Study on Fire Ventilation Control of Subway Tunnel: A Case Study for Dalian Subway

Abstract

:1. Introduction

2. Theoretical Model

2.1. Basic Governing Equation

2.2. Mechanical Smoke-Exhaust-Control Equation

3. Model Construction

3.1. Fire-Growth Model

3.2. Model Parameter

3.2.1. Determination of Simulated-Fire Scale

3.2.2. Determination of Simulation Duration

3.2.3. Ventilation Method and Relevant Parameters

3.2.4. Fire-Hazard Judgment Conditions

- (1)

- Temperature

- (2)

- CO Concentration

- (3)

- Visibility

3.2.5. Simulation Grid Division

3.3. Working-Condition Design

4. Results and Analysis

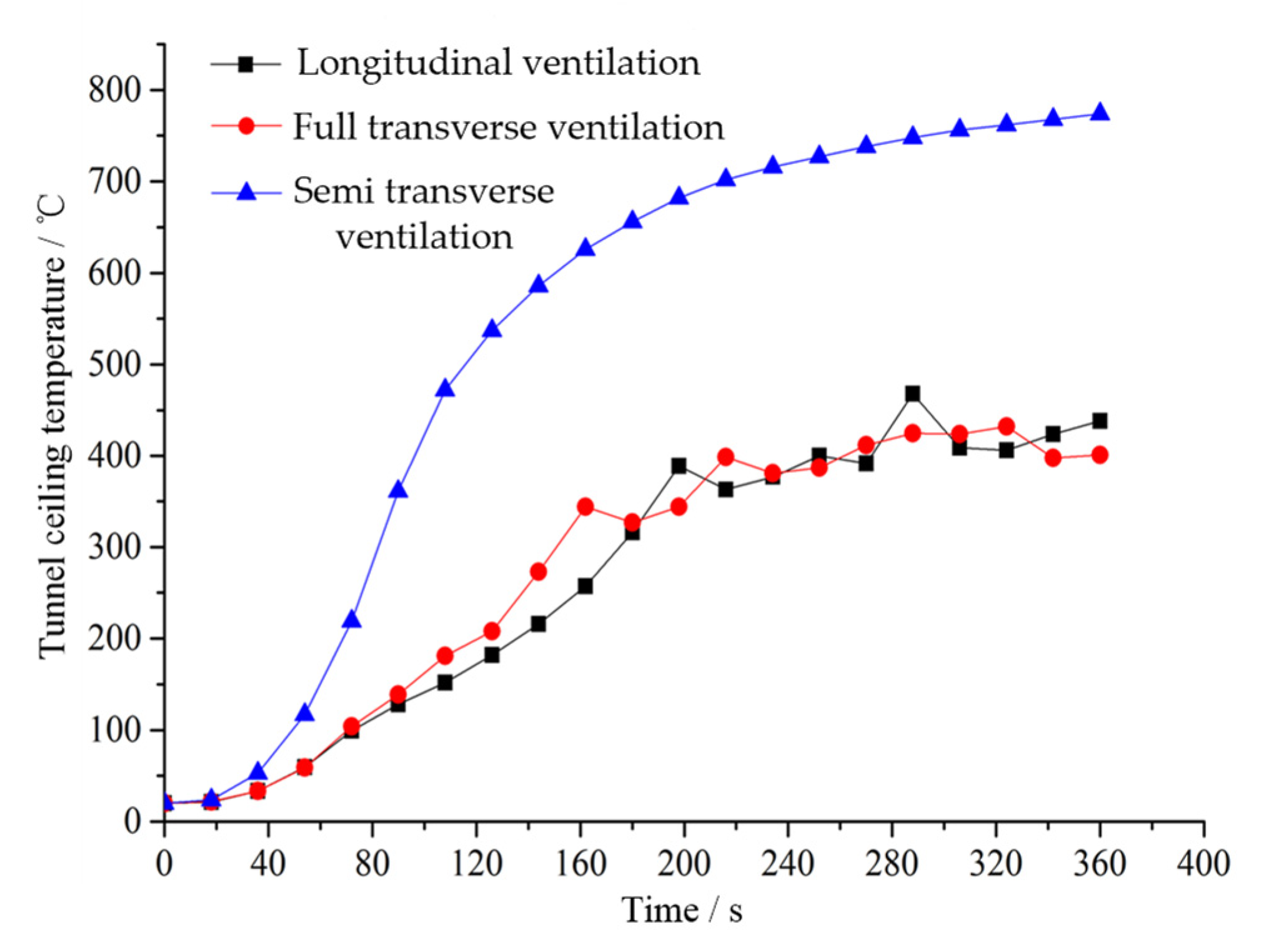

4.1. Ventilation-Mode Analysis for C3

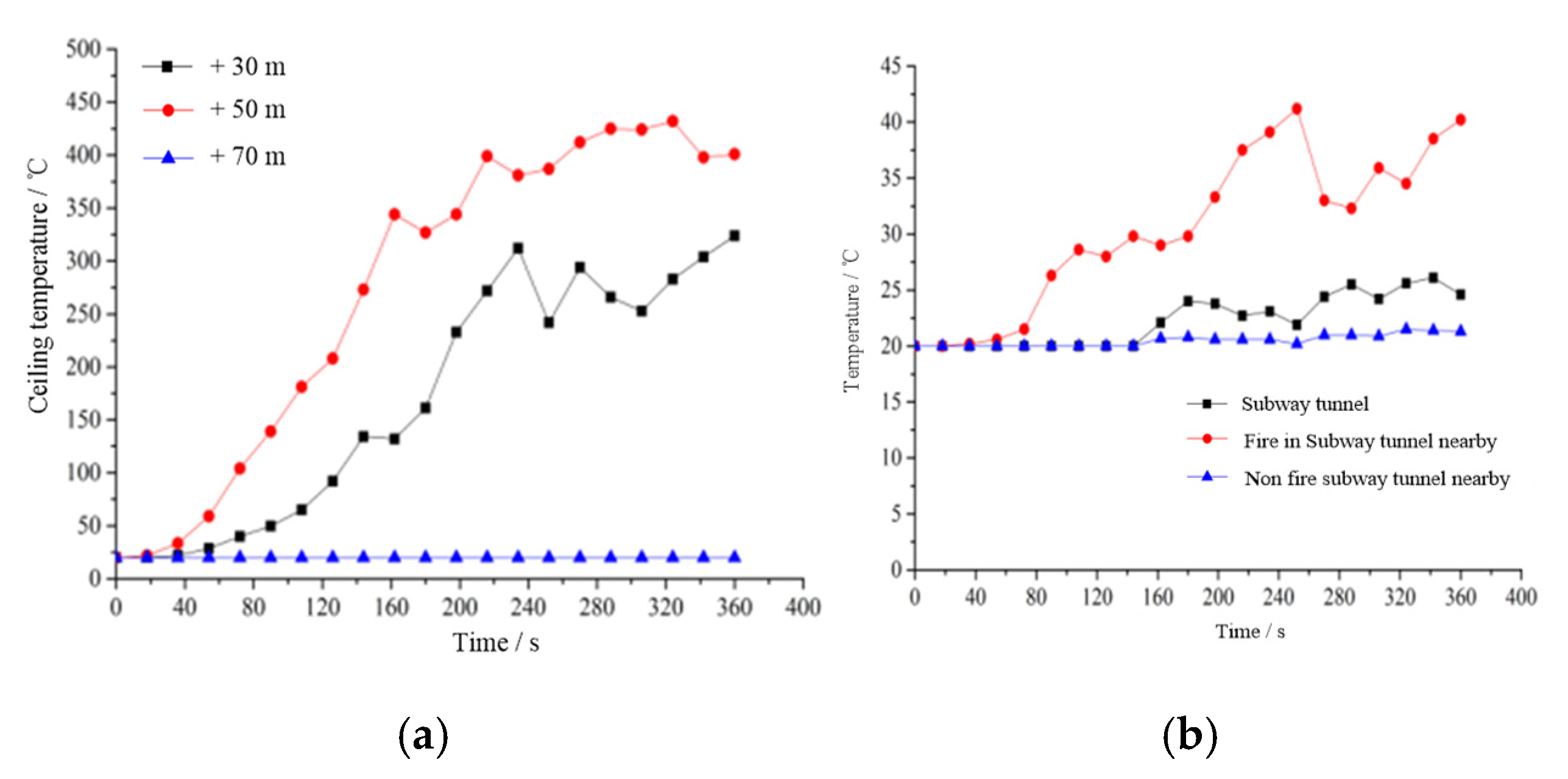

4.2. Analysis for Working Condition C3

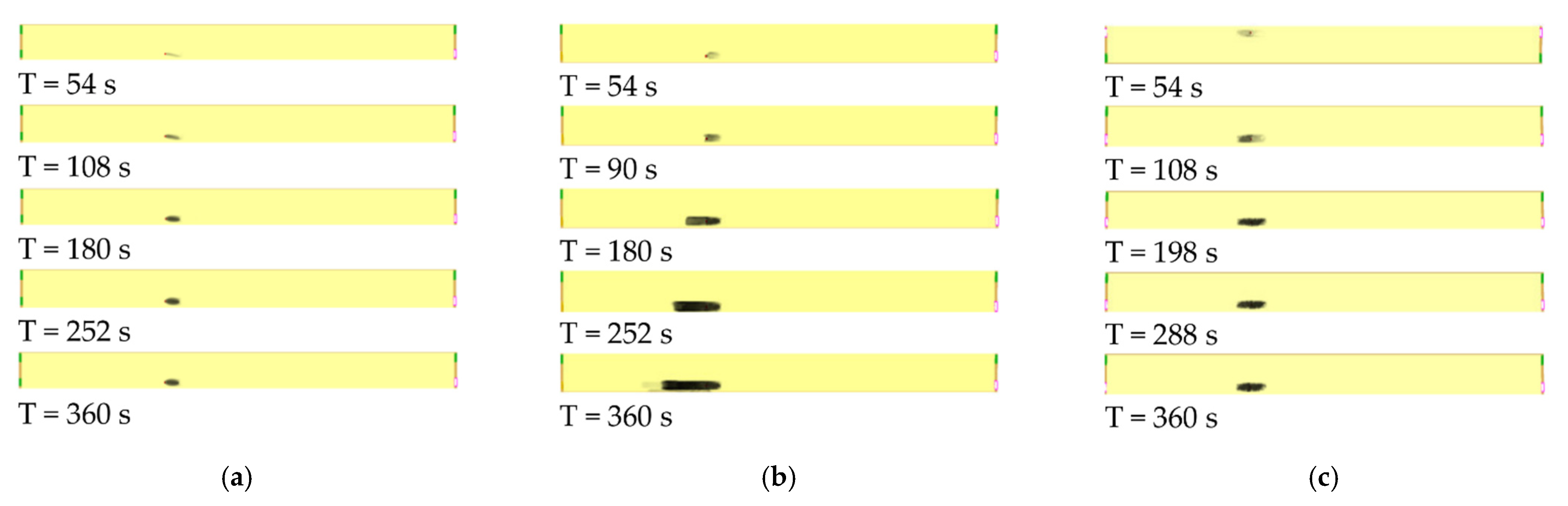

4.3. Study on Semi-Transverse-Ventilation Mode under C3 Working Condition

5. Conclusions

- (1)

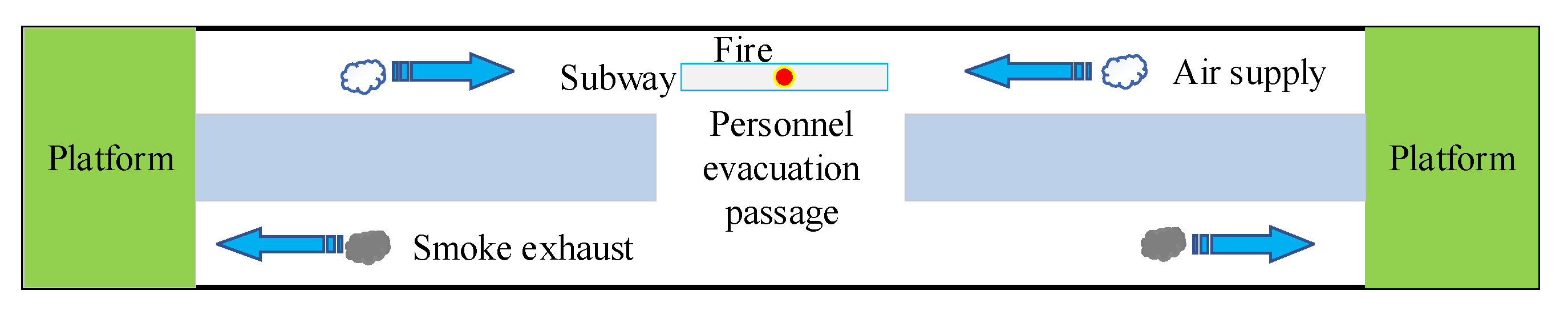

- When the fire source is facing a connecting passage in subway tunnel, the ventilation mode of the air supply at both ends of the fire tunnel and the smoke exhaust in connecting passage in subway tunnel is adopted. The smoke diffuses to the non-fire tunnel through the connecting passage in the subway tunnel, and the smoke can be controlled at about 10 m near the connecting passage in the subway tunnel through the platforms at both ends of the non-fire tunnel. The smoke visibility, CO concentration, and temperature at both ends of the fire tunnel meet the conditions for personnel escape, so personnel can safely escape to both ends of the burning tunnel.

- (2)

- When the fire source is close to the connecting passage in the subway tunnel, the station in front of the fire tunnel shall supply fresh air at 2.6 m/s, while the station behind the fire tunnel shall exhaust the smoke. Both ends of the non-fire tunnel shall supply air at 1.0 m/s (the critical wind speed of the tunnel). The smoke is discharged through the rear station. There is no smoke in the connecting passage in the subway tunnel, which reaches the ideal condition for personnel escape. Under such working conditions, passengers close to the upstream can escape upstream, and passengers close to the downstream can choose to evacuate safely to the contact channel.

- (3)

- When the fire source is close to the connecting channel, the longitudinal smoke-exhaust method will be adopted, and some personnel downstream of the fire source will be submerged in the smoke. The semi-transverse smoke exhaust can solve this problem well. The effect of semi-horizontal smoke exhaust is the safest for personnel to escape safely. The smoke flow can be controlled between the two smoke-exhaust outlets, and personnel can safely evacuate to both ends of the burning tunnel or the non-burning tunnel. To a certain extent, the problem of personnel downstream of the fire source affected by smoke in the longitudinal smoke exhaust mode is solved. Therefore, when the economic and technical conditions were accepted, the semi-transverse smoke-exhaust mode should be preferred to exhaust the smoke of the interval tunnels.

- (4)

- Through the comparison of four different working conditions of semi-horizontal smoke exhaust, in the case of fire, with two open smoke vents near the fire source, the smoke can be controlled between the two smoke vents, and the safe personnel-escape conditions can be achieved without longitudinal ventilation. With two open smoke vents downstream from the fire source, personnel are less affected by the smoke when the longitudinal wind speed is 1.0 m/s, so the safe evacuation of personnel can be also realized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- GB 50157-2013; Code for Design of Metro. 2013. Available online: https://d.wanfangdata.com.cn/standard/ChxTdGFuZGFyZE5ld1MyMDIwMDkxODIwMjIwNTMwEg1HQiA1MDE1Ny0yMDEzGghwdGhlY3o5eA%3D%3D (accessed on 9 April 2022).

- Long, Z.; Liu, C.; Yang, Y.; Qiu, P.; Tian, X.; Zhong, M. Full-scale experimental study on fire-induced smoke movement and control in an underground double-island subway station. Tunn. Undergr. Space Technol. 2020, 103, 103508. [Google Scholar] [CrossRef]

- Krasyuk, A.M.; Lugin, I.V.; Alferova, E.L.; Kiyanitsa, L.A. Evaluation of ventilation flow charts for double-line subway tunnels without air chambers. J. Min. Sci. 2016, 52, 740–751. [Google Scholar] [CrossRef]

- Dong, S.; Wang, K.; Jia, C. A Study on the Influence of Rail Top Smoke Exhaust and Tunnel Smoke Exhaust on Subway Fire Smoke Control. Sustainability 2022, 14, 4049. [Google Scholar] [CrossRef]

- ATS 5387.8; Australian Technical Specification. Guidelines—Fire Safety Engineering. Part 8: Life Safety—Occupant Behaviour, Location and Condition. Standards Australia: Sydney, Australia, 2006.

- Zhou, D.; Hu, T.; Wang, Z.; Chen, T.; Li, X. Influence of tunnel slope on movement characteristics of thermal smoke in a moving subway train fire. Case Stud. Therm. Eng. 2021, 28, 101472. [Google Scholar] [CrossRef]

- International Code Council. International Building Code; International Code Council: Falls Church, VA, USA, 2000. [Google Scholar]

- Teodosiu, C.I.; Ilie, V.; Dumitru, R.G.; Teodosiu, R.S. Assessment of ventilation efficiency for emergency situations in subway systems by CFD modeling. In Building Simulation; Tsinghua University Press: Beijing, China, 2016; Volume 9, pp. 319–334. [Google Scholar]

- Helbing, D.; Farkas, I.; Vicsek, T. Simulating Dynamical Features of Escape Panic. Nature 2000, 407, 487–490. [Google Scholar] [CrossRef] [Green Version]

- Lambert, K.; Welch, S.; Merci, B. The use of positive pressure ventilation fans during firefighting operations in underground stations: An experimental study. Fire Technol. 2018, 54, 625–647. [Google Scholar] [CrossRef] [Green Version]

- Bettis, R.J.; Jagger, S.F.; Wu, Y. Interim validation of tunnel fire consequence models; summary of phase 2 tests. In The Health and Safety Laboratory Report IR/IJFR/93/11; The Health and Safety Executive: Bootle, UK, 1993. [Google Scholar]

- Bettis, R.J.; Jagger, S.F.; Macmillan, A.J.R.; Hambleton, R.T. Interim validation of tunnel fire consequence models; summary of phase 1 tests. In The Health and Safety Laboratory Report IR/IJFR/94/2; The Health and Safety Executive: Bootle, UK, 1994. [Google Scholar]

- Art Bendelius. Memorial tunnel fire ventilation test programme. In One Day Seminar of Smoke and Critical Velocity in Tunnels; Art Bendelius: London, UK, 1996. [Google Scholar]

- Wu, Y.; Bakar, M.Z.A. Control of smoke flow in tunnel fires using longitudinal ventilation systems—A study of critical velocity. Fire Saf. J. 2000, 35, 363–390. [Google Scholar] [CrossRef]

- Kurioka, H.; Oka, Y.; Satoh, H.; Sugawa, O. Fire properties in near field of square fire source with longitudinal ventilation in tunnels. Fire Saf. J. 2003, 38, 319–340. [Google Scholar] [CrossRef]

- Grattan, K.B.; Hamins, A. Numerical Simulation of the Howard Street Tunnel Fire, Baltimore, Maryland, July 2001; NISTIR 6902; Fire Research Division, Building and Fire Research Laboratory, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2002. [Google Scholar]

- Bari, S.; Naser, J. Simulation of smoke from a burning vehicle and pollution levels caused by traffic jam in a road tunnel. Tunn. Undergr. Space Technol. 2005, 20, 281–290. [Google Scholar] [CrossRef]

- Chow, W.K. On Smoke Control for Tunnels by Longitudinal Ventilation. Tunn. Undergr. Space Technol. 1998, 13, 271–275. [Google Scholar] [CrossRef]

- Tavakolian, Z.; Abouali, O.; Yaghoubi, M. 3D simulations of smoke exhaust system in two types of subway station platforms. Int. J. Vent. 2021, 20, 65–81. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, Q. Simulation of fire temperature field and damage analysis of subway station. Struct. Eng. 2021, 37, 6–16. Available online: https://d.wanfangdata.com.cn/periodical/ChlQZXJpb2RpY2FsQ0hJTmV3UzIwMjIwMzIyEg5qZ2djczIwMjEwNDAwMhoIdWpvdGVrZWg%3D (accessed on 9 April 2022).

- Li, Y.Z.; Lei, B.; Ingason, H. Study of critical velocity and backlayering length in longitudinally ventilated tunnel fires. Fire Saf. J. 2010, 45, 361–370. [Google Scholar] [CrossRef]

- Lee, S.R.; Ryou, H.S. A numerical study on smoke movement in longitudinal ventilation tunnel fires for different aspect ratio. Build. Environ. 2006, 41, 719–725. [Google Scholar] [CrossRef]

- Weng, M.C.; Yu, L.X.; Liu, F. Smoke Backlayering Length and Critical Wind Velocity in a Metro Tunnel. J. South China Univ. Technol. (Nat. Sci. Ed.) 2014, 42, 121–128. [Google Scholar] [CrossRef]

- Chen, S.; Bi, H.Q.; Liu, X.X.; Wamg, J. Numerical Simulation Study on Critical Velocity in Subway Tunnel Fire. Refrig. Air Cond. 2017, 31, 245–248. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Mapar, M.; Pasdarshahri, H. A comprehensive study of two fire sources in a road tunnel: Considering different arrangement of obstacles. Tunn. Undergr. Space Technol. 2016, 59, 91–99. [Google Scholar] [CrossRef]

- Xu, Z.S.; Zhao, H.L.; Li, H.; Jiang, X. Theoretical model of critical wind velocity in horizontal tunnel fires. J. Cent. South Univ. (Sci. Technol.) 2013, 44, 1138–1143. [Google Scholar]

- Chow, W.K. Simulation of Tunnel Fire Using a Zone Model. Tunn. Undergr. Space Technol. 1996, 11, 221–236. [Google Scholar] [CrossRef]

- Wang, K.; Pan, H.; Zhang, T.J. Experimental Study of Prefabricated Crack Propagation in Coal Briquettes under the Action of a CO2 Gas Explosion. ACS Omega 2021, 6, 24462–24472. [Google Scholar] [CrossRef]

- Wang, K.; Pan, H.Y.; Zhang, T.J.; Wang, H.T. Experimental study on the radial vibration characteristics of a coal briquette in each stage of its life cycle under the action of CO2 gas explosion. Fuel 2022, 320, 123922. [Google Scholar] [CrossRef]

- Huo, R.; Hu, Y.; Li, Y.Z. Introduction to Building Fire Safety Engineering; Press of University of Science and Technology of China: Anhui, China, 2009. [Google Scholar]

- Chen, F. Study on Smoke Flow and Personnel Evacuation Simulation in Subway Tunnel Fire; Chongqing University: Chongqing, China, 2010. [Google Scholar]

- GB 51298-2018; Standard for Fire Protection Design of Metro. 2018. Available online: https://d.wanfangdata.com.cn/standard/ChxTdGFuZGFyZE5ld1MyMDIwMDkxODIwMjIwNTMwEg1HQiA1MTI5OC0yMDE4GghtcmNyNTFydQ%3D%3D (accessed on 9 April 2022).

- Feng, T. Study on Fire Smoke Flow Characteristic and Control Method in Subway Tunnel; China University of Mining and Technology: Beijing, China, 2017. [Google Scholar]

- Zhou, J.L.; Hu, R.H. Fire hazard and escape Countermeasures. Overv. Disaster Prev. 2002, 3, 14–15. Available online: https://d.wanfangdata.com.cn/periodical/ChlQZXJpb2RpY2FsQ0hJTmV3UzIwMjIwMzIyEg5RSzIwMDIwMTI4ODkzOBoIY2Q1Mmx6djg%3D (accessed on 9 April 2022).

- Xu, Z.S. Smoke Control Works; China Machine Press: Beijing, China, 2011. [Google Scholar]

| Number | Name | Mass/ kg | Released Heat per Unit Mass/ (MJ/kg) | Total Released Heat/ (MJ) |

|---|---|---|---|---|

| 1 | Seat | 201 | 28 | 5629 |

| 2 | Window | 69 | 26 | 1778 |

| 3 | Sound-insulation facilities | 91 | 9 | 844 |

| 4 | Padding | 91 | 26 | 2340 |

| 5 | Floor covering | 102 | 33 | 3376 |

| 6 | Wall- and top-insulation material | 91 | 18 | 1669 |

| 7 | Glass-window washer | 2 | 18 | 43 |

| 8 | Lampshade | 19 | 35 | 687 |

| 9 | End cover | 9 | 26 | 235 |

| 10 | Insulated cable | 454 | 26 | 11,703 |

| 11 | Battery pack | 9 | 26 | 235 |

| 12 | Lubricating oil | 4 | 51 | 184 |

| 13 | Control cover | 68 | 26 | 1754 |

| 14 | Total | 30,477 |

| Type | Region | Grid Size (m) | Number of X, Y, Z Grids (PCs.) | Total Number of Grids (PCs.) |

|---|---|---|---|---|

| 1 | (Y = −150, Y = −30) | 0.4 × 0.8 × 0.4 | 45 × 150 × 15 | 101,250 |

| (Y = −30, Y = 30) | 0.2 × 0.2 × 0.2 | 90 × 300 × 30 | 810,000 | |

| (Y = 30, Y = 150) | 0.4 × 0.8 × 0.4 | 45 × 150 × 15 | 101,250 | |

| 2 | (Y = −150, Y = 30) | 0.4 × 0.8 × 0.4 | 45 × 225 × 15 | 151,875 |

| (Y = 30, Y = 70) | 0.2 × 0.2 × 0.2 | 90 × 200 × 30 | 540,000 | |

| (Y = 70, Y = 150) | 0.4 × 0.8 × 0.4 | 45 × 100 × 15 | 67,500 |

| Working Condition | Train Fire Source Location | Train Stop Position |

|---|---|---|

| A1 | Head | Close to the station ahead |

| A2 | Close to the rear station | |

| A3 | Middle of tunnel section | |

| B1 | Tail | Close to the station ahead |

| B2 | Close to the rear station | |

| B3 | Middle of tunnel section | |

| C1 | Central section | Near the front (rear) station |

| C2 | Middle of tunnel section | |

| C3 | The train stops near connecting passage in subway tunnel |

| Ventilation Mode | Personnel Evacuation Plan | |

|---|---|---|

| A1 | The rear station fan supplies fresh air and the front station fan discharges smoke | Evacuate to the rear station or connecting passage |

| A2 | The rear station fan supplies fresh air and the front station fan discharges smoke | Evacuate to the rear station |

| A3 | The rear station fan supplies fresh air and the front station fan discharges smoke | Evacuate to the rear station or connecting passage |

| B1 | The front station fan supplies fresh air and the rear station fan discharges smoke | Evacuate to the station ahead |

| B2 | The front station fan supplies fresh air and the rear station fan discharges smoke | Evacuate to the station or connecting passage ahead |

| B3 | The front station fan supplies fresh air and the rear station fan discharges smoke | Evacuate to the station or connecting passage ahead |

| C1 | The rear (front) station fan supplies fresh air, and the front (rear) station fan discharges smoke | Personnel near the front (rear) station shall escape towards the station, and other personnel shall evacuate to the rear (front) station or connecting channel |

| C2 | Fresh air is supplied by fans at both ends of the fire tunnel station, and smoke is discharged at both ends of the unfired tunnel | Evacuate to both ends of the burning tunnel |

| C3 | Fresh air is supplied from the station in front (rear) of the fire tunnel, smoke is discharged from the station in rear (front) of the fire tunnel, and air is supplied from both ends of the unfired tunnel | |

| Working Condition | Smoke-Exhaust Wind Speed/(m/s) | Number of Smoke Vents Opened | Smoke-Exhaust Opening Position | Longitudinal-Inlet Wind Speed/(m/s) |

|---|---|---|---|---|

| C31 | 4.5 | 2 | Downstream of fire source | 2.0 |

| C32 | 4.5 | 2 | Downstream of fire source | 1.0 |

| C33 | 4.5 | 2 | Downstream of fire source | 0.5 |

| C34 | 4.5 | 2 | Both sides of fire source | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Zhang, X.; Wang, K. Study on Fire Ventilation Control of Subway Tunnel: A Case Study for Dalian Subway. Sustainability 2022, 14, 8695. https://doi.org/10.3390/su14148695

Dong S, Zhang X, Wang K. Study on Fire Ventilation Control of Subway Tunnel: A Case Study for Dalian Subway. Sustainability. 2022; 14(14):8695. https://doi.org/10.3390/su14148695

Chicago/Turabian StyleDong, Sihui, Xinyu Zhang, and Kang Wang. 2022. "Study on Fire Ventilation Control of Subway Tunnel: A Case Study for Dalian Subway" Sustainability 14, no. 14: 8695. https://doi.org/10.3390/su14148695

APA StyleDong, S., Zhang, X., & Wang, K. (2022). Study on Fire Ventilation Control of Subway Tunnel: A Case Study for Dalian Subway. Sustainability, 14(14), 8695. https://doi.org/10.3390/su14148695