Innovative Solutions and Challenges for the Improvement of Storage Processes

Abstract

1. Introduction

2. Literature Review

2.1. The Concept of Warehousing Logistics

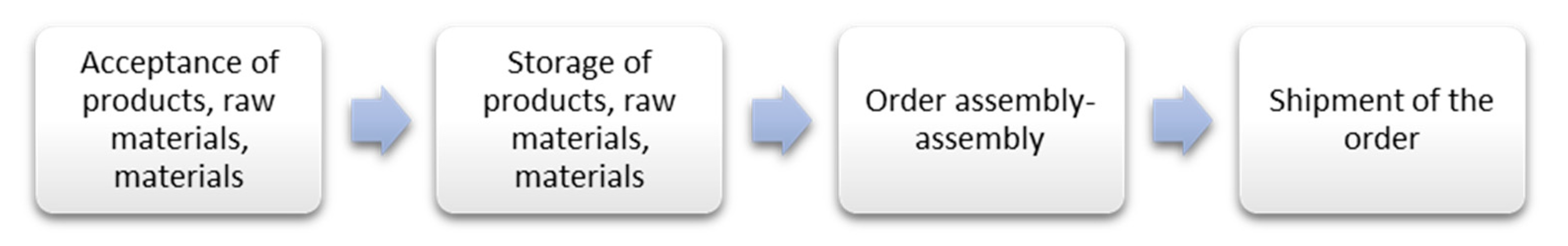

2.2. The Role of Storage Processes

2.3. Problems of Warehousing Logistics Processes

3. Materials and Methods

3.1. Methods

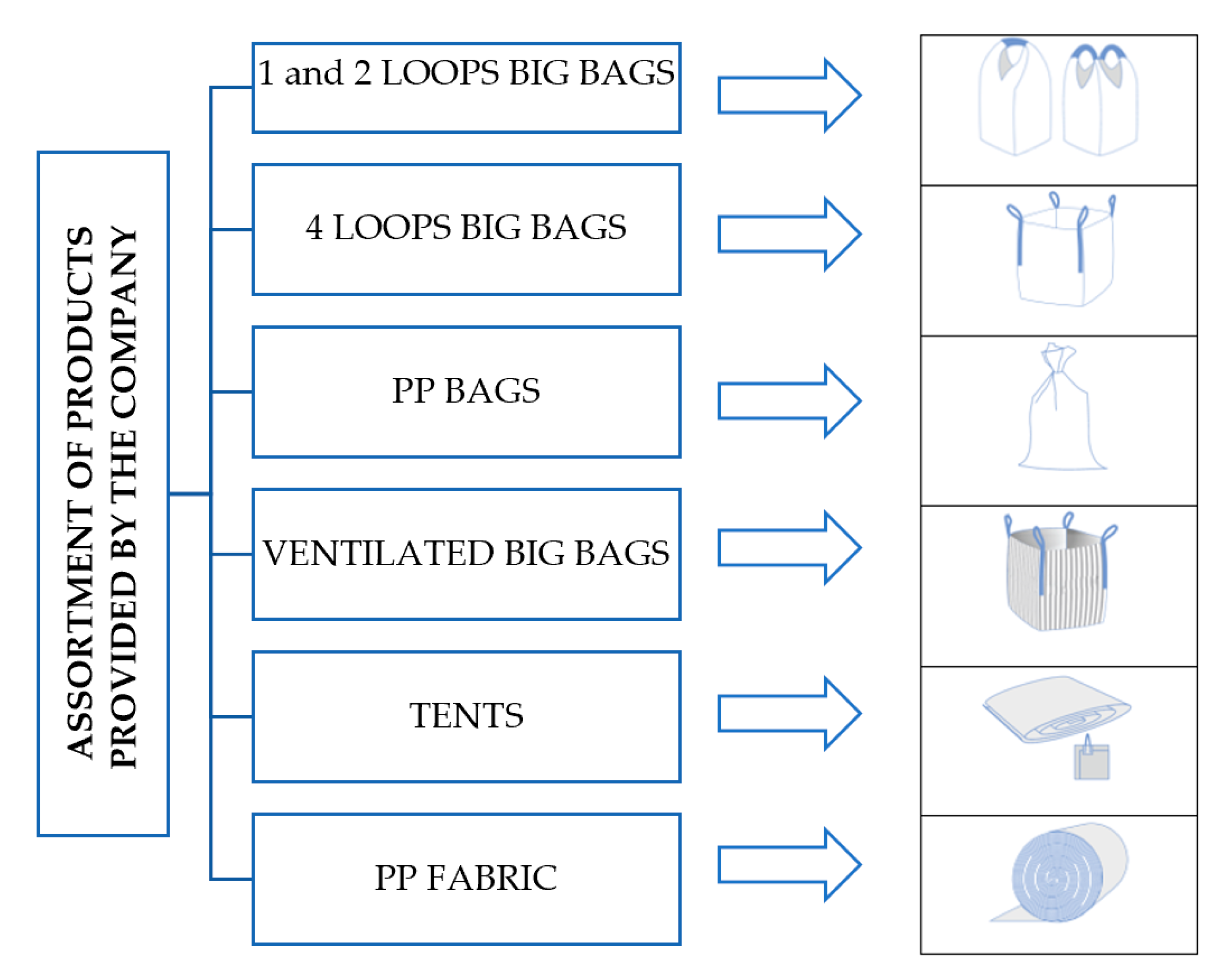

3.2. Case Setting

4. Results

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baregheh, A.; Rowley, J.; Sambrook, S. Towards a Multidisciplinary Definition of Innovation. Manag. Decis. 2009, 47, 1323–1339. [Google Scholar] [CrossRef]

- Zahra, S.A.; Covin, J.G. The financial implications of fit between competitive strategy and innovation types and sources. J. High Technol. Manag. Res. 1994, 5, 183–211. [Google Scholar] [CrossRef]

- Damanpour, F. Organizational innovation—A meta-analysis of effects of determinants and moderators. Acad. Manag. J. 1991, 34, 555–590. [Google Scholar]

- Kłodawski, M.; Jacyna, M.; Lewczuk, K.; Wasiak, M. The Issues of Selection Warehouse Process Strategies. Proc. Int. Sci. Conf. 2017, 187, 451–457. [Google Scholar] [CrossRef]

- Gimelshtein, E.; Godvan, D.; Ikonnikof, N. Warehouse logistics: Processes of integration of automation in modern warehouses. J. Bus. Educ. Knowl. Econ. 2021, 1. [Google Scholar]

- Negreeva, V.V.; Skobeleva, T.V. Research on improvement of warehouse activity of pharmaceutical firm. Sci. J. ITMO Ser. Econ. Environ. Manag. 2017, 3, 20–29. [Google Scholar] [CrossRef]

- Dede, B.; Çengel, O. Efficient Warehouse Management Analysis in Logistics Services; İstanbul Ticaret Üniversitesi Sosyal Bilimler Dergisi: Beyoglu, Turkey, 2020; Volume 1, pp. 341–352. Available online: https://dergipark.org.tr/en/download/article-file/1123558 (accessed on 16 April 2022).

- Aleksandrova, L.J.; Munshi, A.J. Actual problems of warehouse logistics and their solutions. J. Russ. Univ. Coop. 2020, 1. Available online: https://cyberleninka.ru/article/n/aktualnye-problemy-logistiki-na-sklade-i-ih-resheniya (accessed on 6 March 2022).

- Skuzovatova, N.V. Logistic aspects in the activities of trade enterprises. J. Intell. Innov. Invest. 2017, 3, 48–51. Available online: https://cyberleninka.ru/article/n/logisticheskie-aspekty-v-deyatelnosti-predpriyatiy-torgovli-orenburgskoy-oblasti (accessed on 14 March 2022).

- Zernov, E.V. Methods to improve the efficiency of the warehouse complex. J. Econ. 2017, 2. Available online: https://cyberleninka.ru/article/n/metody-povysheniya-effektivnosti-rabot-skladskogo-kompleksa (accessed on 16 May 2022).

- Nekrasov, K.V. Innovative methods of warehouse logistics at the enterprises of agro-industrial complex. J. Agric. Educ. Sci. 2019, 4. Available online: https://cyberleninka.ru/article/n/innovatsionnye-metody-skladskoy-logistiki-na-predpriyatiyah-apk (accessed on 2 March 2022).

- Zinchenko, A.V.; Krasnoplachtova, L.I. Research of automation means of warehouse accounting for trading companies. Int. J. Nat. Humanit. Res. 2017, 3. Available online: https://cyberleninka.ru/article/n/issledovanie-sredstv-avtomatizatsii-skladskogo-ucheta-dlya-torgovyh-kompaniy (accessed on 26 March 2022).

- Mubarik, M.S.; Rawi, D.; Khan, S.A. A DMAIC approach for warehouse storage and order picking process improvement. Int. J. Product. Qual. Manag. 2022; in press. [Google Scholar] [CrossRef]

- Mohamed, R.; Radi, B.; Okar, C. Development of a maturity model for the warehousing function in Moroccan companies. Int. J. Eng. Technol. 2017, 9, 280–290. [Google Scholar] [CrossRef][Green Version]

- Dragomirov, N. Fundamental knowledge areas in warehouse layout design. Knowl. Int. J. 2020, 41, 121–126. [Google Scholar]

- Karim, N.H.; Rahman, A.; Hamid, A.; Ismail, A.; Kader, A.; Muda, M.S. Revising the warehouse productivity measurement indicators: Ratio-based benchmark. Marit. Bus. Rev. 2020, 6, 149–171. [Google Scholar] [CrossRef]

- Kibria, K.; Khan, Y.K.; Morshed, M. Risk Minimization of Warehousing System by showing Probable Total Costs towards any Certain Company with the help of Monte Carlo Simulation. In Proceedings of the IMEOM 2017 Dhaka 1st International Conference on Industrial and Mechanical Engineering and Operations Management (IMEOM), Dhaka, Bangladesh, 23–24 December 2017; Available online: https://www.researchgate.net/publication/341489788_Risk_Minimization_of_Warehousing_System_by_showing_Probable_Total_Costs_towards_any_Certain_Company_with_the_help_of_Monte_Carlo_Simulation (accessed on 7 March 2022).

- Kudelska, I.; Pawłowski, G. Influence of assortment allocation management in the warehouse on the human workload. Cent. Eur. J. Oper. Res. 2020, 28, 779–795. [Google Scholar] [CrossRef]

- Kudelska, I.; Niedbał, R. Technological and Organizational Innovation in Warehousing Process—Research over Workload of Staff and Efficiency of Picking Stations. EM Econ. Manag. 2020, 23, 67–81. [Google Scholar] [CrossRef]

- Škerlič, S.; Muha, R.; Sokolovskij, E. Application of modern warehouse technology in the Slovenian automotive industry. Transport 2017, 32, 415–425. [Google Scholar] [CrossRef]

- Škerlič, S.; Muha, R. Reducing errors in the company’s warehouse process. Transp. Probl. 2017, 12, 83–92. [Google Scholar] [CrossRef][Green Version]

- Mostafa, N.; Hamdy, W.; Alawady, H. Impacts of Internet of Things on Supply Chains: A Framework for Warehousing. Soc. Sci. 2019, 8, 84. [Google Scholar] [CrossRef]

- Čolaković, A.; Čaušević, S.; Kosovac, A.; Muharemović, E. A Review of Enabling Technologies and Solutions for IoT Based Smart Warehouse Monitoring System. In Proceedings of the 6th International Conference “New Technologies, Development and Application”, Sarajevo, Bosnia and Herzegovina, 25–27 June 2020; Available online: https://www.researchgate.net/publication/341145054_A_Review_of_Enabling_Technologies_and_Solutions_for_IoT_Based_Smart_Warehouse_Monitoring_System (accessed on 4 April 2022).

- Chiang, T.; Che, Z.; Lee, C.; Liang, W. Applying Clustering Methods to Develop an Optimal Storage Location Planning-Based Consolidated Picking Methodology for Driving the Smart Manufacturing of Wireless Modules. Appl. Sci. 2021, 11, 9895. [Google Scholar] [CrossRef]

- Ho, T.H.D.; Daniel, J.; Nadeem, S.P.; Garza-Reyes, J.A.; Kumar, V. Improving the reliability of warehouse operations in the 3PL Industry: An Australian 3PL case study. In Proceedings of the Proceedings of the 2018 International Conference of the Production and Operations Management Society (POMS), Kandy, Sri Lanka, 14–16 December 2018; Available online: https://www.researchgate.net/publication/331687926_Improving_the_reliability_of_warehouse_operations_in_the_3PL_Industry_an_Australian_3PL_case_study (accessed on 12 March 2022).

- Freitas, A.M.; Silva, F.J.G.; Ferreira, L.P.; Pereira, J.C.; Sá, M.T.; Pereira, J. Improving efficiency in a hybrid warehouse: A case study. In Proceedings of the 29th International Conference on Flexible Automation and Intelligent Manufacturing, Limerick, Ireland, 24–28 June 2019. [Google Scholar]

- Singh, R.; Chaudharyb, N.; Saxena, N. Selection of warehouse location for a global supply chain: A case study. IIMB Manag. Rev. 2018, 30, 343–356. [Google Scholar] [CrossRef]

- Kusrini, E.; Asmarawati, C.I.; Sari, G.M.; Nurjanah, A.; Kisanjani, A.; Wibowo, S.A.; Prakoso, I. Warehousing performance improvement using Frazelle Model and per group benchmarking: A case study in retail warehouse in Yogyakarta and Central Java. MATEC Web Conf. 2018, 154, 01091. [Google Scholar] [CrossRef]

- Prananingtyasa, P.; Zulaekhah, P. The effect of logistics management, supply chain facilities and competitive storage costs on the use of warehouse financing of agricultural products. Uncertain Supply Chain Manag. 2021, 9, 457–464. [Google Scholar] [CrossRef]

- Olaku, A.P.; Shakantu, W.W.M.; Saidu, I. Assessing construction material manufacturers’ warehouse processes from a customer satisfaction perspective. J. Transp. Supply Chain Manag. 2021, 15, a529. [Google Scholar]

- Rahman, N.S.F.A.; Saifudin, A.M. Evaluation of Warehousing Productivity Performance Indicators by the FAHP Method. In Proceedings of the International Conference on Management in Emerging Markets (ICMEM), Bandung, Indonesia, 3–5 August 2020; Available online: https://www.researchgate.net/publication/344263363_Evaluation_of_Warehousing_Productivity_Performance_Indicators_by_the_FAHP_Method> (accessed on 23 May 2022).

- Appiah, A.; Teye, R.; Asare, J. Precursors of Warehousing Efficiency: An Empirical Study and Evaluation within an Industrialized Hub of a Developing Economy, Ghana. Int. J. Inf. Syst. Supply Chain Manag. 2018, 7, 135–152. [Google Scholar]

- Karim, N.H.; Rahman, A.; Shah, J. Empirical Evidence on Failure Factors of Warehouse Productivity in Malaysian Logistic Service Sector. Asian J. Shipp. Logist. 2018, 34, 151–160. [Google Scholar] [CrossRef]

- Habazin, J.; Glasnović, A.; Bajor, I. Order Picking Process in Warehouse: Case Study of Dairy Industry in Croatia. Traffic Transp. 2017, 29, 57–65. [Google Scholar] [CrossRef]

- Garmash, O.; Marchuk, O.Y.; Ovdiienko, O. World trends in warehousing logistics. Intellect. Logist. Supply Chain Manag. 2020, 2, 32–50. [Google Scholar]

- Putra, M.N.; Nurhakim, M.; Rifni, M.; Himawan, D. Optimization Enterprise Resource Planning (ERP) system on the control flow of material in Kalijapat Warehouse. J. Phys. Conf. Ser. 2020, 1573, 012026. [Google Scholar] [CrossRef]

- Zoubek, M.; Poór, P.; Broum, T.; Šimon, M. Methodology proposal for storage rationalization by implementing principles of industry 4.0. in a technology-driven warehouse. Trans. Famena 2020, 44, 75–98. Available online: https://hrcak.srce.hr/248011 (accessed on 12 March 2022). [CrossRef]

- De Kostera, R.; Johnson, A.; Roya, D. Warehouse design and management. Int. J. Prod. Res. 2017, 55, 6327–6330. [Google Scholar] [CrossRef]

- Yener, F.; Yazgan, H.R. Optimal warehouse design: Literature review and case study application. Comput. Ind. Eng. 2019, 129, 1–13. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0360835219300130?via%3Dihub (accessed on 24 March 2022). [CrossRef]

- Van Gils, T.; Ramaekers Braekers, K.; Depaire, B.; Carisa, A. Increasing Order Picking Efficiency by Integrating Storage, Batching, Zone Picking, and Routing Policy Decisions. Int. J. Prod. Econ. 2018, 197, 243–261. [Google Scholar] [CrossRef]

- Lorenc, A.; Lerher, T. Effectiveness of product storage policy according to classification criteria and warehouse size. FME Trans. 2019, 47, 142–150. [Google Scholar] [CrossRef]

- Gutelius, B.; Theodore, N. The Future of Warehouse Work: Technological Change in the U.S. Logistics Industry. A report from the UC Berkeley Center for Labor Research and Education and Working Partnerships USA. 2019. Available online: https://www.researchgate.net/publication/336723736_The_Future_of_Warehouse_Work_Technological_Change_in_the_US_Logistics_Industry (accessed on 10 May 2022).

- Giannikas, V.; Lu, W.; Robertson, B.; McFarlane, D. An interventionist strategy for warehouse order picking: Evidence from two case studies. Int. J. Prod. Econ. 2017, 189, 63–76. [Google Scholar] [CrossRef]

- Giannikas, V.; Woodall, P.; McFarlane, D.; Lu, W. The impact of B2C commerce on traditional B2B warehousing. In Proceedings of the 22nd International Symposium on Logistics, Ljubljana, Slovenia, 9–11 July 2017; Available online: https://www.researchgate.net/publication/321315173_The_impact_of_B2C_commerce_on_traditional_B2B_warehousing (accessed on 12 March 2022).

- Dauod, H.; Lee, I.; Chung, S.H.; Yoon, S.W. Optimization of Warehouse Storage Assignment Using Community Detection and Integer Programming. In Proceedings of the 6th Annual World Conference of the Society for Industrial and Systems Engineering, Herndon, VA, USA, 19–20 October 2017; Available online: https://www.researchgate.net/publication/327285141_Optimization_of_Warehouse_Storage_Assignment_Using_Community_Detection_and_Integer_Programming (accessed on 5 December 2021).

- Lorenc, A.; Szkoda, M.; Szarata, A.; Jacyna-Gołda, I. Evaluation of the effectiveness of methods and criteria for product classification in the warehouse. Eur. J. Ind. Eng. 2020, 14, 2. [Google Scholar] [CrossRef]

- Caprili, S.; Morelli, F.; Salvatore, W.; Natali, A. Design and Analysis of Automated Rack Supported Warehouses. Open Civ. Eng. J. 2018, 12, 150–166. [Google Scholar] [CrossRef]

- Tsarpalis, D.; Vamvatsikos, D.; Vayas, I.; Delladonna, F. Simplified Modeling for the Seismic Performance Assessment of Automated Rack-Supported Warehouses. J. Struct. Eng. 2021, 147. [Google Scholar] [CrossRef]

- Kudelska, I.; Kosacka, M.; Lewandowska, K.W. How to support storage process in dismantling facility with IT solutions?—Case study. In Proceedings of the 27th International Conference on Flexible Automation and Intelligent Manufacturing, FAIM, Modena, Italy, 27–30 June 2017; Available online: https://www.researchgate.net/publication/319893842_How_to_Support_Storage_Process_in_Dismantling_Facility_with_IT_Solutions_-_Case_Study (accessed on 5 December 2021).

- Martins, R.M.; Pereira, T.; Ferreira, L.P.; Sá, J.C.; Silva, F.J.G. Warehouse operations logistics improvement in a cork stopper factory. Sci. Procedia Manuf. 2020, 51, 1723–1729. [Google Scholar] [CrossRef]

- Petryla, K. LEAN ir Apribojimų Teorija; Didakta: Vilnius, Lithuania, 2018. [Google Scholar]

- Kučera, T. Logistics Cost Calculation of Implementation Warehouse Management System: A Case Study. In Proceedings of the 18th International Scientific Conference—LOGI 2017, Kouty nad Desnou, Czech Republic, 17–19 May 2017; ISBN 2261-236X. Available online: https://dk.upce.cz//handle/10195/69936 (accessed on 15 November 2021).

- Dujmešic, N.; Bajor, I.; Rožic, T. Warehouse Processes Improvement by Pick by Voice Technology. Teh. Vjesn. 2018, 25, 1227–1233. [Google Scholar]

- Najy, R.J. MRP (Material Requirement Planning) Applications in Industry-A REVIEW. J. Bus. Manag. 2020, 6, 2455–2666. [Google Scholar]

- Badewole, A. A Report on material requirement planning I, II & III. Tech. Rep. 2020, 1–15. [Google Scholar] [CrossRef]

- Utami, F.D.; Puspitasari, W.; Saputra, M.P.A. Design of planning model for ERP system in warehouse management: An empirical study of public hospital in Indonesia. IOP Conf. Ser. Mater. Sci. Eng. 2020, 909, 012061. [Google Scholar] [CrossRef]

- Mankazana, S.; Mukwakungu, S.C. The Impact of Just-in-Time (JIT) in Inventory Management System and the Supplier Overall Performance of South African’s Bed Mattress Manufacturing Companies. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Pretoria/Johannesburg, South Africa, 29 October–1 November 2018; Available online: https://www.researchgate.net/publication/333185530_The_Impact_of_Just-in-Time_JIT_in_Inventory_Management_System_and_the_Supplier_Overall_Performance_of_South_African’s_Bed_Mattress_Manufacturing_Companies (accessed on 12 March 2022).

- Jemelka, M.; Chramcov, B.; Kriz, P.; Bata, T. ABC analyses with recursive method for warehouse. In Proceedings of the 4th International Conference on Control, Decision and Information Technologies, CoDIT, Barcelona, Spain, 5–7 April 2017. [Google Scholar] [CrossRef]

- Austin, Z.; Sutton, J. Qualitative research: Getting started. Can. J. Hosp. Pharm. 2014, 67, 436–440. [Google Scholar] [CrossRef]

- Miles, M.B.; Huberman, A.M.; Saldana, J. Qualitative Data Analysis. A Methods Sourcebook, 4th ed.; SAGE Publications: Thousand Oaks, CA, USA, 2019. [Google Scholar]

- Gaižauskaitė, I.; Valavičienė, N. Socialinių Tyrimų Metodai: Kokybinis Interviu; Registrų Centras: Vilnius, Lithuania, 2016. [Google Scholar]

- Kardelis, K. Mokslinių Tyrimų Metodologija ir Metodai; Mokslo ir Enciklopedijų Leidybos Centras: Vilnius, Lithuania, 2016. [Google Scholar]

- Žydžiūnaitė, V.; Sabaliauskas, S. Kokybiniai Tyrimai, Principai ir Metodai; Vaga: Vilnius, Lithuania, 2017. [Google Scholar]

- Md Hanafiah, R.; Karim, N.H.; Abdul Rahman, N.S.F.; Abdul Hamid, S.; Mohammed, A.M. An Innovative Risk Matrix Model for Warehousing Productivity Performance. Sustainability 2022, 14, 4060. [Google Scholar] [CrossRef]

- Tavasszy, L.A. Predicting the effects of logistics innovations on freight systems: Directions for research. Transp. Policy 2020, 86, A1–A6. [Google Scholar] [CrossRef]

- El Hamdi, S.; Abouabdellah, A. Logistics: Impact of Industry 4.0. Appl. Sci. 2022, 12, 4209. [Google Scholar] [CrossRef]

- Klein, M.; Gutowska, E.; Gutowski, P. Innovations in the T&L (Transport and Logistics) Sector during the COVID-19 Pandemic in Sweden, Germany and Poland. Sustainability 2022, 14, 3323. [Google Scholar] [CrossRef]

- Milewski, D. Managerial and Economical Aspects of the Just-In-Time System “Lean Management in the Time of Pandemic”. Sustainability 2022, 14, 1204. [Google Scholar] [CrossRef]

- Raghuram, P.; Arjunan, M.K. Design framework for a lean warehouse—A case study-based approach. Int. J. Product. Perform. Manag. 2022, 71, 2410–2431. [Google Scholar] [CrossRef]

| Authors | Concept |

|---|---|

| Mubarik et al. [13] | Warehousing plays an integrative role in the supply chain as it is the link between production, the market, suppliers, customers, and the overall business environment. |

| Mohamed et al. [14] | Storage plays an important role in modern supply chains. It is the coordinating node of the material flow between the services of the company. It is also a coordinating node between suppliers and customers. |

| Dragomirov [15] | Warehouses are an integral part of any efficient logistics system. Through their integration, issues related to the movement of material flows in the supply chain, from the supplier to the consumer, are addressed. |

| Karim et al. [16] | The role of the warehouse in the supply chain is very important, as it is used during production to store products until they are delivered to consumers on demand. In today’s highly competitive business environment, a warehouse is not just a storage space for products; the warehouse also manages and provides value-added services. |

| Kibria et al. [17] | Storage is a mandatory part of any existing distribution network designed for the long-term storage of goods: raw materials, technological materials, packaging materials, or finished products related to production. Storage provides the usefulness of time and space for any product. |

| Kudelska and Pawłowski [18] | Warehouses are important points in every business and supply chain. |

| Kudelska and Niedbał [19] | Today, almost every company has its own warehouse or rents it out. Modern warehouses, therefore, play an important role in production and service networks. Today’s warehouses should be described as the implementation of rapid warehousing processes between the collection and issuance stages. |

| Škerlič et al. [20] | Warehousing is one of the activities that require many systems to ensure security and the quality of work processes, as errors can occur during warehousing operations. |

| Škerlič and Muha [21] | Warehousing is a labor-intensive process: warehouse operators must use different working methods and equipment and move constantly. |

| Mostafa et al. [22] | Warehouses are a key part of the supply chain. They are used to store products and manage inventory levels. |

| Čolaković et al. [23] | Warehouses are premises used to store goods, the main task of which is to ensure their security, value, and quality. A warehouse is a complex environment that uses a variety of processes and operations to perform acquisition, storage, and issuance. |

| Chiang et al. [24] | Because every link in the supply chain must maintain very high efficiencies, warehousing is an integral part of the supply chain. Warehousing activities include receiving, placing, internal replenishment, order picking, sorting, packing, and shipping. |

| Dieu Ho et al. [25] | Warehouses provide significant added value by providing a competitive advantage, supporting business growth and efficiency throughout the supply chain. |

| Freitas et al. [26] | A warehouse can be defined as a material handling station for the reception, storage, and preparation for dispatch of raw materials, semi-finished or finished products. The role of warehouses in modern logistics is becoming increasingly important due to the rapid growth of e-commerce transactions, the reduction of desired inventory, and rapid response to customer requests. |

| Singh et al. [27] | Warehouses are a very important part of the supply chain in local or international markets. Warehouse location determines speed and efficiency in the supply chain. The warehouse is a large building that stores raw materials and manufactured products before they are sent to customers. |

| Kusrini et al. [28] | Warehousing activities depend on the variety and number of goods, the daily workload, and the diversity of processes required to meet the needs of customers and suppliers. The warehouse activities are divided into five activities: receiving, postponing, storing, collecting, and shipping orders. |

| Prananingtyasa and Zulaekhah [29] | Various studies have confirmed the important role of warehousing as a basis for the supply chain management. |

| Olaku et al. [30] | Warehousing is part of the company’s logistics function, which is responsible for warehousing and inventory management, from the receipt of goods to the dispatch process. |

| Rahman and Saifudin [31] | A warehouse is an important element of logistics operations as it contributes to supply chain performance and management costs. |

| Appiah et al. [32] | Warehouses play a key role in creating added value in the service supply chain. Warehousing involves the performance of administrative and physical functions related to the storage of goods and materials. |

| Karim et al. [33] | A warehouse is more than a place to store. The goals of warehouse management are to increase productivity, reduce inventory levels, and maintain good customer service. |

| Dragomirov [15] | Warehousing is a purposeful stocking activity that ensures the regular flow of production processes. |

| Habazin et al. [34] | Storage means picking up, handling, transporting, loading, unloading, packing, handling, and shipping. |

| Garmash et al. [35] | Warehouse logistics is an essential part of a company’s operations and occupies a large part of it. Warehouses provide warehousing, processing, and distribution services between producers and end users. The warehouse is considered an integrated component in the logistics chain that allows a high level of profitability to be achieved. |

| Putra et al. [36] | A warehouse is an area that performs the function of storing materials or manufactured goods over a period. |

| Authors | Problem Groups | Solutions for the Improvement |

|---|---|---|

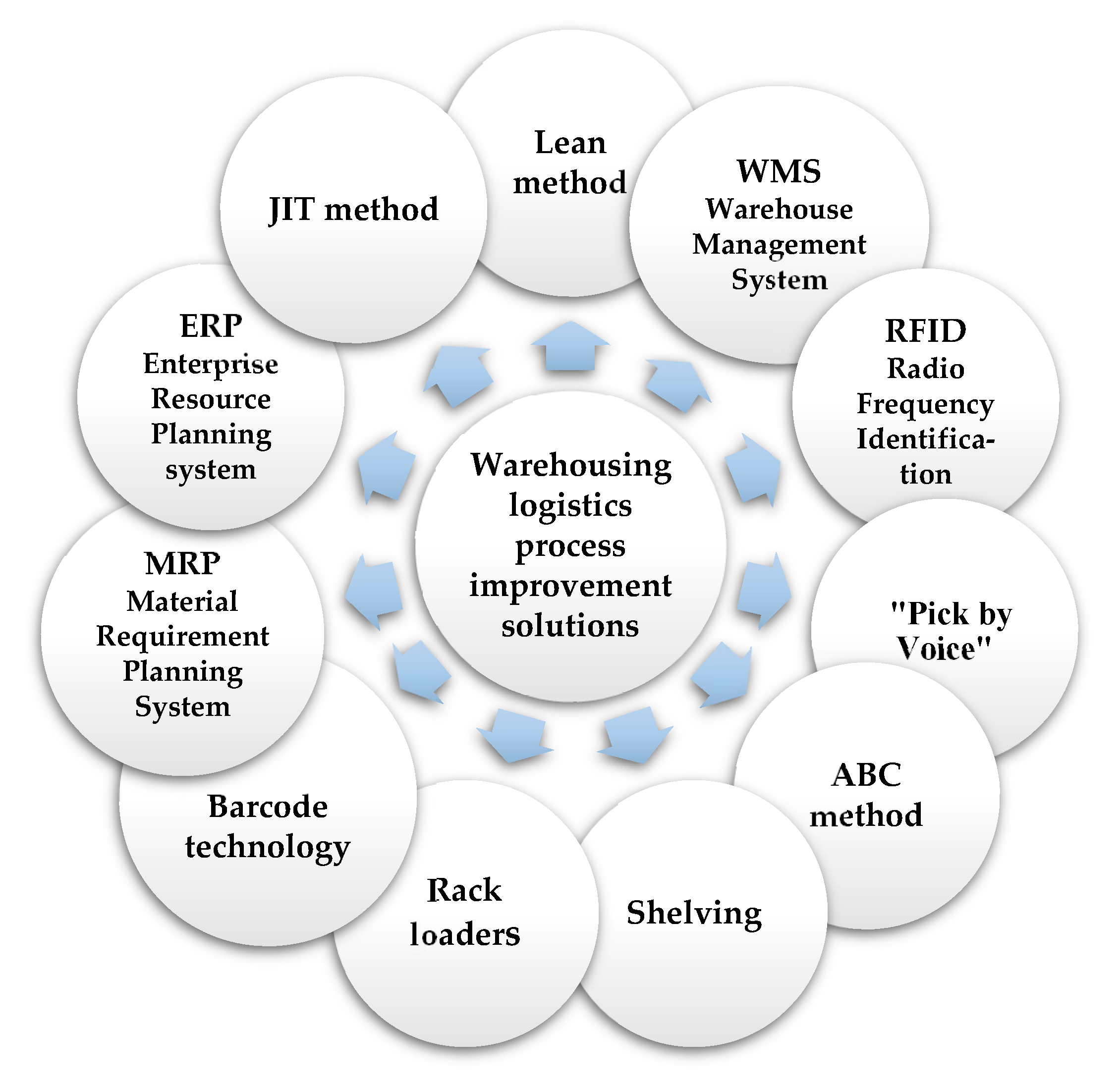

| Habazin et al. [34], Dieu Ho et al. [25], Škerlič and Muha [20,21], Chiang et al. [34], Dauod et al. [24], Kłodawski et al. [4], Mubarik et al. [13], Lorenc et al. [46], Lorenc and Lerher [41], Giannikas et al. [43] | Problems in the warehouse order collection process—70 percent time and 55 percent costs. | Effective planning of warehouse space; optimization of collection time and route; implementation of warehouse management systems (WMS); using the ABC method. |

| Caprili et al. [47], Tsarpalis et al. [48] | Inefficient use of warehouse space. | Use of appropriate functional equipment: racks, rack loaders. |

| Dieu Ho et al. [25], Kudelska and Niedbał [18], Škerlič et al. [20], Zoubek et al. [34] | Occurrence of various errors in warehouse processes; lmproper work of warehouse staff. | Training of employees; Implementation of warehouse management system; Implementation of warehouse process technology “Pick by Voice”. |

| Kusrini et al. [28], Olaku et al. [30], Karim et al. [16], Kudelska and Niedbał [19], Škerlič and Muha [21], Kudelska, et al. [49] | Gaps in warehouse processes: automation—20 percent, manual work—80 percent; long delivery time problems, dissatisfied customers. | Implementation of technological solutions: use of (ERP) enterprise resource planning system, (WMS) warehouse management system implementation. |

| Škerlič and Muha [21] | Automation problems: more complex tasks, mistakes made by warehouse keepers. | Training and motivating employees to work well. |

| Dieu Ho et al. [25], Kudelska and Pawłowski [18] | Security issues. | Use of safe work equipment, good warehouse layout that does not create congestion, and compliance with work safety rules. |

| Martinsa et al. [50], Petryla [51] | Improper planning and lack of storage space. | Applying the Lean method to storage activities. |

| Kučera [52], Aleksandrova and Munshi [8], Prananingtyasa and Zulaekhah [29] | 100 percent underutilization of storage capacity. | Implementation of warehouse management systems (WMS). |

| Dujmešic, Bajor and Rožic [53], Kudelska and Pawłowski [18], Škerlič and Muha [21] | Inefficiency and unproductivity of warehouse processes. | Implementation of warehouse process technology “Pick by Voice”; implementation of Warehouse Management System (WMS). |

| Zoubek et al. [37], Škerlič and Muha [21] | Storage inefficiency and lack of storage space. | Use of barcode technology; (RFID) Use of radio frequency identification technology; Use of Real Time Location System; Smart scanning technology; Using the ABC method; Automated vehicle. |

| Najy [54], Badewole [55], Putra et al. [36], Utami et al. [56], Mankazana and Mukwakungu [57] | Lack of storage space. | Use of (MRP) material requirements planning system; Use of (ERP) enterprise resource planning system; Use of (JIT) Just-in-Time method. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perkumienė, D.; Ratautaitė, K.; Pranskūnienė, R. Innovative Solutions and Challenges for the Improvement of Storage Processes. Sustainability 2022, 14, 10616. https://doi.org/10.3390/su141710616

Perkumienė D, Ratautaitė K, Pranskūnienė R. Innovative Solutions and Challenges for the Improvement of Storage Processes. Sustainability. 2022; 14(17):10616. https://doi.org/10.3390/su141710616

Chicago/Turabian StylePerkumienė, Dalia, Kristina Ratautaitė, and Rasa Pranskūnienė. 2022. "Innovative Solutions and Challenges for the Improvement of Storage Processes" Sustainability 14, no. 17: 10616. https://doi.org/10.3390/su141710616

APA StylePerkumienė, D., Ratautaitė, K., & Pranskūnienė, R. (2022). Innovative Solutions and Challenges for the Improvement of Storage Processes. Sustainability, 14(17), 10616. https://doi.org/10.3390/su141710616