Corn Starch-Based Sandstone Sustainable Materials: Sand Type and Water Content Effect on Their Structure and Mechanical Properties

Abstract

:1. Introduction

2. Preparation of Materials and Experimental Details

2.1. Materials

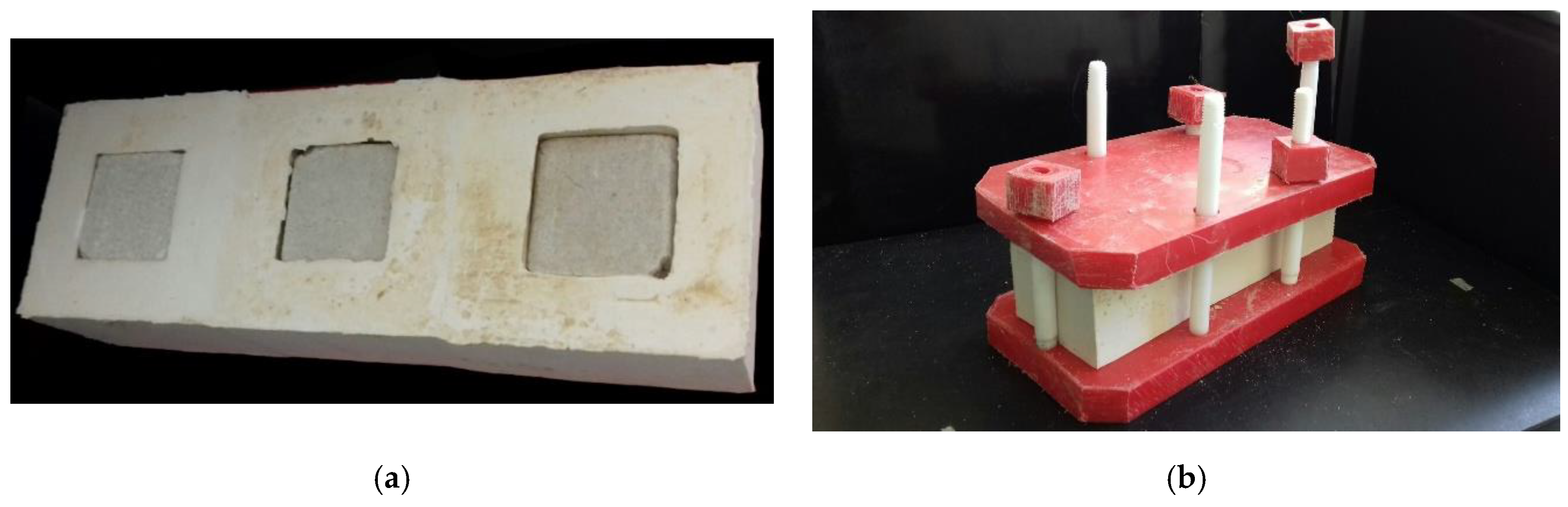

2.2. Preparation of Hardened Starch-Sandstone Material

2.3. Soil Analysis

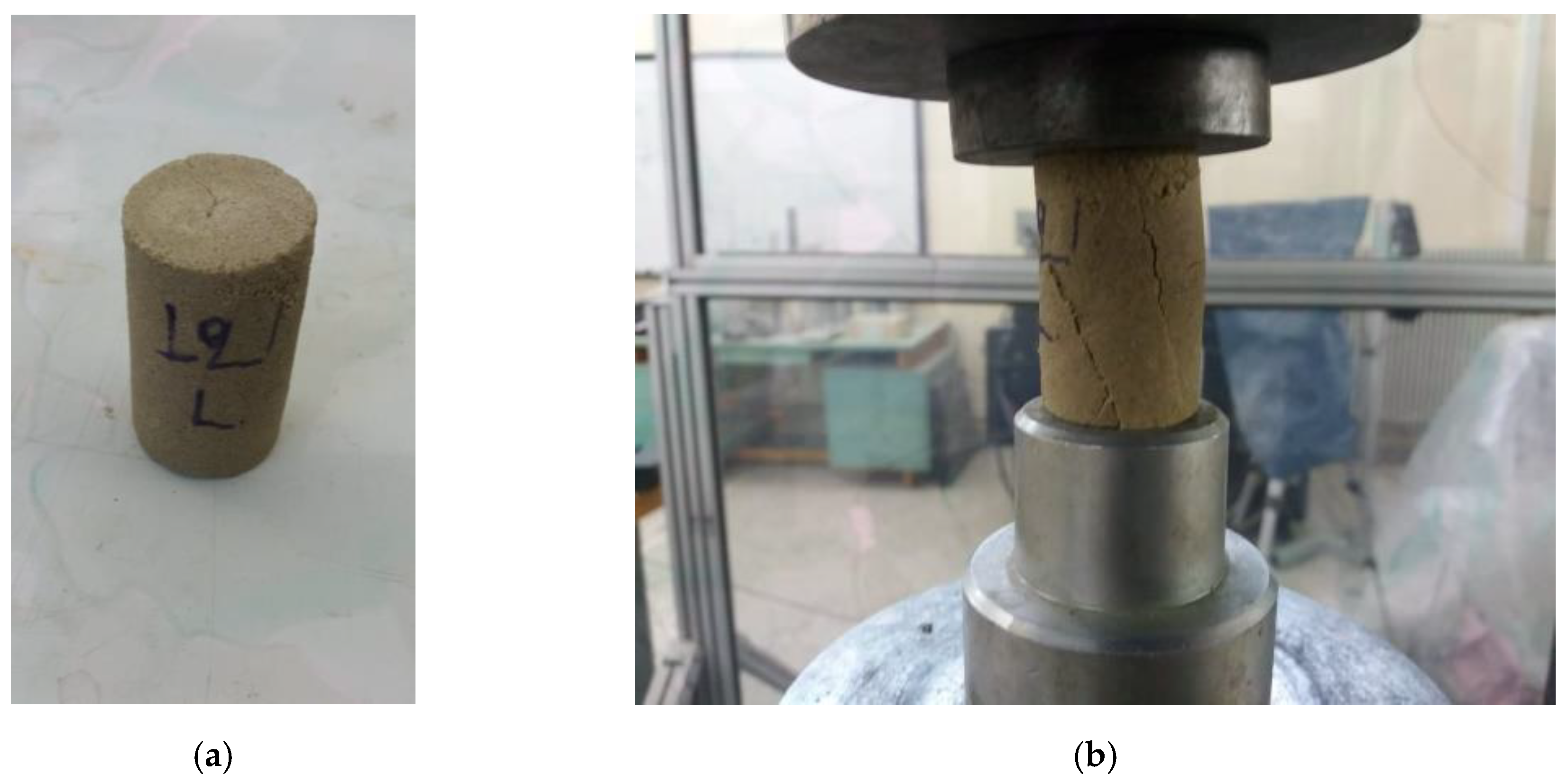

2.4. Mechanical Properties

3. Results and Discussion

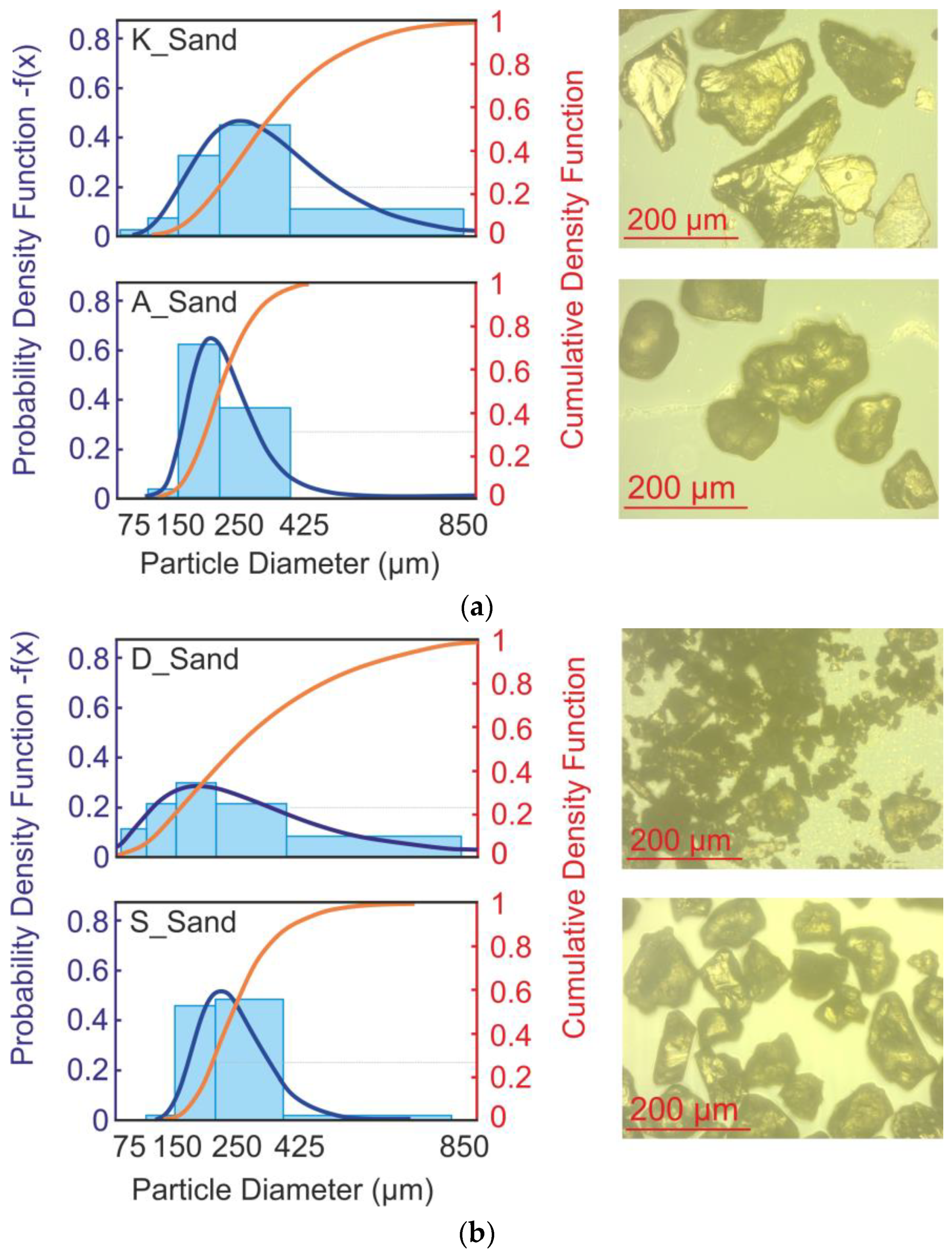

3.1. Morphology of the Sands

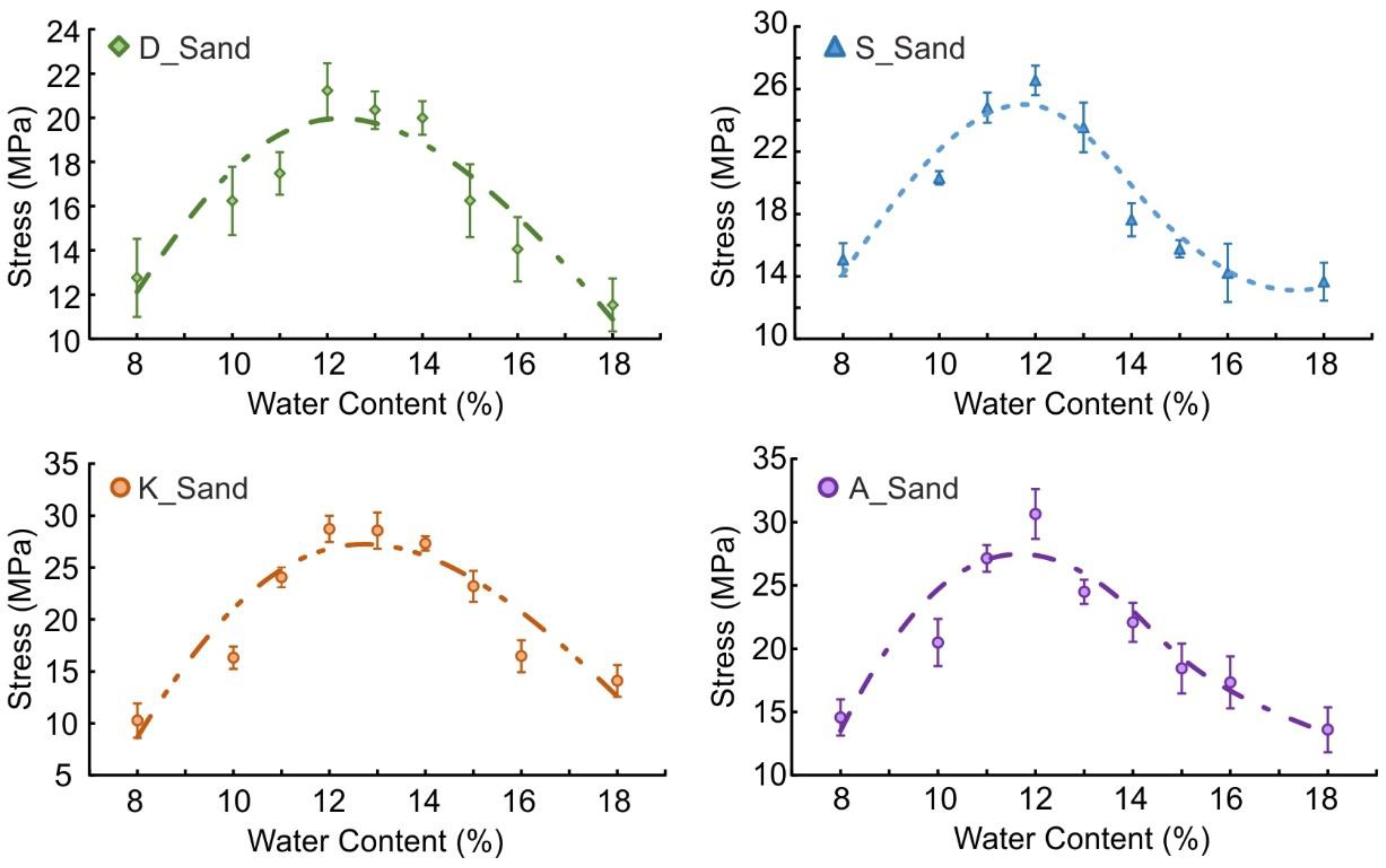

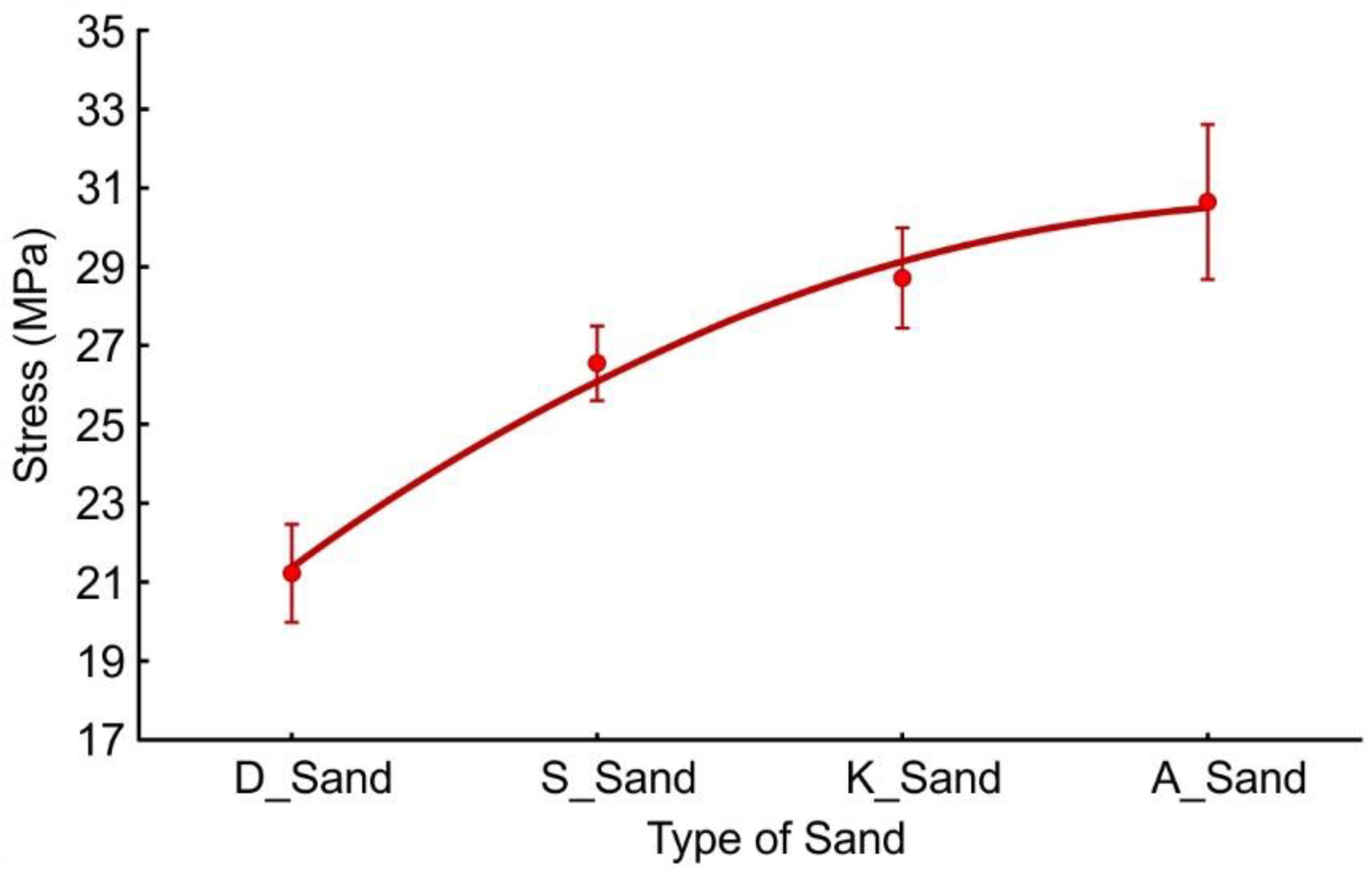

3.2. Compression Test Results

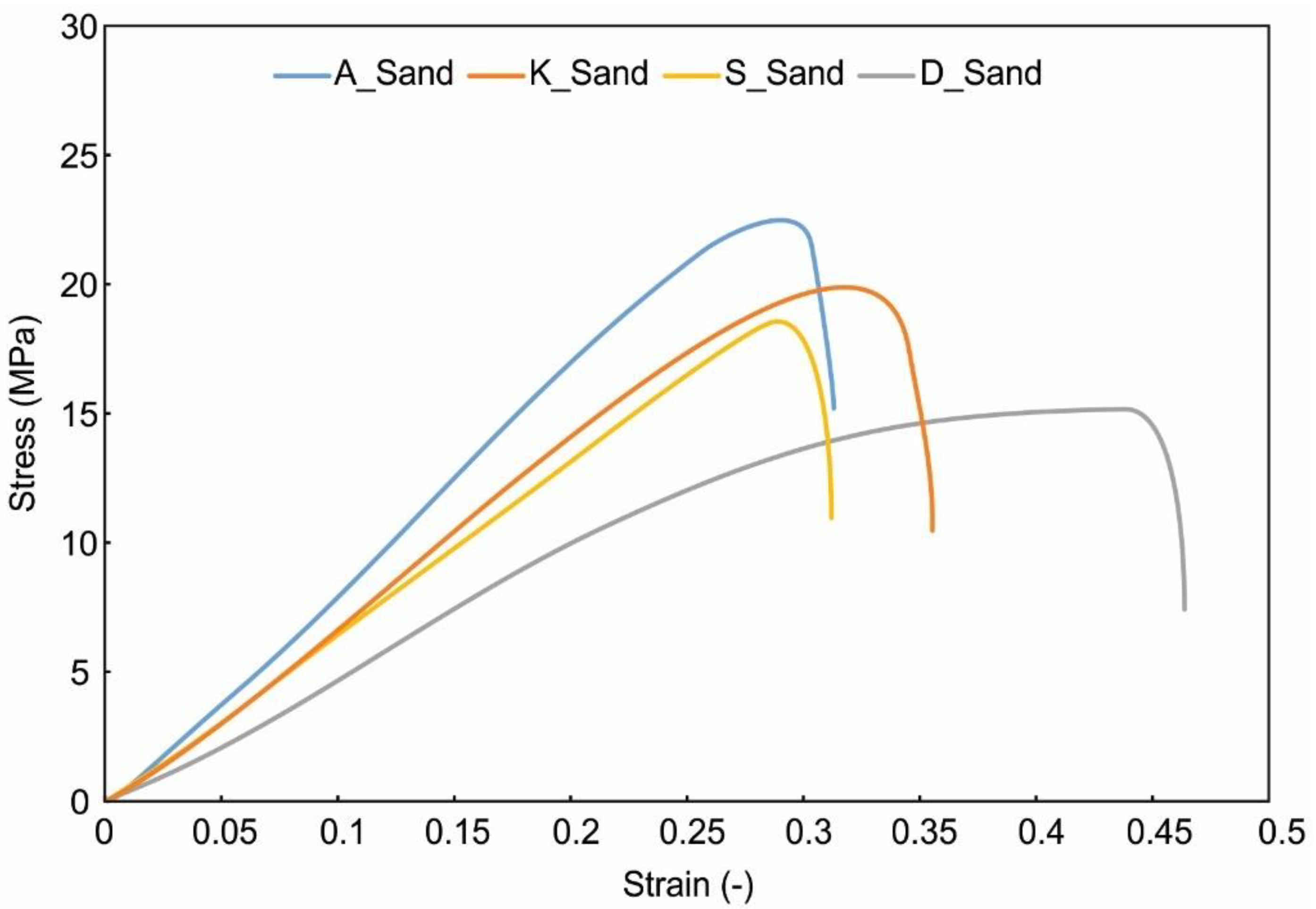

3.3. Brazilian Test and Cylinder Compression Test Results

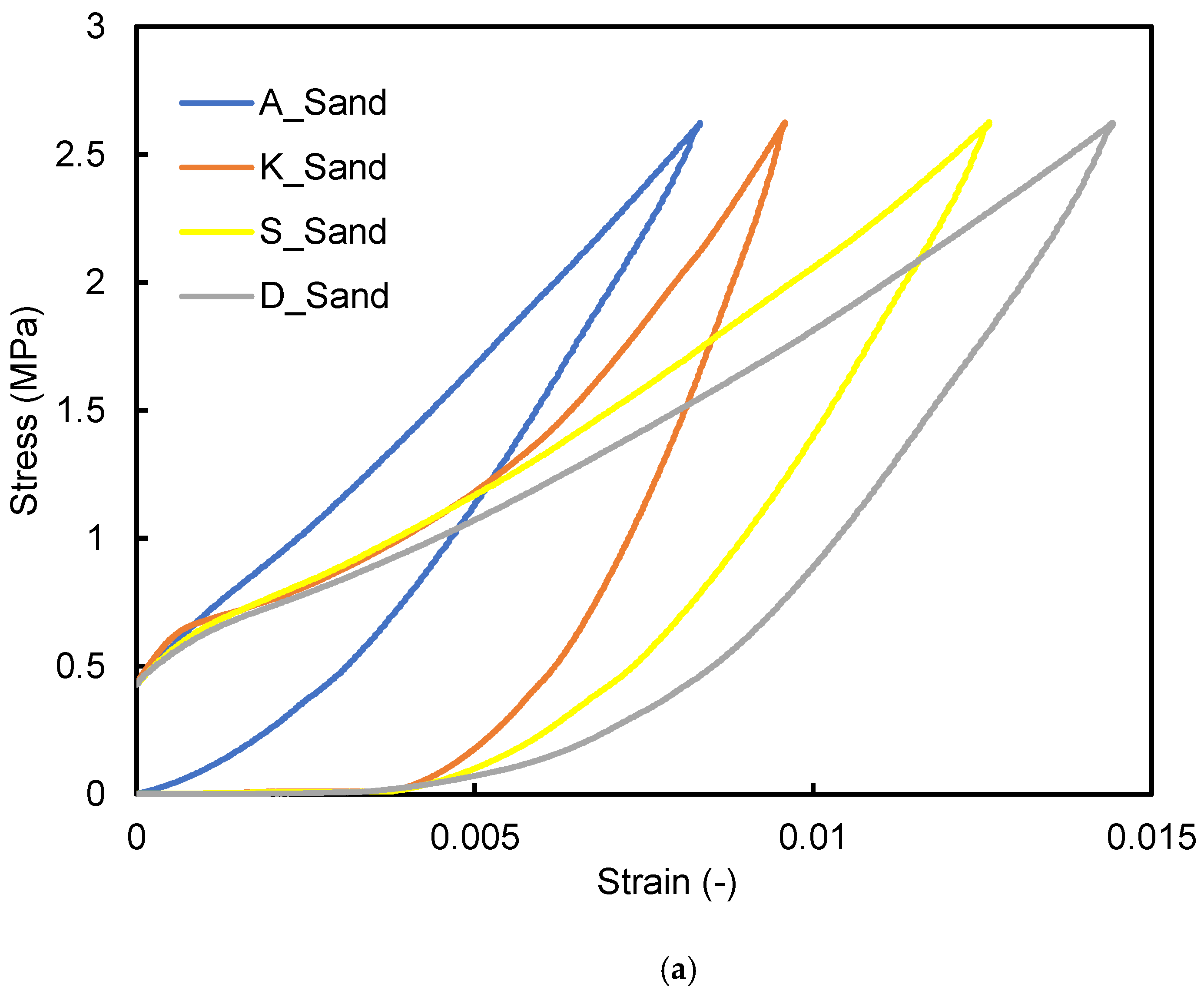

3.4. Cyclic Compression

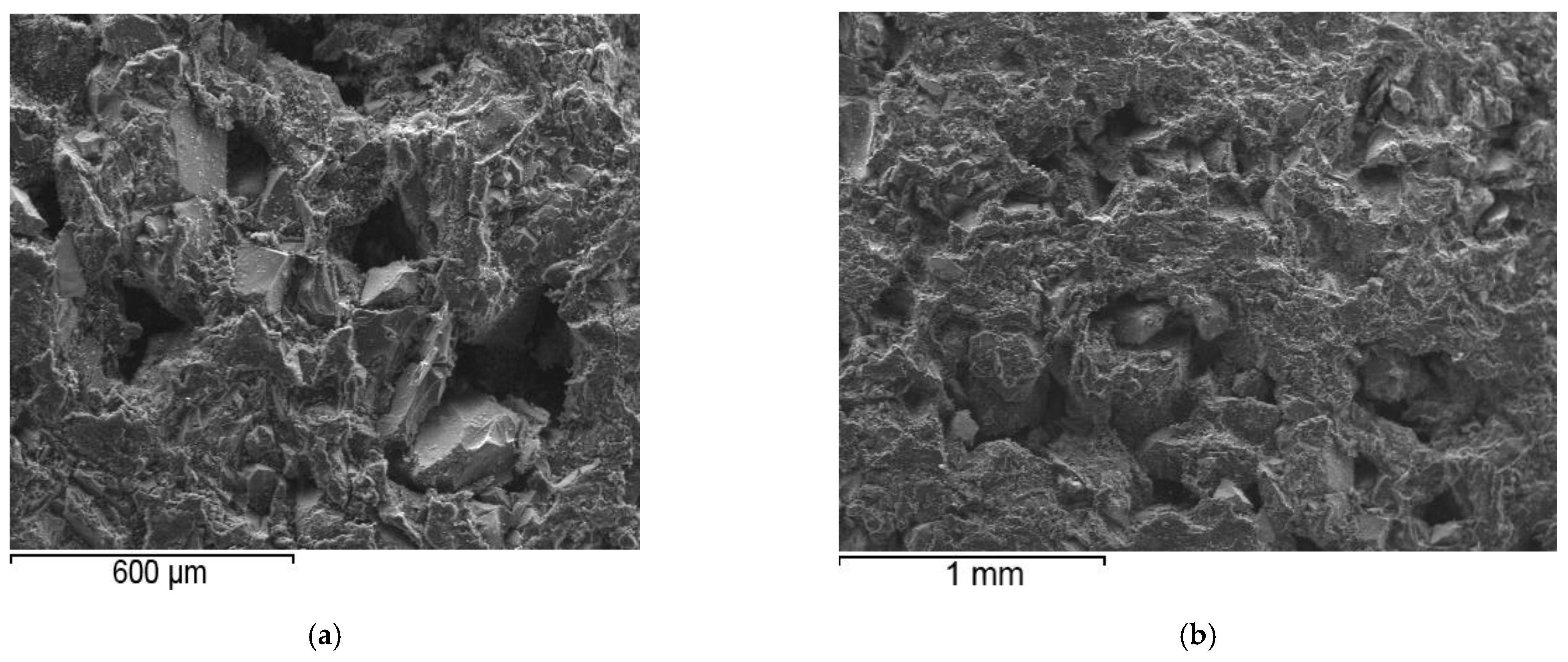

3.5. Scanning Electron Microscopy (SEM) Analysis of the Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Åstrom, D.O.; Forsberg, B.; Rocklov, K.L.E.J. Attributing mortality from extreme temperatures to climate change in Stockholm, Sweden. Nat. Clim. Chang. 2013, 3, 1050–1054. [Google Scholar] [CrossRef]

- Khotbehsara, E.M.; Daemei, A.B.; Malekjahan, F.A. Simulation study of the eco green roof in order to reduce heat transfer in four different climatic zones. Results Eng. 2019, 2, 100010. [Google Scholar] [CrossRef]

- Singha, A.S.; Thakur, V.K. Mechanical properties of natural fiber reinforced polymer composites. Bull. Mater. Sci. 2008, 31, 791–799. [Google Scholar] [CrossRef]

- Singha, A.S.; Thakur, V.K. Chemical resistance, mechanical and physical properties of biofibers-based polymer composites. Polym. Plast. Technol. 2009, 48, 736–744. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Soto, M.G.; Alyousef, R.; Zeadani, M.E.; Alabduljabbar, H.; Aune, V. Performance investigation of high-proportion Saudi-fly-ash-based concrete. Results Eng. 2020, 6, 100118. [Google Scholar] [CrossRef]

- Umurigirwa, B.S.; Vroman, I.; Mai, T.H.; Maalouf, C. Influence of chemical modification on hemp–starch concrete. Constr. Build Mater. 2015, 81, 208–215. [Google Scholar]

- Müller, P.; Kapin, E.; Fekete, E. Effects of preparation methods on the structure and mechanical properties of wet conditioned starch/montmorillonite nanocomposites films. Carbohydr. Polym. 2014, 113, 569–576. [Google Scholar] [CrossRef] [Green Version]

- Mansour, G.; Zoumaki, M.; Marinopoulou, A.; Raphaelides, S.N.; Tzetzis, D.; Zoumakis, N. Investigation on the Effects of Glycerol and Clay Contents on the Structure and Mechanical Properties of Maize Starch Nanocomposite Films. Stärke 2020, 72, 1900166. [Google Scholar] [CrossRef]

- Zoumaki, M.; Tzetzis, D.; Mansour, G. Development and characterization of starch-based nanocomposite materials. In Materials Science and Engineering; IOP Conference Series; IOP Publishing: Bristol, UK, 2019; Volume 564, p. 012037. [Google Scholar]

- Mansour, G.; Zoumaki, M.; Tsongas, K.; Tzetzis, D. Microstructural and Finite Element Analysis-Assisted Nanomechanical Characterization of Maize Starch Nanocomposite Films. Mater. Res. 2021, 24, e20200409. [Google Scholar] [CrossRef]

- Mansour, G.; Zoumaki, M.; Marinopoulou, A.; Tzetzis, D.; Prevezanos, M.; Raphaelides, S. Characterization and properties of non-granular thermoplastic starch–clay biocomposite films. Carbohydr. Polym. 2020, 245, 116629. [Google Scholar] [CrossRef]

- Zoumaki, M.; Mansour, M.; Tsongas, K.; Tzetzis, D.; Mansour, G. Mechanical Characterization and Finite Element Analysis of Hierarchical Sandwich Structures with PLA 3D Printed Core and Composite Maize Starch Biodegradable Skins. J. Compos. Sci. 2022, 6, 118. [Google Scholar] [CrossRef]

- Parker, R.; Ring, S.G. Aspects of the physical chemistry of starch. J. Cereal. Sci. 2001, 34, 1–17. [Google Scholar] [CrossRef]

- Gaudin, S.; Lourdin, D.; Le Botlan, D.; Ilari, J.L.; Colonna, P.J. Plasticisation and Mobility in Starch-Sorbitol Films. Cereal. Sci. 1999, 29, 273. [Google Scholar] [CrossRef]

- Mantzari, G.; Raphaelides, S.N.; Exarhopoulos, S. Effect of sorbitol addition on the physicochemical characteristics of starch–fatty acid systems. Carbohydr. Polym. 2010, 79, 154. [Google Scholar] [CrossRef]

- Morrison, W.R. Starch lipids and how they relate to starch granule structure and functionality. CFW 1995, 40, 437. [Google Scholar]

- Chivrac, F.; Pollet, E.; Dole, P.; Averous, L. Starch-based nanobiocomposites: Plasticizer impact on the montmorillonite exfoliation process. Carbohydr. Polym. 2010, 79, 941–947. [Google Scholar] [CrossRef]

- Kulshreshtha, Y.; Schlangen, E.; Jonkers, H.M.; Vardon, P.J.; Van Paassen, L.A. CoRncrete: A corn starch-based building material. Constr. Build Mater. 2017, 154, 411–442. [Google Scholar] [CrossRef] [Green Version]

- Mansour, G.; Zoumaki, M.; Tsongas, K.; Tzetzis, D. Starch-sandstone materials in the construction industry. Results Eng. 2020, 8, 100182. [Google Scholar] [CrossRef]

- Mansour, G.; Zoumaki, M.; Tzetzis, D. Starch Sandstones in Building Bio-materials. MATEC Web Conf. 2020, 318, 01046. [Google Scholar] [CrossRef]

- Marinopoulou, A.; Karageorgiou, V.; Papastergiadis, E.; Iordanidis, C.; Dagklis, A.; Raphaelides, S.N. Production of spray-dried starch molecular inclusion complexes on an industrial scale. Food Bioprod. Process. 2019, 116, 186–195. [Google Scholar] [CrossRef]

- Raphaelides, S.N.; Georgiadis, N. Effect of fatty acids on the rheological behaviour of maize starch dispersions during heating. Carbohydr. Polym. 2006, 65, 81–92. [Google Scholar] [CrossRef]

- ISRM. Suggested Methods for Determining Tensile Strength of Rock Materials Part 2: Suggested Method for determining indirect tensile strength by the Brazil Test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 99–103. [Google Scholar] [CrossRef]

- EN 196-1:2016; Methods of Testing Cement-Part 1: Determination of Strength. European Standard: Brussels, Belgium, 2015.

- ISEM. ISRM Suggested Methods, Rock Characterization Testing and Monitoring, 1st ed.; Published for the Commission on Testing Methods, International Society for Rock Mechanics (ISRM); Brown, E.T., Ed.; Pergamon Press Ltd.: Oxford, UK; New York, NY, USA, 1981. [Google Scholar]

- Dobereiner, L.; de Freitas, M.H. Geotechnical properties of weak sandstones. Geotechnique 1986, 36, 79–94. [Google Scholar] [CrossRef]

- Andreev, G.E. A Review of the Brazilian test for rock tensile strength determination. Part I: Calculation formula. Int. J. Min. Sci. Technol. 1991, 13, 445–456. [Google Scholar] [CrossRef]

- ASTM, D 2938–95; Standard Test Method for Unconfined Compressive Strength of Intact Rock Core Specimens. ASTM International: West Conshohocken, PA, USA, 1995.

- Newman, J.B. Strength-testing machines for concrete. In Advanced Concrete Technology, 1st ed.; Newman, J.B., Choo, B.S., Eds.; Elsevier: Oxford, UK, 2003; Volume 1, pp. 1–9. [Google Scholar]

- Li, D.; Wong, L.N.Y. The Brazilian Disc Test for Rock Mechanics Applications: Review and New Insights. Rock Mech. Rock Eng. 2013, 46, 269–287. [Google Scholar] [CrossRef]

- Stagg, K.G.; Zienkiewicz, O.C. Rock Mechanics in Engineering Practice, 1st ed.; John Willey & Sons: New York, NY, USA, 1975. [Google Scholar]

- Silva, A.D.; Dionísio, A.; Coelho, L. Flexible-lean processes optimization: A case study in stone sector. Results Eng. 2020, 6, 100129. [Google Scholar] [CrossRef]

- Johnson, R.B.; Degraff, J.V. Principles of Engineering Geology, 1st ed.; John Wiley & Sons: New York, NY, USA, 1988. [Google Scholar]

- García, V.J.; Márquez, C.O.; Zúñiga-Suárez, R.A.; Zuñiga-Torres, B.C.; Villalta-Granda, L.J. Brazilian Test of Concrete Specimens Subjected to Different Loading Geometries: Review and New Insights. IJCSM 2017, 11, 343–363. [Google Scholar] [CrossRef] [Green Version]

- Rocco, C.; Guineae, G.V.; Planas, J.; Elices, M. Size effect and boundary conditions in the brazilian test: Theoretical analysis. Mater. Struct. 1999, 22, 437–444. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Hu, Y.; Mao, T. Brazilian Test for Tensile Failure of Anisotropic Shale under Different Strain Rates at Quasi-static Loading. Energies 2017, 10, 1324. [Google Scholar] [CrossRef] [Green Version]

| Type of Sand | Compressive Stress (MPa) | Stdv (MPa) |

|---|---|---|

| D_Sand | 21.23 | 1.24 |

| S_Sand | 26.55 | 0.95 |

| K_Sand | 28.71 | 1.27 |

| A_Sand | 30.64 | 1.97 |

| Type of Sand | Tensile Strength (MPa) | Stdv (MPa) | Compressive Strength (MPa) | Stdv (MPa) | Ratio (Tensile/Compressive) |

|---|---|---|---|---|---|

| D_Sand | 4.02 | 0.18 | 15.8 | 1.45 | 1/3.93 |

| S_Sand | 3.97 | 0.45 | 18.3 | 1.01 | 1/4.6 |

| K_Sand | 5.86 | 0.83 | 19.69 | 1.25 | 1/3.36 |

| A_Sand | 3.62 | 0.64 | 22.24 | 2.87 | 1/6.14 |

| Type of Sand | Area of Hysteresis Loop (ΔW) | Maximum Energy (W) | Loss Factor (n) |

|---|---|---|---|

| A_Sand | 0.0041 | 0.0123 | 10.5% |

| K_Sand | 0.0071 | 0.0125 | 18.1% |

| S_Sand | 0.0099 | 0.0182 | 17.3% |

| D_Sand | 0.0114 | 0.0208 | 17.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zoumaki, M.; Tsongas, K.; Tzetzis, D.; Mansour, G. Corn Starch-Based Sandstone Sustainable Materials: Sand Type and Water Content Effect on Their Structure and Mechanical Properties. Sustainability 2022, 14, 8901. https://doi.org/10.3390/su14148901

Zoumaki M, Tsongas K, Tzetzis D, Mansour G. Corn Starch-Based Sandstone Sustainable Materials: Sand Type and Water Content Effect on Their Structure and Mechanical Properties. Sustainability. 2022; 14(14):8901. https://doi.org/10.3390/su14148901

Chicago/Turabian StyleZoumaki, Maria, Konstantinos Tsongas, Dimitrios Tzetzis, and Gabriel Mansour. 2022. "Corn Starch-Based Sandstone Sustainable Materials: Sand Type and Water Content Effect on Their Structure and Mechanical Properties" Sustainability 14, no. 14: 8901. https://doi.org/10.3390/su14148901

APA StyleZoumaki, M., Tsongas, K., Tzetzis, D., & Mansour, G. (2022). Corn Starch-Based Sandstone Sustainable Materials: Sand Type and Water Content Effect on Their Structure and Mechanical Properties. Sustainability, 14(14), 8901. https://doi.org/10.3390/su14148901