1. Introduction

Located in the west of China, the Yili River Valley in Xinjiang is an important agricultural, animal husbandry, energy supply base, and a famous tourist destination. The geographic and climatic characteristics of the Yili River Valley are unique. It is an intermountain basin surrounded by mountains on three sides and is broad in the west yet narrow in the east with an opening. The humid airflow from the Arctic and Atlantic Oceans directly enters the Yili River Valley from the west. After being blocked by the east mountains, the moist air flow transforms into abundant precipitation [

1]. According to weather records [

2], the annual rainfall in this area was between 200 and 550 mm, and the average yearly evaporation was approximately 1467.67 mm. Precipitation occurs from April to October when loess landslides frequently happen. Under the influence of the dry-wet cycling process due to evaporation and rainfall, the moisture content in loess widely varied in the Yili River Valley in an alternating way, with the overall characteristics of reduced strength and increased deformation. The resulting loess landslide disasters accounted for more than 70% of this region’s geological disasters threatening local people’s life and property [

3]. Therefore, studying the strength change characteristics of Yili loess under the dry-wet cycling condition is of great significance. The present research results are beneficial for summarizing the occurrence mechanism of loess landslide under the dry-wet cycling condition in this area.

The French engineer Coulomb initiated the study of the strength theory of soil mass. He proposed the soil shear strength theory through many tests and named it the Coulomb formula [

4]. Extending the Coulomb study, Mohr established the Mohr-Coulomb shear failure criterion, which frequently governed the strength analysis of saturated soil [

5]. Subsequent researchers developed other expressions for the strength analysis of unsaturated soil. Among them, the Bishop univariate theory and Fredlund bivariate approach fit well the unsaturated soil’s stress state and strength [

6,

7]. In addition, these theories extensively studied the changes in mechanical properties of different soil mass types under other conditions [

8,

9,

10,

11] and some scholars also focused on the advantages and disadvantages of soil stability and reinforcement technology under the conditions of dry-wet cycles and freeze-thaw cycles; for example, Huang Wei [

12] studied the modification effects of MICP-treated cohesive soils under dry-wet and freeze-thaw cycles, Mohsen Salehi [

13] studied the effect of curing time, soaked and unsoaked conditions and freeze-thaw cycles on the geotechnical characteristics of cement-stabilized specimens, and Seyed Hadi Sahlabadi [

14] studied the effects of freeze-thaw cycles on cement-stabilized soil reinforced with fibers.

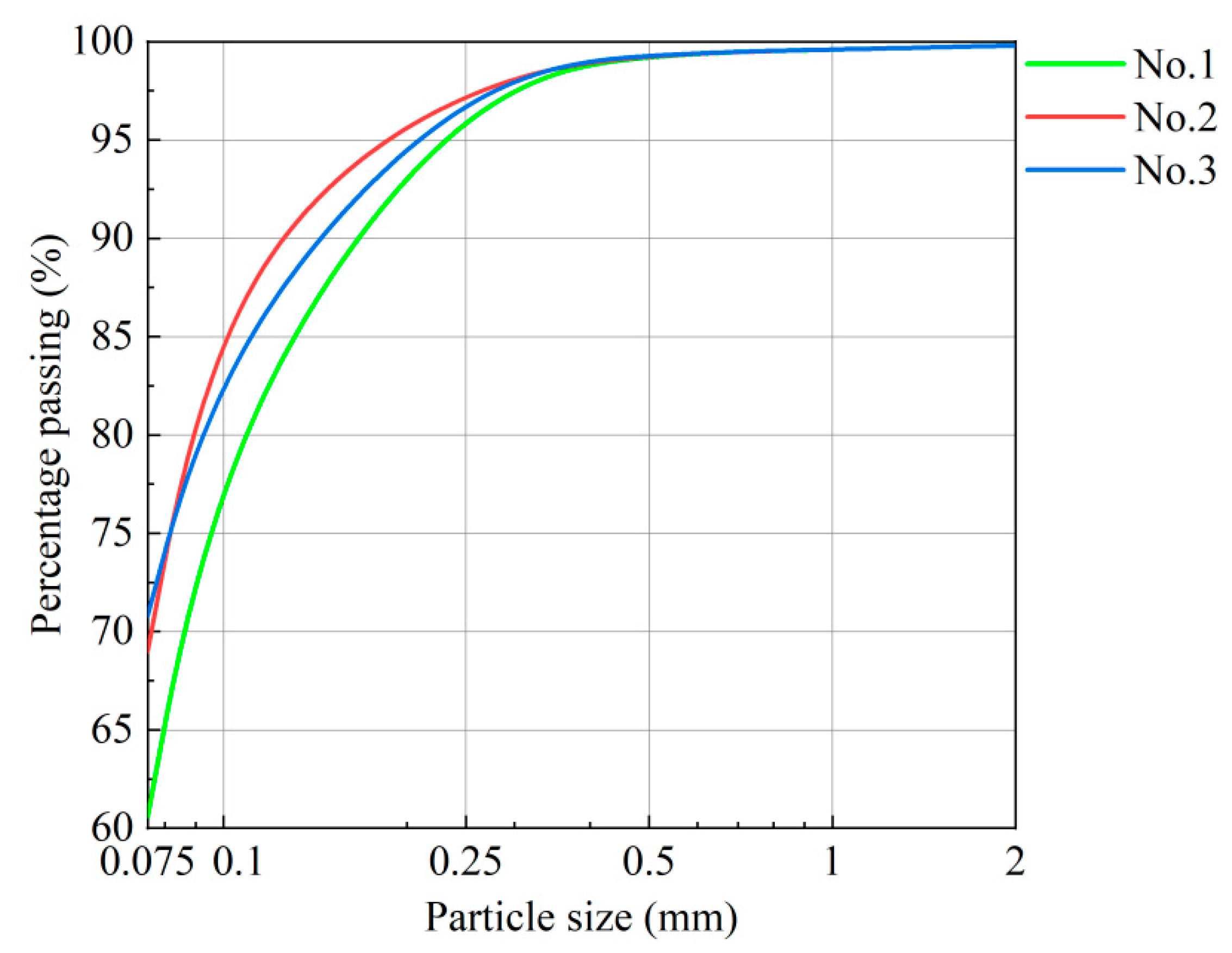

Chinese loess is distributed widely in Northwest, North, and Northeast China. The representative types arise in the Loess Plateau and Yili valley [

15]. In the early stages, researchers mainly studied the formation, sedimentary characteristics, paleoclimate proxy indicators, material sources, and other properties of loess. For example, Ye Wei et al. [

16,

17] conducted many studies on the grain-size aspects and source materials of Yili loess and found that the Yili loess has different provenance from the loess plateau, so the grain-size compositions of loess derived from the Yili region were somewhat different from that in the Loess Plateau. The former had a more homogeneous grain size and contained more mica with a more stable ratio than the latter.

With the water sensitivity studies of loess becoming more profound, researchers gradually paid more attention to the impact of the dry-wet cycling process formed with the seasonal alternation of the loess. Despite mechanical property studies of the loess and on the Loess Plateau in the humidification effect, investigations on the Yili loess were rare. With the loess in the Loess Plateau as the research object, Ye Wanjun [

18] studied the Mechanism Fractured Loess Expansion Joints under the Effect of wet-dry Cycle. Wang Tiehang [

19] made a series of wetting-drying cycles tests, soil dynamic triaxial tests, and scanning electron microscope tests, which were carried out under different wetting-drying cycle paths, and the dynamic strength and microstructure images of compacted loess were obtained. Liu Fengyin [

20] and Zhao Tianyu [

21] studied the impact of the dry-wet cycling effect on the loess-water characteristic profiles. While Pan Zhenxing [

22] studied the undisturbed loess humidification-dehumidification cycle tests with different water contents and different times, carried out to analyze the change rules of porosity, shear strength and parameters of loess induced by dry and wet cycles, Yuan Zhihui [

23,

24] researched the changes in the strength and microstructure of loess. Hao Yanzhou [

25] made a series of drying and wetting cycles tests and triaxial shear tests, which were carried out for the loess samples which were compacted to dry density of 1.7 g/cm3 under the optimum moisture content condition to investigate the influence of the structure damage of the compacted loess caused by the drying and wetting cycles on its stress-strain characteristics and triaxial shear strength. While Li Zuyong [

26] studied the mechanical properties of special loess in Xi’an City, Hu Changming [

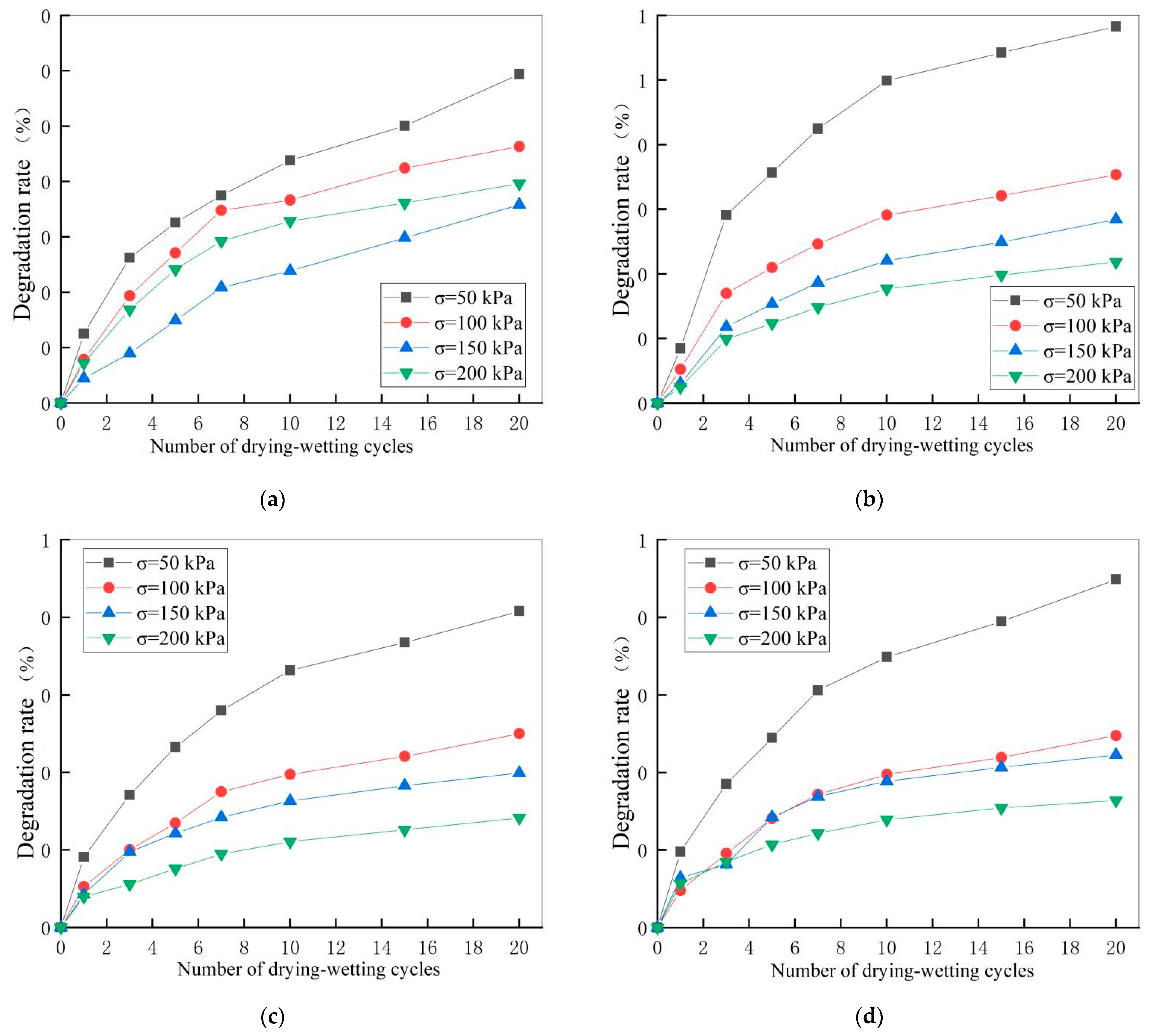

27] studied the degradation of compacted loess under the dry-wet cycling process. Plots of the strength degradation curves of compacted loess under different factors established a strength degradation model of compact with the dry-wet cycling process. Taking the Yili loess as the research object, Tang Guobing [

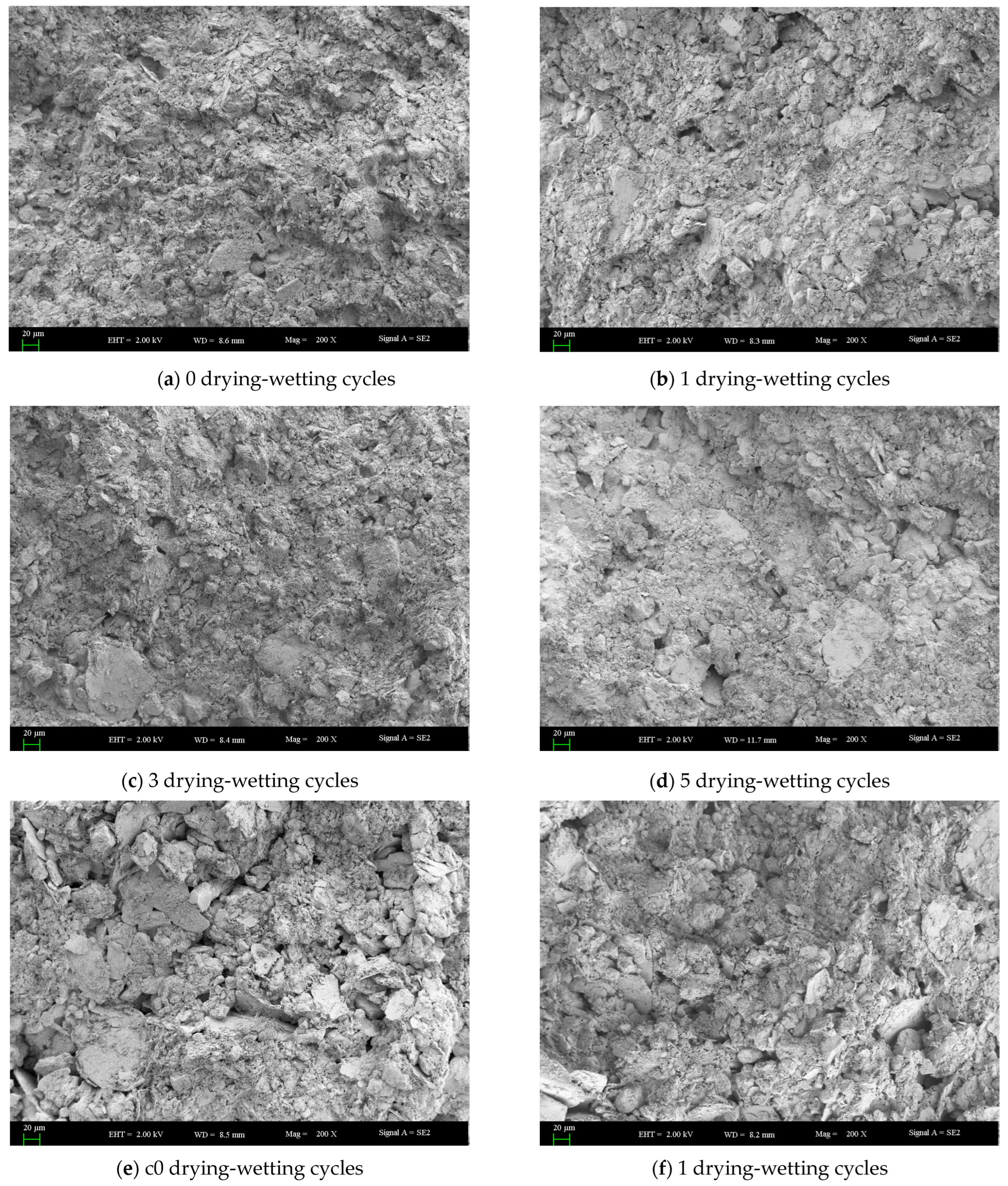

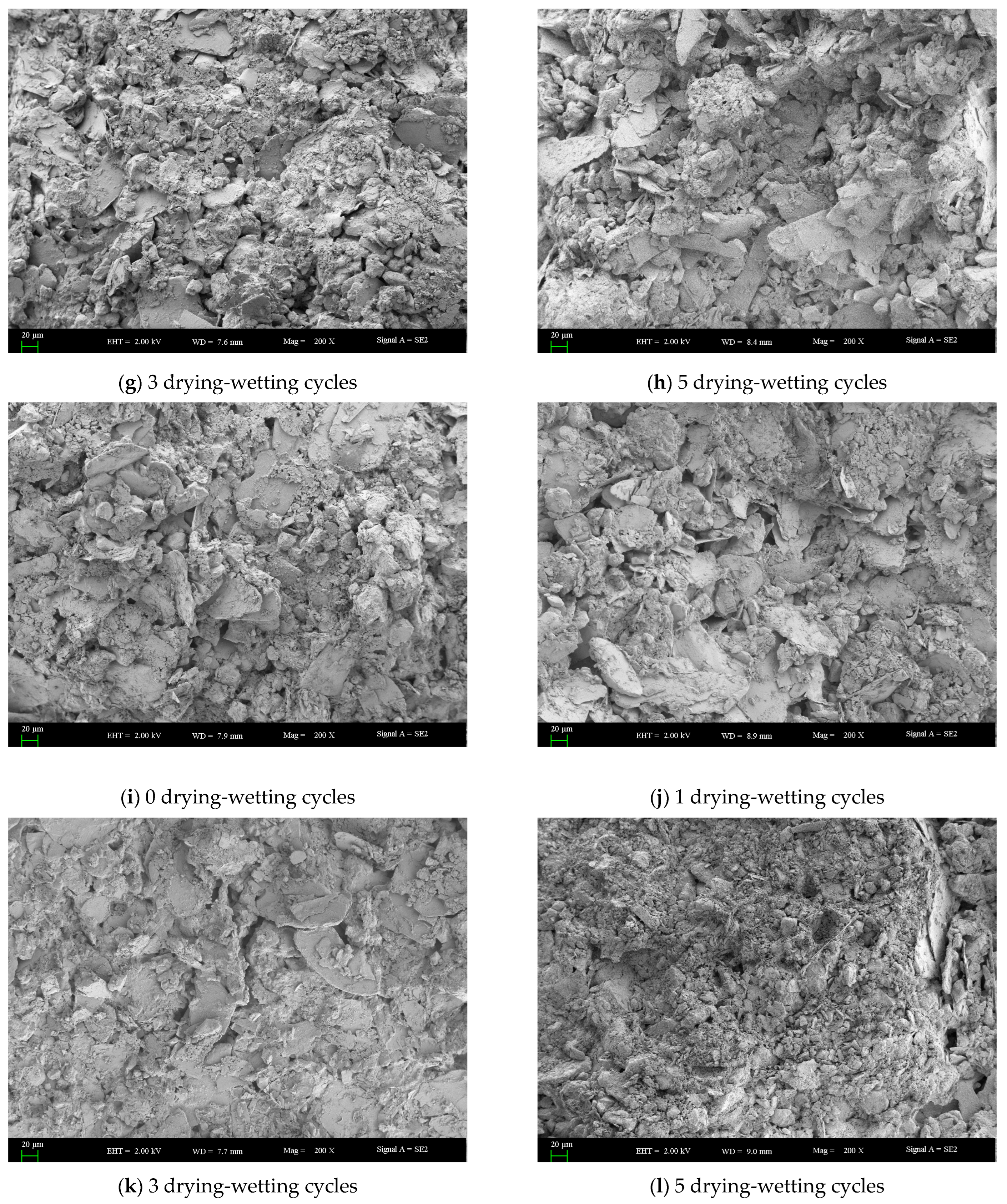

28] and Hao Ruihua [

29] studied the microscopic process corresponding to the macroscopic changes in the shear strength of loess under the dry-wet cycling process. Lv Qianli [

30] studied the changes in the permeability of loess under the influence of freeze-thaw cycling and quantitatively analyzed its microstructure.

In summary, the previous research on the strength degradation characteristics of loess with the dry-wet cycling process primarily focused on the loess of the Loess Plateau and the physical, mechanical, and hydraulic properties. For the Yili loess, on the one hand, related research results are fewer; on the other hand, other scholars mainly focused on the influence of the number of dry-wet cycles, water content, initial dry density, and other factors on the mechanical properties of soil and the internal water migration law in the process of a dry-wet cycle, while the strength degradation effect of mica in loess research is slightly weak.

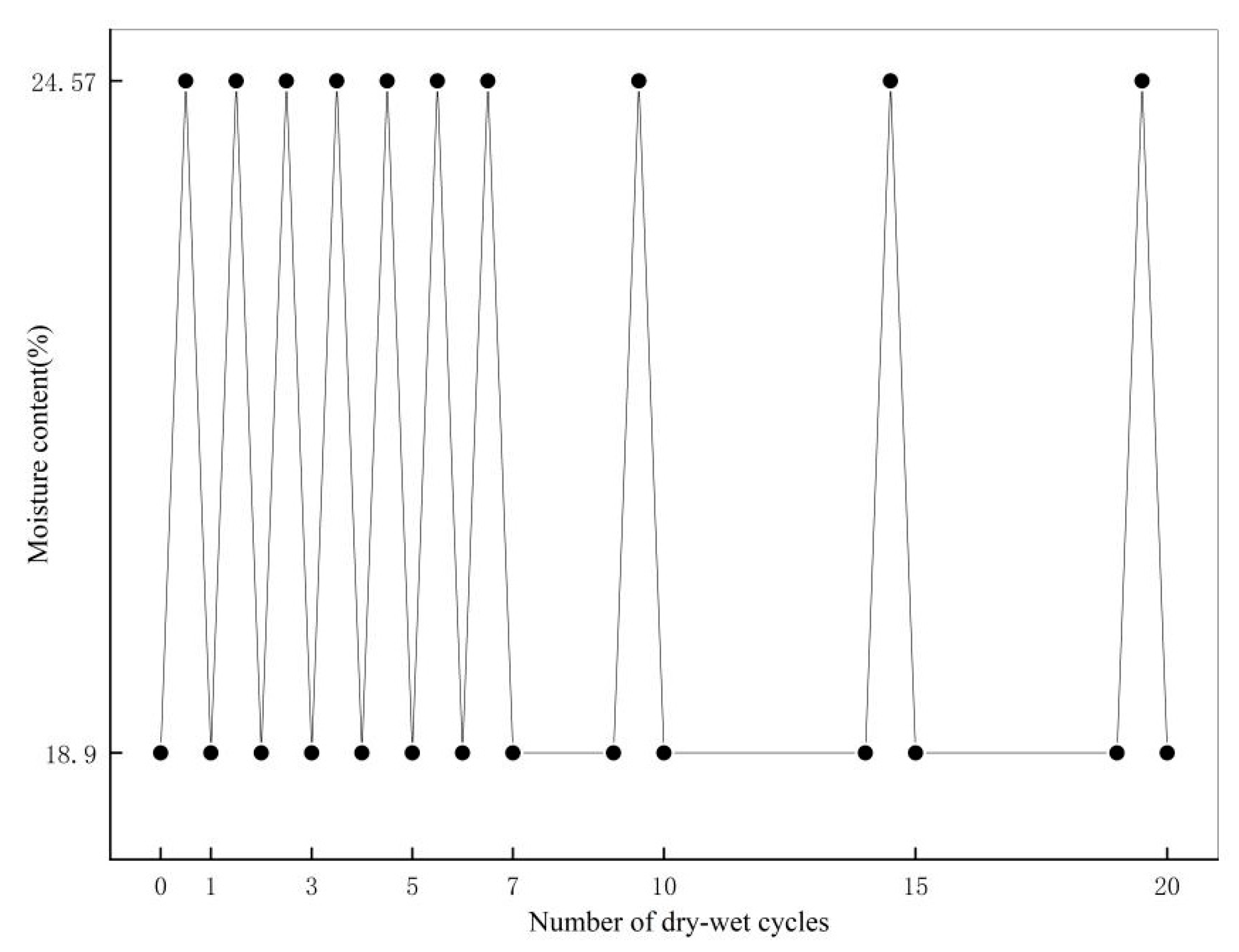

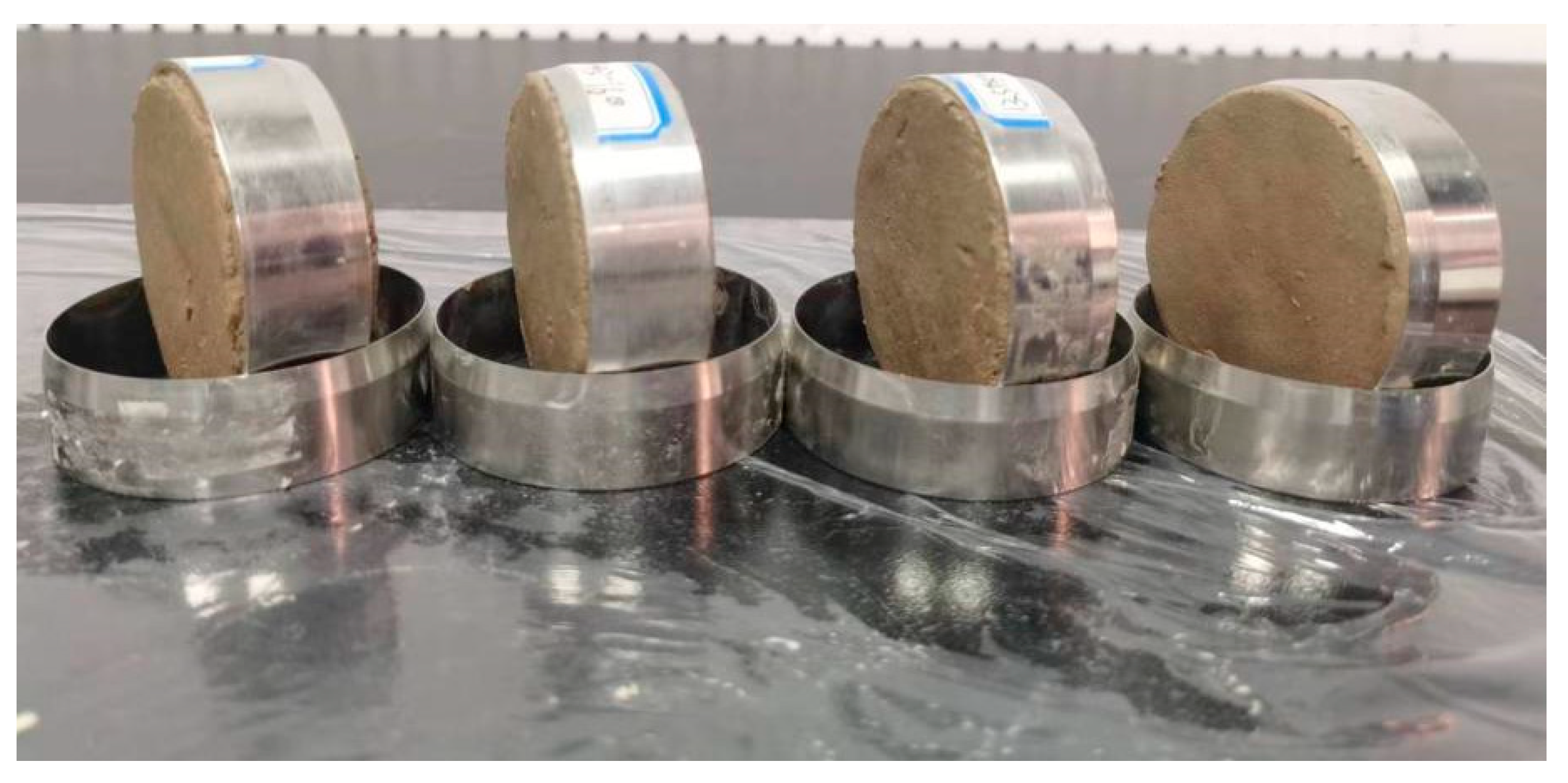

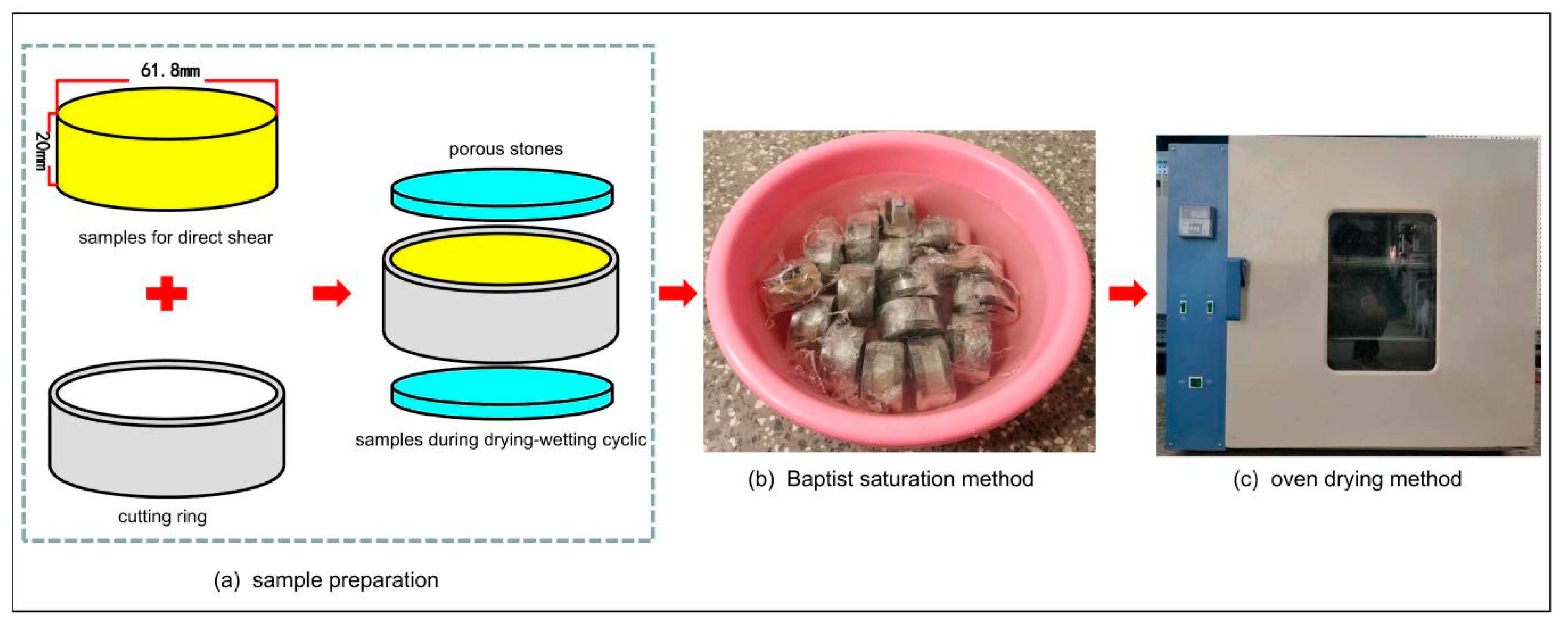

Therefore, this study took Yili loess as the research object, and selected the number of dry-wet cycles and mica content as control variables. The curves of shear stress and shear displacement, the curves of cohesion and internal friction angle, and the changes in shear strength of loess samples with different mica content after different cycles of dry-wet were obtained by direct shear test. Scanning electron microscopy (SEM) was used to analyze the variation of loess particle size and pores in the samples with different mica content after drying and wetting cycles. The results may serve as additional guidance for researchers and engineers making decisions on the prevention of loess landslides induced by the dry-wet effect in Yili and other areas with similar climates.

4. Discussion

The loess is distributed widely with continuous thick deposits in the Yili region. This loess primarily originated from weathering of igneous rocks. Compared to other types of loess, the mica mineral content was higher and stable, and this loess is typical in China and elsewhere in the world. The modern climate of the Yili River Valley region is different from the eastern monsoon region with the synchronous rainy and hot periods and the Mediterranean region with rainy summer. As a transitional type between both climate types, the modern climate of the Yili region is very similar to that of the Central Asia region in the west. The precipitation is uniform over seasons, with considerable rainfall and intensive evaporation. As a result, the Yili loess always suffers from the dry-wet cycling process, and the Yili region also suffers from frequent loess landslides, resulting in tremendous property loss and casualties. This study probed aspects of dry-wet cycling, and the Yili Valley loess landslide highlighted the dominant factors that lead to such failures. This study further focused on the “strength degrading effect of mica on loess in the presence of dry-wet cycling effect,” which was essential but has been seldom studied. The research results are beneficial for understanding the deformation of Yili loess in the dry-wet cycling effect and shed light on the frequent loess landslide in Yili.

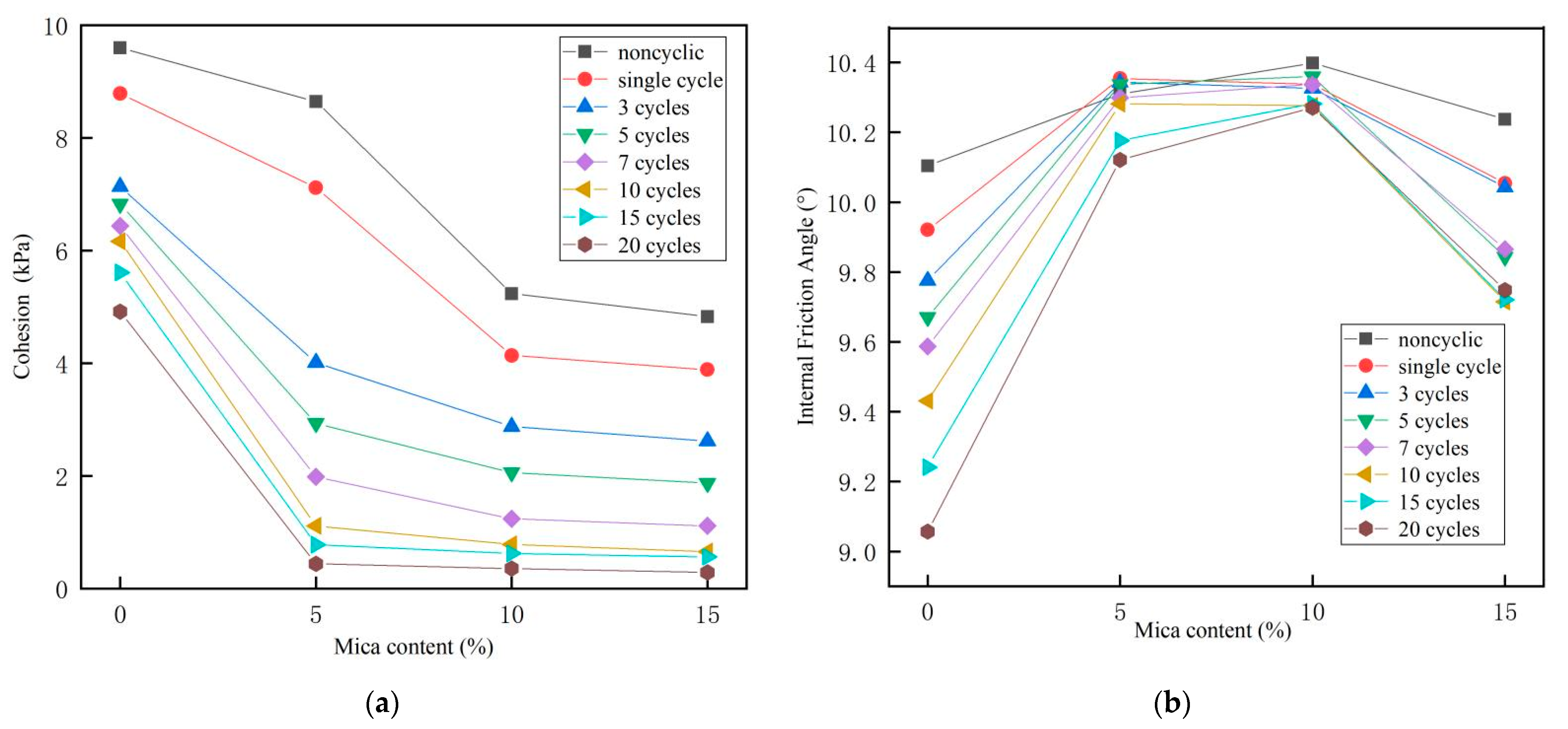

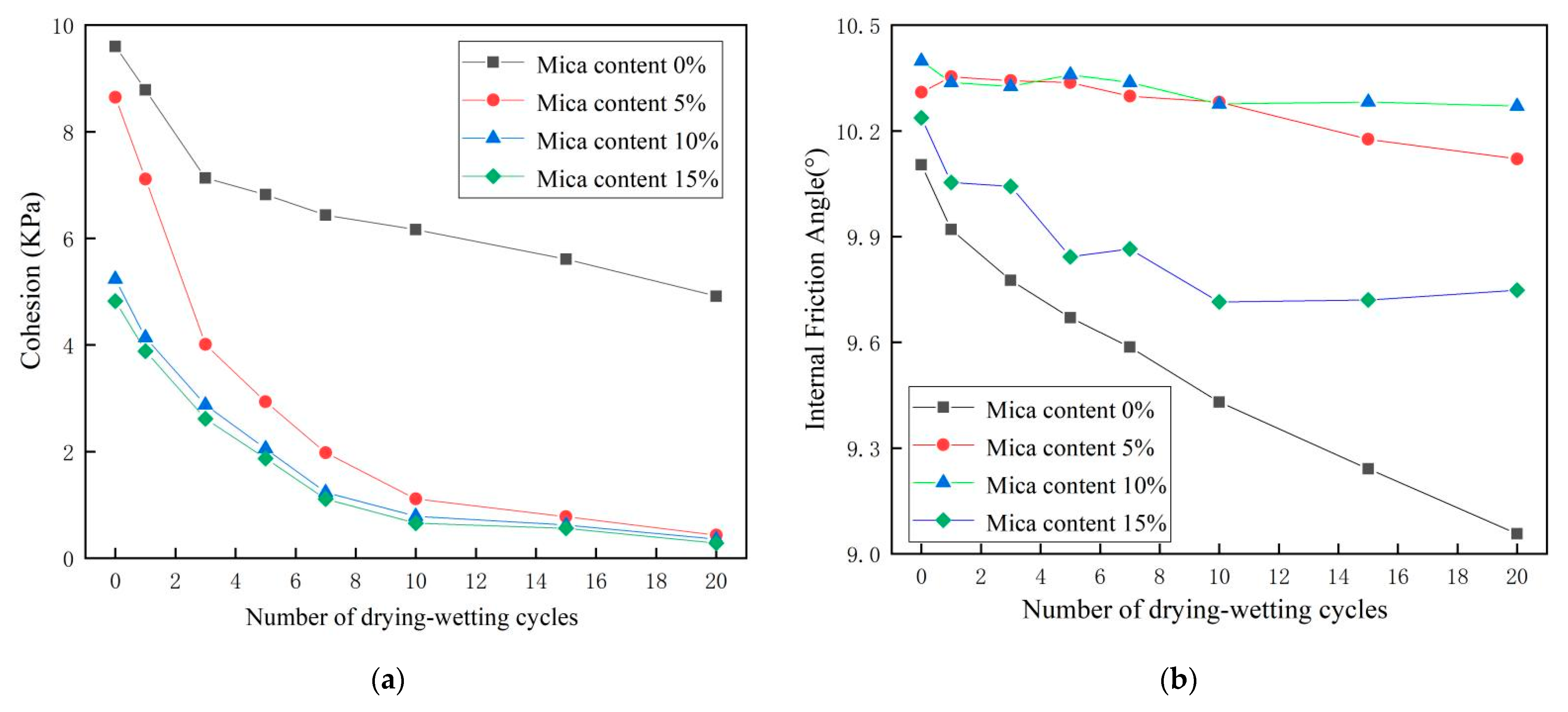

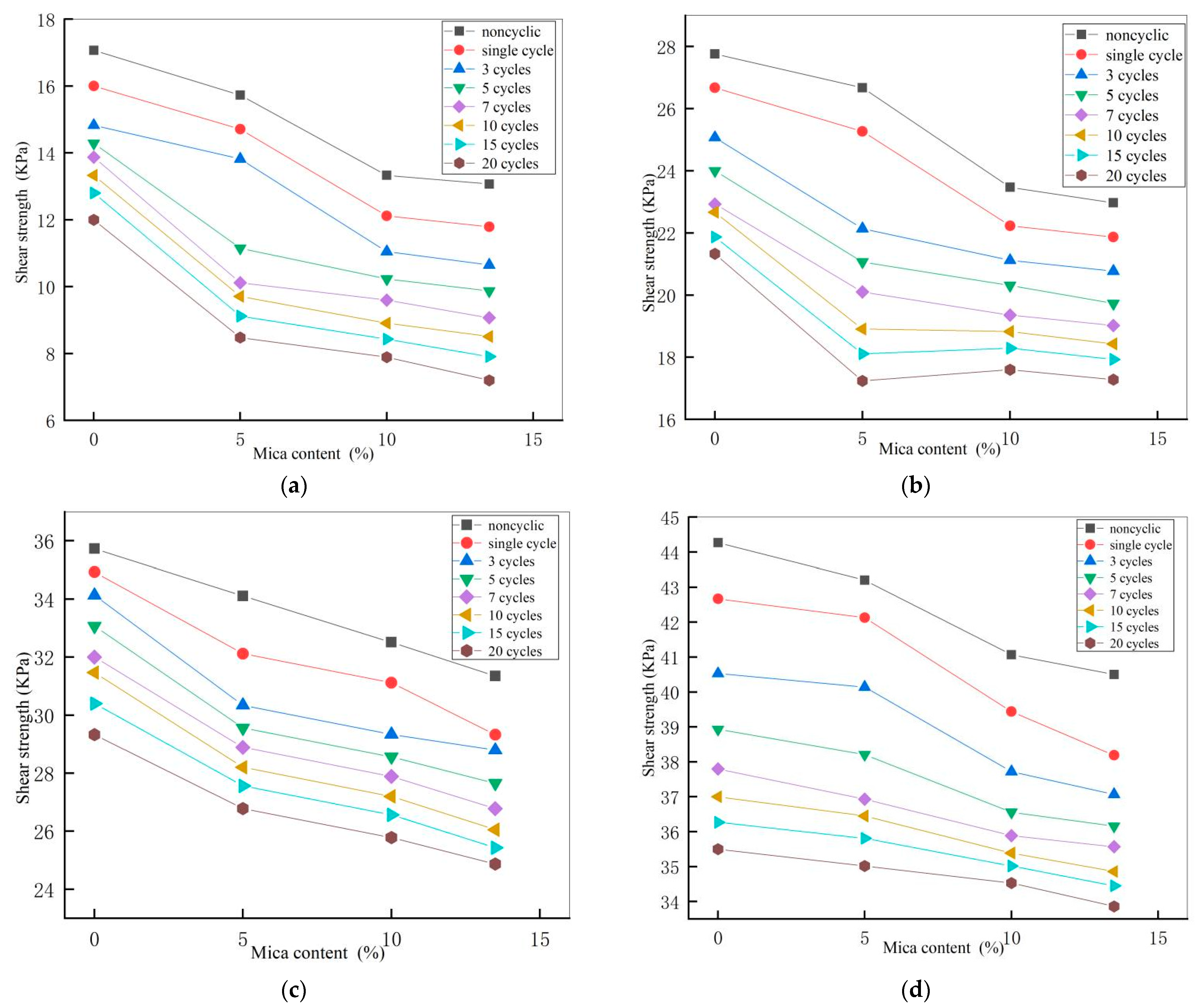

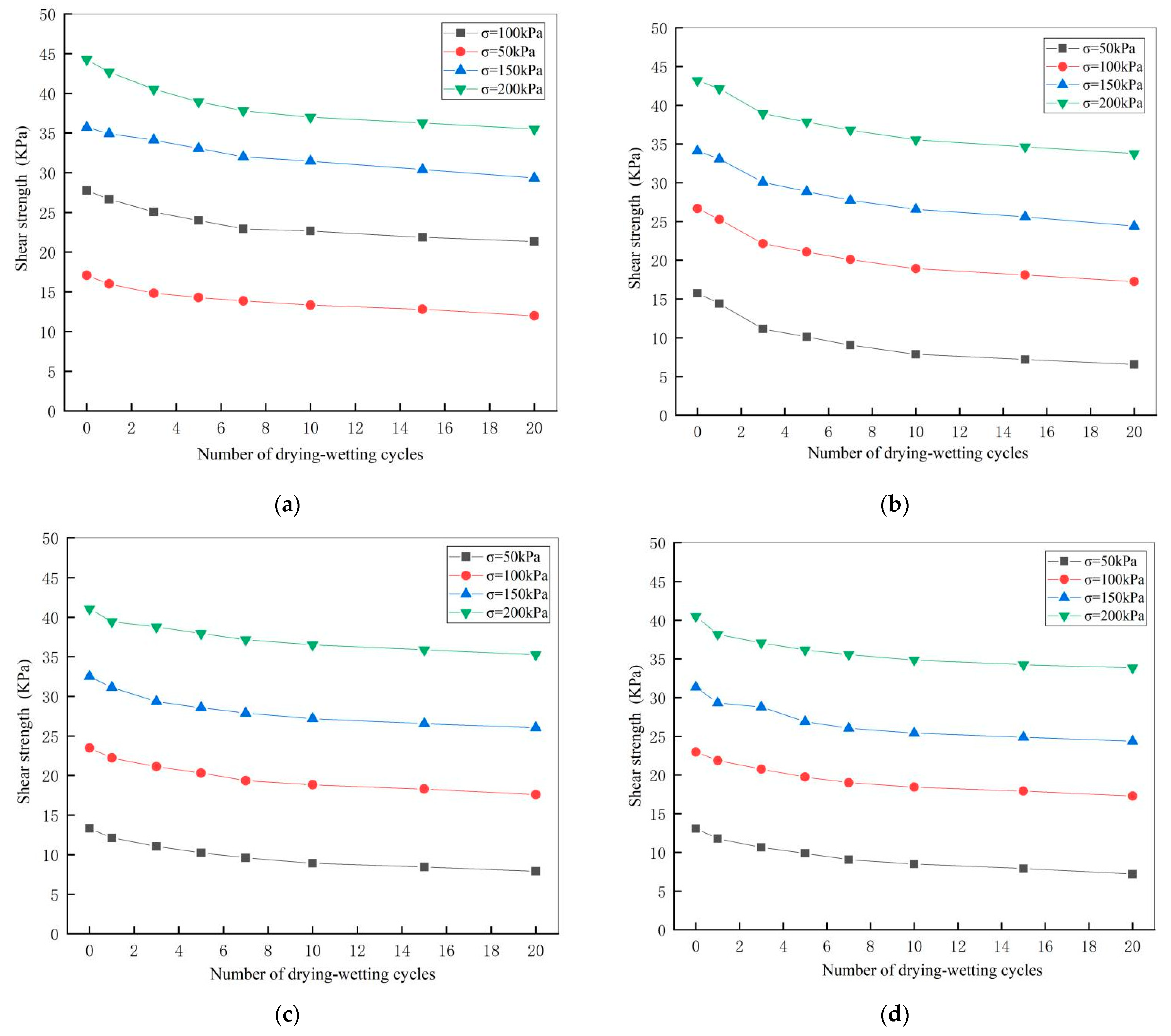

In this study, two control variables, the number of dry-wet cycles and the content of mica, were selected to study the change rule of loess strength in Yili. There are similarities and differences between the research results and those that only consider the influence of the number of dry-wet cycles on the strength of Yili loess. The similarity lies in whether it is the increase of number of dry-wet circulation and the increase of the content of mica that has an effect on the shear strength of loess’ degradation, and the degradation effect is more apparent in the early performance. Experimental data shows that the mica content under certain conditions, the first three dry-wet circulation functions and the dry-wet cycles’ given conditions, mica content increased from 0% to 5%. The deterioration of shear strength of loess is the most significant. With the increase of the number of wetting and drying cycles or the content of mica, it finally becomes stable. The difference lies in the variation law of shear parameters. Previous research results show that the dry-wet cycle mainly has a significant impact on the internal friction angle of soil, which decreases first and then tends to be stable in the whole cycle, but has no significant impact on the cohesion. It is found in this study that considering the content of mica, the wetting and drying cycle mainly has a significant effect on the cohesion of soil, which decreases first and then tends to be stable in the whole cycle, and has a certain effect on the internal friction angle, but the change is small. Causes of this difference may be due to the fact that mica in loess have the effect of a similar “reinforcement”, which is partly offset by dry-wet circulation internal friction angle of degradation. However a large number mica will certainly affect the surrounding soil of stress and strain fields, and the loess particles are weakened always in the direction of development, which may also be a cohesive force of the main cause of degradation.

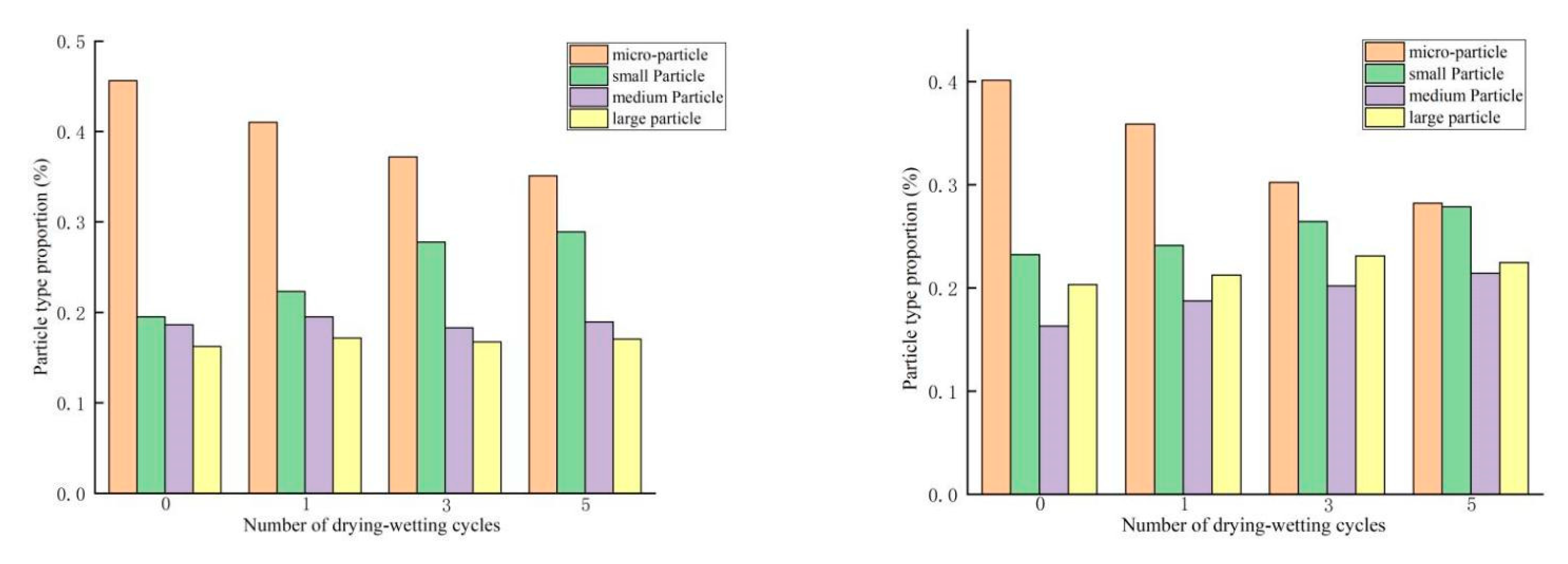

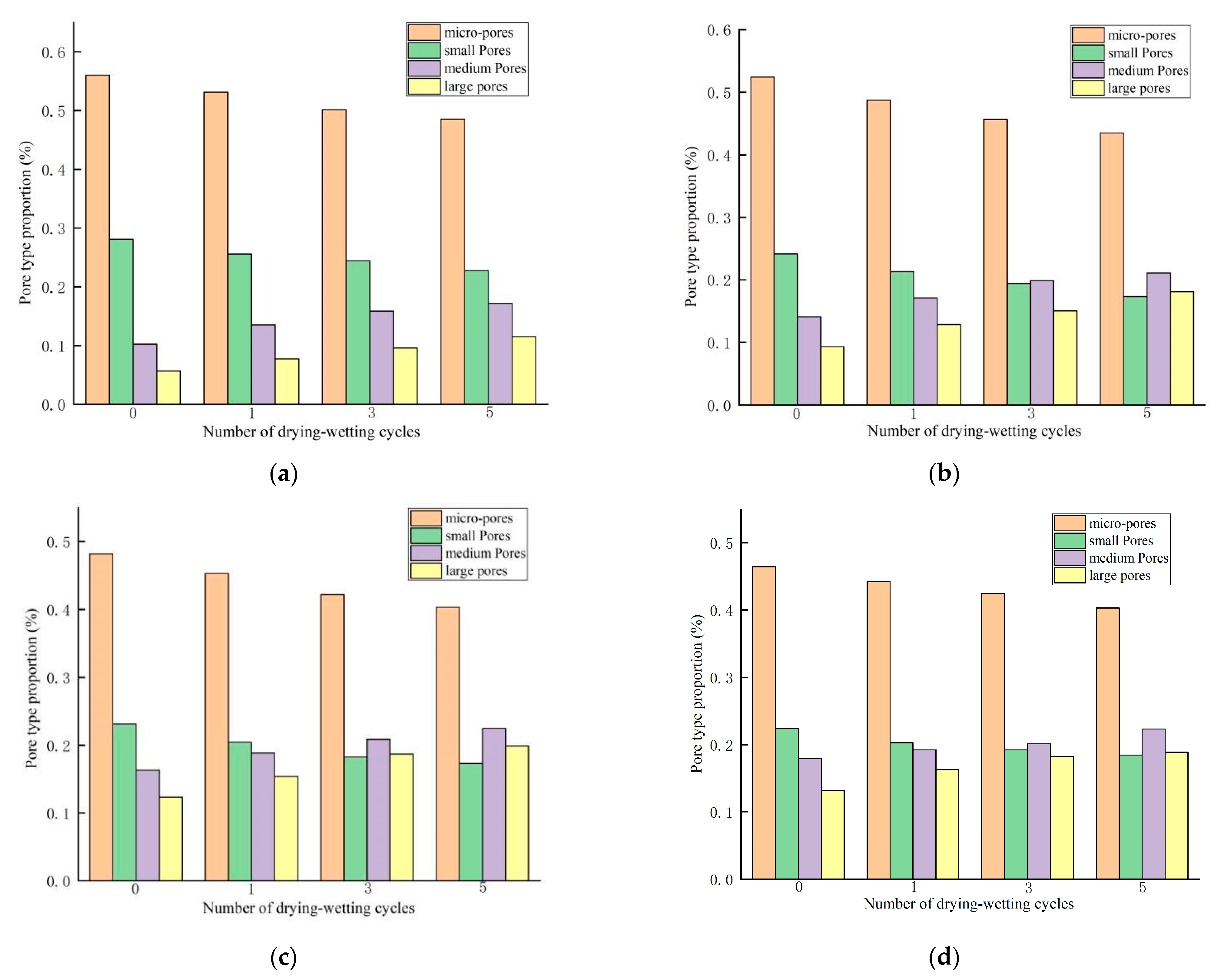

In this study, it was found that the influence of dry-wet cycles on soil microstructure was strongly correlated with the change in soil shear strength, and the change in microstructure parameters was also most significant when the first three dry-wet cycles and the mica content increased from 0% to 5%. Under the action of the dry-wet cycle, the content of micro-particles in loess particles decreases continuously, the content of small particles and medium particles increases, and the content of large particles generally keeps increasing. However, the content of micropores and small pores decreases continuously, and the content of medium pores and large pores increases continuously. This is basically consistent with previous studies. The content of mica and the number of wetting and drying cycles affect the contact mode, contact mode, and connection mode of loess particle units and pores. With the increase of the content of mica and the number of dry-wet cycles, the contact mode, contact mode and connection mode of the loess always tended to weaken, and the strength of the loess also deteriorated.

Additionally, this paper focused on the impact of mica content on the shear strength of loess under different numbers of dry-wet cycles and correlated the macroscopic mechanical characteristics with microscopic structures using microscopic structural measurements. We drew informative conclusions, although some shortcomings prevailed, such as: The remolded Yili loess sample tested in this experiment may differ from the original Yili loess; The relevant strength and microstructure tests on the original Yili loess are necessary for the future; The mechanical strength test was performed once for each group, and thus the shear strength measured may not be globally representative. Therefore, repeat tests are needed, with the mean values taken to minimize errors and improve representability. The accuracy of the rapid direct shear test in this experiment was slightly low; a triaxial shear test can verify the test results further. This study found that with the increase of mica content, the samples expanded to different degrees after humidification compared with the mica-free sample, increasing saturated moisture contents. In the future, the design of experiments needs to explore the influence of mica on the deformation characteristics caused by humidification. In this paper, the Image-Pro Plus 6.0 software did simple image processing and qualitative analysis in the microstructure measurement. In the future, performing quantitative processing of microstructure parameters preliminarily, and the macroscopic mechanical indexes and microstructure parameters can be analyzed quantitatively using correlation models to derive microstructure parameters with good relevance.