Research on the Characteristics of Infrared Radiation and Energy Evolution Law of Red Sandstone with Different Porosity during Uniaxial Compression

Abstract

:1. Introduction

2. Materials and Test Methods

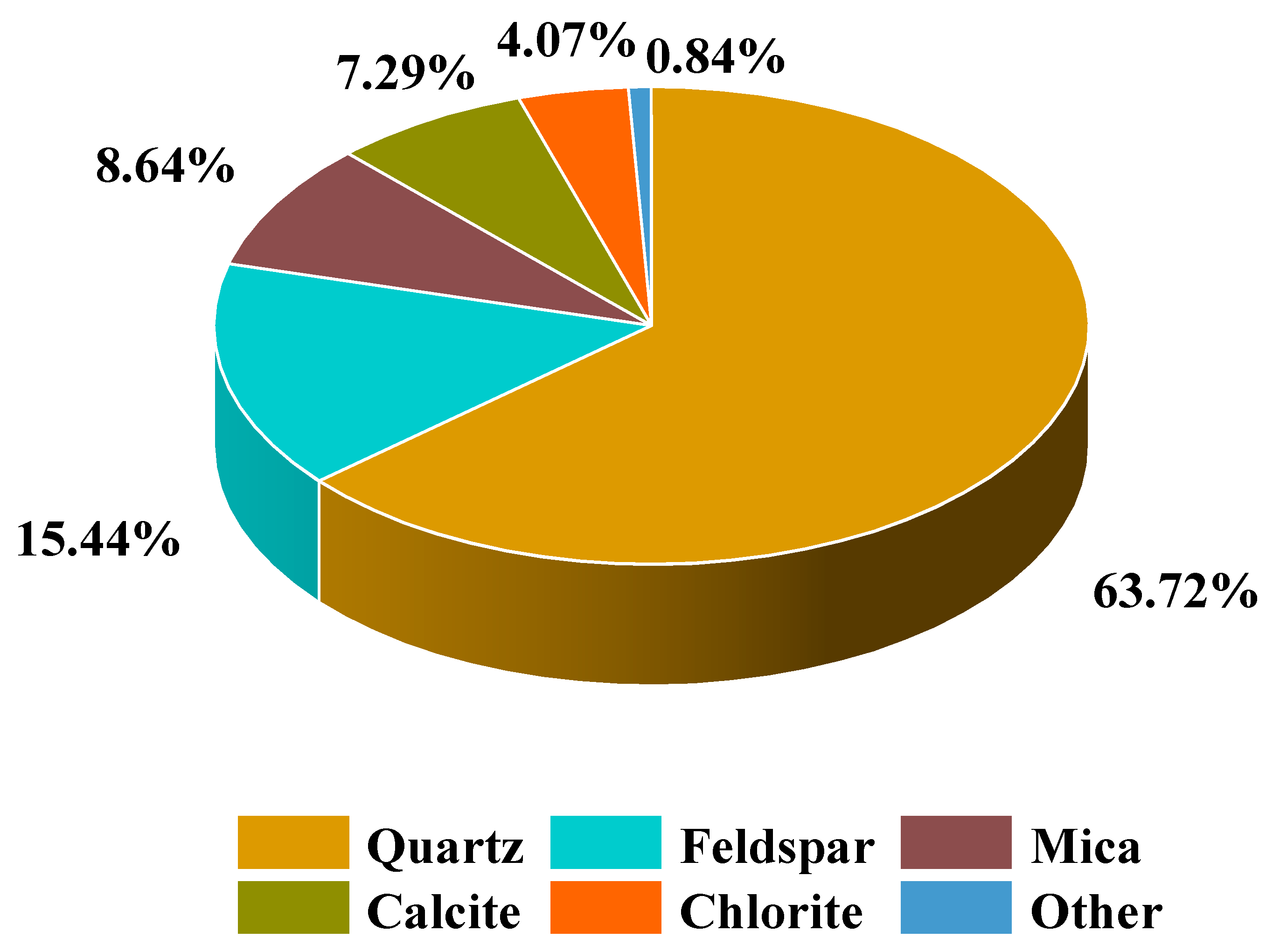

2.1. Specimen Preparation

2.2. Test Methods

2.2.1. NMR Test

2.2.2. Mechanical Tests

- (1)

- The rock sample was placed in the laboratory for 24 h so that the temperature of the specimen is consistent with the temperature environment of the laboratory, then mechanical and infrared detection tests were performed.

- (2)

- During the test, the thermal imaging camera was placed at approximately 1 m from the opposite rock sample (as shown in Figure 2), and loaded in a displacement control mode with a loading rate of 0.15 mm/min. To reduce the influence of the surrounding environment on the infrared radiation of the rock, the doors, windows, and lights were closed during the test to simultaneously reduce the influence of sunlight and lights on the detection effect.

- (3)

- The parameters of the thermal imaging camera were adjusted and pressed so that the thermal image acquisition frequency was consistent with the frequency of the stress displacement collected by the press, and the loading test was performed to obtain relevant information.

3. Results and Discussion

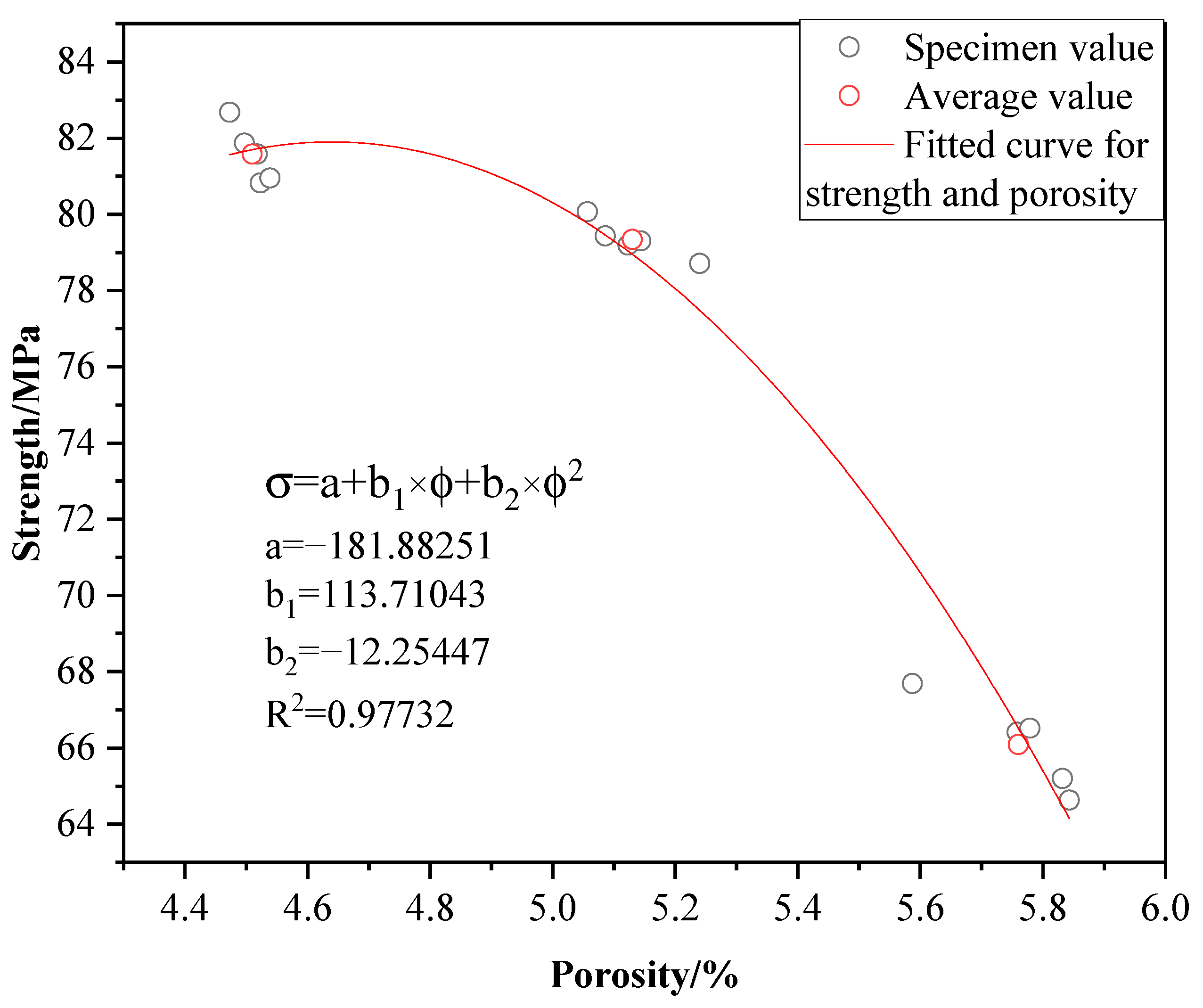

3.1. Rock Mechanical Properties Change with Porosity

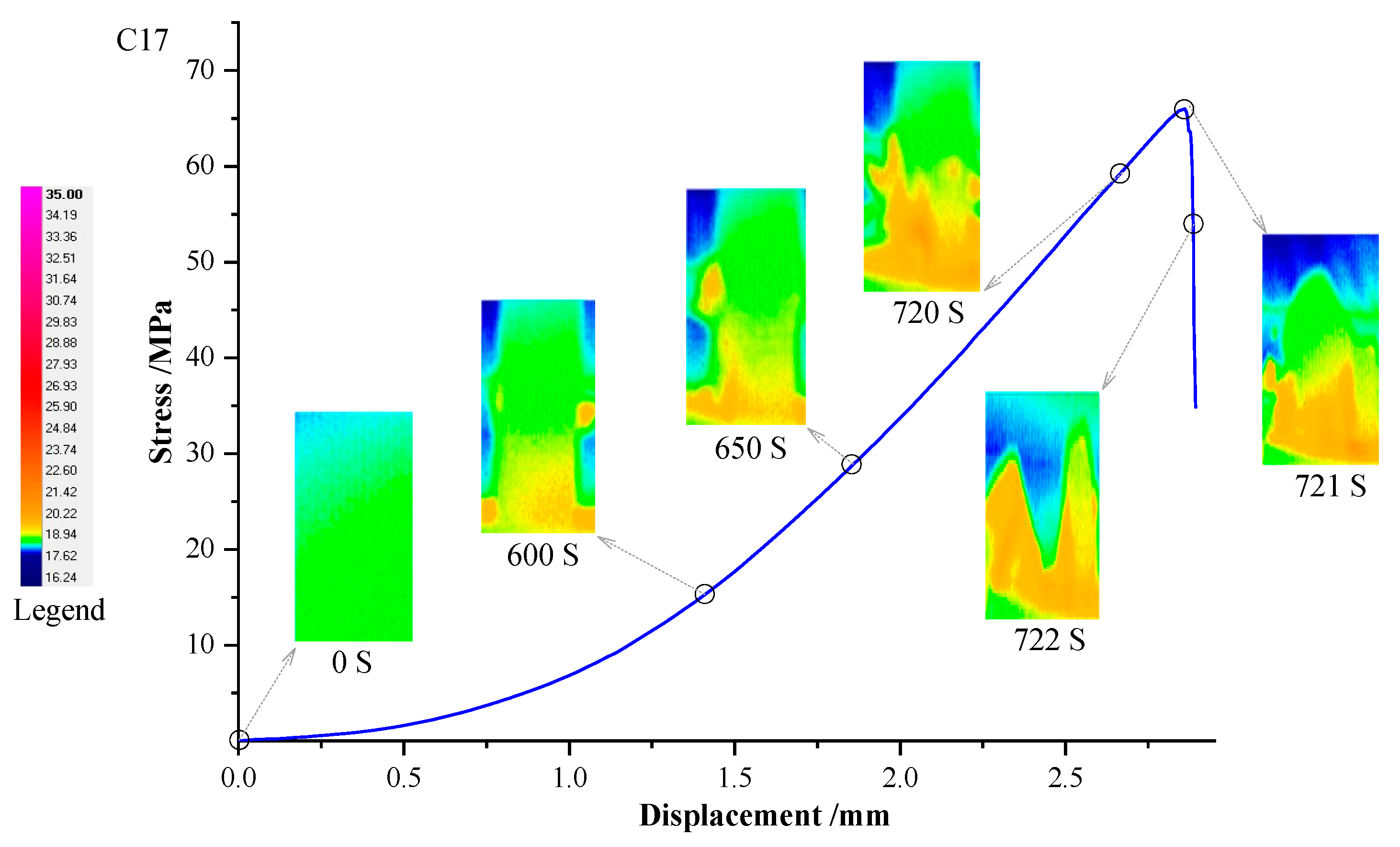

3.2. Infrared Thermal Image Variation Characteristics

3.3. AIRT Evolutionary Characteristics during Loading

3.4. Energy Analysis during Loading

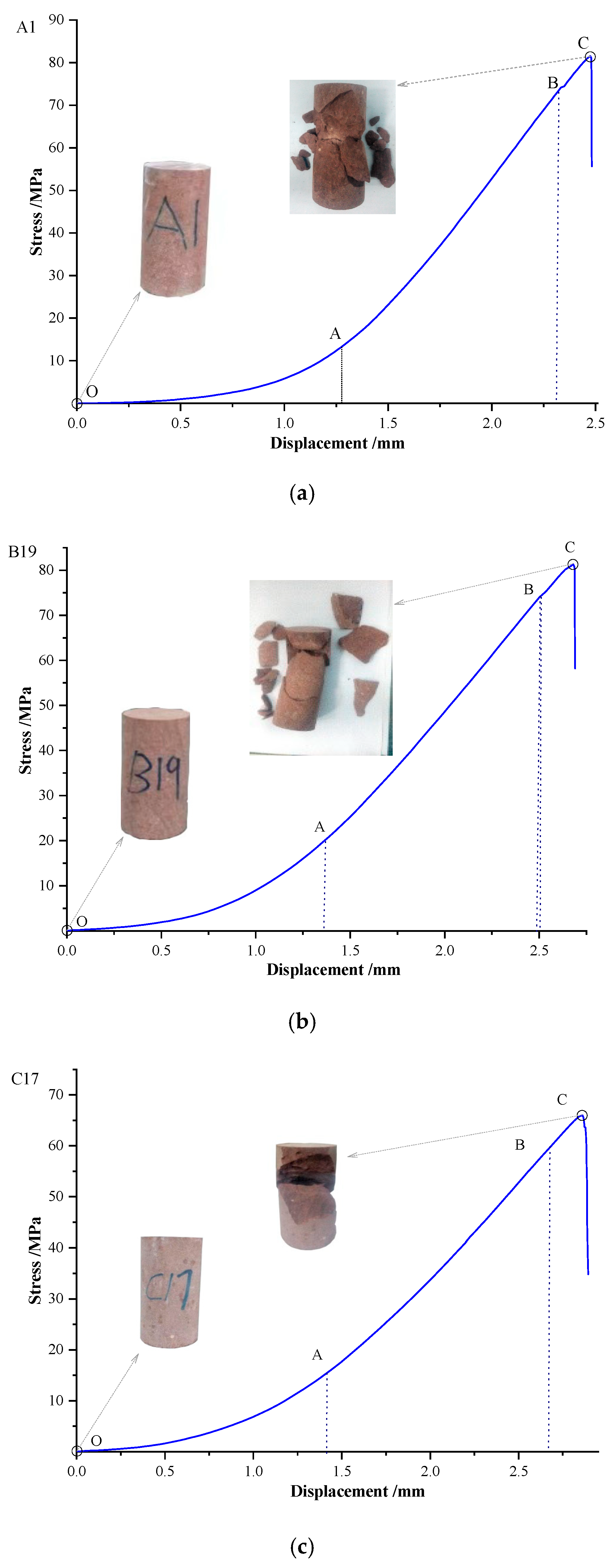

- (1)

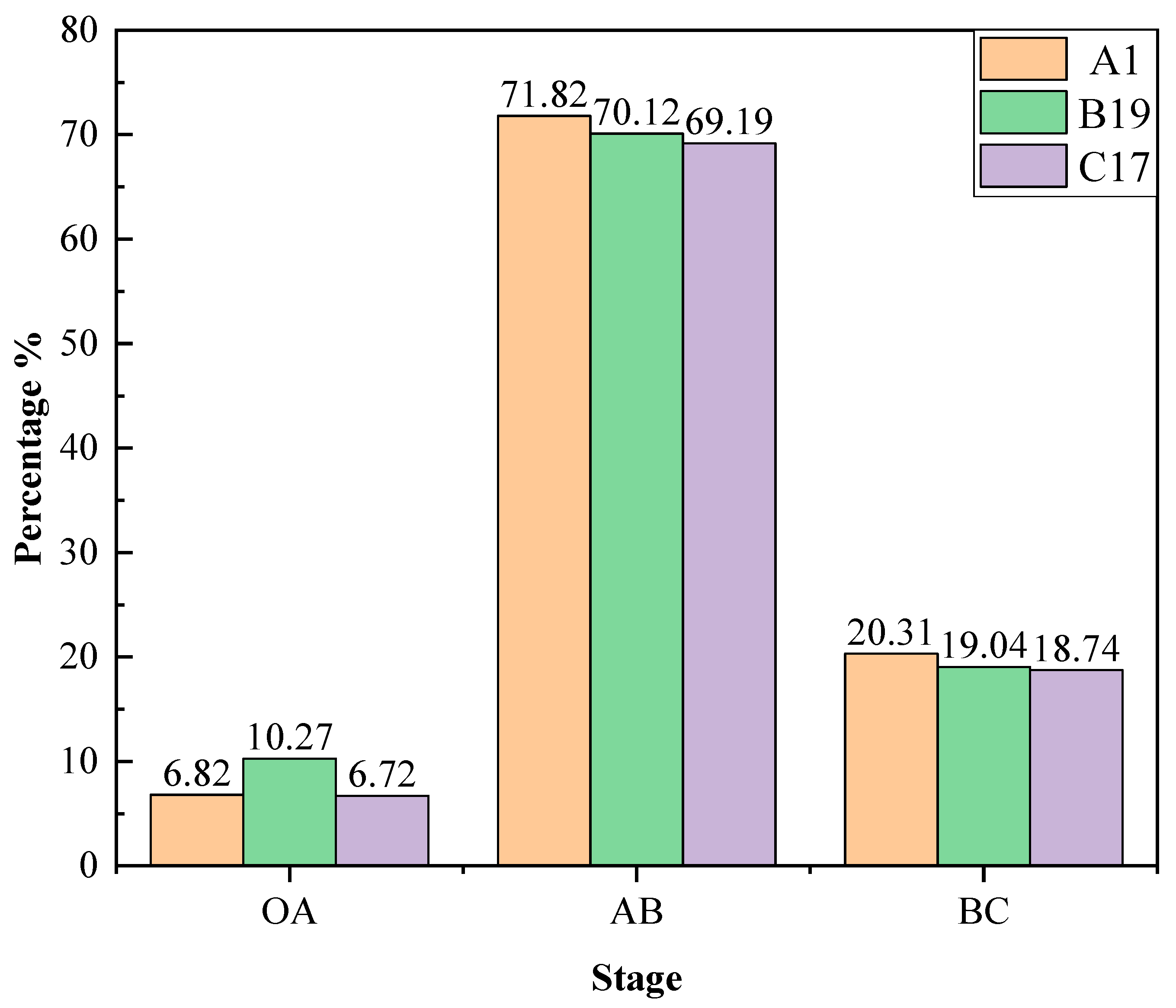

- Microfracture compaction stage (OA segment): At this stage, no microcracks are generated, all work done by the testing machine is converted into the elastic energy of the rock sample, and there is basically no energy dissipation. The energy absorbed by the three rock samples was 4.06, 7.67 and 6.72, and the corresponding ratios of the entire process were 6.82%, 10.27% and 6.72%, respectively. The rate is small but slowly increases.

- (2)

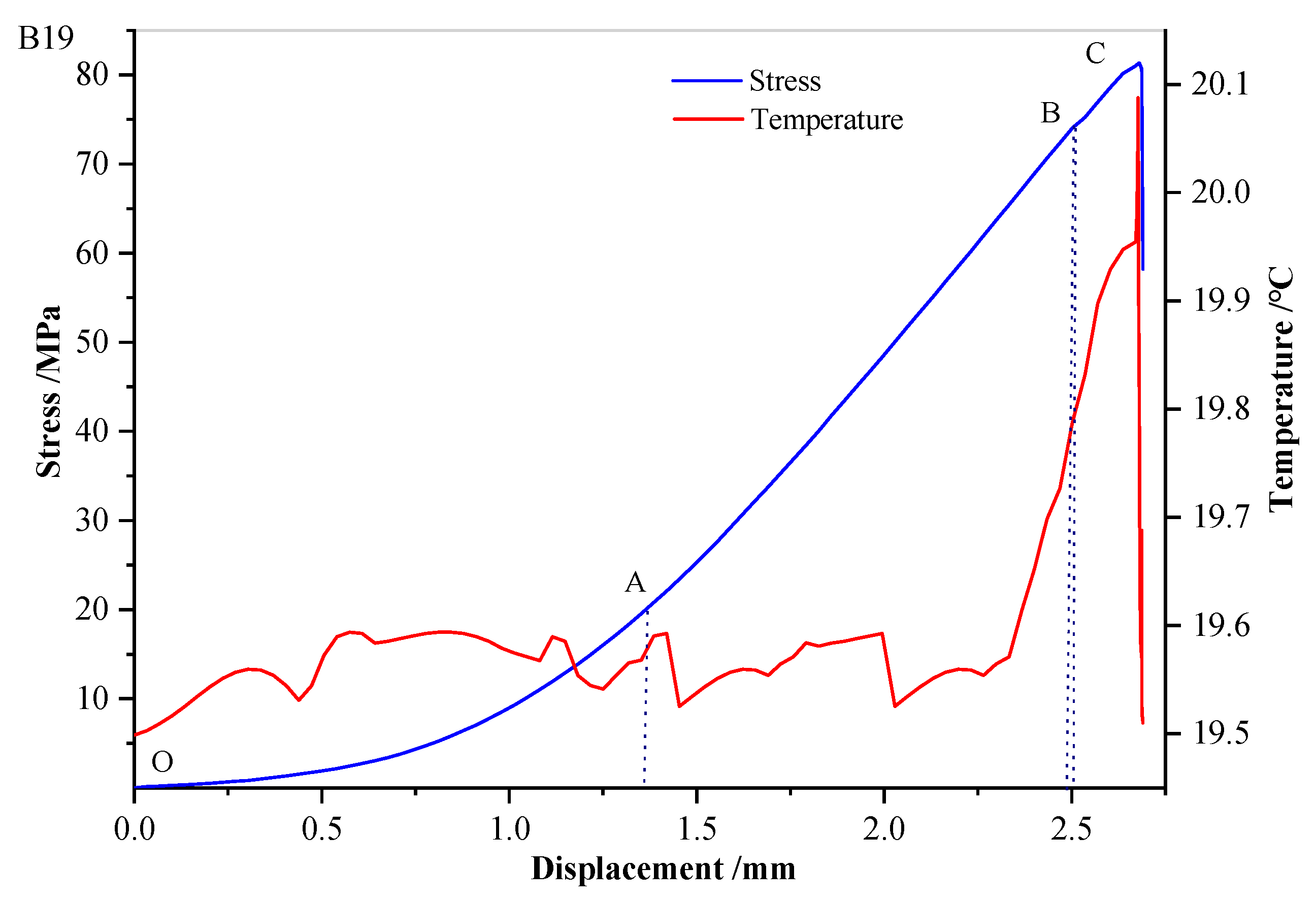

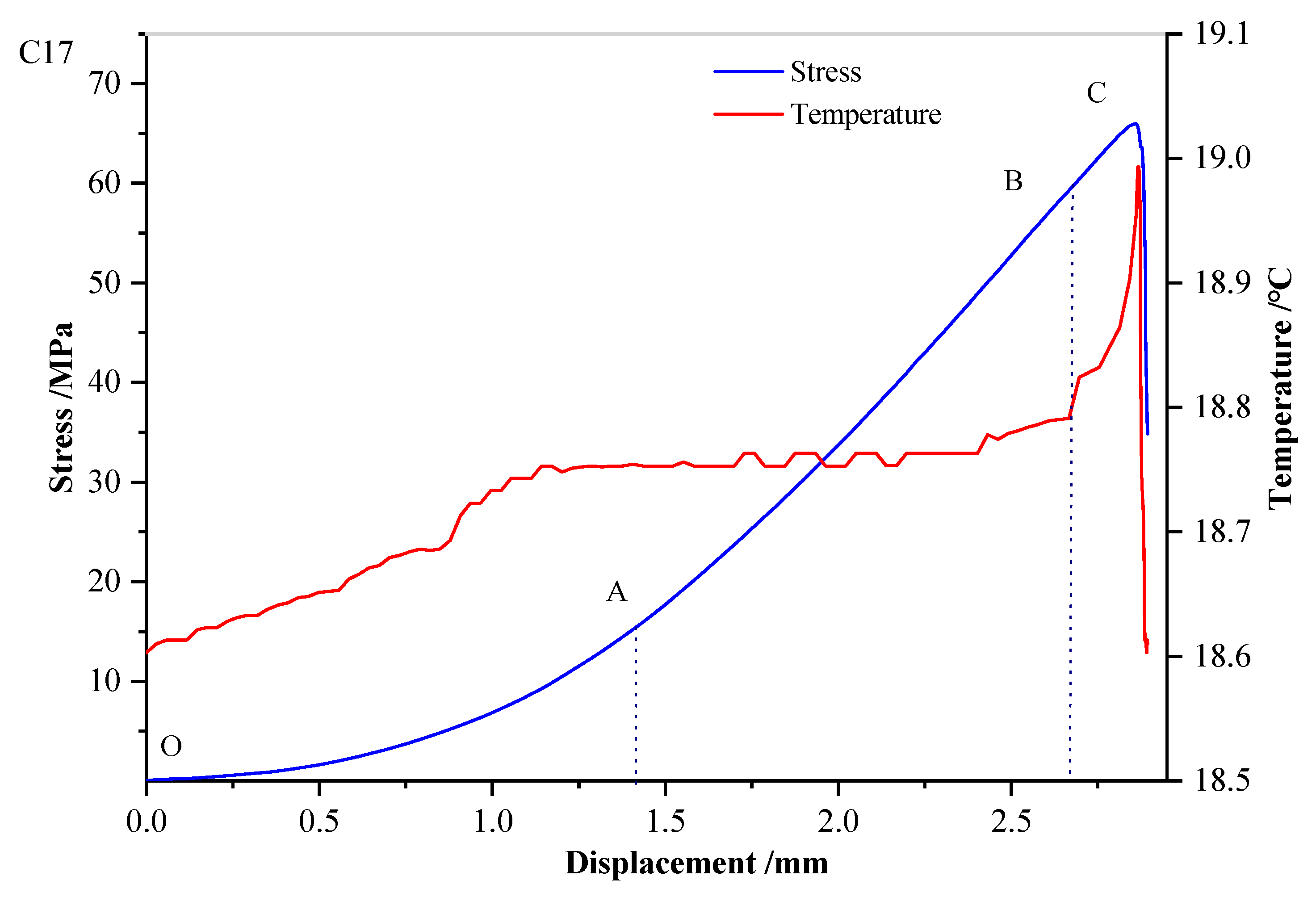

- Elastic deformation stage (AB segment): After point A, the microcrack begins to expand, the curve is close to linear growth, and it is in a stable expansion stage. Most of the work of the testing machine is converted into elastic energy, and a small part is converted into dissipative energy. Combined with the temperature curve, when approaching point B, the temperature of the rock sample has increased, which is confirmed by the local temperature increase on the thermal image map. The energy absorbed by the three rock samples was 42.79, 52.37 and 45.10, respectively, and the corresponding ratios were 71.82%, 70.12% and 69.19%. The energy absorption stage of this rock sample accounts for a large proportion and has a fast rate, which provides an energy basis to destroy the rock sample in the later stage.

- (3)

- Fracture expansion and development stage (BC stage): With increasing stress, the crack expands macroscopic plastic yielding occurs, and the crack is in the stage of accelerated unstable expansion. Most of the work of the testing machine is converted into dissipative energy, and the rate shows an increasing trend; a small part of the work is converted into elastic energy, but the rate is lower than before. After point B, the temperature curve sharply rises, when it reaches point C, there is a brief stagnation. Currently, on the thermal image map, there is large-scale warming at the place where the fault is about to occur. The energy absorbed by the three rock samples at this stage was 12.10, 14.22 and 12.22, which corresponds to 20.31%, 19.04% and 18.74%, respectively. The rate of energy absorption is reduced compared to the AB stage, but it is still much higher than the OA stage.

- (4)

- Post–peak destruction phase (after point C): After the elastic energy of the rock sample reaches its peak at point C, due to the further acceleration of crack propagation, the elastic energy is rapidly released. In Figure 8, Figure 9 and Figure 10, this stage has a temperature rise with an angle of almost 90°. The energy absorption process of this short-lived process is negligible, mainly the energy release of the rock sample destruction process. Combined with the thermal image map, the temperature after the destruction of the rock sample returns to room temperature in a very short time.

4. Conclusions

- (1)

- The infrared thermal image sequence diagram and rock failure morphology of the surface during the uniaxial compression loading process of rock are analyzed, and the evolution law of infrared thermal images during the rock force failure process is mainly manifested as follows: With the increase in stress and compaction of the void, the high temperature radiation belt gradually appears in the thermal image of the rock, gradually concentrates on penetration, and finally produces fracture failure at penetration; the destructive form of the rock and size of the debris are related to the location and area of the high temperature radiation zone.

- (2)

- The zone also could reflect the shape of rock fractures, the cracks of the rock firstly arise in the inner or marginal part of the middle, develop stepwise under load, and eventually form a penetrating fracture that extends from the upper part of one side to the middle and lower part of the other side. With the increase of rock porosity, the distribution area of internal failure increases with the weakening of energy concentration. However, when the porosity increases further, the crack development area of sample is transferred from the middle and upper part to the middle and lower part, and a large area of blocky distribution cracks appears at the bottom with severe end effect. Further studies of this phenomena will be carried out in the future.

- (3)

- During the uniaxial compression loading process of rock, strength of the sandstone decreases with the increase of porosity. With the same amplitude changes of porosity, the strength changes of the samples can up to six or seven times, showing an exponential relationship. The change in AIRT on its surface and energy evolution has obvious stages, and corresponds to several deformation stages of force damage to rock, especially in the accelerated deformation and failure stages. The AIRT on the rock surface sharply rises and then subsequently sharply falls after the destruction. The AIRT evolutionary characteristics of rock surfaces have very significant directivity and can show the energy evolution of different regions of the samples, which can provide a basis for the analysis of force catastrophes of rock masses.

- (4)

- Many factors affect the surface infrared radiation temperature during the stress process of the rock, such as the moisture content of the rock, loading method, and loading rate, which affect the infrared thermal image detection effect and accuracy of the rock. Therefore, attention should be given to eliminating interference during the test process. In future test processes, the quantitative relationship between each relevant factor and the infrared radiation temperature on the rock surface should be strengthened, to damage the rock by a force stability analysis of the rock mass using a viable method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, L.Q.; Zhang, Y.; Sun, H.; Wang, S.K.; Najeem, A. Experimental study on dependence of infrared radiation on stress for coal fracturing process. J. China Coal Soc. 2017, 42, 140–147. [Google Scholar]

- Liqiang, M.A.; Shuokang, W.; Dongsheng, Z. Infrared radiation noise characteristics and its denosing method during coal uniaxial compression loading test. J. Min. Saf. Eng. 2017, 34, 114–120. [Google Scholar]

- Zhang, L.; Chen, Y. Evaluation of plant tolerance to environmental dust pollution based on infrared thermography. Acta Ecol. Sin. 2016, 36, 7960–7970. [Google Scholar]

- Gu, Z.; Zhou, K. Mechanical properties and infrared analysis of granite under uniaxial cyclic loading. J. Saf. Sci. Tech. 2018, 14, 146–151. [Google Scholar]

- Sheinin, V.I.; Blokhin, D.I. Features of thermomechanical effects in rock salt samples under uniaxial compression. J. Min. Sci. 2012, 48, 39–45. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Y.; Cao, K.; Wang, Z. An Experimental Study on Infrared Radiation Characteristics of Sandstone Samples Under Uniaxial Loading. Rock Mech. Rock Eng. 2019, 52, 3493–3500. [Google Scholar] [CrossRef]

- Wu, L.; Liu, S.; Wu, Y.; Wang, C. Precursors for rock fracturing and failure—Part II: IRR T-Curve abnormalities. Int. J. Rock Mech. Min. 2006, 43, 483–493. [Google Scholar] [CrossRef]

- Wu, L.X.; Liu, S.J.; Wu, Y.; Li, Y. Remote sensing-rock mechanics (I)—Laws of thermal infrared radiation from fracturing of discontinous jointed faults and its meanings for tectonic earthquake omens. Chin. J. Rock Mech. Eng. 2004, 23, 24–30. [Google Scholar]

- Liu, S.J.; Wu, L.X.; Zhang, Y.B. Temporal-Spatial Evolution Features of Infrared Thermal Images Before Rock Failure. J. Northeast. Univ. Nat. Sci. 2009, 30, 1034–1038. [Google Scholar]

- Ma, L.; Sun, H. Spatial–temporal infrared radiation precursors of coal failure under uniaxial compressive loading. Inffrared Phys. Tech. 2018, 93, 144–153. [Google Scholar] [CrossRef]

- Zhou, Z.; Chang, Y.; Cai, X. Experimental study of infrared radiation effects of rock with different loading rates. J. Cent. South Univ Sci. Technol. 2019, 50, 1127–1134. [Google Scholar]

- Cao, K.; Ma, L.; Wu, Y.; Spearing, A.S.; Khan, N.M.; Hussain, S.; Rehman, F.U. Statistical damage model for dry and saturated rock under uniaxial loading based on infrared radiation for possible stress prediction. Eng. Fract. Mech. 2022, 260, 108134. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, J.; Hao, T.; Li, F.; Zhao, L. Failure mechanics and infrared radiation characteristics of soft coal at various moisture contents. Geomat. Nat. Haz. Risk. 2021, 12, 1371–1385. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Z.; Liu, L.; Chuai, X.; Lu, H. Predicting points of the infrared precursor for limestone failure under uniaxial compression. Int. J. Rock Mech. Min. 2016, 88, 34–43. [Google Scholar] [CrossRef]

- Ma, L.; Sun, H.; Zhang, Y.; Zhou, T.; Li, K.; Guo, J. Characteristics of infrared radiation of coal specimens under uniaxial loading. Rock Mech. Rock Eng. 2016, 49, 1567–1572. [Google Scholar] [CrossRef]

- Wu, X.; Gao, X.; Zhao, K.; Liu, J.; Liu, X. Abnormality of transient infrared temperature field (ITF) in the process of rock failure. Chin. J. Rock Mech. Eng. 2016, 38, 1578–1594. [Google Scholar]

- Zhang, Y.; Li, J.; Liu, X.; Tian, B. Infrared radiation portentous characteristics of rock burst in roadway. J. Min. Saf. Eng. 2015, 32, 786–792. [Google Scholar]

- Tian, B.; Liu, S.J.; Zhang, Y.B.; Liang, P.; Liu, X.X. Laboratory simulation of temporospatial evolution characteristics of infrared radiation in the process of rockburst in granite tunnel. Rock Soil Mech. 2016, 37, 711–718. [Google Scholar]

- Hao, X.; Xin-li, H.; Hui-ming, T.; Rui, Y.; Jun-wei, M. Application of infrared thermal radiation imaging technology to landslide physical model test. Rock Soil Mech. 2017, 38, 291–298. [Google Scholar]

- Luong, M.P. Infrared thermovision of damage processes in concrete and rock. Eng. Fract. Mech. 1990, 35, 291–301. [Google Scholar] [CrossRef]

- Wu, L.; Liu, S.; Wu, Y.; Wu, H. Changes in infrared radiation with rock deformation. Int. J. Rock Mech. Min. 2002, 39, 825–831. [Google Scholar] [CrossRef]

- Shanjun, L.; Lixin, W.; Huanping, W.; Yuhua, W.; Tao, C.; Guohua, L. Quantitative study on the thermal infrared radiation og dark mineral rock in condition of uniaxial loading. Chin. J. Rock Mech. Eng. 2002, 21, 1585–1589. [Google Scholar]

- Zhang, Y.B.; Liu, X.X.; Liang, Z.Z.; Li, Z.Z. Experimental study of rockburst precursor of granite tunnel based on multi-physical field parameters. Chin. J. Rock Mech. Eng. 2014, 33, 1347–1357. [Google Scholar]

- Xu, Z.; Liu, S.; Wu, L.; Feng, Z. Stress-related thermal infrared spectral variation and sensitive waveband of granite. J. Infrared Millim. Waves 2013, 32, 44–49. [Google Scholar] [CrossRef]

- Cai, X.; Zhou, Z.; Tan, L.; Zang, H.; Song, Z. Water saturation effects on thermal infrared radiation features of rock materials during deformation and fracturing. Rock Mech. Rock Eng. 2020, 53, 4839–4856. [Google Scholar] [CrossRef]

- Van Der Baan, M.; Eaton, D.; Dusseault, M. Microseismic Monitoring Developments in Hydraulic Fracture Stimulation. In Proceedings of the ISRM International Conference for Effective and Sustainable Hydraulic Fracturing, Brisbane, Australia, 20–22 May 2013. [Google Scholar]

- Du, K.; Li, X.; Tao, M.; Wang, S. Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests. Int. J. Rock Mech. Min. 2020, 133, 104411. [Google Scholar] [CrossRef]

- Li, J.L.; Zhou, K.P.; Liu, W.J.; Deng, H.W. NMR research on deterioration characteristics of microscopic structure of sandstones in freeze−thaw cycles. Trans. Nonferrous Met. Soc. China 2016, 26, 2997–3003. [Google Scholar] [CrossRef]

- Bieniawski, Z.T.; Hawkes, I. Suggested methods for determining tensile strength of rock materials. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 99–103. [Google Scholar]

- Xia, K.; Yao, W. Dynamic rock tests using split Hopkinson (Kolsky) bar system—A review. J. Rock Mech. Geotech. 2015, 7, 27–59. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Cai, X.; Cao, W.; Li, X.; Xiong, C. Influence of water content on mechanical properties of rock in both saturation and drying processes. Rock Mech. Rock Eng. 2016, 49, 3009–3025. [Google Scholar] [CrossRef]

- Liu, S.; Wu, L. Infrared Radiation Effect of Rock Stress; Metallurgical Industry Press: Beijing, China, 2005. [Google Scholar]

- Wu, L.; Cui, C.; Geng, N.; Wang, J. Remote sensing rock mechanics (RSRM) and associated experimental studies. Int. J. Rock Mech. Min. 2000, 37, 879–888. [Google Scholar] [CrossRef]

- Wu, L.; Liu, S.; Wu, Y. Introduction to Remote Sensing Rock Mechanics: Infrared Remote Sensing for Rock Catastrophe due to Overloaded; Science Press: Beijing, China, 2007. [Google Scholar]

- Liu, S.J.; Wu, L.X.; Wang, C.Y.; Ge, D.Q.; Wu, Y.H. Remote sensing-rock mechanics((VIII)—TIR omens of rock fracturing. Chin. J. Rock Mech. Eng. 2004, 23, 1621–1627. [Google Scholar]

| No. | Group A | Group B | Group C | |||

|---|---|---|---|---|---|---|

| Porosity/% | Strength/MPa | Porosity/% | Strength/MPa | Porosity/% | Strength/MPa | |

| 4.473 | 82.68 | 5.057 | 80.07 | 5.587 | 67.69 | |

| 4.497 | 81.87 | 5.086 | 79.43 | 5.758 | 66.41 | |

| 4.518 | 81.58 | 5.123 | 79.19 | 5.779 | 66.52 | |

| 4.523 | 80.82 | 5.144 | 79.30 | 5.832 | 65.20 | |

| 4.539 | 80.95 | 5.240 | 78.71 | 5.843 | 64.63 | |

| Average | 4.51 | 81.58 | 5.13 | 79.34 | 5.76 | 66.09 |

| Standard deviation | 0.026 | 0.753 | 0.070 | 0.490 | 0.103 | 1.201 |

| No. | A1 | B19 | C17 |

|---|---|---|---|

| porosity/% | 4.51 | 5.13 | 5.76 |

| strength/MPa | 81.58 | 81.34 | 66.09 |

| Temperature change/°C | 1.60 | 0.60 | 0.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.; Zheng, Z.; Zhou, K.; Gu, Z.; Pan, Z. Research on the Characteristics of Infrared Radiation and Energy Evolution Law of Red Sandstone with Different Porosity during Uniaxial Compression. Sustainability 2022, 14, 7698. https://doi.org/10.3390/su14137698

Lin Y, Zheng Z, Zhou K, Gu Z, Pan Z. Research on the Characteristics of Infrared Radiation and Energy Evolution Law of Red Sandstone with Different Porosity during Uniaxial Compression. Sustainability. 2022; 14(13):7698. https://doi.org/10.3390/su14137698

Chicago/Turabian StyleLin, Yun, Zhibin Zheng, Keping Zhou, Zhongyuan Gu, and Zheng Pan. 2022. "Research on the Characteristics of Infrared Radiation and Energy Evolution Law of Red Sandstone with Different Porosity during Uniaxial Compression" Sustainability 14, no. 13: 7698. https://doi.org/10.3390/su14137698

APA StyleLin, Y., Zheng, Z., Zhou, K., Gu, Z., & Pan, Z. (2022). Research on the Characteristics of Infrared Radiation and Energy Evolution Law of Red Sandstone with Different Porosity during Uniaxial Compression. Sustainability, 14(13), 7698. https://doi.org/10.3390/su14137698