Effect of a Novel Vibration Mixing on the Fiber Distribution and Mechanical Properties of Ultra-High Performance Concrete

Abstract

:1. Introduction

2. Materials

2.1. Raw Materials

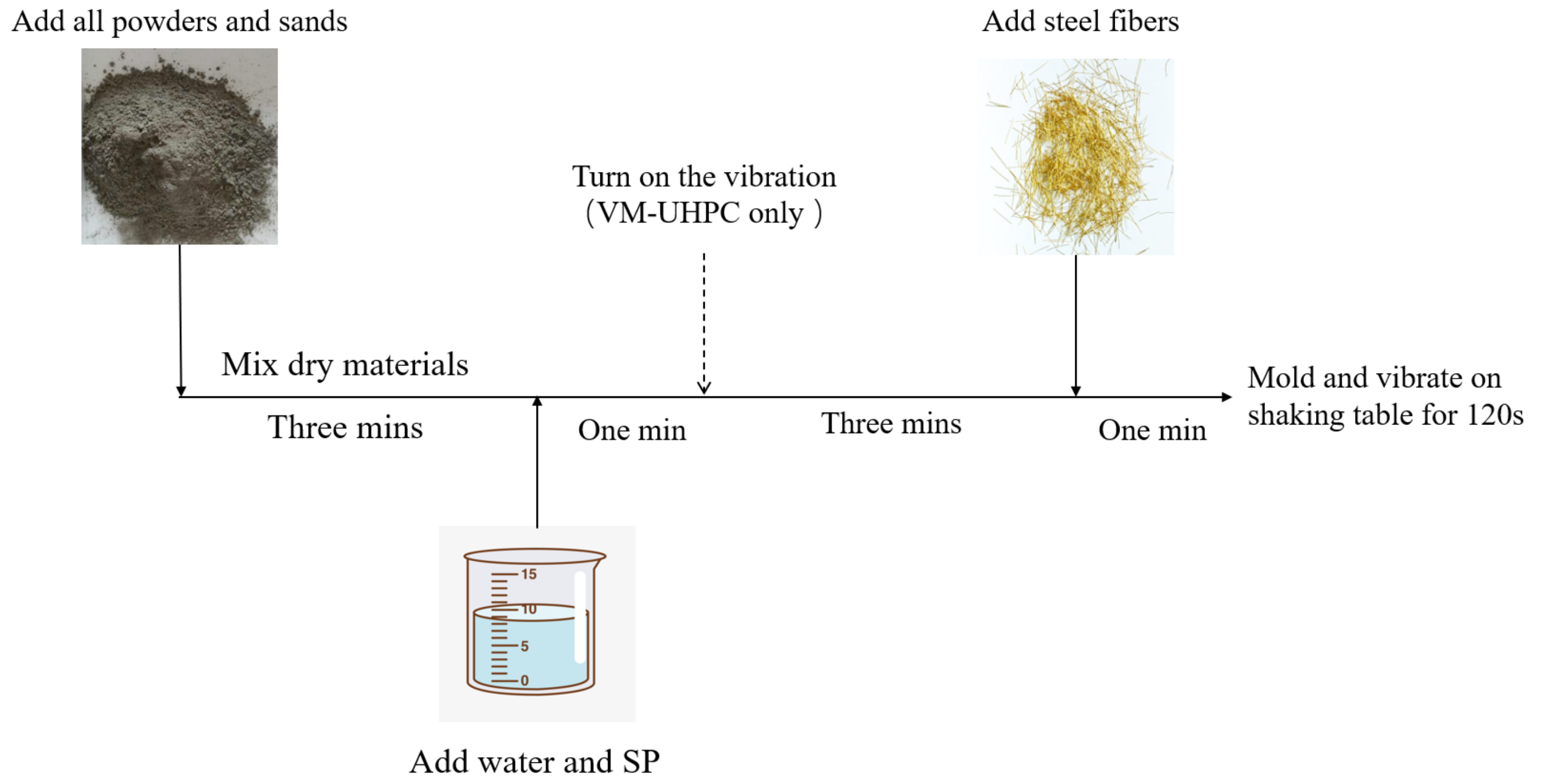

2.2. Specimen Preparation

3. Testing Methods

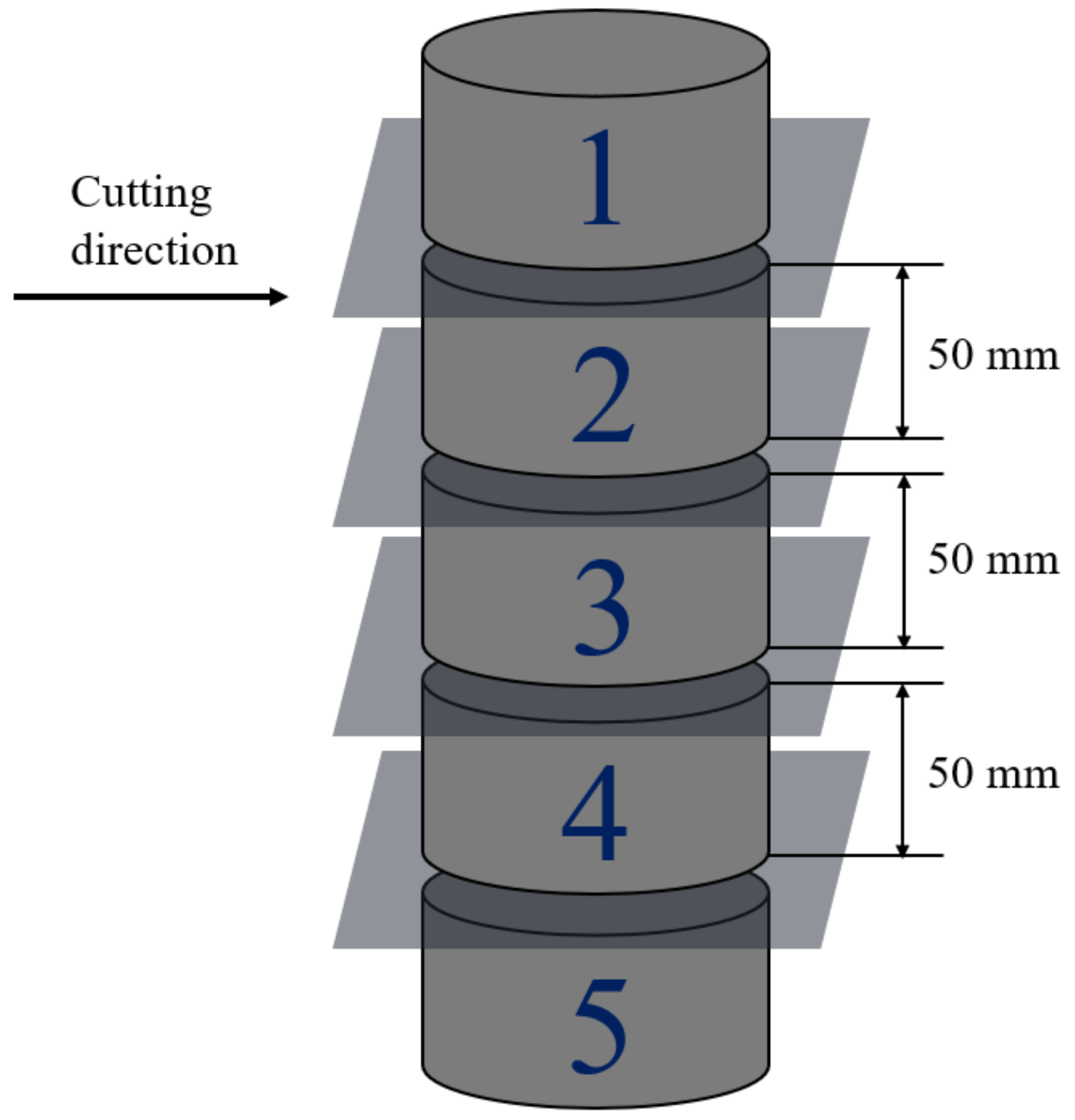

3.1. Fiber Distribution

- n is the number of cross-sectionally evenly divided cells, equal to 16;

- represents the number of fibers in the ith cell; and

- is the average number of fibers in each cell.

3.2. Fiber Orientation

3.3. Pore Structure

3.4. Static Mechanical Tests

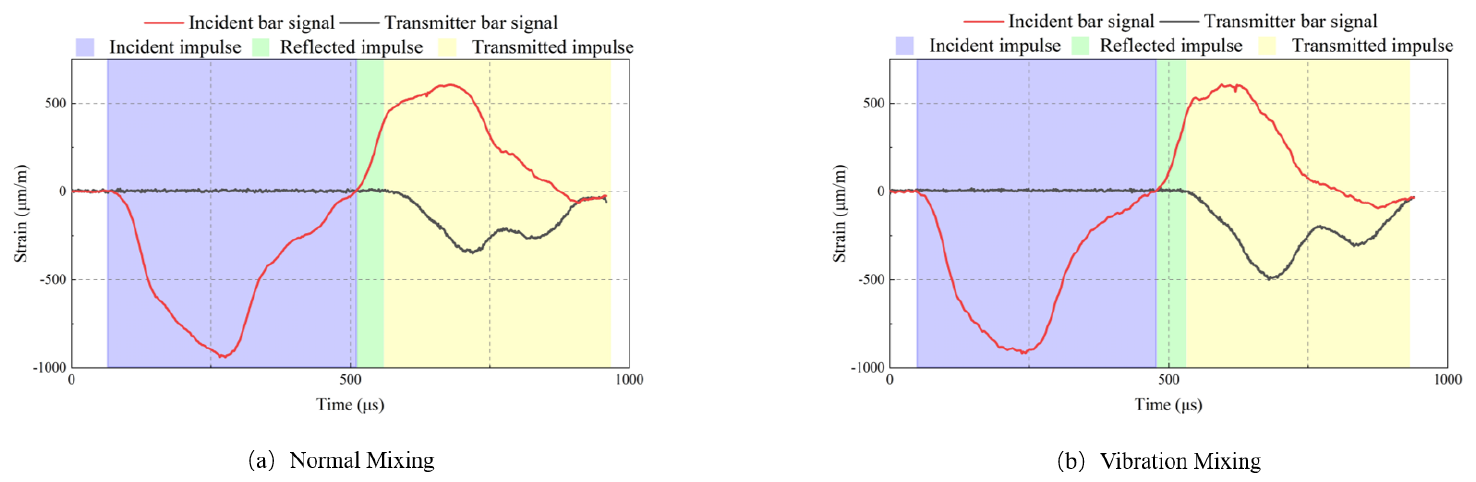

3.5. Impact Resistance Test

- and represent the reflected and transmitted impulse;

- A and denote the cross-sectional area of the bars and specimens;

- represents the length of specimens (50 mm); and

- [46].

4. Results and Analysis

4.1. Fiber Distribution

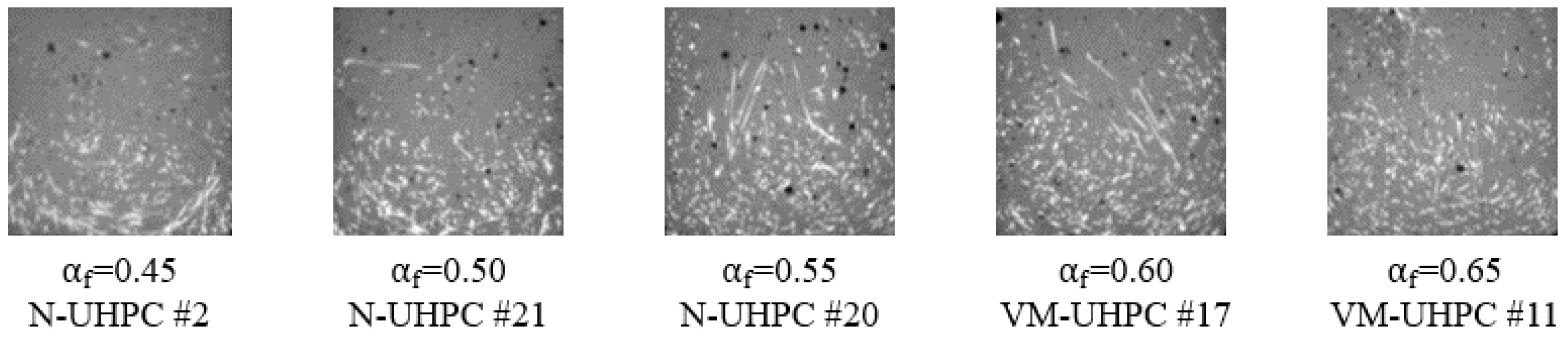

4.2. Fiber Orientation

4.3. Pore Structure and Distribution

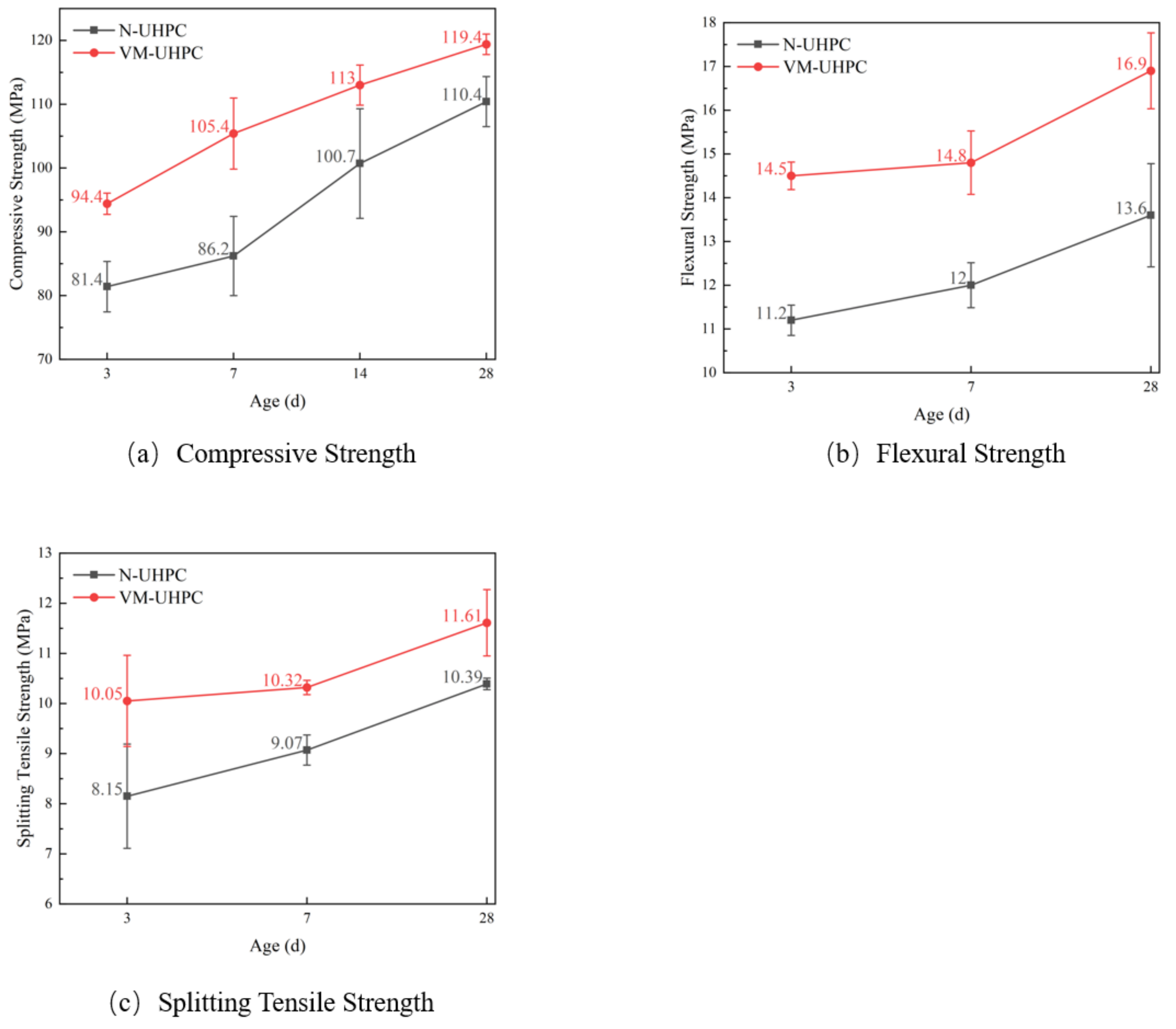

4.4. Mechanical Test Results

4.5. Impact Test Results

4.6. Mechanisms

5. Conclusions

- The vibration mixing technology has a positive effect on enhancing the uniformity of the distribution of steel fibers in UHPC. The cross-sections of different samples were scanned by X-CT and the number of fiber distributions at different locations in the same cross-section was counted using a computer. The fiber distribution coefficient and the percentage of fibers in the favorable direction (within 60°) of tensile strength were calculated and analysis to evaluate the effect of vibratory agitation technique on the enhancement of fiber distribution in UHPC. The results of scanning and calculations show that the vibration mixing technique could enhance the uniformity of fiber distribution in the UHPC matrix and reduce the agglomeration effect of steel fibers. The average fiber distribution coefficient was improved from 0.512 to 0.581 with same uniformity in different sections. Furthermore, the vibration mixing technology has a positive effect on the improvement of fiber orientation, and the effective fiber percentage of tensile strength is increased from 85.2% to 87.7%, which indicates that the vibration mixing technology may have a positive effect on the improvement of tensile properties of UHPC especially in some beam or plate structures.

- Vibratory mixing technology can improve the static properties of UHPC. The static test results show that the vibratory mixing technique can improve the static strength of UHPC at various ages, including compressive strength, tensile strength and flexural strength. In the early age stage, the improvement of static mechanical properties by a more uniform distribution of steel fibers is more obvious because the hydration of concrete is not yet complete. The enhancement of the mechanical properties of UHPC by the vibratory mixing technique is more effective in the early stage of hydration. At the age of 28 days, the static mechanical properties of the vibratory mixing group were still better than those of N-UHPC.

- The results of SHPB based impact tests show that the vibratory mixing technique helps to improve the mechanical strength, impact resistance and toughness of UHPC.

- The vibration mixing method proposed in this research can be used to produce higher quality UHPC or reduce the usage of possible high energy-consuming raw materials, cement for instance, to obtain UHPC with the same performance as traditional mixing methods in the future. The vibration mixing technology would provide a reference for future design and manufacturing of UHPC to mitigate the emission of pollutants, especially, from cement production and transportation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, R.; Spiesz, P.; Brouwers, H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Z.; Gao, Q.; Liu, C. A new mixture design methodology based on the Packing Density Theory for high performance concrete in bridge engineering. Constr. Build. Mater. 2018, 182, 80–93. [Google Scholar] [CrossRef]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and numerical study on mechanical properties of Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 156, 402–411. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Teng, L. Fiber alignment and its effect on mechanical properties of UHPC: An overview. Constr. Build. Mater. 2021, 296, 123741. [Google Scholar] [CrossRef]

- Zhou, Y.; Hou, D.; Jiang, J.; Liu, L.; She, W.; Yu, J. Experimental and molecular dynamics studies on the transport and adsorption of chloride ions in the nano-pores of calcium silicate phase: The influence of calcium to silicate ratios. Microporous Mesoporous Mater. 2018, 255, 23–35. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S.; Liu, Z.; Hansen, W. Effects of silica powder and cement type on durability of ultra high performance concrete (UHPC). Cem. Concr. Compos. 2016, 66, 47–56. [Google Scholar] [CrossRef]

- Zhou, Y.; Hou, D.; Jiang, J.; Wang, P. Chloride ions transport and adsorption in the nano-pores of silicate calcium hydrate: Experimental and molecular dynamics studies. Constr. Build. Mater. 2016, 126, 991–1001. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of ultra-high performance concrete—A review. Constr. Build. Mater. 2020, 255, 119296. [Google Scholar] [CrossRef]

- Xue, J.; Briseghella, B.; Huang, F.; Nuti, C.; Tabatabai, H.; Chen, B. Review of ultra-high performance concrete and its application in bridge engineering. Constr. Build. Mater. 2020, 260, 119844. [Google Scholar] [CrossRef]

- Xu, S.; Wu, P.; Wu, C. Calibration of KCC concrete model for UHPC against low-velocity impact. Int. J. Impact Eng. 2020, 144, 103648. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Li, J.; Liu, Z.; Xu, S.; Liu, K.; Su, Y.; Fang, J.; Chen, G. Projectile impact resistance of fibre-reinforced geopolymer-based ultra-high performance concrete (G-UHPC). Constr. Build. Mater. 2021, 290, 123189. [Google Scholar] [CrossRef]

- Lin, Y.; Yan, J.; Wang, Z.; Zou, C. Effects of steel fibers on failure mechanism of S-UHPC composite beams applied in the Arctic offshore structure. Ocean. Eng. 2021, 234, 109302. [Google Scholar] [CrossRef]

- Tazarv, M.; Saiidi, M.S. UHPC-filled duct connections for accelerated bridge construction of RC columns in high seismic zones. Eng. Struct. 2015, 99, 413–422. [Google Scholar] [CrossRef]

- Fehling, E.; Bunje, K.; Schmidt, M.; Tue, N.V.; Schreiber, W.; Humburg, E. Design of first hybrid UHPC-steel bridge across River Fulda in Kassel, Germany. In Proceedings of the IABSE Symposium: Improving Infrastructure Worldwide, Weimar, Germany, 19–21 September 2007; pp. 328–329. [Google Scholar]

- Ahmad, S.; Rasul, M.; Adekunle, S.K.; Al-Dulaijan, S.U.; Maslehuddin, M.; Ali, S.I. Mechanical properties of steel fiber-reinforced UHPC mixtures exposed to elevated temperature: Effects of exposure duration and fiber content. Compos. Part B Eng. 2019, 168, 291–301. [Google Scholar] [CrossRef]

- Voit, K.; Kirnbauer, J. Tensile characteristics and fracture energy of fiber reinforced and non-reinforced ultra high performance concrete (UHPC). Int. J. Fract. 2014, 188, 147–157. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Su, B.; Turng, L.S. Mechanical properties, fiber orientation, and length distribution of glass fiber-reinforced polypropylene parts: Influence of water-foaming technology. Polym. Compos. 2018, 39, 4386–4399. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. Effect of nano-SiO2 particles and curing time on development of fiber-matrix bond properties and microstructure of ultra-high strength concrete. Cem. Concr. Res. 2017, 95, 247–256. [Google Scholar] [CrossRef] [Green Version]

- Larsen, I.L.; Thorstensen, R.T. The influence of steel fibres on compressive and tensile strength of ultra high performance concrete: A review. Constr. Build. Mater. 2020, 256, 119459. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, S.; Park, G.J.; Park, J.J.; Kim, S.W. Effects of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high-performance fiber-reinforced cement composites. Compos. Struct. 2017, 174, 375–388. [Google Scholar] [CrossRef]

- Crawford, M.A. Copper-Coated Containers and Their Impact on the Environment. Available online: https://books.google.com.hk/books?hl=zh-CN&lr=&id=mx_xAAAAMAAJ&oi=fnd&pg=PA76&dq=Copper-coated+containers+and+their+impact+on+the+environment.&ots=j1BKN9ZpR6&sig=Cig8OB2qWClGzg3YtYA7Lq9xD2U&redir_esc=y&hl=zh-CN&sourceid=cndr#v=onepage&q=Copper-coated%20containers%20and%20their%20impact%20on%20the%20environment.&f=false (accessed on 8 May 2022).

- Khayat, K.H.; Meng, W.; Vallurupalli, K.; Teng, L. Rheological properties of ultra-high-performance concrete—An overview. Cem. Concr. Res. 2019, 124, 105828. [Google Scholar] [CrossRef]

- Atzeni, C.; Massidda, L.; Sanna, U. Comparison between rheological models for portland cement pastes. Cem. Concr. Res. 1985, 15, 511–519. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, J.; Yang, X.; Dong, Y.; Feng, T.; Liu, J. Enhancing the PVA fiber-matrix interface properties in ultra high performance concrete: An experimental and molecular dynamics study. Constr. Build. Mater. 2021, 285, 122862. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, H.; Wang, R. Influence of steel fiber distribution on splitting damage and transport properties of ultra-high performance concrete. Cem. Concr. Compos. 2022, 126, 104373. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X.; Huang, H.; Han, G. Influence of rheological properties of cement mortar on steel fiber distribution in UHPC. Constr. Build. Mater. 2017, 144, 65–73. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Qu, S.; Kumar, A.; Shao, X. Improvement of flexural and tensile strength of layered-casting UHPC with aligned steel fibers. Constr. Build. Mater. 2020, 251, 118893. [Google Scholar] [CrossRef]

- Yahia, A.; Khayat, K. Applicability of rheological models to high-performance grouts containing supplementary cementitious materials and viscosity enhancing admixture. Mater. Struct. 2003, 36, 402–412. [Google Scholar] [CrossRef]

- Choi, M.S.; Lee, J.S.; Ryu, K.S.; Koh, K.T.; Kwon, S.H. Estimation of rheological properties of UHPC using mini slump test. Constr. Build. Mater. 2016, 106, 632–639. [Google Scholar] [CrossRef]

- Cui, J.; He, Z.; Zhang, G.; Cai, X. Rheological properties of sprayable ultra-high performance concrete with different viscosity-enhancing agents. Constr. Build. Mater. 2022, 321, 126154. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, Y.; Huang, X.; Min, Y.; Luo, H.; Chen, Y.; Li, W. Study on performance improvement of ultra-high performance concrete by vibration mixing. Constr. Build. Mater. 2022, 327, 126823. [Google Scholar] [CrossRef]

- Feng, X.N.; Feng, Z.X.; Wang, W.Z. Review on concrete vibratory mixing techniques. Chin. J. Constr. Mach. 2007, 5, 113–116. [Google Scholar]

- Shen, H.; Duan, Z.S.; Li, F. The Evaluation about Vibratory Mixing Methods. Available online: https://www.scientific.net/AMM.217-219.2678 (accessed on 8 May 2022).

- Chu, H.; Gao, L.; Qin, J.; Jiang, J.; Wang, D. Mechanical properties and microstructure of ultra-high-performance concrete with high elastic modulus. Constr. Build. Mater. 2022, 335, 127385. [Google Scholar] [CrossRef]

- Yu, Q.; Brouwers, H. Development of a self-compacting gypsum-based lightweight composite. Cem. Concr. Compos. 2012, 34, 1033–1043. [Google Scholar] [CrossRef]

- Bi, J.; Zheng, N.; Zhang, F. Study on the application of vibration mixing for cement stabilized crushed stone. In Proceedings of the Southern African Transport Conference, Pretoria, South Africa, 10–13 July 2017. [Google Scholar]

- Fu, S.Y.; Lauke, B. Effects of fiber length and fiber orientation distributions on the tensile strength of short-fiber-reinforced polymers. Compos. Sci. Technol. 1996, 56, 1179–1190. [Google Scholar] [CrossRef]

- Advani, S.G.; Tucker, C.L., III. The use of tensors to describe and predict fiber orientation in short fiber composites. J. Rheol. 1987, 31, 751–784. [Google Scholar] [CrossRef]

- Pansuk, W.; Sato, H.; Sato, Y.; Shionaga, R. Tensile behaviors and fiber orientation of UHPC. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; Kassel University Press: Kassel, Germany; pp. 161–168. [Google Scholar]

- Huang, H.; Gao, X.; Li, L.; Wang, H. Improvement effect of steel fiber orientation control on mechanical performance of UHPC. Constr. Build. Mater. 2018, 188, 709–721. [Google Scholar] [CrossRef]

- De Larrard, F.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, R.; Shui, Z.; Liu, K. Hydration kinetics and microstructure development of Ultra-High Performance Concrete (UHPC) subjected to microwave pre-curing. Cem. Concr. Compos. 2022, 129, 104484. [Google Scholar] [CrossRef]

- Liu, P.; Hu, D.; Wu, Q.; Liu, X. Sensitivity and uncertainty analysis of interfacial effect in SHPB tests for concrete-like materials. Constr. Build. Mater. 2018, 163, 414–427. [Google Scholar] [CrossRef]

- Bai, Y.l.; Yan, Z.W.; Jia, J.F.; Ozbakkaloglu, T.; Liu, Y. Dynamic compressive behavior of concrete confined with unidirectional natural flax FRP based on SHPB tests. Compos. Struct. 2021, 259, 113233. [Google Scholar] [CrossRef]

- Al-Mousawi, M.; Reid, S.; Deans, W. The use of the split Hopkinson pressure bar techniques in high strain rate materials testing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1997, 211, 273–292. [Google Scholar] [CrossRef]

- Raju, R.A.; Lim, S.; Akiyama, M.; Kageyama, T. Effects of concrete flow on the distribution and orientation of fibers and flexural behavior of steel fiber-reinforced self-compacting concrete beams. Constr. Build. Mater. 2020, 262, 119963. [Google Scholar] [CrossRef]

- Zheng, J.J.; Li, C.Q. Three-dimensional aggregate density in concrete with wall effect. Mater. J. 2002, 99, 568–575. [Google Scholar]

- Xu, W.; Lv, Z.; Chen, H. Effects of particle size distribution, shape and volume fraction of aggregates on the wall effect of concrete via random sequential packing of polydispersed ellipsoidal particles. Phys. A Stat. Mech. Its Appl. 2013, 392, 416–426. [Google Scholar] [CrossRef]

- Lee, Y.; Kang, S.T.; Kim, J.K. Pullout behavior of inclined steel fiber in an ultra-high strength cementitious matrix. Constr. Build. Mater. 2010, 24, 2030–2041. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Yoon, Y.S. Effect of fiber length and placement method on flexural behavior, tension-softening curve, and fiber distribution characteristics of UHPFRC. Constr. Build. Mater. 2014, 64, 67–81. [Google Scholar] [CrossRef]

- Ren, G.; Wu, H.; Fang, Q.; Liu, J. Effects of steel fiber content and type on dynamic compressive mechanical properties of UHPCC. Constr. Build. Mater. 2018, 164, 29–43. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Sun, H.; Wu, S. Transient dynamic behavior of polypropylene fiber reinforced mortar under compressive impact loading. Constr. Build. Mater. 2016, 111, 30–42. [Google Scholar] [CrossRef]

- Yao, Y.; Feng, Z.; Chen, S.; Li, B.Q.; Zhao, L.; Zhao, W. A double-blade mixer for concrete with improved mixing quality. Arab. J. Sci. Eng. 2016, 41, 4809–4816. [Google Scholar] [CrossRef]

- Feng, Z.X.; Zhao, L.J.; Yao, Y.S.; Jiang, J.W.; Wang, W.Z. Mixing inefficient zone of concrete mixer and its eliminating methods. J. Chang. Univ. (Nat. Sci. Ed.) 2005, 6, 82–85. [Google Scholar]

- Zhou, Y.; Zheng, H.; Li, W.; Ma, T.; Miao, C. A deep learning potential applied in tobermorite phases and extended to calcium silicate hydrates. Cem. Concr. Res. 2022, 152, 106685. [Google Scholar] [CrossRef]

- Zhou, Y.; Hou, D.; Manzano, H.; Orozco, C.A.; Geng, G.; Monteiro, P.J.; Liu, J. Interfacial connection mechanisms in calcium–silicate–hydrates/polymer nanocomposites: A molecular dynamics study. ACS Appl. Mater. Interfaces 2017, 9, 41014–41025. [Google Scholar] [CrossRef]

- Feng, X.; Feng, Z.; Wang, W. A review of concrete vibratory mixing technology research. Chin. J. Constr. Mach. 2007, 1, 113–116. [Google Scholar]

- Feng, Z.; Zhao, L.; Chen, W.; Zhang, L. Lecture on mixing equipment design (20th lecture) 1 m3 double horizontal shaft concrete vibratory mixer. Constr. Mach. 2014, 4, 63–68. [Google Scholar]

| Materials | Cement | Fly Ash | Silica Fume |

|---|---|---|---|

| CaO | 63.6% | 17.60% | 0.2% |

| SiO2 | 19.7% | 65.65% | 95.4% |

| Al2O3 | 4.5% | 6.91% | 0.3% |

| Fe2O3 | 3.0% | 0.06% | 0.8% |

| SO3 | 2.9% | - | 0.2% |

| MgO | 1.3% | 0.08% | - |

| K2O | 0.7% | 0.04% | - |

| Na2O | 0.1% | 0.35% | - |

| TiO2 | 0.3% | 0.15% | - |

| P2O5 | - | 0.02% | - |

| Age | N-UHPC | VM-UHPC | Enhancement Rate |

|---|---|---|---|

| (d) | (MPa) | (MPa) | (%) |

| 3 | 81.4 | 94.4 | 16.0 |

| 7 | 86.2 | 105.4 | 22.2 |

| 14 | 100.7 | 113.0 | 12.2 |

| 28 | 110.4 | 119.4 | 8.1 |

| Age | N-UHPC | VM-UHPC | Enhancement Rate |

|---|---|---|---|

| (d) | (MPa) | (MPa) | (%) |

| 3 | 11.2 | 14.5 | 29.5 |

| 7 | 12.0 | 14.8 | 23.1 |

| 28 | 13.6 | 16.9 | 24.6 |

| Age | N-UHPC | VM-UHPC | Enhancement Rate |

|---|---|---|---|

| (d) | (MPa) | (MPa) | (%) |

| 3 | 8.15 | 10.05 | 23.6 |

| 7 | 9.07 | 10.32 | 13.8 |

| 28 | 10.39 | 11.61 | 11.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Zhou, Y.; Nie, F.; Luo, H.; Huang, X. Effect of a Novel Vibration Mixing on the Fiber Distribution and Mechanical Properties of Ultra-High Performance Concrete. Sustainability 2022, 14, 7920. https://doi.org/10.3390/su14137920

Zheng Y, Zhou Y, Nie F, Luo H, Huang X. Effect of a Novel Vibration Mixing on the Fiber Distribution and Mechanical Properties of Ultra-High Performance Concrete. Sustainability. 2022; 14(13):7920. https://doi.org/10.3390/su14137920

Chicago/Turabian StyleZheng, Yangzezhi, Yang Zhou, Fan Nie, Haoyuan Luo, and Xiaoming Huang. 2022. "Effect of a Novel Vibration Mixing on the Fiber Distribution and Mechanical Properties of Ultra-High Performance Concrete" Sustainability 14, no. 13: 7920. https://doi.org/10.3390/su14137920

APA StyleZheng, Y., Zhou, Y., Nie, F., Luo, H., & Huang, X. (2022). Effect of a Novel Vibration Mixing on the Fiber Distribution and Mechanical Properties of Ultra-High Performance Concrete. Sustainability, 14(13), 7920. https://doi.org/10.3390/su14137920