Multi-Objective Prediction of the Mechanical Properties and Environmental Impact Appraisals of Self-Healing Concrete for Sustainable Structures

Abstract

:1. Introduction

1.1. Background

1.2. Strength and Workability of Self-Healing Concrete

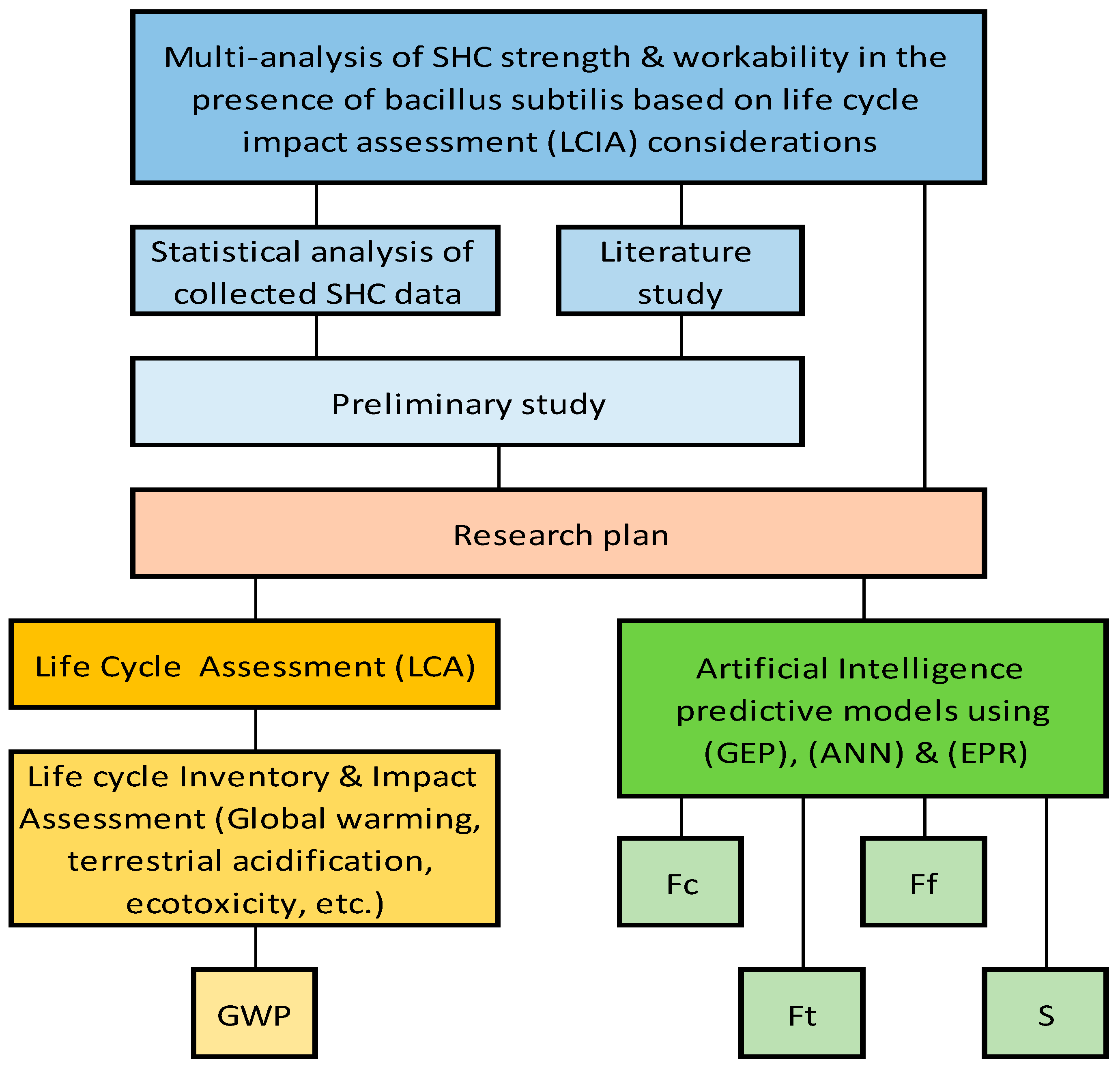

2. Methodology

2.1. Data Collection

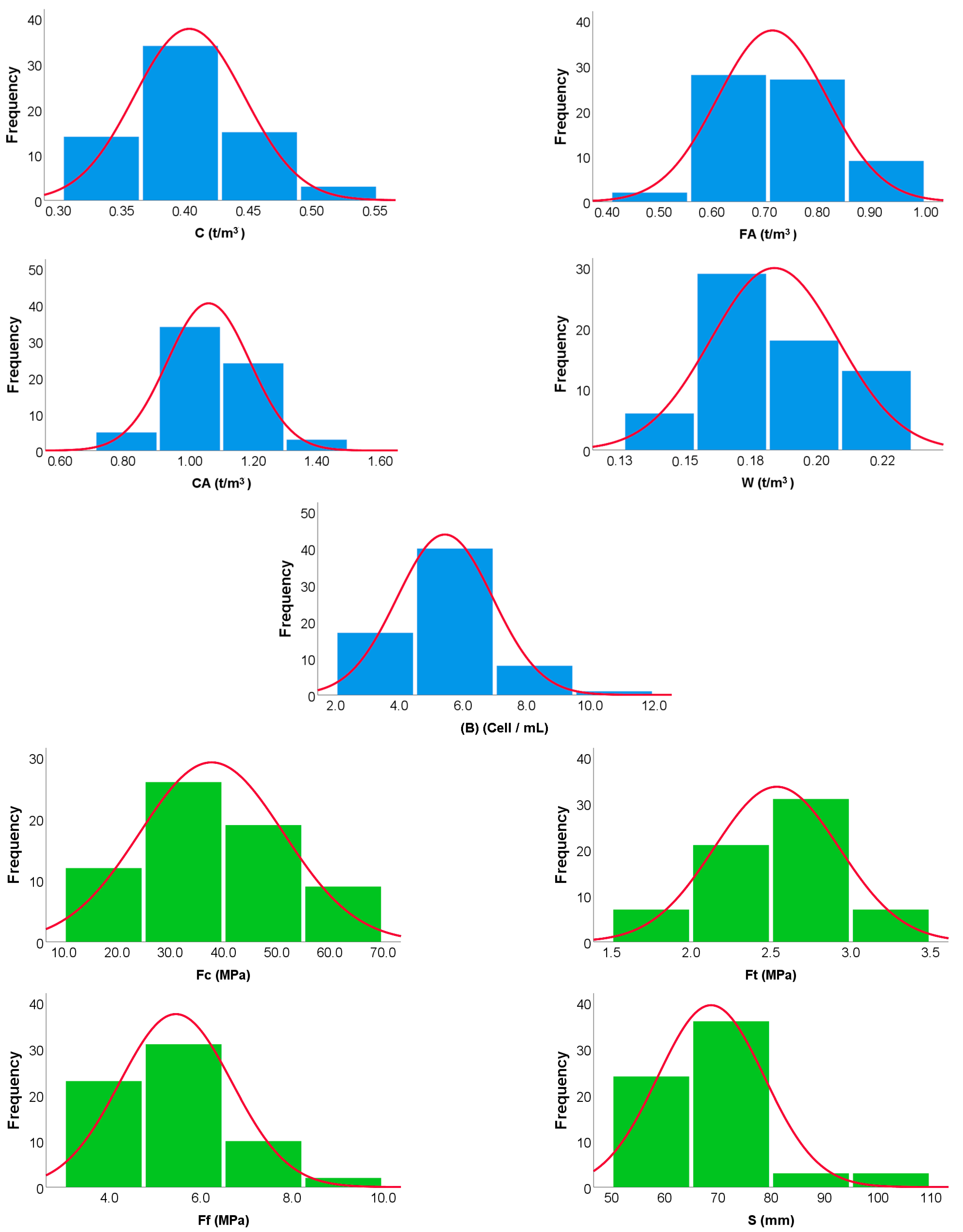

2.2. Statistical Analysis of Collected Database

2.3. Research Program

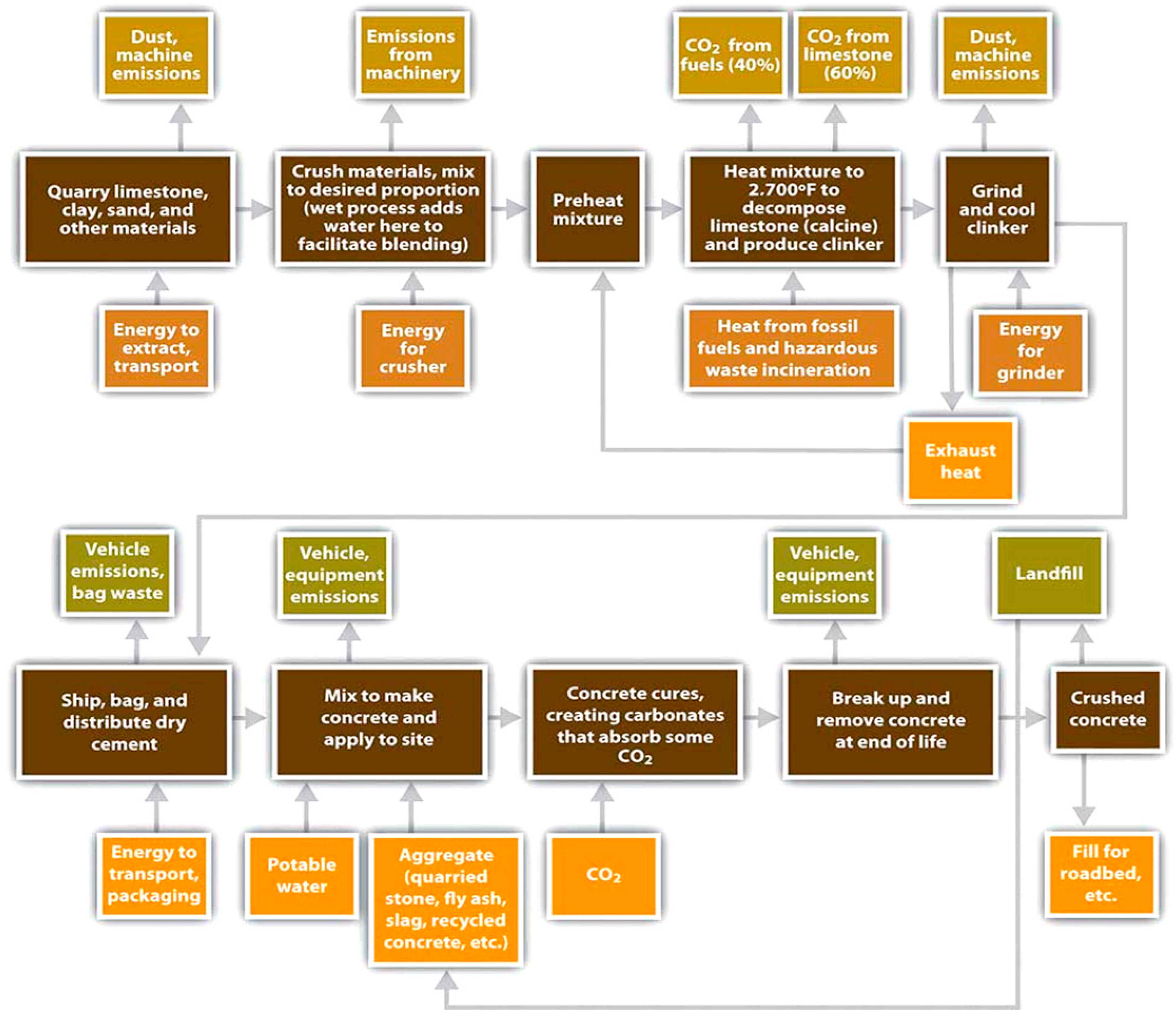

2.3.1. Life Cycle Assessment, Goal and Scope

2.3.2. Life Cycle Inventory

2.3.3. Impact Assessment Method

2.3.4. Soft Computing Plan

3. Results and Discussion

3.1. General Behavior of the Self-Healing Concrete

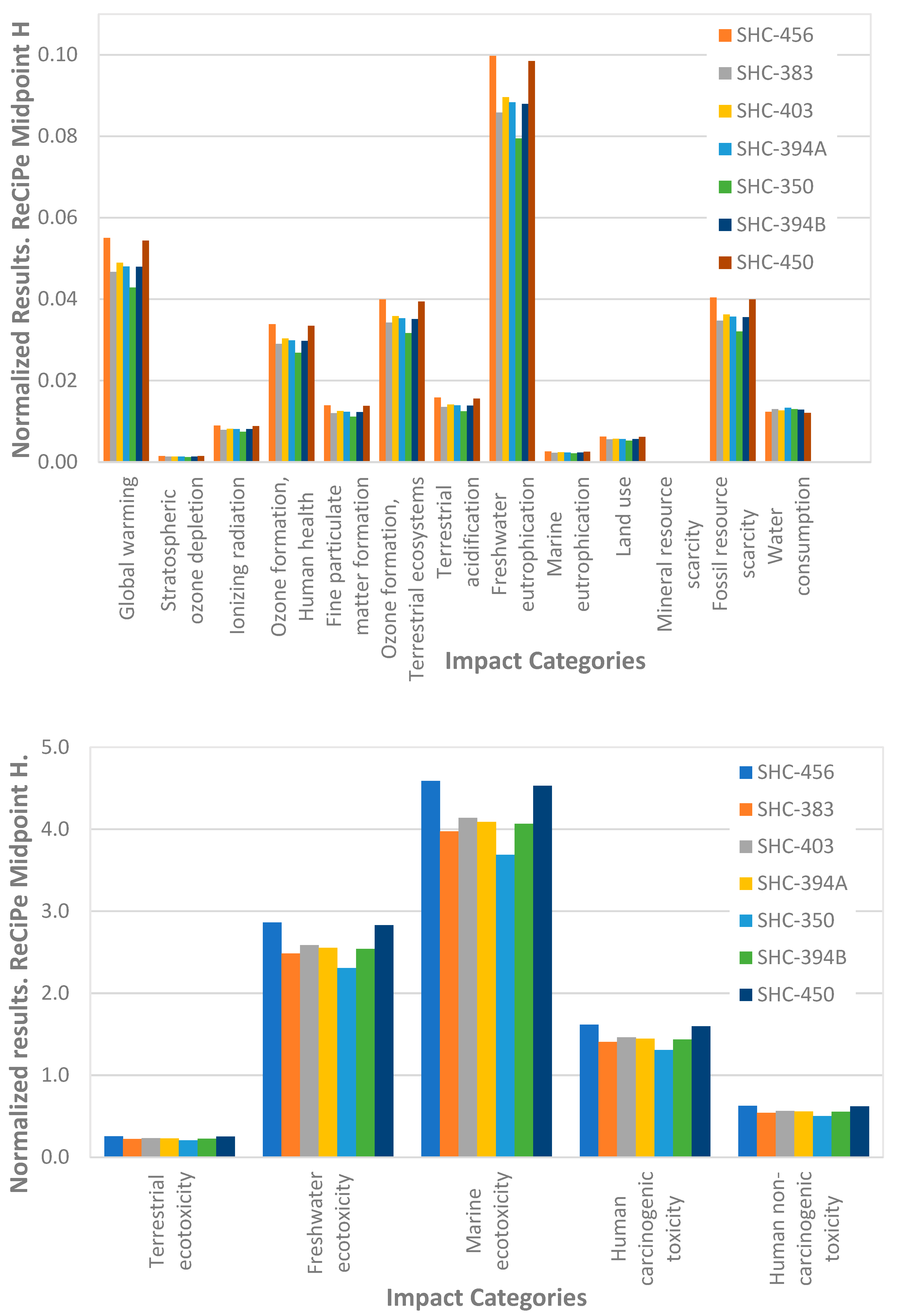

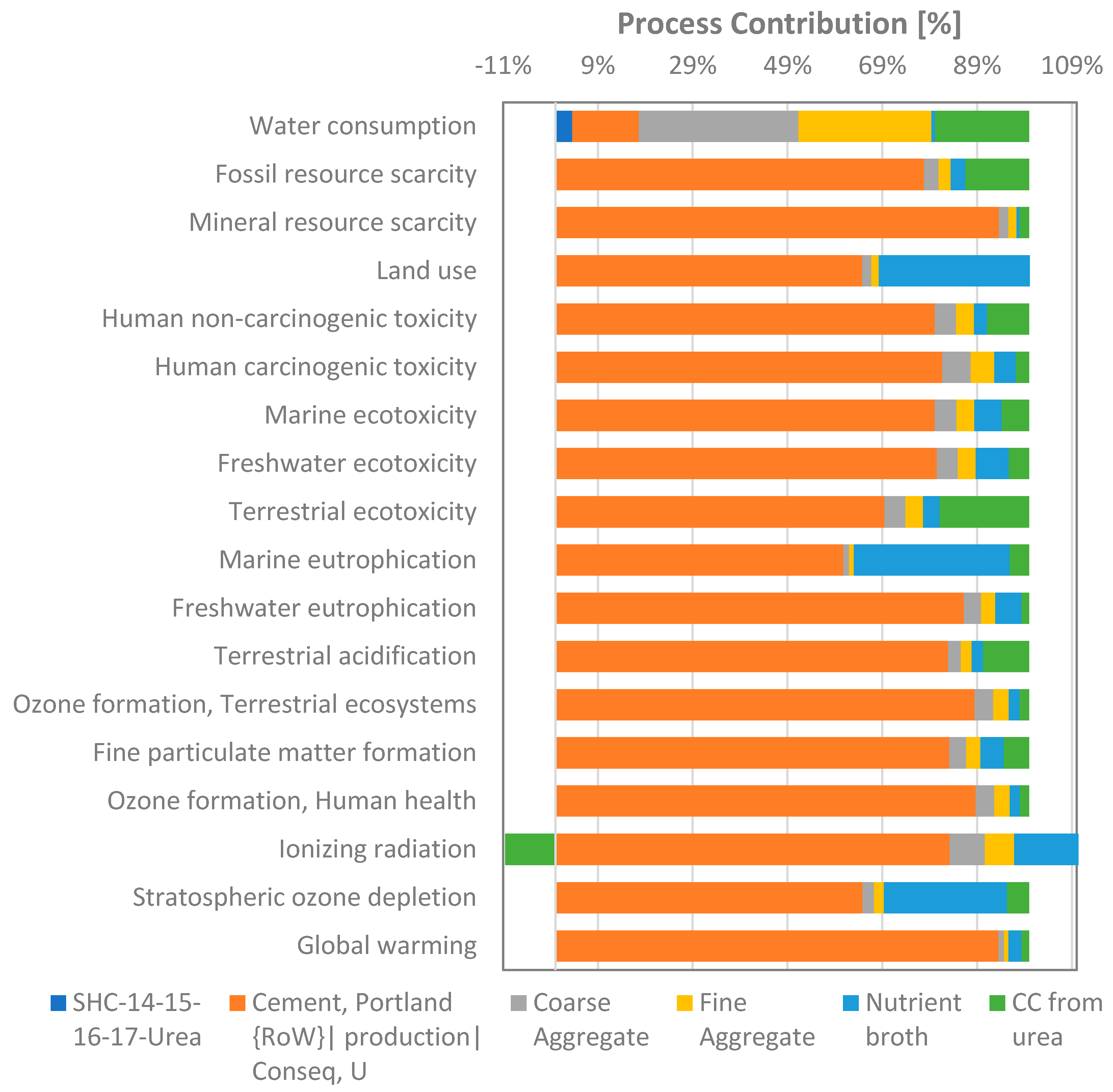

3.2. Life Cycle Assessment and Analysis

3.3. Models Prediction

3.3.1. Model (1)—Using (GEP) Technique

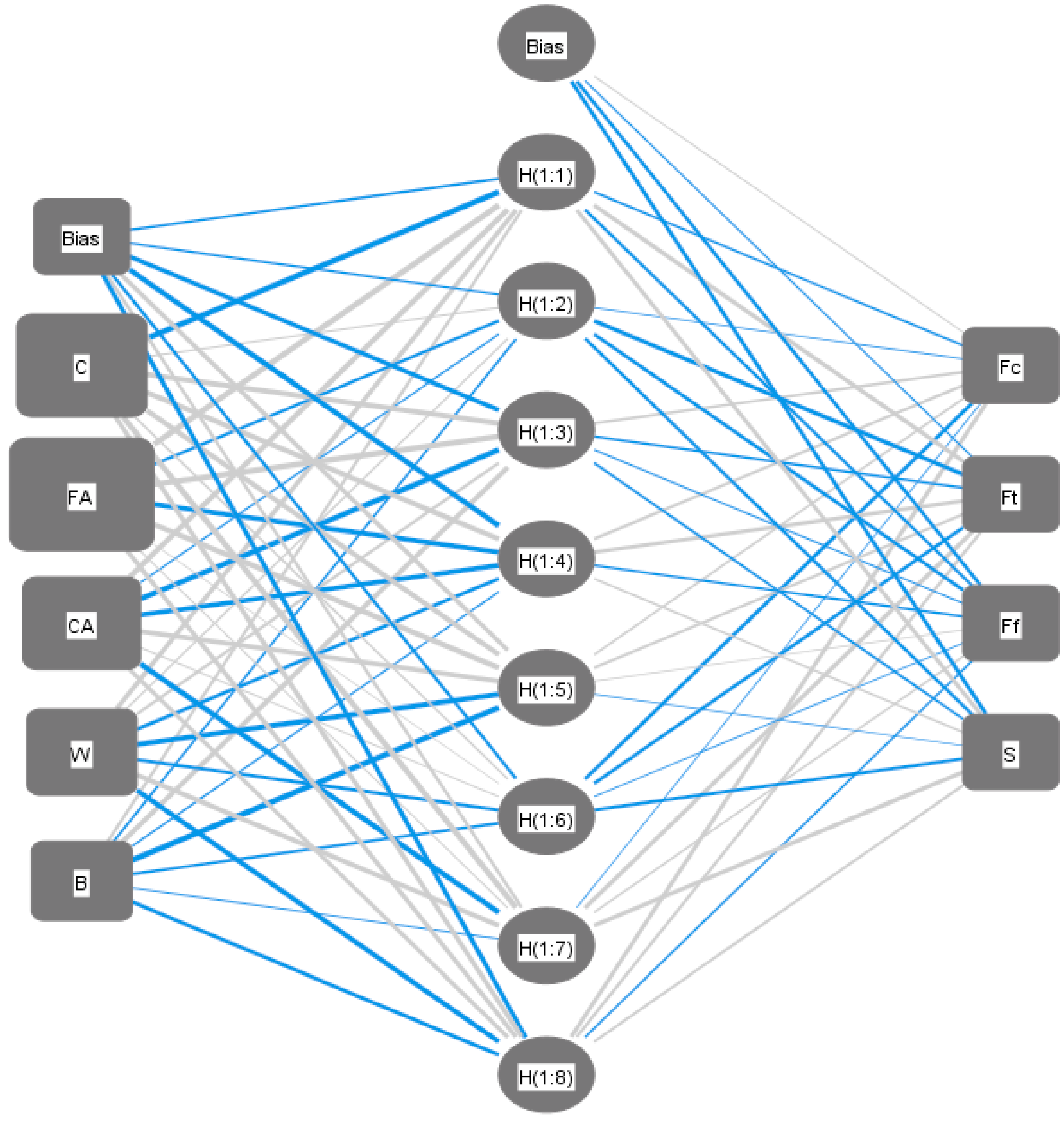

3.3.2. Model (2)—Using (ANN) Technique

3.3.3. Model (3)—Using (EPR) Technique

4. Conclusions

- -

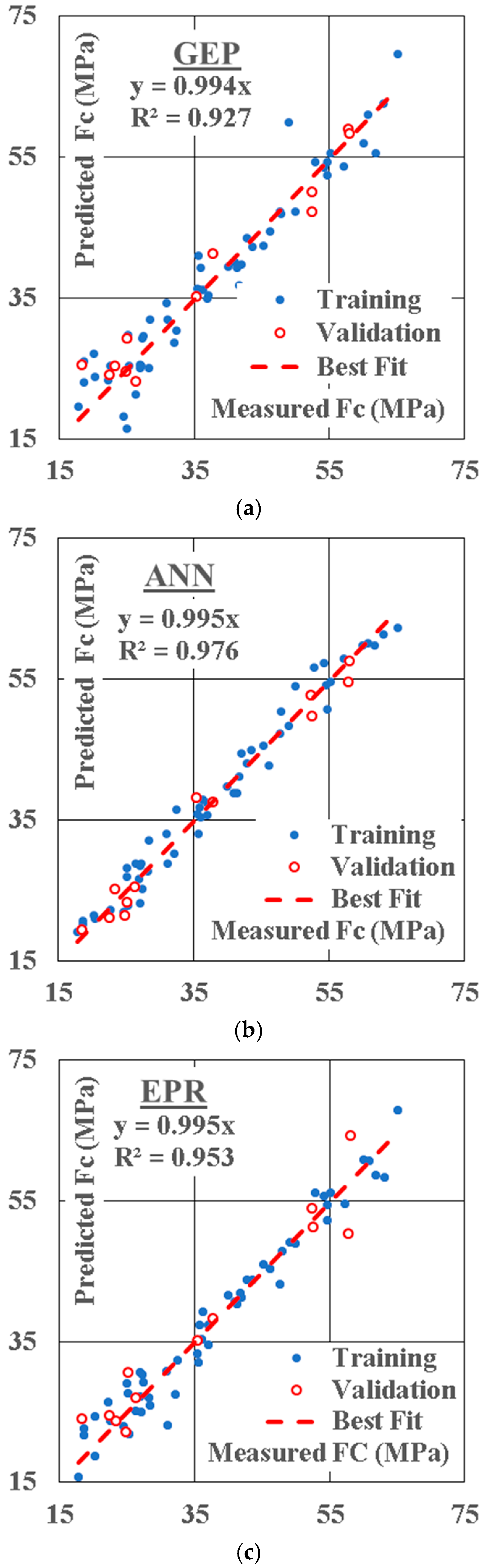

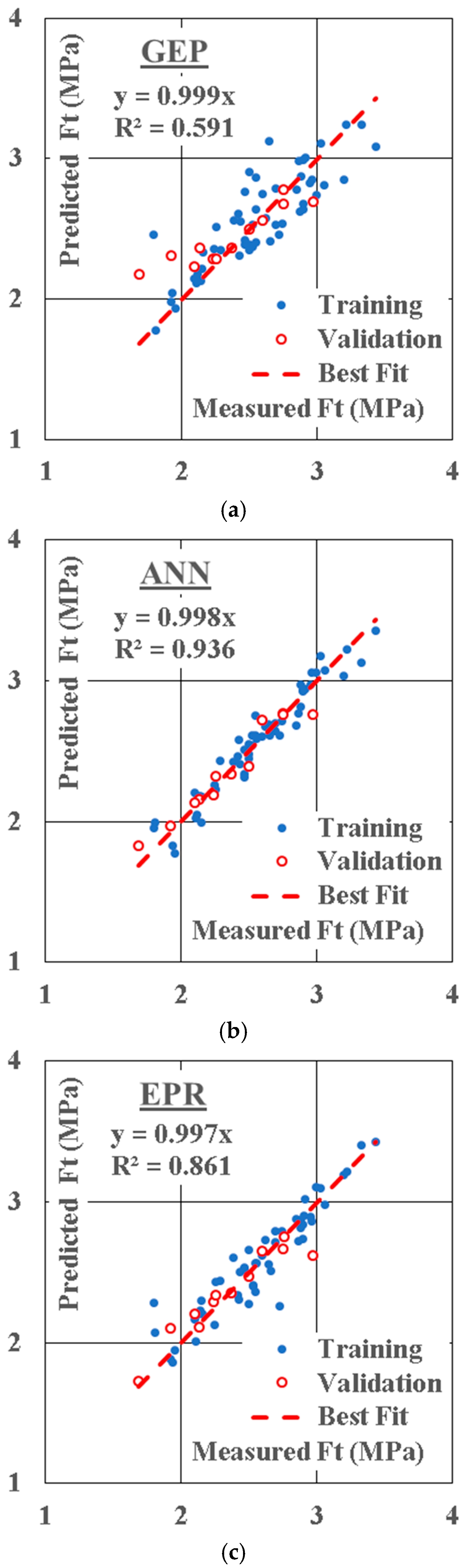

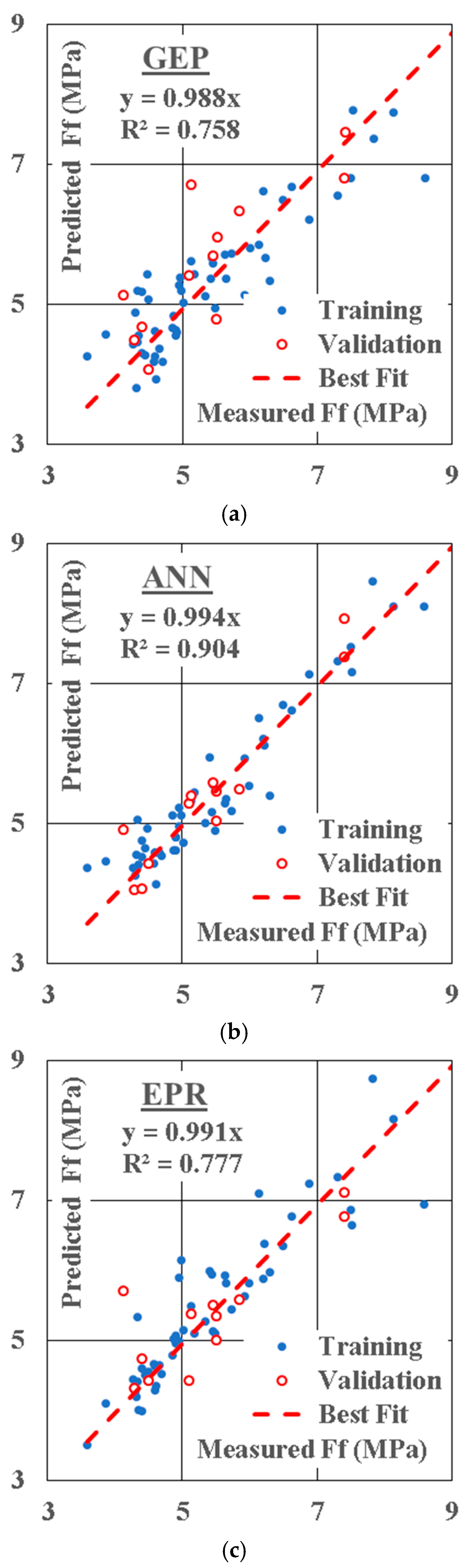

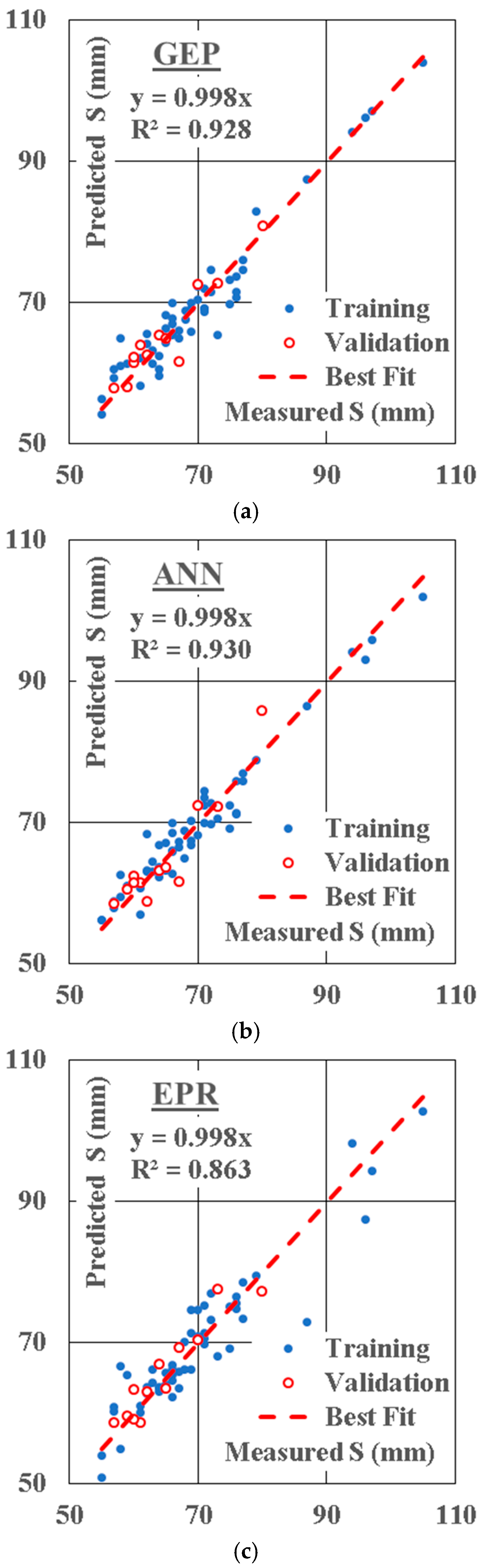

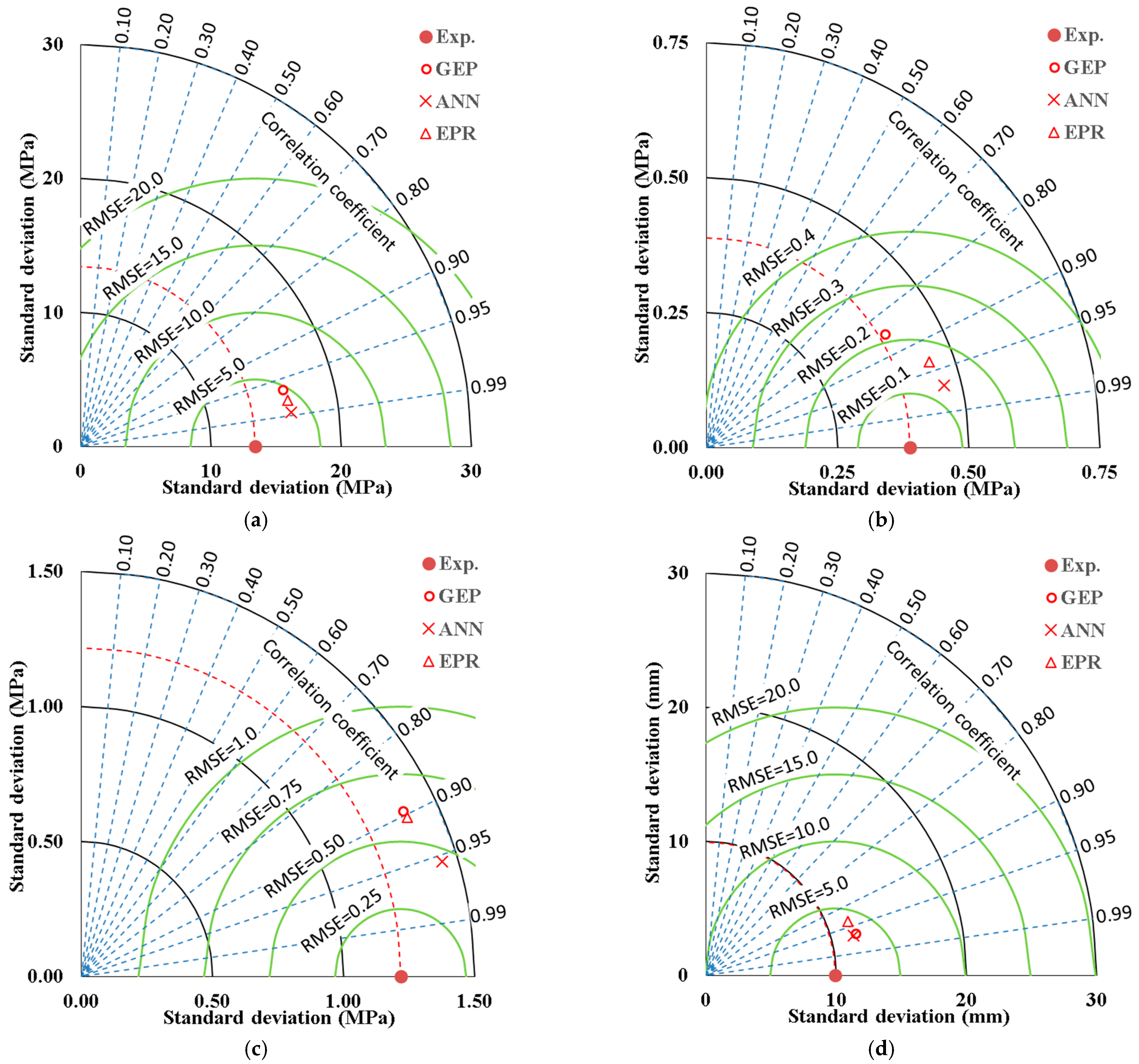

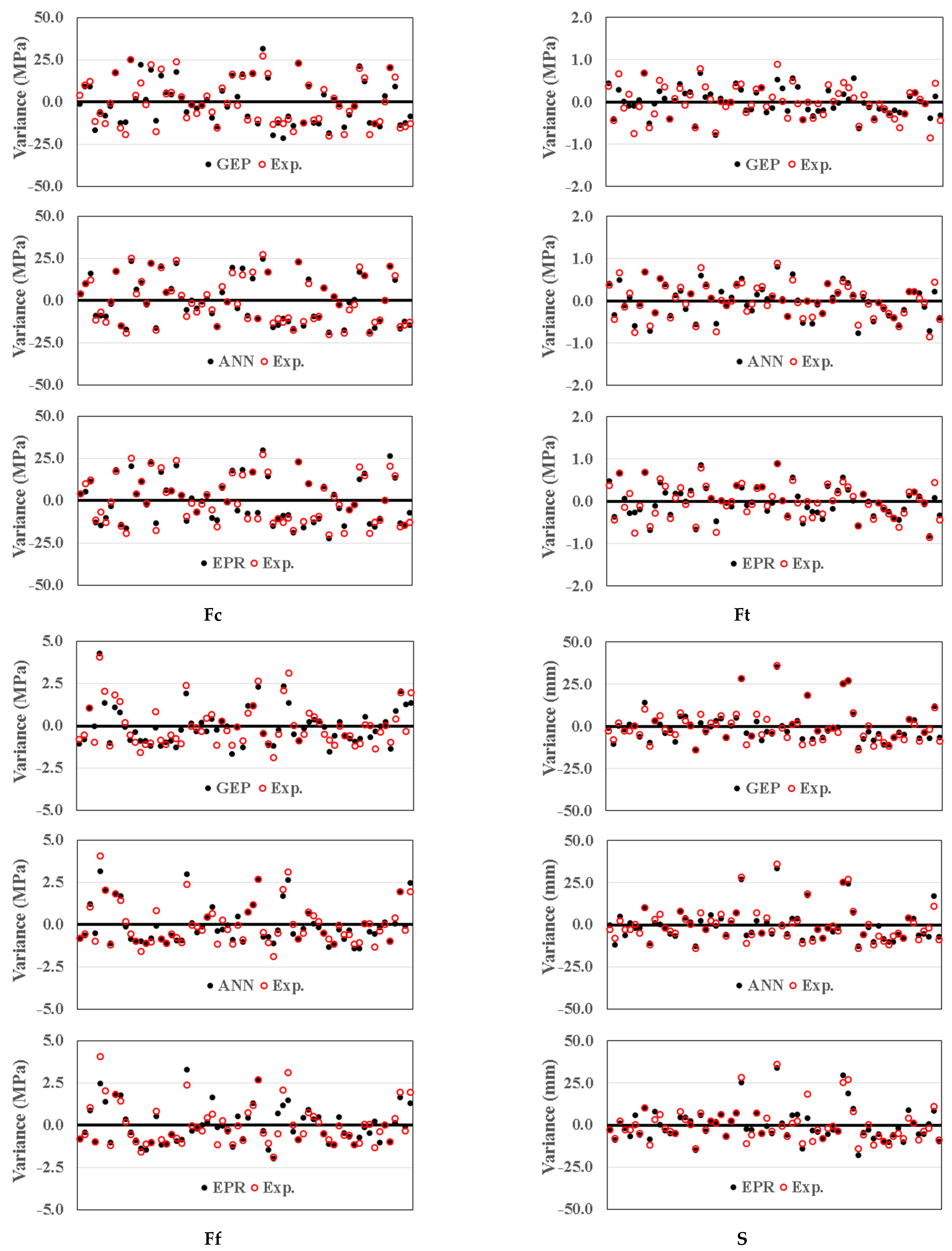

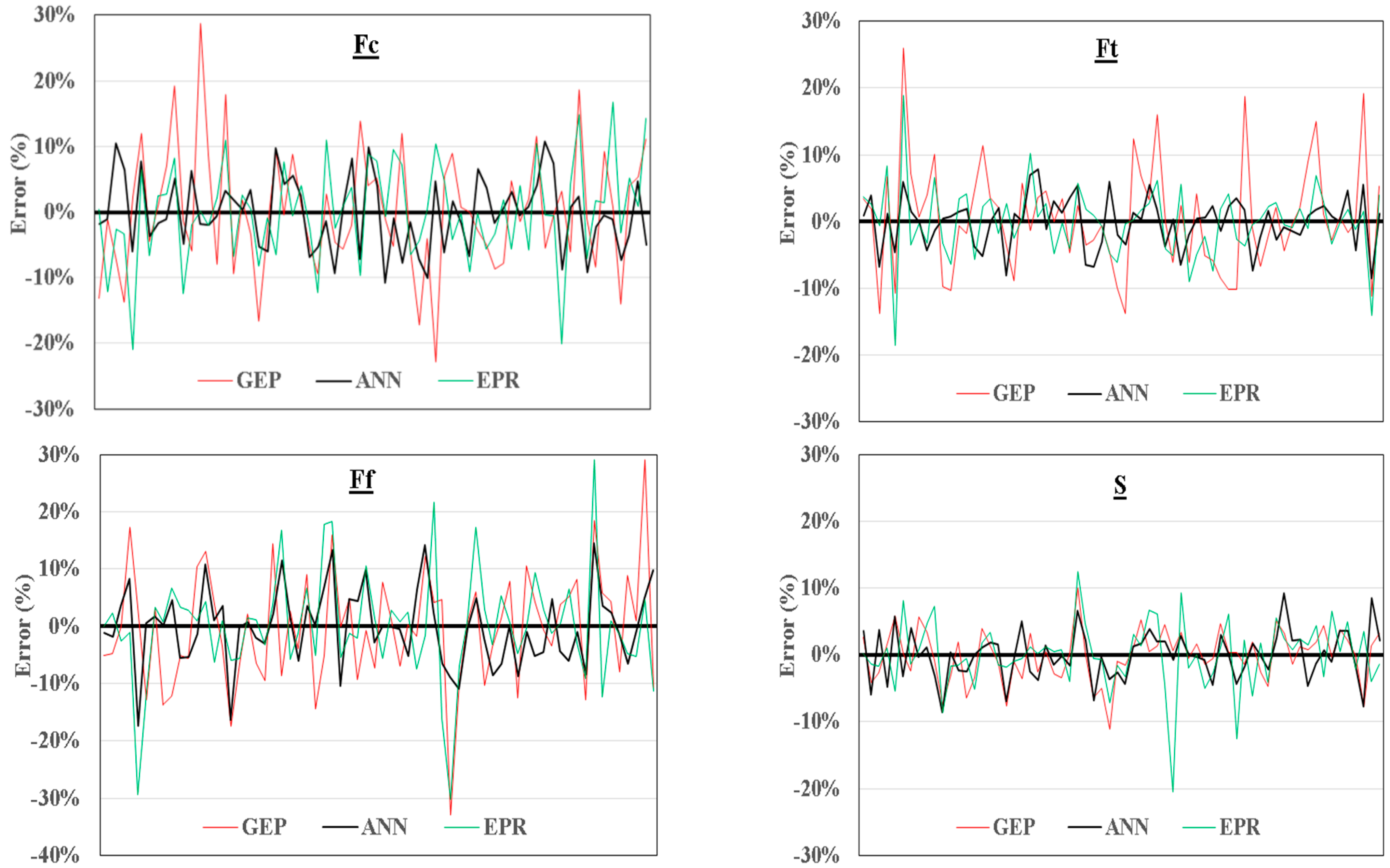

- GEP and EPR models shared almost the same level of accuracy; GEP: 90.7%, 91.9%, 90.0%, and 96.2%, EPR: 92.5%, 94.6%, 90.4%, and 95.0% for Fc, Ft, Ff, and S, respectively. They both generated a set of closed form equations with almost the same level of complexity. Hence, both modes are equivalent and could be applied manually.

- -

- The ANN model presented slightly higher levels of complexity, accuracy, and lower scattering than GP and EPR (ANN, 94.5%, 96.2%, 93.4%, and 96.4% for Fc, Ft, Ff, and S, respectively). Although it has a better accuracy, the generated model cannot be applied manually.

- -

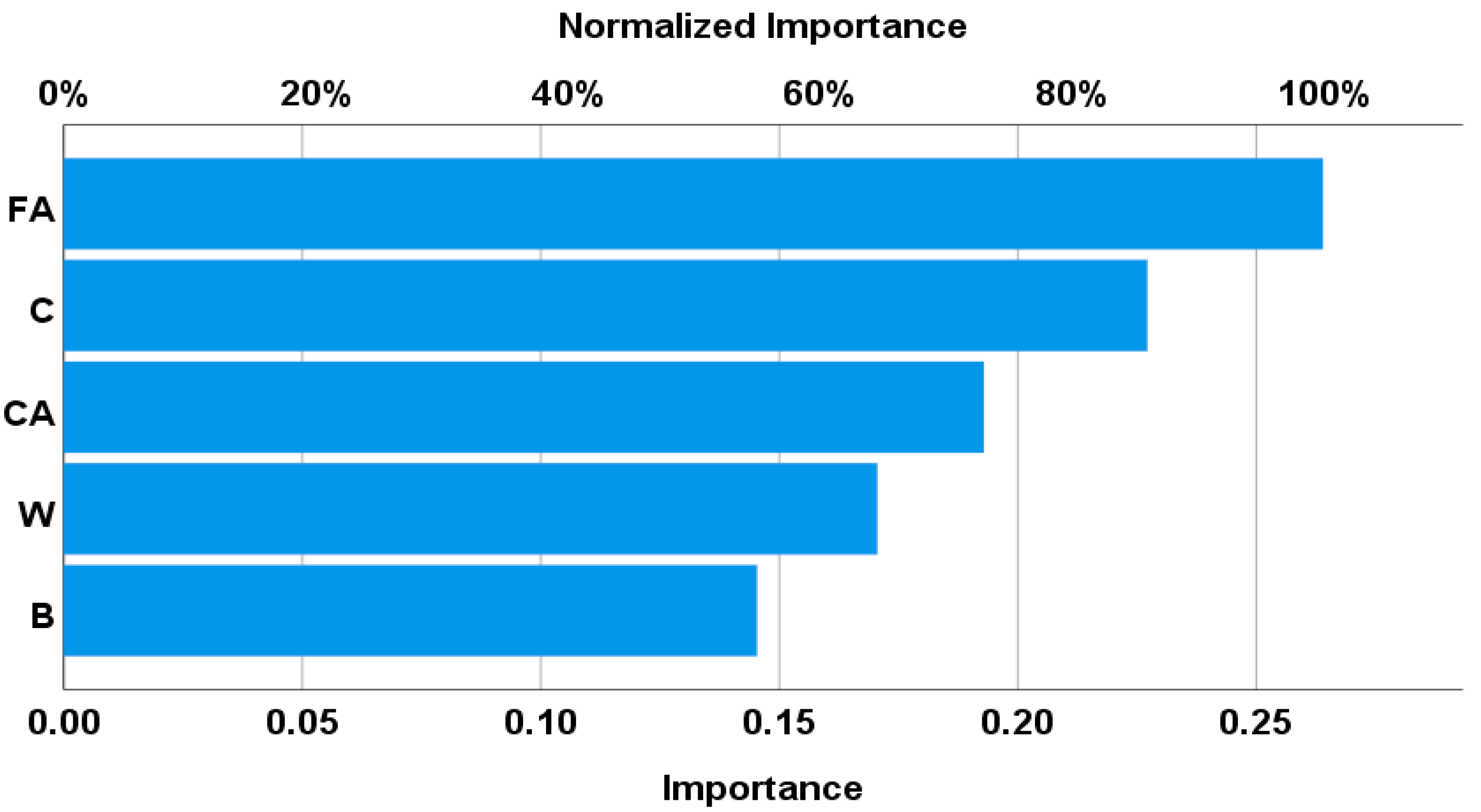

- The summation of the absolute weights of each neuron in the input layer of the developed (ANN) model indicated that cement and fine aggregate contents (C, FA) are the most important factors, which presents about 50% of the total influence. Water and coarse aggregate contents (W, CA) come second in the importance ranking with about (35%) of the influence. Finally, bacteria concentration (B) had the lowest effect with about (15%).

- -

- Taylor charts in Figure 15 showed that the correlation coefficients exceeded 95% for ANN models, 90% for EPR, and GEP models except GEP-Ft ≈ 85%.

- -

- GA technique successfully reduced the 56 terms of conventional polynomial regression quadrilateral formula to only 32 terms without significant impact on its accuracy.

- -

- Like any other regression technique, the generated formulas are valid within the considered range of parameter values, beyond this range; the prediction accuracy should be verified.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, R.; Woo, U.; Shin, M.; Ahn, E.; Choi, H. Evaluation of self-healing in concrete using linear and nonlinear resonance spectroscopy. Constr. Build. Mater. 2022, 335, 127492. [Google Scholar] [CrossRef]

- Wang, X.F.; Yang, Z.H.; Fang, C.; Han, N.X.; Zhu, G.M.; Tang, J.N.; Xing, F. Evaluation of the mechanical performance recovery of self-healing cementitious materials–its methods and future development: A review. Constr. Build. Mater. 2019, 212, 400–421. [Google Scholar] [CrossRef]

- Allahyari, H.; Heidarpour, A.; Shayan, A. Experimental and analytical studies of bacterial self-healing concrete subjected to alkali-silica-reaction. Constr. Build. Mater. 2021, 310, 125149. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-healing cement concrete composites for resilient infrastructures: A review. Compos. Part. B Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Yıldırım, G.; Keskin, Ö.K.; Keskin, S.B.; Şahmaran, M.; Lachemi, M. A review of intrinsic self-healing capability of engineered cementitious composites: Recovery of transport and mechanical properties. Constr. Build. Mater. 2015, 101, 10–21. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-Healing in Cementitious Materials—A Review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Ye, G.; Qian, C.; Schlangen, E. Self-healing in cementitious materials: Materials, methods and service conditions. Mater. Des. 2016, 92, 499–511. [Google Scholar] [CrossRef]

- Hearn, N. Self-sealing, autogenous healing and continued hydration: What is the difference? Mater. Struct. 1998, 31, 563–567. [Google Scholar] [CrossRef]

- Aldea, C.M.; Song, W.J.; Popovics, J.S.; Shah, S.P. Extent of Healing of Cracked Normal Strength Concrete. J. Mater. Civ. Eng. 2000, 12, 92–96. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Ryu, J.-S. An experimental study on the repair of concrete crack by electrochemical technique. Mater. Struct. 2001, 34, 433–437. [Google Scholar] [CrossRef]

- Wang, X.F.; Xing, F.; Xie, Q.; Han, N.X.; Kishi, T.; Ahn, T.H. Mechanical behavior of a capsule embedded in cementitious matrix-macro model and numerical simulation. J. Ceram. Process. Res. 2015, 16, 74–82. [Google Scholar]

- Chandra Sekhara Reddy, T.; Ravitheja, A. Macro mechanical properties of self healing concrete with crystalline admixture under different environments. Ain Shams Eng. J. 2019, 10, 23–32. [Google Scholar] [CrossRef]

- de Rooij, M.; Van Tittelboom, K.; De Belie, N.; Schlangen, E. (Eds.) Self-Healing Phenomena in Cement-Based Materials. In RILEM State-of-the-Art Reports; Springer: Dordrecht, The Netherlands, 2013; Volume 11, ISBN 978-94-007-6623-5. [Google Scholar]

- Ivanov, F.M.; Polyakov, B.I. Self-healing and durability of hydraulic concrete. Hydrotech. Constr. 1974, 8, 844–849. [Google Scholar] [CrossRef]

- Gray, R.J. Autogenous healing of fibre/matrix interfacial bond in fibre-reinforced mortar. Cem. Concr. Res. 1984, 14, 315–317. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. Repeated Autogenous Healing in Strain-Hardening Cementitious Composites by Using Superabsorbent Polymers. J. Mater. Civ. Eng. 2016, 28, 4015086. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.S.; Schlangen, E. Super absorbent polymers to simulate self healing in ECC. In Proceedings of the 2nd International Symposium on Service Life Design for Infrastructures, RILEM Publications SARL, Delft, The Netherlands, 4–6 October 2010; pp. 849–858. [Google Scholar]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Xu, J.; Chen, B.; Xie, T. Experimental and theoretical analysis of bubble departure behavior in narrow rectangular channel. Prog. Nucl. Energy 2014, 77, 1–10. [Google Scholar] [CrossRef]

- Yang, Z.; Hollar, J.; He, X.; Shi, X. A self-healing cementitious composite using oil core/silica gel shell microcapsules. Cem. Concr. Compos. 2011, 33, 506–512. [Google Scholar] [CrossRef]

- Chunxiang, Q.; Jianyun, W.; Ruixing, W.; Liang, C. Corrosion protection of cement-based building materials by surface deposition of CaCO3 by Bacillus pasteurii. Mater. Sci. Eng. C 2009, 29, 1273–1280. [Google Scholar] [CrossRef]

- Keller, M.W.; Sottos, N.R. Mechanical Properties of Microcapsules Used in a Self-Healing Polymer. Exp. Mech. 2006, 46, 725–733. [Google Scholar] [CrossRef] [Green Version]

- De Muynck, W.; Debrouwer, D.; De Belie, N.; Verstraete, W. Bacterial carbonate precipitation improves the durability of cementitious materials. Cem. Concr. Res. 2008, 38, 1005–1014. [Google Scholar] [CrossRef]

- Snoeck, D.; Van Tittelboom, K.; Steuperaert, S.; Dubruel, P.; De Belie, N. Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers. J. Intell. Mater. Syst. Struct. 2014, 25, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Kessler, M.; Sottos, N.; White, S. Self-healing structural composite materials. Compos. Part. A Appl. Sci. Manuf. 2003, 34, 743–753. [Google Scholar] [CrossRef]

- Tziviloglou, E.; Wiktor, V.; Jonkers, H.M.; Schlangen, E. Bacteria-based self-healing concrete to increase liquid tightness of cracks. Constr. Build. Mater. 2016, 122, 118–125. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Kanellopoulos, A.; Al-Tabbaa, A. Encapsulation of expansive powder minerals within a concentric glass capsule system for self-healing concrete. Constr. Build. Mater. 2016, 121, 629–643. [Google Scholar] [CrossRef]

- Perez, G.; Gaitero, J.J.; Erkizia, E.; Jimenez, I.; Guerrero, A. Characterisation of cement pastes with innovative self-healing system based in epoxy-amine adhesive. Cem. Concr. Compos. 2015, 60, 55–64. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Shui, Z. Feasibility of self-healing in cementitious materials–By using capsules or a vascular system? Constr. Build. Mater. 2014, 63, 108–118. [Google Scholar] [CrossRef]

- Wang, J.Y.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; Van Loo, D.; Jacobs, P. Self-healing efficiency of cementitious materials containing tubular capsules filled with healing agent. Cem. Concr. Compos. 2011, 33, 497–505. [Google Scholar] [CrossRef]

- Pei, R.; Liu, J.; Wang, S.; Yang, M. Use of bacterial cell walls to improve the mechanical performance of concrete. Cem. Concr. Compos. 2013, 39, 122–130. [Google Scholar] [CrossRef]

- Mondal, S.; Ghosh, A. (Dey) Investigation into the optimal bacterial concentration for compressive strength enhancement of microbial concrete. Constr. Build. Mater. 2018, 183, 202–214. [Google Scholar] [CrossRef]

- Schreiberová, H.; Bílý, P.; Fládr, J.; Šeps, K.; Chylík, R.; Trtík, T. Impact of the self-healing agent composition on material characteristics of bio-based self-healing concrete. Case Stud. Constr. Mater. 2019, 11, e00250. [Google Scholar] [CrossRef]

- Hermawan, H.; Minne, P.; Serna, P.; Gruyaert, E. Understanding the Impacts of Healing Agents on the Properties of Fresh and Hardened Self-Healing Concrete: A Review. Processes 2021, 9, 2206. [Google Scholar] [CrossRef]

- Vijay, K.; Murmu, M. Self-repairing of concrete cracks by using bacteria and basalt fiber. SN Appl. Sci. 2019, 1, 1344. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, H.; Ortoneda-Pedrola, M.; Nakouti, I.; Bras, A. Experimental characterisation of non-encapsulated bio-based concrete with self-healing capacity. Constr. Build. Mater. 2020, 256, 119411. [Google Scholar] [CrossRef]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of concrete incorporating silica fume. Constr. Build. Mater. 2012, 37, 645–651. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Bahrami, N.; Vaezi, M.; Ozbakkaloglu, T. Optimum rice husk ash content and bacterial concentration in self-compacting concrete. Constr. Build. Mater. 2019, 222, 796–813. [Google Scholar] [CrossRef]

- Jafarnia, M.S.; Khodadad Saryazdi, M.; Moshtaghioun, S.M. Use of bacteria for repairing cracks and improving properties of concrete containing limestone powder and natural zeolite. Constr. Build. Mater. 2020, 242, 118059. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, M.B. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Wang, H.; Habibi, M.; Marzouki, R.; Majdi, A.; Shariati, M.; Denic, N.; Zaki´c, A.; Khorami, M.; Khadimallah, M.A.; Ebid, A.A.K. Improving the Self-Healing of Cementitious Materials with a Hydrogel System. Gels 2022, 8, 278. [Google Scholar] [CrossRef]

- Pré-Sustainability, B.V. LCA Software for Informed Change-Makers, SimaPro 9.2; Pré-Sustainability, B.V.: LE Amersfoort, The Netherlands, 2019. [Google Scholar]

- ISO 14040; Environmental Management–Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Ramagiri, K.K.; Chintha, R.; Bandlamudi, R.K.; De Maeijer, P.K.; Kar, A. Cradle-to-gate life cycle and economic assessment of sustainable concrete mixes—alkali-activated concrete (Aac) and bacterial concrete (bc). Infrastructures 2021, 6, 104. [Google Scholar] [CrossRef]

- Sahnoun, M.; Kriaa, M.; Elgharbi, F.; Ayadi, D.Z.; Bejar, S.; Kammoun, R. Aspergillus oryzae S2 alpha-amylase production under solid state fermentation: Optimization of culture conditions. Int. J. Biol. Macromol. 2015, 75, 73–80. [Google Scholar] [CrossRef] [PubMed]

- Myhr, A.; Røyne, F.; Brandtsegg, A.S.; Bjerkseter, C.; Throne-Holst, H.; Borch, A.; Wentzel, A.; Røyne, A. Towards a low CO2 emission building material employing bacterial metabolism (2/2): Prospects for global warming potential reduction in the concrete industry. PLoS ONE 2019, 14, e0208643. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.H.; Ghorbel, E.; Fares, H.; Cousture, A. Bacterial self-healing of concrete and durability assessment. Cem. Concr. Compos. 2019, 104, 103340. [Google Scholar] [CrossRef]

- Yatish Reddy, P.V.; Ramesh, B.; Prem Kumar, L. Influence of bacteria in self healing of concrete-a review. Mater. Today Proc. 2020, 33, 4212–4218. [Google Scholar] [CrossRef]

- Safiuddin, M.; Ihtheshaam, S.; Kareem, R.A.; Shalam. A study on self-healing concrete. Mater. Today Proc. 2022, 52, 1175–1181. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Riofrio, A.; Cornejo, M.; Baykara, H. Life cycle and environmental impact evaluation of polylactic acid (PLA) production in Ecuador. Int. J. Life Cycle Assess. 2022, 27, 834–848. [Google Scholar] [CrossRef]

- Garces, J.I.T.; Dollente, I.J.; Beltran, A.B.; Tan, R.R.; Promentilla, M.A.B. Life cycle assessment of self-healing geopolymer concrete. Clean. Eng. Technol. 2021, 4, 100147. [Google Scholar] [CrossRef]

- Asadollahfardi, G.; Katebi, A.; Taherian, P.; Panahandeh, A. Environmental life cycle assessment of concrete with different mixed designs. Int. J. Constr. Manag. 2021, 21, 665–676. [Google Scholar] [CrossRef]

- Politecnico, F.P.; Milano, D.; Zurich, E.; Van Den Heede, P.; De Belie, N.; Pittau, F.; Habert, G.; Mignon, A. Life Cycle Assessment of Self-Healing Engineered Cementitious Composite (SH-ECC) Used for the Rehabilitation of Bridges. 2018. Available online: https://www.researchgate.net/publication/332443894 (accessed on 18 May 2022).

- Garces, J.I.T.; Tan, R.R.; Beltran, A.B.; Ongpeng, J.M.C.; Promentilla, M.A.B. Environmental Life Cycle Assessment of Alkali-activated Material with Different Mix Designs and Self-healing Agents Chemical Engineering Transactions Environmental Life Cycle Assessment of Alkali-activated Material with Different Mix Designs and Self-heal. Chem. Eng. J. 2021, 88, 835–841. [Google Scholar] [CrossRef]

| Range | Minimum | Maximum | Mean | S.D. | Variance | Skewness | Kurtosis | |

|---|---|---|---|---|---|---|---|---|

| C | 0.20 | 0.31 | 0.51 | 0.40 | 0.04 | 0.00 | 0.51 | −0.09 |

| FA | 0.50 | 0.48 | 0.98 | 0.71 | 0.10 | 0.01 | 0.24 | 0.03 |

| CA | 0.63 | 0.78 | 1.41 | 1.06 | 0.13 | 0.02 | 0.48 | 0.48 |

| W | 0.10 | 0.13 | 0.23 | 0.18 | 0.02 | 0.00 | −0.04 | −0.67 |

| B | 7.49 | 2.57 | 10.06 | 5.44 | 1.50 | 2.26 | 0.40 | 0.65 |

| Fc | 47.3 | 17.8 | 65.10 | 37.8 | 13.52 | 182.8 | 0.36 | −1.08 |

| Ft | 1.75 | 1.69 | 3.44 | 2.54 | 0.39 | 0.15 | −0.01 | −0.44 |

| Ff | 5.96 | 3.58 | 9.54 | 5.45 | 1.23 | 1.51 | 1.23 | 1.25 |

| S | 50.0 | 55.0 | 105.0 | 68.7 | 10.00 | 100.02 | 1.57 | 3.10 |

| C | FA | CA | W | B | Fc | Ft | Ff | S | |

|---|---|---|---|---|---|---|---|---|---|

| C | 1.00 | ||||||||

| FA | −0.41 | 1.00 | |||||||

| CA | 0.06 | 0.12 | 1.00 | ||||||

| W | 0.73 | −0.24 | 0.16 | 1.00 | |||||

| B | 0.33 | 0.04 | −0.02 | 0.12 | 1.00 | ||||

| Fc | −0.01 | 0.44 | −0.16 | −0.34 | 0.24 | 1.00 | |||

| Ft | 0.16 | 0.32 | 0.31 | 0.09 | 0.52 | 0.45 | 1.00 | ||

| Ff | 0.44 | −0.15 | −0.09 | 0.38 | 0.27 | −0.29 | −0.12 | 1.00 | |

| S | 0.25 | 0.19 | 0.25 | 0.35 | 0.60 | −0.02 | 0.62 | 0.14 | 1.00 |

| C | FA | CA | W | B | Fc | Ft | Ff | S |

|---|---|---|---|---|---|---|---|---|

| t/m3 | t/m3 | t/m3 | t/m3 | Log (cell/mL) | MPa | MPa | MPa | mm |

| Training set | ||||||||

| 0.396 | 0.675 | 1.410 | 0.178 | 4.534 | 41.754 | 2.918 | 4.653 | 66.00 |

| 0.450 | 0.675 | 0.900 | 0.189 | 3.000 | 47.700 | 2.100 | 4.900 | 61.00 |

| 0.450 | 0.675 | 0.900 | 0.189 | 9.000 | 50.000 | 3.200 | 6.500 | 71.00 |

| 0.403 | 0.792 | 1.149 | 0.212 | 4.076 | 26.415 | 2.390 | 4.482 | 66.00 |

| 0.419 | 0.711 | 1.170 | 0.196 | 5.404 | 31.084 | 2.726 | 9.544 | 66.00 |

| 0.403 | 0.708 | 1.036 | 0.181 | 6.000 | 25.200 | 1.800 | 7.500 | 69.00 |

| 0.351 | 0.641 | 1.102 | 0.139 | 5.683 | 37.090 | 2.423 | 4.266 | 64.00 |

| 0.507 | 0.746 | 0.937 | 0.197 | 10.061 | 55.187 | 3.222 | 7.307 | 79.00 |

| 0.398 | 0.615 | 0.982 | 0.168 | 3.787 | 22.660 | 1.938 | 6.883 | 57.00 |

| 0.383 | 0.727 | 1.103 | 0.192 | 6.000 | 18.670 | 2.260 | 5.650 | 72.00 |

| 0.376 | 0.914 | 1.093 | 0.168 | 5.285 | 63.076 | 3.059 | 4.911 | 75.00 |

| 0.394 | 0.675 | 1.228 | 0.158 | 5.000 | 42.000 | 2.900 | 4.500 | 67.00 |

| 0.347 | 0.838 | 0.965 | 0.134 | 6.481 | 49.077 | 2.142 | 3.866 | 65.00 |

| 0.362 | 0.658 | 1.114 | 0.135 | 4.908 | 36.051 | 2.622 | 4.353 | 64.00 |

| 0.362 | 0.889 | 1.104 | 0.164 | 7.504 | 59.999 | 2.865 | 4.453 | 77.00 |

| 0.400 | 0.738 | 1.242 | 0.216 | 6.295 | 20.239 | 2.471 | 6.295 | 72.00 |

| 0.350 | 0.861 | 1.031 | 0.158 | 6.000 | 57.210 | 2.700 | 4.600 | 69.00 |

| 0.438 | 0.580 | 0.781 | 0.172 | 2.573 | 42.803 | 1.927 | 4.339 | 55.00 |

| 0.400 | 0.705 | 1.398 | 0.161 | 5.611 | 43.589 | 3.333 | 4.909 | 76.00 |

| 0.350 | 0.861 | 1.031 | 0.158 | 5.000 | 61.790 | 2.900 | 4.700 | 66.00 |

| 0.394 | 0.675 | 1.228 | 0.158 | 6.000 | 41.000 | 2.600 | 4.400 | 71.00 |

| 0.442 | 0.728 | 1.172 | 0.199 | 6.597 | 28.412 | 1.812 | 7.836 | 70.00 |

| 0.456 | 0.555 | 1.040 | 0.205 | 7.000 | 36.300 | 2.550 | 5.450 | 75.00 |

| 0.436 | 0.483 | 1.032 | 0.192 | 4.876 | 30.971 | 2.437 | 5.339 | 62.00 |

| 0.456 | 0.555 | 1.040 | 0.205 | 6.000 | 35.800 | 2.530 | 5.130 | 71.00 |

| 0.492 | 0.570 | 1.158 | 0.216 | 7.957 | 41.353 | 2.905 | 5.920 | 76.00 |

| 0.432 | 0.755 | 1.189 | 0.223 | 6.301 | 32.145 | 2.967 | 6.136 | 97.00 |

| 0.369 | 0.719 | 1.021 | 0.177 | 4.884 | 22.285 | 2.293 | 4.332 | 58.00 |

| 0.396 | 0.601 | 0.842 | 0.186 | 5.449 | 46.211 | 2.472 | 5.739 | 63.00 |

| 0.468 | 0.558 | 1.173 | 0.223 | 6.065 | 37.025 | 2.850 | 5.178 | 76.00 |

| 0.310 | 0.859 | 0.884 | 0.145 | 4.703 | 54.229 | 2.886 | 4.312 | 64.00 |

| 0.395 | 0.547 | 0.917 | 0.179 | 6.607 | 35.693 | 2.429 | 5.415 | 73.00 |

| 0.338 | 0.784 | 1.001 | 0.139 | 5.904 | 52.844 | 2.660 | 4.584 | 65.00 |

| 0.438 | 0.811 | 1.177 | 0.224 | 7.011 | 27.274 | 3.435 | 6.196 | 105.00 |

| 0.467 | 0.753 | 0.937 | 0.211 | 6.860 | 54.721 | 2.555 | 6.629 | 68.00 |

| 0.439 | 0.719 | 1.111 | 0.203 | 4.201 | 26.997 | 2.162 | 8.130 | 62.00 |

| 0.392 | 0.976 | 1.096 | 0.171 | 6.122 | 65.103 | 3.028 | 5.012 | 70.00 |

| 0.350 | 0.861 | 1.031 | 0.158 | 7.000 | 54.660 | 2.500 | 4.400 | 71.00 |

| 0.341 | 0.645 | 1.047 | 0.189 | 3.601 | 24.600 | 2.113 | 3.584 | 58.00 |

| 0.381 | 0.677 | 0.940 | 0.175 | 5.414 | 27.028 | 2.530 | 4.978 | 87.00 |

| 0.377 | 0.602 | 0.884 | 0.177 | 4.848 | 25.061 | 2.154 | 7.528 | 59.00 |

| 0.403 | 0.708 | 1.036 | 0.181 | 5.000 | 27.470 | 2.500 | 8.600 | 66.00 |

| 0.399 | 0.768 | 1.161 | 0.199 | 3.076 | 20.366 | 2.247 | 5.485 | 61.00 |

| 0.372 | 0.925 | 1.048 | 0.173 | 4.397 | 60.801 | 2.953 | 4.595 | 67.00 |

| 0.383 | 0.727 | 1.103 | 0.192 | 5.000 | 25.330 | 2.550 | 4.950 | 68.00 |

| 0.424 | 0.598 | 0.853 | 0.163 | 8.581 | 47.936 | 2.747 | 6.227 | 65.00 |

| 0.394 | 0.750 | 1.037 | 0.197 | 7.000 | 27.140 | 3.000 | 6.000 | 94.00 |

| 0.394 | 0.750 | 1.037 | 0.197 | 6.000 | 28.250 | 2.880 | 5.640 | 96.00 |

| 0.419 | 0.691 | 1.377 | 0.173 | 6.718 | 45.289 | 2.646 | 4.960 | 77.00 |

| 0.338 | 0.623 | 1.025 | 0.174 | 2.620 | 17.833 | 1.957 | 4.605 | 55.00 |

| 0.394 | 0.675 | 1.228 | 0.158 | 4.000 | 40.000 | 2.700 | 4.300 | 63.00 |

| 0.456 | 0.555 | 1.040 | 0.205 | 5.000 | 35.500 | 2.470 | 5.440 | 69.00 |

| 0.383 | 0.727 | 1.103 | 0.192 | 3.000 | 18.670 | 2.120 | 4.870 | 57.00 |

| 0.403 | 0.495 | 0.951 | 0.197 | 5.708 | 32.470 | 2.501 | 4.859 | 62.00 |

| Validation set | ||||||||

| 0.377 | 0.656 | 1.169 | 0.155 | 3.408 | 35.384 | 2.375 | 4.292 | 59.00 |

| 0.343 | 0.745 | 0.920 | 0.149 | 3.829 | 57.829 | 2.239 | 4.392 | 57.00 |

| 0.462 | 0.737 | 0.926 | 0.217 | 3.046 | 52.397 | 2.138 | 5.512 | 62.00 |

| 0.352 | 0.679 | 1.029 | 0.163 | 5.642 | 18.437 | 1.926 | 5.498 | 64.00 |

| 0.383 | 0.727 | 1.103 | 0.192 | 4.000 | 24.880 | 2.260 | 4.120 | 61.00 |

| 0.396 | 0.767 | 1.158 | 0.215 | 5.295 | 26.301 | 2.752 | 5.099 | 73.00 |

| 0.514 | 0.626 | 1.185 | 0.233 | 5.723 | 37.769 | 2.757 | 5.461 | 70.00 |

| 0.350 | 0.861 | 1.031 | 0.158 | 4.000 | 58.020 | 2.600 | 4.500 | 60.00 |

| 0.450 | 0.675 | 0.900 | 0.189 | 6.000 | 52.500 | 2.500 | 5.850 | 65.00 |

| 0.386 | 0.610 | 0.918 | 0.157 | 5.618 | 22.509 | 1.690 | 7.414 | 67.00 |

| 0.378 | 0.748 | 0.929 | 0.168 | 6.585 | 23.356 | 2.975 | 5.133 | 80.00 |

| 0.403 | 0.708 | 1.036 | 0.181 | 4.000 | 25.130 | 2.100 | 7.400 | 60.00 |

| Impact Category | Global Warming | Terrestrial Acidification | Terrestrial Eco-Toxicity | Freshwater Eco-Toxicity | Marine Eco-toxicity | Human Carcinogenic Toxicity | Human Non-carcinogenic Toxicity |

|---|---|---|---|---|---|---|---|

| Unit | kg CO2 eq | kg SO2 eq | kg 1,4-DCB | kg 1,4-DCB | kg 1,4-DCB | kg 1,4-DCB | kg 1,4-DCB |

| SHC (456 kg/m3) | 439.56 | 0.696 | 266 | 3.514 | 4.735 | 4.474 | 93.28 |

| SHC (383 kg/m3) | 372.62 | 0.554 | 230.4 | 3.047 | 4.102 | 3.891 | 80.46 |

| SHC (403 kg/m3) | 390.88 | 0.58 | 239.9 | 3.172 | 4.271 | 4.046 | 83.89 |

| SHC (394 kg/m3) | 383.4 | 0.57 | 237.2 | 3.134 | 4.22 | 4.006 | 82.84 |

| SHC (350 kg/m3) | 342.2 | 0.511 | 213.9 | 2.831 | 3.807 | 3.618 | 74.51 |

| SHC (394 kg/m3, more aggregates) | 382.7 | 0.568 | 235.7 | 3.117 | 4.196 | 3.977 | 82.37 |

| SHC (450 kg/m3) | 433.9 | 0.64 | 262.6 | 3.471 | 4.676 | 4.418 | 92.1 |

| Hidden Layer | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| H(1:1) | H(1:2) | H(1:3) | H(1:4) | H(1:5) | H(1:6) | H(1:7) | H(1:8) | |||

| Input Layer | (Bias) | −0.34 | −0.24 | −1.80 | −7.88 | 1.31 | −0.58 | 0.52 | −2.62 | |

| C | −23.33 | 0.13 | 5.71 | 5.29 | 3.80 | 0.20 | 13.74 | 1.90 | ||

| FA | 15.33 | −0.51 | 14.49 | −4.40 | 6.51 | 0.03 | 0.10 | 1.55 | ||

| CA | 5.99 | −0.18 | −9.99 | −3.29 | 3.00 | 0.09 | −7.90 | 1.00 | ||

| W | 1.67 | 0.18 | 0.43 | −0.83 | −6.45 | −0.72 | 3.05 | −4.74 | ||

| B | 0.48 | −0.26 | 3.10 | −0.20 | −32.02 | −0.42 | −0.12 | −0.97 | ||

| Hidden Layer | ||||||||||

| H(1:1) | H(1:2) | H(1:3) | H(1:4) | H(1:5) | H(1:6) | H(1:7) | H(1:8) | (Bias) | ||

| Output Layer | Fc | −0.24 | −0.04 | 0.35 | 0.37 | 0.22 | −0.85 | −0.04 | 0.98 | 0.07 |

| Ft | 1.02 | −1.25 | −0.33 | 0.83 | 0.37 | −0.72 | 1.09 | 0.45 | −0.16 | |

| Ff | −0.50 | −0.80 | −0.14 | −0.26 | 0.04 | −0.06 | 0.21 | −0.22 | −0.73 | |

| S | 0.90 | −0.71 | −0.27 | 0.21 | −0.03 | −0.71 | 1.06 | 0.35 | −0.90 | |

| Item | Technique | Model | SSE | Average Error % | R2 |

|---|---|---|---|---|---|

| Fc | GEP | Equation (1) | 817 | 9.3 | 0.927 |

| ANN | Figure 3, Table 3 | 284 | 5.5 | 0.976 | |

| EPR | Equation (5) | 531 | 7.5 | 0.953 | |

| Ft | GEP | Equation (2) | 3 | 8.1 | 0.591 |

| ANN | Figure 3, Table 3 | 1 | 3.8 | 0.936 | |

| EPR | Equation (6) | 1 | 5.4 | 0.861 | |

| Ff | GEP | Equation (3) | 19 | 10 | 0.758 |

| ANN | Figure 3, Table 3 | 9 | 6.6 | 0.904 | |

| EPR | Equation (7) | 18 | 9.6 | 0.777 | |

| S | GEP | Equation (4) | 443 | 3.8 | 0.928 |

| ANN | Figure 3, Table 3 | 412 | 3.6 | 0.930 | |

| EPR | Equation (8) | 784 | 5.0 | 0.863 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onyelowe, K.C.; Ebid, A.M.; Riofrio, A.; Baykara, H.; Soleymani, A.; Mahdi, H.A.; Jahangir, H.; Ibe, K. Multi-Objective Prediction of the Mechanical Properties and Environmental Impact Appraisals of Self-Healing Concrete for Sustainable Structures. Sustainability 2022, 14, 9573. https://doi.org/10.3390/su14159573

Onyelowe KC, Ebid AM, Riofrio A, Baykara H, Soleymani A, Mahdi HA, Jahangir H, Ibe K. Multi-Objective Prediction of the Mechanical Properties and Environmental Impact Appraisals of Self-Healing Concrete for Sustainable Structures. Sustainability. 2022; 14(15):9573. https://doi.org/10.3390/su14159573

Chicago/Turabian StyleOnyelowe, Kennedy C., Ahmed M. Ebid, Ariel Riofrio, Haci Baykara, Atefeh Soleymani, Hisham A. Mahdi, Hashem Jahangir, and Kizito Ibe. 2022. "Multi-Objective Prediction of the Mechanical Properties and Environmental Impact Appraisals of Self-Healing Concrete for Sustainable Structures" Sustainability 14, no. 15: 9573. https://doi.org/10.3390/su14159573

APA StyleOnyelowe, K. C., Ebid, A. M., Riofrio, A., Baykara, H., Soleymani, A., Mahdi, H. A., Jahangir, H., & Ibe, K. (2022). Multi-Objective Prediction of the Mechanical Properties and Environmental Impact Appraisals of Self-Healing Concrete for Sustainable Structures. Sustainability, 14(15), 9573. https://doi.org/10.3390/su14159573