Effect of Weak Zones on Resilience of Sustainable Surface Course Mixtures of Fresh-Reclaimed Asphalt Pavement

Abstract

:1. Introduction

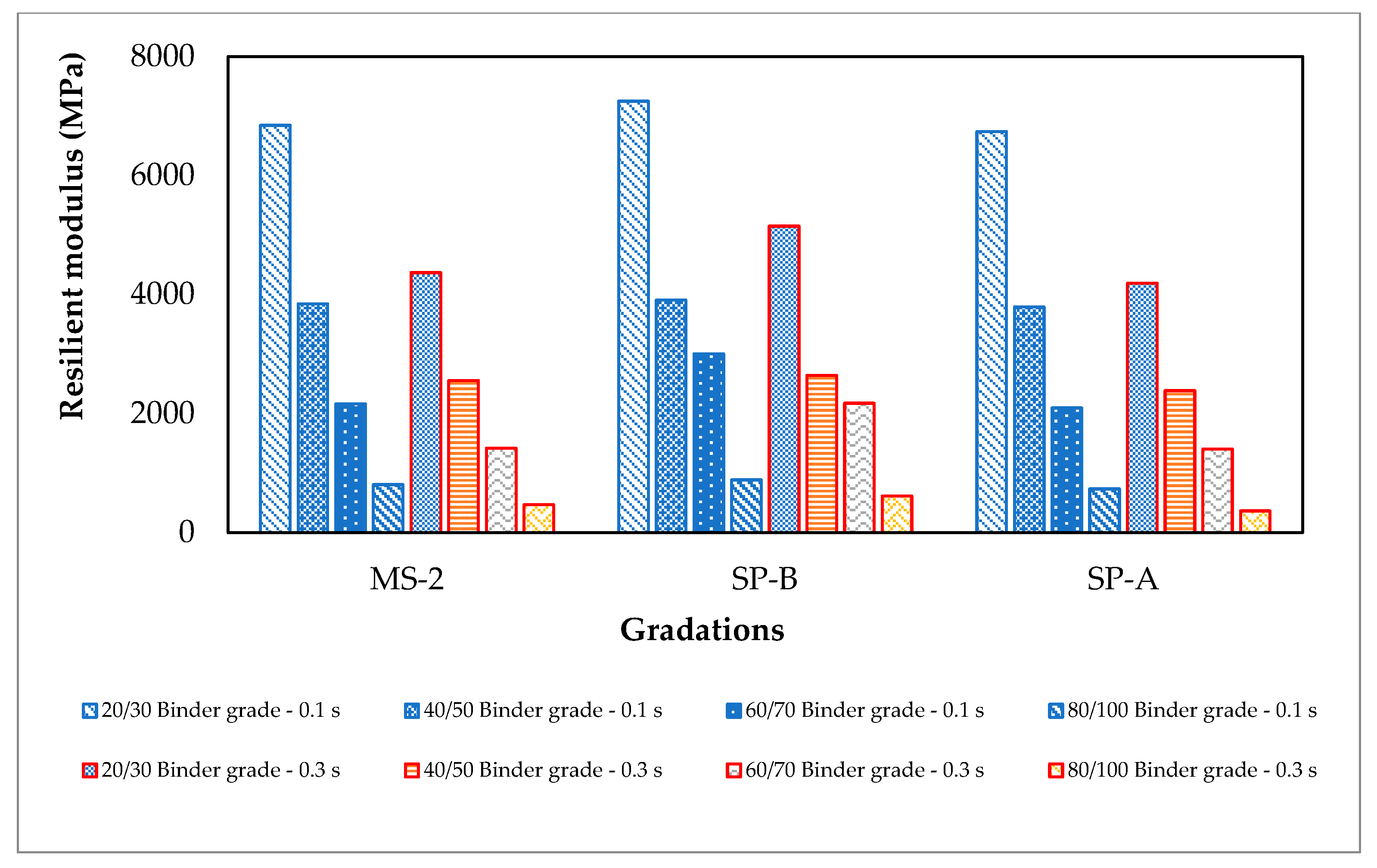

- To determine the resilient modulus (MRT) of asphalt mixtures prepared with 20/30, 40/50, 60/70 and 80/100 grade binders for surface course gradations (such as SP-A, SP-B and MS-2) of fresh asphalt aggregate and 20% reclaimed asphalt pavement (RAP) mixture at different temperatures and load durations.

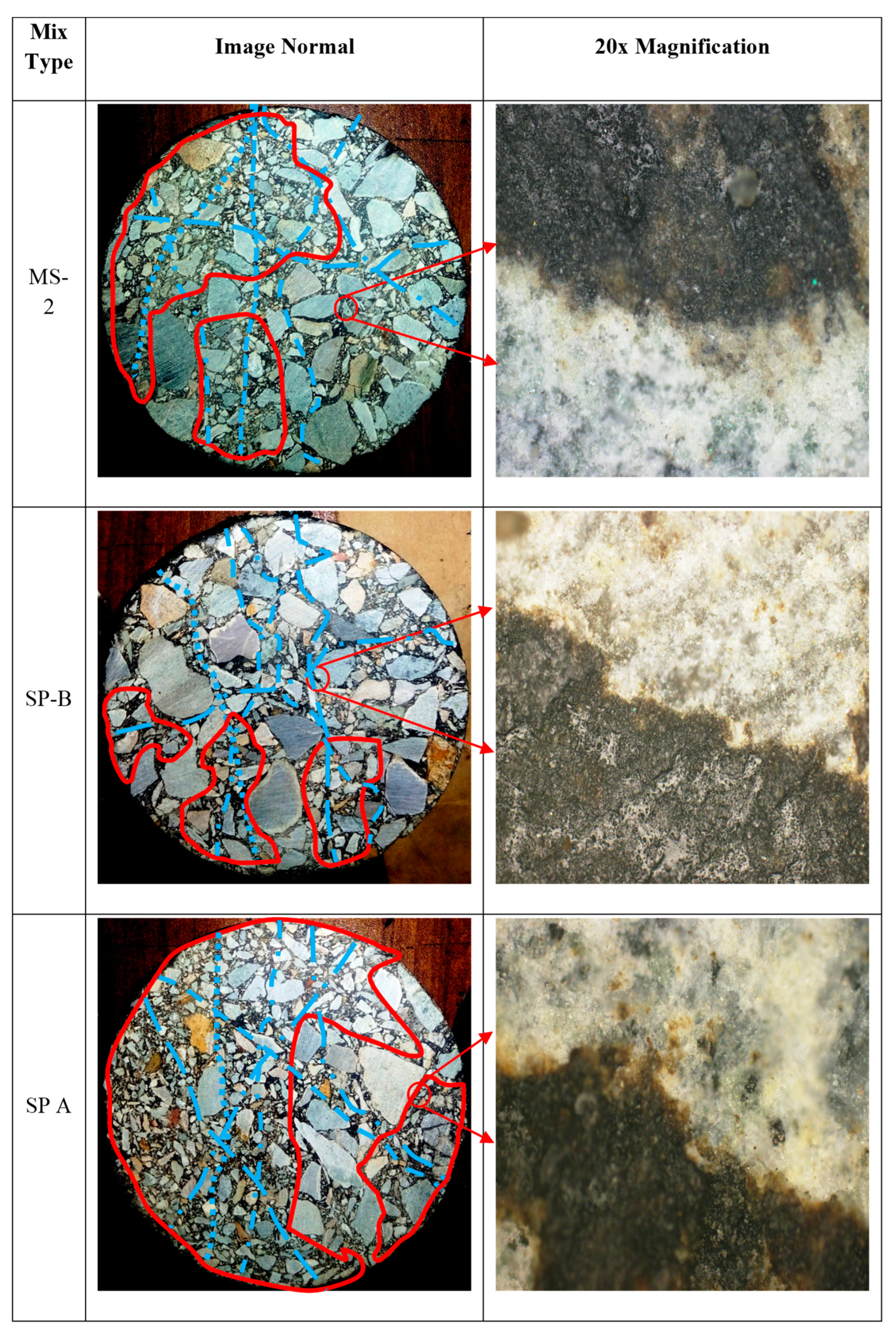

- To conduct image analysis to view the orientation of aggregate particles of fresh asphalt and RAP for the determination of weak zones.

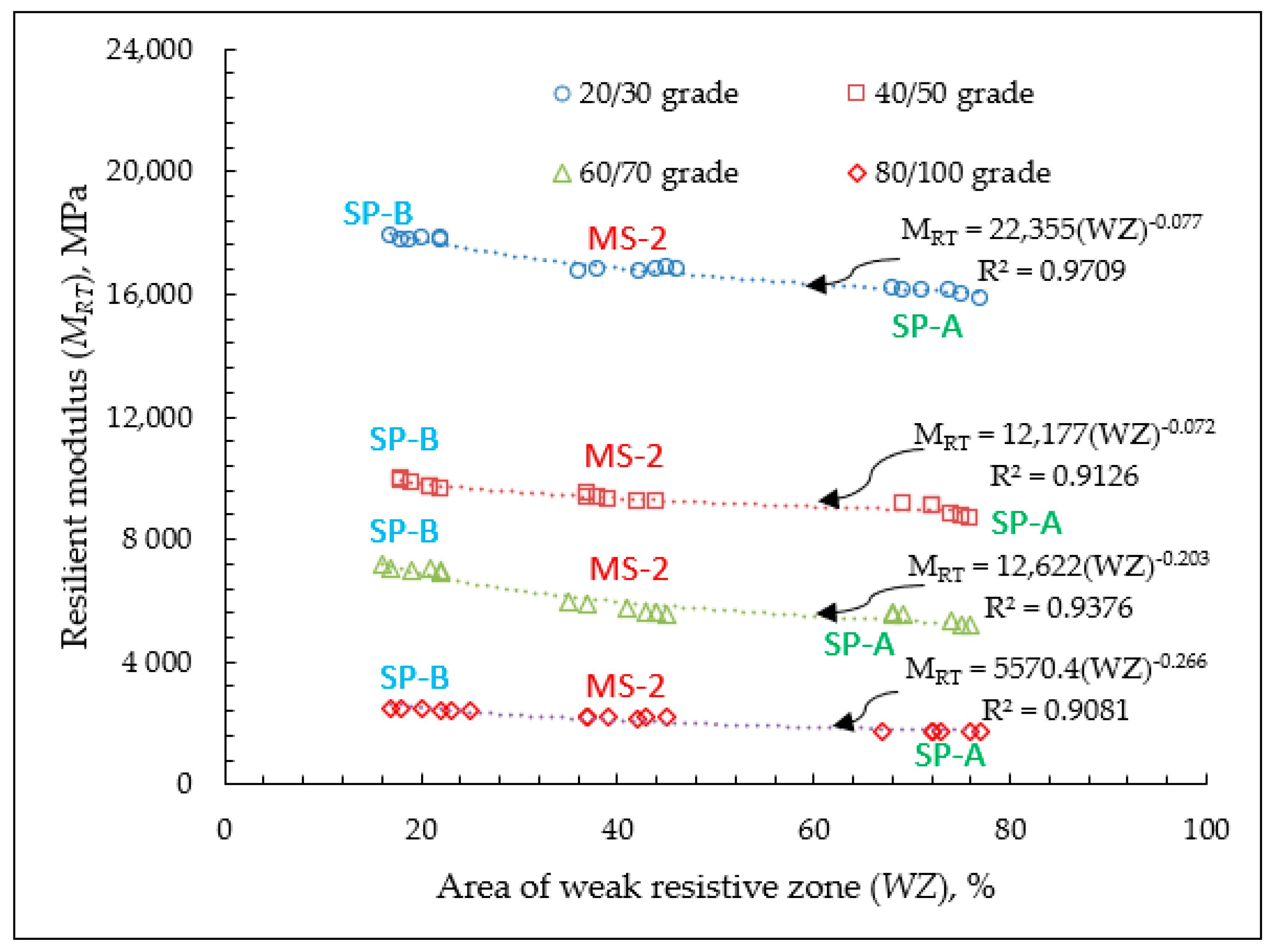

- To compare the areas of weak zones and MRT.

2. Materials and Methods

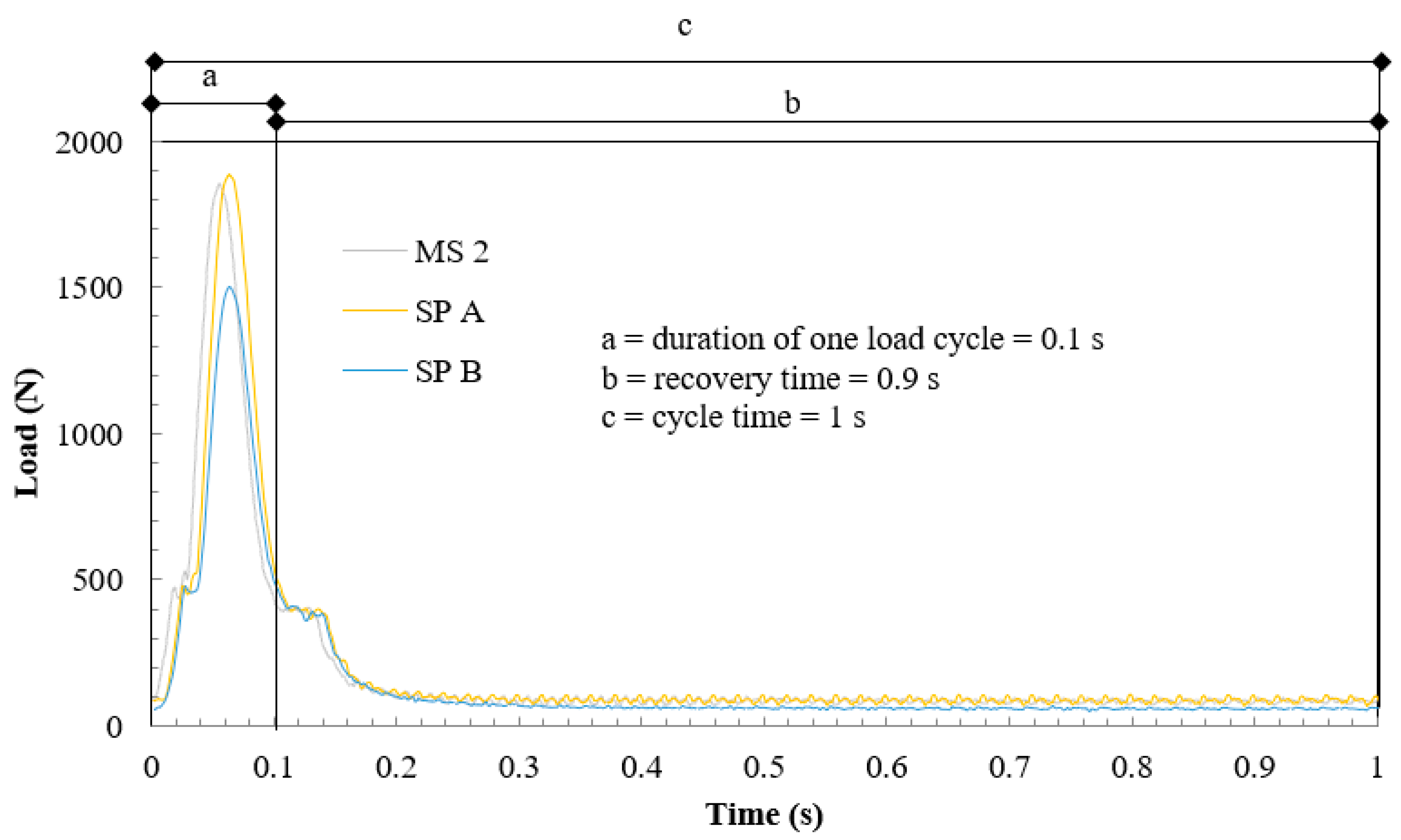

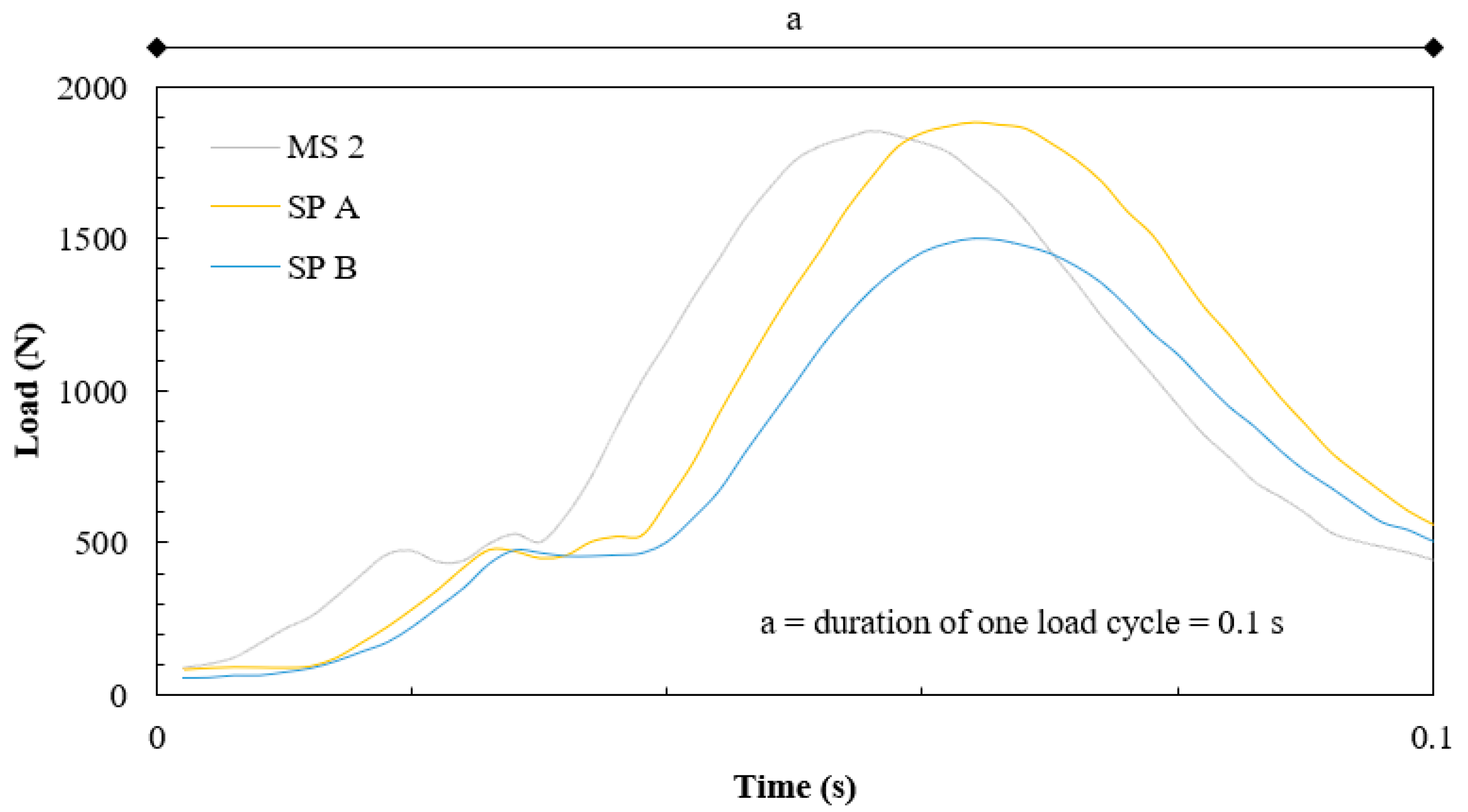

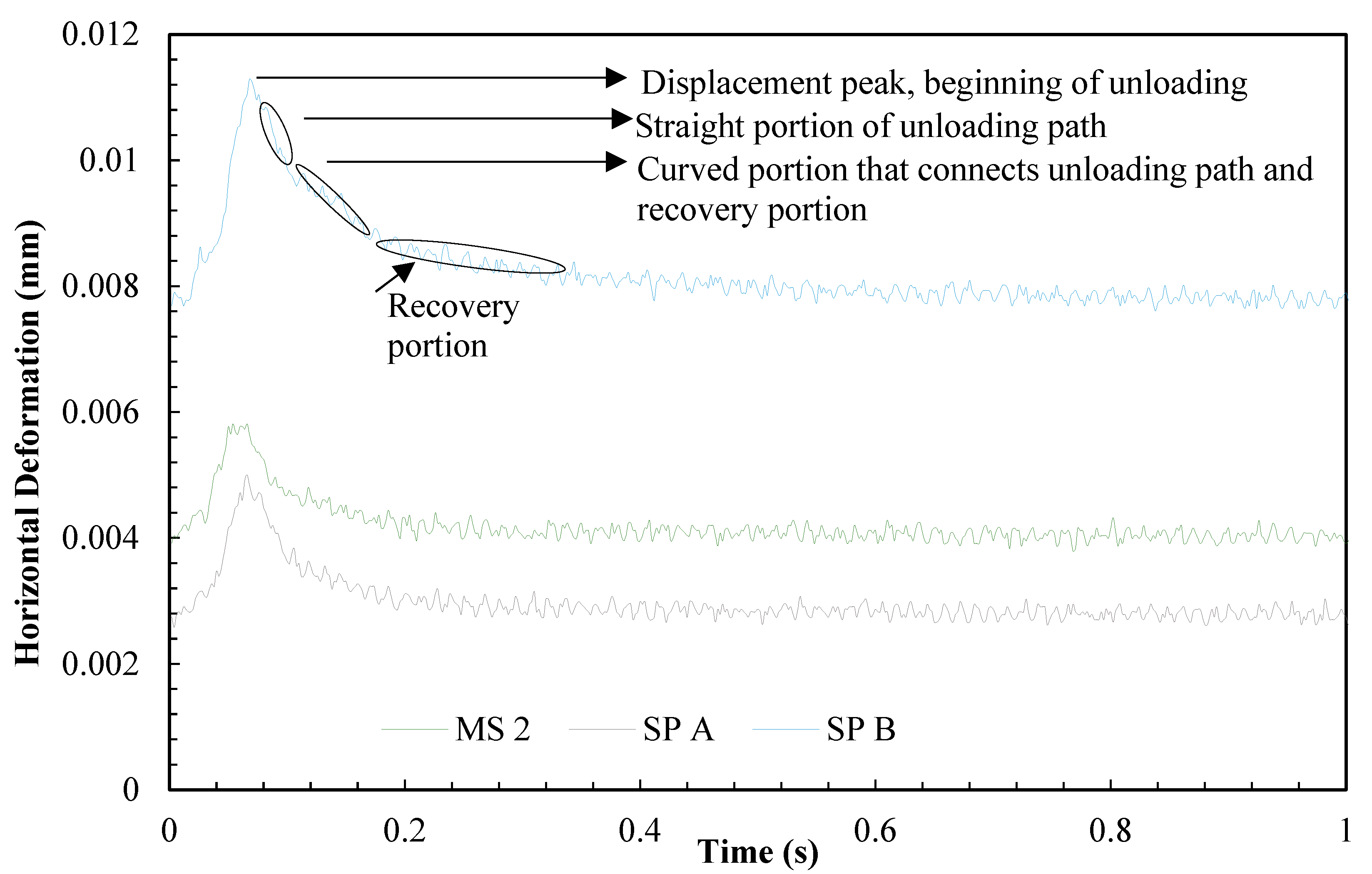

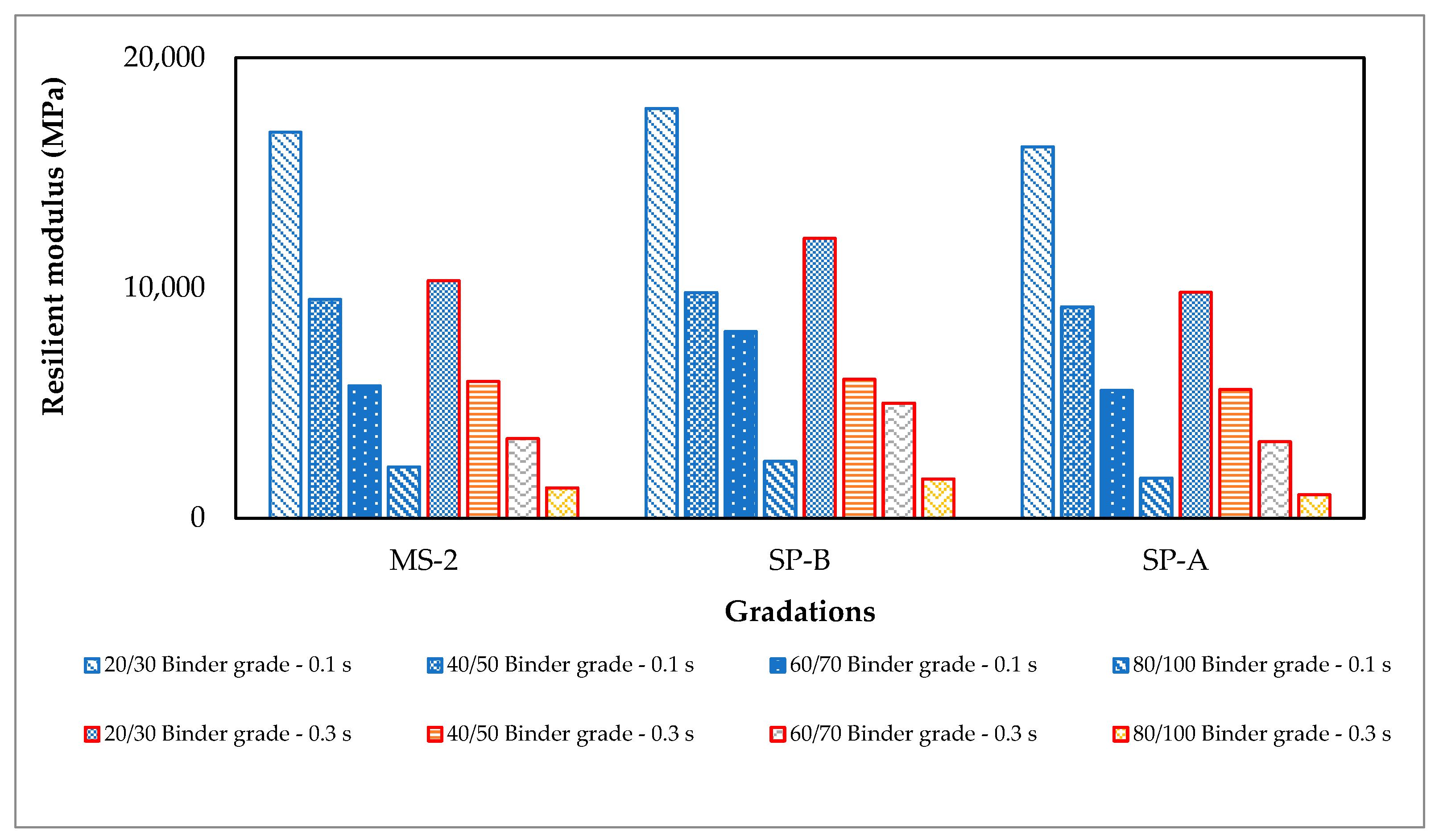

3. Results and Discussions

4. Conclusions

- This study shows that the 20/30 grade binder enhanced the MRT up to 1.8, 2.9 and 9.2 times for a 0.1 s load duration and 2.4, 3.0 and 9.7 times for a 0.3 s load duration at 25 °C, whereas a rise in MRT was observed to enhance the MRT 1.9, 3.1 and 9.7 times for 0.1 s load duration and 1.9, 3.0 and 12.4 times for 0.3 s load duration at 40 °C, when compared with 40/50, 60/70 and 80/100 binder grades, respectively. Hence, this study presents the selection of a sustainable grade of binder to achieve a high resilience in roads.

- MRT was observed to decrease, in order, for different grades such as 20/30 > 40/50 > 60/70 > 80/100, and for different gradations in the order SP-B > MS-2 > SP-A. The SP-B showed the highest resilient modulus and maximum sustainability potential. Experimental results were validated by factorial analyses and found the data in good health.

- Images of asphalt mixture specimens can be used to measure the area of weak zones (WZ) for the reasonable prediction of resilient modulus of sustainable surface course road mixtures.

- Area of weak zones (WZ) in asphalt mixes is controlled more by aggregate RAP gradations than the asphalt binder grade.

- Resilient modulus (MRT) decreases with the increase in the area of weak zones (WZ) for 20/30, 40/50, 60/70 and 80/100 binder grades involving MS-2, SP-B and SP-A gradations for 0.1 s and 0.3 s load durations at both 25 °C and 40 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, M.Z.H.; Koting, S.; Katman, H.Y.B.; Ibrahim, M.R.; Babalghaith, A.M.; Asqool, O. Performance of High Content Reclaimed Asphalt Pavement (RAP) in Asphaltic Mix with Crumb Rubber Modifier and Waste Engine Oil as Rejuvenator. Appl. Sci. 2021, 11, 5226. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Tanakizadeh, A. Evaluation of resilient behavior of flexible pavement asphalt layers. Mater. Struct. 2016, 49, 2829–2840. [Google Scholar] [CrossRef]

- Ji, S.J. Investigation of Factors Affecting Resilient Modulus for Hot Mix Asphalt. Master’s Thesis, University of Canterbury, Christchurch, New Zealand, 2006. [Google Scholar]

- Maqbool, S.; Khan, A.H.; Rizvi, M.A.; Inam, A.; Kashmiri, F.A. Modelling and evaluating moisture suceptability of laboratory prepared asphalt concrete mixtures. Ain. Shams Eng. J. 2022, 13, 101512. [Google Scholar] [CrossRef]

- Maqbool, S.; Khan, A.H.; Inam, A.; Sultan, T.; Rashid, M.U.; Rizvi, M.A. Effects of fines content on dry and saturated indirect tensile strength of hot mix asphalt mxtures. Tech. J. Univ. Eng. Technol. Taxila Pak. 2015, 20, 2015. [Google Scholar]

- Wang, X.S.; Fan, T.T. Optimization in Process Parameters of Calcium Sulfate Whisker Modified Asphalt Using Response Surface Methodology. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 2841–2851. [Google Scholar] [CrossRef]

- Gong, X.; Liu, W.; Ying, H. Phase Change Heat-induced Structure of Asphalt Pavement for Reducing the Pavement Temperature. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 46, 1–14. [Google Scholar] [CrossRef]

- Sánchez-Leal, F.J. Gradation chart for asphalt mixes: Development. J. Mater. Civ. Eng. 2007, 19, 185–197. [Google Scholar] [CrossRef]

- Rinaldini, E.; Schuetz, P.; Partl, M.N.; Tebaldi, G.; Poulikakos, L.D. Investigating the blending of reclaimed asphalt with virgin materials using rheology, electron microscopy and computer tomography. Compos. Part B Eng. 2014, 67, 579–587. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant produced pavements: State of the art. Int. J. Pavement Eng. 2014, 16, 39–55. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% Hot Mix Asphalt Recycling: Challenges and Benefits. Transp. Res. Procedia 2016, 14, 3493–3502. [Google Scholar] [CrossRef]

- Xu, X.; Luo, Y.; Sreeram, A.; Wu, Q.; Chen, G.; Cheng, S.; Chen, Z.; Chen, X. Potential use of recycled concrete aggregate (RCA) for sustainable asphalt pavements of the future: A state-of-the-art review. J. Clean. Prod. 2022, 344, 130893. [Google Scholar] [CrossRef]

- Huang, Y.H. Pavement Analysis and Design; Pearson Education: London, UK, 1993. [Google Scholar]

- Fakhri, M.; Ghanizadeh, A.R. An experimental study on the effect of l0oading history parameters on the resilient modulus of conventional and SBS-modified asphalt mixes. Constr. Build. Mater. 2014, 53, 284–293. [Google Scholar] [CrossRef]

- Rizvi, M.A.; Khan, A.H.; Rehman, Z.; Inam, A.; Masoud, Z. Evaluation of linear deformation and unloading stiffness characteristics of asphalt mixtures incorporating various aggregate gradations. Sustainability 2021, 13, 8865. [Google Scholar] [CrossRef]

- Tahmoorian, F.; Yeaman, J.; Mirzababaei, M. Comparisons of the resilient moduli of asphalt mixes containing recycled materials through empirical and experimental methods. J. Mater. Civ. Eng. 2020, 32, 04020255. [Google Scholar] [CrossRef]

- Vaitkus, A.; Vorobjovas, V. Use of local aggregates in high modulus asphalt concrete layers. Građevinar 2013, 65, 353–360. [Google Scholar]

- Zou, X.; Sha, A.; Jiang, W.; Huang, X. Modification mechanism of high modulus asphalt binders and mixtures performance evaluation. Constr. Build. Mater. 2015, 90, 53–58. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Zhao, L.; Cao, D. Experimental study on rheological characteristics and performance of high modulus asphalt binder with different modifiers. Constr. Build. Mater. 2017, 155, 26–36. [Google Scholar] [CrossRef]

- Leiva-Villacorta, F.; Taylor, A.; Willis, R. High-Modulus Asphalt Concrete (HMAC) Mixtures for Use as Base Course; National Center for Asphalt Technology Report; FHWA: Auburn, AL, USA, 2017; pp. 17–24. [Google Scholar]

- Qian, G.; Yao, D.; Gong, X.; Yu, H.; Li, N. Performance evaluation and field application of hard asphalt concrete under heavy traffic conditions. Constr. Build. Mater. 2019, 228, 116729. [Google Scholar] [CrossRef]

- Xu, X.; Lu, G.; Yang, J.; Liu, X. Mechanism and rheological properties of high-modulus asphalt. Adv. Mater. Sci. Eng. 2020, 2020, 8795429. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Xu, S.; You, Z. High modulus asphalt concrete: A state-of-the-art review. Constr. Build. Mater. 2020, 237, 117653. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Bu, Y.; You, Z.; Yang, X.; Oeser, M. Correlate aggregate angularity characteristics to the skid resistance of asphalt pavement based on image analysis technology. Constr. Build. Mater. 2020, 242, 118150. [Google Scholar] [CrossRef]

- OuYang, W.; Yu, G.F.; Zhu, F.F. Research on anti-rutting performance of high modulus asphalt concrete pavement. Adv. Mater. Res. 2011, 163, 4474–4477. [Google Scholar]

- Espersson, M. Effect in the high modulus asphalt concrete with the temperature. Constr. Build. Mater. 2014, 71, 638–643. [Google Scholar] [CrossRef]

- Boudreau, R.L.; Hicks, R.G.; Furber, A.M. Effects of test parameters on resilient modulus of laboratory-compacted asphalt concrete specimens. Transp. Res. Rec. 1992, 1353, 46–52. [Google Scholar]

- Tabatabaie, S.A.; Ziari, H.; Khalili, M. Modeling temperature and resilient modulus of asphalt pavements for tropic zones of Iran. Asian J. Sci. Res. 2008, 1, 579–588. [Google Scholar] [CrossRef]

- Khattak, A.; Khan, M.B.; Irfan, M.; Ahmed, S. Experimental investigation of factors affecting the resilient modulus of bituminous paving mixes using indirect tension test. ARPN J. Sci. Technol. 2012, 2, 133–139. [Google Scholar]

- Albayati, A.H.; Lateif, R.H. Evaluating the performance of high modulus asphalt concrete mixture for base course in Iraq. J. Eng. 2017, 23, 14–33. [Google Scholar]

- Tarar, M.A.; Khan, A.H.; Rehman, Z.U. Evaluation of effects of soybean derived oil and aggregate petrology on the performance of asphalt mixes. Road Mater. Pavement Des. 2022, 23, 308–334. [Google Scholar] [CrossRef]

- Barksdale, R.D.; Alba, J.A.L.; Khosla, N.P.; Kim, R.; Lambe, P.C.; Rahman, M.S. Laboratory Determination of Resilient Modulus for Flexible Pavement Design; No. NCHRP Project 1-28; Transportation Research Board: Washington, DC, USA, 1997. [Google Scholar]

- Hussain, A.; Tahir, H.B.; Sheikh, M.Z.; Waheed, A.; Khurshid, M.B. Evaluation of resilient modulus of HMA mixtures from highway construction projects in Pakistan. J. Basic Appl. Res. Int. 2016, 17, 290–301. [Google Scholar]

- Kamal, M.A.; Shazib, F.; Yasin, B. Resilient behaviour of asphalt concrete under repeated loading & effects of temperature. J. Eastern Asia Soc. Trans. Stud. 2005, 6, 1329–1343. [Google Scholar]

- Neham, S.S. Nominal aggregate size an index to the resilient modulus value of hot mix asphalt. Int. J. Eng. Technol. 2018, 7, 59–66. [Google Scholar] [CrossRef]

- Nguyen, M.T.; Lee, H.J.; Beek, J.; Moon, J.S. A new fatigue failure criterion based on crack width of asphalt concrete under indirect tensile mode of loading. J. Test. Eval. ASTM 2014, 44, 55–66. [Google Scholar] [CrossRef]

- ASTM C131/C131M-20; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D 2419-14; Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4791-19; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C88/C88M-18; Standard Test Method for Soundness of Aggregates by Use of Sodium Sulphate or Magnesium Sulphate. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D113; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D92; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D6931; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D7369; Standard Test Method for Determining the Resilient Modulus of Bituminous Mixtures by Indirect Tension Test. ASTM International: West Conshohocken, PA, USA, 2020.

- Poulikakos, L.D.; Partl, M.N. Investigation of Porous Asphalt Microstructure using Optical and Electron Microscopy. J. Microsc. 2010, 240, 145–154. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Ma, W.; Pei, J. Characterizing heterogeneity of asphalt mixture based on aggregate particles movements. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 81–91. [Google Scholar] [CrossRef]

- Sani, A.; Hasan, M.R.M.; Shariff, K.A.; Jamshidi, A.; Poovaneshvaran, S.; Shahid, K.A. Physico-Mechanical and Morphological Properties of Wax Latex-Modified Asphalt Binder. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 865–878. [Google Scholar] [CrossRef]

- Xue, X.; Gao, J.; Hu, K. Performance Evaluation of Cement Stabilized Mixture with Recycled Aggregate from Construction and Demolition Waste. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 1–14. [Google Scholar] [CrossRef]

- Emery, J.J.; Schenk, W.; Carrick, J.J.; Davidson, J.K.; MacInnis, W.K.; Kennepohl, G.J. Stone mastic asphalt trials in Ontario. Transp. Res. Rec. 1993, 1427, 47–53. [Google Scholar]

- Chen, J.S.; Shiah, M.S.; Chen, H.J. Quantification of coarse aggregate shape and its effect on engineering properties of hot-mix asphalt mixtures. J. Test. Eval. 2001, 29, 513–519. [Google Scholar]

- Chen, J.S.; Liao, M.C. Evaluation of internal resistance in hot-mix asphalt (HMA) concrete. Constr. Build. Mater. 2002, 16, 313–319. [Google Scholar] [CrossRef]

- Rizvi, M.A.; Khan, A.H.; Masoud, Z.; Rehman, Z.; Inam, A. Effect of Fractured Aggregate Particles on Linear Stress Ratio of Aggregate and Resilience Properties of Asphalt Mixes—A Way Forward for Sustainable Pavements. Sustainability 2021, 13, 8630. [Google Scholar] [CrossRef]

- Ghanizadeh, A.R.; Fakhri, M. Effect of waveform, duration and rest period on the resilient modulus of asphalt mixes. Proc. Soc. Behav. Sci. 2013, 104, 79–88. [Google Scholar] [CrossRef]

| Aggregate Property | Test Results * |

|---|---|

| LA Abrasion loss (%) | 17.9 |

| Sand Equivalent (%) | 70 |

| Flakiness (%) | 8 |

| Elongation (%) | 6 |

| Water Absorption (%) | 0.96 |

| Bulk Density (kg/m3) | 1533 |

| Sodium Sulphate Soundness (%)—Coarse | 4.3 |

| Sodium Sulphate Soundness (%)—Fine | 3.6 |

| Type of Test | RAP Binder * | 20/30 * | 40/50 * | 60/70 * | 80/100 * |

|---|---|---|---|---|---|

| Penetration at 25 °C, 0.1 mm | 37 | 25 | 44 | 65.2 | 85 |

| Softening point (°C) | 54 | 58.2 | 51.6 | 47.5 | 46 |

| Ductility at 25 °C (cm) | 65 | 18 | 126.7 | 134 | 144 |

| Flashpoint (°C) | 295 | 300 | 335 | 329 | 252 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7 | 1,425,598,363 | 203,656,909 | 851.77 | 0.0001 |

| Linear | 3 | 1,325,354,497 | 441,784,832 | 1847.7 | 0.0001 |

| A | 1 | 18,222,300 | 18,222,300 | 76.21 | 0.0001 |

| B | 1 | 1,046,392,604 | 1,046,392,604 | 4376.39 | 0.0001 |

| C | 1 | 260,739,593 | 260,739,593 | 1090.51 | 0.0001 |

| 2-Way Interactions | 3 | 70,416,614 | 23,472,205 | 98.17 | 0.0001 |

| AB | 1 | 4,976,832 | 4,976,832 | 20.81 | 0.0001 |

| AC | 1 | 154,422 | 154,422 | 0.65 | 0.425 |

| BC | 1 | 65,285,360 | 65,285,360 | 273.05 | 0.0001 |

| 3-Way Interactions | 1 | 1932 | 1932 | 0.01 | 0.929 |

| ABC | 1 | 1932 | 1932 | 0.01 | 0.929 |

| Error | 52 | 12,433,172 | 239,099 | ||

| Total | 59 | 1,438,031,535 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, S.I.; Khan, A.H.; Rehman, Z.u.; Abbas, W.; Abbas, S.; Mohamed, A.M.; Fathi, D.M.; Aziz, M. Effect of Weak Zones on Resilience of Sustainable Surface Course Mixtures of Fresh-Reclaimed Asphalt Pavement. Sustainability 2022, 14, 9966. https://doi.org/10.3390/su14169966

Hussain SI, Khan AH, Rehman Zu, Abbas W, Abbas S, Mohamed AM, Fathi DM, Aziz M. Effect of Weak Zones on Resilience of Sustainable Surface Course Mixtures of Fresh-Reclaimed Asphalt Pavement. Sustainability. 2022; 14(16):9966. https://doi.org/10.3390/su14169966

Chicago/Turabian StyleHussain, Syed Iqrar, Ammad Hassan Khan, Zia ur Rehman, Wasim Abbas, Safeer Abbas, Abdeliazim Mustafa Mohamed, Dina Mohamed Fathi, and Mubashir Aziz. 2022. "Effect of Weak Zones on Resilience of Sustainable Surface Course Mixtures of Fresh-Reclaimed Asphalt Pavement" Sustainability 14, no. 16: 9966. https://doi.org/10.3390/su14169966

APA StyleHussain, S. I., Khan, A. H., Rehman, Z. u., Abbas, W., Abbas, S., Mohamed, A. M., Fathi, D. M., & Aziz, M. (2022). Effect of Weak Zones on Resilience of Sustainable Surface Course Mixtures of Fresh-Reclaimed Asphalt Pavement. Sustainability, 14(16), 9966. https://doi.org/10.3390/su14169966