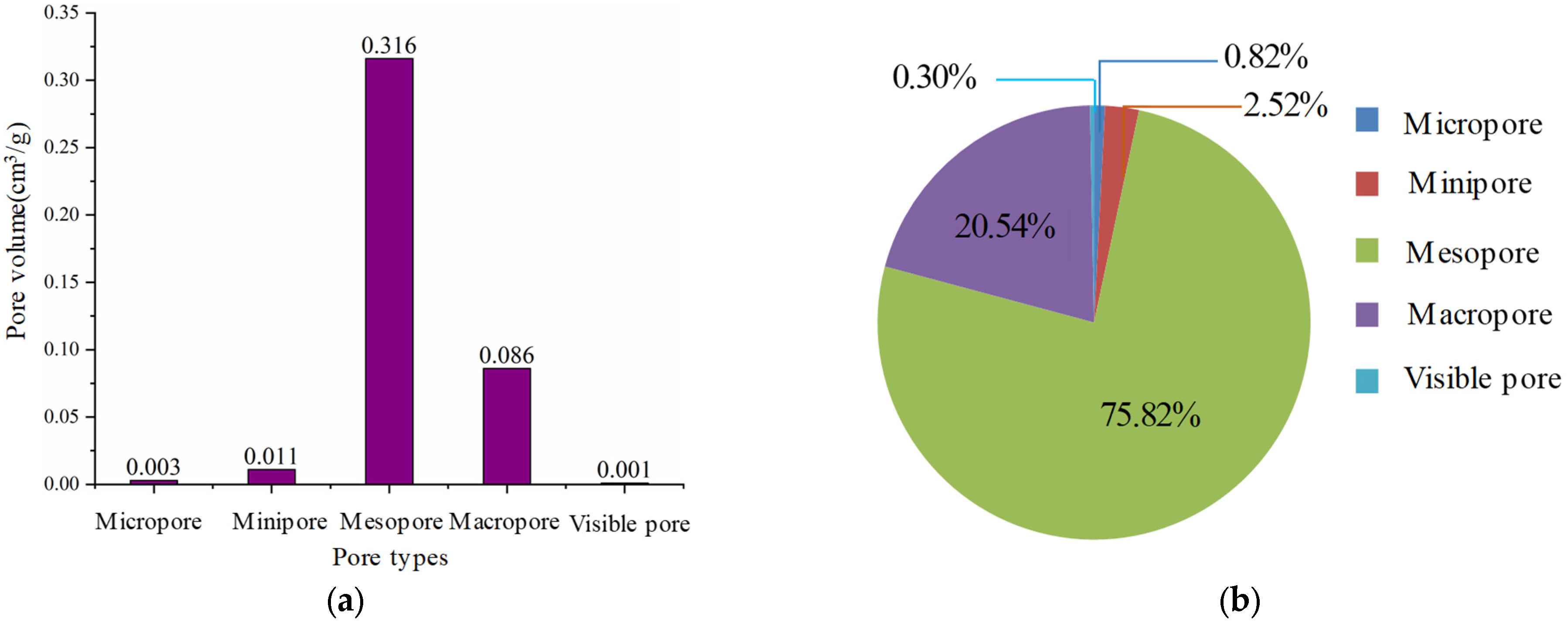

3.4. Simulation Research and Result Analysis of Spraying Process

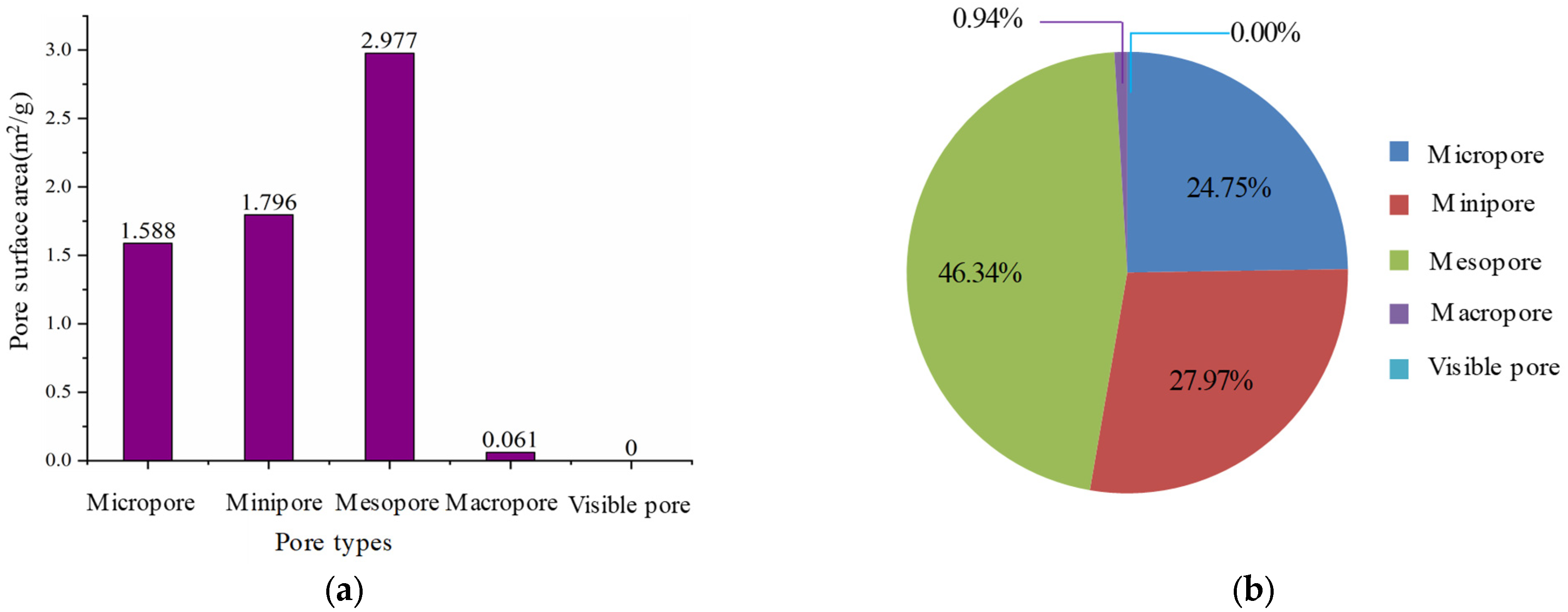

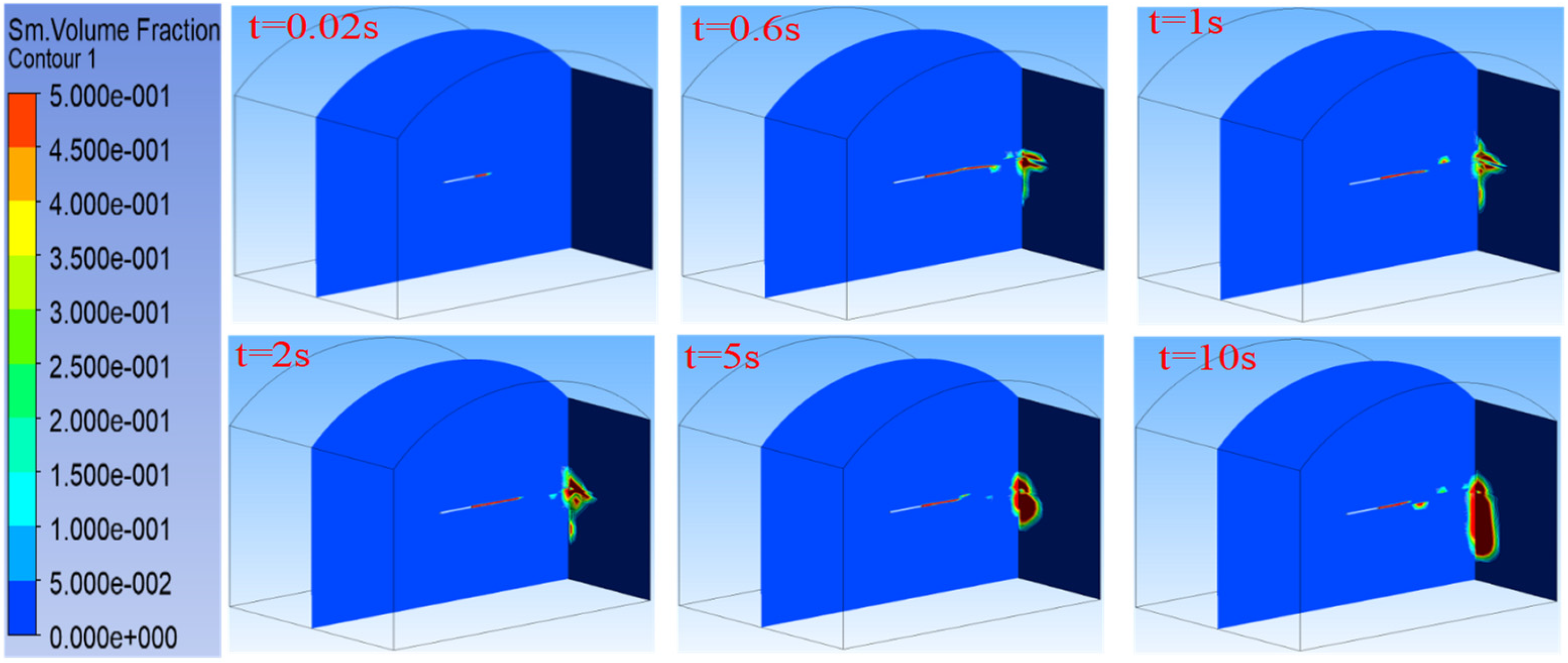

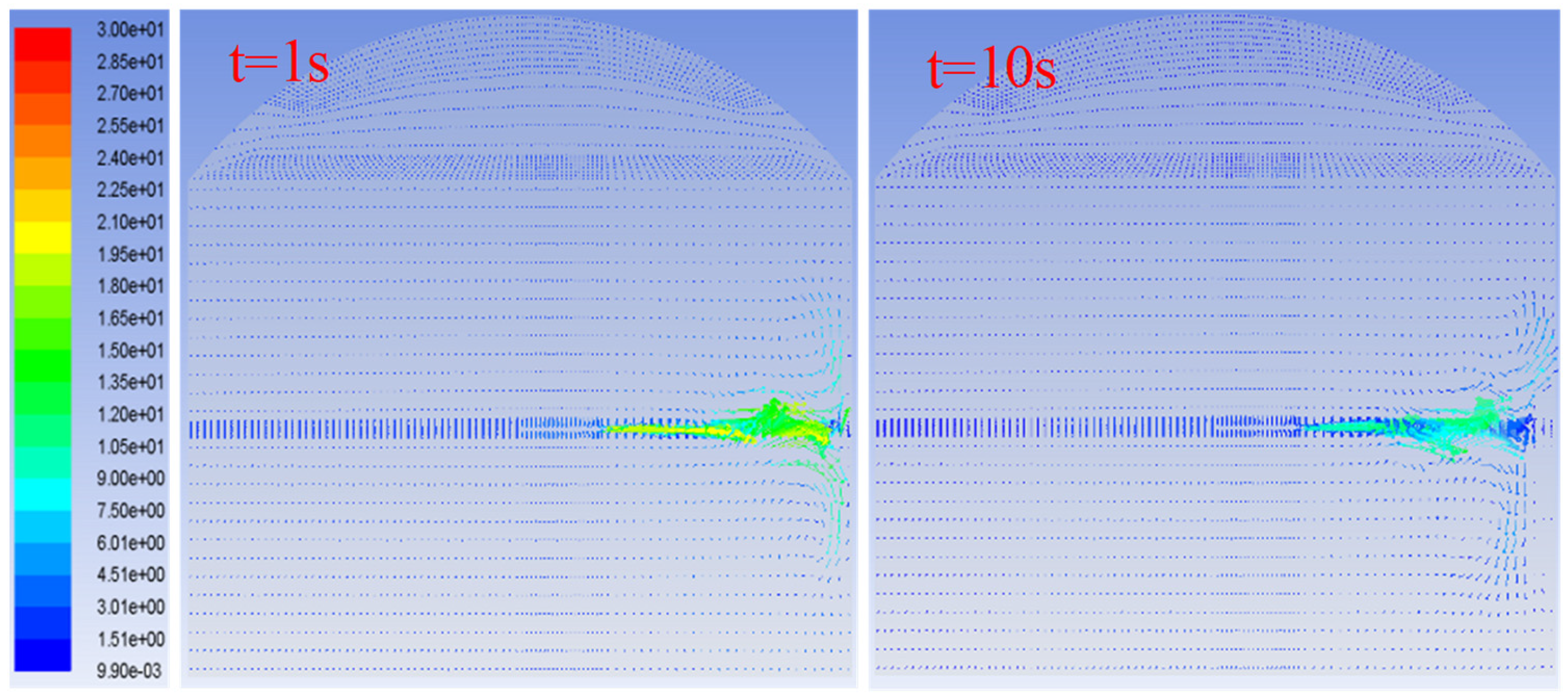

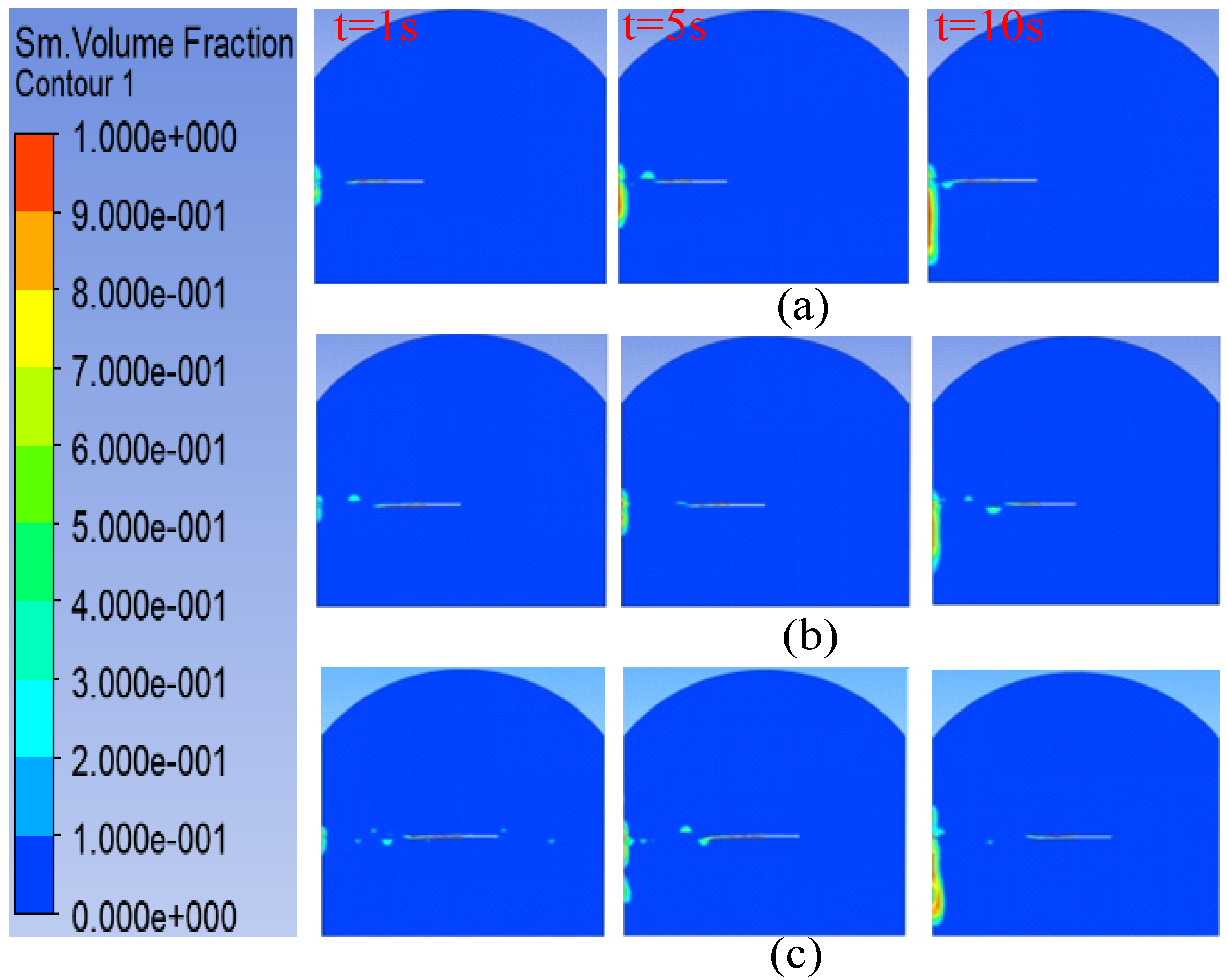

Figure 7 shows the details of the slurry spraying process. It can be seen from

Figure 7 that the slurry is sprayed by the spray gun under pressure and directly sprayed to the side wall in the form of jet. In the process of flowing to the side wall, due to the obstruction of the surrounding air flow, the velocity of the front end of the jet gradually decreases, the jet surface gradually increases, and the spraying area slightly decreases under the action of gravity, see t = 0.6 s.

The front end of the jet gradually increases in the process of advancing, and while diffusing around, it also sucks the surrounding air flow, as shown in

Figure 8, until it reaches the side wall and spreads out on the side wall. As the spraying process proceeds, more slurry reaches the side wall and spreads around the side wall, and the diffusion area gradually increases, as shown in

Figure 7. In the process of spraying to the side wall, a small amount of slurry will escape from the mainstream, see t = 0.6 s, but under the action of inertia, it will also flow to the side wall and adhere to the side wall, forming a smaller spraying area, which is relatively independent of the spraying area formed by the mainstream on the side wall. Therefore, on the whole, the spraying surface formed on the side wall is not always uniform, see t = 2.0 s. However, with the progress of the spraying process, the slurry that subsequently reaches the side wall can make up for the discontinuity of the spraying area and form a relatively uniform spraying area, see t = 5.0 s. As time goes on, the slurry adhered to the wall will develop downward under the action of gravity, so that the spraying area will extend downward, see t = 10.0 s.

In addition, the spraying area on the side wall is not a regular circle. When the front end of the jet of the slurry contacts the side wall, each part of it has different momentum, so it has different initial velocities when diffusing on the side wall. Under the adhesion of the wall, the distance of the slurry dispersed in different directions is also different. Thus, diffusion regions of different specifications are formed on the side wall.

From the above analysis, it can be seen that the slurry spraying process and the spraying area formed on the wall are related to many factors, including the pressure at the nozzle (or the initial flow rate), the spraying distance, the spraying time, the spraying direction, and the characteristics of the slurry itself. We next analyze the influence on the spraying process and spraying area from several main factors.

(1) Influence of spraying distance.

Spraying distance is an important parameter in the actual spraying operation process, which is directly related to the spraying effect, spraying time, and efficiency. Later, taking a horizontal spraying as an example, the spraying process under different spraying distances and its influence on the spraying effect are studied. The distance between the horizontal nozzle outlet and the spraying wall is 0.5 m, 1.0 m, 1.5 m, and 2.0 m respectively.

(1) Spraying process.

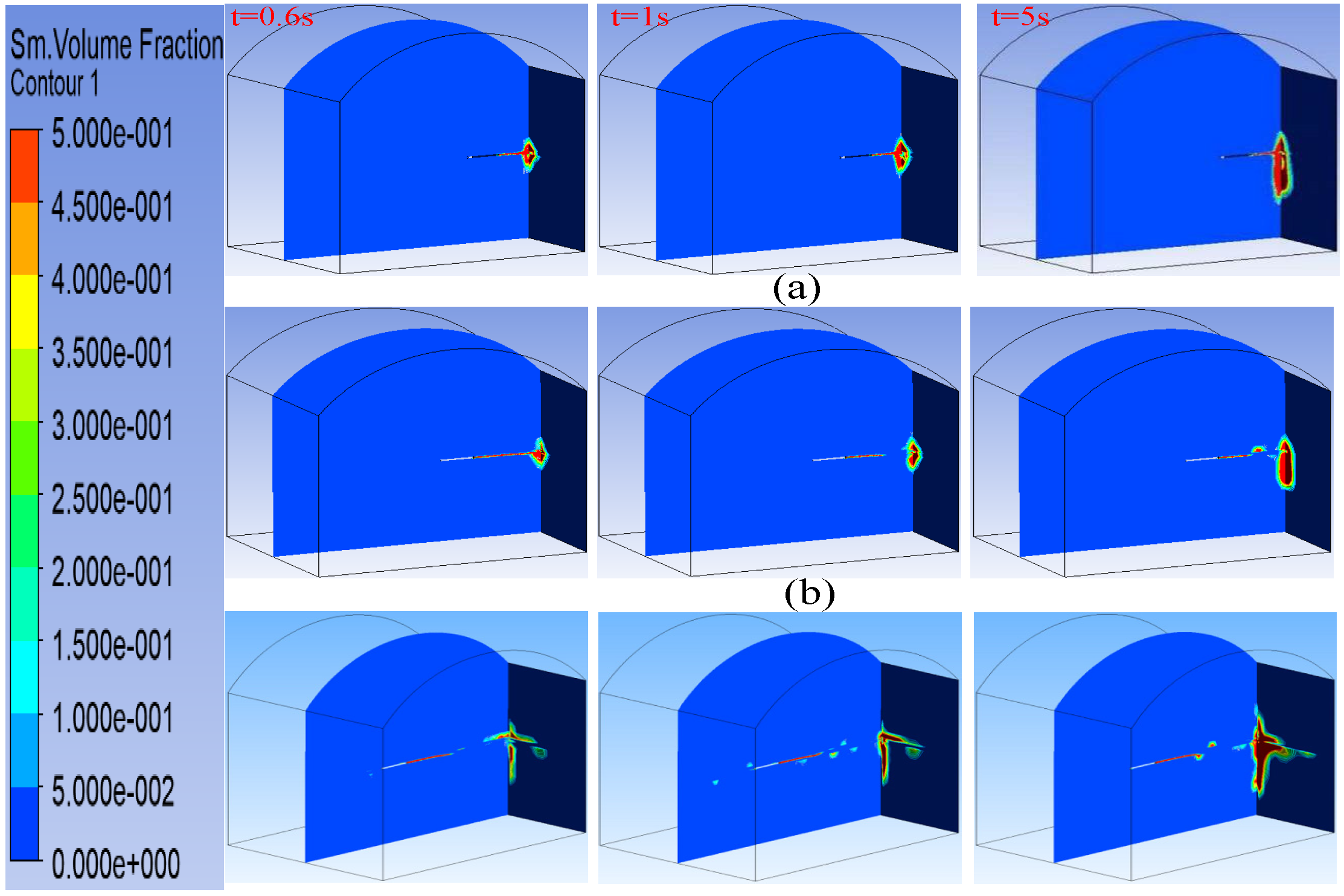

It can be seen from

Figure 9 that the spraying distance has a direct impact on the spraying process, the spraying area formed by the slurry on the wall, and the spraying thickness. When the spraying distance is 0.5 m, because the nozzle is close to the spraying wall, the slurry can reach the spraying wall quickly and spread rapidly, and the spraying area is nearly round and relatively regular. In contrast, when the spraying distance is far, such as 2.0 m, it takes longer for the slurry to reach the spraying wall. In the process of spraying towards the wall, the slurry keeps developing and changing, such as the velocity attenuation and volume increase at the front end, the downward inclination caused by gravity, and part of the slurry departs from the mainstream. The larger the spraying distance is, the more the slurry changes before reaching the wall. Therefore, when the slurry reaches the spraying surface, the spraying area formed on the wall becomes more complex, as shown in

Figure 9c. When the spraying distance is small, more slurry reaches the side wall in a short time, and the slurry thickness is relatively large. As it takes time for the slurry to solidify, the thicker slurry will flow slowly downward under the action of gravity, so that the spraying area will expand significantly downward.

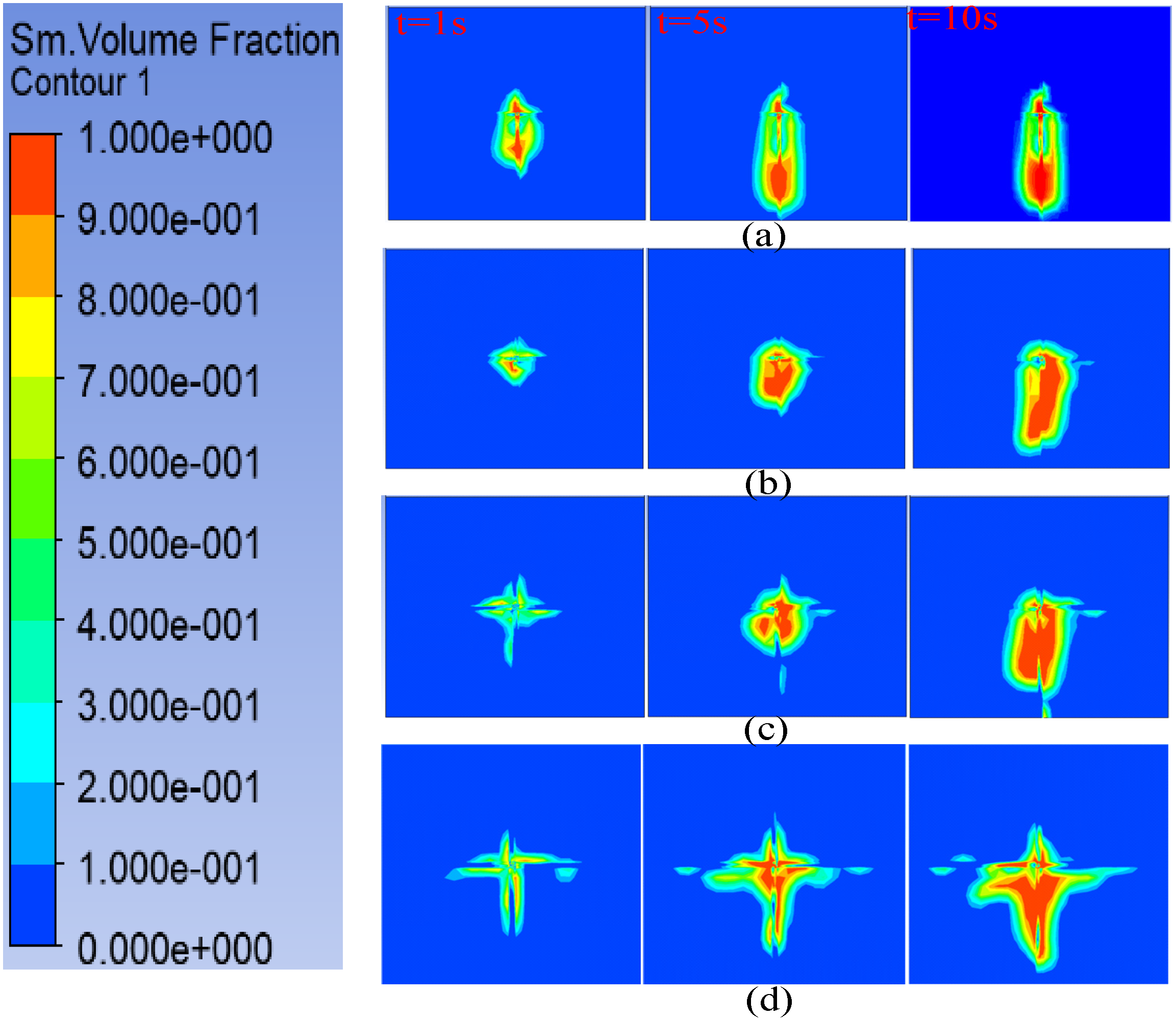

Taking the content product share of the spraying area as the limit, the average diameter of the spraying area under different spraying distances is counted, and the results are shown in

Figure 10. It can be seen from the Figure that the smaller the spraying distance, the shorter the time for the slurry to reach the side wall, and thus the smaller the development of the jet section in a short time. With the progress of spraying, the slurry has not yet fully solidified, and the later, slurry accumulates on the front slurry surface. The slurry layer thickens and flows downward slowly under the action of gravity. The volume share gradient is large (

Figure 10), and the area within its statistical range increases, but the growth is slow. In contrast, the longer the spraying distance is, the longer the slurry reaches the side wall, and the larger the development of the jet section, the larger the spraying area is formed on the side wall, and the coverage area is irregular and the volume share gradient is small (

Figure 10); that is, the slurry layer is thin and uniform, and the area within its statistical range increases significantly.

The average diameter of the spraying area under different spraying distance con-ditions is counted with a content product share of the spraying area greater than or equal to 0.7. The results are shown in

Figure 11. It can be seen from the figure that the smaller the spraying distance, the shorter the time for the slurry to reach the side wall and the smaller the development of the jet section in a short time. With the progress of spraying, the slurry has not yet fully solidified, and the later slurry accumulates on the front slurry surface. The slurry layer thickens and flows slowly downward under the action of gravity. The volume share gradient is large (

Figure 12), and the area within the statistical range increases, but the growth is slow. In contrast, the longer the spraying distance, the longer the time for the slurry to reach the side wall, the larger the devel-opment of the jet section, and the larger the spraying area is formed on the side wall, and the coverage area is irregular and the volume share gradient is small (

Figure 12); that is, the slurry layer is thin and uniform, and the area growth within the statistical range is obvious.

It can also be seen from

Figure 11 that the spraying area increases with the increase in spraying time, and the increase is relatively rapid in the initial stage. In addition, after the spraying process is carried out for a period of time, the area will increase with the increase in distance. Comparing the spraying area under various spraying distance conditions, it can be found that the slurry is not uniform in the area covered by the slurry, and changes with the development of time and space. It can be seen from

Figure 10 and

Figure 11 that when t = 1.0 s, the smaller the spraying distance is, the larger the spraying area is. However, from the volume share of the phase diagram, it can also be seen that the volume share gradient of the spraying area is larger, that is, the uniformity of the spraying area is poor. The larger the spraying distance is, although the spraying area is irregular, the volume share gradient of the spraying area is smaller, so the uniformity of the spraying area is better. This is because when the spraying distance is large, the slurry reaching the side wall in a short time is less, and the slurry thickness is relatively small, so the effect of gravity is less, and the slurry distribution in the spraying area is more uniform. In the subsequent development and change process, the areas with more uniform spraying are mostly distributed in the lower position in front of the nozzle, especially in the case of small spraying distance. Therefore, it can be seen from the comprehensive spraying area and spraying uniformity that the spraying distance should not be too small or too large, and the spraying distance of 1.5 m is relatively good.

(2) Spraying thickness.

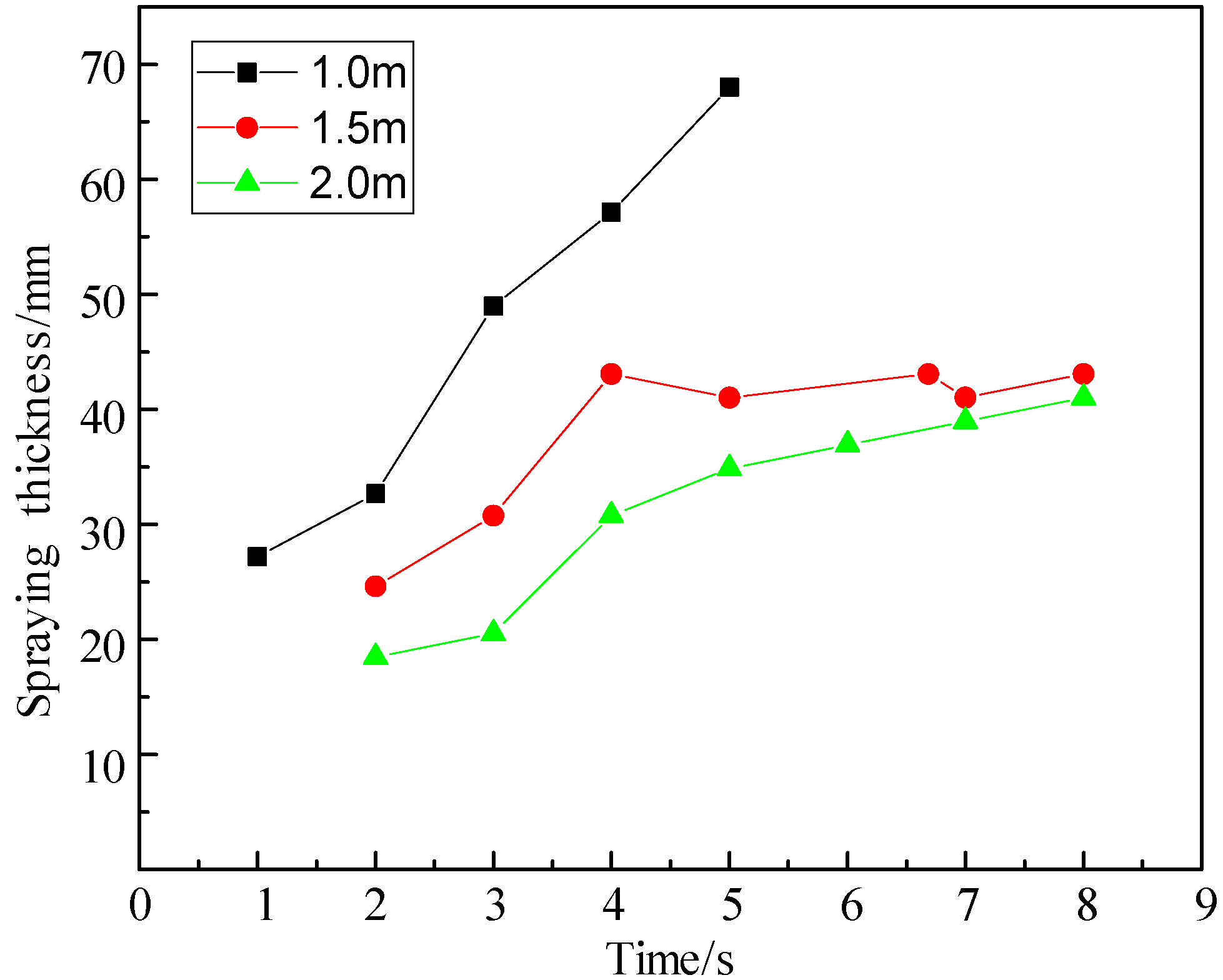

The coating thickness is related to the plugging effect. From the above analysis, it can be seen that the spraying distance is small, the spraying thickness is large, it is easy to move down under the influence of gravity, and the spraying thickness is too thin to meet the plugging requirements. The development process of spraying thickness is shown in

Figure 13. The spraying thickness increases with the increase in spraying time, and the initial stage increases faster. When the spraying distance is 1.5 m and 2.0 m, the spraying thickness increases significantly faster, the subsequent increase speed is slow, and the fluctuation degree is small. The spraying thickness corresponding to these two working conditions is within the range of 20–40 mm, as shown in

Figure 14, which is consistent with the spraying thickness of 2–4 cm obtained from the experiment. Therefore, the spraying distance of 1.5 m is appropriate.

(3) Experimental verification.

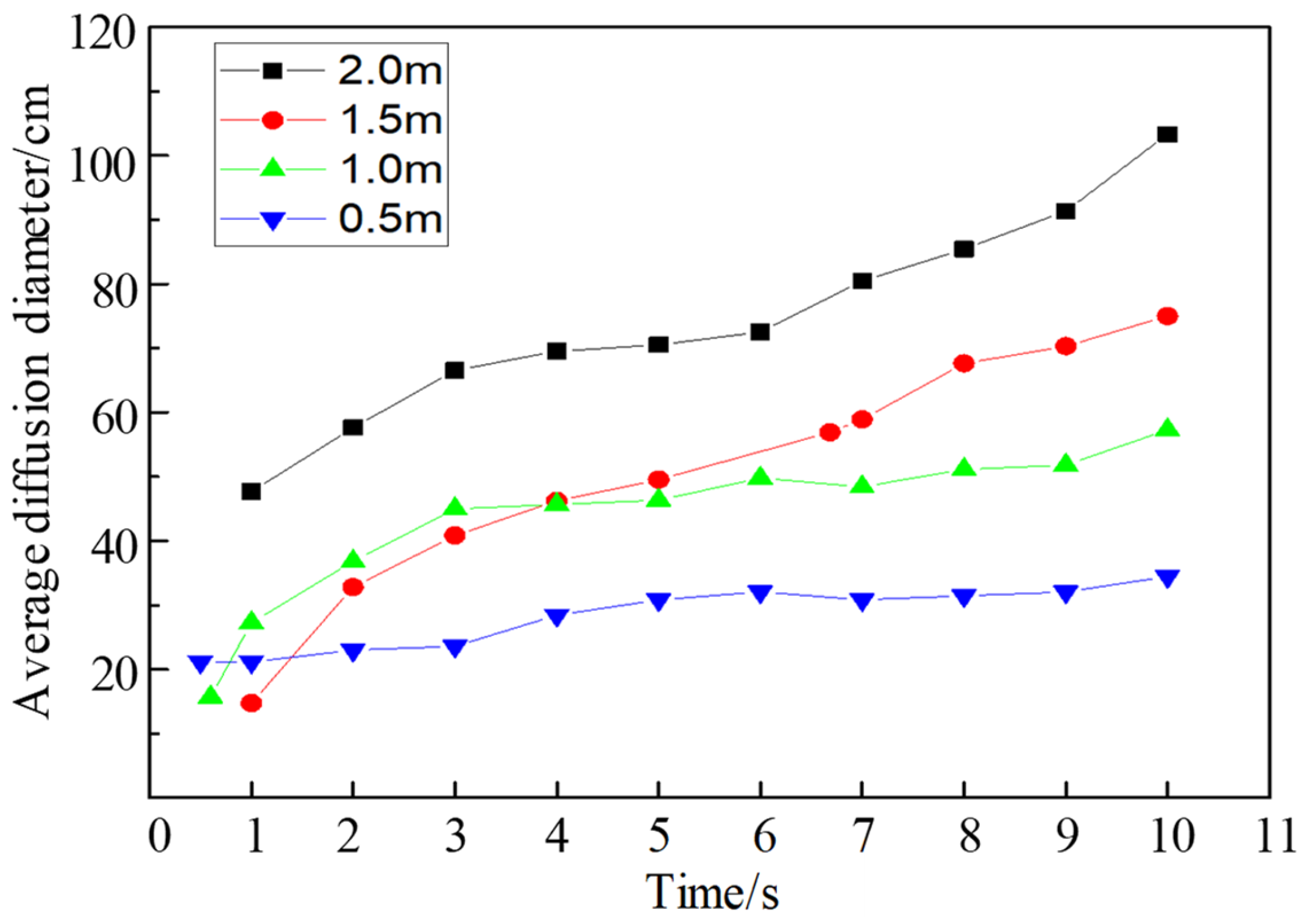

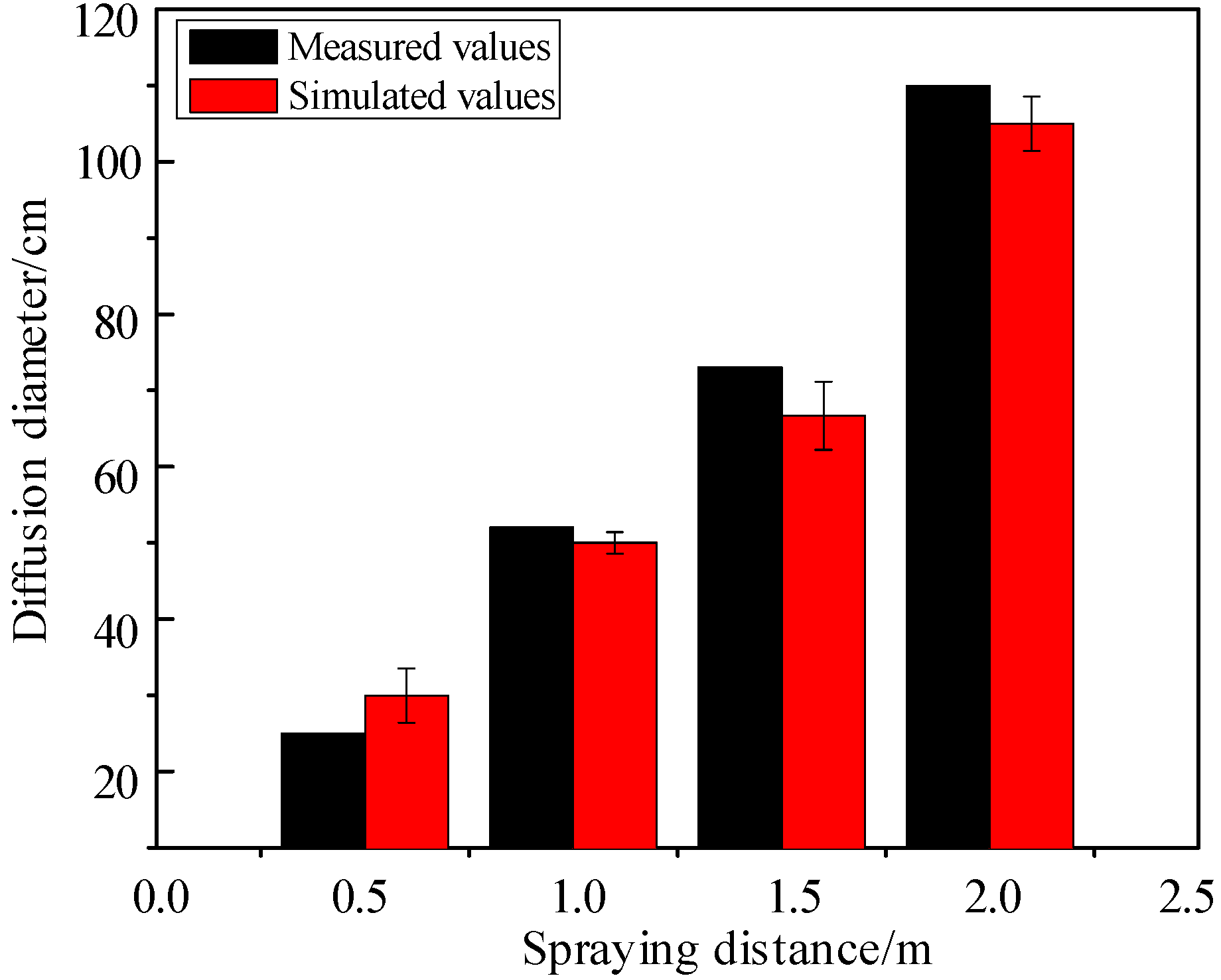

In order to verify the calculated simulation results of diffusion diameter under different spraying distances, we compare the experimental data with the simulation results, as shown in

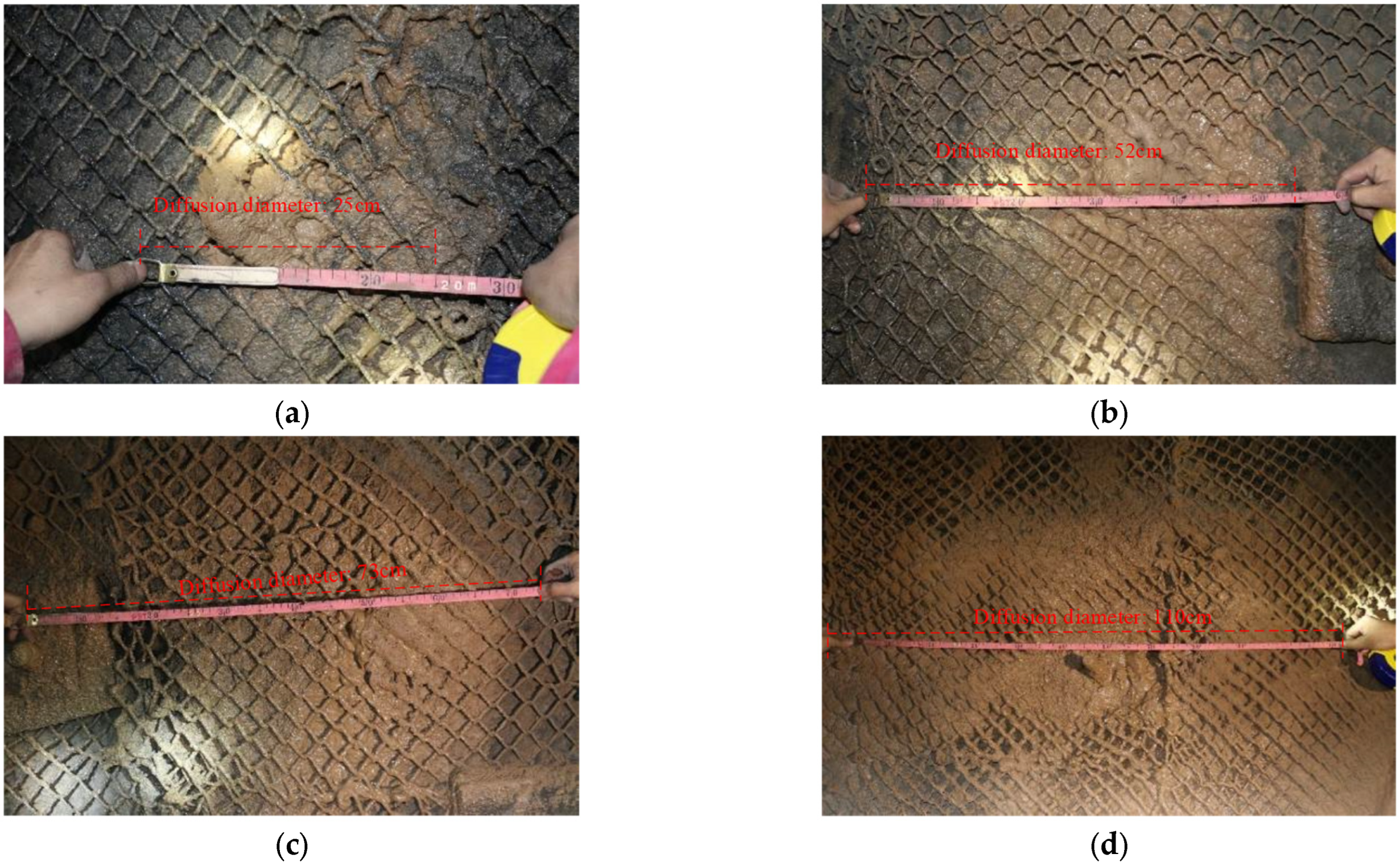

Figure 15. The field spraying effect is shown in

Figure 16.

It can be seen from

Figure 15 that the experimental data and simulation results are in agreement, and both reflect the linear positive correlation between diffusion diameter and spraying distance. Combined with

Figure 10,

Figure 14,

Figure 15 and

Figure 16 from the perspective of the size of the spraying area and the uniformity of the spraying thickness, the corresponding spraying area is relatively large when the spraying distance is 1.5 m, and the slurry distribution in the spraying area is the most uniform, so the working condition is relatively better.

(2) Influence of nozzle initial velocity.

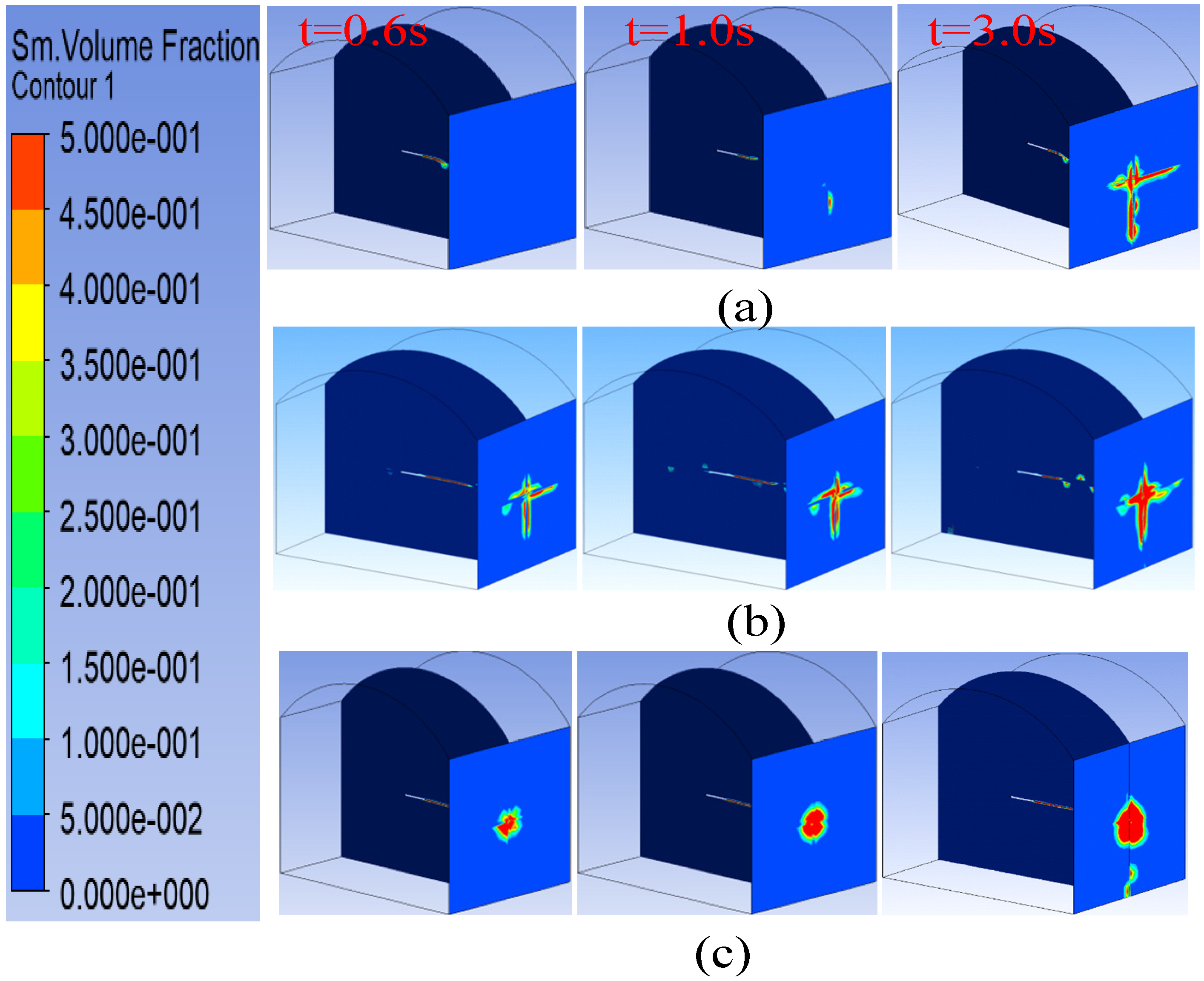

It takes a certain time for the slurry to solidify on the wall. The amount of slurry reaching the wall in a short time should not be too much or too thick. Therefore, the initial spraying speed should not be too large. Under the conditions of different initial speeds, the spray morphology and its thickness change most significantly in the first 3S, so only the simulation results in the first 3 s are shown in

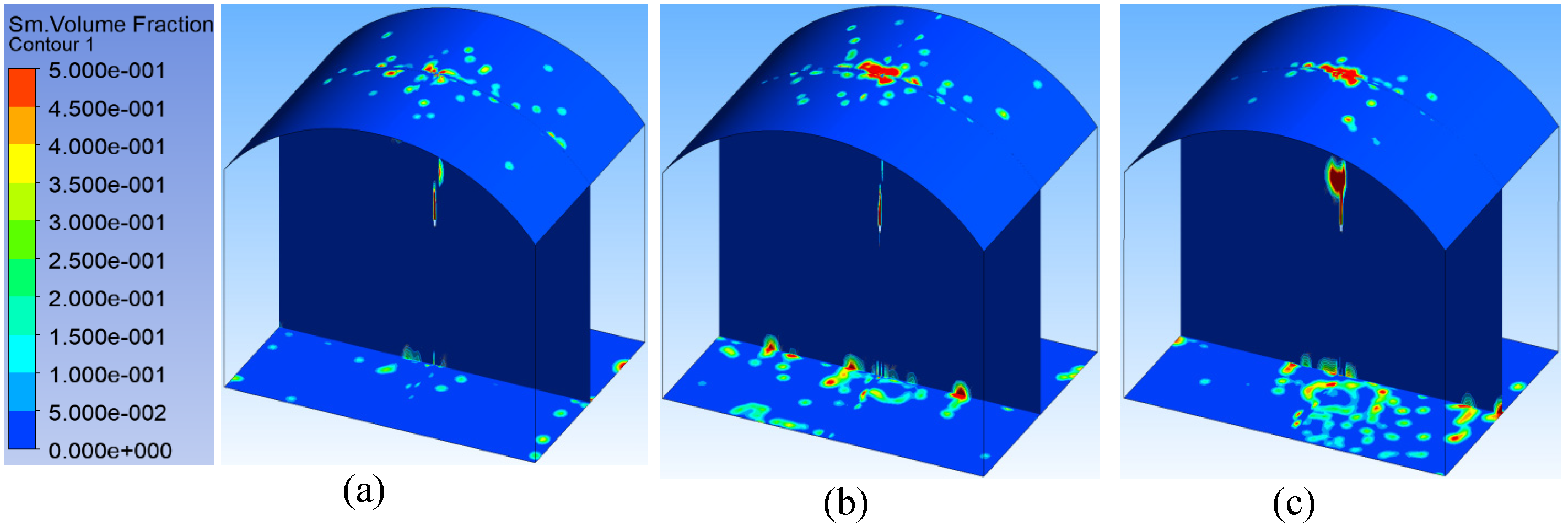

Figure 17. It can be seen from

Figure 17 that irregular spraying areas are formed on the side wall due to the different diffusion capacities of each part of the front end of the jet under the action of different momentum. When the initial velocity is small, the spraying area on the wall is low, as shown in

Figure 17a t = 1.0 s. When the initial speed is high, as the spraying continues, a relatively regular circular area is formed in front of the spray gun, and the slurry in front has not yet solidified. The subsequent slurry accumulates on the surface of the slurry in front, and the area within its statistical range will increase, but the growth rate is slow, and the spraying area formed on the side wall is more uniform, as shown in

Figure 17c.

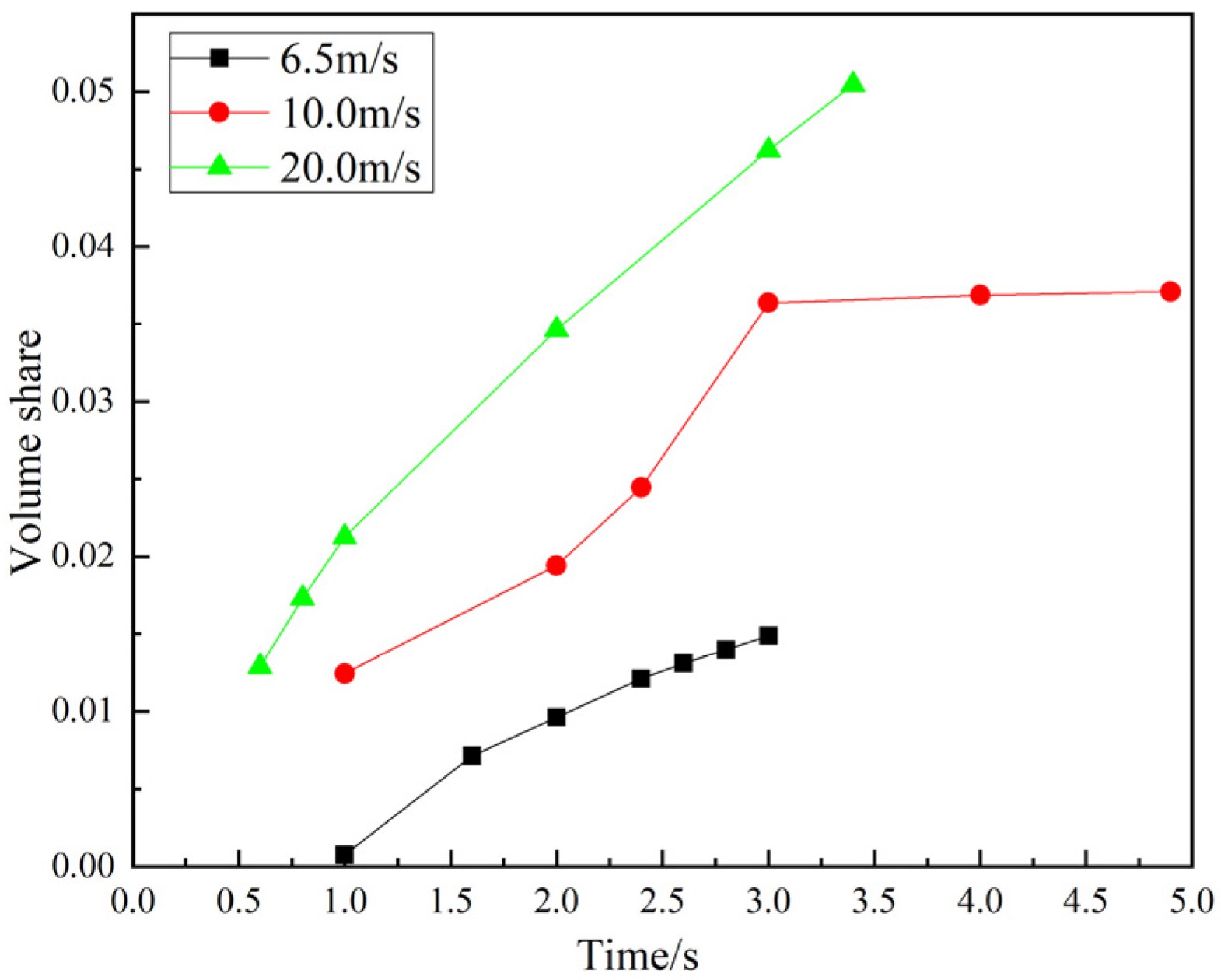

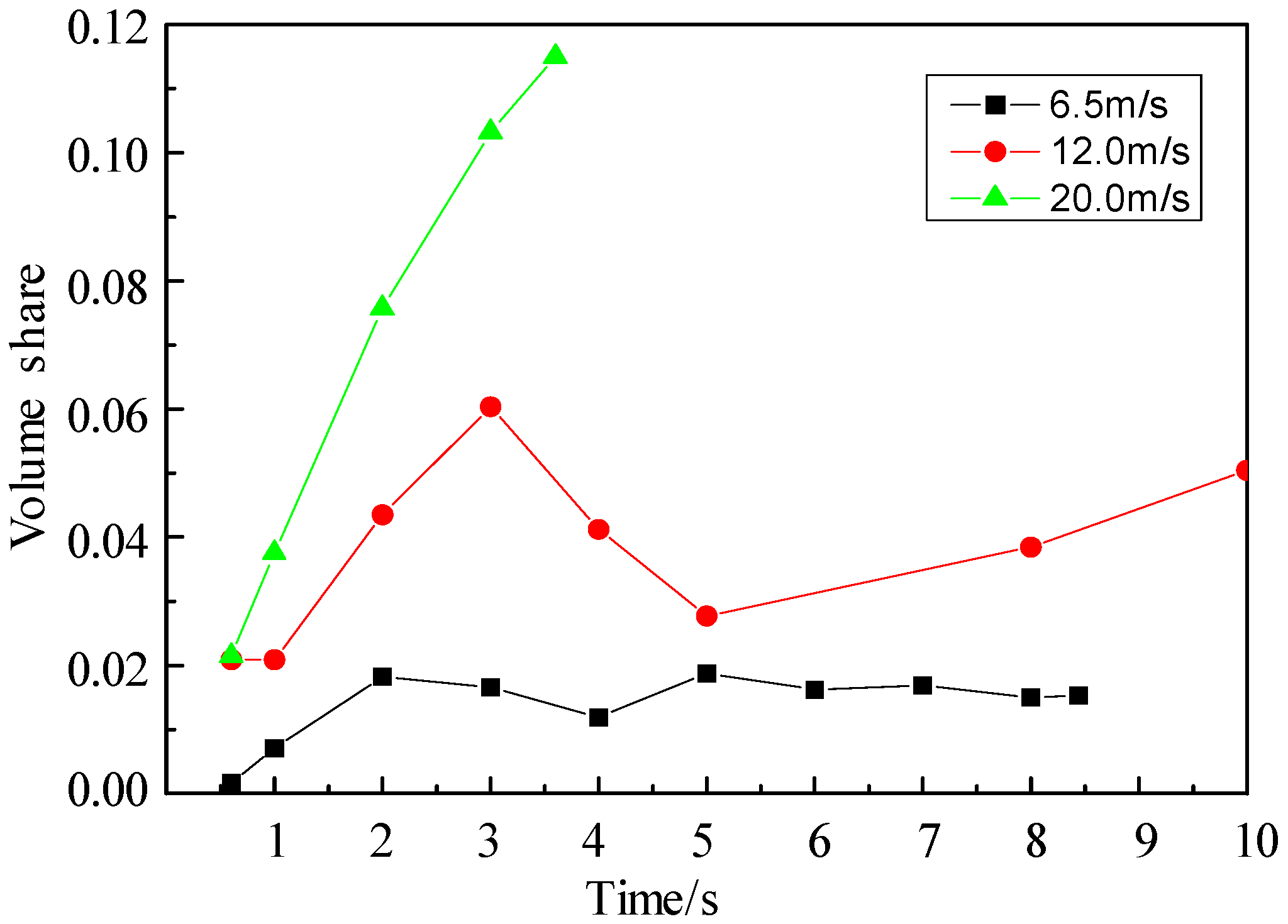

It can be seen from

Figure 18 (1) that the amount of slurry reaching the spraying wall increases with the increase in spraying time, and gradually tends to a certain value, and (2) when the initial spraying speed is 20.0 m/s, the volume share of slurry on the wall is significantly larger than that when the initial spraying speed is 6.5 m/s. It can be seen that the larger the initial spraying speed is, the more the volume share is of the slurry reaching the wall in the same amount of time.

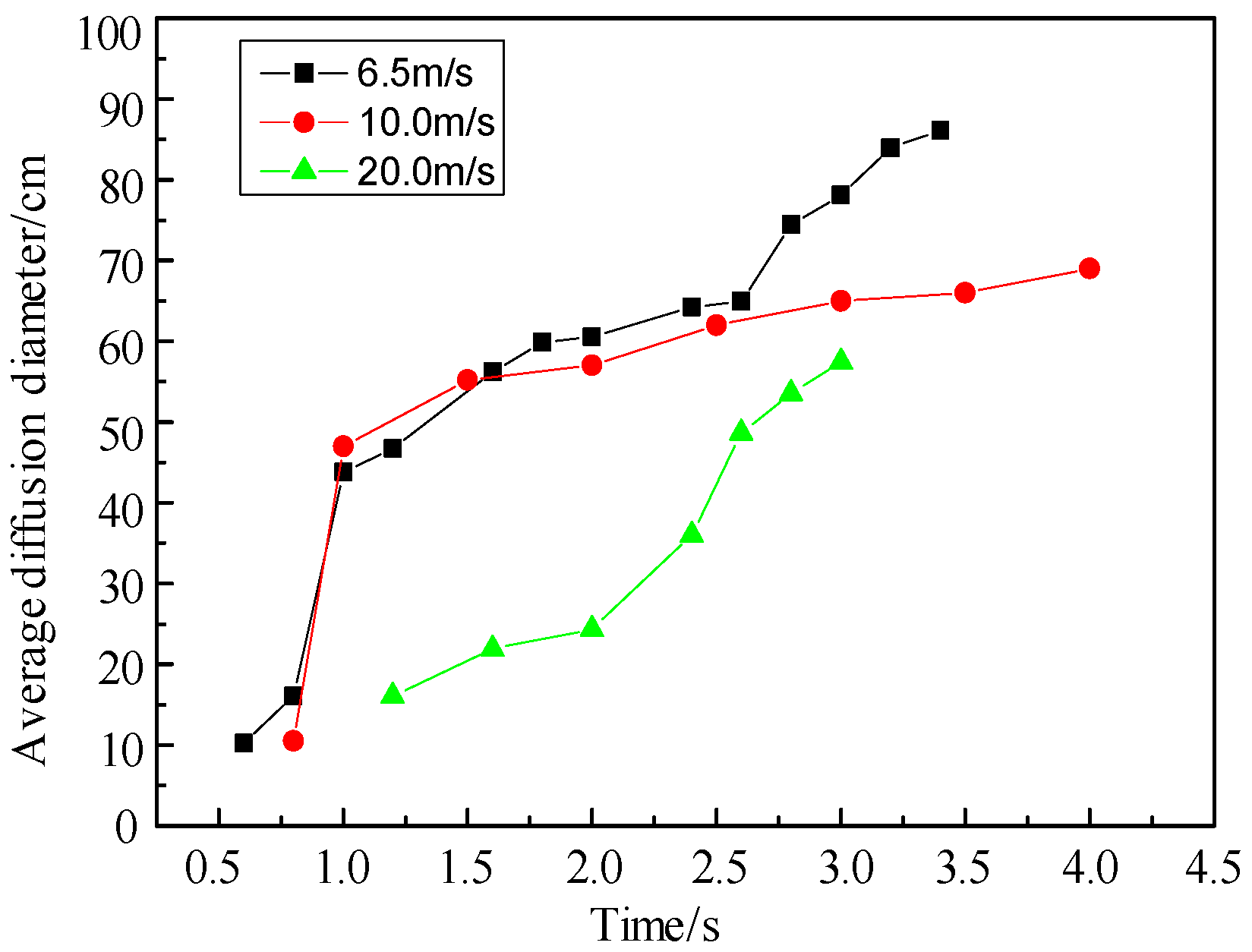

As shown in

Figure 19, the spraying area decreases with the increase in the initial spraying speed within the calculation time period with the limit that the content product share of the spraying area is greater than or equal to 0.7. When the initial spraying speed is small, the slurry takes a relatively long time to reach the side wall, and the jet cross-section increases continuously in the process of spraying to the side wall, as shown in

Figure 17a. On the whole, the shape and uniformity of the spraying area are essentially related to the time when the slurry reaches the side wall. The longer the slurry takes to reach the side wall, the greater the influence of gravity and surrounding fluids, and the more changes along the way—when it reaches the wall, the diffusion capacity of each part of the front end of the jet is also different, thus forming spraying areas with different characteristics.

To sum up, in order to reduce the changes of jet development along the way, it is necessary to shorten the time for the slurry to reach the wall, that is, to increase the outlet velocity of the slurry.

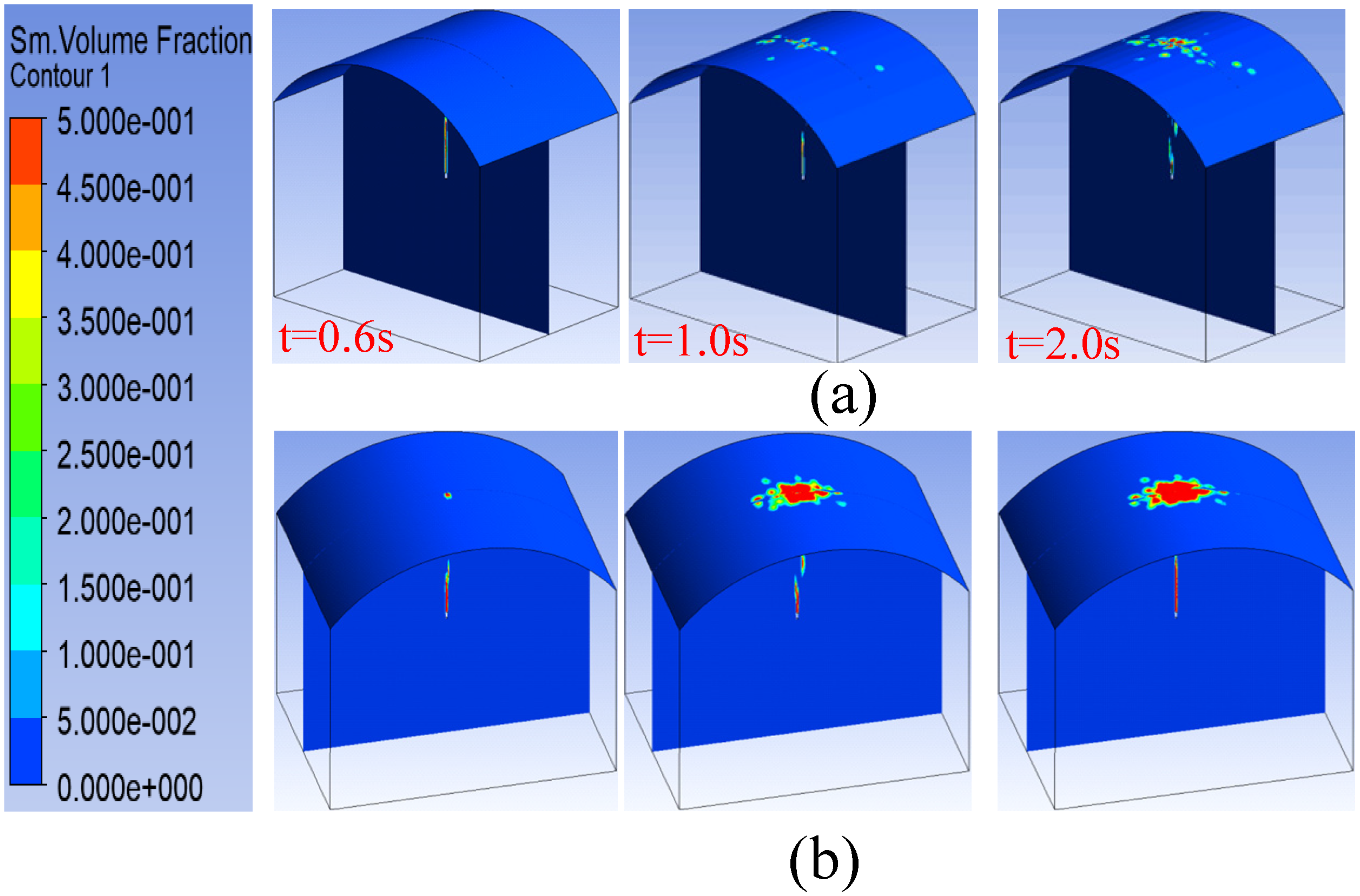

(3) Influence of spraying direction.

When the spraying surface is at the top, the spraying process is significantly affected by gravity. When the initial velocity is small, the slurry should not only overcome the lateral wind flow, but also overcome the gravity. The moving speed of the slurry gradually decreases. Along the way, most of the slurry deviates to the surrounding area under the influence of various factors such as the lateral wind flow. One part forms a discontinuous spraying area with the mainstream on the top surface, and the other part scatters to the ground under the action of gravity, which is the so-called rebound phenomenon, as shown in

Figure 20a. When the initial velocity is large, the slurry can successfully overcome the influence of lateral wind flow and gravity, and finally form a spraying surface with good continuity in the central area on the top surface, as shown in

Figure 20b.

As shown in

Figure 21, the amount of slurry reaching the spraying wall increases with the increase in spraying time, and then shows an unstable fluctuation trend. This fluctuation is mainly determined by the viscosity and solidification speed of the slurry. Some slurry will fall under the action of gravity and rebound, as shown in

Figure 22.

To sum up, the larger the initial spraying speed is, the more the amount of slurry reaching the wall in the same amount of time, and the larger the continuous area formed on the wall, but the more the rebound amount is. When the initial velocity is small, only a small discontinuous spraying area is formed on the wall.