The Use of Non-Plastic Materials for Oyster Reef and Shoreline Restoration: Understanding What Is Needed and Where the Field Is Headed

Abstract

:1. Introduction

1.1. The Problem with Plastic

1.2. The Need for a Statewide Assessment of Progress

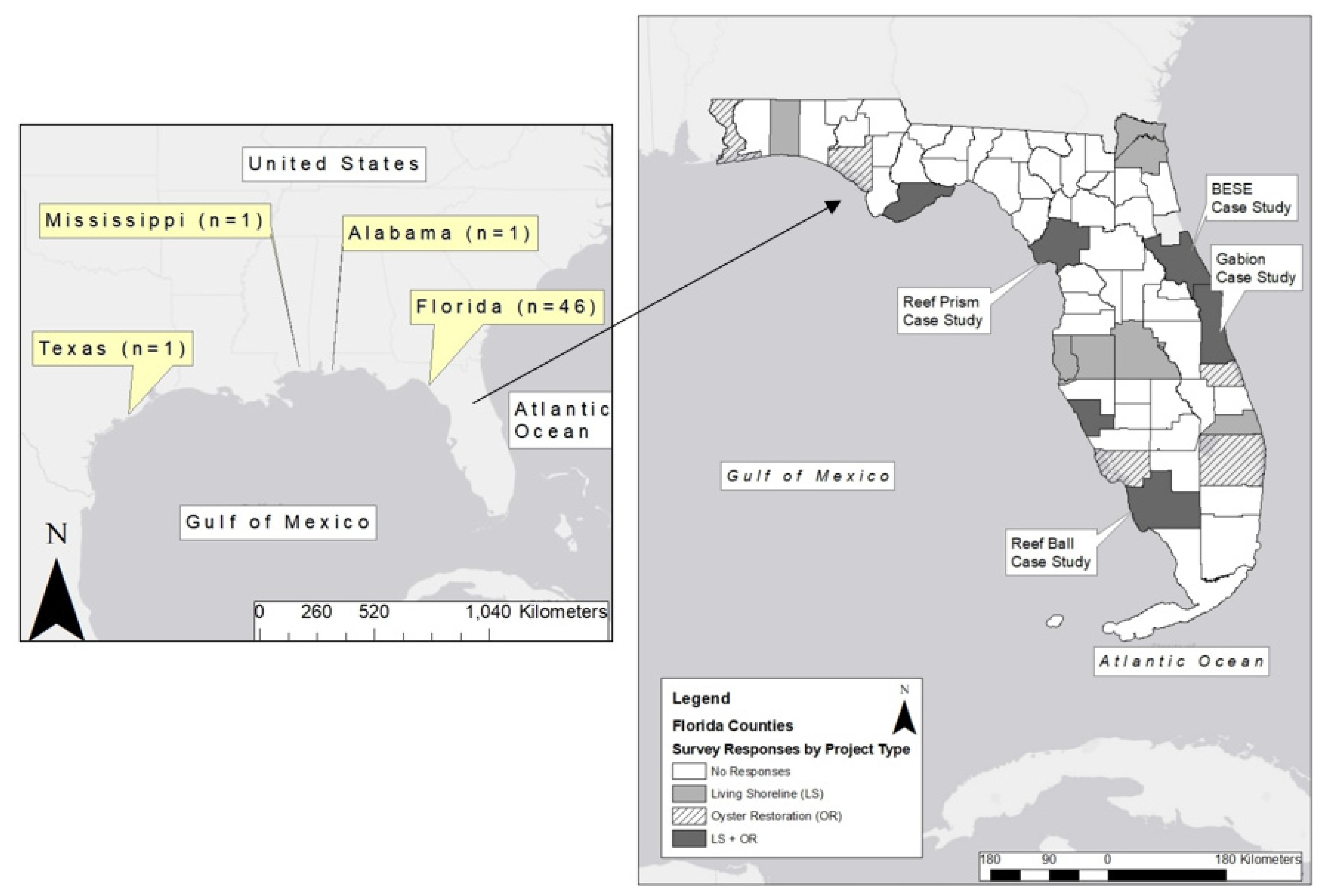

2. Methods

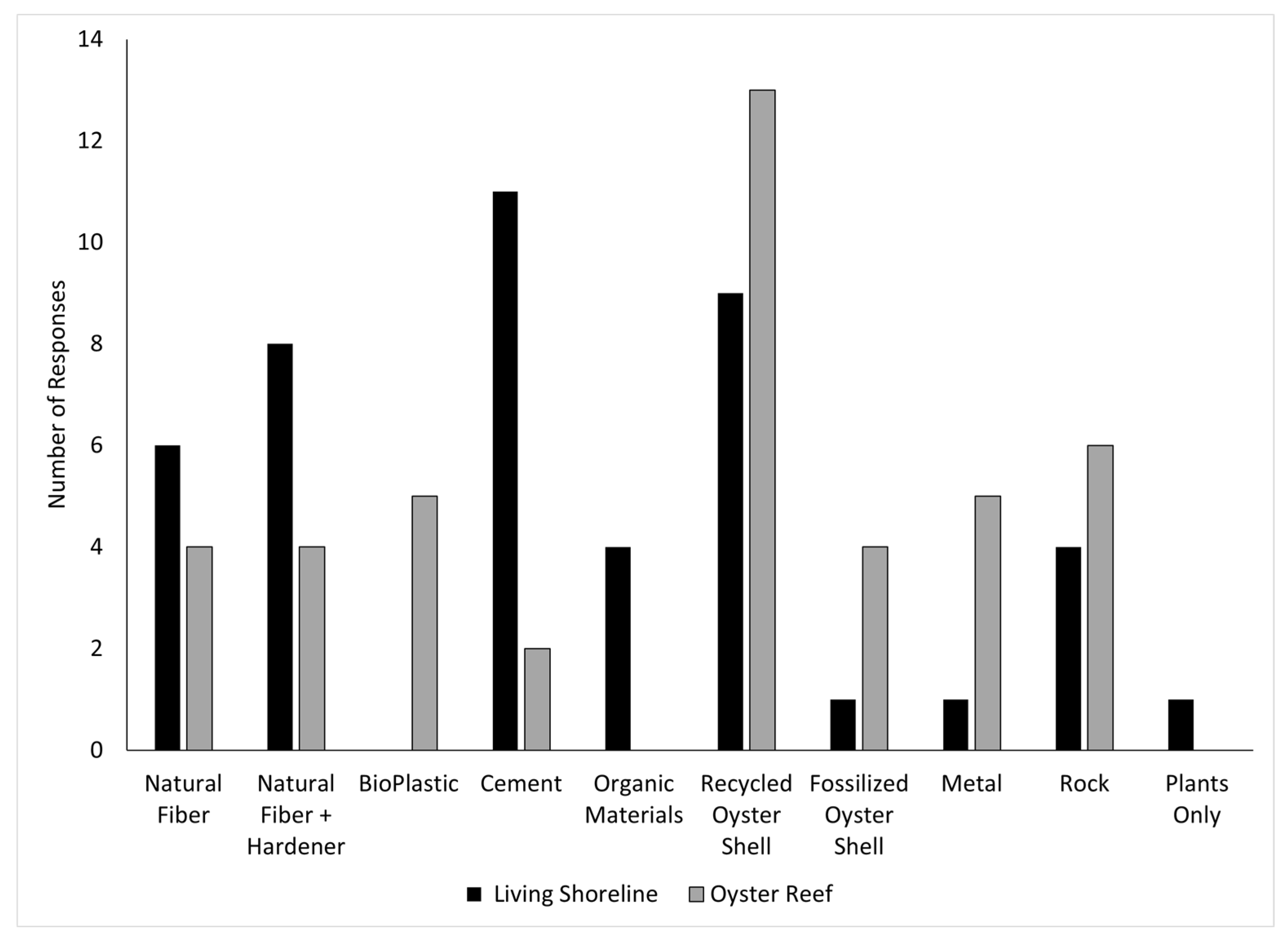

3. Results

3.1. Survey Outcomes

3.2. Case Studies

3.2.1. BESE-Elements® Oyster Restoration Mats by University Group

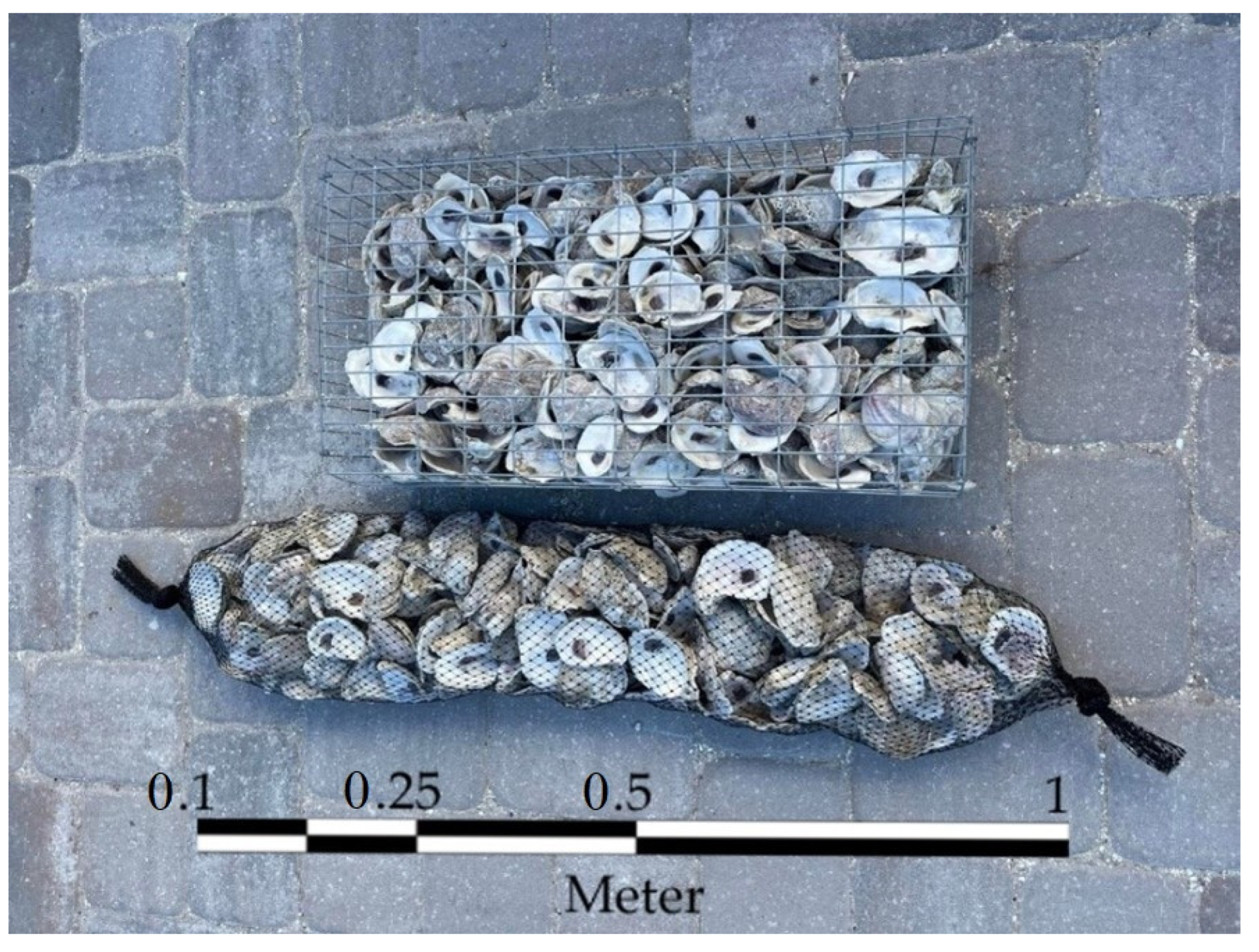

3.2.2. GAW Rigid Gabions for Oyster Restoration by Conservation Non-Profit

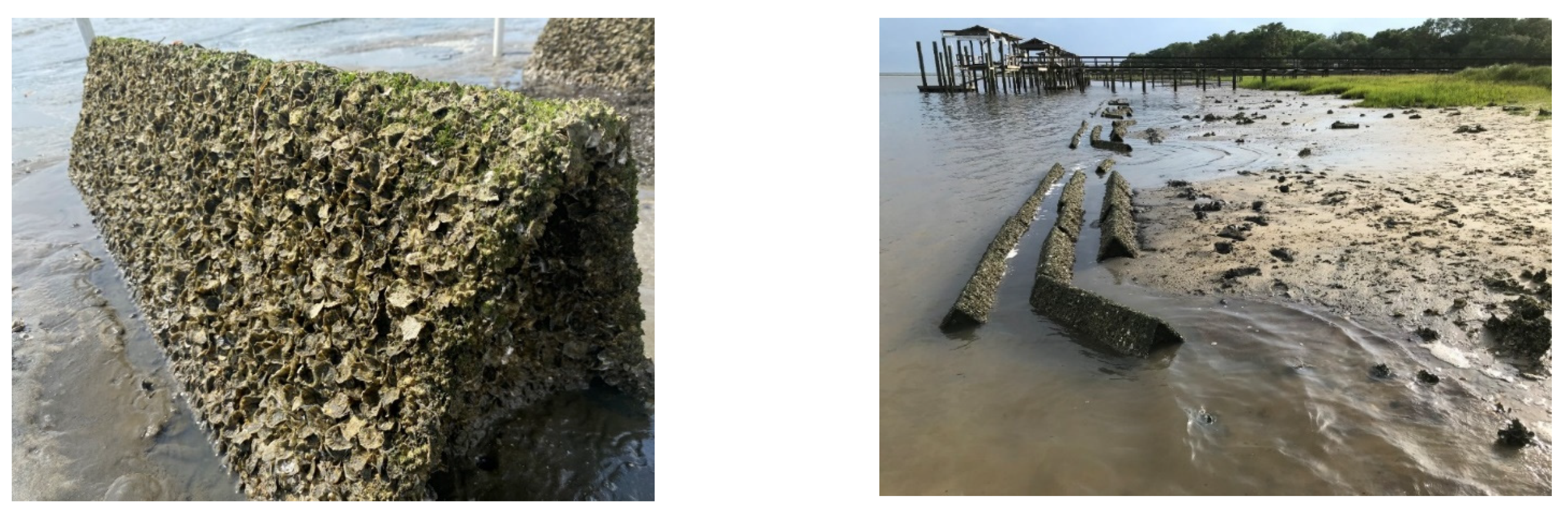

3.2.3. Reef Prisms, University Group, including Sea Grant Extension Office

3.2.4. Loose Shell, Limestone Rocks, and Reef Balls, City/County

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Survey Question | Response Categories | Number of Respondents |

|---|---|---|

| What was the first year of deployment? | 2000 | 1 |

| 2010–2014 | 3 | |

| 2015–2018 | 11 | |

| 2019–2021 | 32 | |

| N/A (Design Phase) | 2 | |

| What is the approximate size of the project? | Pilot (1–few units) | 9 |

| Small scale (20–100 m2) | 14 | |

| Medium scale (101–500 m2) | 7 | |

| Large scale (>500 m2) | 17 | |

| N/A | 2 | |

| Did you experience any permitting challenges related to this project? | Yes | 9 |

| No | 40 | |

| If yes, what were the permitting challenges related to? Check all that apply. | Non-plastic material | 0 |

| Other material used in project | 0 | |

| Project size | 5 | |

| Project location | 5 | |

| Project layout | 4 | |

| Does your funding prioritize biodegradables? | Yes | 18 |

| No | 31 | |

| Ease of production/sourcing? | Easy | 30 |

| Moderate | 10 | |

| Difficult | 9 | |

| Material is appropriate for able-bodied volunteers to assist with material preparation? | Yes | 32 |

| No | 17 | |

| Material is suitable for able-bodied volunteers to assist with installation? | Yes | 34 |

| No | 15 | |

| Safety precautions must be taken during production of these materials? | Yes | 22 |

| No | 27 | |

| Material is appropriate for K-12 students to assist with material preparation? | Yes | 12 |

| No | 37 | |

| Material is suitable for K-12 students to assist with installation? | Yes | 10 |

| No | 39 | |

| Ease of Installation? | Easy | 16 |

| Moderate | 23 | |

| Difficult | 9 | |

| N/A | 1 | |

| Can be transported using basic equipment (e.g., truck, small trailer, small boats)? | Yes | 34 |

| No | 15 | |

| Financial cost as compared to plastic materials? | Less | 8 |

| About the Same | 2 | |

| More | 23 | |

| Unknown/Unsure | 16 | |

| Time commitment required as compared to plastic materials? | Less | 8 |

| About the Same | 11 | |

| More | 21 | |

| Unknown/Unsure | 9 | |

| Would you use again? | No | 1 |

| Yes | 30 | |

| Yes, w/Modifications | 12 | |

| Unknown/Unsure | 6 | |

| Monitoring Frequency? | Monthly | 10 |

| Quarter | 13 | |

| Annual | 14 | |

| 2 Times per Year | 8 | |

| Other | 4 | |

| Duration of monitoring plan? | 6 months | 1 |

| 1 year | 6 | |

| 2 years | 13 | |

| >2 years | 24 | |

| Other | 5 | |

| How did the non-plastic materials in your project perform regarding structural integrity? | Lower than Expected | 0 |

| As Expected | 13 | |

| Better than Expected | 27 | |

| Unknown/Unsure | 9 | |

| How did the non-plastic materials in your project perform regarding oyster recruitment? | Minimal Recruitment | 3 |

| Moderate Recruitment | 7 | |

| High Recruitment | 24 | |

| Unknown/Unsure | 15 | |

| How did the non-plastic materials in your project perform regarding wave attenuation and shoreline protection? | Lower than Expected | 3 |

| As Expected | 3 | |

| Better than Expected | 16 | |

| Unknown/Unsure | 27 |

References

- Worm, B.; Barbier, E.B.; Beaumont, N.; Duffy, J.E.; Folke, C.; Halpern, B.S.; Jackson, J.B.C.; Lotze, H.K.; Micheli, F.; Palumbi, S.R.; et al. Impacts of Biodiversity Loss on Ocean Ecosystem Services. Science 2006, 314, 787–790. [Google Scholar] [CrossRef] [Green Version]

- Beck, M.; Brumbaugh, R.; Airoldi, L.; Carranza, A.; Coen, L.; Crawford, C.; Defeo, O.; Edgar, G.; Hancock, B.; Kay, M.; et al. Oyster reefs at risk and recommendations for conservation, restoration, and management. Bioscience 2011, 61, 107–116. [Google Scholar] [CrossRef] [Green Version]

- McOwen, C.J.; Weatherdon, L.V.; Van Bochove, J.-W.; Sullivan, E.; Blyth, S.; Zockler, C.; Stanwell-Smith, D.; Kingston, N.; Martin, C.S.; Spalding, M.; et al. A global map of saltmarshes. Biodivers. Data J. 2017, 5, e11764. [Google Scholar] [CrossRef]

- Friess, D.A.; Rogers, K.; Lovelock, C.E.; Krauss, K.W.; Hamilton, S.E.; Lee, S.Y.; Lucas, R.; Primavera, J.; Rajkaran, A.; Shi, S. The State of the World’s Mangrove Forests: Past, Present, and Future. Annu. Rev. Environ. Resour. 2019, 44, 89–115. [Google Scholar] [CrossRef] [Green Version]

- Waycott, M.; Duarte, C.M.; Carruthers, T.J.B.; Orth, R.J.; Dennison, W.C.; Olyarnik, S.; Calladine, A.; Fourqurean, J.W.; Heck, K.L., Jr.; Hughes, A.R.; et al. Accelerating loss of seagrasses across the globe threatens coastal ecosystems. Proc. Natl. Acad. Sci. USA 2009, 106, 12377–12381. [Google Scholar] [CrossRef] [Green Version]

- Hancock, B.; zu Ermgassen, P. Enhanced Production of Finfish and Large Crustaceans by Bivalve Reefs. In Goods and Services of Marine Bivalves; Smaal, A., Ferreira, J., Grant, J., Petersen, J., Strand, Ø., Eds.; Springer: Cham, Switzerland, 2019; pp. 295–312. [Google Scholar] [CrossRef] [Green Version]

- Lai, Q.T.; Irwin, E.R.; Zhang, Y. Estimating nitrogen removal services of eastern oyster (Crassostrea virginica) in Mobile Bay, Alabama. Ecol. Indic. 2020, 117, 106541. [Google Scholar] [CrossRef]

- Piehler, M.F.; Smyth, A.R. Habitat-specific distinctions in estuarine denitrification affect both ecosystem function and services. Ecosphere 2011, 2, 1–16. [Google Scholar] [CrossRef]

- Galimany, E.; Lunt, J.; Freeman, C.J.; Reed, S.; Segura-García, I.; Paul, V.J. Feeding behavior of eastern oysters Crassostrea virginica and hard clams Mercenaria mercenaria in shallow estuaries. Mar. Ecol. Prog. Ser. 2017, 567, 125–137. [Google Scholar] [CrossRef] [Green Version]

- Fodrie, F.J.; Rodriguez, A.B.; Gittman, R.K.; Grabowski, J.H.; Lindquist, N.L.; Peterson, C.H.; Piehler, M.F.; Ridge, J.T. Oyster reefs as carbon sources and sinks. Proc. R. Soc. B 2017, 284, 20170891. [Google Scholar] [CrossRef]

- Scyphers, S.B.; Powers, S.P.; Heck, K.L., Jr.; Byron, D. Oyster Reefs as Natural Breakwaters Mitigate Shoreline Loss and Facilitate Fisheries. PLoS ONE 2011, 6, e22396. [Google Scholar] [CrossRef]

- Ysebaert, T.; Walles, B.; Haner, J.; Hancock, B. Habitat Modification and Coastal Protection by Ecosystem-Engineering Reef-Building Bivalves. In Goods and Services of Marine Bivalves; Smaal, A., Ferreira, J., Grant, J., Petersen, J., Strand, Ø., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef] [Green Version]

- Barbier, E.; Hacker, S.; Kennedy, C.; Stier, A.; Silliman, B. The value of estuarine and coastal ecosystem services. Ecol. Monogr. 2011, 81, 169–193. [Google Scholar] [CrossRef]

- Ayvazian, S.; Gerber-Williams, A.; Grabbert, S.; Miller, K.; Hancock, B.; Helt, W.; Cobb, D.; Strobel, C. Habitat Benefits of Restored Oyster Reefs and Aquaculture to Fish and Invertebrates in a Coastal Pond in Rhode Island, United States. J. Shellfish Res. 2020, 39, 563–587. [Google Scholar] [CrossRef] [PubMed]

- Coen, L.D.; Brumbaugh, R.D.; Bushek, D.; Grizzle, R.; Luckenbach, M.; Posey, M.H.; Powers, S.P.; Tolley, S.G. Ecosystem services related to oyster restoration. Mar. Ecol. Prog. Ser. 2007, 341, 303–307. [Google Scholar] [CrossRef]

- Chambers, L.; Gaspar, S.; Pilato, C.; Steinmuller, H.; McCarthy, K.; Sacks, P.; Walters, L. How well do restored intertidal oyster reefs support key biogeochemical functions in a coastal lagoon? Estuaries Coasts 2018, 41, 784–799. [Google Scholar] [CrossRef]

- Grabowski, J.; Peterson, C. Restoring oyster reefs to recover ecosystem services. Theor. Ecol. Ser. 2007, 4, 291–298. [Google Scholar] [CrossRef]

- La Peyre, M.; Furlong, J.; Brown, L.A.; Piazza, B.P.; Brown, K. Oyster reef restoration in the northern Gulf of Mexico: Extent, methods and outcomes. Ocean. Coast. Manag. 2014, 89, 20–28. [Google Scholar] [CrossRef]

- Peterson, C.H.; Grabowski, J.H.; Powers, S.P. Estimated enhancement of fish production resulting from restoring oyster reef habitat: Quantitative valuation. Mar. Ecol. Prog. Ser. 2003, 264, 249–264. [Google Scholar] [CrossRef] [Green Version]

- Ray, N.E.; Fulweiler, R.W. Meta-analysis of oyster impacts on coastal biogeochemistry. Nat. Sustain. 2021, 4, 261–269. [Google Scholar] [CrossRef]

- Radabaugh, K.R.; Moyer, R.P.; Geiger, S.P. (Eds.) Oyster Integrated Mapping and Monitoring Program Report for the State of Florida; FWRI Technical Report 22; Fish and Wildlife Research Institute, Florida Fish and Wildlife Conservation Commission: St. Petersburg, FL, USA, 2019; 174p. [Google Scholar]

- Walters, L.; Sacks, P.; Campbell, D. Boating impacts and boat-wake resilient restoration of the eastern oyster Crassostrea virginica in Mosquito Lagoon, Florida, USA. FL Sci. 2021, 84, 173–199. [Google Scholar]

- Zu Ermgassen, P.S.E.; Spalding, M.D.; Blake, B.; Coen, L.D.; Dumbauld, B.; Geiger, S.; Grabowski, J.H.; Grizzle, R.; Luckenbach, M.; McGraw, K.; et al. Historical ecology with real numbers: Past and present extent and biomass of an imperiled estuarine habitat. Proc. R. Soc. B. 2012, 279, 3393–3400. [Google Scholar] [CrossRef] [Green Version]

- Bersoza Hernández, A.; Brumbaugh, R.D.; Frederick, P.; Grizzle, R.; Luckenbach, M.W.; Peterson, C.H.; Angelini, C. Restoring the eastern oyster: How much progress has been made in 53 years? Front. Ecol. Environ. 2018, 16, 463–471. [Google Scholar] [CrossRef] [Green Version]

- Morris, R.; Bilkovic, D.M.; Boswell, M.; Bushek, D.; Cebrian, J.; Goff, J.; Kibler, K.; Le Peyre, M.; McClenachan, G.; Moody, J.; et al. Large-scale variation in wave attenuation of oyster reef living shorelines and the influence of inundation duration. Ecol. Appl. 2021, 31, e02382. [Google Scholar] [CrossRef]

- Schulte, D.M.; Burke, R.P.; Lipcius, R.N. Unprecedented restoration of a native oyster metapopulation. Science 2009, 325, 1124–1128. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, V.S.; Breitburg, D.L.; Christman, M.C.; Luckenbach, M.W.; Paynter, K.; Kramer, J.; Sellner, K.G.; Dew-Baxter, J.; Keller, C.; Mann, R. Lessons Learned from Efforts to Restore Oyster Populations in Maryland and Virginia, 1990 to 2007. J. Shellfish Res. 2011, 30, 719–731. [Google Scholar] [CrossRef] [Green Version]

- Graham, P.; Palmer, T.; Pollack, J. Oyster reef restoration: Substrate suitability may depend on specific restoration goals: Substrate suitability for restoration. Restor. Ecol. 2016, 25, 459–470. [Google Scholar] [CrossRef]

- Chesapeake Bay Program. Oyster Restoration Outcome Management Strategy 2015–2025, v.2. Available online: https://www.chesapeakebay.net/documents/22030/2020-2021_oyster_management_strategy_2.pdf (accessed on 13 January 2022).

- Theuerkauf, S.J.; Burke, R.P.; Lipcius, R.N. Settlement, growth, and survival of Eastern Oysters on alternative reef substrates. J. Shellfish Res. 2015, 34, 241–250. [Google Scholar] [CrossRef] [Green Version]

- Kittinger, J.N.; Ayers, A.L. Shoreline armoring, risk management, and coastal resilience under rising seas. Coast. Manag. 2010, 38, 634–653. [Google Scholar] [CrossRef]

- Gittman, R.K.; Fodrie, F.J.; Popowich, A.M.; Keller, D.A.; Bruno, J.F.; Currin, C.A.; Peterson, C.H.; Piehler, M.F. Engineering away our natural defenses: An analysis of shoreline hardening in the United States. Front. Ecol. Environ. 2015, 13, 301–307. [Google Scholar] [CrossRef]

- Manis, J.; Garvis, S.; Jachec, S.; Walters, L. Wave attenuation experiments over living shorelines over time: A wave tank study to assess recreational boating pressures. J. Coast. Conserv. 2014, 19, 1–11. [Google Scholar] [CrossRef]

- Fillyaw, R.M.; Donnelly, M.J.; Litwak, J.W.; Rifenberg, J.L.; Walters, L.J. Strategies for successful mangrove living shoreline stabilizations in shallow water subtropical estuaries. Sustainability 2021, 13, 11704. [Google Scholar] [CrossRef]

- Morris, R.; Bilkovic, D.; Boswell, M.; Bushek, D.; Cebrian, J.; Goff, J.; Kibler, K.; La Peyre, M.; McClenachan, G.; Moody, J.; et al. The application of oyster reefs in shoreline protection: Are we over-engineering for an ecosystem engineer? J. Appl. Ecol. 2019, 56, 1703–1711. [Google Scholar] [CrossRef]

- Barber, A.; Walters, L.; Birch, A. Potential for restoring biodiversity of macroflora and macrofauna on oyster reefs in Mosquito Lagoon, Florida. FL Sci. 2010, 73, 47–62. [Google Scholar]

- Copertino, J.; Harris, K.; Chute, L.; Walters, L. Impact of oyster (Crassostrea virginica) reef restoration on benthic invertebrates and coastal birds in a subtropical estuary. Sustainability 2022, 14, 2371. [Google Scholar] [CrossRef]

- Loch, J.M.H.; Walters, L.J.; Donnelly, M.L.; Cook, G.S. Restored Coastal Habitat Can “Reel In” Juvenile Sportfish: Population and Community Responses in the Indian River Lagoon, Florida, USA. Sustainability 2021, 13, 12832. [Google Scholar] [CrossRef]

- Riffenberg, J.; Litwak, J.; Fillyaw, R.M. Vertebrate impact on a newly deployed shoreline stabilization project by wildlife trail camera analysis. Pegasus Rev. UCF Undergrad. Res. 2021, 13, 25–36. Available online: https://stars.library.ucf.edu/urj/vol13/iss2/3 (accessed on 15 January 2022).

- Masura, J.; Baker, J.; Foster, G.; Arthur, C.; Herring, C. Laboratory Methods for the Analysis of Microplastics in the Marine Environment: Recommendations for Quantifying Synthetic Particles in Waters and Sediments; NOAA Technical Memorandum NOS-OR&R-48; NOAA Marine Debris Division: Silver Spring, MD, USA, 2015. [Google Scholar]

- Hale, R.C.; Seeley, M.E.; La Guardia, M.J.; Mai, L.; Zeng, E.Y. A Global Perspective on Microplastics. J. Geophys. Res. Oceans 2020, 125, e2018JC014719. [Google Scholar] [CrossRef]

- Rochman, C.; Hoellein, T. The global odyssey of plastic pollution. Science 2020, 368, 1184–1185. [Google Scholar] [CrossRef]

- Craig, C. Correlations in Microplastic Abundance between Water, the Eastern Oyster, Crassostrea virginica, and Their Biodeposits in a Dynamic Florida Estuary. Master’s Thesis, University of Central Florida, Orlando, FL, USA, 2021. Available online: https://stars.library.ucf.edu/etd2020/488 (accessed on 20 December 2021).

- Wang, J.; Tan, Z.; Peng, J.; Qui, Q.; Li, M.M. The behaviors of microplastics in the marine environment. Mar. Environ. Res. 2016, 113, 7–17. [Google Scholar] [CrossRef]

- Waite, H.; Donnelly, M.; Walters, L. Quantity and types of microplastics in the organic tissues of the eastern oyster Crassostrea virginica and Atlantic mud crab Panopeus herbstii from a Florida estuary. Mar. Pollut. Bull. 2018, 129, 179–185. [Google Scholar] [CrossRef]

- Carlin, J.; Craig, C.; Little, S.; Donnelly, M.; Fox, D.; Zhai, L.; Walters, L. Microplastic accumulation in the gastrointestinal tracts in birds of prey in Central Florida, USA. Environ. Pollut. 2020, 264, 114633. [Google Scholar] [CrossRef]

- Craig, C.; Fox, D.; Zhai, L.; Walters, L.J. In-situ microplastic egestion efficiency of the eastern oyster Crassostrea virginica. Mar. Pollut. Bull. 2022, 178, 113653. [Google Scholar] [CrossRef] [PubMed]

- Sussarellu, R.; Suquet, M.; Thomas, Y.; Lambert, C.; Fabioux, C.; Pernet, M.E.J.; Goic, N.L.; Quillien, V.; Mingant, C.; Epelboin, Y.; et al. Oyster reproduction is affected by exposure to polystyrene microplastics. Proc. Natl. Acad. Sci. USA 2015, 113, 2430–2435. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sorini, R.; Kordal, M.; Apuzza, B.; Eierman, L.E. Skewed sex ratio and gametogenesis gene expression in eastern oysters (Crassostrea virginica) exposed to plastic pollution. J. Exp. Mar. Bio. Ecol. 2021, 544, 151605. [Google Scholar] [CrossRef]

- Garvis, S.; Sacks, P.; Walters, L. Formation, movement, and restoration of dead intertidal oyster reefs in Canaveral National Seashore and Mosquito Lagoon, Florida. J. Shellfish Res. 2015, 34, 251–258. [Google Scholar] [CrossRef]

- Grizzle, R.; Adams, J.; Walters, L. Historical changes in intertidal oyster (Crassostrea virginica) reefs in a Florida lagoon potentially related to boating activities. J. Shellfish Res. 2022, 21, 749–756. [Google Scholar]

- Nitsch, C.K.; Walters, L.J.; Sacks, J.S.; Sacks, P.E.; Chambers, L.G. Biodegradable Material for Oyster Reef Restoration: First-Year Performance and Biogeochemical Considerations in a Coastal Lagoon. Sustainability 2021, 13, 7415. [Google Scholar] [CrossRef]

- Temmink, R.; Christianen, M.; Fivash, G.; Angelini, C.; Boström, C.; Didderen, K.; Engel, M.S.; Esteban, N.; Gaeckle, J.; Gagnon, K.; et al. Mimicry of emergent traits amplifies coastal restoration success. Nat. Commun. 2020, 11, 3668. [Google Scholar] [CrossRef]

- Sanibel-Captiva Conservation Foundation. Living Shoreline Structure Completed on Woodring Road for Mangrove Restoration. 2021. Available online: https://www.sccf.org/news/blog/living-shoreline-structure-completed-on-woodring-road-for-mangrove-restoration (accessed on 13 January 2022).

- Futch, C.R. A Survey of the Oyster Resources of Brevard County, Florida; Special Scientific Report No. 18; Florida Board of Conservation: St. Petersburg, FL, USA, 1967; 6p. [Google Scholar]

- Parker, M.; Encomio, V.; Beal, J.; Klarmann, P.A.; Dark, E.; Breithaupt, J.; Radabaugh, K.R. Chapter 8: Central Eastern Florida. In Oyster Integrated Mapping and Monitoring Program Report for the State of Florida; Radabaugh, K.R., Geiger, S.P., Moyer, R.P., Eds.; Florida Fish and Wildlife Conservation Commission Fish and Wildlife Research Institute Technical Report No. 22; Florida Fish and Wildlife Conservation Commission: Tallahassee, FL, USA, 2019; pp. 124–142. Available online: https://myfwc.com/research/habitat/coastal-wetlands/projects/oimmp/ (accessed on 24 April 2022).

- Save Our Indian River Lagoon (SOIRL) Website. 2022. Available online: http://www.brevardfl.gov/SaveOurLagoon/ProjectPlan (accessed on 24 April 2022).

- Anderson, L.; Sacks, P.; Donnelly, M.; Barker, V.; Anderson, S.; Walters, L. Oyster reef enhancement utilizing gardened oysters in a subtropical estuary. Restor. Ecol. 2019, 27, 966–973. [Google Scholar] [CrossRef]

- Safak, I.; Norby, P.L.; Dix, N.; Grizzle, R.E.; Southwell, M.; Veenstra, J.J.; Acevedo, A.; Cooper-Kolb, T.; Massey, L.; Sheremet, A.; et al. Coupling breakwalls with oyster restoration structures enhances living shoreline performance along energetic shoreline. Ecol. Eng. 2020, 158, 106071. [Google Scholar] [CrossRef]

- Stokes, S.; Wunderink, S.; Lowe, M.; Gereffi, G. Restoring Gulf Oysters Reefs: Opportunities for Innovation. Duke University Center on Globalization, Governance, & Competitiveness. 13. 2012. Available online: https://gvcc.duke.edu/cggclisting/restoring-gulf-oyster-reefs-opportunities-for-innovation/ (accessed on 24 April 2022).

- Ysebaert, T.; Walles, B.; Dorsch, C.; Dijkstra, J.; Troost, K.; Volp, N.; van Prooijen, B.; de Vries, M.; Herman, P.; Hibma, A. Ecodynamic solutions for the protection of intertidal habitats: The use of oyster reefs. J. Shellfish Res. 2012, 31, 362. [Google Scholar]

- Schmid, J.R.; Worley, K.; Addison, D.S.; Zimmerman, A.R.; Eaton, A.V. Naples Bay Past and Present: A Chronology of Disturbance to an Estuary. Technical Report to the City of Naples, Funded by the South Florida Water Management District. 2005, p. 58. Available online: https://www.naplesgov.com/sites/default/files/fileattachments/purchasing/page/44911/15-017_addendum_1_-_exhibit_d.pdf (accessed on 24 April 2022).

- Walters, L.; Phlips, E.; Badylak, S.; McClenachan, G.; Sacks, P.; Donnelly, M. Field observations of the negative association between recruitment of the eastern oyster Crassostrea virginica and the brown tide Aureoumbra lagunensis in Mosquito Lagoon, FL. FL Sci. 2021, 84, 81–91. [Google Scholar]

- Wellman, E.H.; Baillie, C.J.; Puckett, B.J.; Donaher, S.E.; Trackenberg, S.N.; Gitman, R. Reef design and site hydrodynamics mediate oyster restoration and marsh stabilization outcomes. Ecol. Appl. 2021, 32, e2506. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.J.; Smith, K.J.; Hargis, C.W. Development of pervious oyster shell habitat (POSH) concrete for reef restoration and living shorelines. Constr. Build. Mater. 2021, 295, 123685. [Google Scholar] [CrossRef]

- Baggett, L.P.; Powers, S.P.; Brumbaugh, R.; Coen, L.D.; DeAngelis, B.; Green, J.; Hancock, B.; Morlock, S. Oyster Habitat Restoration Monitoring and Assessment Handbook; The Nature Conservancy: Arlington, VA, USA, 2014; 96p. [Google Scholar]

| Material | Footprint/Unit | Cost/Unit | Cost/m2 |

|---|---|---|---|

| VEXAR® plastic oyster mat | 0.25 m2 | $2.43 | $9.72 |

| BESE-elements® oyster mat | 0.25 m2 | $9.18 | $36.72 |

| Naltex® plastic oyster shell bag | 0.3 m2 | $1.00 | $3.33 |

| GAW metal gabion | 0.185 m2 | $8.28 | $44.56 |

| Reef Prism | 0.5 m2 | $15.00 | $30.00 |

| Soft-sided metal gabion | 0.3 m2 | $6.00 | $20.00 |

| Oyster CORE module | 0.1 m2 | $3.00 | $30.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walters, L.J.; Roddenberry, A.; Crandall, C.; Wayles, J.; Donnelly, M.; Barry, S.C.; Clark, M.W.; Escandell, O.; Hansen, J.C.; Laakkonen, K.; et al. The Use of Non-Plastic Materials for Oyster Reef and Shoreline Restoration: Understanding What Is Needed and Where the Field Is Headed. Sustainability 2022, 14, 8055. https://doi.org/10.3390/su14138055

Walters LJ, Roddenberry A, Crandall C, Wayles J, Donnelly M, Barry SC, Clark MW, Escandell O, Hansen JC, Laakkonen K, et al. The Use of Non-Plastic Materials for Oyster Reef and Shoreline Restoration: Understanding What Is Needed and Where the Field Is Headed. Sustainability. 2022; 14(13):8055. https://doi.org/10.3390/su14138055

Chicago/Turabian StyleWalters, Linda J., Annie Roddenberry, Chelsey Crandall, Jessy Wayles, Melinda Donnelly, Savanna C. Barry, Mark W. Clark, Olivia Escandell, Jennifer C. Hansen, Katie Laakkonen, and et al. 2022. "The Use of Non-Plastic Materials for Oyster Reef and Shoreline Restoration: Understanding What Is Needed and Where the Field Is Headed" Sustainability 14, no. 13: 8055. https://doi.org/10.3390/su14138055

APA StyleWalters, L. J., Roddenberry, A., Crandall, C., Wayles, J., Donnelly, M., Barry, S. C., Clark, M. W., Escandell, O., Hansen, J. C., Laakkonen, K., & Sacks, P. E. (2022). The Use of Non-Plastic Materials for Oyster Reef and Shoreline Restoration: Understanding What Is Needed and Where the Field Is Headed. Sustainability, 14(13), 8055. https://doi.org/10.3390/su14138055