Abstract

Production companies throughout the world are currently facing challenges with the extensive transformation of their processes with regard to digitalisation and other features of Industry 4.0. Simultaneously, traditional quality management processes must be significantly changed, and the umbrella term “Quality 4.0” is used to represent this transformation. Many companies, including Czech enterprises, are still struggling with the concept of Quality 4.0, as there are a lot of uncertainties, misunderstandings, and false approaches. Additionally, a lot of questions arise about how to provide an objective and comprehensive assessment of the company’s maturity or readiness for Quality 4.0. Therefore, the main objective of this article is to present our proposal of a framework and methodology on how to assess and measure the maturity level for the implementation of Quality 4.0. This proposal will be supplemented by a presentation of the main results obtained from a special field study, which was conducted at Czech production companies with the aim of obtaining a representative set of information showing their readiness to adopt Quality 4.0 and convert existing quality management systems into the new era. The authors also identify some research gaps, including the necessity to confirm the mutual relationship between the dimensions and items of Quality 4.0 and the sustainable development of companies or society.

1. Introduction

Business models, as well as management systems, will continue to dramatically change over the next decade. If advanced quality management is to contribute to such changes, it needs to be continuously developed towards the concept of Quality 4.0. Much has been said about the importance of quality and quality management and their impact to business and society. Now, quality management is recognized as a fundamental factor since it assures the compliance of products and services with all the requirements of the stakeholders. Thousands of articles and books has been published in this area over the last twenty years and it is not possible to refer to all of them in this article. That is why we only mention three representative books, published by Oakland, J., Oakland, R.J. and Turner, M.A. [1]; D. Hoyle [2]; and D.R. Kiran [3]. The authors exactly and closely explain the most important issues linked to advanced quality management and its key impacts. Although quality is permanent value and its definition is accepted throughout the world as the “degree to which set of inherent characteristics of an object fulfils requirements” [4], the quality world has already been shifting from a traditional perspective to a new one for some years. There is no doubt about the fact that such movement is caused by Industry 4.0 transformation which is frequently investigated and discussed (see [5,6,7,8,9] and many others). Such sets of processes, usually referred to as quality planning, quality control, quality assurance, and quality improvement, are now covered in the concept of Quality 4.0. Unfortunately, there is no unified definition of the term “Quality 4.0” and Sader, Husti, and Daroczi [10] argue that in the meanwhile, Quality 4.0 has not been adequately discussed from a scientific perspective. A few journal articles have defined Quality 4.0 but without a comprehensive interpretation for the scientific foundations behind it. They suggest that Quality 4.0 is an extended approach to quality management, where recent technologies are being integrated with traditional quality practices to expand the scope of quality management and to improve quality activities. Other opinions related to Quality 4.0 will be presented in Section 3.

Shortly describing the current situation in Czech organizations, we must admit that the concept of Quality 4.0 is still in the early stages of its adaptation, even though the awareness about it is relatively high. There are many uncertainties related to possible approaches to the practical implementation of Quality 4.0. Thousands of Czech production companies have established and certified quality management systems against ISO 9001:2015 or International Automotive Task Force standard IATF 16949:2016 requirements, but such systems are mostly only maintained and an effort aimed at the development towards a higher level of digitisation is rather an exception. Additionally, as we learned, Czech organizations have no diagnostic tool for internal assessment of whether or not they are ready to adapt Quality 4.0. Hence, the authors established two fundamental research questions:

- RQ1: Are current literature resources able to offer suitable assessment tools for Quality 4.0 maturity?

- RQ2: What level of Quality 4.0 maturity/readiness is typical for Czech production companies?

This article addresses these questions with the help of approaches and methods that are briefly presented in the following section.

Some results of our research should be considered as new contributions:

- (a).

- We developed an original conceptual model of maturity assessment for Quality 4.0, including 22 assessment items, 7 maturity levels, and formulas for quantification of the organization’s maturity level. See Section 4.1 especially.

- (b).

- We present eight key conditions for the successful transformation of traditional quality management to Quality 4.0. See Section 5 especially.

- (c).

- We performed the first investigation aimed at discovering the current level of Czech production companies’ maturity or readiness for Quality 4.0. See Section 4.2 especially.

- (d).

- We propose some research gaps and areas for future research works, including searching the mutual relationship between sustainability and Quality 4.0. See Section 6 especially.

The authors are sure that contributions (a), (b), and (d) have universal validity and could be attractive for many research groups throughout the world. The findings belonging to contribution (c) should serve as a convenient benchmark for other similar investigations.

2. Materials and Methods

There are five main stages of our research, presented in Table 1. This table also shows what approaches and methods were used to achieve these respective aims.

Table 1.

Approaches and methods used in our research.

A deep literature review in the area of the theory and practical implementation of Quality 4.0 was an initial step. For this purpose, we preferred articles and books which are included in databases such as Web of Science, Scopus, or Science Direct. Only English literature resources were considered. Relevant papers were analysed, and we present the main findings in Section 3. These findings were turned into the input information for the design and development stage. To develop the special assessment framework of Quality 4.0 maturity assessment (tailored primarily to Czech organizations), some time-proven methods of teamwork were used. An effort was made to convert these findings to the results which are described in Section 4.1. The developed framework for the Quality 4.0 maturity assessment gave a foundation for structured E-questionnaire development, as it served as a key tool for data gathering during the special field study. According to C.R. Kothari [11], structured surveys create a good opportunity to collect and quantify a large set of data for further analysis. A total of 121 Czech production companies provided data and information related to the readiness to convert existing quality management systems into digital closed-loop systems and to adopt Quality 4.0. Section 4.2 of this article provides information on the survey’s features and the survey’s main findings. To obtain them, selected statistical methods were applied. Statistical data processing covered a mixture of quantitative and qualitative data. On basis of the data synthesis, authors were able to formulate not only some conclusions, but also some interesting areas for future academic research. Section 5 and Section 6 should be seen as a challenge, not only for academicians, but also for managers of organizations.

3. Theory and Background—A Literature Review

Further development in the area of quality management is expected to proceed naturally for the next decade. Now, we will present some opinions and statements from selected literature resources. We will differentiate them according to three main topics:

- (a).

- Quality 4.0 fundamentals and features;

- (b).

- The definition of Quality 4.0;

- (c).

- Quality 4.0 assessment models.

3.1. Quality 4.0 Fundamentals and Features

Gunasekaran, A., Subramanian, N., and Ngai, W.T.E. [12] argued that although quality management became popular in the 1980s, enterprises are still struggling with the concept of Industry 4.0. They discussed the economic aspects of quality in the era of Industry 4.0 among other things, and argued that digitalisation creates unique circumstances wherein traditional quality management will have to incorporate technological advances to arrive at new optimums in operational excellence, performance, and innovation. Shin, W.S., Dahlgaard, J.J., Dahlgaard-Park, S.M., Kim, M.G. [13] presented a framework for a quality discipline supporting the fourth industrial revolution. They proposed to call it “Quality 4.0” and also offered future directions for quality engineering that leverage opportunities derived from the fourth industrial revolution:

- quality as a data-driven discipline;

- the application of modelling and simulation for evidence-based quality engineering;

- health monitoring and prognostics for quality;

- integrated quality management;

- maturity levels with respect to the fourth industrial revolution;

- integrating innovation with quality and managing for innovation;

- Quality 4.0 and data science;

- integrating reliability engineering with quality engineering;

- information quality.

They claimed that these nine points constituted a substantial basis to update the body of knowledge and practices of the quality profession. Additionally, G. Santos, Sá, J.C., Félix, M.J., Barreto, L., Carvalho, F., Doiro, F., Zgodavová, K. and Stefanović, M. [14] described their view dedicated to new skills for quality professionals in the Industry 4.0 era. Such job positions must have skills such as creative thinking and knowledge of new technologies. They will have to combine traditional quality management practices with new technologies, make decisions will be based on big data, be able to encourage teamwork, etc. D. Jacob [15] also claims that most industrial companies will have to be transformed to Industry 4.0, including quality management conversion, and that Quality 4.0 connects new technologies with traditional quality management methods. Barreto, L., Amaral, A., Pereira, T. [16] and many other authors include the internet of things, machine learning, data mining, artificial intelligence, cyber-physical systems, etc., as part of these new technologies. Carvalho, A.V., Enrique, D.V., Chouchene, A., Charrua-Santos, F. [17] identified a close link between these new technologies and quality management practices such as management commitment, customer involvement, supplier involvement, employee involvement, benchmarking, process management, information analysis, and strategic planning. Each of these practices can use new technologies. Park, S.H., Dahlgaard-Park, S.M. and Kim, D. [18] underlined that the quality of data and software will be a critical issue in era of Industry 4.0 because new technologies are all based on data and software. Eventually, data and quality management supporting software becomes more important and smart quality management systems will be necessary.

3.2. Quality 4.0 Definition

Regarding the definition of the term “Quality 4.0”, we can say that there is not any unified and commonly recognized definition at present, in spite of the fact that a lot of different statements can be discovered in this area. For example, experts from the recognised British professional body for quality specialists CQI/IRCA [19] declared that Quality 4.0 is the leveraging of technology with people to improve the quality of an organisation, its products, services, and the outcomes it creates. Juran´s institute [20] has said that Quality 4.0 is about aligning the practice of quality management with the emerging capabilities of Industry 4.0 to help drive organizations toward operational excellence. D. Jacob [21] said that Quality 4.0 blends new technologies with traditional quality methods to arrive at new optimums in operational excellence, performance, and innovation. D. Küpper, C. Knizek, D. Ryeson and J. Noecker [22] argued that Quality 4.0 is about much more than technology; it is a new way of managing quality in which digital tools enhance the organization’s ability to consistently give customers high-performing products. They also underlined that manufacturing, design, and development can immensely benefit due to implementation of Quality 4.0. M. Javaid, A. Haleem, R. P. Singh and R. Suman [23] identified Quality 4.0 as an item for integrating emerging technology with conventional quality approaches. M. Sony, J. Antony and J. A. Douglas [24] showed that Quality 4.0 closely aligns quality management with Industry 4.0 to enable enterprise efficiencies, performance, innovation, and improved business models. In addition, they identified eight “ingredients” for effective implementation of Quality 4.0 in organizations: (i) handling big data; (ii) improving prescriptive analytics; (iii) effective vertical, horizontal and end-to-end integration; (iv) using Quality 4.0 for strategic advantage; (v) leadership in Quality 4.0; (vi) training in Quality 4.0; (vii) organizational culture for Quality 4.0; and lastly, (viii) top management support for Quality 4.0, so that organizations could use these ingredients to perform a self-assessment on the current state of each element. However, an ambiguity of the term “Quality 4.0” was also confirmed by M. Turner and J. Oakland [25]. Through their investigations, no single definition has been commonly adopted. As a result of the diverse statements, they identified following features of the Quality 4.0:

- Quality 4.0 refers to the future of quality and organizational excellence;

- It builds upon traditional approaches and tools by considering connectedness, automation, and intelligence for improving performance and reducing risk;

- Quality 4.0 includes the digitalisation of quality of design, quality of conformance, and quality of performance using modern technologies.

3.3. Quality 4.0 Assessment Models

When starting the path to improved performance, organizations usually investigate their current position. The term “maturity assessment” is used for such activities. In general, the term “maturity” refers to state of being complete, comprehensive, ready or perfect. The word “maturity” can be substituted for the term “readiness”. According to Cambridge Dictionary [26], readiness is the willingness or state of being prepared for something. We will respect this definition, as it is relevant for our research. The definition of the term “assessment” is also assumed from this representative dictionary [27]: assessment is the act of judging or deciding the amount, value, quality, or importance of something, or the judgement or decision that is made. A maturity assessment can be generally used to measure the current maturity/readiness level of a certain aspect of an organization in a meaningful way, enabling stakeholders to clearly identify strengths and improvement points, and prioritize what to do in order to reach higher maturity levels accordingly. Maturity/readiness assessment activities are mostly focused on the organizations as a whole or their parts as management systems, technology, products, processes, etc.

Let us describe two comprehensive approaches to organizational maturity assessment. The first is associated with assessment against excellence models criteria, such as the EFQM Model [28,29], the Baldrige Performance Excellence Program [30], and some others. The majority of assessment actions are based on a self-assessment which was previously defined by experts from the European Foundation for Quality Management (EFQM) in 2003 [31] as a comprehensive, systematic, and regular review by an organization of its activities and results against the model. The RADAR diagnostic tool [28] is recommended for quantifying the maturity level and discovering the strengths and weaknesses of the organization. In addition, Annex A of ISO 9004:2018 [32] should be applied for the purpose of doing self-assessment. The second approach to comprehensive organizational maturity assessment is covered by the balanced scorecard methodology. This comprehensive approach translates the organization’s strategic direction into a coherent set of performance measures. The four perspectives of the scorecard, financial measures, customer knowledge, internal business processes, and learning and growth, offer a mutually balanced view between short-term and long-term objectives, between outcomes desired and performance drivers of those outcomes, and between hard objective measures and softer, more subjective measures. Kaplan and Norton´s monograph [33] initiated a lot of special projects, investigations, and publications dedicated to the balanced scorecard approach. A summary and conclusions were determined and presented by Kaplan and McMillan [34].

As for management systems assessment, the most widespread way is probably management systems certification. Certification is defined by ISO/IEC 17000:2020 [35] as a provision by an independent and accredited body of written assurance (a certificate) that the product, service, or management system in question meets specific requirements. A lot of articles dedicated to the impact, effects, role, and analysis of quality management systems certification within the current business environment have been published; see [36,37,38] for example.

However, let us turn our attention to the Quality 4.0 maturity or readiness assessment supported by various maturity models. D. Proença says [39] that maturity models are commonly recognised as important improvement tools for organizations since the 1970s. With respect to the concept of Industry 4.0, the maturity of a company is seen by A. Schumacher, Selim, A. and Sihn, W. [40] as the state of progression of internal and external conditions under the concepts of horizontal, vertical, and end-to-end engineering integration of Industry 4.0 on manufacturing systems.

Unfortunately, there are very few articles focusing primarily on Quality 4.0 maturity assessment. A majority of studies are oriented towards Industry 4.0 maturity or readiness assessment and review. A. Zonnenshain and R.S. Kenett [41] proposed a special quality scorecard (QSC) performance measurement model to evaluate the quality aspects of an organization in Industry 4.0. This model incorporates quality elements considered in recent international standard revisions as well as some economic items related to quality costing. Experts from AlisQI [42] describe Quality 4.0 as “quality intelligence” and have developed a special assessment grid to highlight strengths and expose potential areas for improvement by way of scoring the maturity level in eight key areas: process execution, performance management, organization, supply chain integration, data management, analytics and reporting, quality costs, and tooling. M. Glogovac, J. Ruso and M. Maricic [43] put the ISO 9004:2018 standard´s recommendations to the test, and their findings indicated that the model is usable in the context of the Quality 4.0. Such a model could be utilised as a basis for developing a sustainable Quality 4.0 system roadmap. However, in our opinion ISO 9004:2018 was not initially published for Quality 4.0 and its adaptation in order to perform Quality 4.0 maturity assessment is not adequate. C. Armani et al. [44] proposed a framework to measure the Quality 4.0 maturity of companies that are adapting to the new paradigm of Industry 4.0. The framework covers the assessment of 11 organizational dimensions and the degree of maturity is represented by five stages of evolution.

A decisive majority of approaches investigated are oriented towards various maturity assessments in the area of Industry 4.0 without special consideration to quality management. K. Lichtblau et al. [45] published their comprehensive and detailed framework of such assessment titled IMPULS in 2015. Various scientific works dedicated to Industry 4.0 maturity assessment have been published since then. G. Schuh, Anderl, R., Dumintrescu, R., Kruger, A. and ten Hompel, N. [46] designed and published their approach to the Industry 4.0 maturity assessment in 2017 and they updated it in 2020. Their comprehensive model recognizes three areas of interest:

- corporate structure (resources, organizational structure, information systems, and culture);

- corporate processes (development, production, logistics, services, marketing, and sales);

- corporate development (through six stages of the organization´s transformation roadmap).

Evaluation of all areas enables the establishment of a key indicator—the Industry 4.0 Maturity Index.

Another assessment tool was developed by a research team from The University of Warwick [47]. It considers six core dimensions: products and services, manufacturing and operations, strategy and organization, supply chain, business model, and legal considerations. These six core dimensions are divided into 37 sub-dimensions. For example, the core dimension “products and services” includes five sub-dimensions: product customisation, digital features of products, data-driven services, level of product data usage, and share of revenue. Each dimension is assessed through four levels of readiness. In addition to the development of comprehensive maturity models, models considering certain specific features of industry have also been developed. An Industry 4.0 maturity model for machine tool companies [48], an industrial artificial intelligence model [49], and a digital maturity assessment model [50] can serve as suitable examples. The authors did not intend to conduct a deep and systematic literature investigation in this area. Therefore, we only refer to articles which are very focused on such research [6,40,51,52,53].

3.4. Preliminary Findings

On this basis of literature review and analysis we are able to word some preliminary findings and lessons, which can be looked at as starting points for our research, as well as identify three research gaps:

- (a).

- There is not a unified and commonly recognized definition of what Quality 4.0 is at present. Hence, we accept the following definition: Quality 4.0 is a comprehensive approach that blends new technologies with traditional quality methods to arrive at new optimums in operational excellence, performance, and innovation.

- (b).

- There are only few articles focusing on Quality 4.0 maturity/readiness assessment and respecting core processes of quality management and related information flows. Development of such an assessment methodology could be seen as a challenge.

- (c).

- The majority of articles are fully oriented towards Industry 4.0 maturity assessment through special maturity models. Some principles and fundamentals of these models can be adapted to Quality 4.0 maturity assessment methodology:

- maturity models are usually structured into main criteria, called dimensions, and sets of partial criteria, called items or elements. The number of dimensions vary between 4 and 16, and the number of items can be very different, with some models including over 30 items;

- all maturity models distinguish levels of maturity/readiness, and they vary between 4 and 10;

- some of the models lead to a maturity index calculation which serves as an indicator describing the degree of progress made by an organization in the area of Industry 4.0 implementation;

- maturity assessment is provided either by self-assessment or by external assessment. A combination of self-assessment with external assessment is also recommended by some authors.

4. Results

The provisional conclusions presented at the end of previous section became impulses and ideas for the authors´ investigations and development activities. This section provides the main results.

4.1. Development of the Model for Quality 4.0 Maturity Assessment

After attaining the knowledge that there is no diagnostic tool for internal and external assessment of Quality 4.0 maturity/readiness at present, the research team decided to eliminate this gap with the development of a special assessment model. The development process was comprised of five key steps.

Step 1:

First of all, the key characteristics of such model had to be determined. By consensus, the model should comply with following features:

- It should comply with the definition of Quality 4.0 presented in the previous section;

- It should go beyond mere technologies and should cover social issues as well;

- It should be easy to understand for all stakeholders and the company´s staff;

- It should be easy to use during the assessment process;

- It should be generic, i.e., feasible in all industrial plants, regardless of the size of the company or branch of industry.

- It should inspire manufacturing organizations to continuously develop.

Step 2:

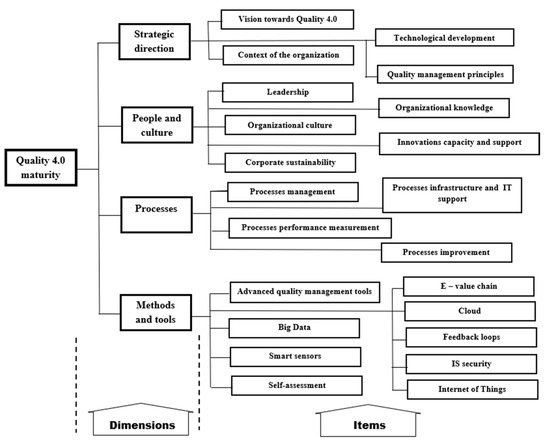

To meet these characteristics, authors generated tens of Quality 4.0 elements through a brainstorming session in response to the fundamental question: What must not be omitted when implementing Quality 4.0? Each element was written onto cards. After that, the authors used an affinity diagram to look for relationships between elements. From these relationships, the first set of categories was defined and covered by a header card. A suitable title for the header card was created and 22 items of the future model were devised. Then, similarly, relationships between items were explored and four “supergroups” were identified. These supergroups were converted to the future model’s dimensions. The conceptual framework of the Quality 4.0 maturity assessment model was developed this way. It is presented in Figure 1.

Figure 1.

The conceptual framework of the Quality 4.0 maturity assessment model.

Step 3:

Establishing maturity levels was another task. The research team opted for seven different levels, as they are ample to distinguish and evaluate a company´s reality. Table 2 describes these levels very briefly.

Table 2.

The Quality 4.0 maturity levels.

Step 4:

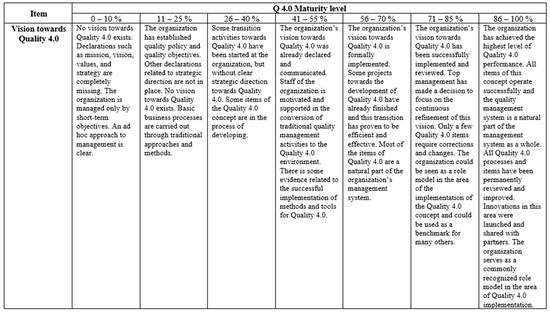

In order to perform maturity assessment in an objective manner, as well as to make a model easy to understand and use in practice, a detailed description of each maturity level under each dimension and item is expected, as if it is underestimated, it could lead to uncertainties during the assessment process. That is why the research team developed a special assessment matrix in which all items are described by generic descriptors. Descriptors clearly provide the intent of the inherent level and a detailed description of its typical features. An example of such a description related to the item “Vision towards Quality 4.0” is illustrated in Figure 2.

Figure 2.

Example of assessment matrix for the item “Vision towards Quality 4.0” under the dimension “Strategic direction”.

Step 5:

Finally, two suitable mathematic formulas enabling the quantification of the organization’s maturity in area of Quality 4.0 was designed. Formula (1) provides the organization´s view on what level of the Quality 4.0 maturity is currently acheived:

where MIQ4 denotes the Quality 4.0 maturity index, N is the number of maturity items (N = 22 for our proposal), n is an item, Mn is the maturity level of item n (its value can range from one to seven in compliance with Table 2 and Figure 2), and wn is the weighting factor of item n, when must abide by the condition:

The following Formula (3) offers the possibility to express in percentage what portion of the maturity model´s requirements were already met by the organization:

The denominator value 7, complies with the highest maturity level presented by Table 2 above.

4.2. Current State of Quality 4.0 Maturity in Czech Production Companies

To investigate how Czech production companies are practically ready for the implementation of Quality 4.0, the research team performed an empirical field study from November 2020 to March 2021.

Two basic research hypotheses were declared:

Hypothesis 1 (H1).

Overall Quality 4.0 maturity level is below average in Czech production companies and therefore they are not ready for Quality 4.0 implementation.

Hypothesis 2 (H2).

Czech production companies in automotive industry have achieved a higher level of Quality 4.0 maturity when compared to other companies.

A total of 573 Czech production companies from various areas of business were randomly selected with support of the Albertina database. Data gathering was based on a structured questionnaire which could be (due to pandemic restrictions) filled solely electronically. Representants from 121 companies, mostly quality managers, gave a fair response, as they are fully competent in this area. We are aware of fact that total number of interested companies is not a fully representative sample. We justify it by two main aspects: (i) only a small portion of all Czech production companies are seriously interested in Quality 4.0 transformation at present, and (ii) our research was underway during a very difficult situation caused by hard pandemic restrictions in Czech Republic. Real response rate reached 21.12%. Table 3 shows the distribution of companies from a business area point of view.

Table 3.

Distribution of companies from a business area point of view.

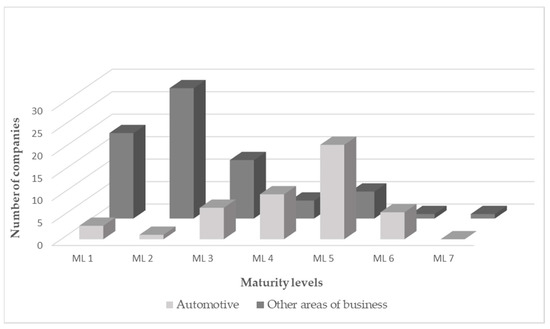

A key question was dedicated to the Quality 4.0 maturity level assessment. On the basis of the company´s real situation self-assessment, the representatives of companies had to mark one of seven maturity levels which were described in the questionnaire in conformity with Table 2. The answers were separated to two main groups: automotive sector and other areas of business. Table 4 presents the obtained findings. The numbers in this table represent the total amount of respondents (organizations) which belong to a certain ML as according to their self-assessment. Figure 3 shows clear differences between companies that operate within the automotive supply chain and the rest of Czech companies.

Table 4.

Results of maturity level (ML) self-assessment.

Figure 3.

Current Quality 4.0 maturity levels (ML) of Czech production companies: difference between automotive organizations and other areas of business.

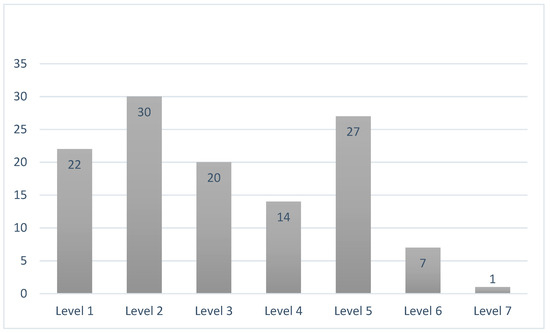

The overall distribution of current Quality 4.0 maturity levels is presented in Figure 4. Nearly 60% of all companies are below average (maturity levels 1–3 only). On the contrary, a scant portion of companies (6.3%) have already achieved level 6 or 7.

Figure 4.

Overall distribution of current Quality 4.0 maturity levels at Czech production companies (according to Table 4—Total number of companies).

When adapting data from Table 4 we are able to calculate the mean value of current maturity levels—MLm:

- for all Czech companies: MLmtotal = 3.174;

- for automotive only: MLmauto = 4.313;

- for the rest of business area: MLmother = 2.40.

While the automotive branch of industry achieves a mean value slightly above average, other branches of Czech production companies are definitely below average and they will have to invest a huge effort to transform their quality management systems with compliance to Quality 4.0 expectations.

This set of data allows us to declare that both research Hypotheses H1 and H2 can be confirmed.

For the purpose of evaluating the interdependence of the degree of implementation on the industry, the data were adjusted into four summary major categories. The categories were created as follows—Table 5.

Table 5.

Results of maturity level (ML) self-assessment.

The data were evaluated using Pearson’s chi-squared test. Both p-values (Pearson chi-square, likelihood ratio chi-Square) are smaller than 0.05 and we can reject the null hypothesis. We can venture to say that there is a certain dependence between the maturity level of self-assessment and the fact whether the enterprise is in the automotive area or belongs to another area. Because slightly less than 20% (two of six) have expected counts less than five, we may want to interpret the results with caution. The claimed dependence between maturity level and business area (automotive × other area of business) is also evident in Figure 3.

5. Discussion

Quality remains and will remain one of the key success factors in relation to long-term economic sustainability and organizational excellence [1,54,55]. Advanced quality management systems will transform companies to qualify for quality champions and make them more competitive. Simultaneously, traditional quality management activities must be transformed with regard to the quick technology innovations and digitalisation [56,57]. Integration of Industry 4.0 technologies makes the quality management processes more transparent, risk-free, optimised, improved efficiency, and more profitable [58].

We developed a conceptual model of maturity assessment for Quality 4.0. It is based on a multi-lenses approach to assessment according to M. Zairi’s [50] recommendations. It allows for the collection of data on the state of development of Czech production companies across different branches of industry in a meaningful way, enabling stakeholders to clearly identify strengths and areas for improvement, and prioritize what to do in order to reach higher levels of Quality 4.0 accordingly. An assessment and review such as this enables detailed, step-by-step, quantitative scoring to diagnose the current state of the company. The rigorous nature of this assessment ensures that the journey going forward will lead the production company towards a future state of satisfying external customer needs, improving internal processes performance, motivating staff, and keeping the balance sheet strong. It matches the opinions of Sader, Husti and Daroczi [10]; Barreto, L., Amaral, A., Pereira, T. [16]; D. Küpper, C. Knizek, D. Ryeson and J. Noecker [22]; M. Glogovac, J. Ruso and M. Maricic [43]; and Fundin, A., Lilia, J., Langrosen, Y. and Berquist, B. [54].

In our opinion, if Czech organizations set out on a journey towards Quality 4.0, they will have to establish the following set of management changes:

- Declare, implement, and develop their vision focused on Quality 4.0 and clearly communicate this vision internally and externally. The less clear the vision is, the higher the chances of failure in Quality 4.0 implementation are. Such strategic declaration is a forceful incentive [59].

- Provide comprehensive risks and opportunities assessment as transformation towards Quality 4.0 represents extensive and difficult project. A. Nagyova, Pacaiova, H., Markulik, S., Turisova, R., Kozel, R. ad. Dzugan, J. [60] offered a nice guideline for such assessment.

- Determine and release the resources needed for Quality 4.0 establishment, assessment, and continuous development. Antony, J., Sony, M. and Cudney, E. [61] presented findings from special pilot survey in which 36 quality directors from European firms testified a necessity for investments and skills as one of five crucial requirements associated with the implementation of Quality 4.0.

- Special attention must be paid to building new skills of job positions such as quality managers and quality technicians at all production companies. The lack of digital quality skills can act as a barrier in implementing the Quality 4.0 initiatives. G. Santos, Félix, M.J., Barreto, L., Carvalho, F., Doiro, F., Zgodavová, K. and Stefanović, M [14] have already identified these skills and R. Dovleac [62] proposed a knowledge management life cycle for Quality 4.0 based on the traditional PDCA cycle.

- Adapt to current supply chains and relationships with suppliers according to challenges of digitalisation, from trade-offs to the suppliers´ performance measurement. Gunasekaran, A., Subramanian, N., and Ngai, W.T.E. [12] put emphasis on it too.

- After converting traditional quality management structure and processes into the Quality 4.0 concept, the new quality management system must be periodically audited, reviewed, and evaluated to ensure its continuing suitability, adequacy, effectiveness and alignment with strategic direction of the organization. It is an ISO 9001:2015 [63] requirement. J. Nenadál [64] introduced a set of indicators which should be relevant for this purpose.

- As the most efficient approach to learning from better Quality 4.0 reality, a generic type of benchmarking should be used. For example, Erdil and Erbiyik [65] gave a guideline on how to connect benchmarking and total quality management. Some Czech automotive companies could serve as a suitable benchmark for other organizations.

- Depending on the findings from audits, self-assessment or benchmarking, the Quality 4.0 concept and associated processes should be continuously refined. ISO 9001:2015 [63] in clause 10.3 or the latest version of the EFQM Model [28] especially within partial criterion 5.2 ask for such activities from the organizations.

It is necessary to see these eight changes as minimum activities covered by leadership principle if the journey to Quality 4.0 ought to be successful.

6. Conclusions (With Respect to Sustainability)

6.1. Objectives of the Paper

The main objective of this article was to present our proposal of a framework and methodology of how to assess and measure the maturity level for the implementation of Quality 4.0. We reviewed the present literature from three points of view: Quality 4.0 fundamentals and features, the definition of Quality 4.0, and Quality 4.0 assessment models. On basis of this review, we declared that Quality 4.0 should be seen as a comprehensive approach that blends new technologies with traditional quality methods to arrive at new optimums in operational excellence, performance, and innovation. The authors are sure that the two fundamental research questions established in Section 1 were also answered in previous sections.

6.2. Achieved Results

Due to the absence of any maturity assessment model taking into consideration all aspects of quality management in era of digitalisation (all similar models are oriented to the Industry 4.0 only), we developed a special Quality 4.0 assessment model comprising four main dimensions and 22 partial items. The Quality 4.0 maturity assessment creates seven levels of maturity. Through empirical field research, we investigated the real level of Czech production companies for the Quality 4.0 concept implementation. Data processing from 121 companies, as well as statistical testing confirmed both research hypotheses declared in Section 4.2.

6.3. Theoretical and Practical Implications

The results of the literature review presented in Section 3.3 confirmed that there are very few studies focused on models and methodologies of Quality 4.0 maturity assessment up to the present day. The developed original conceptual model of maturity assessment for Quality 4.0 should serve as a suitable guidance for all organizations striving successfully to convert their quality management systems to the new era. This model can be used or refined at all types of production companies regardless of the business sector. The conceptual model would enable production companies to obtain a deeper understanding of the fundamentals and main features of Quality 4.0.

We see this as one of the most practical implications of this paper. From the theoretical point of view, all findings and discovered research gaps (presented in following Section 6.4) represent serious impulses and challenges for future international research activities. The model seems to be a universal tool for Quality 4.0 maturity assessment, includes formulas for Quality 4.0 maturity index calculation, and could be an inspiration for others.

6.4. Future Research

We are fully aware of the fact that there are very interesting areas for future research activities. As for our model of maturity assessment, the weighting factors of all items (presented by Formulas (1)–(3)) should be determined, but we are doubtful of whether if it is fair to set common and fixed values of these factors independent of the individual company´s context. However, there are some general opportunities for the elimination of research gaps in the area of the quality management in the era of digitalisation. A. Fundin, Lilja., J., Lagrose, Y. and Berquist, B. [54] investigated possible topics for the future of quality management during special workshops. These workshops produced five collectively elaborated and designed future research themes for quality management:

- (a).

- systems perspectives applied;

- (b).

- stability in change;

- (c).

- models for smart self-organising;

- (d).

- integrating sustainable development;

- (e).

- higher purpose as quality management booster.

The process also identified a positive core of quality management, defined as the core values and aspects in the field and practices that need to be preserved and nurtured in the future. Collaterally, new quality management challenges occur. M. Elg, Birch-Jensen, A., Gremyr, I. Matin, J. and Melin, U. [66] revealed opportunities in the areas of cross-functional collaboration with IT specialists and process managers, better understanding of customer perception by using software for real-time monitoring, managing quality failure discussions on social media, adapting internal online communication, enabling new online ways to adhere to quality requirements, online service delivery, etc. M. Javaid, Haleem, A., Sigh, R.P. and Suman, R. [23], on the basis of literature review, discovered 18 areas of effective application of Quality 4.0 such as automation of inspection activities, quality cost reducing, research and development, continuous monitoring, etc. Corti, D., Masiero, S. and Gladysz, B. [67] argued for the fact that less than 10% of manufacturing companies uses non-production data, such as customer usage and feedback data, service data or environmental data. A. Chiarini [68] stressed, besides other things, that it is necessary develop Quality 4.0 skills and a culture for quality people. According to J. Emblemsvag [69] and Ammar, M., Haleem, A., Javaid, M., Bahl, S. and Varma, A.S. [58], Quality 4.0 technologies must be brought into the research on contracting because this technology can help build trust and therefore collaboration through increased transparency and credibility.

We intentionally left some remarks focused on mutual relationship between Quality 4.0 and sustainability until end of the article. Unfortunately, when providing the literature review, we discovered that there were not any relevant studies which investigated the mutual relationship between Quality 4.0 and sustainability or sustainable development available. We only found a lot of papers that dealt with various aspects of relations between sustainability and Industry 4.0. For example, Habib, M.K. and Chimson, C. [70] discussed the sustainability of Industry 4.0 in light of the United Nations Sustainable Development Goals. Cochran, D.S. and Rauch, E. [71] proposed possible physical solutions to achieve a long-term sustainable enterprise design. According to Beravi, M.A. [72] Industry 4.0 technologies play a significant role in sustainable social, environmental, and economic development. Raj, P.E., Wahab, S.A., Zawawi, N.F.M., Awang, K.W. and Ibrahim, W.Z.A.A.W. [73] claim that Industry 4.0 can be clustered newly in operational methods to represent the creation of a new platform to improved performance. Khan, I.S., Ahmad, M.O. and Majawa, J. [74] analyzed opinions from 81 primary papers and determined that sustainable development in the Industry 4.0 context contributes to circular economic objectives by achieving social, economic, and environmental benefits. They proposed that future studies should address topics such as product quality improvement, sustainable manufacturing, and business performance. Finally, Beltrami, M., Orzes, G., Sarkis, J. and Santor, M. [75] presented a statement that said that the relation between Industry 4.0 and sustainability—as revealed by many authors—is still unclear and the literature is fragmented. Hence, our investigation discovered another interesting research gap: to confirm the mutual relationship between the dimensions and items of Quality 4.0 and sustainable development of companies or society. This should be considered as a challenge for all academicians and other research teams!

To summarize, the authors highlight the importance of research studies that would look for a solution in following areas:

- the influence of Quality 4.0 on an organization´s ability to meet or exceed stakeholders´ requirements;

- data management focused on data generation and gathering, data quality and relevance, data security, data ownership, data processing, data handling and storage, etc.;

- the impact of Quality 4.0 on reducing the cost of poor quality, especially on internal and external failure cost,

- the support of the Quality 4.0 for all types of feedback loops within the advanced quality management systems;

- the possible refinement of maturity dimensions and items accuracy, including taking into consideration certain specific features of some industries (food, chemical, civil engineering, etc.);

- the impacts of company culture and leadership on the successful and effective implementation of Quality 4.0 in a longitudinal manner;

- the identification of possible differences between critical success factors (related to Quality 4.0 implementation) for large companies vs. small and medium sized companies;

- ways and tools for providing staff training for Quality 4.0 technical and transformational skills;

- confirmation on how Quality 4.0 contributes to achieving sustainable development goals, etc.

In short, Quality 4.0 is still developing. Therefore, there are still many topics and tasks for researchers throughout the world. Quality 4.0 has a significant role in viewing the way quality is perceived in the age of Industry 4.0. Quality 4.0 can be used to strengthen the core competency of Czech production companies, thereby bringing revolutionary changes to the business operations, making them future-ready. The majority of Czech production companies must search for the most effective and efficient way how to transform current quality management to the Industry 4.0 setting. In this case, they will wish to make the transition towards Quality 4.0 and to have a clear view and a path to follow. Therefore, it is necessary to assess Quality 4.0 maturity so that they can implement it successfully. The article should be seen as a small contribution to this effort, which also supports sustainable development of all types of organizations, not only in the Czech Republic, but everywhere throughout the world.

6.5. Limitations

The major limitation of the results presented above is that our field research was performed in a time span accompanied by stern measures caused by COVID-19, and no physical survey could be carried out. All contact with companies´ representatives were restricted only to remote investigations and we had no possibility to validate the findings of electronic questionnaires through personal interviews. Second, we also registered a lack of serious awareness related to Quality 4.0 features within Czech companies. Furthermore, only English language literature resources were considered, and other language studies were excluded.

Author Contributions

Conceptualisation, J.N. and D.V.; methodology, J.N., D.V., P.H. and E.T.; funding acquisition, J.N. and D.V.; formal analysis, J.N., D.V., P.H. and E.T.; investigation, J.N., D.V., P.H. and E.T.; data curation, P.H.; validation, J.N., D.V., P.H. and E.T.; original draft preparation, J.N., D.V., P.H. and E.T.; visualisation, D.V. and E.T.; project administration, J.N. and D.V. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the European Regional Development Fund under grant “A Research Platform Focused on Industry 4.0 and Robotics in the Ostrava Agglomeration” project, No. CZ.02.1.01/0.0/0.0/17_049/000845 and VŠB-Technical University of Ostrava. This research was also funded by the specific research project No. SP 2022/72 “Development of selected approaches, methods and tools for quality management in the context of Quality 4.0 concept adaptation” which was founded at the Faculty of Materials Science and Technology, VŠB-Technical University of Ostrava, with the support of the Ministry of Education, Youth and Sports, Czech Republic. We fully appreciate these sources of funding.

Acknowledgments

The authors would like to thank all of the quality professionals who responded to the survey.

Conflicts of Interest

The authors declare no conflict of interest. Vykydal, Nenadál, Halfarová, and Tylečková are members of academic staff of The VSB–Technical University of Ostrava, but they are not members of any management team from other organizations.

References

- Oakland, J.S.; Oakland, R.J.; Turner, M.A. Total Quality Management and Operational Excellence. In Text with Cases, 5th ed.; Routledge: London, UK, 2020. [Google Scholar]

- Hoyle, D. Quality Management Essentials; Taylor & Francis Ltd.: London, UK, 2015. [Google Scholar]

- Kiran, D.R. Total Quality Management. In Key Concept and Case Studies; Butheworth Heinemann: Cambridge, UK, 2017. [Google Scholar]

- ISO 9000:2015; Quality Management Systems—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2015.

- Liao, Y.; Deschamps, F.; Loures, E.D.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Rejikumar, G.; Raja Sreedharan, V.; Arunprasad, P.; Persis, J.; Sreeraj, K.M. Industry 4.0: Key findings and analysis from the literature arena. Benchmarking Int. J. 2019, 26, 2514–2542. [Google Scholar] [CrossRef]

- Horváth, D.; Szabó, Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Industry 4.0 Engages Customers. Available online: www2.deloitte.com (accessed on 12 November 2020).

- Gotz, M.; Jankowska, B. Clusters and Industry 4.0—Do they fit together? Eur. Plan. Stud. 2017, 25, 1633–1653. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daroczi, M. A review of quality 4.0: Definitions, features, technologies, applications, and challenges. Total Qual. Manag. Bus. Excell. 2021. [Google Scholar] [CrossRef]

- Kothari, C.R. Research Methodology, Methods and Techniques, 2nd ed.; New Age International Limited: New Delhi, India, 2011. [Google Scholar]

- Gunasekaran, A.; Subramanian, N.; Ngai, W.T.E. Quality management in the 21 century enterprises: Research pathway towards Industry 4.0. Int. J. Prod. Econ. 2018, 207, 125–129. [Google Scholar] [CrossRef]

- B Shin, W.S.; Dahlgaard, J.J.; Dahlgaard-Park, S.M.; Kim, M.G. A Quality Scorecard for the era of Industry 4.0. Total Qual. Manag. Bus. Excell. 2018, 29, 959–976. [Google Scholar] [CrossRef]

- Santos, G.; Sá, J.C.; Félix, M.J.; Barreto, L.; Carvalho, F.; Doiro, M.; Zgodavova, K.; Stefanović, M. New Needed Quality Management Skills for Quality Managers 4.0. Sustainability 2021, 13, 6149. [Google Scholar] [CrossRef]

- Jacob, D. Quality 4.0 Impact and Strategy Handbook. In Getting Digitally Connected to Transform Quality Management; LNS Research: Cambridge, UK, 2017. [Google Scholar]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Carvalho, A.V.; Enrique, D.V.; Chouchene, A.; Charrua-Santos, F. Quality 4.0: An Overview. Procedia Comput. Sci. 2021, 181, 341–346. [Google Scholar] [CrossRef]

- Park, S.H.; Dhalgaard-Park, S.M.; Kim, D. New Paradigm of Lean Six Sigma in the 4th Industrial Revolution Era. Qual. Innov. Prosper. 2020, 24, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Available online: www.quality.org/quality-4-point-0 (accessed on 7 October 2021).

- Available online: https://www.juran.com/blog/quality-4-0-the-future-of-quality/ (accessed on 23 September 2020).

- Jacob, D. What is Quality 4.0? Available online: https://blog.lnsresearch.com/quality40 (accessed on 15 November 2020).

- Küpper, D.; Knizek, C.; Ryeson, D.; Noecker, J. Quality 4.0 Takes More than Technology. Available online: https://www.bcg.com/publications/2019/quality-4.0-takes-more-than-technology (accessed on 23 February 2020).

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Significance of Quality 4.0 towards comprehensive enhancement in manufacturing sector. Sens. Int. 2021, 2, 100109. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Douglas, J.A. Essential Ingredients for the Implementation of Quality 4.0: A narrative review of literature and future directions for research. TQM J. 2020, 32, 779–793. [Google Scholar] [CrossRef]

- Turner, M.; Oakland, J. Defining Quality 4.0. Quality World, 30 July 2021. [Google Scholar]

- Available online: www.dictionarycambridge.org/dictionary/english/readiness (accessed on 21 October 2020).

- Available online: www.dictionarycambridge.org/dictionary/english/assessment (accessed on 21 October 2020).

- The EFQM Model; EFQM: Brussels, Belgium, 2019.

- Nenadál, J. The New EFQM Model: What is Really New and Could Be Considered as a Suitable Tool with Respect to Quality 4.0 Concept? Qual. Innov. Prosper. 2020, 24, 17–28. [Google Scholar] [CrossRef] [Green Version]

- Available online: www.nist.gov/baldrige (accessed on 14 September 2021).

- Assessing for Excellence. In A Practical Guide for Successfully Developing, Executing and Reviewing a Self-Assessment Strategy for Your Organisation; EFQM representative Office: Brussels, Belgium, 2003.

- ISO 9004:2018; Quality Management—Quality of the Organization—Guidance to Achieve Sustained Success. ISO: Geneva, Switzerland, 2018.

- Kaplan, R.S.; Norton, D.P. The Balanced Scorecard: Translating Strategy into Action; Harvard Business Review Press: Brighton, MA, USA, 1996. [Google Scholar]

- Kaplan, R.S.; McMillan, D. Updating the Balanced Scorecard for Triple Bottom Line Strategies, Working Paper 21-028. Available online: www.hbs.edu/ris/ (accessed on 7 July 2021).

- ISO/IEC 17000:2020; Conformity Assessment Vocabulary and General Principles. ISO: Geneva, Switzerland, 2020.

- Ikram, M.; Zhang, Q.; Sroufe, R. Future of quality management system (ISO 9001) certification: Novel grey forecasting approach. Total Qual. Manag. Bus. Excell. 2020, 32, 1666–1693. [Google Scholar] [CrossRef]

- Fonseca, L.; Domingues, P.; Baylina, P.; Calderon, M. Management System Certification Benefits: Where Do We Stand? J. Ind. Eng. Manag. 2017, 10, 476–494. [Google Scholar] [CrossRef] [Green Version]

- Bravi, L.; Murmura, F.; Santos, G. The ISO 9001:2015 Quality Management System Standard: Companies’ Drivers, Benefits and Barriers to Its Implementation. Qual. Innov. Prosper. 2019, 23, 64. [Google Scholar] [CrossRef] [Green Version]

- Proença, D. Methods and Techniques for Maturity Assessment. In Proceedings of the 11th Iberian Conference on Information Systems and Technologies, Gran Canaria, Spain, 15–18 June 2016. [Google Scholar] [CrossRef]

- Schumacher, A.; Selim, E.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Zonnenshain, A.; Kenett, R.S. Quality 4.0—The challenging future of quality engineering. Qual. Eng. 2020, 32, 614–626. [Google Scholar] [CrossRef]

- Quality Intelligence Maturity Model. Available online: www.alisqi.com (accessed on 16 July 2021).

- Glogovac, M.; Ruso, J.; Maricic, M. ISO 9004 maturity model for quality in industry 4.0. Total Qual. Manag. Bus. Excell. 2020, 33, 529–547. [Google Scholar] [CrossRef]

- Armani, C.G.; de Oliveira, K.F.; Munhoz, I.P.; Akkari, A.C.S. Chapter 6—Proposal and application of a framework to measure the degree of maturity in Quality 4.0: A multiple case study. In Advances in Mathematics for Industry 4.0; Academic Press: London, UK, 2021. [Google Scholar] [CrossRef]

- Lichtblau, K.; Goericke, D.; Stich, V. IMPULS—Industrie 4.0-Readiness. Impuls-Stiftung des VDMA. 2015. Aachen-Köln. Available online: https://www.industrie40-readiness.de/?lang=en (accessed on 25 August 2021).

- Schuh, G.; Anderl, R.; Dumintrescu, R.; Krüger, A.; ten Hompel, M. Industrie 4.0 Maturity Index. Available online: https://en.acatech.de/publication/industrie-4-0-maturity-index-update-2020/ (accessed on 24 May 2021).

- An Industry 4 Readiness Assessment Tool. Available online: https://warwick.ac.uk (accessed on 24 August 2021).

- Lizarralde, D.R.; Ganzarain, E.J.; López, C.; Serrano, L.I. An Industry 4.0 maturity model for machine tool companies. Technol. Forecast. Soc. Chang. 2020, 159, 120203. [Google Scholar] [CrossRef]

- Chen, W.; Liu, C.; Xing, F.; Peng, G.; Yang, X. Establishment of a maturity model to assess the development of industrial AI in smart manufacturing. J. Enterp. Inf. Manag. 2021, 35, 701–728. [Google Scholar] [CrossRef]

- Zairi, M. Quality 4.0 Leading into the Future through Excellence. An Assessment Guide; European Centre for Best Practice Management: Keighley, UK, 2019. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implication for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Ramos, L.F.P.; de Freitas Rocha Lourse, E.; Deschamps, F. An Analysis of Maturity Models and Current Sate Assessment of Organizations for Industry 4.0 Implementation. Procedia Manuf. 2020, 51, 1098–1105. [Google Scholar] [CrossRef]

- Alcácer, V.; Rodrigues, C.; Carvalho, H.; Cruz-Machado, V. Tracking the maturity of industry 4.0: The perspective of a real scenario. Int. J. Adv. Manuf. Technol. 2021, 116, 2161–2181. [Google Scholar] [CrossRef]

- Fundin, A.; Lilja, J.; Lagrosen, Y.; Bergquist, B. Quality 2030: Quality management for the future. Total Qual. Manag. Bus. Excell. 2020. [Google Scholar] [CrossRef]

- Kiran, D.R. Total Quality Management, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Goeks, L.S.; dos Santos, A.A.; Korzenowski, A.L. Decision-making trends in quality management: A literature review about Industry 4.0. Production 2020, 30. [Google Scholar] [CrossRef]

- Ponsignon, F.; Kleinhans, S.; Bressolles, G. The contribution of quality management to an organisation’s digital transformation: A qualitative study. Total Qual. Manag. Bus. Excell. 2019, 30, S17–S34. [Google Scholar] [CrossRef]

- Ammar, M.; Haleem, A.; Javaid, M.; Bahl, S.; Verma, A.S. Implementing Industry 4.0 technologies in self-healing materials and digitally managing the quality of manufacturing. Mater. Today Proc. 2021, 52, 2285–2294. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Douglas, J.A.; McDermott, O. Motivations, barriers and readiness factors for Quality 4.0 implementation: An exploratory study. TQM J. 2021, 33, 1502–1515. [Google Scholar] [CrossRef]

- Nagyova, A.; Pacaiova, H.; Markulik, S.; Turisova, R.; Kozel, R.; Dzugan, J. Design of a Model for Risk Reduction in Project Management in Small and Medium Sized Enterprises (SMEs). Symmetry 2021, 13, 763. [Google Scholar] [CrossRef]

- Antony, J.; Sony, M.; Cudney, E. Quality 4.0: Motivation and Challenges from a Pilot Survey in Europeans Firms. Available online: https://www.thefuturefactory.com/blog/53 (accessed on 6 November 2021).

- Dovleac, R. Knowledge management systems in Quality 4.0. MATEC Web Conf. 2021, 342, 09003. [Google Scholar] [CrossRef]

- ISO 9001:2015; Quality Management Systems—Requirements. ISO: Geneva, Switzerland, 2015.

- Nenadál, J. Adequacy, Suitability, Effectiveness and Efficiency of Quality Management Systems: How to perceive and assess them? Qual. Innov. Prosper. 2016, 20, 39–52. [Google Scholar] [CrossRef] [Green Version]

- Erdil, A.; Erbiyik, H. The Importance of Benchmarking for the Management of the Firm: The Relation between Total Quality Management and Benchmarking. Procedia Comput. Sci. 2019, 158, 705–714. [Google Scholar] [CrossRef]

- Elg, M.; Birch-Jensen, A.; Gremyr, I.; Matin, J.; Melin, U. Digitalisation and quality management: Problems and prospects. Prod. Plan. Control 2020, 32, 990–1003. [Google Scholar] [CrossRef]

- Corti, D.; Masiero, S.; Gladysz, B. Impact of Industry 4.0 on Quality Management: Identification of main challenges towards a Quality 4.0 approach. In Proceedings of the IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 21–23 June 2021. [Google Scholar] [CrossRef]

- Chiarini, A. Industry 4.0, quality management and TQM world. A systematic literature review and a proposed agenda for further research. TQM J. 2020, 32, 603–616. [Google Scholar] [CrossRef]

- Emblemsvag, J. On Quality 4.0 in project-based industries. TQM J. 2020, 32, 725–739. [Google Scholar] [CrossRef]

- Habib, M.K.; Chrismon, C. Industry 4.0: Sustainability and Design Principles. In Proceedings of the 20th International Conference on Research and Education in Mechatronics, Wels, Austria, 23–24 May 2019. [Google Scholar] [CrossRef]

- Cochran, D.S.; Rauch, E. Sustainable Enterprise Design 4.0: Addressing Industry 4.0 Technologies from the Perspective of Sustainability. Procedia Manuf. 2020, 51, 1237–1244. [Google Scholar] [CrossRef]

- Beravi, M.A. The Role of Industry 4.0 in Achieving Sustainable Development Goals. Int. J. Technol. 2019, 10, 644. [Google Scholar] [CrossRef] [Green Version]

- Raj, P.E.; Wahab, S.A.; Zawawi, N.F.M.; Awang, K.W.; Ibrahim, W.Z.A.A.W. The benefits of Industry 4.0 on Sustainable Development and Malaysia´s Vision. IOP Conf. Ser. Earth Environ. Sci. 2020, 549, 012080. [Google Scholar] [CrossRef]

- Khan, I.S.; Ahmad, M.O.; Majawa, J. Industry 4.0 and sustainable development: A systematic mapping of triple bottom line, Circular Economy and Sustainable Business Model perspectives. J. Clean. Prod. 2021, 297, 126655. [Google Scholar] [CrossRef]

- Beltrami, M.; Orzes, G.; Sarkis, J.; Santor, M. Industry 4.0 and sustainability: Towards conceptualization and theory. J. Clean. Prod. 2021, 312, 127733. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).