Advantages and Challenges of Composting Reactors for Household Use: Smart Reactor Concept

Abstract

:1. Introduction

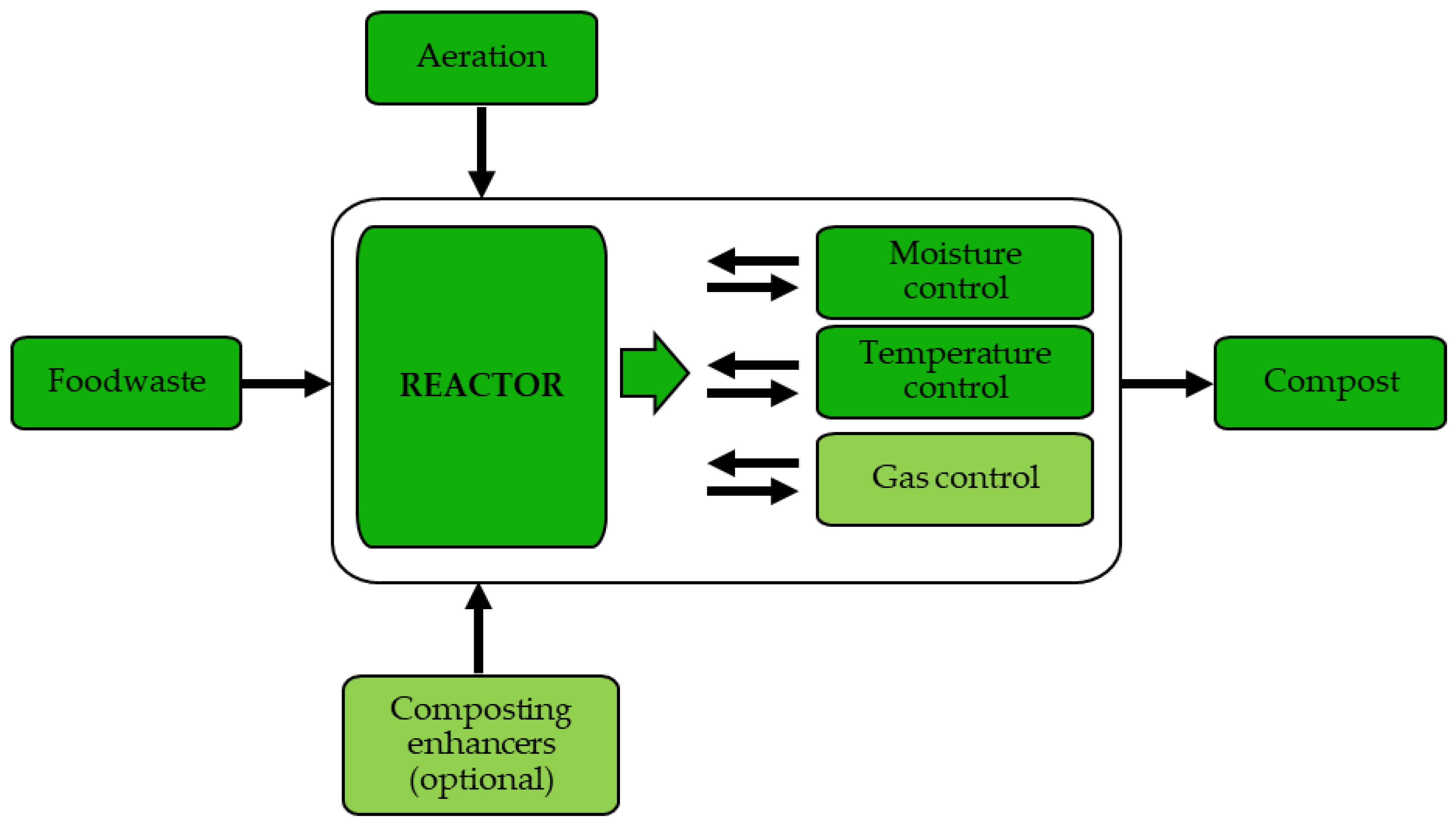

2. Composting Reactors for Households

| Origin | Name for TOPSIS MCDM Analysis | Work Volume, L | Composting Time, Days | Compost Pre-Treatment | Monitoring of Composting Process | Refs. |

|---|---|---|---|---|---|---|

| Reactors manufactured under laboratory conditions | 21 | 100 | Dry in the oven (65 °C) | Moisture (maintained between certain limits). | [29] | |

| 60 | 21 | Mix; adjust moisture content and exact C/N ratio | Temperature, CO2, ammonia (for 1 h measurements every day), taking samples each day for further analysis (bacterial populations, GI etc.). | [30] | ||

| 64 | 10 | Without pre-treatment | Temperature, CO2. | [31] | ||

| 22 | ~13 (300 h) | All the materials mixed together | Tracking temperature and moisture at different heights, oxygen content, and leachate water. Measuring weight at time intervals. | [20] | ||

| A—rapid composting device for households | 20 | 10 | Built-in grinder. | The composting device comprises a grinder, a plug-flow composting bin, a heater, a spiral stirrer, a deodorizer, a leachate collector, and an operation control system. The plug-flow composting bin comprised the initial, heating, thermophilic composting, and cooling composting (or post-composting) sections, operating at different temperatures. The deodorizer comprised a small fan, an ultraviolet light with a wavelength of 185 nm, and a duct. The operation control system included switch buttons, timers, software systems, and an operator interface. | [13] | |

| B—experimental continuous composting reactor | 30 | 30 | Four options: (a) crush in a garbage disposal unit; (b) mince with particle sizes of approximately 15 mm; (c) crush, heat at 70 °C and cook for 70 min; (d) crush and freeze for 12 h at −15 °C, then melt in an oven at 40 °C for 30 min. | By a high-resolution camera with night vision. The system can be monitored via the internet. The performed hourly data of pH and biogas analysis is recorded. | [32] | |

| C—experimental reactor with monitoring system | 55 | 15 | A special selection of materials for the study with specific proportions. All the materials mixed together | Temperature continuously. Moisture, weight loss, C:N ratio, H ion conc. weekly. | [12] | |

| D—experimental composting reactor; | 32 | 14 | Mixing | Temperature. | [33] | |

| E—reactor unit with optimized control system | 9 | 60 | Mixing | Temperature, airflow, CO2, O2. | [34] | |

| F—closed-loop, heat-composting experiment | 68 | 70 | Mixing | Moisture level, temperature, sample collection. | [35] | |

| G—small-scale composter used for indoor composting | 15 | 30 | Cutting the materials to 30–70 mm in size; add garden waste as a bulking agent (ratio 3:17) | Temperature. | [36] | |

| Commercially available composting reactors | I—commercially available small-scale composter for households | 20 | 0.3–3 | Without pre-treatment | No monitoring systems. | [37] |

| H—commercially available large-scale composter for households | 40 | 0.5–1 | Without pre-treatment | Temperature sensors and timer. | [38] | |

| Smart Reactor System for Household Use | J—household composting device prototype | 70 | 14–28 | Without pre-treatment, however, thermal pre-treatment is recommended to shorten the composting time. | Gas, moisture and temperature sensors, monitoring process possible remotely. | This study |

3. Materials and Methods

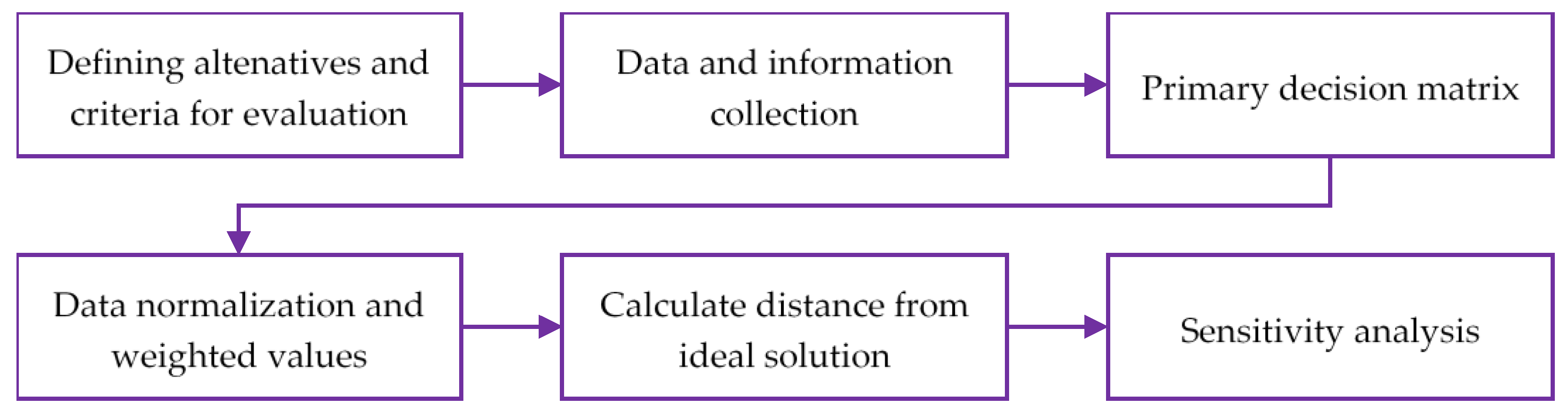

3.1. Multi-Criteria, Decision-Making Analysis to Select Optimal Composting Solutions

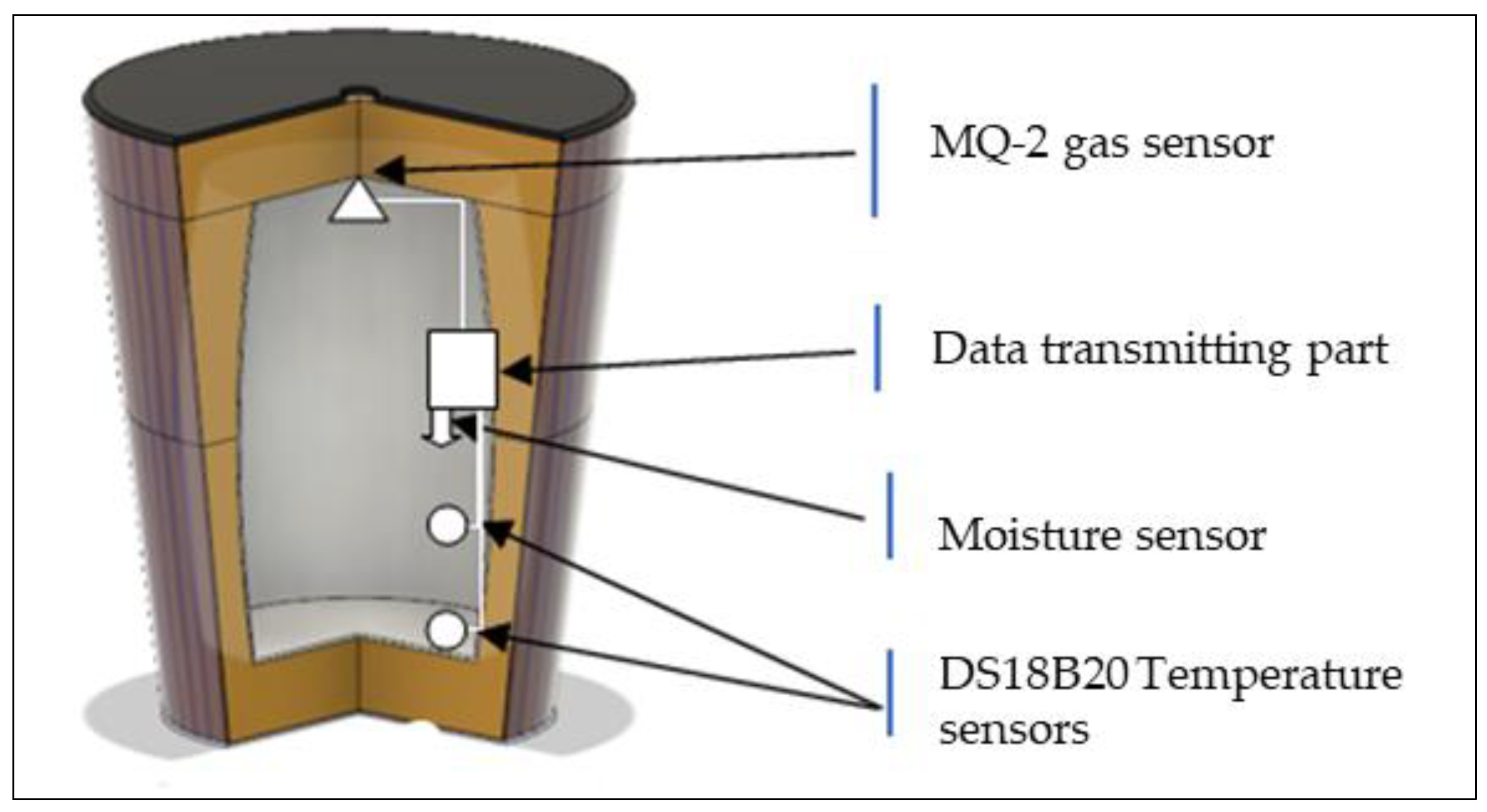

3.2. Smart Composting Reactor Monitoring System Construction

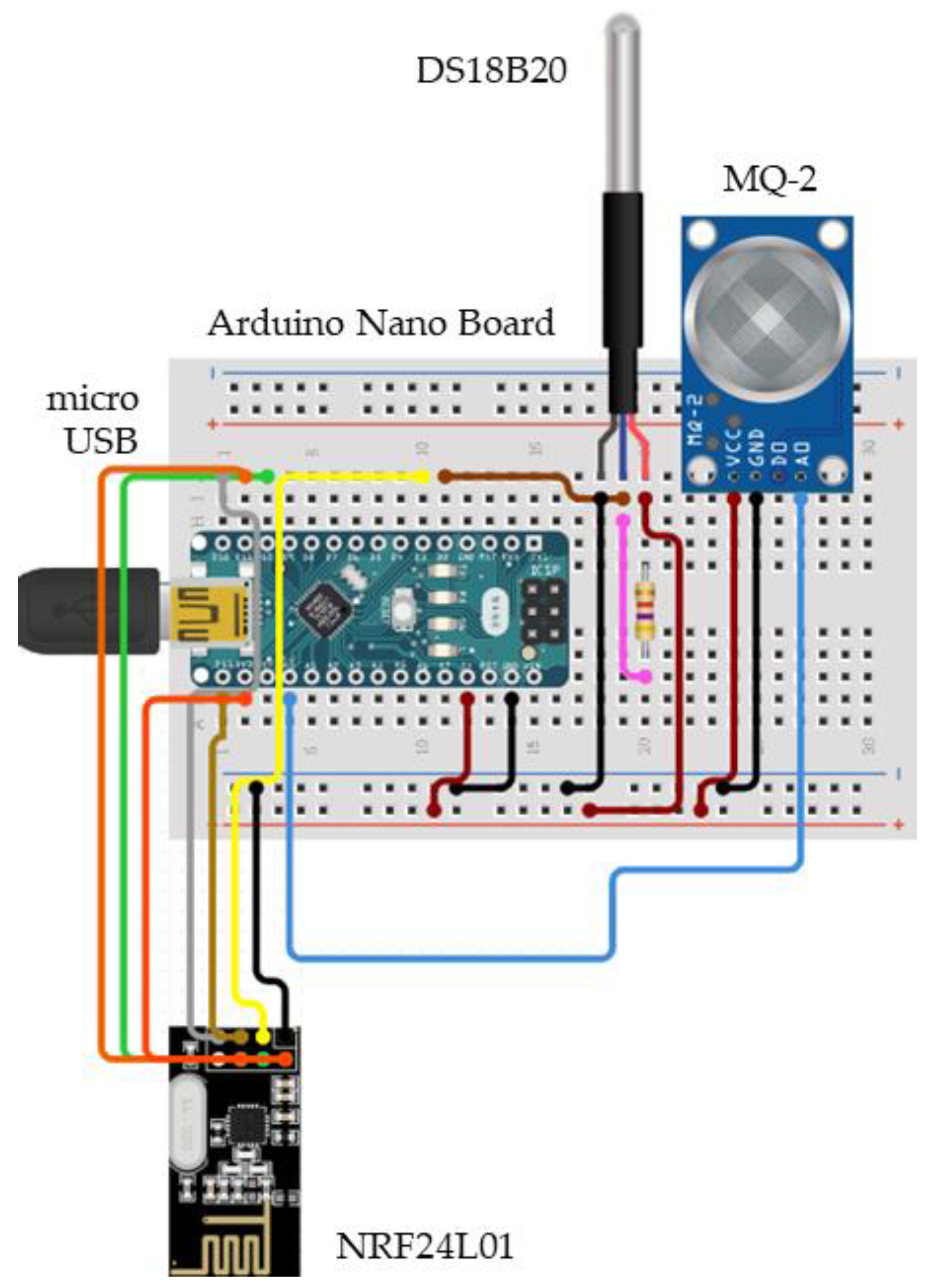

3.2.1. Sensors

3.2.2. Development Board

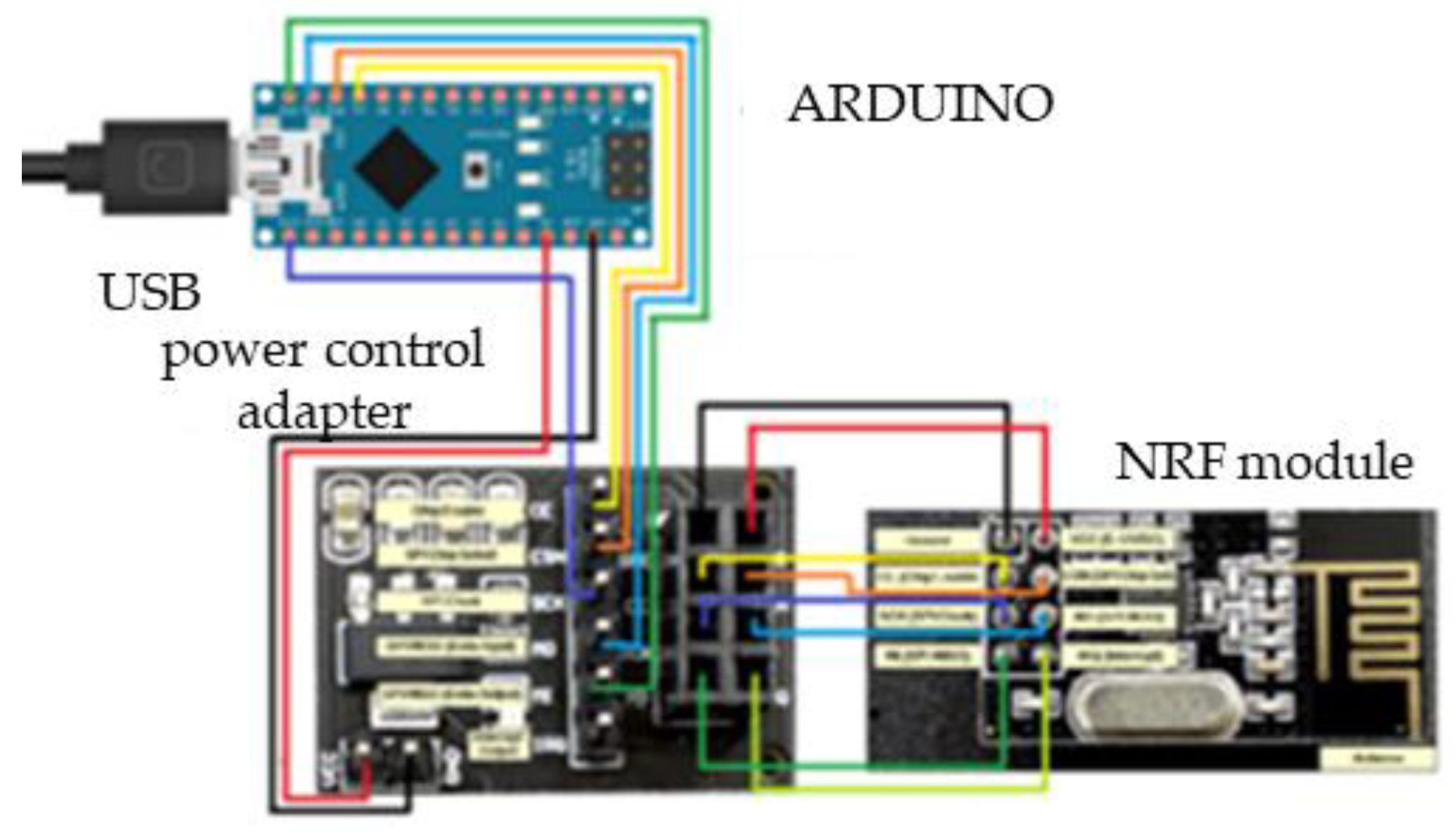

3.2.3. Data Transfer

3.2.4. Data Acquisition Systems

3.2.5. Data Transfer System

3.2.6. Power Supply and Electrical Part of the Smart Composting Reactor

3.2.7. Code Development for Data Receiving and Transferring Parts

3.3. Reactor Construction and Operation

3.3.1. In-Vessel Compost Reactor

3.3.2. Placement of the Monitoring System

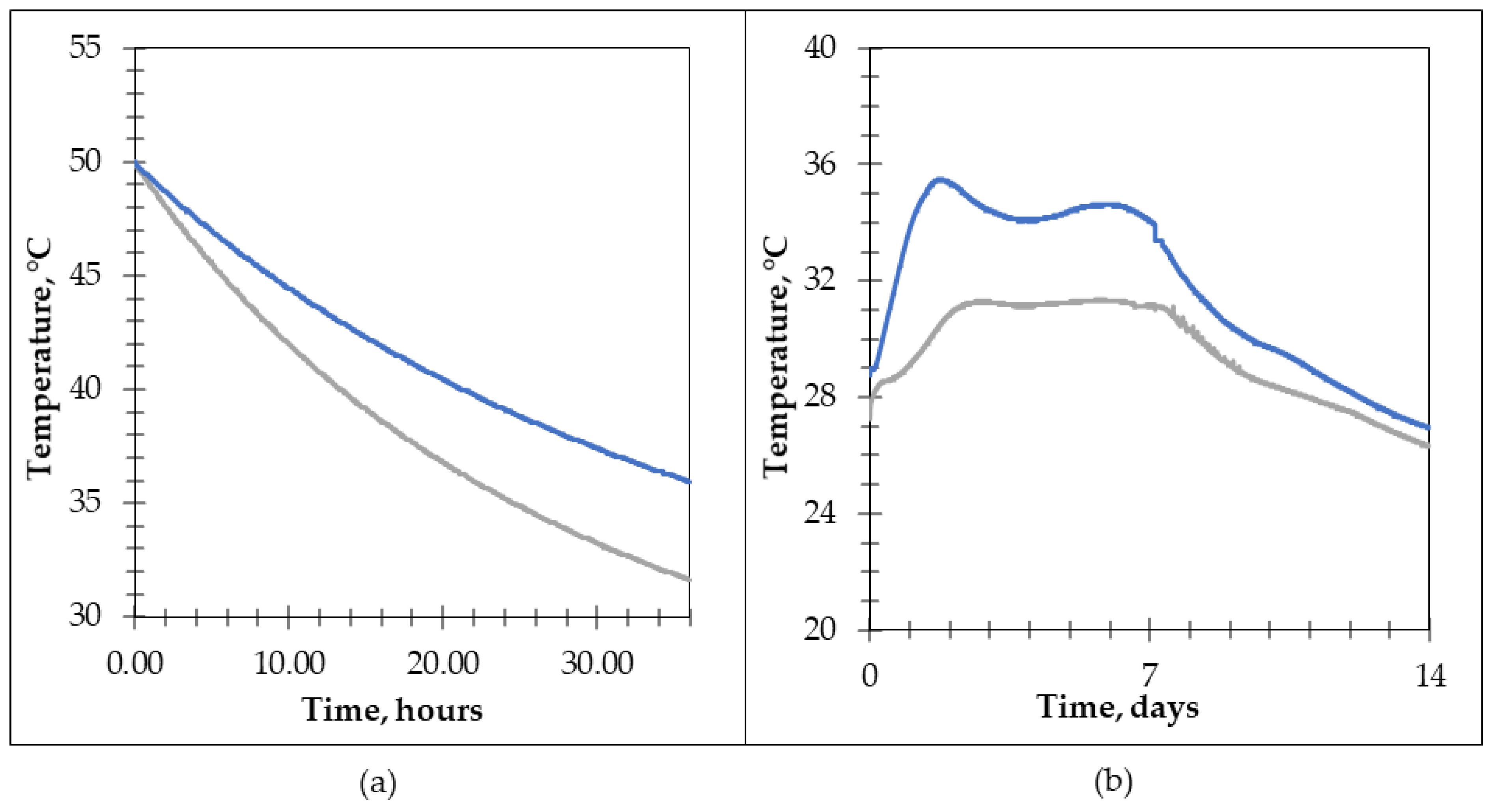

3.3.3. Test Conditions

4. Results and Discussion

4.1. Validation of the Smart Pilot Scale Compost Reactor

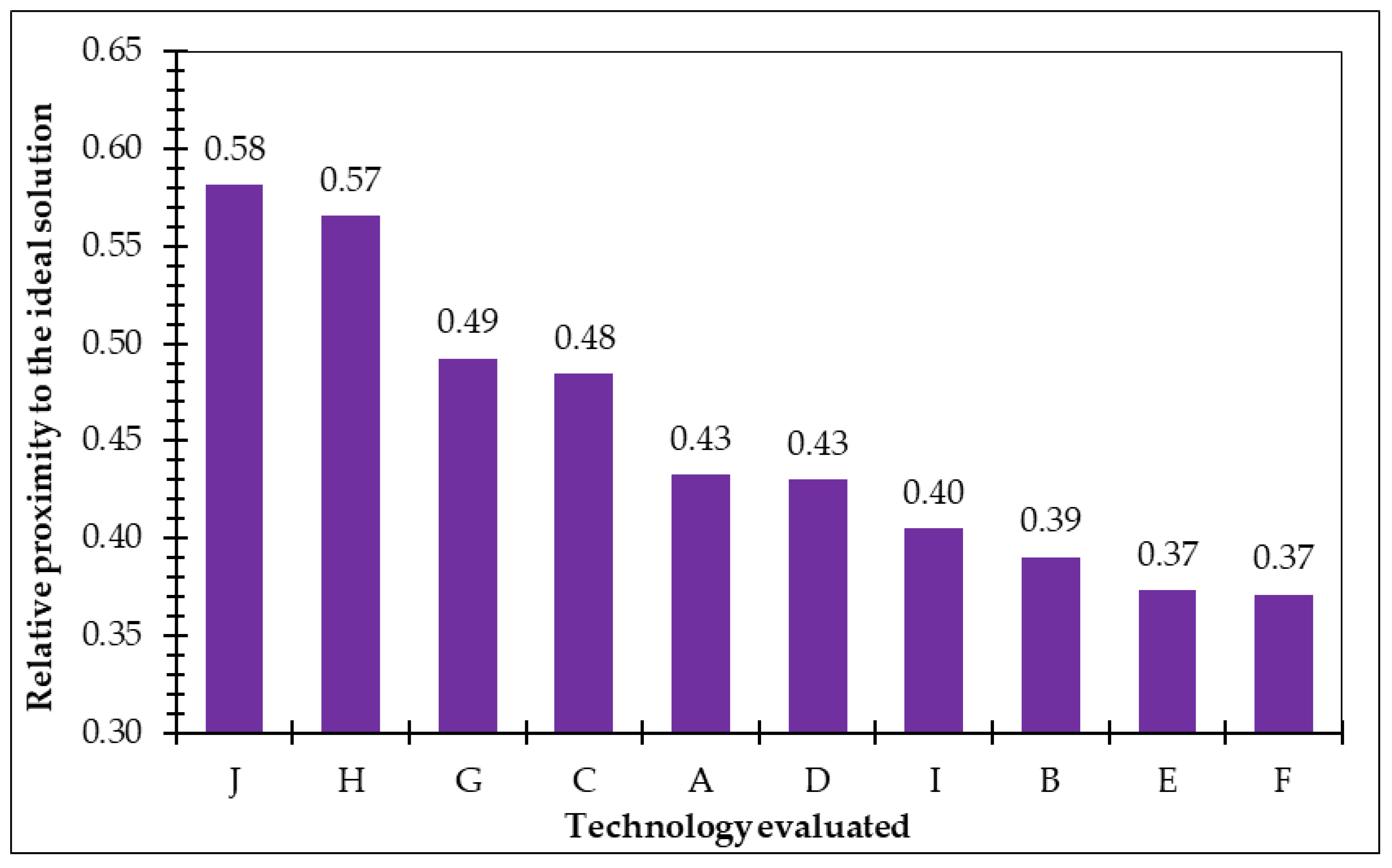

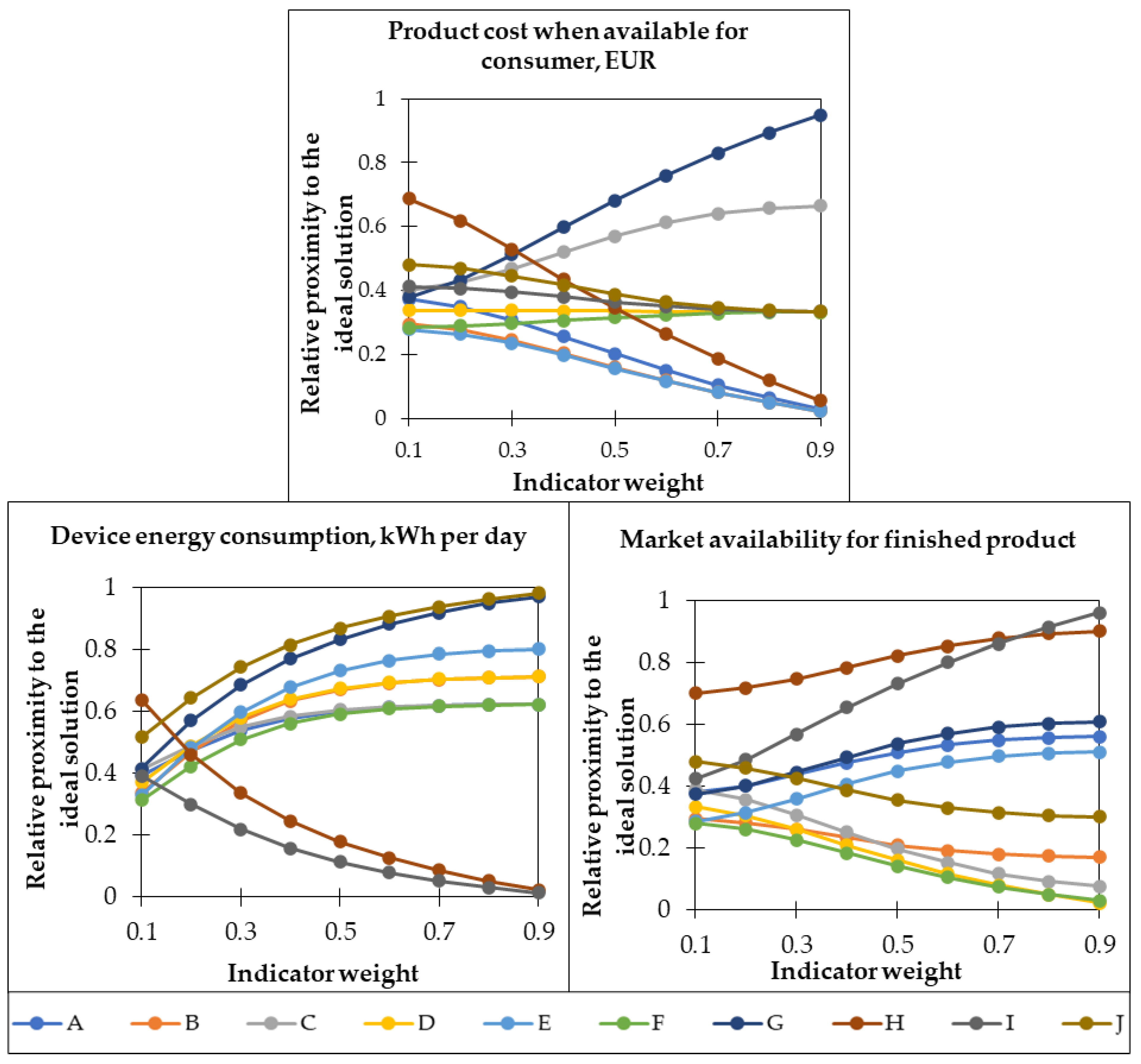

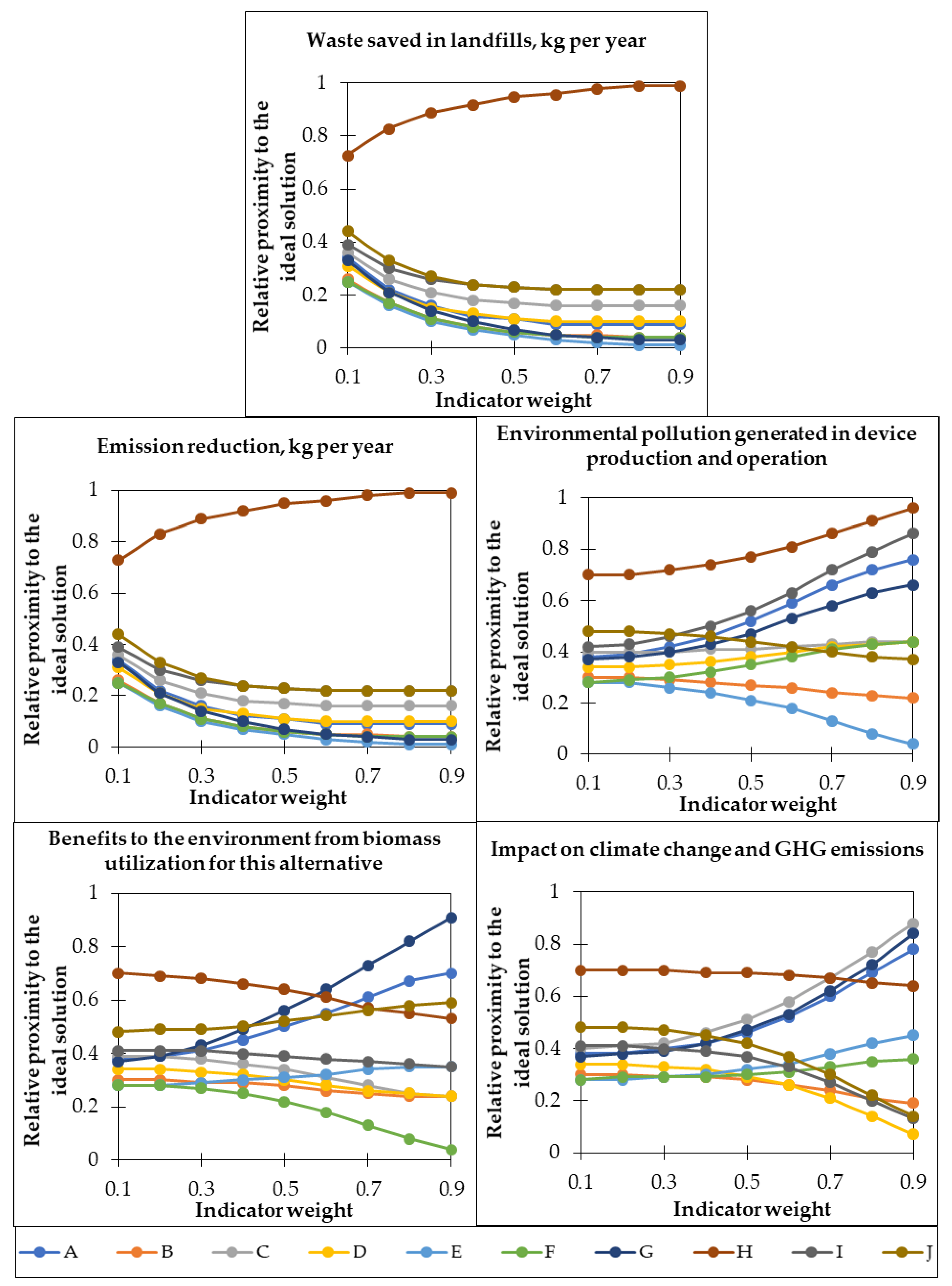

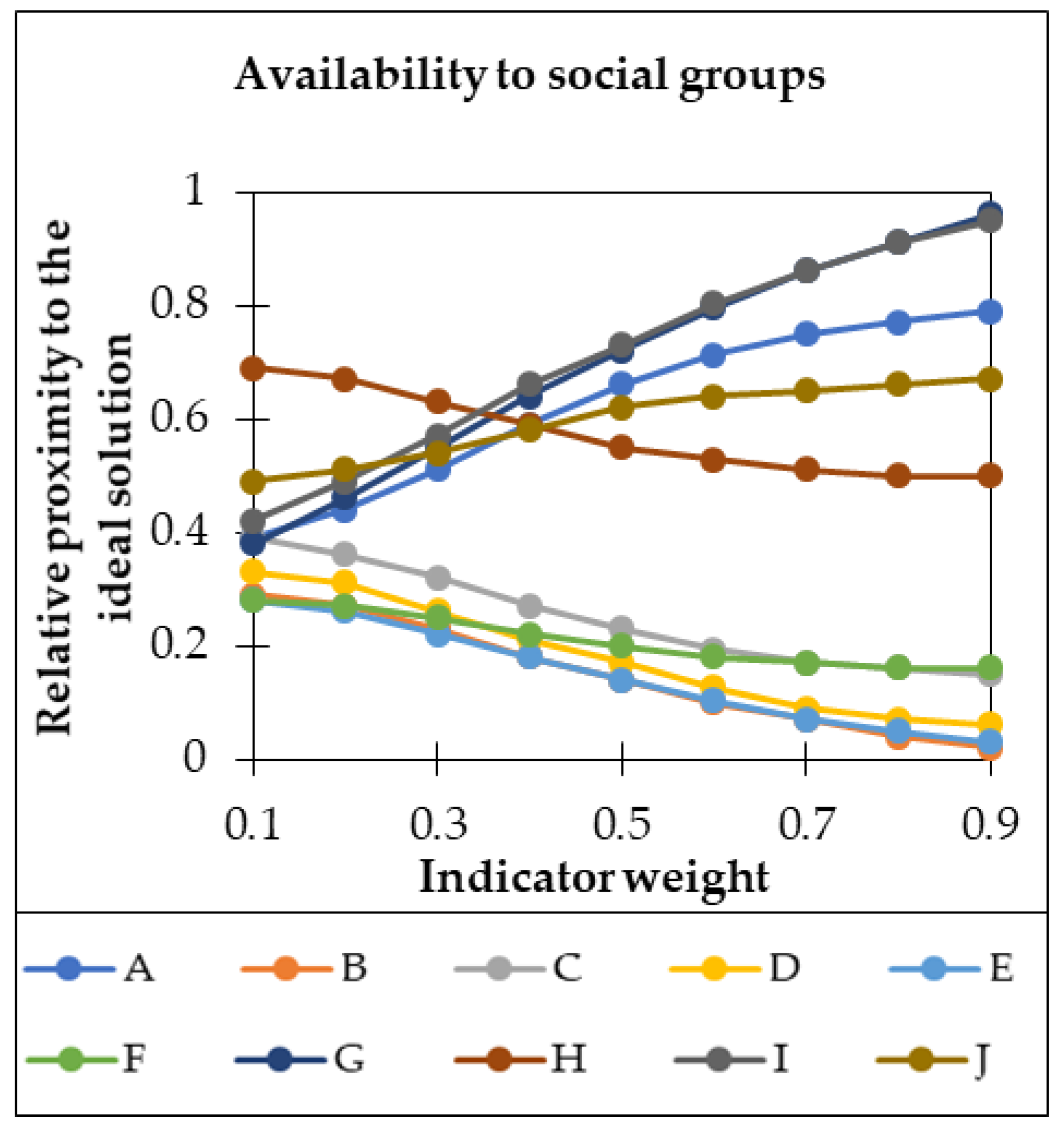

4.2. MCDM Results to Select Optimal Composting Solutions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UNEP Food Waste Index Report 2021|U–EP—UN Environment Programme. Available online: https://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 17 March 2022).

- Half a Tonne of Municipal Waste Generated per Person in the–EU—Products Eurostat N–ws—Eurostat. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/ddn-20210216-1 (accessed on 19 May 2022).

- Bio-Waste in Europe—Turning Challenges into Opportunities—European Environment Agency. Available online: https://www.eea.europa.eu/publications/bio-waste-in-europe (accessed on 19 May 2022).

- Stenmarck, A.; Jensen, C.; Quested, T.; Moates, G. Estimates of European Food Waste Levels; European Comission FP7 Project FUSIONS: Stockholm, Sweden, 2016; pp. 1–80.

- Recycling of Municipal Waste—European Environment Agency. Available online: https://www.eea.europa.eu/airs/2018/resource-efficiency-and-low-carbon-economy/recycling-of-municipal-waste (accessed on 19 May 2022).

- Municipal Waste Statist–cs—Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics (accessed on 19 May 2022).

- Chia, W.Y.; Chew, K.W.; Le, C.F.; Lam, S.S.; Chee, C.S.C.; Ooi, M.S.L.; Show, P.L. Sustainable Utilization of Biowaste Compost for Renewable Energy and Soil Amendments. Environ. Pollut. 2020, 267, 115662. [Google Scholar] [CrossRef]

- Smith, M.M.; Aber, J.D.; Rynk, R. Heat Recovery from Composting: A Comprehensive Review of System Design, Recovery Rate, and Utilization. Compost. Sci. Util. 2017, 25, 511–522. [Google Scholar] [CrossRef]

- Malesani, R.; Pivato, A.; Bocchi, S.; Lavagnolo, M.C.; Muraro, S.; Schievano, A. Compost Heat Recovery Systems: An Alternative to Produce Renewable Heat and Promoting Ecosystem Services. Environ. Chall. 2021, 4, 100131. [Google Scholar] [CrossRef]

- Louie, R. Compost City: Practical Composting Know-How for Small-Space Living; Shambhala, 2015; ISBN 9780834800182. Available online: https://www.amazon.com/Compost-City-Practical-Composting-Small-Space/dp/1611802202 (accessed on 1 May 2022).

- Petiot, C.; de Guardia, A. Composting in a Laboratory Reactor: A Review. Compost. Sci. Util. 2013, 12, 69–79. [Google Scholar] [CrossRef]

- Lau, A.K.; Lo, K.v.; Liao, P.H.; Yu, J.C. Aeration Experiments for Swine Waste Composting. Bioresour. Technol. 1992, 41, 145–152. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, J.; Xu, S.; Wang, J.; Zhou, Q.; Li, Y.; Tong, X. Rapid In-Situ Composting of Household Food Waste. Process Saf. Environ. Prot. 2020, 141, 259–266. [Google Scholar] [CrossRef]

- Sakarika, M.; Spiller, M.; Baetens, R.; Donies, G.; Vanderstuyf, J.; Vinck, K.; Vrancken, K.C.; van Barel, G.; du Bois, E.; Vlaeminck, S.E. Proof of Concept of High-Rate Decentralized Pre-Composting of Kitchen Waste: Optimizing Design and Operation of a Novel Drum Reactor. Waste Manag. 2019, 91, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Mahapatra, S.; Ali, M.H.; Samal, K. Assessment of Compost Maturity-Stability Indices and Recent Development of Composting Bin. Energy Nexus 2022, 6, 100062. [Google Scholar] [CrossRef]

- Waqas, M.; Almeelbi, T.; Nizami, A.S. Resource Recovery of Food Waste through Continuous Thermophilic In-Vessel Composting. Environ. Sci. Pollut. Res. 2017, 25, 5212–5222. [Google Scholar] [CrossRef]

- Katakula, A.A.N.; Handura, B.; Gawanab, W.; Itanna, F.; Mupambwa, H.A. Optimized Vermicomposting of a Goat Manure-Vegetable Food Waste Mixture for Enhanced Nutrient Release. Sci. Afr. 2021, 12, e00727. [Google Scholar] [CrossRef]

- Chennaoui, M.; Salama, Y.; Aouinty, B.; Mountadar, M.; Assobhei, O. Evolution of Bacterial and Fungal Flora during In-Vessel Composting of Organic Household Waste under Air Pressure. J. Mater. Environ. Sci. 2018, 9, 680–688. [Google Scholar]

- Liu, Z.; Wang, X.; Wang, F.; Bai, Z.; Chadwick, D.; Misselbrook, T.; Ma, L. The Progress of Composting Technologies from Static Heap to Intelligent Reactor: Benefits and Limitations. J. Clean. Prod. 2020, 270, 122328. [Google Scholar] [CrossRef]

- Shishido, T.; Seki, H. Laboratory-Scale Experiment for an Active-Stage Composting Process under the Same Material and Operating Conditions. J. Agric. Meteorol. 2015, 71, 111–123. [Google Scholar] [CrossRef]

- Lashermes, G.; Barriuso, E.; le Villio-Poitrenaud, M.; Houot, S. Composting in Small Laboratory Pilots: Performance and Reproducibility. Waste Manag. 2012, 32, 271–277. [Google Scholar] [CrossRef] [PubMed]

- El Haggar, S.M. Rural and Developing Country Solutions. Environ. Solut. 2005, 313–400. [Google Scholar] [CrossRef]

- Pansari, N.B.; Deosarkar, S.B.; Nandgaonkar, A.B. Smart Compost System. In Proceedings of the 2nd International Conference on Intelligent Computing and Control Systems, Madurai, India, 14–15 June 2018; pp. 597–600. [Google Scholar]

- Elalami, M.; Baskoun, Y.; Zahra Beraich, F.; Arouch, M.; Taouzari, M.; Qanadli, S.D. Design and Test of the Smart Composter Controlled by Sensors. In Proceedings of the 2019 7th International Renewable and Sustainable Energy Conference, Agadir, Morocco, 27–30 November 2019. [Google Scholar] [CrossRef]

- Zarghami, M.; Szidarovszky, F. Introduction to Multicriteria Decision Analysis. In Multicriteria Analysis; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–12. [Google Scholar]

- Zlaugotne, B.; Zihare, L.; Balode, L.; Kalnbalkite, A.; Khabdullin, A.; Blumberga, D. Multi-Criteria Decision Analysis Methods Comparison. Environ. Clim. Technol. 2020, 24, 454–471. [Google Scholar] [CrossRef]

- Jahan, A.; Bahraminasab, M.; Edwards, K.L. A Target-Based Normalization Technique for Materials Selection. Mater. Des. 2012, 35, 647–654. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, L.; Liu, Z.; Sutherland, J.W. Multi-Criteria Decision Making and Uncertainty Analysis for Materials Selection in Environmentally Conscious Design. Int. J. Adv. Manuf. Technol. 2010, 52, 421–432. [Google Scholar] [CrossRef]

- Cook, B.D.; Bloom, P.R.; Halbach, T.R. Fate of a Polyacrylate Polymer during Composting of Simulated Municipal Solid Waste. J. Environ. Qual. 1997, 26, 618–625. [Google Scholar] [CrossRef]

- Qasim, W.; Moon, B.E.; Okyere, F.G.; Khan, F.; Nafees, M.; Kim, H.T. Influence of Aeration Rate and Reactor Shape on the Composting of Poultry Manure and Sawdust. J. Air Waste Manag. Assoc. 2019, 69, 633–645. [Google Scholar] [CrossRef]

- Deschamps, A.M.; Henno, P.; Pernelle, C.; Caignault, L.; Lebeault, J.M. Bench-Scale Reactors for Composting Research. Biotechnol. Lett. 1979, 1, 239–244. [Google Scholar] [CrossRef]

- Dlabaja, T.; Malaťák, J. Optimization of Anaerobic Fermentation of Kitchen Waste. Res. Agric. Eng. 2013, 59, 1–8. [Google Scholar] [CrossRef]

- Li, Q.; Wang, X.C.; Zhang, H.H.; Shi, H.L.; Hu, T.; Ngo, H.H. Characteristics of Nitrogen Transformation and Microbial Community in an Aerobic Composting Reactor under Two Typical Temperatures. Bioresour. Technol. 2013, 137, 270–277. [Google Scholar] [CrossRef]

- Oazana, S.; Naor, M.; Grinshpun, J.; Halachmi, I.; Raviv, M.; Saadi, I.; Avidov, R.; Varma, V.S.; Rosenfeld, L.; Gross, A.; et al. A Flexible Control System Designed for Lab-Scale Simulations and Optimization of Composting Processes. Waste Manag. 2018, 72, 150–160. [Google Scholar] [CrossRef] [PubMed]

- Pandey, P.K.; Cao, W.; Biswas, S.; Vaddella, V. A New Closed Loop Heating System for Composting of Green and Food Wastes. J. Clean. Prod. 2016, 133, 1252–1259. [Google Scholar] [CrossRef]

- Gao, X.; Yang, F.; Yan, Z.; Zhao, J.; Li, S.; Nghiem, L.; Li, G.; Luo, W. Humification and Maturation of Kitchen Waste during Indoor Composting by Individual Households. Sci. Total Environ. 2022, 814, 152509. [Google Scholar] [CrossRef]

- FoodCycler FC-50. Available online: https://www.vitamix.com/us/en_us/shop/foodcycler-fc-50?COUPON=06-178&cjevent=334d7f69c01811ec838e53960a18050c&cjdata=MXxZfDB8WXww (accessed on 19 May 2022).

- Kitchen Waste Composter, TOGO Organic Food Waste Recycling Machine. Available online: https://www.togocomposter.com/products/kitchen-waste-composter/ (accessed on 19 May 2022).

- Goepel, K. Implementation of an Online Software Tool for the Analytic Hierarchy Process (AHP-OS). Int. J. Anal. Hierarchy Process 2018, 10, 469–487. [Google Scholar]

- Ryckeboer, J.; Mergaert, J.; Vaes, K.; Klammer, S.; de Clercq, D.; Coosemans, J.; Insam, H.; Swings, J. A Survey of Bacteria and Fungi Occurring during Composting and Self-Heating Processes. Ann. Microbiol. 2003, 53, 349–410. [Google Scholar]

- Blum, J. Exploring Arduino: Tools and Techniques for Engineering Wizardry; Wiley: Hoboken, NJ, USA, 2019; ISBN 9781119405375. [Google Scholar]

- Galkin, I.; Vorobyov, M.; Gainutdinovs, O.; Studers, P. Customized Vibration Generator for State of Health Monitoring of Prosthetic Implants and Pseudo-Bionic Machine-Human Feedbacks. Electronics 2019, 8, 810. [Google Scholar] [CrossRef]

- Sundberg, C.; Yu, D.; Franke-Whittle, I.; Kauppi, S.; Smårs, S.; Insam, H.; Romantschuk, M.; Jönsson, H. Effects of PH and Microbial Composition on Odour in Food Waste Composting. Waste Manag. 2013, 33, 204. [Google Scholar] [CrossRef] [PubMed]

| Factor Group | Indicators | Value | Best Alternative |

|---|---|---|---|

| Economic indicators | Product cost when available for consumer, EUR | EUR | MIN |

| Market availability for a finished product | 1 to 5 | MAX | |

| Device energy consumption | kWh per day | MIN | |

| Technological indicators | Device volume | liters | MAX |

| Composting time | days | MIN | |

| Monitoring system for composting stability | 1 to 5 | MAX | |

| Pretreatment required outside the device | 1 to 5 | MIN | |

| Technological readiness and availability for production | 1 to 5 | MAX | |

| Environmental indicators | Waste saved in landfills | kg per year | MAX |

| Emission reduction | kg per year | MAX | |

| Environmental pollution generated in device production and operation | 1 to 5 | MIN | |

| Benefits to the environment from biomass utilization for this alternative | 1 to 5 | MAX | |

| Impact on climate change and GHG emissions | 1 to 5 | MAX | |

| Social indicators | Availability to social groups | 1 to 5 | MAX |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stipniece, A.A.; Vladinovskis, V.; Daugulis, P.; Zemite, M.; Vitola, L.; Mezule, L. Advantages and Challenges of Composting Reactors for Household Use: Smart Reactor Concept. Sustainability 2022, 14, 10030. https://doi.org/10.3390/su141610030

Stipniece AA, Vladinovskis V, Daugulis P, Zemite M, Vitola L, Mezule L. Advantages and Challenges of Composting Reactors for Household Use: Smart Reactor Concept. Sustainability. 2022; 14(16):10030. https://doi.org/10.3390/su141610030

Chicago/Turabian StyleStipniece, Alise Anna, Vlads Vladinovskis, Pauls Daugulis, Marta Zemite, Laura Vitola, and Linda Mezule. 2022. "Advantages and Challenges of Composting Reactors for Household Use: Smart Reactor Concept" Sustainability 14, no. 16: 10030. https://doi.org/10.3390/su141610030

APA StyleStipniece, A. A., Vladinovskis, V., Daugulis, P., Zemite, M., Vitola, L., & Mezule, L. (2022). Advantages and Challenges of Composting Reactors for Household Use: Smart Reactor Concept. Sustainability, 14(16), 10030. https://doi.org/10.3390/su141610030