Abstract

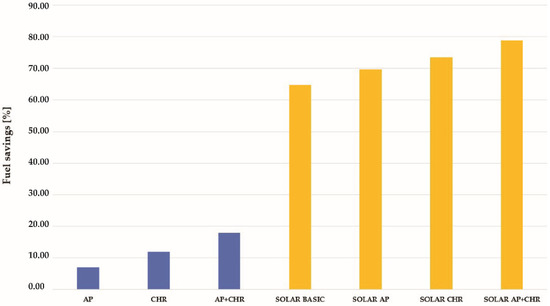

The evaluation of energy efficiency improvements in polyisoprene footwear production is shown. By installing air preheater, combustion air natural gas consumption is reduced by 7%. Simultaneously, the boiler outlet flue gases’ temperature is decreased from 204 °C to 66.93 °C, providing a sound basis for both economical savings and energy efficiency improvements, as well as ecological benefits to the environment. The application of condensate heat recovery resulted in flue gases’ volume decreasing by 11.85% and a thermal pollution decrease of 91.34%. Combining air preheating by exhaust flue gases and condensate heat recovery resulted in a decrease in the flue gases’ volume by 17.97%, and in the temperature lowering to 66.93 °C. The energy consumption for a combined system on location ) with a collector field of was investigated. The hybrid system was calculated for four variants: (1) solarized process without flue gases’ heat recovery, (2) solarized processes with heat contend in flue gases using an air preheater, (3) solarized processes with condensate heat recovery, and (4) solarized processes with heat contend in flue gases using air preheater and condensate heat recovery. The highest fuel savings were shown in solarized processes with heat contend in flue gases using air preheater and condensate heat recovery, resulting in savings of up to 78.92%, while the flue gases’ volume decreased from to .

1. Introduction

One of the most well-known natural polymers is polyisoprene, which is derived from rubber trees. However, it also exists as a man-made fiber and is used as an adhesive bond in the footwear industry or as a coating in the textile processing industry. Isoprene is another important conjugated diene for synthetic rubber production [1]. Man-made polyisoprene has better mechanical and thermal properties when compared to natural rubber due to its good inherent tack, good hot tensile strength and hot tear resistance, a high modulus, a high degree of resilience, and excellent compression values [1,2].

It is superior in the mixing, extrusion, molding, and calendering processes [2]. Polyisoprene is a synthetic polymer (elastomer) that can be vulcanized through the addition of sulfur. Cis-polyisoprene has properties similar to that of natural rubber; however, it is characterized by high tensile strength and insensitivity to temperature changes and has low abrasion resistance. Trans-polyisoprene, on the other hand, has different properties from the cis form, and cannot be vulcanized [2].

The rubbers most commonly used for latex adhesives or in shoe manufacturing are natural rubber (polyisoprene) or synthetic rubber (cis-polyisoprene). Other end-uses for polyisoprene include adhesives, lubricants, and useful elastomers such as surgical gloves and golf balls. Important uses of cis-polyisoprene include the production of tires, specialized mechanical products, conveyor belts, footwear, and insulation [2]. Exceptional characteristics of high purity and high gum tensile strength polyisoprene can be used in the coating of textiles, the products of which are used for medical, pharmaceutical, food-processing, and sports-goods applications [3].

In recent years, new innovative usage has brought the spotlight back to polyisoprene due to his versatile usage; however, ecological aspects in production have been raised. An organic polyisoprene is found in natural rubber trees; however, mono-crop plantations severely destroy local ecosystems since most of the world’s tree-based polyisoprene production is located mainly in Southeast Asia, primarily Thailand [4]. On the other hand, synthetic isoprene is polymerized and obtained from the thermal cracking and fraction of the petroleum, thus consuming fossil energy resources. However, the intensified demand over polymeric materials leads to waste growth [5], and, moreover, raises ecological footprint for more than 92% of the total ecological footprint, intensifies the greenhouse gas emission, and leads to global warming [6,7,8]. Jawjit et al.’s study, which discussed the potential environmental impacts of condom production in Thailand, compared the production of polyisoprene and natural rubber condoms. The production of polyisoprene condoms resulted in a 1.5–2.5 times greater environmental impact due to higher electricity consumption, leading to the conclusion that the reduction in electricity usage will experience a 10–17% reduction in environmental impacts [9]. The study on bio-polyisoprene that is produced through isoprene fermentation supposes the bio-based polyisoprene to be a sustainable alternative to the natural and synthetic rubber supply due to its decrease in greenhouse gas emission, its significantly lower land use intensity, additional energy conservation, and its reduced contribution to climate change [10]. So far, enhanced demand on rubber-based products has led to an increase in rubber plantations, which negatively affects biodiversity [11]. However, the increased interest in sustainability has resulted in studies on more ecologically acceptable forms of isoprene production, such as the above-mentioned fermentation and biomass [12]. However, despite all ecological controversy, about 95% of isoprene production is used to produce synthetic cis-1,4-polyisoprene [13].

Industrial processes generate substantial waste heat that could be returned to the process as a valuable energy source. The heat recovery leads to energy optimization, cost reduction, and a decrease in the environmental pollution. Improving the energy supply to a basic process is of critical concern, especially regarding the growth of fuel prices, the trend of global warming, and climate change, as well as the need to reduce greenhouse gas emissions. The sources of waste heat include both heat loss from products, equipment, and processes as well as combustion heat discharge [14]. Waste heat recovery (WHR) systems are grouped in relation to temperature range. High-temperature WHR systems use temperatures greater than 400 °C from direct combustion processes, medium-temperature WHR systems recover heat in the temperature range from 100 to 400 °C, deployed from the exhaust of combustion units, while the low-temperature WHR systems operate in a temperature range below 100 °C for industrial products, equipment, and processes [15]. Substantial efficiency improvements and ecological advantage could be achieved even in the standard synthetic polyisoprene production by applying medium waste recovery systems such as combustion air preheating, condensate heat recovery, and a combination of both, as well as solarized processes. The flue gases with a high temperature show significant potential for energy conservation. The possibility of natural gas savings using flue gases’ heat recovery and solar energy as a partial substitution for natural gas could lead to significant energy conservation.

The natural gas heating systems burn natural gas and eject hot flue gases. The flue gases’ exhaust temperature of gas boilers is about 70 °C to 120 °C’ of building-combined cooling heating and power (BCHP) systems, it is about 120 °C to 150 °C; and, in natural gas power plants, it is about 90 °C to 130 °C [16]. The natural gas boilers, such as the one used for the purpose of this study, burn gas in their furnaces, while also generating large amounts of water vapor containing a considerable amount of latent heat and toxic elements contained in flue gases, which are usually released directly to the environment with exhaust temperatures above 150 °C, leading to environmental pollution. The flue gas with the exhaust temperature of 130 °C contains 25% to 30% of the latent heat in building-combined cooling heating and power (BCHP) systems. The heat loss due to the exhaust flue gas is significant, as is the condensation heat [17].

At present, a significant amount of hot condensate and hot flue gases are introduced to the surrounding environment. The high temperature of flue gases presents a potential solution for energy conservation. The investigation of the boiler exhaust flue gases for feed water and air preheating as well as a combination of both can improve the technological process [18,19]. The gas-fired boiler is used in the present study on the energy efficiency improvements in polyisoprene footwear production due the advantages it offers, such as higher efficiency and lower pollutant emission compared to coal combustion boilers [20].

The flue gases’ heat recovery allows for significant efficiency improvements and a simultaneous decrease in the waste heat that is rejected to the surrounding environment. This heat contained in flue gases could be recovered. The exhaust flue gases from oil and natural gas boilers contain large amounts of water vapor and latent heat that could be recovered since the outlet temperature is usually higher than 150 °C. Another important concern is the toxic components’ release into the environment [20,21]. Using the waste heat recovery through the heat pipes’ exchanger leads to energy savings, simultaneously preventing global warming [22].

The heat recovery systems for hot water circulation in gas-fired boilers are: (a) direct heat recovery systems, which recover the sensible heat of exhaust flue gases for heating supply water and preheating the supply air; (b) condensate heat recovery systems, which uses the recovery of a part of the flue gases’ latent heat for the heating boiler feed water, and (c) absorption heat pump recovery systems, which use the heat of flue gas and transfer it to the feed water [20,23].

The direct heat recovery systems still do not employ large amounts of waste heat in flue gases and result in a boiler efficiency rating of around 95%, while the boiler efficiency of the condensate heat recovery systems is increased, simultaneously decreasing the flue gases’ temperature and increasing the energy savings’ rate by 10% by employing the flue gases’ latent heat recovery. The absorption heat pump significantly improves boiler efficiency, by as much as 103%, since the part of latent heat can be recovered; however, the installation costs and system volume are relatively high. The exhaust flue gas temperature can be decreased below the dew point temperature [20,24,25].

To reduce expensive fuel consumption, the heat of flue gases produced by fuel combustion is preferable for air preheating. Heat recovery using exhaust-to-air heat recovery and low to medium temperature applications is mainly achieved by air preheaters. Air preheater designs come in two different types, with the first being the plate type and the second being the heat pipe type [26]. To reduce furnace stack emissions, it is important to install the air preheaters, and advanced process controls can increase the overall furnace efficiency. The primary air is heated using an air preheater prior to entering the furnace of a boiler. The air preheaters (AP) are the shell, and tube type heat exchangers are used for preheating the air, which is fed to the boiler or furnaces/kilns for combustion of fuels. The air preheater’s primary objective is to extract the waste heat from the flue gases leaving the boiler. Normally, in a simple process configuration, the fuel is fed to the boiler at normal room temperature and for combustion to take place; the temperature of the fuel is increased from its room temperature to its ignition temperature. In order to increase the efficiency of the combustion process as well as a boiler, hot air is fed from the air preheater to the furnace for the combustion of fuel. In general, the air preheaters are designed to maximize the efficiency by increasing the heating surface area without increasing the space requirement and are designed for both flue gases and air to extract the maximum amount of heat from the flue gases. The air preheaters are used to extract waste heat from the flue gases leaving the boiler exhaust, thereby increasing the boiler efficiency by 2–3%.

This process could be further improved using the condensate heat recovery, which should be applied for a feed water preheating. The return condensate combined with the flue gases’ heat recovery can be utilized for the feed water preheating. The process condensate with the exhaust flue gases could be applied for the combustion air preheating.

A significant amount of water vapor (steam) in process exhaust flue gases carries a great deal of latent heat, which can be recaptured through the condensation of the vapor. When the process exhaust flue gases are cooled below its dewpoint (the temperature at which water starts to condense), the latent heat can be recovered and reused for process applications. The latent heat harnessing by condensing the water vapors of the flue gas brings both economic and environmental benefits. The gas-fired condensing boilers are studied regarding the maximization of the combustion efficiency and minimization of the emissions produced by combustion. The heat gained by condensing the water vapors from the flue gas is proportional to the quantity of the condensate collected [27]. The benefits of the condensate’s return to the boiler include fuel savings, make-up water savings, and chemical and treatment costs’ reduction. The less condensate that is discharged into a sewer system, the lower the disposal costs. The return of the high purity condensate also reduces energy losses due to boiler blowdown. Significant fuel savings occur as most returned condensate is relatively hot, reducing the amount of cold make-up water feeding the boiler.

Finally, the process condensate, together with the flue gases, can be utilized for the feed water and air preheating; however, further study is needed. Employing the reuse of the heat condensate with the exhaust flue gases for the feed water and air preheating using the boiler feed tank and an air preheater leads to increased energy efficiency, simultaneously reducing the environment impact by lowering losses. Above all, the substitution of natural gas with a renewable energy source, i.e., solar energy, provides the best results regarding the fuel savings and environmental protection [28].

Over the last decades, scientists have started exploring hybrid heat recovery systems (HHRSs) for reusing a high amount of flue gases’ thermal energy by combining more than one purpose, such as combining electricity generation, heating, cooling and energy storing, resulting in energy, fuel, and input water/air savings [29]. Jamil et al. studied the waste heat recovery (WHR) system, which can be utilized to heat the boiler return water, boiler supply air, and building heating air, for the purpose of capturing sensible and latent heat from flue gas [30]. However, most of the studies are designed to only utilize the heat recovered from exhaust flue gases. The novelty of this study is the impact of a hybrid system in polyisoprene production, which combines natural gas, solar energy, flue gases’ heat recovery, and condensate heat recovery. The environmental analysis showed a reduction in natural gas consumption while simultaneously diminishing the flue gases’ exhaust temperature and volume when using both an air preheater, the boiler feed tank allowing condensate recycling, and solar energy. The presented combination of sources provides greater efficiency improvements in polyisoprene production and is also environmentally acceptable.

2. Process Data and Methods of the Energy Efficiency Improvements

The purpose of the paper is to provide a preliminary assessment of the quality and quantity of useful waste heat potential in the proposed polyisoprene footwear production plant (latitude φ = 45°49′ N, longitude λ = 15°58′ E). Two major waste streams identified are the hot condensate and the boiler exhaust flue gases. The proposed heat recovery applications involve two major optimization potentials together with their combinations. The first is the waste heat utilization method, which uses the heat potential of flue gases and air preheating by installing the air preheater (AP). The second proposed optimization describes the energy potential of condensate heat recovery (CHR). Further process optimization is analysed by applying both flue gases and condensate heat recovery together with solar energy (AP + CHR). The results of the study are shown in relation to potential fuel savings, as well as in the flue gases’ exhaust temperature and in the decrease in quantity.

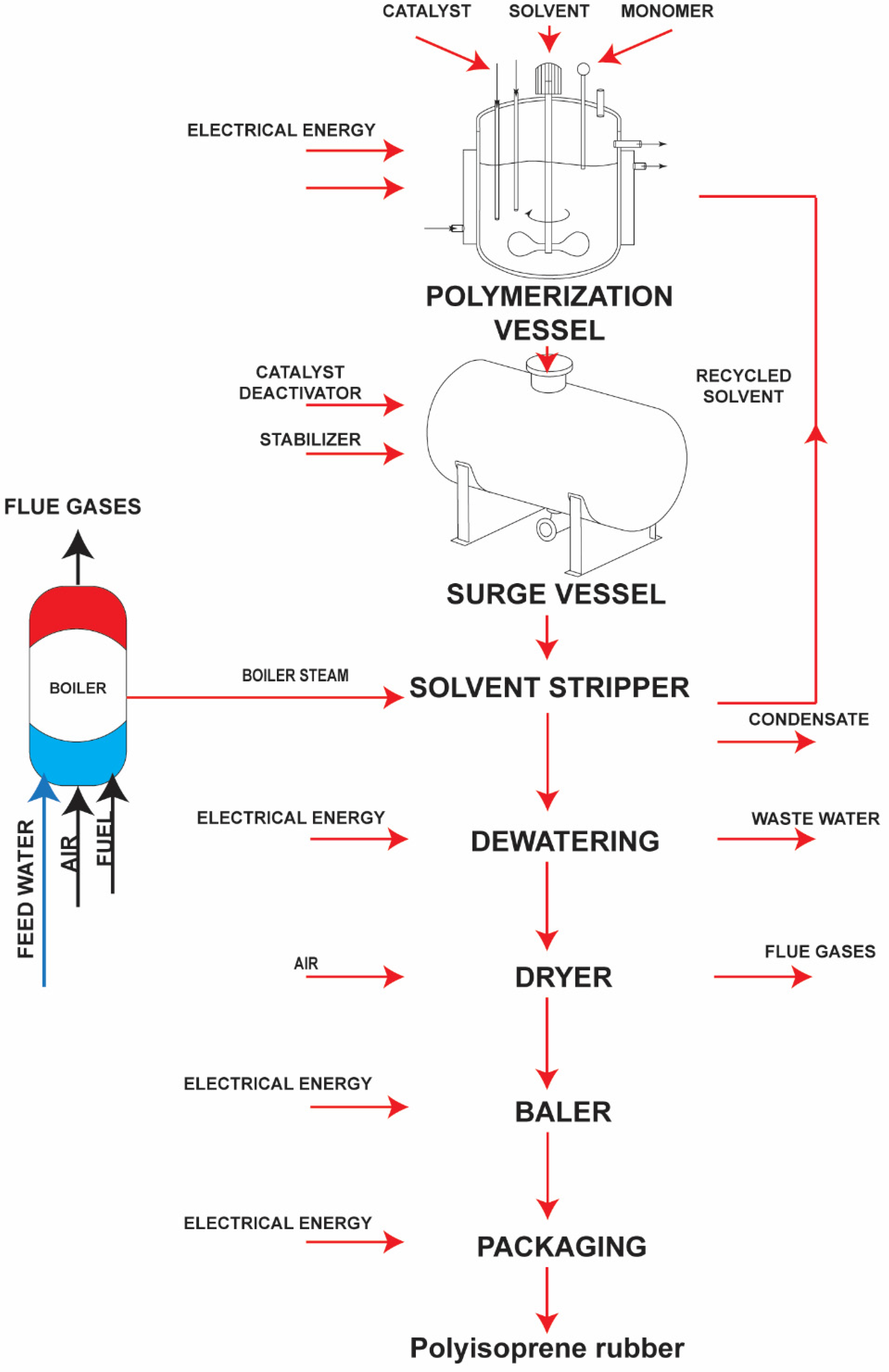

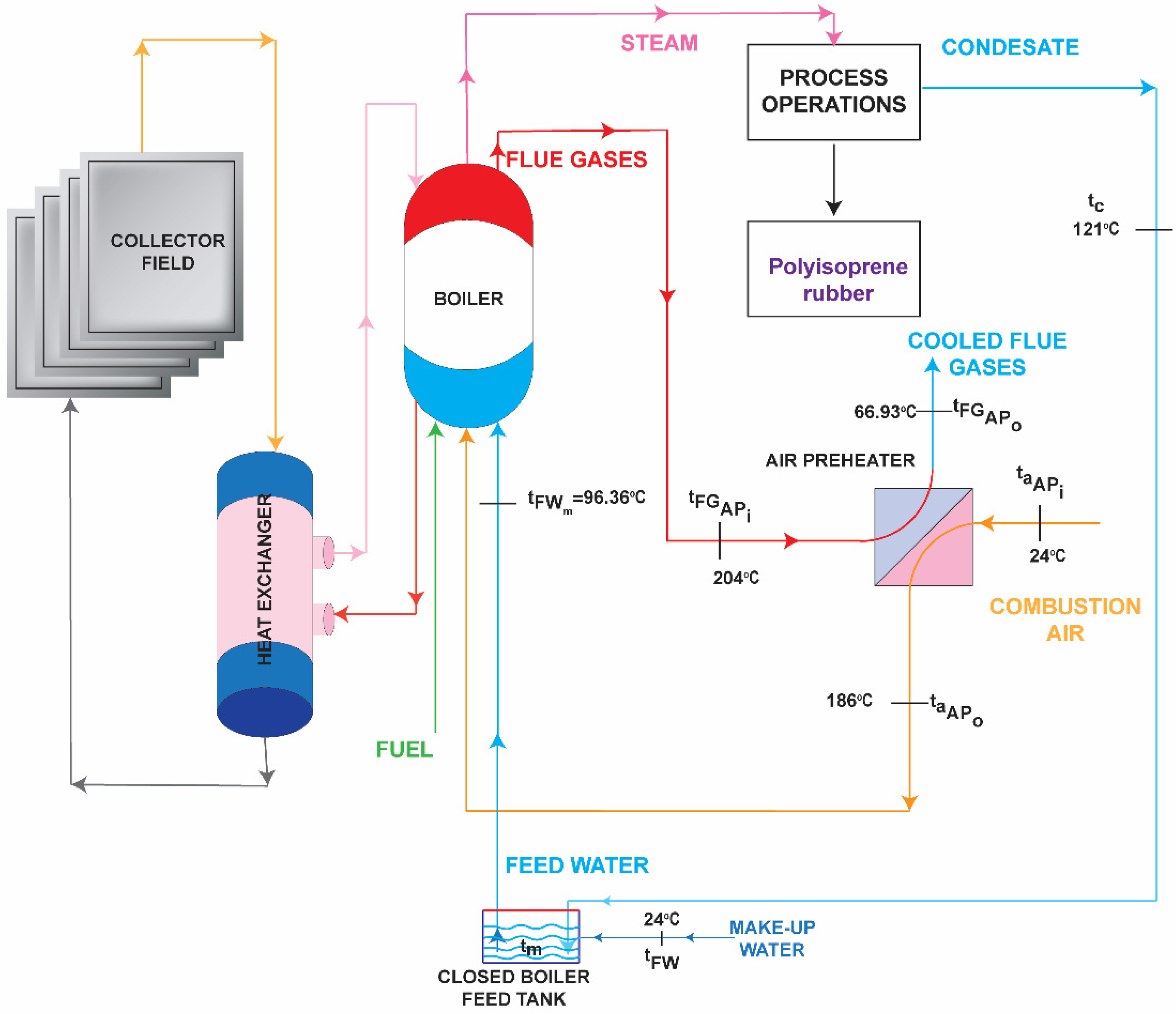

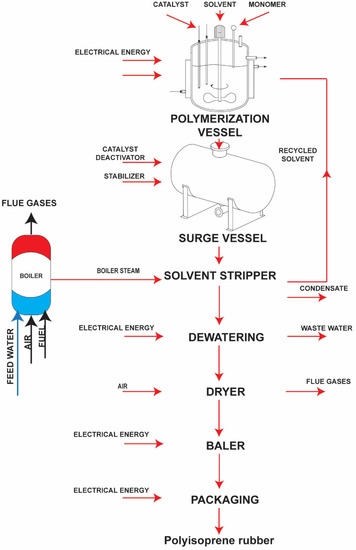

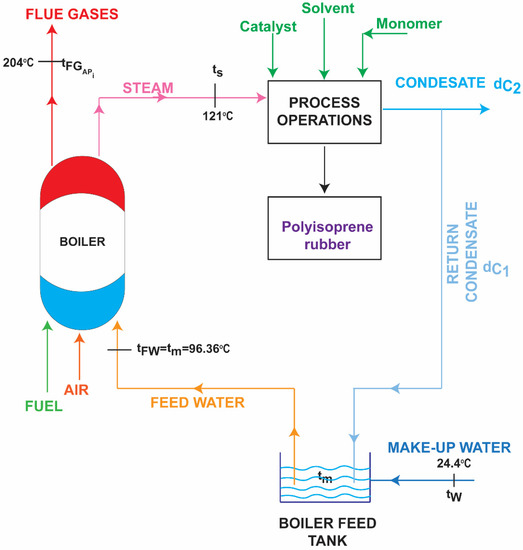

This study presents the energy consumption in the continuous manufacturing process of polyisoprene production, and such a process requires large amounts of thermal and electrical energy as well as water. To evaluate such a system, a realistic study is carried out using the industrial process data. A flow diagram of the process is shown in Figure 1, where the following operations are presented: polymerization, surge vessel, solvent stripper, dewatering, drier, baler, and packaging. The basic process needs electrical energy in the amount of , which is supplied from the grid and used by polymerization vessel (), dewatering machine (), baler (), and packaging machines () [31].

Figure 1.

Block flow diagram of polyisoprene rubber production.

The dry saturated steam in the amount of is produced in a boiler with efficiency and is supplied to the solvent stripper with a temperature of . The process also uses cold water for polymerization in the amount of . The present study of energy consumption in the polyisoprene production process, working in two shifts at rate , is carried out. The plant works 16 h in a day, 25 days in a month (); therefore, the plant use factor becomes .

The production capacity is calculated as:

Feed water enters the boiler with temperature and the whole condensate with temperature is withdrawn to the surrounding. The air required for combustion passes into a firebox with temperature , while the temperature of the exhaust stacks is , Figure 1 [31].

The natural gas with composition , , , , , , and is burned with the excess air coefficient . Based on this composition, the lower heating value of the fuel is calculated by the following formula [32] as:

The heat transferred to the boiler per unit of product is:

where () and () are the steam and water enthalpies taken from thermodynamically tables [33].

From this data, the unit volume of the fuel requirement using heat balance is:

The fuel consumption becomes:

The heat transferred to the boiler becomes:

The specific steam consumption is:

The heat of the condensate is calculated as:

where is enthalpy value taken from thermodynamically tables [32].

The whole quantity of condensate from the process is calculated as:

with temperature is withdrawn to the surrounding.

2.1. Exhaust Product Analysis

The products of fuel combustion are mostly gaseous. For complete gas combustion, 25% excess air is supplied (excess air coefficient ). The minimum oxygen volume and stehiometric air volume are required for combustion [34].

The minimum oxygen volume () is calculated as:

The minimum air volume () is calculated as:

The actual volume of air calculated with the excess air coefficient is:

Volume of each gas component is calculated using following expressions:

The volume of carbon dioxide:

The volume of water vapor:

where is air moisture and is steam density.

The volume of nitrogen:

The volume of oxygen:

The total volume of flue gases is summed by adding together the volume of carbon dioxide, water vapor, nitrogen unconsumed during the combustion process, and excess oxygen:

The component percentage in flue gases’ composition:

The specific heat of exhaust gases with temperature and the percentage by volume of products, as well as the specific heat of each gas, should be obtained [35]:

The energy derived on complete combustion per unit volume of natural gas or per unit of polyisoprene product depends on the total flue gases’ volume (), specific heat (), and flue gases’ temperature ():

The volume of exhaust flue gases per unit of the product rejected to the surrounding in the basic process is:

The fuel consumption is:

The volume of the exhaust flue gases per hour rejected to the surrounding in basic process is:

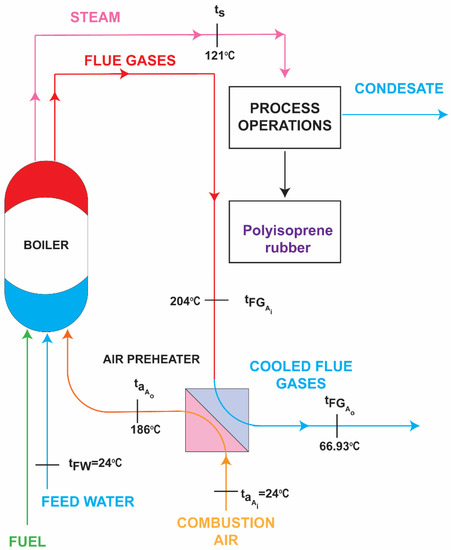

2.2. Air Preheating Using Heat of Exhaust Flue Gases in Air Preheater

The conventional furnace units within the boiler produce large amounts of the exhaust flue gases, which are released directly into the environment, releasing large amounts of the waste heat and leading to environmental pollution. Using the heat pipe heat exchanger (HPHE), also known as the air preheater (AP), reduces the primary energy consumption and protects the environment. The air preheaters (AP) with the heat pipe units are effective in heat recovery. They are characterized by compactness, a lack of parts, light weight, relative economy, smaller pressure-drop of fluid flow across, complete separation of hot and cold fluids, and reliability [23].

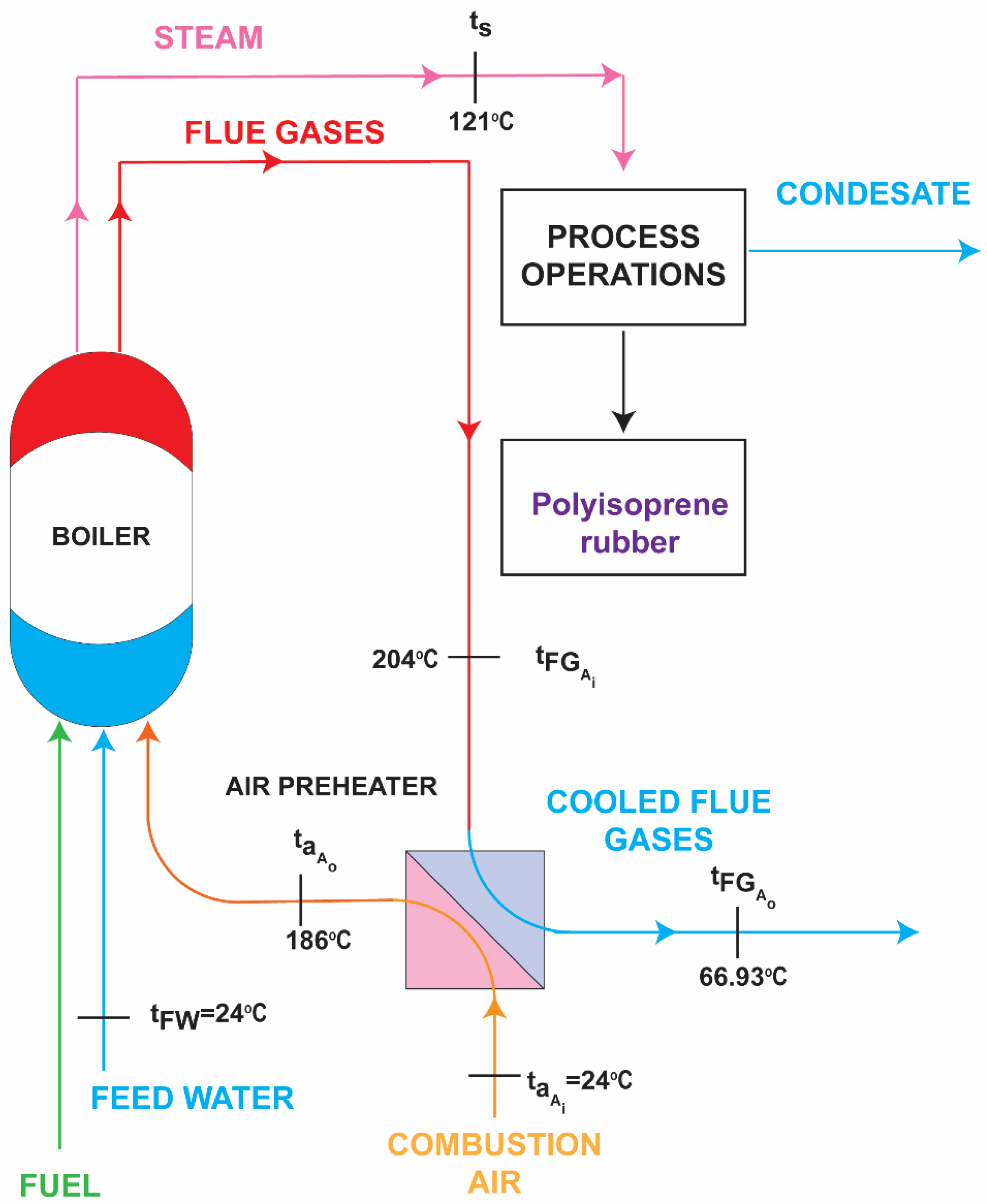

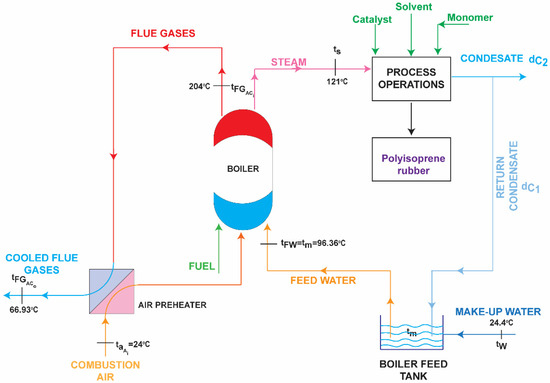

To improve process plant efficiency, the exhaust flue gases could be used to preheat air, which is required for fuel combustion. The summary of the process’ optimization is shown in Table 1. The flue gases with the temperature in the amount of enter the heat exchanger, i.e., an air preheater with efficiency (Figure 2). The ambient air enters the air preheater with the temperature . The excess air coefficient is , and the actual volume of air becomes . The specific heat of flue gases is and, for air,

Table 1.

Summarized data in process with air preheating (AP).

Figure 2.

Process of polyisoprene rubber production with air preheater.

The air preheater (AP) acts as a heat exchanger, preheating the combustion air before entering the boiler [36]. A simple air preheater (AP) designed as the heat pipe heat exchanger (HPHE) acts as an air-to-air heat recovery device, where the latent heat of vaporization is utilized to transfer heat with a corresponding low-temperature difference [18]. The air preheaters are usually designed as closed tubes filled with a proper working fluid and are divided into three groups: (a) a conventional heat pipe (CHP), a two-phase closed thermosyphon (TPCT), and an oscillating heat pipe (OHP) [23].

The high flue gases’ outlet temperature exhaust gases from the boiler to the surroundings. However, flue gases’ temperature can be lowered using an air preheater system, simultaneously resulting in smaller fuel consumption, and thus solving the problem of clean energy generation.

The air preheater heat balance equation [34] is:

The air preheater air outlet temperature () can be calculated using the air preheater heat balance equation, while :

The ambient air with temperature at in volume passes through the air preheater, where they are heated by flue gases to a temperature of .

The flue gases’ outlet temperature () can also be calculated using the air preheater heat balance equation:

The flue gases’ heat recovery in process with air preheating:

The natural gas savings in process with air preheater:

The natural gas consumption is:

The fuel consumption becomes:

The heat transferred to the boiler becomes:

Comparison made with a basic process without flue gases’ heat recovery for air preheating shows natural gas savings in the amount of:

The volume of exhaust flue gases per unit of the product rejected to the surrounding in the process with the air preheater is:

The volume of the exhaust flue gases per hour rejected to the surrounding in the process with air preheater is:

Air preheating using the flue gases’ heat recovery results in natural gas savings of 7%, the flue gases’ exhaust temperature is decreased from to , and the volume of the flue gases is lowered from to or by 7.01%.

2.3. Condensate Heat Recovery

Reusing the water and sensible heat contained in the condensate discharged from the process leads to significant energy and gas savings, chemical treatment, and make-up water reduction. In this study, the condensate is simply returned and mixed with the make-up water to increase the temperature of the feed water entering the boiler and thus decreasing the gas consumption to heat the water for process steam production. By sending the hot condensate back to the boiler’s deaerator and heating the feed water, fuel costs can be reduced by as much as 20%. Since less energy is required to turn water into steam, this also leads to the plant’s carbon footprint reduction.

The high temperature condensate is usually discharged to the surroundings, thus increasing the thermal pollution; however, it can be reused in the production process. Some of the ways to use the condensate waste heat include steam production replacement by heat energy production, the implementation of the condensate heat recovery (CHR) system, and feed water preheating [37]. The high-temperature condensate is mixed with make-up water entering the boiler feed tank and is returned back into the boiler feed tank, facilitating condensate recycling. The process’ steam eventually condenses through cooling and can be recirculated back to the boiler, thus recovering some sensible heat loss and reducing the need for fresh-treated feed water. This contributes significantly to the primary energy consumption in the utility system, and this substantial saving on energy costs and chemicals makes building a return piping system attractive, as seen in Table 2 [38,39].

Table 2.

Summarized data in process with condensate heat recovery (CHR).

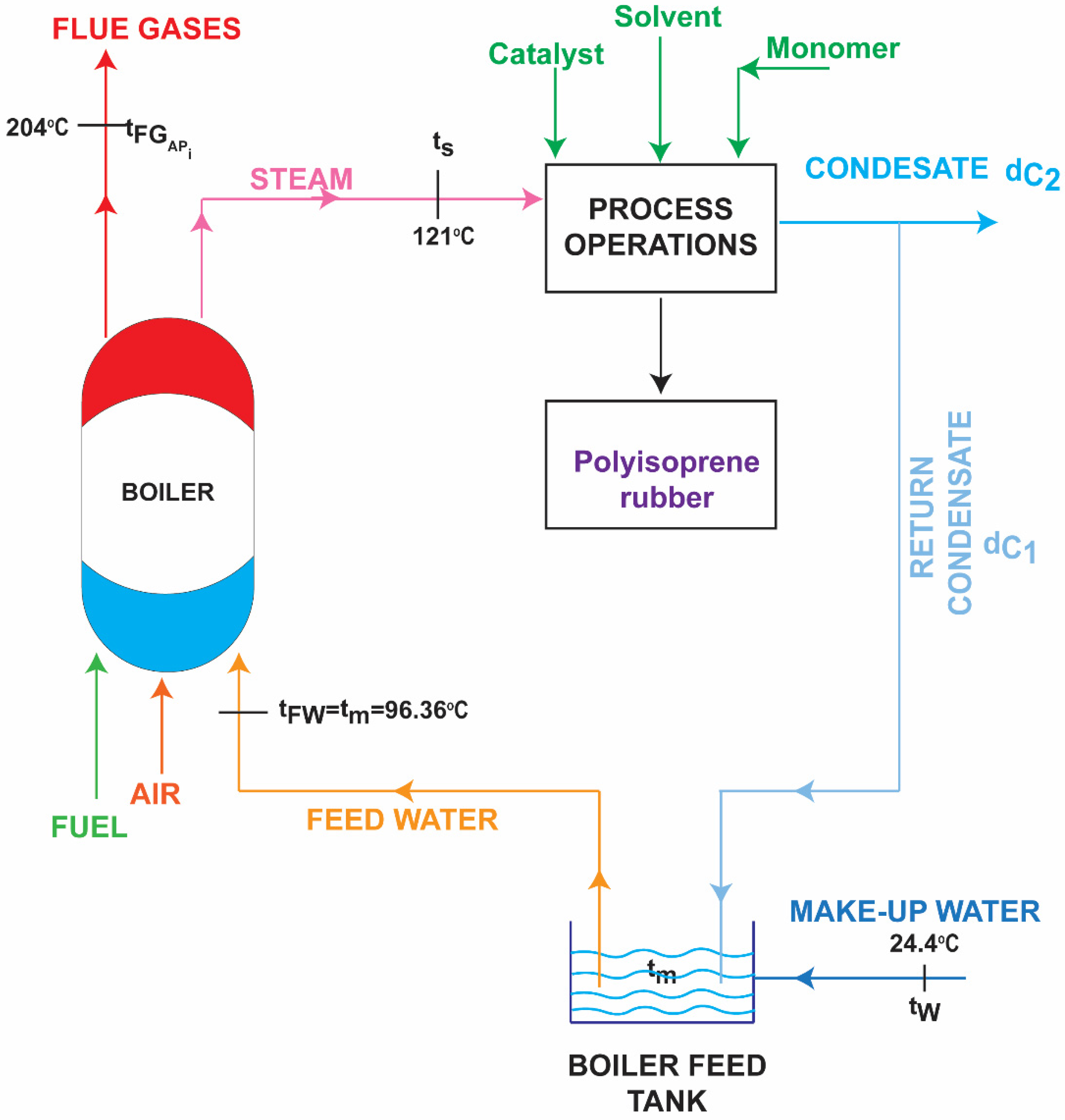

In the synthetic polyisoprene production, significant natural gas savings are possible if the process condensate is recovered and used to preheat boiler feed water (Figure 3). In this case, 90%, i.e., , of condensate with temperature is saturated and mixed with make-up water in the amount of with temperature in the boiler feed tank.

Figure 3.

Process of polyisoprene rubber production with the condensate heat recovery.

The mass of the saturated steam is . Assuming that the mixing of the saturated process condensate and the make-up water takes place adiabatically, the boiler feed water will enter the boiler with the temperature:

Using the heat balance, the natural gas consumption can be calculated as:

where () and () are the steam and water enthalpies taken from thermodynamically tables [33].

The fuel consumption becomes:

The fuel consumption is calculated, respectively, as:

The heat transferred to the boiler becomes:

The heat transferred to the boiler is calculated, respectively, as:

The specific steam consumption becomes:

The process heat for feed water heating is:

where is the enthalpy value taken from thermodynamically tables [33].

The process with the condensate heat recovery could be compared with the basic process, i.e., the process without condensate heat recovery, and this comparison shows natural gas savings in the amount of:

The condensate heat, which is ejected to the environment, is:

From the above calculated data, it can be concluded that the thermal pollution decreases from to or by 91.34%.

The flue gases’ volume rejected to the atmosphere with temperature in this case becomes:

or, calculated per hour:

The volume of the flue gases is lowered from to or by 11.84%.

2.4. Air Preheating with Flue Gases in Process with Condensate Heat Recovery

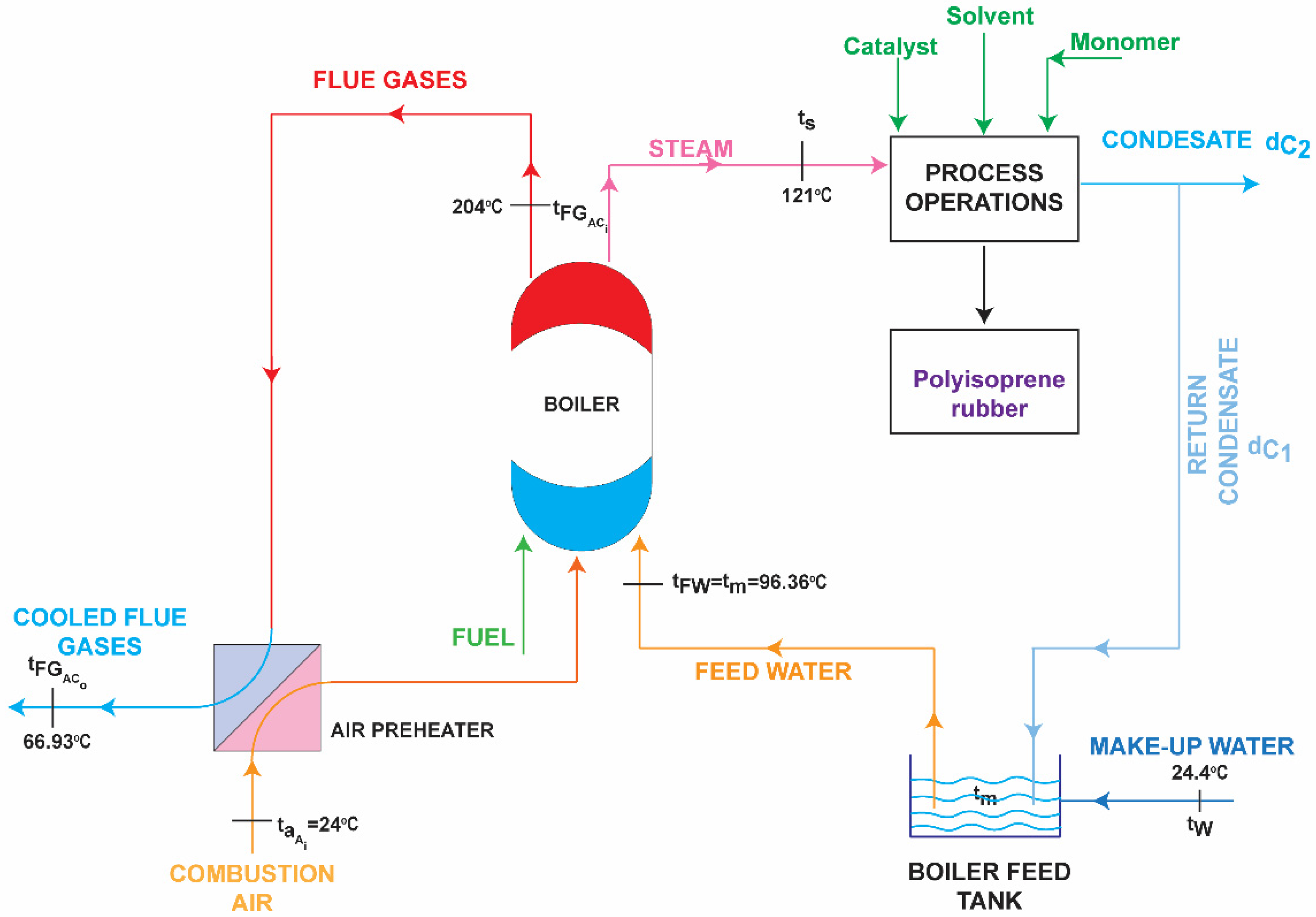

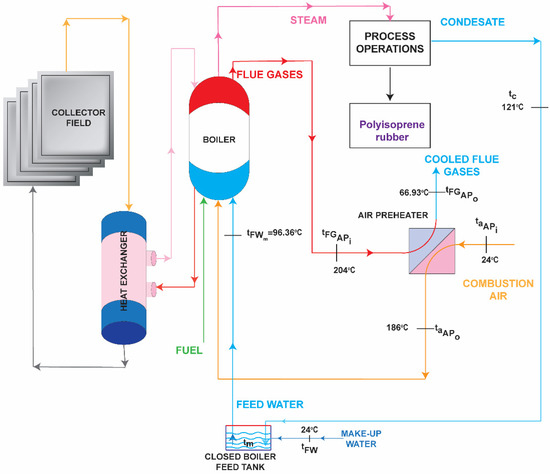

The air, which is essential for natural gas consumption, should be preheated with the flue gases together with the condensate heat recovery in order to increase the process’ overall efficiency (Figure 4, Table 3). The heat of the flue gases will be delivered to the combustion air in an air preheater unit with the efficiency of . The flue gases’ temperature of . The fuel consumption calculated earlier is , and the flue gases outlet temperature . The volume of the flue gases is . The specific heat of flue gases was calculated as .

Figure 4.

Process of polyisoprene rubber production with combination of air preheating using flue gases and the condensate heat recovery.

Table 3.

Summarized data in process with air preheating and condensate heat recovery (AP + CHR).

Considering the above-mentioned data, the flue gases’ heat recovery in the process combining air preheating using flue gases and condensate heat recovery is calculated as:

or, expressed as the amount of natural gas savings in the process combing both air preheating and condensate heat recovery:

The natural gas consumption is now:

The fuel consumption is calculated, respectively, as:

The heat transferred to the boiler becomes:

The heat transferred to the boiler is calculated, respectively, as:

Comparison made with a basic process without flue gases’ heat recovery for air preheating and process without condensate heat recovery shows natural gas savings in the amount of:

The volume of the exhaust flue gases per unit of the product rejected to the surrounding in the process with the air preheater combined with condensate heat recovery is:

The fuel consumption is:

The volume of exhaust flue gases per hour rejected to the surrounding in the process with the air preheater combined with condensate heat recovery can be calculated as:

Air preheating using the flue gases’ heat recovery and condensate heat recovery results in natural gas savings of 18%, and the flue gases’ exhaust temperature is diminished from to , while the volume of the flue gases is reduced from to or also by 17.97%.

The make-up water could be pretreated to avoid corrosion and to reduce total suspended solids by applying the clarification or filter systems. The reduction in total suspended solids can reduce the potential for the settling of solids in the circulating water system, thus improving maintainability. Another important step is water softening in order to eliminate calcium, magnesium, and iron in the process system [40].

2.5. Solar Energy Application in Polyisoprene Footwear Production

Since significant concerns are raised regarding greenhouse emission in the fossil fuel combustion process, and since the majority of industrial applications still rely on classical fossil fuel sources, scientist have attempted to facilitate renewable energy options to speed up the clean energy transition and reduce production cost. Another major concern has been raised regarding fossil fuel’s market price, which has been fluctuating considerably due to global COVID-19 pandemics, wars, and supply chain interruptions. There is a wide range of renewables suitable for application in households; however, large-scale industrial plants use a substantial amount of versatile energy sources and require a lot of fast energy inputs. This study was performed for the proposed solar application (Figure 5) in polyisoprene footwear production for the combined system on location ) with a collector field of . The summary of the process optimization is shown in Table 4.

Figure 5.

The solarized process of polyisoprene production with condensate heat recovery and air preheating using flue gases.

Table 4.

The comparison of the fuel consumption, flue gases’ volume, and fuel savings between the processes with solar energy application.

The useful daily solar radiation () can be calculated from the monthly average daily radiation () and solar collector efficiency (), which differ during the one-year span from 65% during summertime and 50% in transition to 25% in the wintertime.

The required solar collector area is expressed as:

where is the security factor for the large collector installation and is the daily heat input to the boiler in the plant with air preheater and condensate heat recovery.

The mean flat plate collector area is calculated on the basis of the average values for the area during the summer period, as seen in Table 5 (June, July, August):

Table 5.

The installed field of the flat plate collectors is located at the location (), and the total useful radiation on the horizontal surface is calculated.

The monthly useful solar energy with mean collector area can be received using the following equation:

where are days in the month.

The total useful yearly solar radiation is:

The solarized process in all examined cases is shown:

1. Basic process (process without process condensate and flue gases’ heat recovery)

Natural gas consumption is [41]:

and fuel savings becomes [41]:

The volume of exhaust flue gases is [41]:

2. Process with air preheater

Natural gas consumption is [41]:

and fuel savings becomes [41]:

The volume of exhaust flue gases is [41]:

3. Process with condensate heat recovery using feed water tank

Natural gas consumption is [41]:

and fuel savings becomes [41]:

The volume of exhaust flue gases is [41]:

4. Process with condensate heat recovery and combustion air preheating using flue gases (Figure 5)

Natural gas consumption is [41]:

and fuel savings becomes [41]:

The volume of exhaust flue gases is [41]:

3. Cost and Savings Analysis

The total installation costs of solar thermal system range from minimum , average , to maximum [42]. The yearly consumption of heat transferred to the boiler in the basic polyisoprene footwear production process was previously calculated as . For the purpose of this cost analysis, we calculated the price of the average system cost of . With the proposed collector field of , and the price of the specific system cost of , the whole installation cost is calculated as . Input data for the cost analysis are explained in Table 6.

Table 6.

Input data.

Annual fuel cost in the basic polyisoprene footwear production system:

The annual fuel costs and savings are summarized in Table 7 as calculated earlier in the text.

Table 7.

Annual fuel costs and cost savings for the solar-based process variants.

The payback period equals the share of investment and annual savings, and thus becomes:

4. Results and Discussion

All of the industrial process, and therefore the polyisoprene footwear production, being one of them, generates large amounts of the waste heat that could be utilized back in the process, resulting in energy optimization, cost reduction, and a decrease in environmental pollution. In order to improve energy efficiency through the minimization of natural gas consumption and pollutants’ emission in the polyisoprene footwear production process, four basic optimization process methods are presented.

Due to the recent growth of the fuel prices and growing concern regarding global warming and environmental pollution, waste heat recovery provides a sound basis with which to optimize the production, simultaneously preventing hot exhaust flue gases’ release to the environment. The process with air preheating using exhaust flue gases resulted in the flue gases’ volume decreasing by 7.01%. A further reduction in the exhaust flue gases’ volume was shown in the process using condensate heat recovery, which lead to a decrease of 11.84%. However, the highest reduction in the volume of the exhaust flue gases was achieved in the process combining both air preheating using the flue gases’ heat recovery and condensate heat recovery, leading to a decrease in volume by as much as 17.97%.

The basic process becomes energy efficient and environmentally friendly by decreasing fuel consumption through reusing waste condensate and flue gases’ waste heat (Table 8). The use of condensate heat recovery decreased the thermal pollution by 91.34%. There are numerous benefits from the condensate heat return provided by this study, from fuel and make-up water savings to costs reduction. Less condensate discharged into a sewer system reduces disposal costs. Significant fuel savings occur as returned condensate decreases the amount of cold make-up water feeding the boiler.

Table 8.

Comparison of fuel saving among proposed optimization processes in polyisoprene footwear production.

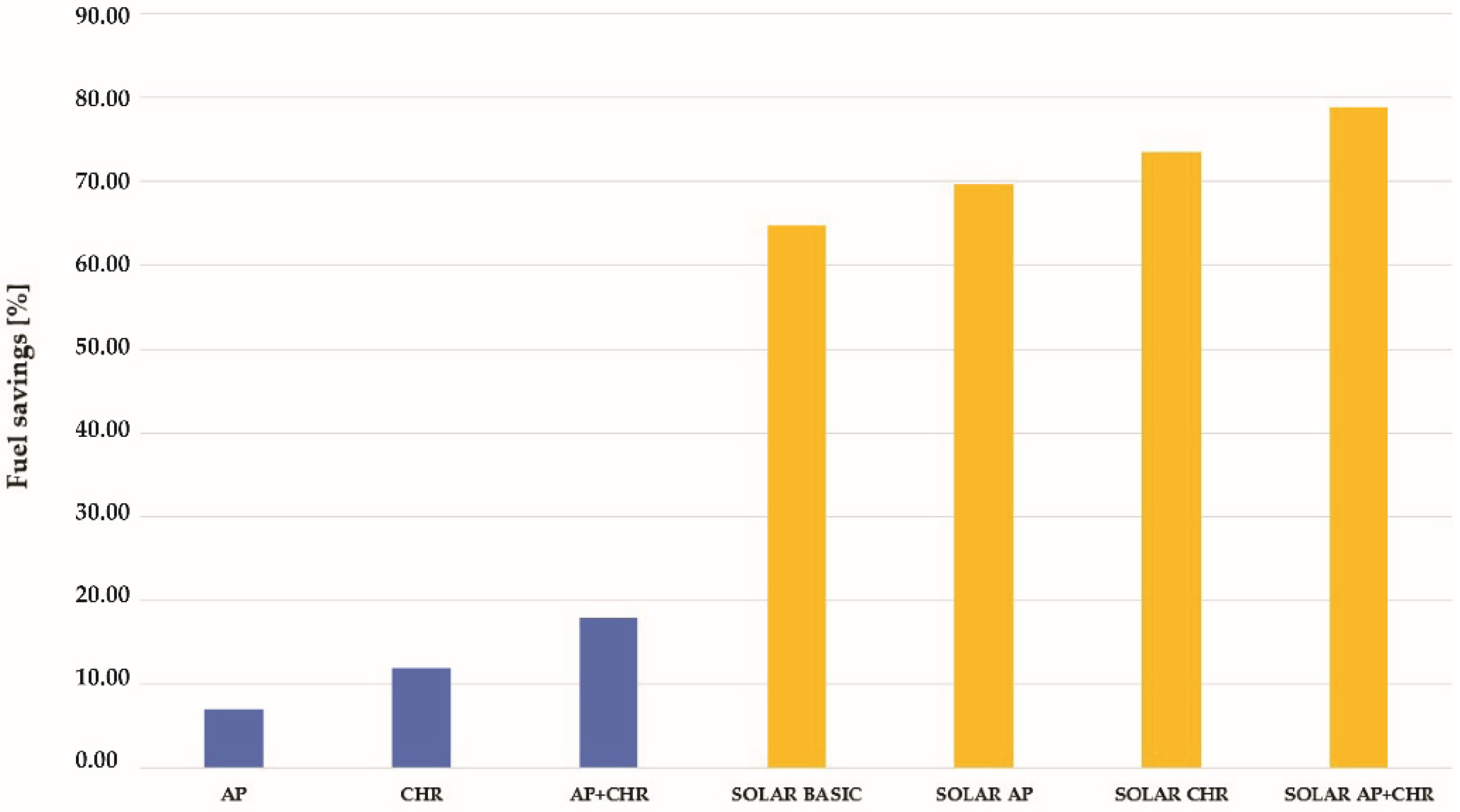

The calculated results of the presented energy consumption in the polyisoprene footwear production process show the highest benefit when utilizing natural gas and the solar energy system together with process condensate and flue gases’ heat recovery, as summarized in Figure 6.

Figure 6.

The fuel savings compared across all of the calculated processes.

The results are based on the calculated natural gas requirements and the measured data for solar radiation in polyisoprene production. In order to save natural gas, energy for feed water and combustion air preheating with solar energy are presented. This calculation includes data for selected location () using a collector field of .

The hybrid system with solar energy is computed for four options. Two of them are analyzed in processes without process condensate heat recovery and the other two are for processes wherein the return condensate was included. The results show natural gas savings in the basic process of 64.71%, in the process with an air preheater of 69.6%, in the process with a condensate return of 73.4%, and in the process with an air preheater and condensate return of 78.92%. Finally, the volume of flue gases is lowered from to , while the flue gases outlet temperature decreases from to .

5. Conclusions

In order to improve energy efficiency through the minimization of natural gas consumption and pollutants’ emission in the polyisoprene footwear production process, process with air preheating using exhaust flue gases was analyzed. Using an air preheater for combustion air preheating results in the exhaust temperature lowering to , while the volume of the flue gases is lowered to . The energy and environmental analysis shows that the efficiency increases when using flue gases for combustion air preheating. Comparison made with a basic process without flue gases’ heat recovery for air preheating shows natural gas savings in the amount of 7%. Further improvements in the polyisoprene footwear production process could be made by using exhaust flue gases’ waste heat and by reusing boiler condensate for feed water preheating, as well as combining all methods to gain maximum natural gas savings.

The greatest energy savings were shown when combining all of the energy sources together, i.e., the solarized process with flue gases’ heat recovery using an air preheater together with condensate heat recovery. The environmental analysis showed the greatest reduction in natural gas consumption by up to 78.92%. The flue gases’ emission is reduced from to while the gases’ exhaust temperature is diminished from to . Future work should focus on both feed water and air preheating using flue gases by transferring waste heat through not only air preheater, but also through the incorporation of the economizer. This will lead to further gas savings and thermal pollution reduction. Since the global economy is shaken by fossil fuel reduction, other means of incorporating renewable energy sources should also be investigated to achieve both environmentally friendly and cost-effective production.

Author Contributions

Research concept, A.M.-B. and I.Š.; Figures, I.Š.; methodology, A.M.-B.; results design, I.Š. discussion, A.M.-B. preparation of paper for submission, I.Š.; project leader: A.M.-B. All authors have read and agreed to the published version of the manuscript.

Funding

The research was supported by short-term financial support by the University of Zagreb, under title antimicrobial efficacy of the material aided by plasma and natural extracts (grant number TP9/22).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Nomenclature | Symbol | Unit |

| specific heat of water | ||

| specific heat of carbon dioxide | ||

| specific heat of nitrogen | ||

| specific heat of oxygen | ||

| specific heat of air | ||

| specific heat of flue gases | ||

| unit mass of process water per unit of product | ||

| unit mass of saturated steam for industrial process per unit of product | ||

| unit mass of condensate used in industrial process per unit of product | ||

| specific steam consumption for basic process per unit of product | ||

| unit mass of specific steam consumption for process with condensate heat recovery per unit of product | ||

| fuel consumption needed in process with condensate heat recovery | ||

| unit mass of fuel consumption needed for feed water preheating with air preheater in process with condensate heat recovery | ||

| unit volume of fuel consumption needed for air preheating with air preheater (AP) | ||

| fuel savings in process with air preheater | ||

| fuel savings in process with condensate heat recovery and air preheater | ||

| hourly production capacity | ||

| daily production capacity | ||

| monthly production capacity | ||

| yearly production capacity | ||

| the rate of fuel consumption per hour in basic process | ||

| the rate of fuel consumption per day in basic process | ||

| the rate of fuel consumption per month in basic process | ||

| the rate of fuel consumption per year in basic process | ||

| quantity of condensate from the process | ||

| the rate of fuel consumption per hour in process with air preheater | ||

| the rate of fuel consumption per day in process with air preheater | ||

| the rate of fuel consumption per month in process with air preheater | ||

| the rate of fuel consumption per year in process with air preheater | ||

| the rate of fuel consumption per hour in process with condensate heat recovery | ||

| the rate of fuel consumption per day in process with condensate heat recovery | ||

| the rate of fuel consumption per month in process with condensate heat recovery | ||

| the rate of fuel consumption per year in process with condensate heat recovery | ||

| the rate of fuel consumption per hour in process with condensate heat recovery and air preheater | ||

| the rate of fuel consumption per day in process with condensate heat recovery and air preheater | ||

| the rate of fuel consumption per month in process with condensate heat recovery and air preheater | ||

| the rate of fuel consumption per year in process with condensate heat recovery and air preheater | ||

| the rate of fuel consumption per hour in solarized basic process | ||

| the rate of fuel consumption per hour in solarized process with air preheater | ||

| the rate of fuel consumption per hour in solarized process with process condensate heat recovery | ||

| the rate of fuel consumption per hour in solarized process with condensate heat recovery and combustion air preheating using flue gases | ||

| electrical energy consumption per unit of product | ||

| enthalpy of steam | ||

| enthalpy of boiler feed water | ||

| enthalpy of condensate | ||

| lower heating value | ||

| heat transferred to the boiler per unit of product | ||

| heat of condensate per unit of product in basic process | ||

| heat of process condensate to preheat water per unit of product in process with condensate heat recovery | ||

| condensate heat discharged to the surroundings in process with condensate heat recovery | ||

| energy released during complete combustion per unit mass of the fuel | ||

| energy released during complete combustion per unit of products | ||

| flue gas heat recovery in process with air preheater per unit of products | ||

| flue gas heat recovery in process with condensate heat recovery and air preheating | ||

| overall heat transfer rate to the boiler per hour in basic process | ||

| overall heat transfer rate to the boiler per day in basic process | ||

| overall heat transfer rate to the boiler per month in basic process | ||

| overall heat transfer rate to the boiler per year in basic process | ||

| overall heat transfer rate with air preheater to the boiler per hour | ||

| overall heat transfer rate with air preheater to the boiler per day | ||

| overall heat transfer rate with air preheater to the boiler per month | ||

| overall heat transfer rate with air preheater to the boiler per year | ||

| overall heat transfer rate to the boiler per hour in process with condensate heat recovery | ||

| overall heat transfer rate to the boiler per day in process with condensate heat recovery | ||

| overall heat transfer rate to the boiler per month in process with condensate heat recovery | ||

| overall heat transfer rate to the boiler per year in process with condensate heat recovery | ||

| overall heat transfer rate to the boiler per hour in process with condensate heat recovery and air preheater | ||

| overall heat transfer rate to the boiler per day in process with condensate heat recovery and air preheater | ||

| overall heat transfer rate to the boiler per month in process with condensate heat recovery and air preheater | ||

| overall heat transfer rate to the boiler per year in process with condensate heat recovery and air preheater | ||

| fuel savings in process with air preheater | ||

| fuel savings in process with condensate heat recovery | ||

| fuel savings in process with condensate heat recovery and air preheater | ||

| fuel savings in solarized basic process | ||

| fuel savings in solarized process with air preheater | ||

| fuel savings in solarized process with process condensate heat recovery | ||

| fuel savings in solarized process with condensate heat recovery and combustion air preheating using flue gases | ||

| temperature of condensate | ||

| temperature of boiler steam | ||

| temperature of water after mixing of the condensate and make up water | ||

| temperature of exhaust flue gases | ||

| air preheater flue gases outlet temperature in process with condensate heat recovery | ||

| air preheater flue gases inlet temperature in process with condensate heat recovery | ||

| Inlet temperature of air | ||

| air preheater air outlet temperature | ||

| air preheater air inlet temperature | ||

| air preheater flue gases outlet temperature | ||

| air preheater flue gases outlet temperature | ||

| temperature of boiler feed water inlet | ||

| actual volume of air calculated with the excess air coefficient | ||

| volume of inlet boiler air per unit of fuel | ||

| unit volume of fuel requirement | ||

| volume of flue gases per unit of fuel | ||

| volume of carbon dioxide in flue gases per unit of fuel | ||

| volume of nitrogen in flue gases per unit of fuel | ||

| minimum volume of oxygen in flue gases per unit of fuel | ||

| volume of oxygen in flue gases per unit of fuel | ||

| volume of water vapour in flue gases per unit of fuel | ||

| volume of rejected exhaust flue gases calculated per hour to the surrounding in process with economizer | ||

| volume of rejected exhaust flue gases calculated per hour to the surrounding in process with air preheater | ||

| volume of rejected exhaust flue gases calculated per hour to the surrounding in process with condensate heat recovery | ||

| volume of rejected exhaust flue gases calculated per hour to the surrounding in process with condensate heat recovery and air preheater | ||

| volume of rejected exhaust flue gases calculated per hour to the surrounding in solarized basic process | ||

| volume of rejected exhaust flue gases calculated per hour to the surrounding in solarized process with air preheater | ||

| volume of rejected exhaust flue gases calculated per hour to the surrounding in solarized process with process condensate heat recovery | ||

| volume of rejected exhaust flue gases calculated per hour to the surrounding in solarized process with condensate heat recovery and combustion air preheating using flue gases | ||

| volume of flue gases per unit of product | ||

| total volume of flue gases per unit of fuel | ||

| volume of exhaust flue gases per unit of product rejected to the surrounding in process with air preheater | ||

| volume of rejected exhaust flue gases calculated per unit of product to the surrounding in process with condensate heat recovery | ||

| volume of rejected exhaust flue gases calculated per unit of product to the surrounding in process with condensate heat recovery and air preheater | ||

| volume of excess air per unit of fuel | ||

| boiler efficiency | % | |

| air preheater efficiency | % | |

| collector efficiency | % | |

| collector area | ||

| mean flat plate collector area | ||

| daily heat input to the boiler | ||

| useful daily radiation | ||

| average daily radiation (insolation) | ||

| monthly useful solar energy | ||

| yearly useful radiation | ||

| number of days in a month | ||

| security factor for large collector installation | - | |

| excess air coefficient | - | |

| usage factor | % | |

| operating time |

Abbreviations

| BCHP | building combined cooling heating and power |

| AP | air preheater |

| HPHE | heat pipe heat exchanger |

| CHP | conventional heat pipe |

| TPCT | two-phase closed thermosyphon |

| OHP | oscillating heat pipe |

| WHR | waste heat recovery systems |

| HHRS | hybrid heat recovery systems |

| CHR | condensate heat recovery |

References

- Speight, J.G. Handbook of Petrochemical Processes; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2019; ISBN 978-1-4987-2970-3. [Google Scholar]

- Wehlan, A.; Lee, K.S. Developments in Rubber Technology—2; Springer: Dordrecht, The Netherlands, 1981; ISBN 978-9-40098-110-2. [Google Scholar]

- Akovali, G. Advances in Polymer Coated Textiles; Smithers Rapra Technology Ltd.: Shropshire, UK, 2012; ISBN 978-1-84735-497-6. [Google Scholar]

- Ahrends, A.; Hollingsworth, P.M.; Ziegler, A.D.; Fox, J.; Chen, H.; Su, Y.; Xu, J. Current trends of rubber plantation expansion may threaten biodiversity and livelihoods. Glob. Environ. Chang. 2015, 34, 48–58. [Google Scholar] [CrossRef]

- Valiev, A.; Zemskii, D. The catalytic cracking of the off-spec polyisoprene rubber thermolysis products. E3S Web Conf. 2020, 157, 02027. [Google Scholar] [CrossRef]

- Musikavong, C.; Gheewala, S.H. Assessing ecological footprints of products from the rubber industry and palm oil mills in Thailand. J. Clean. Prod. 2017, 142, 1148–1157. [Google Scholar] [CrossRef]

- Jawjit, W.; Pavansant, P.; Kroeze, C. Evaluation environmental performance of concentrated latex production in Thailand. J Clean. Prod. 2015, 98, 84–91. [Google Scholar] [CrossRef]

- Jawjit, W.; Rattanapan, S.; Kroeze, C. Greenhouse gases emissions of rubber industry in Thailand. J. Clean. Prod. 2010, 18, 403–411. [Google Scholar] [CrossRef]

- Jawjit, W.; Pavasant, P.; Kroeze, C.; Tuffrey, J. Evaluation of the potential environmental impacts of condom production in Thailand. J. Integr. Environ. Sci. 2021, 18, 89–114. [Google Scholar] [CrossRef]

- Batten, R.; Karanjikar, M.; Spatari, S. Bio-Based Polyisoprene Can Mitigate Climate Change and Deforestation in Expanding Rubber Production. Fermentation 2021, 7, 204. [Google Scholar] [CrossRef]

- Panda, B.K.; Sarkar, S. Environmental impact of rubber plantation: Ecological vs. economical perspectives. Asian J. Microbiol. Biotechnol. Environ. Sci. 2020, 22, 657–661. [Google Scholar]

- Sarkar, P.; Bhowmick, A.K. Sustainable rubbers and rubber additives. J. Appl. Polym. Sci. 2018, 135, 45701. [Google Scholar] [CrossRef]

- Asghar, U.; Masoom, A.; Javed, A.; Abbas, A. Economic Analysis of Isoprene Production from Good Year Scientific Process. Austin Chem. Eng. 2020, 7, 1071. [Google Scholar] [CrossRef]

- Johnson, I.; Choate, W.T.; Davidson, A. Waste Heat Recovery. Technology and Opportunities in U.S. Industry; Technical Report; BSC Inc.: Laurel, MS, USA, 2008. [Google Scholar]

- Bruckner, S.; Liu, S.; Laia, M.; Radspieler, M.; Cabeza, L.F.; Eberhard, L. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Zhao, X.L.; Fu, L.; Zhang, S.G.; Jiang, Y.; Li, H. Performance improvement of a 70 kWe natural gas combined heat and power (CHP) system. Energy 2010, 35, 1848–1853. [Google Scholar] [CrossRef]

- Fu, L.; Zhao, X.L.; Zhang, S.G.; Jiang, Y.; Li, H.; Yang, W.W. Laboratory research on combined cooling, heating and power (CCHP) systems. Energy Convers. Manag. 2009, 50, 977–982. [Google Scholar] [CrossRef]

- Thumann, A. Plant Engineers & Managers; Guide to Energy Conservation, 8th ed., The Fairmont Press: Lilburn, GA, USA, 2002. [Google Scholar]

- Mihelić-Bogdanić, A.; Budin, R.; Špelić, I. Impact of hybrid system in polyester production. Cogent. Eng. 2017, 4, 1362198. [Google Scholar] [CrossRef]

- Chen, W.; Shi, W.; Wang, B.; Shang, S.; Li, X. A deep heat recovery device between flue gas and supply air of gas-fired boiler by using non-contact total heat exchanger. Energy Procedia 2017, 105, 4976–4982. [Google Scholar] [CrossRef]

- Jia, L.; Peng, X.F.; Sun, J.D.; Chen, T.B. An Experimental Study on Vapor Condensation of Wet Flue Gas in a Plastic Heat Exchanger. Heat Trans. Asian Res. 2001, 30, 571–580. [Google Scholar] [CrossRef]

- Srimuang, W.; Amatachaya, P. A review of the applications of heat pipe heat exchangers for heat recovery. Renew. Sustain. Energy Rev. 2012, 16, 4303–4315. [Google Scholar] [CrossRef]

- Hou, J.; Che, D.; Liu, Y.; Jiang, Q. A New System of Absorption Heat Pump Vs. Boiler for Recovering Heat and Water Vapor in Flue Gas. Energy Procedia 2018, 152, 1266–1271. [Google Scholar] [CrossRef]

- Wang, S.L.; Zhang, J.F.; Wen, Z.; Pan, S.Y.; Liu, J.; Wu, Y.Y. Forced convective heat transfer of flue gas on anticorrosion plane surface with condensation. In Proceedings of the 13th International Heat Transfer Conference, Sydney Convention and Exhibition Centre, Sydney, Australia, 13–18 August 2006; Leonardi, E., De Vahl Davis, G., Eds.; Begell House Inc.: Danbury, CT, USA, 2006. [Google Scholar]

- Kan, Z.; Xia, J.; Xie, X.; Jiang, Y. Total heat recovery of gas boiler by absorption heat pump and direct-contact heat exchanger. Appl. Therm. Eng. 2014, 71, 213–218. [Google Scholar]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste heat recovery technologies and applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Bălănescu, D.T.; Homutescu, V.T.; Popescu, A. In situ study on the condensate latent heat recovery and its economic impact in the case of a 60 kW condensing boilers system. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 9th International Conference on Advanced Concepts in Mechanical Engineering—ACME 2020, Iași, Romania, 4–5 June 2020; Mechanical Engineering Faculty, Gheorghe Asachi Technical University of Iasi: Iasi, Romania, 2020; Volume 997, p. 012139. [Google Scholar]

- Kalogirou, S.A. The potential of solar industrial process heat applications. Appl. Energy 2003, 76, 337–361. [Google Scholar] [CrossRef]

- Farhat, O.; Faraj, J.; Hachem, F.; Castelain, C.; Khaled, M. A recent review on waste heat recovery methodologies and applications: Comprehensive review, critical analysis and potential recommendations. Clean. Eng. Technol. 2022, 6, 100387. [Google Scholar] [CrossRef]

- Jamil, S.R.; Wang, L.; Che, D. Techno-economic analysis of a novel hybrid heat pump system to recover waste heat and condensate from the low- temperature boiler exhaust gas. Int. J. Energy Res. 2020, 44, 3821–3838. [Google Scholar] [CrossRef]

- Brown, L.H.; Hamel, B.B.; Hedman, B.A. Energy Analysis of 108 Industrial Processes; Fairmont Press: Philadelphia, PA, USA, 1996; ISBN 0-915586-93-2. [Google Scholar]

- Budin, R.; Mihelić-Bogdanić, A.; Vujasinović, E. Cogeneration and Heat Recovery in the Industrial Process. Chem. Ind. 2007, 56, 551–555. [Google Scholar]

- Budin, R.; Mihelić-Bogdanić, A. Basics of Technical Thermodynamics, 3rd ed.; Školska Knjiga: Zagreb, Croatia, 2012; ISBN 9789530316881. [Google Scholar]

- Turner, W.C. (Ed.) Energy Management Handbook, 8th ed.; Fairmont Press: Philadelphia, PA, USA, 2012; ISBN 9781466578289. [Google Scholar]

- Bošnjaković, F. The Science of Heat; Grafis: Zagreb, Croatia, 2012; Volume 1, pp. 2–3. ISBN 9789532790177. [Google Scholar]

- Flue Gas Heat Recovery. Power Systems, Babcock Borsig Steinmüller GmbH. Brochure. 2012. Available online: http://www.bbs.bilfinger.com/fileadmin/power_steinmuller/Mediathek/Broschuere_Rauchgasw_rmenutzung_BBS_web_E.pdf (accessed on 13 July 2017).

- Eades, W.G. Energy and water recovery using air-handling unit condensate from laboratory HVAC systems. Sustain. Cities Soc. 2018, 42, 162–175. [Google Scholar] [CrossRef]

- Einstein, D.; Worrell, E.; Khrushch, M. Steam systems in industry: Energy use and energy efficiency improvement potentials. In Proceedings of the ACEEE 2001 Summer Study on Energy Efficiency in Industry; American Council for an Energy-Efficient Economy (ACEEE): Washington, DC, USA, 2001; pp. 535–547. [Google Scholar]

- Luo, X.; Huang, X.; El-Halwagi, M.M.; Ponce-Ortega, J.M.; Chen, Y. Simultaneous synthesis of utility system and heat exchanger network incorporating steam condensate and boiler feedwater. Energy 2016, 113, 875–893. [Google Scholar] [CrossRef]

- Levy, E.; Bilirgen, H.; DuPont, J. Recovery of Water from Boiler Flue Gas Using Condensing Heat Exchangers; Final Technical Report; Energy Research Center: Bethlehem, PA, USA, 2011. [Google Scholar]

- Budin, R.; Mihelić-Bogdanić, A. Sources and Energy Management in Industry; Element: Zagreb, Croatia, 2013. [Google Scholar]

- Rockenbaugh, C.; Dean, J.; Lovullo, D.; Lisell, L.; Barker, G.; Hanckock, E.; Norton, P. High Performance Flat Plate Solar Thermal Collector Evaluation; General Services Administration by the National Renewable Energy Laboratory: Golden, CO, USA, 2016. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).