F. Alkali-Silica Reaction and High Performance Concrete; NIST Interagency/Internal Report (NISTIR); National Institute of Standards and Technology: Gaithersburg, MD, USA, 1995. [Google Scholar] [CrossRef]

- Chen, F.H. Foundations on Expansive Soils; Elsevier: Amsterdam, The Netherlands, 2012; Volume 12. [Google Scholar]

- Janjuhah, H.T.; Ishfaque, M.; Mehmood, M.I.; Kontakiotis, G.; Shahzad, S.M.; Zarkogiannis, S.D. Integrated Underground Mining Hazard Assessment, Management, Environmental Monitoring, and Policy Control in Pakistan. Sustainability 2021, 13, 13505. [Google Scholar] [CrossRef]

- Dunham, R.J. Classification of Carbonate Rocks According to Depositional Textures; American Association of Petroleum Geosciences: Tulsa, OK, USA, 1962; pp. 108–121. [Google Scholar]

- Ramsay, D.; Dhir, R.; Spence, I. The role of rock and clast fabric in the physical performance of crushed-rock aggregate. Eng. Geol. 1974, 8, 267–285. [Google Scholar] [CrossRef]

- Hartley, A. A review of the geological factors influencing the mechanical properties of road surface aggregates. Q. J. Eng. Geol. 1974, 7, 69–100. [Google Scholar] [CrossRef]

- Lees, G.; Kennedy, C.K. Quality, shape and degradation of aggregates. Q. J. Eng. Geol. 1975, 8, 193–209. [Google Scholar] [CrossRef]

- ASTM C150/C150M-18; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2018.

- Oates, J. Lime and Limestone: Chemistry and Technology, Production and Uses; WileyVCH: Weinheim, Germany, 1998. [Google Scholar]

- Hewlett, P. Lea’s Chemistry of Cement and Concrete. 2004; Volume 4. Available online: https://www.elsevier.com/books/leas-chemistry-of-cement-and-concrete/hewlett/978-0-7506-6256-7 (accessed on 28 July 2022).

- Ertek, N.; Öner, F. Mineralogy, geochemistry of altered tuff from Cappadocia (Central Anatolia) and its use as potential raw material for the manufacturing of white cement. Appl. Clay Sci. 2008, 42, 300–309. [Google Scholar] [CrossRef]

- Insley, H. Microscopy of Ceramics and Cements; Academic Press, Inc.: New York, NY, USA, 1950. [Google Scholar]

- Tayeh, B.A.; Hasaniyah, M.W.; Zeyad, A.; Yusuf, M.O. Properties of concrete containing recycled seashells as cement partial replacement: A review. J. Clean. Prod. 2019, 237, 117723. [Google Scholar] [CrossRef]

- Smith, R.C. Materials of Construction; McGraw Hill Book, Gregg Division: New York, NY, USA, 1979. [Google Scholar]

- Derucher, K.N.; Heins, C.P. Materials for Civil and Highway Engineers. Prentice-Hill: Englewood Cliffs, NJ, USA, 1981.

- Hobbs, D.W. Alkali-Silica Reaction in Concrete; Thomas Telford Publishing: London, UK, 1988. [Google Scholar]

- Mehta, P.K. Concrete: Structure, Properties, and Materials; Prentice-Hall: Englewood Cliffs, NJ, USA, 1986. [Google Scholar]

- Aboutaleb, S.; Bagherpour, R.; Behnia, M.; Aghababaei, M. Combination of the physical and ultrasonic tests in estimating the uniaxial compressive strength and Young’s modulus of intact limestone rocks. Geotech. Geol. Eng. 2017, 35, 3015–3023. [Google Scholar] [CrossRef]

- Read, J.; Thornton, P.; Regan, W. A rational approach to the point load test. In Proceedings of the Third Australia-New Zealand Conference on Geomechanics, Wellington, New Zealand, 12–16 May 1980; p. 2. [Google Scholar]

- Aldeeky, H.; Al Hattamleh, O. Prediction of engineering properties of basalt rock in Jordan using ultrasonic pulse velocity test. Geotech. Geol. Eng. 2018, 36, 3511–3525. [Google Scholar] [CrossRef]

- Tandon, R.S.; Gupta, V. Estimation of strength characteristics of different Himalayan rocks from Schmidt hammer rebound, point load index, and compressional wave velocity. Bull. Eng. Geol. Environ. 2015, 74, 521–533. [Google Scholar] [CrossRef]

- Sajid, M.; Coggan, J.; Arif, M.; Andersen, J.; Rollinson, G. Petrographic features as an effective indicator for the variation in strength of granites. Eng. Geol. 2016, 202, 44–54. [Google Scholar] [CrossRef]

| Sample ID | SG | WA (%) | BD (g/cm3) | FI (%) | EI (%) | S (%) | AIV (%) | LAAV (%) | CL (%) |

|---|---|---|---|---|---|---|---|---|---|

| SSK1 | 2.67 | 0.50 | 1.57 | 19.40 | 18.80 | 1.7 | 15.13 | 25.00 | 0.40 |

| SSK2 | 2.66 | 0.49 | 1.58 | 16.08 | 17.16 | 1.7 | 14.18 | 23.32 | 0.39 |

| SSK3 | 2.67 | 0.47 | 1.59 | 15.20 | 14.12 | 1.6 | 13.46 | 22.66 | 0.37 |

| SSK4 | 2.67 | 0.40 | 1.59 | 16.16 | 15.12 | 1.3 | 12.37 | 21.76 | 0.24 |

| SSK5 | 2.67 | 0.45 | 1.59 | 16.64 | 16.96 | 1.5 | 12.79 | 22.26 | 0.28 |

| SSK6 | 2.66 | 0.51 | 1.54 | 17.56 | 16.16 | 1.9 | 16.44 | 26.04 | 0.42 |

| Minimum | 2.66 | 0.40 | 1.54 | 15.20 | 14.12 | 1.3 | 12.37 | 21.76 | 0.24 |

| Maximum | 2.67 | 0.51 | 1.59 | 19.40 | 18.80 | 1.9 | 16.44 | 26.04 | 0.42 |

| Mean | 2.66 | 0.47 | 1.58 | 16.84 | 16.39 | 1.6 | 14.06 | 23.51 | 0.35 |

| Standards (limits) for aggregates | ASTM 127 (<2.6) for road and concrete aggregate | ASTM 127 (<2.5%) for concrete aggregate | ASTM C-29 (1.2–1.75 g/cm3) | BS-882 (<40%) for road and cement concrete | BS-812 105.2 (max. limit 25%) for cement concrete | ASTM C88 (L < 12%) for concrete aggregate | BS 812:112 (max. 30%) for cement concrete | ASTM C-131 (<40%) for road aggregates | ASTM C-142-10 (<1%) for road aggregate |

| Sample ID | UCS (MPa) | PLT (MPa) | UPV (m/s) | SHRT (N) |

|---|---|---|---|---|

| SSK1a | 78.44 | 4.92 | 5148.65 | 44 |

| SSK1b | 81.92 | 5.08 | 5219.18 | 46 |

| SSK1c | 76.46 | 4.81 | 5046.36 | 43 |

| SSK2a | 83.41 | 5.25 | 5328.67 | 48 |

| SSK2b | 80.09 | 4.92 | 5219.18 | 47 |

| SSK2c | 77.39 | 4.81 | 5114.09 | 45 |

| SSK3a | 85.60 | 4.92 | 5291.67 | 49 |

| SSK3b | 90.98 | 5.03 | 5366.20 | 51 |

| SSK3c | 92.07 | 5.30 | 5442.86 | 52 |

| SSK4a | 98.34 | 5.68 | 5482.01 | 52 |

| SSK4b | 100.28 | 5.79 | 5602.94 | 56 |

| SSK4c | 101.47 | 5.89 | 5729.32 | 58 |

| SSK5a | 97.51 | 5.46 | 5562.04 | 50 |

| SSK5b | 95.27 | 5.35 | 5482.01 | 52 |

| SSK5c | 92.26 | 5.08 | 5404.26 | 53 |

| SSK6a | 79.75 | 5.08 | 4980.39 | 43 |

| SSK6b | 76.86 | 5.03 | 4948.05 | 45 |

| SSK6c | 73.83 | 4.76 | 4853.50 | 46 |

| Minimum | 73.83 | 4.76 | 4853.50 | 43 |

| Maximum | 101.47 | 5.89 | 5729.32 | 58 |

| Mean | 86.77 | 5.18 | 5290.08 | 49 |

| Standards (Limits) | High strength 60–200 MPa ISRM (ISRM 2008) | Strong rock 4–10 MPa (Selby 1980) | UPV > 4575 m/s (Excellent) (Malhotra 1976) | Moderate to strong rock 40–60 N (Selby 1980) |

| Major Oxides | CaO | MgO | Na2O | Fe2O3 | MnO | SiO2 | P2O5 | TiO2 | Al2O3 | LOI | CaCO3 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | 1.00 | - | - | - | - | - | - | - | - | - | - |

| MgO | −0.857 | 1.00 | - | - | - | - | - | - | - | - | - |

| Na2O | −0.133 | 0.305 | 1.00 | - | - | - | - | - | - | - | - |

| Fe2O3 | −0.171 | 0.200 | 0.277 | 1.00 | - | - | - | - | - | - | - |

| MnO | −0.304 | 0.055 | −0.385 | 0.277 | 1.00 | - | - | - | - | - | - |

| SiO2 | −0.794 | 0.645 | 0.136 | 0.222 | 0.136 | 1.00 | - | - | - | - | - |

| P2O5 | 0.143 | −0.060 | −0.033 | 0.239 | −0.033 | −0.027 | 1.00 | - | - | - | - |

| TiO2 | −0.297 | 0.025 | 0.014 | 0.357 | 0.269 | 0.215 | −0.152 | 1.00 | - | - | - |

| Al2O3 | −0.653 | 0.430 | 0.085 | −0.061 | 0.085 | 0.560 | 0.073 | 0.391 | 1.00 | - | - |

| LOI | 0.867 | −0.781 | −0.079 | −0.284 | −0.504 | −0.632 | −0.068 | −0.232 | −0.0611 | 1.00 | - |

| CaCO3 | 0.946 | −0.838 | −0.112 | −0.259 | −0.363 | −0.769 | −0.045 | −0.324 | −0.0702 | 0.950 | 1.00 |

| Sample. ID. | Micrite % | Sparite % | Allochems | Dolomite % | Silica % | Stylolites/Fractures | Dunham Classification | Silica Reactivity | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ooids | Peloids | Bioclasts | Total | ||||||||

| SSK1 | 11 | 31 | 24 | 21 | 13 | 58 | 0 | 0 | yes | Packstone | Innocuous |

| SSK2 | 3 | 6 | 32 | 39 | 18 | 89 | 2 | 0 | yes | Grainstone | Innocuous |

| SSK3 | 1 | 5 | 62 | 21 | 10 | 93 | 1 | 0 | yes | Grainstone | Innocuous |

| SSK4 | 2 | 8 | 52 | 30 | 8 | 90 | 0 | 0 | no | Grainstone | Innocuous |

| SSK5 | 3 | 6 | 45 | 34 | 12 | 91 | 0 | 0 | no | Grainstone | Innocuous |

| SSK6 | 75 | 2 | 3 | 1 | 19 | 23 | 0 | 0 | yes | Wackstone | Innocuous |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamran, A.; Ali, L.; Ahmed, W.; Zoreen, S.; Jehan, S.; Janjuhah, H.T.; Vasilatos, C.; Kontakiotis, G. Aggregate Evaluation and Geochemical Investigation of Limestone for Construction Industries in Pakistan: An Approach for Sustainable Economic Development. Sustainability 2022, 14, 10812. https://doi.org/10.3390/su141710812

Kamran A, Ali L, Ahmed W, Zoreen S, Jehan S, Janjuhah HT, Vasilatos C, Kontakiotis G. Aggregate Evaluation and Geochemical Investigation of Limestone for Construction Industries in Pakistan: An Approach for Sustainable Economic Development. Sustainability. 2022; 14(17):10812. https://doi.org/10.3390/su141710812

Chicago/Turabian StyleKamran, Asad, Liaqat Ali, Waqas Ahmed, Sobia Zoreen, Shah Jehan, Hammad Tariq Janjuhah, Charalampos Vasilatos, and George Kontakiotis. 2022. "Aggregate Evaluation and Geochemical Investigation of Limestone for Construction Industries in Pakistan: An Approach for Sustainable Economic Development" Sustainability 14, no. 17: 10812. https://doi.org/10.3390/su141710812

APA StyleKamran, A., Ali, L., Ahmed, W., Zoreen, S., Jehan, S., Janjuhah, H. T., Vasilatos, C., & Kontakiotis, G. (2022). Aggregate Evaluation and Geochemical Investigation of Limestone for Construction Industries in Pakistan: An Approach for Sustainable Economic Development. Sustainability, 14(17), 10812. https://doi.org/10.3390/su141710812