Investigation of the Impact Resistance Behavior of Customized Hair Clipper Comb Fabricated by Fused Deposition Modeling

Abstract

1. Introduction

2. Materials and Methods

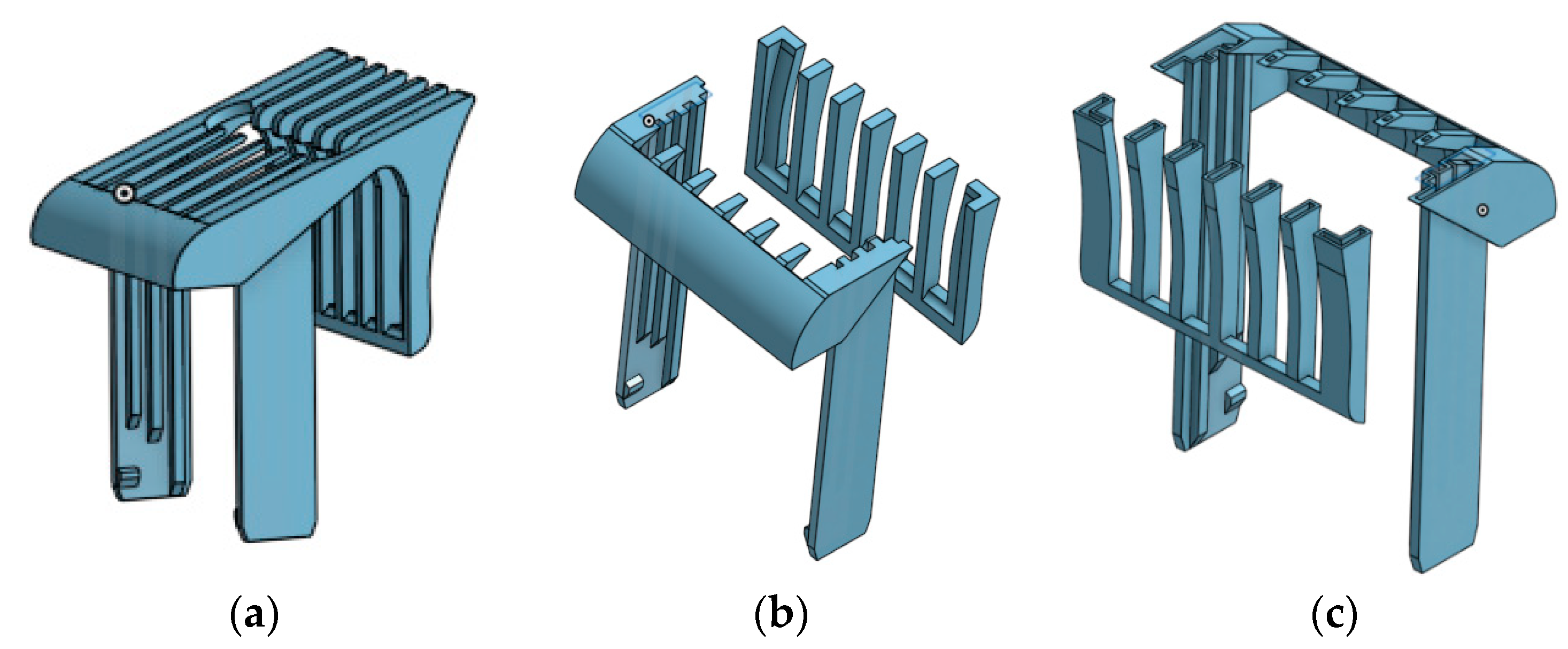

2.1. 3D Model

2.2. Finite Element Analysis

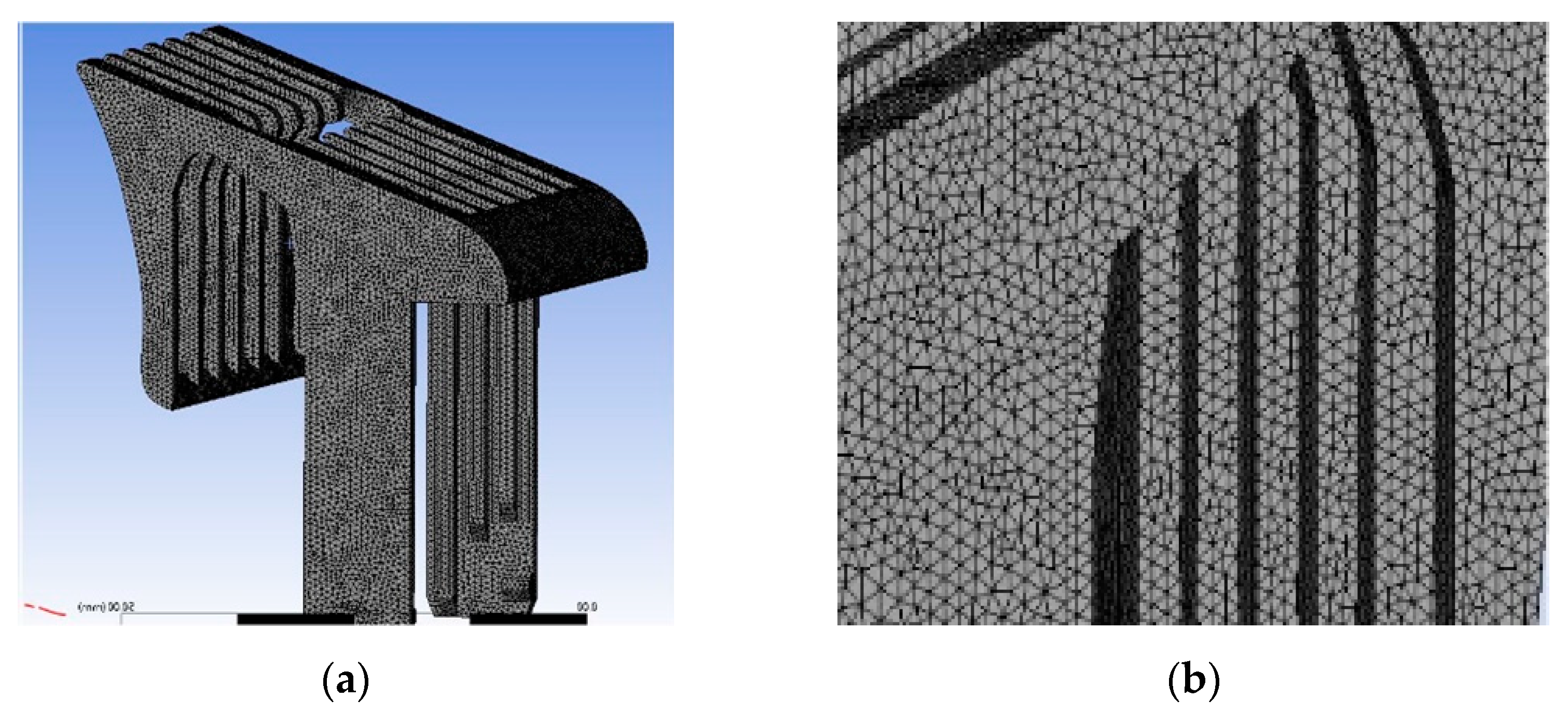

2.3. Meshing

2.4. Material Selection

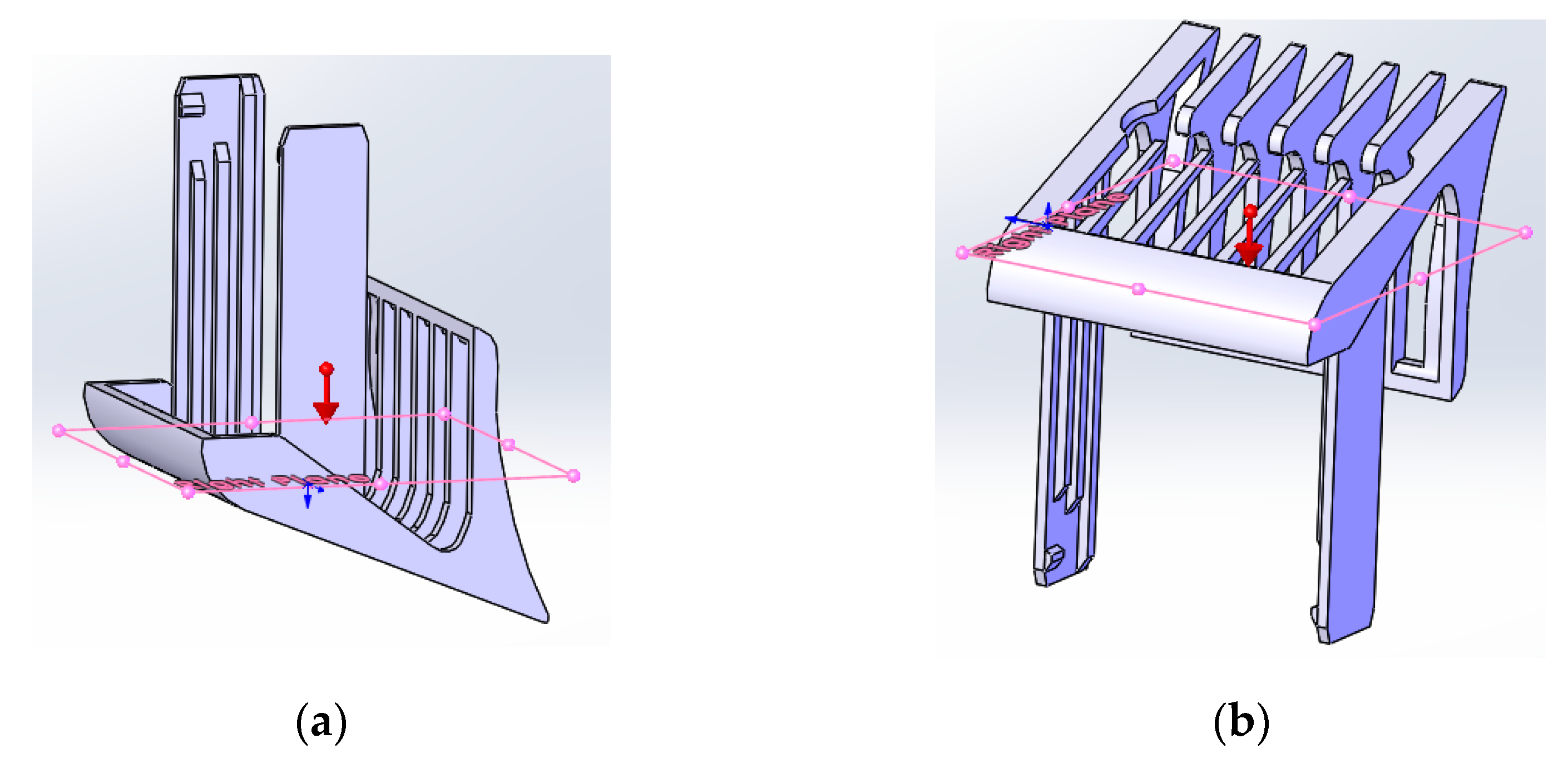

2.5. Analysis Setup

2.6. Fused Deposition Modeling

2.7. Scaning Electron Microscopy

3. Results and Discussion

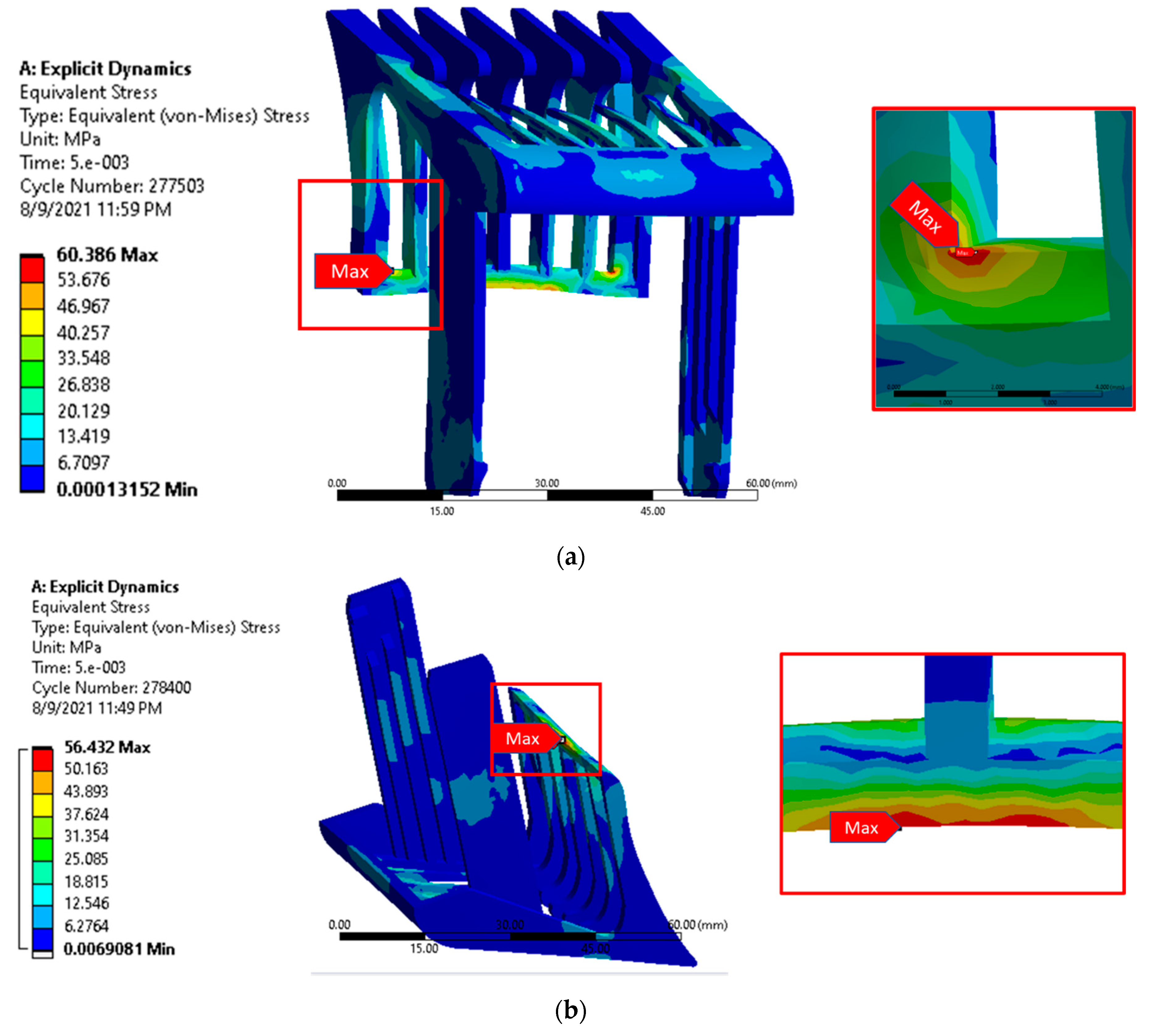

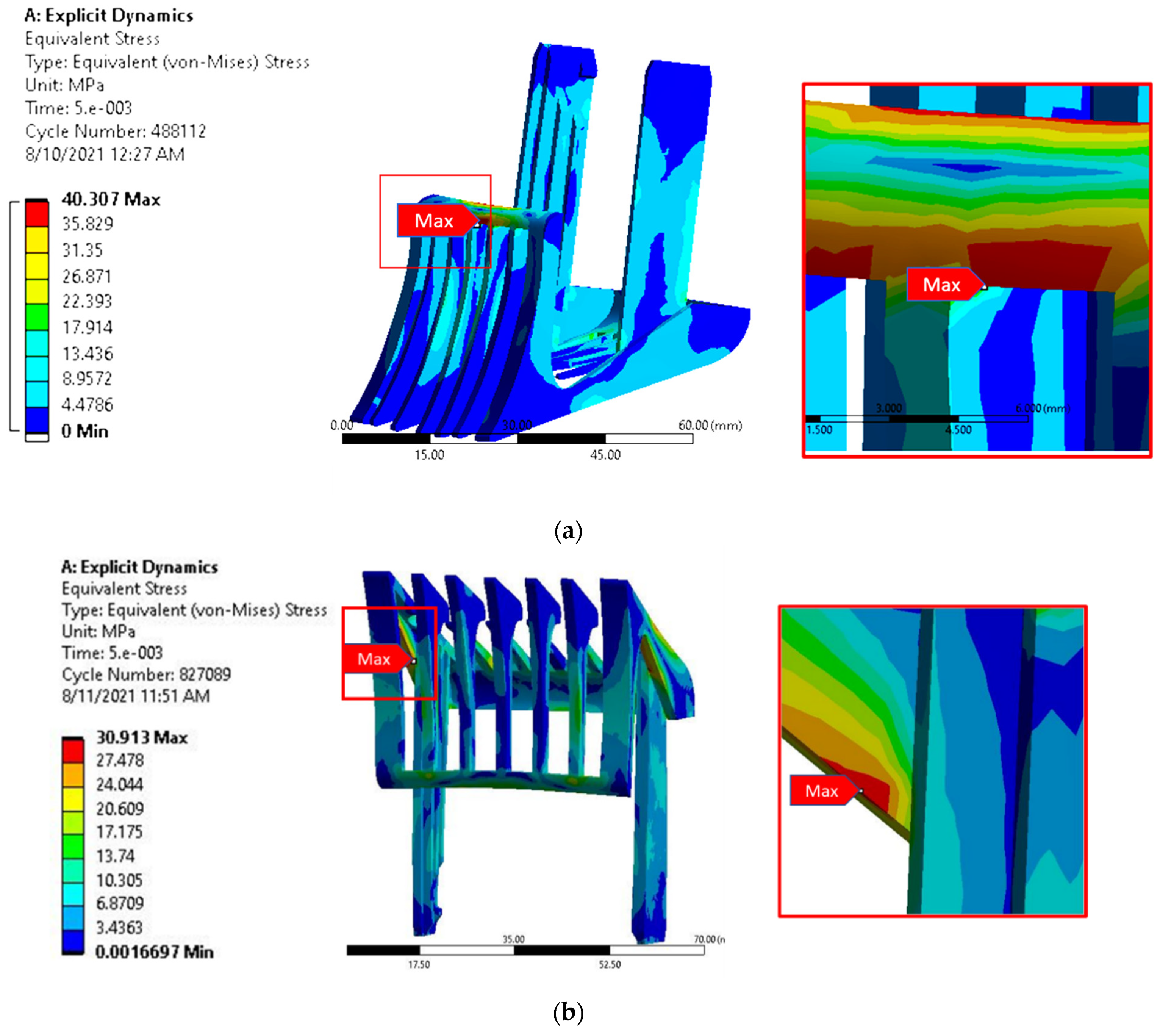

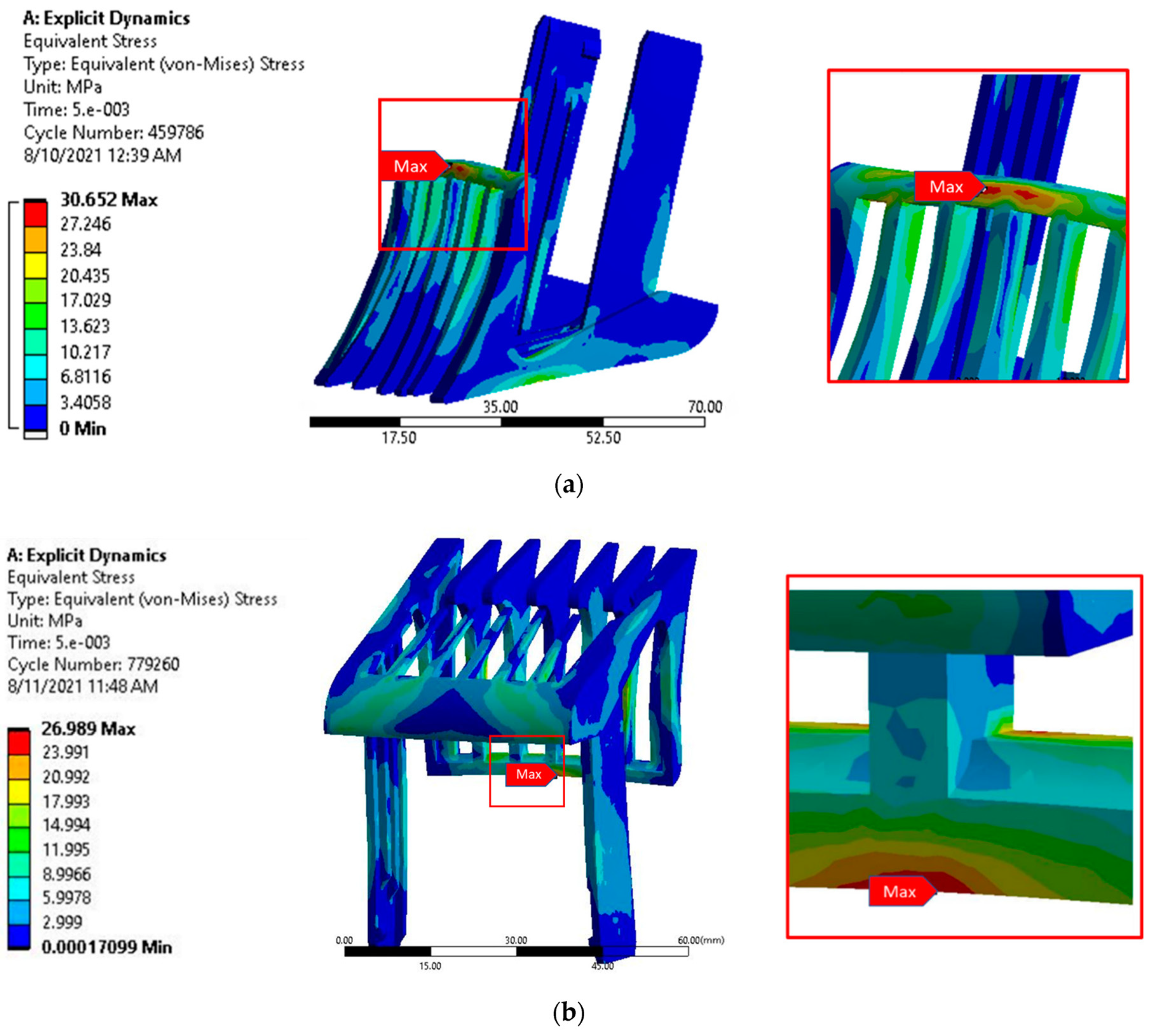

3.1. Drop Test Analysis of the PLA Model

3.2. Drop Test Analysis of the ABS Model

3.3. Drop Test of PLA & ABS Fused Deposition Models

3.4. Scanning Electron Microscopy

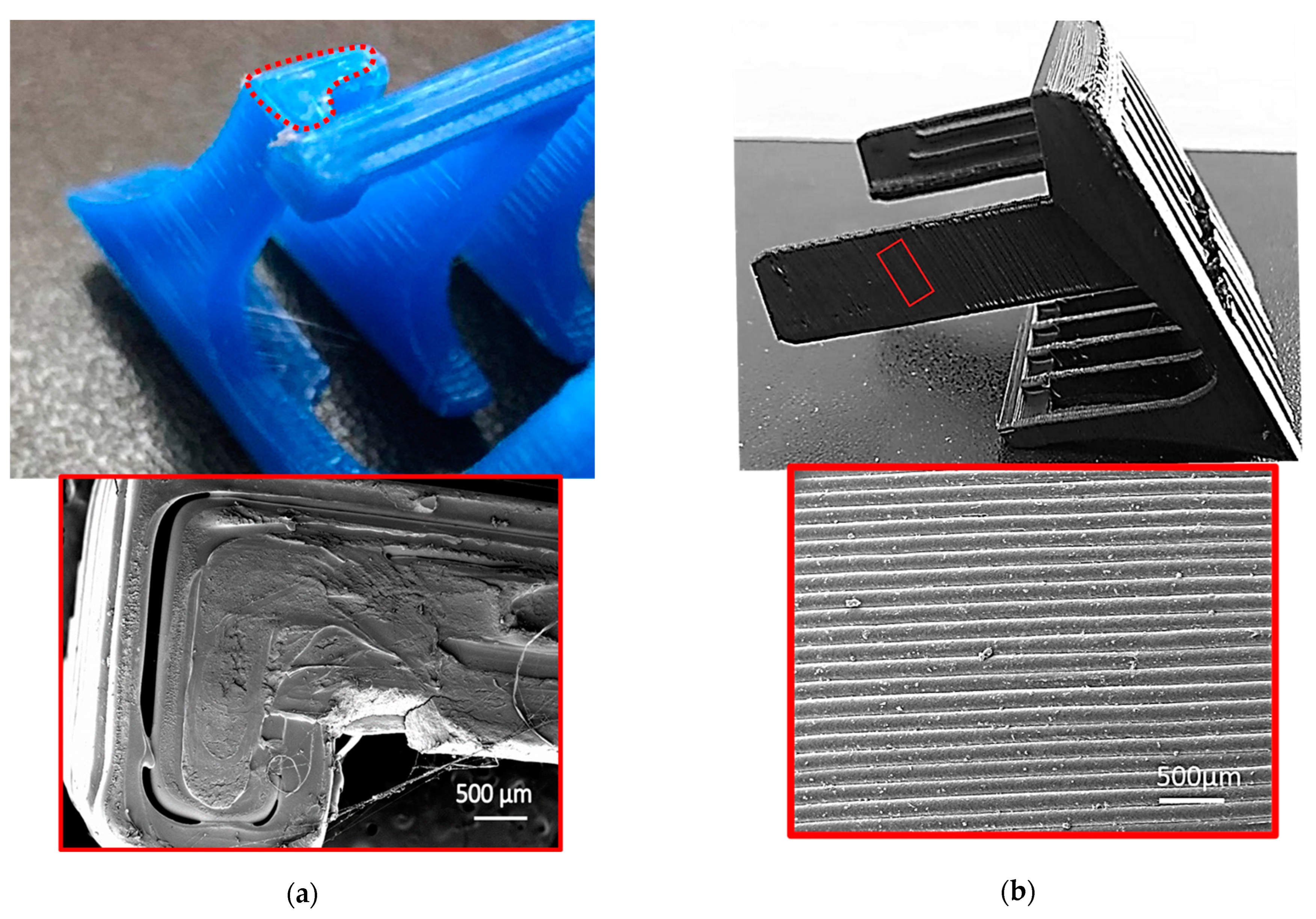

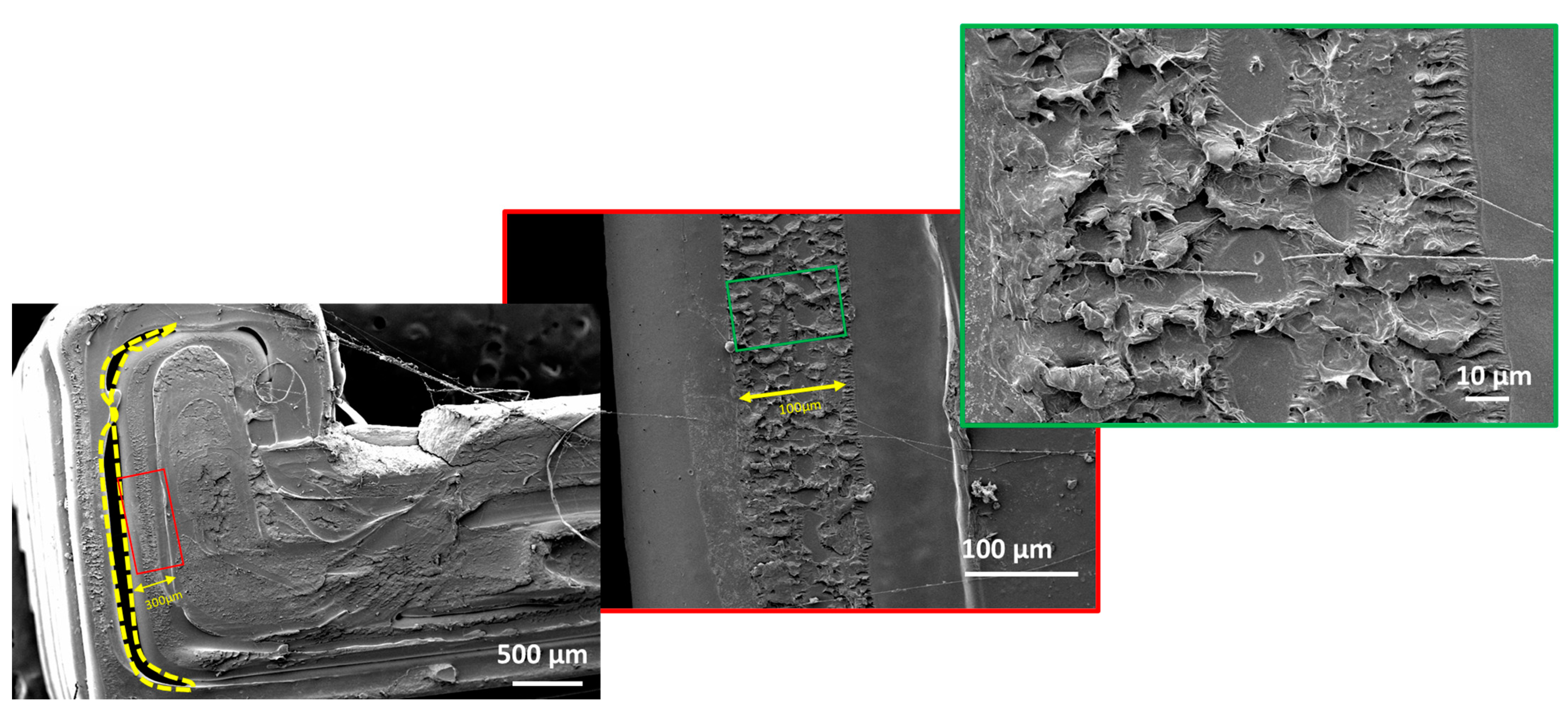

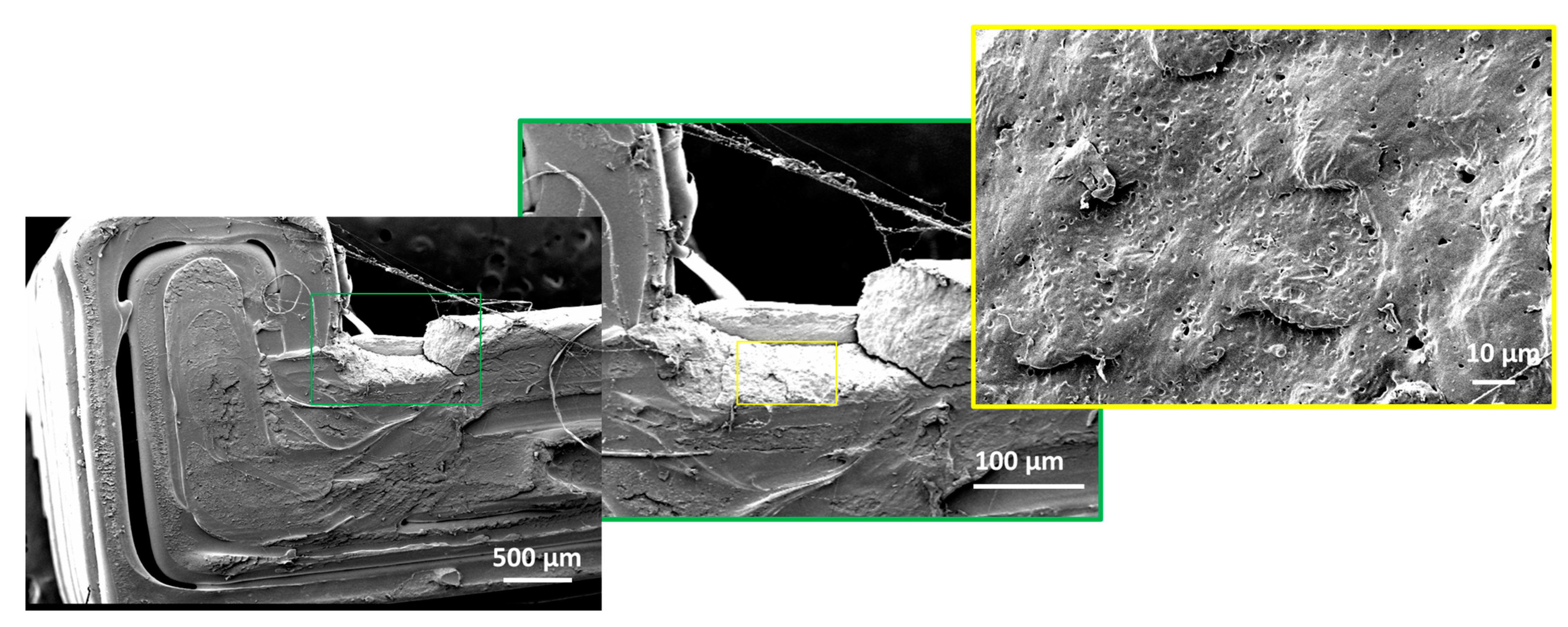

3.4.1. SEM of PLA

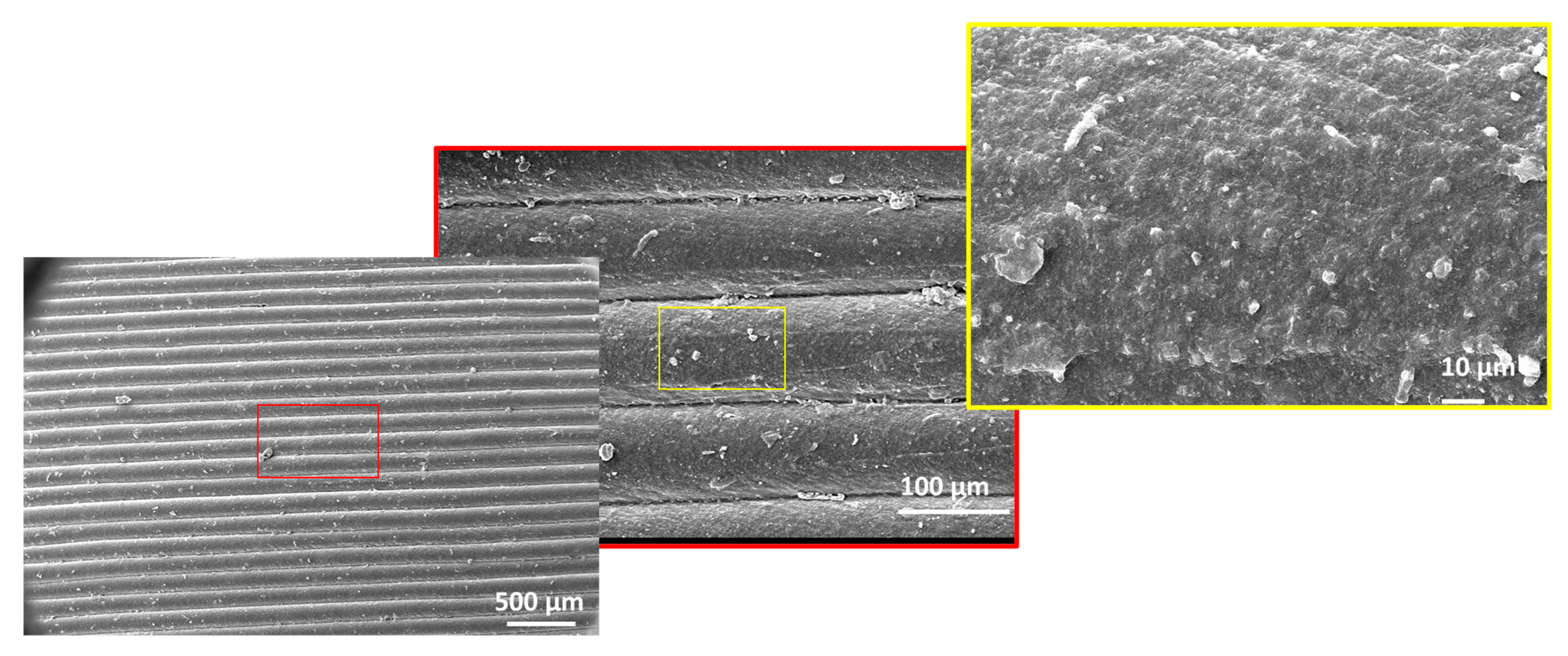

3.4.2. SEM of as Printed ABS

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef]

- Pérez, M.; Carou, D.; Rubio, E.M.; Teti, R. Current advances in additive manufacturing. Procedia CIRP 2020, 88, 439–444. [Google Scholar] [CrossRef]

- Hossain, M.A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A review of 3D printing in construction and its impact on the labor market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- Le Duigou, A.; Correa, D.; Ueda, M.; Matsuzaki, R.; Castro, M. A review of 3D and 4D printing of natural fibre biocomposites. Mater. Des. 2020, 194, 108911. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Safai, L.; Cuellar, J.S.; Smit, G.; Zadpoor, A.A. A review of the fatigue behavior of 3D printed polymers. Addit. Manuf. 2019, 28, 87–97. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef]

- Farbman, D.; McCoy, C. Materials testing of 3D printed ABS and PLA samples to guide mechanical design. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016; Volume 2, pp. 1–12. [Google Scholar] [CrossRef]

- Chevrychkina, A.A.; Volkov, G.A.; Estifeev, A.D. An experimental investigation of the strength characteristics of ABS plastic under dynamic loads. Procedia Struct. Integr. 2017, 6, 283–285. [Google Scholar] [CrossRef]

- Raney, K.; Lani, E.; Kalla, D.K. Experimental characterization of the tensile strength of ABS parts manufactured by fused deposition modeling process. Mater. Today Proc. 2017, 4, 7956–7961. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. CAD Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann.-Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Jiang, J.; Su, L.; Zhang, K.; Wu, G. Rubber-toughened PLA blends with low thermal expansion. J. Appl. Polym. Sci. 2013, 128, 3993–4000. [Google Scholar] [CrossRef]

- Novakova-Marcincinova, L.; Novak-Marcincin, J.; Barna, J.; Torok, J. Special materials used in FDM rapid prototyping technology application. In Proceedings of the 2012 IEEE 16th International Conference on Intelligent Engineering Systems (INES), Lisbon, Portugal, 13–15 June 2012; p. 578. [Google Scholar]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Wu, N.; Zhang, H. Mechanical properties and phase morphology of super-tough PLA/PBAT/EMA-GMA multicomponent blends. Mater. Lett. 2017, 192, 17–20. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Maurya, N.K.; Rastogi, V.; Singh, P. Experimental and computational investigation on mechanical properties of reinforced additive manufactured component. Evergreen 2019, 6, 207–214. [Google Scholar] [CrossRef]

- Majid, F.; Zekeriti, N.; Rhanim, R.; Lahlou, M.; Rhanim, H.; Mrani, B. Mechanical behavior and crack propagation of ABS 3D printed specimens. Procedia Struct. Integr. 2020, 28, 1719–1726. [Google Scholar] [CrossRef]

- Basurto-Vázquez, O.; Sánchez-Rodríguez, E.P.; McShane, G.J.; Medina, D.I. Load distribution on pet-g 3d prints of honeycomb cellular structures under compression load. Polymers 2021, 13, 1983. [Google Scholar] [CrossRef]

- Wang, W.; Wang, T.Y.; Yang, Z.; Liu, L.; Tong, X.; Tong, W.; Deng, J.; Chen, F.; Liu, X. Cost-effective printing of 3D objects with skin-frame structures. ACM Trans. Graph. 2013, 32, 1–10. [Google Scholar] [CrossRef]

- Lu, L.; Chen, B.; Sharf, A.; Zhao, H.; Wei, Y.; Fan, Q.; Chen, X.; Savoye, Y.; Tu, C.; Cohen-Or, D. Build-to-last. ACM Trans. Graph. 2014, 33, 1–10. [Google Scholar] [CrossRef]

- Feng, J.; Fu, J.; Lin, Z.; Shang, C.; Li, B. A review of the design methods of complex topology structures for 3D printing. Vis. Comput. Ind. Biomed. Art 2018, 1, 1–16. [Google Scholar] [CrossRef]

- MedeiroseSá, A.; Mello, V.M.; Rodriguez Echavarria, K.; Covill, D. Adaptive voids: Primal and dual adaptive cellular structures for additive manufacturing. Vis. Comput. 2015, 31, 799–808. [Google Scholar] [CrossRef]

- Yasin, S.B.M.; Aziz, K.N.A.; Bakar, I.A.A.; Hayeemasae, N.; Asiah, S.N. Durability of helmet material under longitudinal and lateral drop impact. AIP Conf. Proc. 2018, 2031, 020035. [Google Scholar] [CrossRef]

- Gandhi, V.C.S.; Kumaravelan, R.; Venkatesan, M. Performance Analysis of Motor Cycle Helmet under Static and Dynamic Loading. Mech. Mech. Eng. 2014, 18, 85–96. [Google Scholar]

- Yeh, M.K.; Huang, T.H. Drop test and finite element analysis of test board. Procedia Eng. 2014, 79, 238–243. [Google Scholar] [CrossRef][Green Version]

- Munoz, G.A. Lecture 7: Mesh Quality & Advanced Topics; ANSYS Inc.: Canonsburg, PA, USA, 2015; 14p. [Google Scholar]

- Gok, K.; Inal, S.; Gok, A.; Gulbandilar, E. Comparison of effects of different screw materials in the triangle fixation of femoral neck fractures. J. Mater. Sci. Mater. Med. 2017, 28, 81. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Galeja, M.; Hejna, A.; Kosmela, P.; Kulawik, A. Static and dynamic mechanical properties of 3D printed ABS as a function of raster angle. Materials 2020, 13, 297. [Google Scholar] [CrossRef]

- Matweb MatWeb, Your Source for Materials Information. MatWeb 2015, 1–2.

- Naveed, N. Investigating the material properties and microstructural changes of fused filament fabricated PLA and tough-PLA parts. Polymers 2021, 13, 1487. [Google Scholar] [CrossRef]

- Mazumder, M.; Ahmed, R.; Wajahat Ali, A.; Lee, S.J. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 186, 313–329. [Google Scholar] [CrossRef]

| Model | Solid Body | Shell Body |

|---|---|---|

| Mesh quality | High | High |

| Element size | 0.62 mm | 0.62 mm |

| Total elements | 350,734 | 192,986 |

| Total nodes | 77,024 | 63,122 |

| Material | PLA | ABS | ||

| Model | Solid Body | Shell Body | Solid Body | Shell Body |

| Mass (g) | 11.71 g | 8.40 g | 9.74 g | 6.99 g |

| Mass density () | 1250 | 1040 | ||

| Tensile Strength (MPa) | 54.1 | 41.4 | ||

| Ultimate Tensile Strength (MPa) | 59.2 | 44.3 | ||

| Young’s Modulus (MPa) | 3450 | 2390 | ||

| Poisson’s ratio | 0.39 | 0.399 | ||

| Fixed FDM Parameters | ||

|---|---|---|

| 3D Printer | Creality Ender-3 | |

| Material Used | PLA | ABS |

| Bed Temperature | 60 °C | 100 °C |

| Nozzle Temperature | 210 °C | 240 °C |

| Layer Height | 0.2 mm | 0.2 mm |

| Infill Density | 100% | 100% |

| Print Speed | 50 mm/s | 50 mm/s |

| Slicing Software | Creality 3D | Creality 3D |

| Nozzle Diameter | 0.4 mm | 0.4 mm |

| Material | UTS (MPa) | Maximum Stress Solid Model (MPa) | Maximum Stress Shell Model (MPa) | ||

|---|---|---|---|---|---|

| Head Drop | Leg Drop | Head Drop | Leg Drop | ||

| PLA | 59.2 | 56.4 | 60.4 | 40.3 | 30.9 |

| ABS | 44.3 | 42.8 | 34.3 | 30.6 | 26.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, U.; Saeed, H.A.; Ahmed, B.A.; Butt, S.U.; Khan, R. Investigation of the Impact Resistance Behavior of Customized Hair Clipper Comb Fabricated by Fused Deposition Modeling. Sustainability 2022, 14, 8071. https://doi.org/10.3390/su14138071

Ali U, Saeed HA, Ahmed BA, Butt SU, Khan R. Investigation of the Impact Resistance Behavior of Customized Hair Clipper Comb Fabricated by Fused Deposition Modeling. Sustainability. 2022; 14(13):8071. https://doi.org/10.3390/su14138071

Chicago/Turabian StyleAli, Uzair, Hasan Aftab Saeed, Bilal Anjum Ahmed, Sajid Ullah Butt, and Rehan Khan. 2022. "Investigation of the Impact Resistance Behavior of Customized Hair Clipper Comb Fabricated by Fused Deposition Modeling" Sustainability 14, no. 13: 8071. https://doi.org/10.3390/su14138071

APA StyleAli, U., Saeed, H. A., Ahmed, B. A., Butt, S. U., & Khan, R. (2022). Investigation of the Impact Resistance Behavior of Customized Hair Clipper Comb Fabricated by Fused Deposition Modeling. Sustainability, 14(13), 8071. https://doi.org/10.3390/su14138071