Driving Factors and Mechanisms of AMT Application Levels for Equipment Manufacturing Enterprises: Based on Programmatic Grounded Theory

Abstract

1. Introduction

2. Literature Review

2.1. Theoretical Analysis of the Driving Factors of Technical Capacity Related to the AMT Application Level

2.2. Theoretical Analysis of the Driving Factors of Management Capacity Related to the AMT Application Level

2.3. Theoretical Analysis of the Driving Factors of Material Incentive Related to the AMT Application Level

2.4. Theoretical Analysis of the Driving Factors of Development Incentives Related to the AMT Application Level

2.5. Theoretical Analysis of the Driving Factors of External Stakeholders Related to the AMT Application Level

2.6. Integrated Analysis of AMO Driving Factors of the AMT Application Level

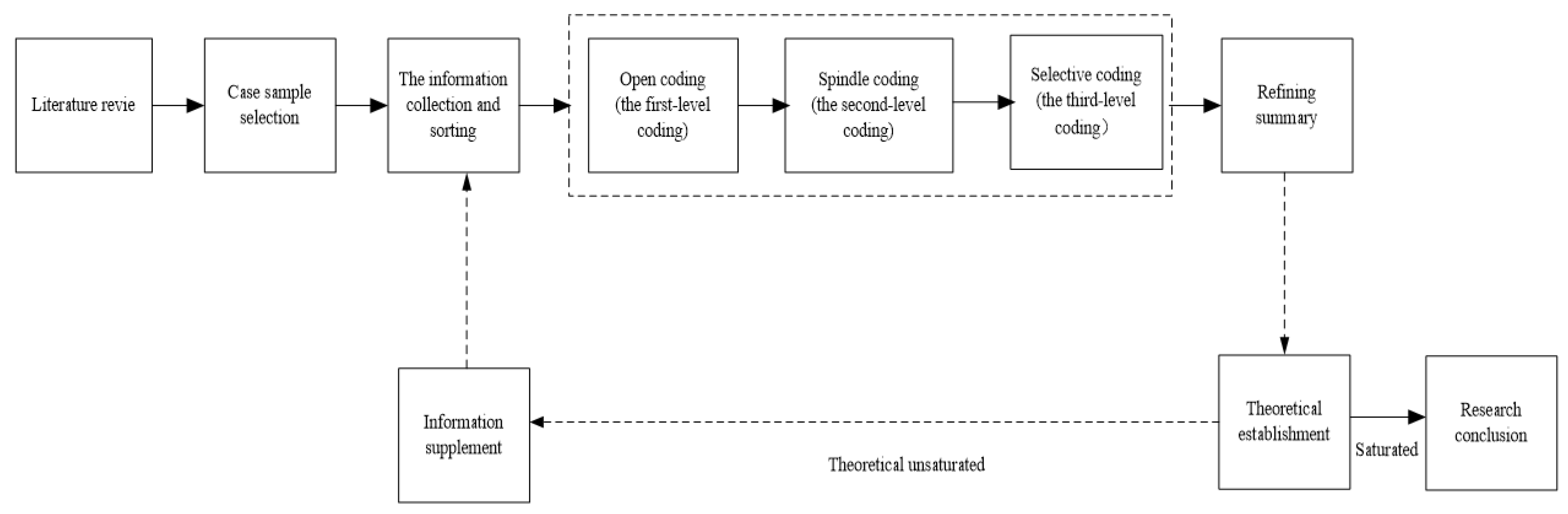

3. Research Design

3.1. Research Methods

3.2. Sampling

3.3. Data Collection

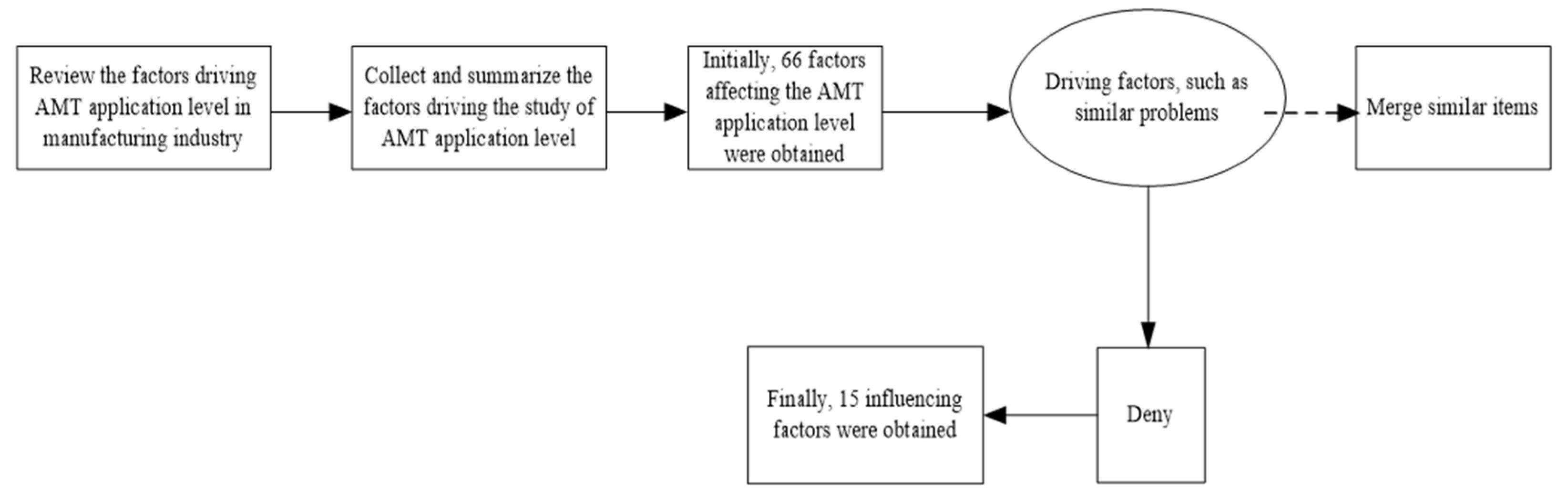

4. Data Analysis

4.1. Open Coding

4.2. Spindle Coding

4.3. Selective Coding

4.4. Theoretical Saturation Test

4.5. Identification Results of Driving Factors

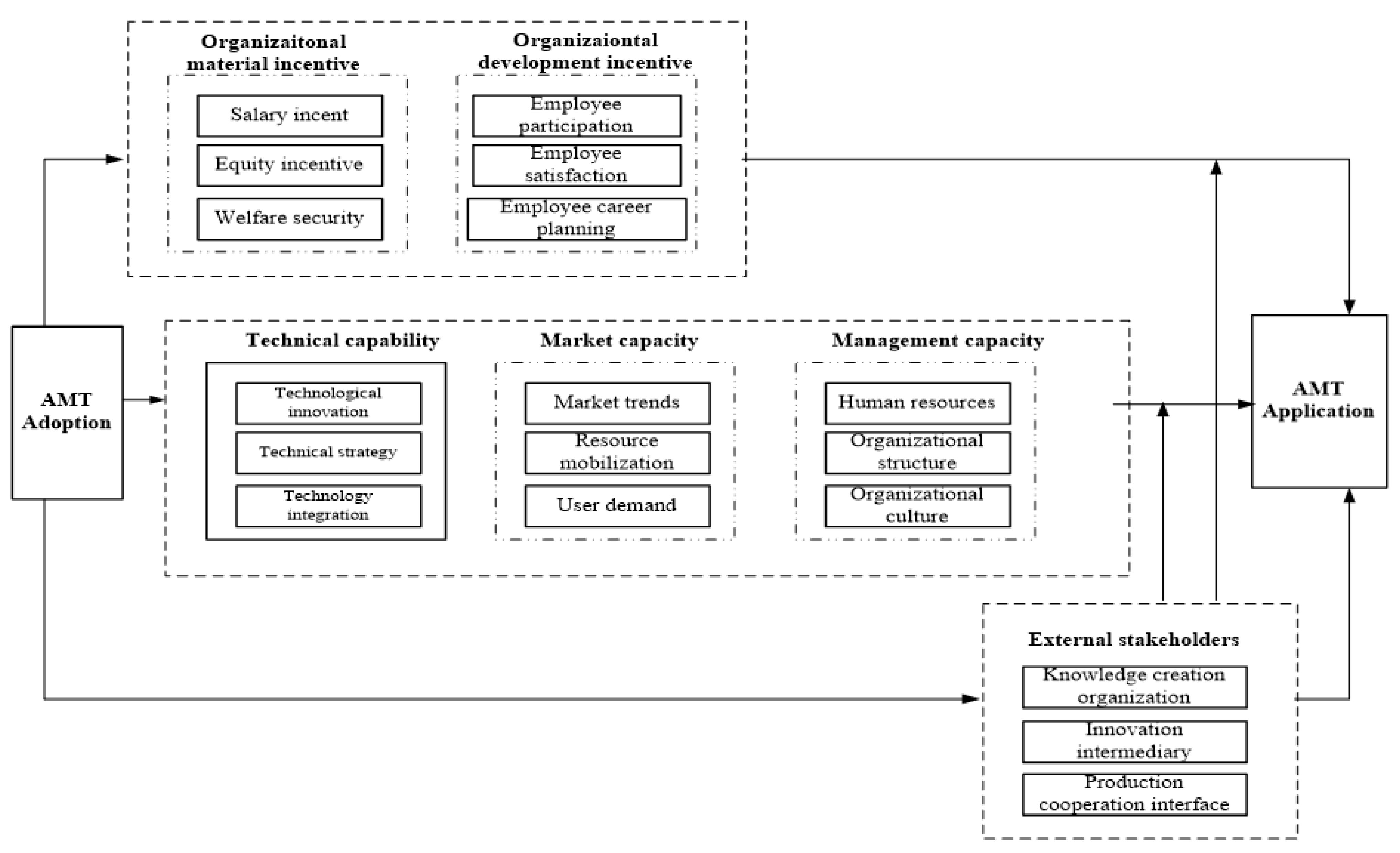

5. The Mechanism of Driving Factors

- Capability-driven mechanism of the AMT application level

- 2.

- Motivation-driven mechanism of the AMT application level

- 3.

- Opportunity-driven mechanism of the AMT application level

6. Conclusions and Contribution

6.1. Conclusions

6.2. Managerial Implications

6.3. Research Contributions

6.4. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ren, M. Why is the application of technology successful—Interpretation of an organizational legitimacy framework. Soc. Res. 2017, 3, 24. [Google Scholar]

- Venkatesh, V. Determinants of perceived ease of use: Integrating control, intrinsic motivation and emotion into the technology acceptance model. Inf. Syst. Res. 2000, 11, 342–365. [Google Scholar] [CrossRef]

- Martinsons, M.G. ERP in China: One package, two profiles. Commun. ACM 2004, 47, 65–68. [Google Scholar] [CrossRef]

- Hong, K.K.; Kim, Y.G. The critical success factors for ERP implementation: An organizational fit perspective. Inf. Manag. 2002, 40, 25–40. [Google Scholar]

- Yin, G.P.; Chen, Y. Empirical research on enterprise information technology capability and its impact on informatization success—From the perspective of RBV theory. Nankai Manag. Rev. 2009, 12, 152–160. [Google Scholar]

- Yu, N.; Shen, L.; Lewark, S. Drivers and barriers for implementing advanced manufacturing technology in China’s furniture industry: An exploratory study. For. Prod. J. 2011, 61, 83–91. [Google Scholar] [CrossRef]

- Cardoso, R.; Lima, E.; Costa, S. Identifying organizational requirements for the implementation of advanced manufacturing technologies (AMT). J. Manuf. Syst. 2012, 31, 367–378. [Google Scholar] [CrossRef]

- Mcdermott, C.M.; Stockm, G.N. Organizational culture and advanced manufacturing technology implementation. J. Oper. Manag. 1999, 17, 521–533. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Gong, Y.; Peng, M.W. Expatriate knowledge transfer, subsidiary absorptive capacity and subsidiary performance. Acad. Manag. J. 2012, 55, 927–948. [Google Scholar] [CrossRef]

- Wang, Y.G.; Ma, S.; Yang, H.E. Research on the measurement, improvement and performance impact of innovation ability in service outsourcing-is based on the perspective of knowledge transfer between both contracting and contracting. Manag. World 2015, 14, 85–98. [Google Scholar]

- Rosanh, M.Y.; Ahmad, M.; Sulaiman, S.; Mohamad, Z. Organizational adaptation for amt implementationin the smis. Int. J. Eng. Technol. 2004, 1, 131–138. [Google Scholar]

- Dangayach, G.S.; Deshmukh, S.G. Evidence of manufacturing strategies in Indian industry: A survey. Int. J. Prod. Econ. 2003, 83, 279–298. [Google Scholar] [CrossRef]

- Raymond, L.; Croteau, A.M.; Bergeron, F. The Integrative Role of IT in Product and Process Innovation: Growth and Productivity Outcomes for Manufacturing; ICEIS: Milan, Italy, 2009. [Google Scholar]

- Nielsen, Z. Sources of capabilities, integration and technology commercialization. Strateg. Manag. J. 2010, 23, 377–398. [Google Scholar]

- Kiel, D.; Arnold, C.; Voigt, K.I. The influence of the industrial internet of things on business models of established manufacturing companies-A business level of perspective. Technovation 2017, 68, 4–19. [Google Scholar] [CrossRef]

- Szalavetz, A. Industry 4.0 and capability development in manufacturing subsidiaries. Technol. Forecast. Soc. Chang. 2019, 145, 384–395. [Google Scholar] [CrossRef]

- Efstathiades, A.; Tassou, A.S.; Antoniou, A. Strategic considerations in the introduction of advanced manufacturing technologies in the Cypriot industry. Technovation 1999, 19, 105–115. [Google Scholar] [CrossRef]

- Lewis, M.W.; Boyer, K.K. Factors impacting AMT implementation: An integrative and controlled study. J. Eng. Technol. Manag. 2002, 19, 111–130. [Google Scholar] [CrossRef]

- Niaki, M.K.; Torabi, S.A.; Nonino, F. Why manufacturers adopt additive manufacturing technologies: The role of sustainability. J. Clean. Prod. 2019, 222, 381–392. [Google Scholar] [CrossRef]

- Hewitt-Dundas, N. The Adoption of advanced manufacturing technology and innovation strategy in small firms. Int. J. Innov. Technol. 2004, 1, 17–36. [Google Scholar] [CrossRef]

- Barge-Gil, A.; Jesus Nieto, M.; Santamaria, L. Hidden innovators: The role of Non-RD activities. Technol. Anal. Strateg. 2011, 23, 415–432. [Google Scholar] [CrossRef]

- Bourke, J.; Roper, S. AMT adoption and innovation: An investigation of dynamic and complementary effects. Technovation 2016, 55, 42–55. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Stornelli, A.; Ozcan, S.; Simms, C. Advanced manufacturing technology adoption and innovation: A systematic literature review on barriers, enablers, and innovation types. Res. Policy 2018, 50, 104229. [Google Scholar] [CrossRef]

- Zammuto, R.F.; O’Connor, E.J. Gaining advanced manufacturing technologies’benefits: The roles of organization design and culture. Acad. Manag. Rev. 1992, 17, 701–728. [Google Scholar] [CrossRef]

- Ranta, J.; Tchijov, I. Economics and success factors of flexible manufacturing system: The conventional explanation revisited. Int. J. Flex. Manuf. Syst. 1990, 2, 169–190. [Google Scholar] [CrossRef]

- Beatty, C.A. Implementing advanced manufacturing technologies: Rules of the road. Sloan Manag. Rev. 1992, 33, 49–56. [Google Scholar] [CrossRef]

- Snower, L.D.J. Multitask learning and the reorganization of work: From tayloristic to holistic organization. J. Labor. Econ. 2000, 18, 353–376. [Google Scholar]

- Song, J.; Dai, D.; Wang, D.; Song, Y. Research on successful implementation of advanced manufacturing technology based on human factors. Sci. Res. Manag. 2007, 28, 19–25. [Google Scholar]

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart factory implementation and process innovation: A preliminary maturity model for leveraging digitalization in manufacturing moving to smart factories presents specific challenges that can be addressed through a structured approach focused on people, processes, and technologies. Res. Technol. Manag. 2018, 61, 22–31. [Google Scholar]

- Millen, R.; Sohal, A.S. Planning processes for advanced manufacturing technology by large American manufacturers. Technovation 1998, 18, 741–750. [Google Scholar] [CrossRef]

- Teixeira, R.; Koufteros, X.; Xiaosong, D. Organizational structure, integration, and manufacturing performance: A conceptual model and propositions. J. Oper. Supply Chain Manag. 2012, 5, 69–81. [Google Scholar] [CrossRef][Green Version]

- Bates, K.A.; Amundson, S.D.; Morris, S.W.T. The crucial interrelationship between manufacturing strategy and organizational culture. Manag. Sci. 1995, 41, 1565–1580. [Google Scholar] [CrossRef]

- Ungan, M. Factors affecting the adoption of manufacturing best practices. Benchmarking Int. J. 2004, 11, 504–520. [Google Scholar] [CrossRef]

- Fu, Q.; Rahman, A.; Jiang, H.; Abbas, J.; Comite, U. Sustainable supply chain and business performance: The impact of strategy, network design, information systems, and organizational structure. Sustainability 2022, 14, 1080. [Google Scholar] [CrossRef]

- Bibby, L.; Dehe, B. Defining and assessing industry 4.0 maturity levels–case of the defence sector. Prod. Plan. Control 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Determinants of information and digital technology implementation for smart manufacturing. Int. J. Prod. Res. 2019, 58, 1–22. [Google Scholar] [CrossRef]

- Legros, P.; Newman, A.F. Contracts, ownership, and industrial organization: Past and future. J. Law Econ. 2014, 30, i82–i117. [Google Scholar] [CrossRef]

- Narain, R.; Yadav, R.C.; Sarkis, J. Investment justification of advanced manufacturing technology: A review. Int. J. Serv. Oper. Manag. 2007, 3, 41–73. [Google Scholar] [CrossRef]

- Tsai, K.H.; Yang, S.Y. The contingent value of firm innovativeness for business performance under environmental turbulence. Int. Entrep. Manag. J. 2014, 10, 343–366. [Google Scholar] [CrossRef]

- Singh, R.K.; Garg, S.K.; Deshmukh, S.G.; Kumar, M. Modelling of critical success factors for implementation of AMTs. J. Model. Manag. 2007, 2, 232–250. [Google Scholar] [CrossRef]

- Cai, S.; Lv, Z. An empirical study on the impact of R & D personnel incentive system on enterprises’ technological innovation ability—A case study of scientific and technological small and medium-sized enterprises. Ind. Technol. Econ. 2015, 34, 144–149. [Google Scholar]

- Wu, J.; Liu, B.; Zeng, Y.; Luo, H. Good for the firm, good for the society? Causal evidence of the impact of equity incentives on a firm’s green investment. Int. Rev. Econ. Financ. 2022, 77, 435–449. [Google Scholar] [CrossRef]

- Campbell, S.C. Psychological climate: Relevance for sales managers and impact on consequent job satisfaction. J. Mark. Theory Pract. 1998, 6, 27–37. [Google Scholar]

- Waldeck, N.E.; Leffakis, Z.M. HR perceptions and the provision of workforce training in an AMT environment: An empirical study. Omega 2007, 35, 161–172. [Google Scholar] [CrossRef]

- Cano, C.P.; Cano, P.Q. Human resources management and its impact on innovatio n performance in companies. Int. J. Technol. Manag. 2006, 11–27. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The machine that changed the world. Bus. Horiz. 1992, 35, 81–82. [Google Scholar]

- Gunasekaran, A.; Marri, H.B.; Mcgaughey, R.; Grieve, R.J. Implications of organization and human behaviour on the implementation of CIM in SMEs: An empirical analysis. Int. J. Comput. Integr. Manuf. 2001, 14, 175–185. [Google Scholar] [CrossRef]

- James, W.M. Best HR practices for today’s innovation management. Res. Technol. Manag. 2002, 45, 57–60. [Google Scholar] [CrossRef]

- Gupta, A.K.; Singhal, A. Managing human resources for innovation and creativity. Res.Technol. Manag. 1993, 36, 41–48. [Google Scholar] [CrossRef]

- Lay, G. Government support of computer integrated manufacturing in Germany: First results of an impact analysis. Technovation 1993, 13, 283–297. [Google Scholar] [CrossRef]

- Singh, H.; Khamba, J.S. An empirical examination for enhancing the utilization level of advanced manufacturing technologies in India. J. Adv. Manag. Res. 2010, 7, 112–126. [Google Scholar] [CrossRef]

- Bessant, J.; Rush, H. Government support of manufacturing innovations: Two country-level case studies. IEEE Trans. Eng. Manag. 1993, 40, 79–91. [Google Scholar] [CrossRef]

- Ancarani, A.; Di Mauro, C.; Mascali, F. Backshoring strategy and the adoption of Industry 4.0: Evidence from Europe. J. World Bus. 2019, 54, 360–371. [Google Scholar] [CrossRef]

- Dachs, B.; Kinkel, S.; Jäger, A. Bringing it all back home? backshoring of manufacturing activities and the adoption of Industry 4.0 technologies. J. World Bus. 2019, 54, 101017. [Google Scholar] [CrossRef]

- Samford, S.; Warrian, P.; Goracinova, E. Public and private goods in the development of additive manufacturing capacity. Bus. Politics 2017, 19, 482–509. [Google Scholar] [CrossRef]

- Yeh, C.C.; Chen, Y.F. Critical success factors for adoption of 3D printing. Technol. Forecast. Soc. Change 2018, 132, 209–216. [Google Scholar] [CrossRef]

- Glaser, B.G.; Strauss, A.L. The Discovery of Grounded Theory: Strategies for Qualitative Research; Aldine De Gruyter: New York, NY, USA, 1967. [Google Scholar]

- Denzin, Y.; Lincoln, S. The Sage Handbook of Qualitative Research; Sage Publications: Thousand Oaks, CA, USA, 2011. [Google Scholar]

- Denzin, Y.; Lincoln, S. Handbook of Qualitative Research; Sage: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- Suddaby, R. From the editors: What grounded theory is not. Acad. Manag. J. 2006, 49, 633–642. [Google Scholar] [CrossRef]

- Strauss, A.; Corbin, J.M. Basics of Qualitative Research: Grounded Theory Procedures and Techniques; Sage Publications: Thousand Oaks, CA, USA, 1990. [Google Scholar]

- Charmaz, K. Constructing Grounded Theory; Sage Publications: Thousand Oaks, CA, USA, 2006. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods, 5th ed.; Blackwell Science Ltd.: Oxfod, UK, 2013. [Google Scholar]

- Blumberg, M.; Pringle, C.D. The missing opportunity in organizational research: Some implications for a theory of work performance. Acad. Manag. Rev. 1982, 7, 560–569. [Google Scholar] [CrossRef]

- Moller, A.C.; Deci, R.E.L. Self-determination theory and public policy: Improving the quality of consumer decisions without using coercion. J. Public Policy Mark. 2006, 25, 104–116. [Google Scholar] [CrossRef]

| Driving Factor | Driving Mechanism | Principal Researcher |

|---|---|---|

| Technology integration | AMT is integrated between marketing, engineering, production, and after-sales maintenance by computer. | Rosanh et al. (2004) [11]; Nielsen (2010) [14]; Kiel et al.(2017) [15]; Szalavetz (2019) [16] |

| Technical strategy | Through the implementation of AMT, enterprises have attained competitive priority in manufacturing strategies, such as cost, quality, flexibility, and reliability/delivery. | Dangayach and Deshmukh (2003) [12]; Efstathiades et al. (1999) [17]; Lewis and Boyer (2002) [18]; Niaki et al. (2019) [19] |

| Technological innovation | By implementing AMT in enterprises, product innovation, process innovation, and market innovation are promoted. | Hewitt-Dundas (2004) [20]; Raymond et al. (2009) [13]; Barge-Gil and Jesus Nieto (2011) [21]; Bourke and Roper (2016) [22]; Müller et al. (2018) [23]; Stornelli (2021) [24] |

| Driving Factor | Driving Mechanism | Principal Researcher |

|---|---|---|

| Human resources | The education and training of workers and team cooperation are key factors that affect the AMT application level. | Hewit-Dundas (2004) [20]; Ranta and Tchijov (1990) [26]; Beatty (1992) [27]; Snower and Lindbeck (2000) [28]; Song et al. (2007) [29]; Sjödin et al. (2018) [30] |

| Organizational structure | The simplification of the organizational level and the organic structure are conducive to the successful implementation of AMT. | Millen and Sohal (1998) [31]; Cardoso et al. (2012) [7]; Teixeira et al. [32] |

| Organizational culture | The successful implementation of AMT tends to adopt a flexible-oriented culture in a more favorable environment to simplify the implementation. | Bates et al. (1995) [33]; Ungan (2004) [34]; Zammuto and O’Connor (1992) [25]; Fu et al. [35]; Bibby and Dehe (2018) [36]; Ghobakhloo (2019) [37] |

| Driving Factor | Driving Mechanism | Principal Researcher |

|---|---|---|

| Salary incentive | Attract the maximum potential of employees through the difference in personal salary and effectively use new technology. | Tsai and Yang (2014) [40]; Singh et al. (2007) [41] |

| Equity incentive | By providing equity incentives to enterprise management members and core technology employees, the enterprise operating efficiency and technological innovation performance are promoted. | Legros and Newman (2015) [38]; Cai (2015) [42]; Wu et al. (2022) [43] |

| Welfare guarantee | Providing medical care and vacations plays a vital role in ensuring that employees are in good condition. | Swift and Campbell (1998) [44]; Narain et al. (2007) [39] |

| Driving Factor | Driving Mechanism | Principal Researcher |

|---|---|---|

| Employee participation | Giving employees extra autonomy and encouraging them to participate in decision making are conducive to the successful implementation of AMT. | Waldeck (2007) [45]; Song et al. (2007) [29]; Womack (1991) [47] |

| Employee satisfaction | Work safety, comfortable working environment, and happy working relationship in enterprises are conducive to promoting AMT application. | Yu and Shen (2011) [6]; Gunasekaran et al. (2001) [48] |

| Employee career development | The role of human resource planning, goal recognition, and career management in technological change and application. | James (2002) [49]; Gupta and Singhal (1993) [50]; Cano and Cano (2006) [46] |

| Driving Factor | Driving Mechanism | Principal Researcher |

|---|---|---|

| External organization interaction | Enterprises promote the AMT application through government subsidies, suppliers, and industrial organizations. | Gunter and Lay (1993) [51]; Singh (2010) [52]; Bessant and Rush (1993) [53]; Ancarani et al. (2019) [54]; Dachs et al. (2019) [55]; Samford et al. (2017) [56]; Yeh and Chen (2018) [57] |

| Driving Dimension | Driving Factor | Mechanism of Action | Action Result |

|---|---|---|---|

| Technical capability | Technology integration | Pursuing the operational performance and innovative output of the enterprise’s production and innovation links. | Operational priorities, new technologies and other innovations. |

| Technical strategy | |||

| Technological innovation | |||

| Management capability | Human resources | Human resource recruitment, training, team training, organizational level adjustment, and transformation to organic culture promote the AMT application. | Improvement of enterprise management capacity |

| Organizational structure | |||

| Organizational culture | |||

| Material incentive | Salary incentive | Through the material incentive, senior management personnel, core technical personnel, and production site workers are encouraged to actively learn and actively respond to the transformation of the production mode brought by the new technology. | Overall improvement of employees’ technical level |

| Equity incentive | |||

| Welfare guarantee | |||

| Development incentive | Employee participation | Encourage employees to actively respond to the changes in production methods brought about by new technologies by giving them authorized responsibilities, a safer and more comfortable working environment, and clear target planning. | Overall improvement of employees’ technical level |

| Employee satisfaction | |||

| Employee career development | |||

| External stakeholders | External organization interaction | Promote the AMT application from the external environment, such as government, suppliers, and industrial institutions. | Actively affect the external environment of enterprises. |

| Serial Number | Enterprise Name | Industry | Case Use |

|---|---|---|---|

| 1 | Tianjin Boyiqidong Co., Ltd. (Tianjin, China) | Instrument and cultural office supplies machinery manufacturing industry | Modeling |

| 2 | Chenxing (Tianjin) Automation Equipment Co., Ltd. (Tianjin, China) | Electrical machinery and equipment manufacturing industry | Modeling |

| 3 | Tianjin Automobile Mould Co., Ltd. (Tianjin, China) | Transportation equipment manufacturing industry | Modeling |

| 4 | Tianjin Bonuo Zhichuang Robot Technology Co., Ltd. (Tianjin, China) | Electronics and Communication equipment manufacturing industry | Modeling |

| 5 | Tianjin Saixiang Technology Co., Ltd. (Tianjin, China) | Special equipment manufacturing industry | Modeling |

| 6 | Tianjin Aerospace Changzheng Rocket Manufacturing Co., Ltd. (Tianjin, China) | Electronic and communication equipment manufacturing industry | Modeling |

| 7 | Tianjin Xiaoquan Precision Metal Products Co., Ltd. (Tianjin, China) | Metal products manufacturing industry | Modeling |

| 8 | Tianjin Jingcheng Machine Tool Co., Ltd. (Tianjin, China) | General machinery manufacturing industry | Modeling |

| 9 | Danfoss (Tianjin) Co., Ltd. (Tianjin, China) | Electrical and equipment manufacturing industry | Modeling |

| 10 | Tianjin Huajian Tianheng Transmission Co., Ltd. (Tianjin, China) | General machinery manufacturing industry | Inspection |

| 11 | Tianjin Lishen battery Co., Ltd. (Tianjin, China) | Electrical machinery and equipment manufacturing industry | Inspection |

| 12 | Hitachi Elevator (Tianjin) Co., Ltd. (Tianjin, China) | Special equipment manufacturing industry | Inspection |

| Original Statement | Conceptualize | Categorization |

|---|---|---|

| Company developed YH606 CNC arc gear cone gear milling machine, YH6250A CNC arc gear cone gear pulling machine, JCC32M CNC cyclone gear milling machine, YHL9380 type CNC gear-inverted machine; these new products reflect the mainstream demand of the market as the entry point and innovation point of product upgrading, to fulfill the expectations, concerns, and aspirations of high-end machine tool users to the greatest extent | User product requirements | User |

| We have enhanced the application of the device’s perception system in the customer’s site through the Internet of Things, and through the big data system, we can understand the user’s operation habits, detect the running state of the device, monitor the data of the device parts, and realize the digital remote operation and maintenance service, which can markedly shorten the fault handling time and improve the fault handling efficiency. It decreases the operation and maintenance cost of our company and reduces the working intensity of employees, thereby attaining a win–win situation for both economy and personnel. | Customer’s after-sales service requirements | |

| The company has 10 offices across the country, and market coordination requires CRM (customer relationship management) to improve business processes. | Improve external business processes | Resource mobilization |

| We use ERP (enterprise resource planning) to control the production process, realize the management of the whole business process from order, procurement, production, assembly, factory testing, delivery, and final customer service, and optimize these links by using ERP to create value for enterprises. | Improve the internal management process | |

| The company has completed the transformation of intelligent manufacturing, integrating robot, big data and the Internet of Things with traditional tire equipment, deeply applying AGV, automated logistics technology and equipment in tire manufacturing enterprises, building an intelligent tire factory, and successfully developing the company’s cloud service platform by using big data and Internet of Things to provide services for tire customer equipment performance improvement and trouble-free operation. | Leads the market | Market trend |

| Astro Boy Robot focuses on industry benchmark customers. The goal of our product development is to develop in the direction of integration automation, miniaturization, integration, and interface to make our products more intelligent. | Industry benchmark |

| Main Category | Corresponding Category | Connotation of Category |

|---|---|---|

| Market capability | The demand of users | Drive the AMT application level by meeting the needs of users’ products and after-sales service. |

| Resource mobilization | Improve the external business process and internal management process to drive the AMT application level. | |

| Market trend | To attain the goal of leading the market and drive the AMT application level by setting an industry benchmark. | |

| Technical capability | Technology integration | Attain the purpose of equipment compatibility and flexible production capacity to drive the AMT application level. |

| Technical strategy | Enterprise performance objectives, such as reducing cost, delivery cycle, and improving output, quality, and productivity, are attained through the AMT application. | |

| Technological innovation | The whole process innovation, such as process, product, organization, and marketing, will drive the AMT application level. | |

| Management capability | Human resources | Strengthen internal training, external recruitment, and teamwork to drive the AMT application level. |

| Organizational structure | The purpose of reducing management levels and breaking the boundaries of functional departments drives the AMT application level. | |

| Organizational culture | Cultural heterogeneity, such as flexibility and control orientation, affects the AMT application level. | |

| Material incentive | Salary incentive | Promote the AMT application level through salary structure, salary level, and salary benefits. |

| Equity incentive | Drive the AMT application level through a partner system and employee incentive mechanism. | |

| Welfare guarantee | Driving the AMT application level through a vacation system and social insurance. | |

| Development incentive | Employee participation | Strengthen participation incentive, authorization incentive, honor incentive, and innovation incentive to drive the AMT application level. |

| Employee satisfaction | The implementation effect of AMT is driven by improving job enrichment and fairness of work. | |

| Employee career development | Drive the AMT application level through a promotion mechanism, post transfer mechanism. | |

| External stakeholders | Knowledge-creation organization | The purpose of promoting the interaction between universities and research institutions drives the effect of the AMT application. |

| Innovation intermediary | To drive the AMT application effect, promote the interaction among trade associations, financial institutions, and government departments. | |

| Production cooperation interface | Promoting the interaction between suppliers and noncompetitors in the industry drives the AMT application effect. |

| Typical Relational Structure | Connotation of Relationship Structure |

|---|---|

| Market capability → AMT application level | Market factors, such as user demand, resource mobilization, and market trend are the direct driving factors, which directly drive the improvement of the AMT application level. |

| Technical capability → AMT application level | The pursuit of technology integration, technology strategy, and technological innovation are the direct driving factors, which directly drive the improvement of the AMT application level. |

| Management capacity → AMT application level | Human resources, organizational structure, and organizational culture are the direct driving factors, which directly drive the improvement of the AMT application level. |

| Material incentive → AMT application level | Strengthening equity incentives and welfare guarantees are the direct driving factors, which directly drive the improvement of the AMT application level. |

| Development incentive → AMT application level | Employee participation, employee satisfaction, and employee career development are indirect factors, which indirectly drive the improvement of the AMT application level. |

| External stakeholders → AMT application level | The external stakeholders, such as knowledge creation institutions, innovation intermediaries, and production cooperation interfaces, are the external situational conditions for organizing the AMT implementation, which affect the AMT application level. |

| Enterprise capability → AMT application level ↑ External stakeholders | External stakeholders play a regulatory role in the relationship between technical, market, management capabilities, and AMT application level. |

| Organization incentivies → AMT application level ↑ External stakeholders | External stakeholders play a regulatory role in the relationship between organizational material incentive, development incentive, and AMT application level. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Zhang, L.; Guo, J. Driving Factors and Mechanisms of AMT Application Levels for Equipment Manufacturing Enterprises: Based on Programmatic Grounded Theory. Sustainability 2022, 14, 8415. https://doi.org/10.3390/su14148415

Wang G, Zhang L, Guo J. Driving Factors and Mechanisms of AMT Application Levels for Equipment Manufacturing Enterprises: Based on Programmatic Grounded Theory. Sustainability. 2022; 14(14):8415. https://doi.org/10.3390/su14148415

Chicago/Turabian StyleWang, Guilian, Liyan Zhang, and Jing Guo. 2022. "Driving Factors and Mechanisms of AMT Application Levels for Equipment Manufacturing Enterprises: Based on Programmatic Grounded Theory" Sustainability 14, no. 14: 8415. https://doi.org/10.3390/su14148415

APA StyleWang, G., Zhang, L., & Guo, J. (2022). Driving Factors and Mechanisms of AMT Application Levels for Equipment Manufacturing Enterprises: Based on Programmatic Grounded Theory. Sustainability, 14(14), 8415. https://doi.org/10.3390/su14148415