Sludge Management at the Kraków-Płaszów WWTP—Case Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate

2.1.1. Digested Sludge

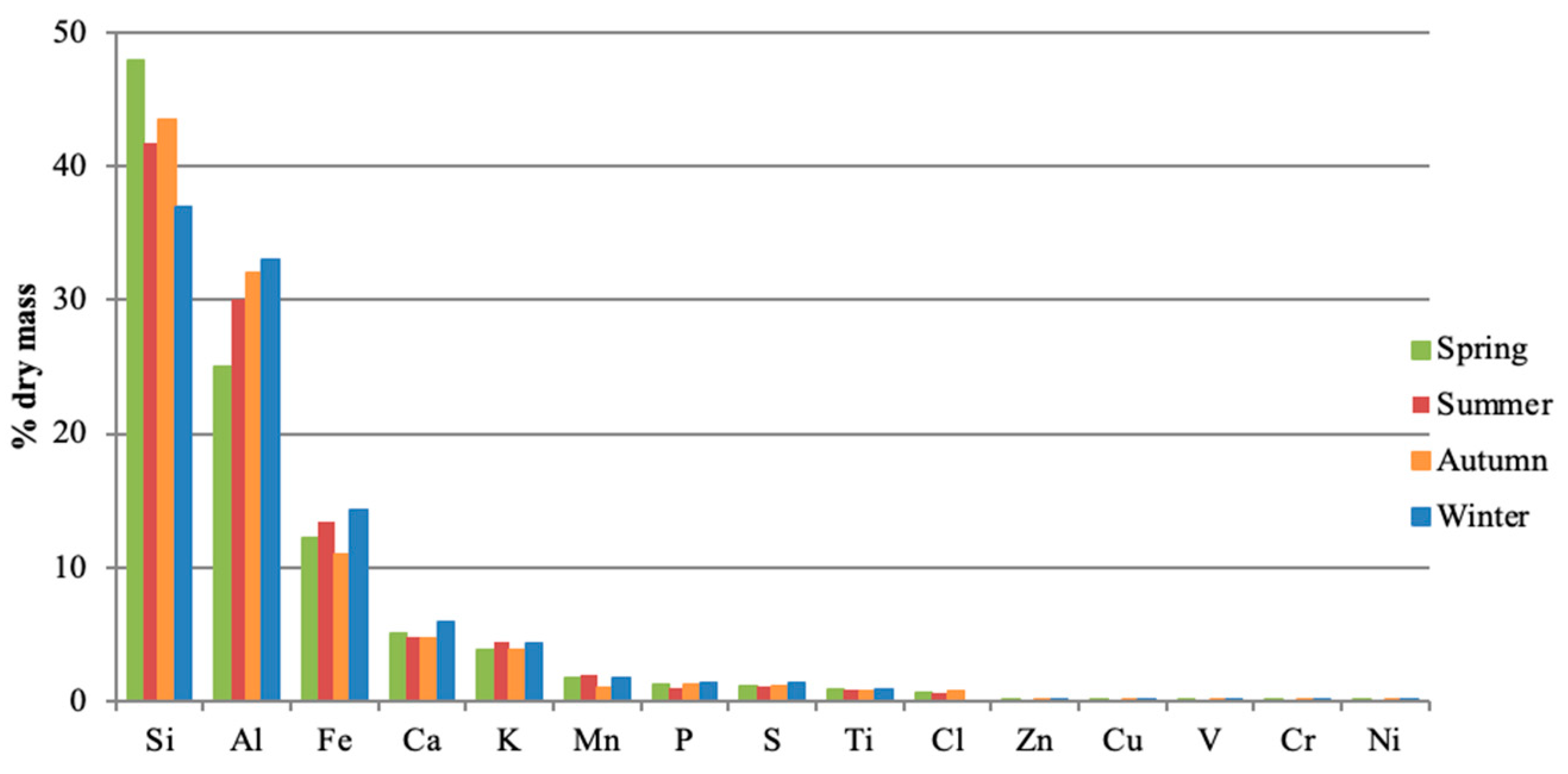

2.1.2. Water Treatment Sludge

2.2. Experiments

2.2.1. Laboratory Experiments—Sample Analysis for Biomethane Potential Tests

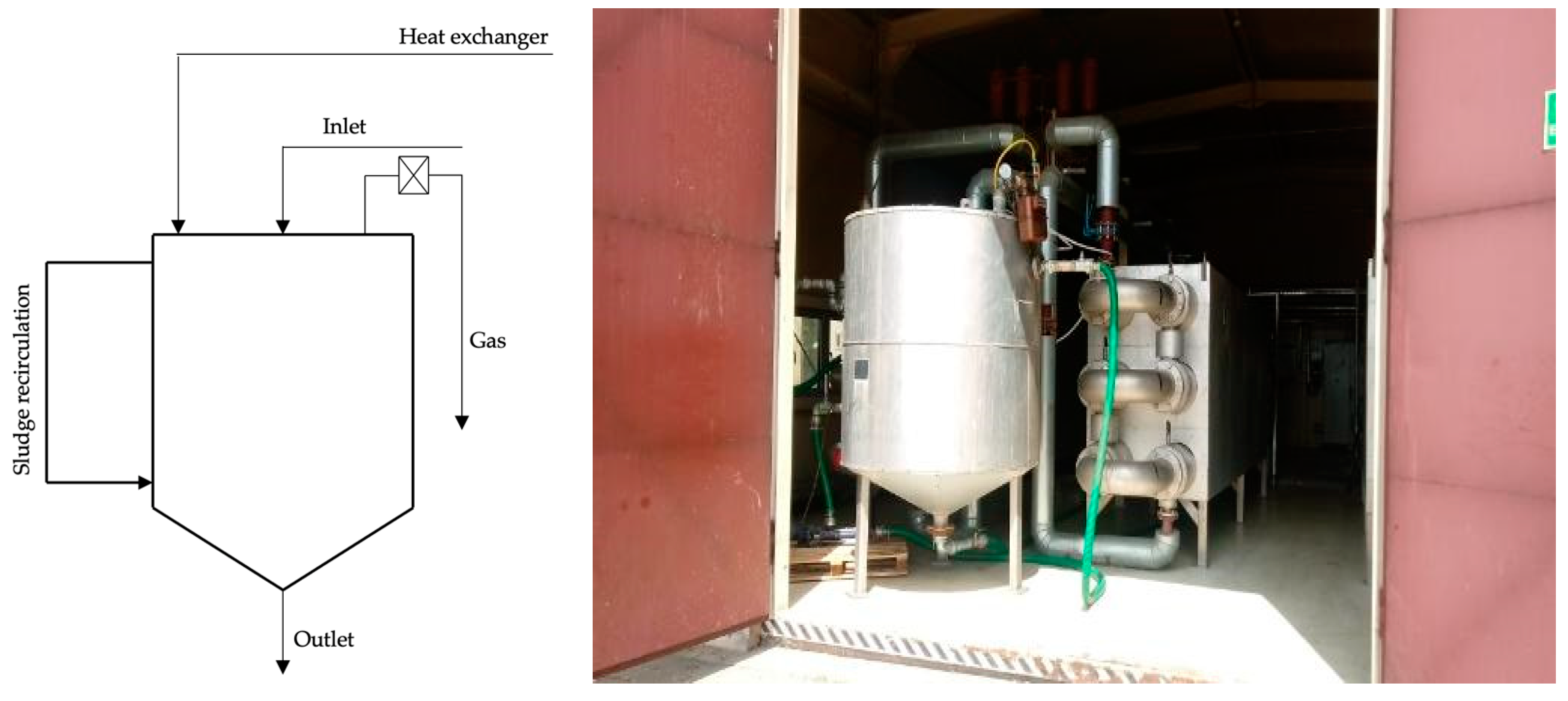

2.2.2. Pilot Studies

3. Results

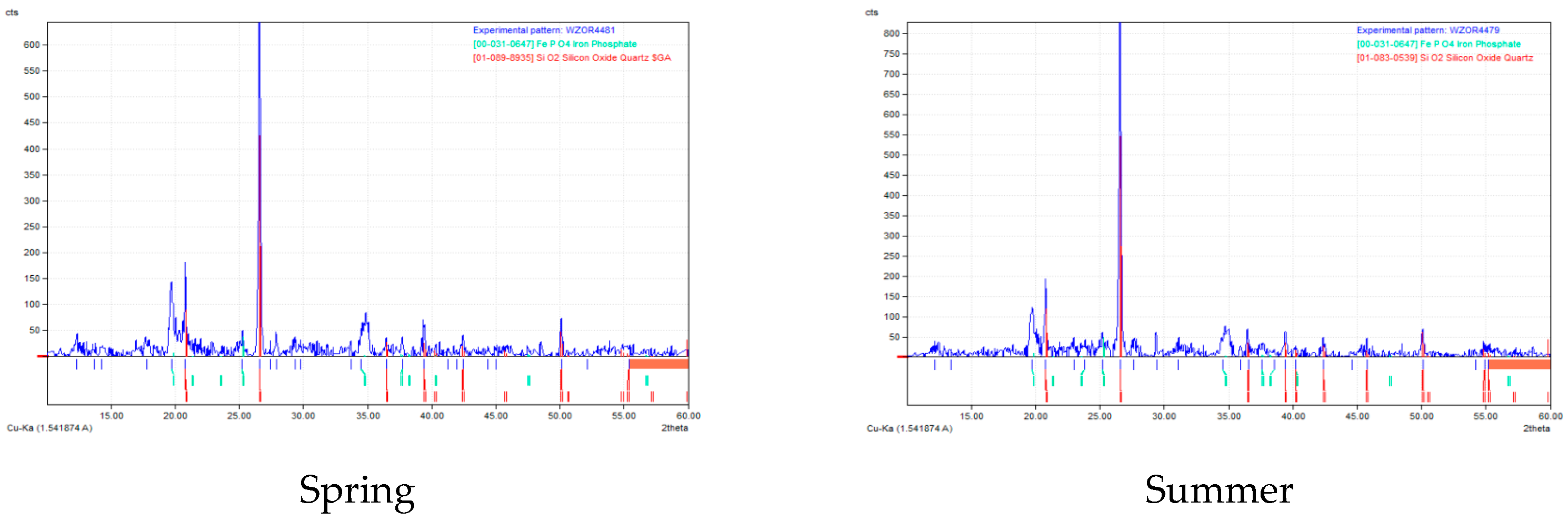

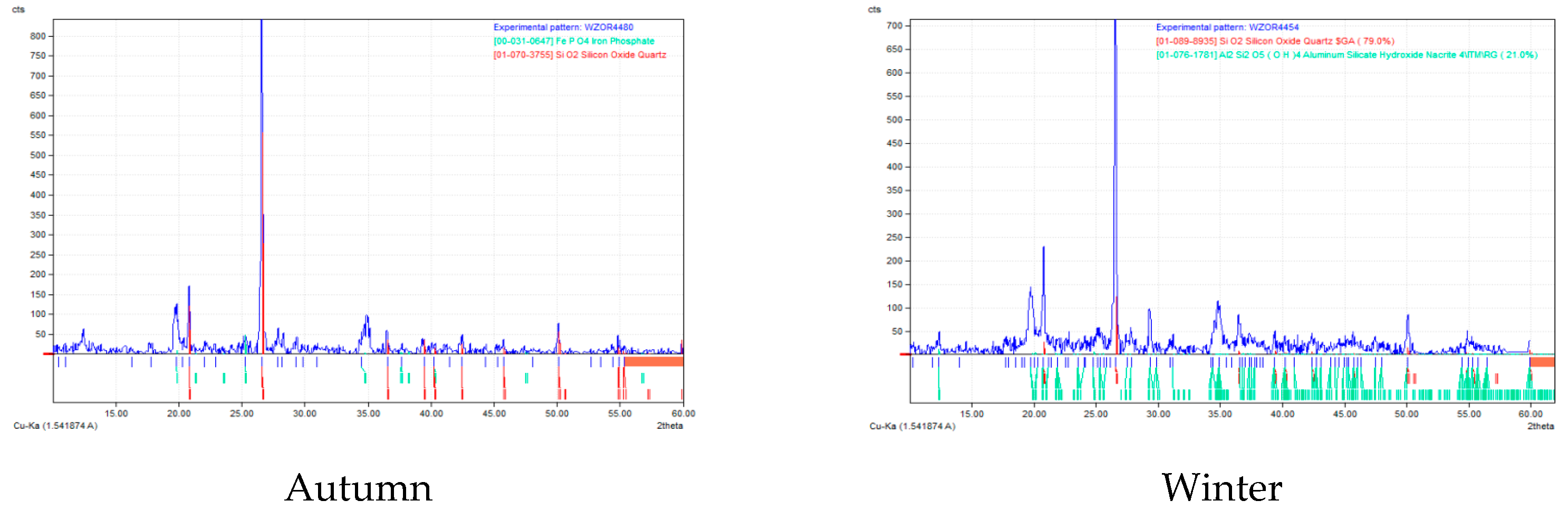

3.1. Characteristics of Water Treatment Sludge

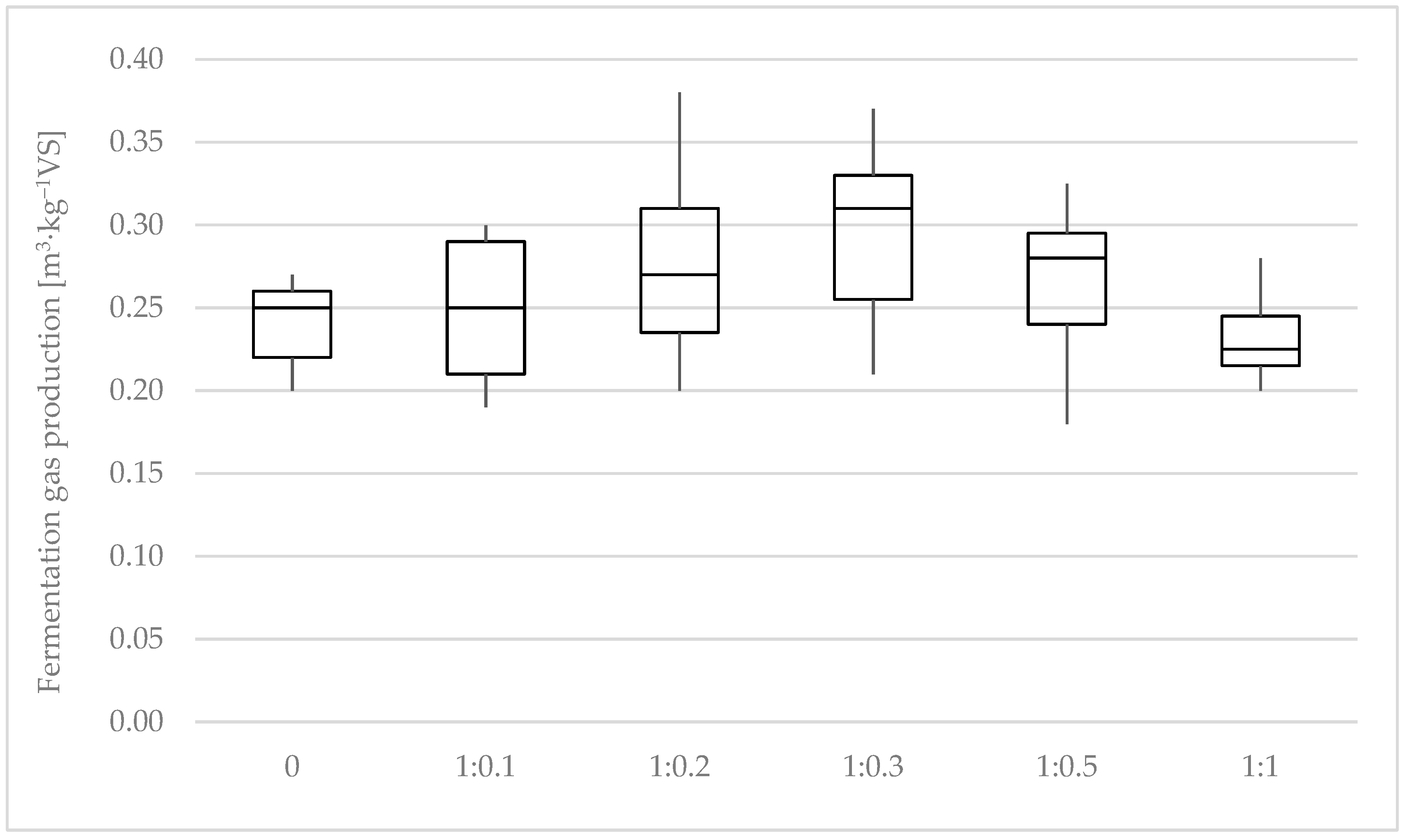

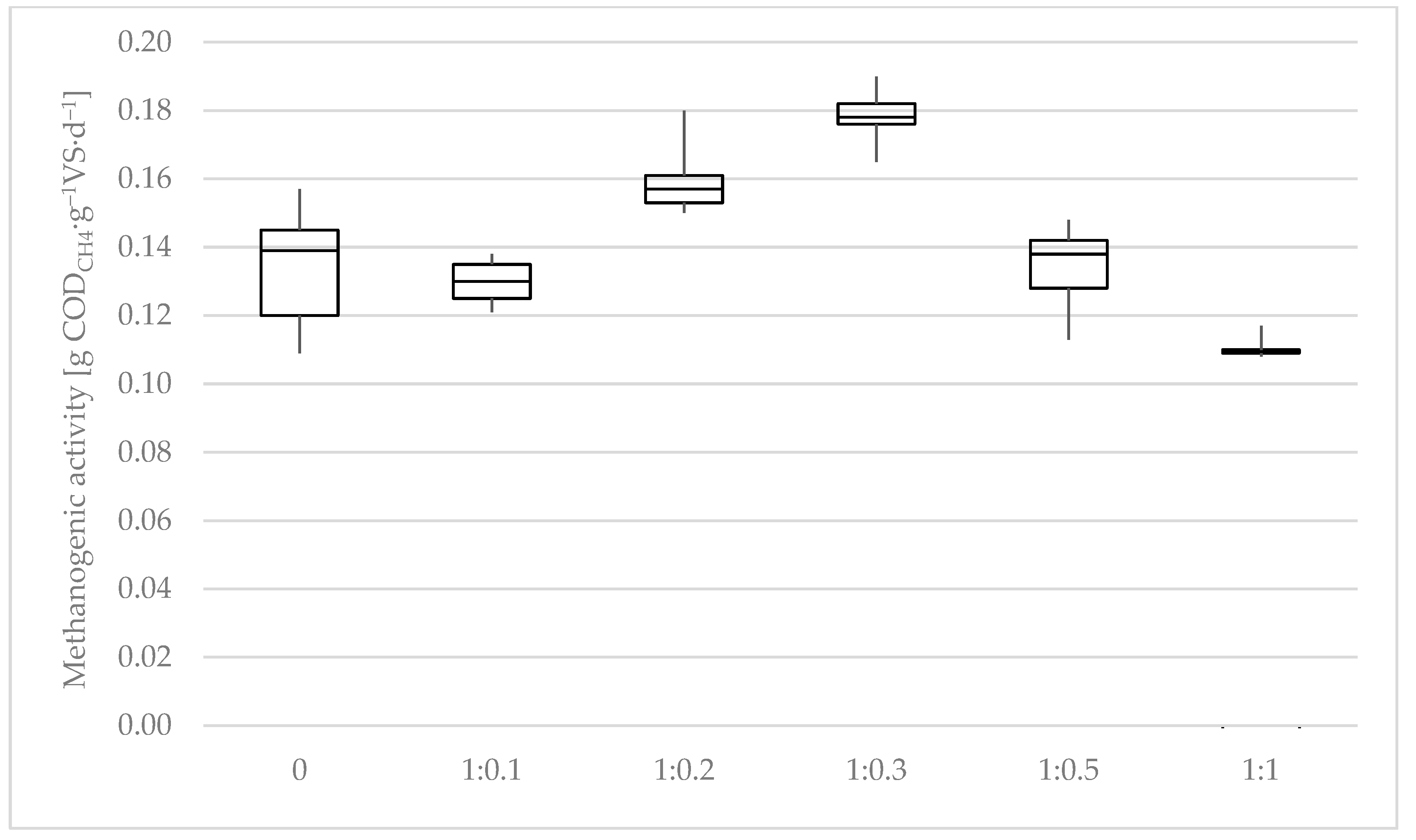

3.2. Laboratory Experiments

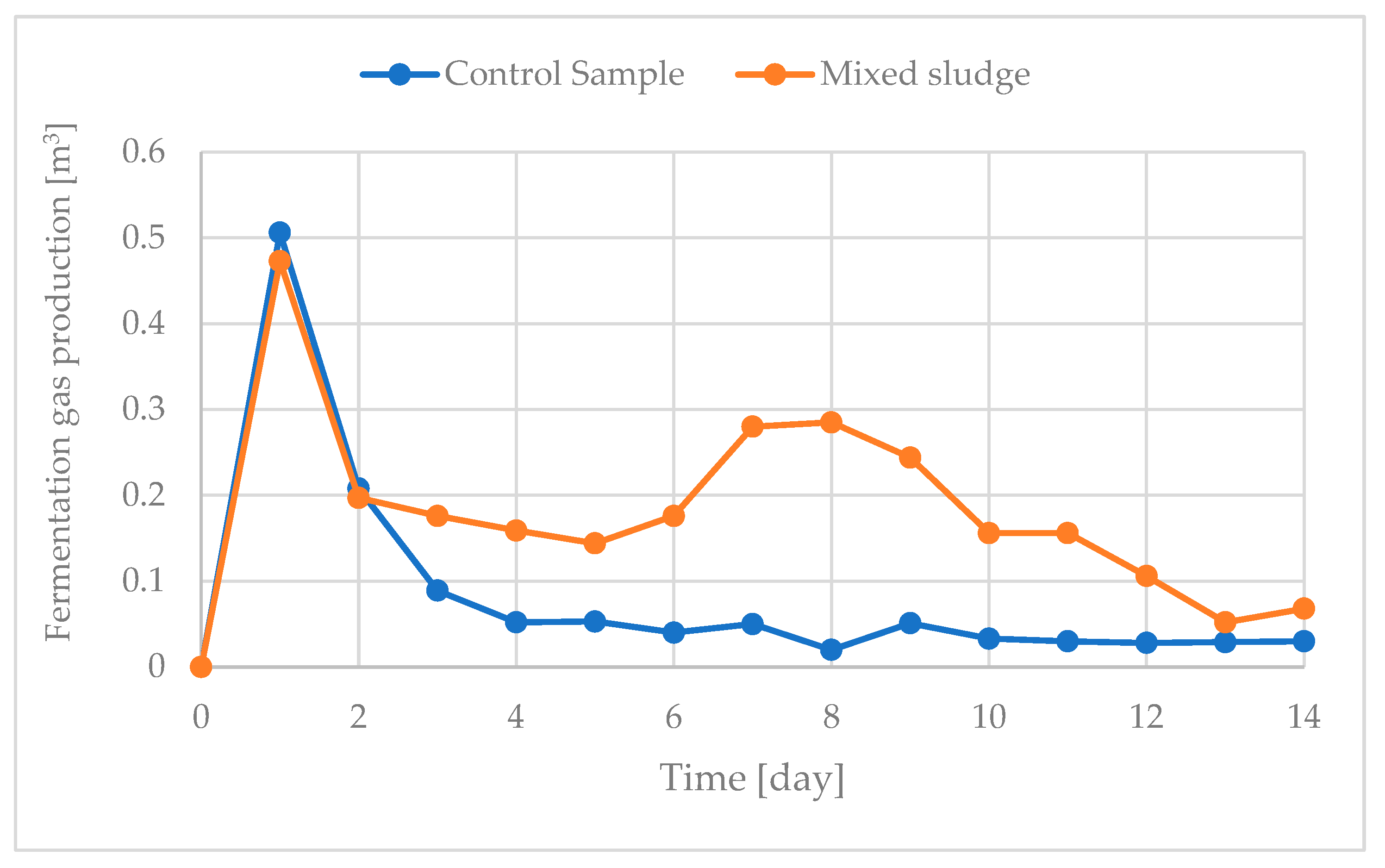

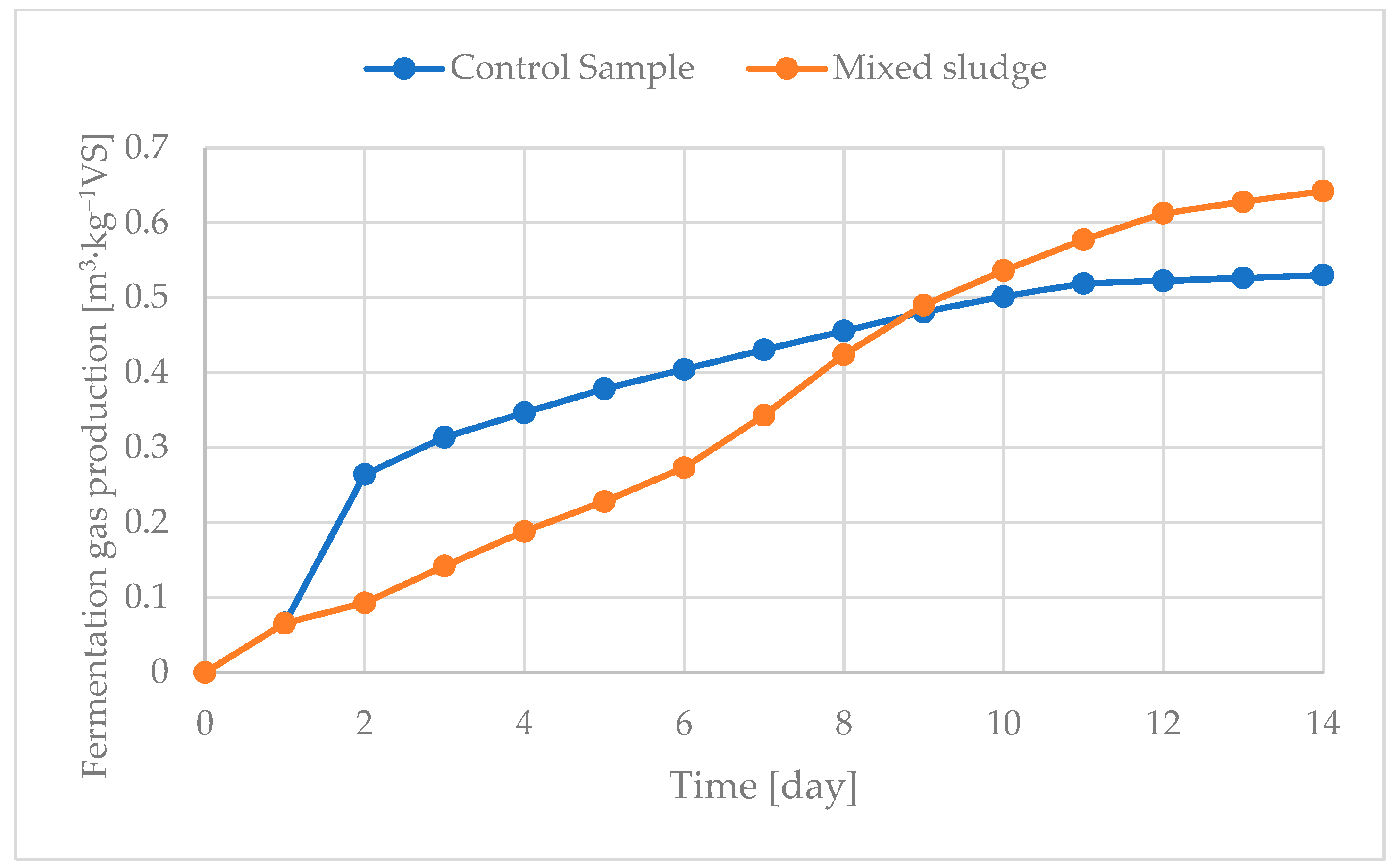

3.3. Pilot Studies

4. Discussion

5. Conclusions

- In the experimental studies, mixing and co-fermentation of water and sewage sludge had a positive effect on biogas production. Efficiency of the anaerobic stabilization of the sludge mixture was evaluated by sludge methanogenic potential. It was determined by a volume of the fermentation gas produced and the methanogenic activity of microorganisms. The laboratory analysis proved that the highest production of biogas was observed in the sludge sample with 30% water sludge (as sludge VS); in the samples with a higher water sludge proportion, a decrease in the process efficiency was observed.

- The pilot studies also confirmed that anaerobic stabilization of sewage sludge mixed with water sludge improved the process efficiency (more biogas produced). The pilot scale experiments copied the real conditions and dynamics of the full-scale process. The research enabled us to determine the parameters of the methane fermentation process, i.e., unit biogas production or reduction of an organic content in the sludge. This way proper parameters of co-fermentation in a technical scale can be selected.

- Application of water sludge in the processes of sewage sludge handling may have a positive impact on the management of waste generated in municipal water and sewage facilities (e.g., changes in sludge recovery and disposal technology).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sales, A.; De Souza, F.R.; Almeida, F.R. Mechanical properties of concrete produced with a composite of water treatment sludge and sawdust. Constr. Build. Mater. 2011, 25, 2793–2798. [Google Scholar]

- Krajewski, P.; Sozański, M. Możliwości i metody wykorzystania osadów z uzdatniania wody. Technol. Wody 2010, 5, 30–36. [Google Scholar]

- Luo, H.L.; Kuo, W.T.; Lin, D.F. The application of waterworks sludge ash to stabilization the volume of cement paste. Water Sci. Technol. 2008, 57, 243–250. [Google Scholar]

- Zdeb, T.; Tracz, T.; Adamczyk, M. Characterisation of basic properties of mineral binders with calcined water treatment sludge. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 032034. [Google Scholar]

- Zdeb, T.; Tracz, T.; Adamczyk, M. Physical, mechanical properties and durability of cement mortars containing fly ash from the sewage incineration process. J. Clean. Prod. 2022, 345, 131055. [Google Scholar]

- Dunster, A.; Petavratzi, E.; Wilson, S. Water treatment residues as a clay replacement and colorant in facing bricks. Case study: WRT 177/WR0115. Mirobre 2007. Available online: https://kipdf.com/water-treatment-residues-as-a-clay-replacement-and-colorant-in-facing-bricks_5ac259801723dd857261a33e.html (accessed on 26 June 2022).

- Ueda, N.; Okumura, Y.; Iida, Y.; Baba, K. Recovery of coagulant from water supply plant sludge and its effect on clarification. J. Mater. Cycles Waste Manag. 2007, 9, 167–172. [Google Scholar]

- Kyncl, M.; Cihalova, S.; Jurkova, M.; Langarova, S. Disposal and reuse of the water processing sludge. Inżynieria Miner. 2012, 13, 11–20. [Google Scholar]

- Ahmad, T.; Ahmad, K.; Alam, M. Sustainable management of water treatment sludge through 3R concept. J. Clean. Prod. 2016, 124, 1–13. [Google Scholar]

- Dassanayake, K.B.; Jayasinghe, G.Y.; Surapaneni, A.; Hetherington, C. A review on alum sludge reuse with special reference to agricultural applications and future challenges. Waste Manag. 2015, 38, 321–335. [Google Scholar]

- Guan, X.; Chen, G.; Shang, C. Reuse of water treatment work sludge to enhance particulate pollutant removal from sewage. Water Resour. 2005, 39, 3433–3440. [Google Scholar]

- Nair, A.T.; Ahammed, M.M. The reuse of water treatment sludge as a coagulant for post-treatment of UASB reactor treating urban wastewater. J. Clean. Prod. 2015, 96, 272–281. [Google Scholar]

- Wiewiorska, I.; Rybicki, S.M. Analysis of a coagulation sludge contamination with metals using X-ray crystallography. Desalin. Water Treat. 2022, 254, 151–159. [Google Scholar] [CrossRef]

- Yang, L.; Wei, J.; Zhang, Y.; Wang, J.; Wang, D. Reuse of acid coagulant-recovered drinking waterworks sludge residual to remove phosphorous from wastewater. Appl. Surf. Sci. 2014, 305, 337–346. [Google Scholar]

- Martins, G. Special Issue on the Intensified Conversion of Organic Waste into Biogas. Appl. Sci. 2022, 12, 3573. [Google Scholar]

- Rybicki, S.M. Specific conditions of a biogas use in sludge incineration at wastewater treatment plants. Przemysł Chem. 2020, 99, 1363–1365. [Google Scholar]

- Cimochowicz-Rybicka, M. Integrated sludge management in the water sewage sector of the urban agglomeration. Przemysł Chem. 2020, 99, 1000–1003. [Google Scholar]

- Olek, M.; Bradło, D.; Baron, J. Co-combustion of sewage sludge with post-coagulation or bottom sediments in fluidized bed boilers. Przemysł Chem. 2019, 98, 1000–1004. [Google Scholar]

- Czyżyk, F.; Kozdraś, M. Właściwości chemiczne i kompostowanie osadów z wiejskich oczyszczalni ścieków. Woda-Sr.-Obsz. Wiej. 2004, 4, 559–569. [Google Scholar]

- Rybicki, S.M.; Cimochowicz-Rybicka, M. Dimensioning of digestion chamber at wastewater treatment plant for increasing gas recovery. Arch. Environ. Prot. 2013, 39, 105–112. [Google Scholar]

- Elalami, D.; Carrere, H.; Monlau, F.; Abdelouahdi, K.; Oukarroum, A.; Barakat, A. Pretreatment and co-digestion of wastewater sludge for biogas production: Recent research advances and trends. Renew. Sustain. Energy Rev. 2019, 114, 109287. [Google Scholar]

- Abdel-Shafy, H.I.; Mansour, M.S.M. Biogas production as affected by heavy metals in the anaerobic digestion of sludge. Egypt J. Pet. 2014, 23, 409–417. [Google Scholar]

- Scarlat, N.; Dallemand, J.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar]

- Alshawaf, M.; Alsulaili, A.; Alwaeli, M.; Allanqawi, H. The Role of Biomethane from Sewage Sludge in the Energy Transition: Potentials and Barriers in the Arab Gulf States Power Sector. Appl. Sci. 2021, 11, 10275. [Google Scholar]

- Cai, M.; Wilkins, D.; Ng, S.K.; Lu, H.; Jia, Y.; Lee, P. Metagenomic reconstruction of key anaerobic digestion pathways in municipal sludge and industrial wastewater biogas-producing systems. Front. Microbiol. 2016, 7, 778. [Google Scholar]

- Murillo-Roos, M.; Uribe-Lorío, L.; Fuentes-Schweizer, P.; Vidaurre-Barahona, D.; Brenes-Guillén, L.; Jiménez, I.; Arguedas, T.; Liao, W.; Uribe, L. Biogas Production and Microbial Communities of Mesophilic and Thermophilic Anaerobic Co-Digestion of Animal Manures and Food Wastes in Costa Rica. Energies 2022, 15, 3252. [Google Scholar]

- Chala, B.; Oeschner, H.; Latif, S.; Muller, J. Biogas potential of coffee processing waste in Ethiopia. Sustainability 2018, 10, 2678. [Google Scholar]

- Wandera, S.M.; Qiao, W.; Algapani, D.E.; Bi, S.; Yin, D.; Qi, X.; Liu, Y.; Dach, J.; Dong, R. Searching for possibilities to improve the performance of full scale agricultural biogas plants. Renew. Energy 2018, 116, 720–727. [Google Scholar]

- Zhen, G.; Lu, X.; Kato, H.; Zhao, Y.; Li, Y.Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances, full-scale application, and future perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar]

- Carlini, M.; Mosconi, E.M.; Castelluci, S.; Villarini, M.; Colantoni, A. An Economical evaluation of anaerobic digestion plants with organic agro-industrial waste. Energies 2017, 10, 1165. [Google Scholar]

- Buivydas, E.; Navickas, K.; Venslauskas, K.; Žalys, B.; Župerka, V.; Rubežius, M. Biogas Production Enhancement through Chicken Manure Co-Digestion with Pig Fat. Appl. Sci. 2022, 12, 4652. [Google Scholar]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476. [Google Scholar]

- Lai, J.Y.; Liu, J.C. Co-conditioning and dewatering of alum sludge and waste activated sludge. Water Sci. Technol. 2004, 9, 41–48. [Google Scholar]

- Górka, J. Sewage sludge conditioning with water treatment sludge. Przemysł Chem. 2020, 99, 1315–1317. [Google Scholar]

- Xie, S.; Li, X.; Pham, C.U.; Nguyen, H.V.; Song, Y.; Chetty, K.; Kulandauvelu, J.; Wang, C.; Hai, F.; Jiang, G. Co-digestion of primary sewage sludge with drinking water treatment sludge: A comprehensive evaluation of benefits. Bioresour. Technol. 2021, 330, 124994. [Google Scholar]

- Cimochowicz-Rybicka, M.; Łuszczek, B.; Poproch, D.; Górka, J. Co-fermentation process of sewage sludge with water treatment sludge. Pilot scale case study. Przemysł Chem. 2021, 100, 829–831. [Google Scholar]

- Górka, J.; Cimochowicz-Rybicka, M. Water sludge co-digestion: Characteristic of the process and its possible applications. Arch. Environ. Prot. 2019, 45, 84–91. [Google Scholar]

- Płonka, I.; Barbusiński, K. Badania Wpływu Osadów z Uzdatniania Wody na Ich Przeróbkę. Ph.D. Thesis, Silesian University of Technology, Gliwice, Poland, 2008. [Google Scholar]

- Wilson, T.E.; Bizarri, R.E.; Burke, T.; Langdon, P.E.; Courson, C.M. Upgrading primary treatment with chemicals and water treatment sludge. Water Pollut. Control. Fed. 1975, 47, 2820–2833. [Google Scholar]

- Angelidaki, I.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; van Lier, J.B. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: A proposed protocol for batch assays. Water Sci. Technol. 2009, 59, 927–934. [Google Scholar]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; De Wilde, V.; et al. Towards a standardization of biomethane potential tests. Water Sci. Technol. 2016, 74, 2515–2522. [Google Scholar]

- Yazdani, M.; Ebrahimi-Nik, M.; Heidari, A.; Abbaspour-Fard, M.H. Improvement of biogas production from slaughterhouse wastewater using biosynthesized iron nanoparticles from water treatment sludge. Renew. Energy 2019, 135, 496–501. [Google Scholar]

- Ebrahimi-Nik, M.; Heidari, A.; Ramezani Azghandi, S.; Asadi Mohammadi, F.; Younesi, H. Drinking water treatment sludge as an effective additive for biogas production from food waste; kinetic evaluation and biomethane potential test. Bioresour. Technol. 2018, 260, 421–426. [Google Scholar]

| Parameters | Unit | Control Sample | Mixed Sludge | ||||

|---|---|---|---|---|---|---|---|

| Day | day | 0 | 7 | 14 | 0 | 7 | 14 |

| TS | % | 3.4 | 2.5 | 2.6 | 3.5 | 3.2 | 2.9 |

| VS | % TS | 62.7 | 67.3 | 59.2 | 62.0 | 55.7 | 55.7 |

| Alkalinity | mgCaCO3/dm3 | 4155 | 5650 | 4898 | 4310 | 5588 | 6010 |

| Volatile fatty acids | mg/dm3 | 106 | 1423 | 624 | 100 | 1516 | 445 |

| pH | - | 7.3 | 7.6 | 7.3 | 7.3 | 7.7 | 8.0 |

| Ammonium nitrogen | % TS | 3.59 | 6.71 | 5.55 | 3.69 | 5.42 | 6.07 |

| Total phosphorus | % TS | 2.44 | 2.75 | 2.58 | 2.81 | 2.76 | 2.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Górka, J.; Cimochowicz-Rybicka, M.; Poproch, D. Sludge Management at the Kraków-Płaszów WWTP—Case Study. Sustainability 2022, 14, 7982. https://doi.org/10.3390/su14137982

Górka J, Cimochowicz-Rybicka M, Poproch D. Sludge Management at the Kraków-Płaszów WWTP—Case Study. Sustainability. 2022; 14(13):7982. https://doi.org/10.3390/su14137982

Chicago/Turabian StyleGórka, Justyna, Małgorzata Cimochowicz-Rybicka, and Dominika Poproch. 2022. "Sludge Management at the Kraków-Płaszów WWTP—Case Study" Sustainability 14, no. 13: 7982. https://doi.org/10.3390/su14137982

APA StyleGórka, J., Cimochowicz-Rybicka, M., & Poproch, D. (2022). Sludge Management at the Kraków-Płaszów WWTP—Case Study. Sustainability, 14(13), 7982. https://doi.org/10.3390/su14137982