Abstract

In this study, the effects of various parameters of the filter bag cleaning system, such as the blow tube size (20A, 40A, 50A), the nozzle diameter (5, 10, 15, 20, 25, 30 mm), the initial tank pressure (0.3, 0.4, 0.5, 0.6, 0.7 MPa), and the pulse duration (50, 100, 150, 200, 250, 300 ms), were evaluated with a view of peak pressure and pressure impulse. This study shows that the peak pressure and pressure impulse are not always in a proportional relationship, since pressure impulse aggregates static pressure and pressure over elapsed time together. For the system investigated, it is found that increasing the blow tube size and pulse duration induce a larger pressure impulse with little change in peak pressure, while higher initial tank pressure enhances both peak pressure and pressure impulse. On the other hand, a larger nozzle diameter was found to increase peak pressure rather than pressure impulse throughout the bag. The experimental results suggest that a higher initial tank pressure is a convenient way to elevate the overall dust-cleaning performance of pulse-jet systems, while other parameters (blow tube size, nozzle diameter, initial tank pressure) can be adopted according to the desired effect for given environment.

1. Introduction

The fabric filtration system is one of the most widely used technologies for dust removal from emitted gas in various industrial fields. In a pulse-jet fabric filtration system, inlet gas containing dust passes through a fabric filter bag, inducing dust particles to be caught by the fiber structure of the filter bag. With continuous filtration, a dust cake, which is a layer of aggregated dust particles, is formed on the outer surface of the filter bag. As the dust cake grows, the pressure drop across the filter bag increases, resulting in a decrease in the filtration velocity or an increase in the power consumption [1,2]. Therefore, to enhance filtration efficiency while lowering operational costs, it is critically required to maintain a low pressure drop throughout the filtration system, which can be obtained by maximizing the filter cleaning performance through periodic pulse-jet air ejection [3,4,5]. A pulse-jet filter bag cleaning system, which is usually composed of an air compressor, gas container, diaphragm valve, blow tube, and nozzle, discharges compressed air toward the opening of the filter bag for an instant. Here, as the pulse of air moves downward along the axial direction of the filter bag, the static pressure inside the bag is increased and strikes the inner wall of the bag, inducing the dust cake to detach from the outer surface of the filter bag [3,4,5,6,7].

There have been numerous studies attempting to understand the mechanism of filter bag cleaning and optimize the parameters of a bag cleaning system to enhance the cleaning performance [5,6,7,8,9,10,11,12,13,14,15,16,17,18]. Qian et al. investigated the optimal relationship of nozzle diameter with jet distance and blow tube size, while Shim et al. and Andersen et al. developed novel configurations of pulse-jet nozzles and examined them through experimental and computational methods [7,8,9,10]. Additionally, other operational parameters such as initial tank pressure [5,6,7,11,13,14,15,18], pulse-jet duration [5,6,7,17], induced airflow [5,7,14,16], and surface treatment [12,14,17] have been discussed.

In these prior studies, several features have been used to evaluate the filter bag cleaning performance, such as peak pressure [8,10,11,14,16,17,18], peak pressure arrival time [16], average pulse overpressure [12,19], and fabric acceleration [6,10]. As mentioned by Cuiping et al. and Lo et al., however, when the compressed pulse-jet air reaches the opening of the filter bag, incomplete cleaning occurs, especially at the top part of the filter bag [13,19]. This is because as the high-speed compressed air moves downward, the top part, where the air speed is the highest, instantly becomes vacant with air, creating a negative pressure for a certain time. This results in the formation of a backflow from the outer side of the filter bag toward the inside across the fiber, causing reattachment of dust particles on the filter bag surface. Since the features for evaluation of the filter bag cleaning performance mentioned above cannot accurately reflect the negative pressure occurrence, a different point of view is required that simultaneously considers both positive static pressure, which is helpful for filter bag cleaning, and negative pressure, which causes backflow. Accordingly, the pressure impulse (PI), which is an integrated value of static pressure measured at the interior wall of the filter bag according to the elapsed time of pulsing air passage (Pa∙s) [3,5], should be adopted as an index for the bag cleaning performance. However, compared to other evaluation indexes of the filter bag cleaning performance such as peak pressure and fabric acceleration, pressure impulse (PI) has not been widely investigated with various system parameters adjusted.

Therefore, in this study, the influence of the configurational and operational parameters of a pulse-jet filter bag cleaning system was investigated by adopting peak pressure and pressure impulse (PI), which are two critical criteria for filter bag cleaning performance. Here, the major parameters of the filter bag cleaning system, such as blow tube size, nozzle diameter, initial tank pressure, and pulse duration, were varied, and their effects on the bag filter were analyzed by measuring the real-time static pressure distribution along the axial direction of the filter bag. The detailed results of this study are expected to provide a basic understanding of the relationship between the components of bag cleaning systems and how they can be applied to enhance the bag cleaning performance from two different perspectives.

2. Materials and Methods

2.1. Experimental Setup

The experimental setup used in this study was specially designed to measure the pulse-jet air pressure delivered to the inner wall of the filter bag during the bag cleaning process. As shown in Figure 1, a single filter bag made of polyester (PE) with a diameter and length of 156 mm and 5000 mm, respectively, was installed on a steel support in parallel with the ground. A filter bag cage made of stainless steel with ribs and a bottom plate was inserted into the filter bag to sustain the filter bag structure. Pulse-jet air, commonly used for the filter bag cleaning process, was provided by a compressed-air-supplying system composed of an air compressor (SC35-40, Samsung, Seoul, Korea), a gas container (100 L), a diaphragm valve, a blow tube, and a nozzle. Here, the pressurized cleaning air was kept constant at the desired pressure value in the gas container by the air compressor. Then, the pulse-jet air was generated by opening the diaphragm valve, with the pulse duration regulated by a pulse controller. Immediately after the pulse-jet air ejection, the pressure of the gas container was recovered by the air compressor for the next discharge. Seven high-precision pressure transducers (Model PSH, Sensys, Seoul, Korea) were employed in series on the side wall of the filter bag to monitor the static pressure transition. The distance interval between each pressure transducer was 700 mm, and the top one (PT1, Figure 1) was located at 700 mm from the opening of the filter bag. The experiments in this study were carried out without dust to avoid possible interference resulting from the physicochemical properties of the dust.

Figure 1.

The experimental setup for evaluating the pulse-jet filter bag cleaning system.

2.2. Characterization of the Filter Bag Cleaning Performance

As mentioned above, this study examined the two key features of peak pressure and pressure impulse (PI) as the evaluation indexes for the filter bag cleaning performance. Here, the peak pressure was defined as the highest static pressure value from the pressure distribution measured during the elapsed pulsing time, while the pressure impulse was derived from the integral of the static pressure according to the elapsed time (t), or , at a specific measuring point [3,5,13]. The concept of total pressure impulse, which is the summation of the pressure impulse throughout a single filter bag, was introduced as an indicator for the overall filter bag cleaning performance. In this study, it was assumed that positive pressure of any magnitude plays a role in cleaning the filter bag, while negative pressure is detrimental to effective bag cleaning performance, since the experiment was conducted without dust. Also, to investigate how each component of pulse-jet cleaning stystem affects the peak pressure and pressure impulse of filter bag, system parameters were varied as shown in Table 1.

Table 1.

Experimental parameters.

3. Results and Discussion

3.1. Influence of Blow Tube Size on the Filter Bag Cleaning Performance

Figure 2 shows the commonly observed pressure transition profile at each measuring point of a single filter bag when the compressed cleaning air is ejected. Here, the peak pressure monitored at each point showed a decreasing tendency at the upper-half part while presenting a slightly increasing trend at the lower-half part, along the axial direction of the filter bag. The peak pressure decrease in the upper-half part of the filter bag can be explained by the cleaning air movement, the majority of which is axially transmitted downward along the filter bag, while part of the air moves outward through the filter. At the bottom part, however, the peak pressure is slightly recovered due to air reflux, which occurs from the reflection of pulse air on the bottom plate of the filter cage. This is in accordance with prior studies by X. Simon et al. and B.O. Anderson et al. [6,7,10,14].

Figure 2.

The overall profile of the static pressure transition that occurred by pulse air ejection measured at seven measuring points located axially along a single filter bag. The X-axis represents the elapsed time for pulse air discharge at each measuring point, and the figure presents the pressure transition measured for 2 s.

Figure 3 presents the effect of the pulse-jet air on the static pressure distribution, when discharged toward the opening of the filter bag through different blow tube sizes (20A, 40A, 50A). Here, the blow tubes used in this study were made of stainless steel 304 (SCH10S), and the detailed dimensions of those are expressed in Table 2. Figure 3a shows the peak pressure distribution according to blow tube sizes, and it indicates that there is no significant difference between the peak pressure values at the same measuring position regardless of blow tube size. This is because the pressure of the pulse air at the nozzle tip is nearly consistent regardless of the blow tube size. Since the specifications of the diaphragm valve correspond to the blow tube size, an increase in the blow tube size requires a larger diaphragm valve. Diaphragm valves with larger valve diameters eject a larger pulse airflow under constant initial tank pressure and pulse duration conditions. Because the pulse airflow increases proportionally to the blow tube’s cross-sectional area, the total pressure in the blow tube does not increase significantly. In addition, since the pulse air passes through a nozzle with a fixed diameter, the peak pressure distributions measured at the filter bag show similarity regardless of the blow tube sizes.

Figure 3.

Effect of the blow tube size on the (a) peak pressure distribution, (b) pressure impulse distribution, and (c) total pressure impulse of a filter bag.

Table 2.

Blow tube pipe dimension.

Conversely, the pressure impulse shows considerable variations according to differences in blow tube sizes, as presented in Figure 3b. At the top measuring point (PT1), due to the high velocity of the pulse air passage, immediate vanishment of air is induced into the upper part of the filter bag. Since the negative pressure is sustained until equalized by external gas and the positive pressure is only maintained for a remarkably short time, the pressure impulse reflecting both situations becomes very low. As the pulse air expands dramatically after passing the top part (PT1) of the filter bag, the pressure of the cleaning air decreases rapidly due to the gas expansion. At the same time, the kinetic energy of the pulse air decreases as it proceeds downward, resulting in a longer residence time at PT2. Combining these factors, the pressure impulse increases at PT2 compared to PT1, even compensating for the possible occurrence of negative pressure from the air passage. Then, the pressure impulse decreases at PT3, since a part of the pulse air flows outward from the interior of the filter bag while the velocity of the majority of the air is still high enough to create negative pressure. Meanwhile, the effective pressure impulse at the lower half of the filter bag shows somewhat different behavior. Here, the pulsing air becomes mixed with the rebounded air flow which has been reflected from the steel plate of the filter cage, therefore extending the pressure residence time as the pulsing air moves downward. This contrasting tendency of the pressure impulse between the upper and lower halves of the filter bag appears to be in common with the other experimental conditions introduced in this study. Figure 3b indicates that the extent of the pressure impulse increases with larger blow tubes due to the increase in pulse airflow proportional to the blow tube sizes.

Figure 3c compares the summation of the pressure impulse throughout a single filter bag with different blow tube sizes. It reveals that blow tubes with larger dimensions can improve the bag cleaning performance. However, it must be noted that an imbalance in the bag cleaning performance appears to be more significant with larger blow tubes, as shown in Figure 3b.

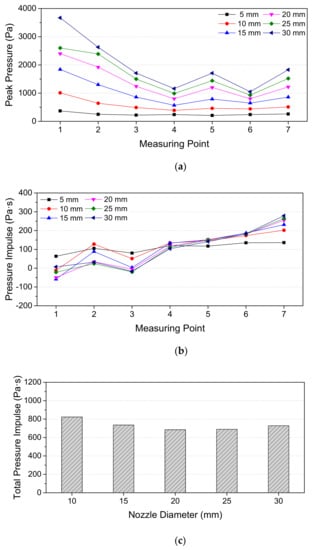

3.2. Influence of Nozzle Diameter on the Filter Bag Cleaning Performance

Figure 4 presents the static pressure distribution at seven measuring points of the filter bag when the pulse air was ejected through a nipple nozzle of 46 mm length and with various diameters. As shown in Figure 4a, it is evident that the peak pressure at each measuring point increases with increasing nozzle diameter, which corresponds to the prior studies by Simon et al. and Lu et al. [6,13]. The slight increasing tendency of the peak pressure at PT5 can be inferred to occur because the encounter of pulse air and reflux air from the bottom plate mainly occurs at this location. Figure 4b reveals that the pressure impulse distribution with different nozzle diameters has a similar tendency along the filter bag. This occurs due to the proportional relationship of the pulse airflow rate with the nozzle diameter when the other operating parameters are fixed [5,10]. This results in comparatively shorter times required for the pulse air to travel throughout the filter bag when discharged from the larger nozzle diameters. Therefore, though the peak pressure increases with the larger nozzle diameters, the pressure impulse, which is the integral of pressure over elapsed time, does not show a significant difference according to the nozzle conditions. On the other hand, the smallest nozzle with a diameter of 5 mm presents a gentle slope in both peak pressure and pressure impulse distribution, due to the very slow pulse air velocity causing long residence time with no negative pressure occurrence.

Figure 4.

Effect of the nozzle diameter on the (a) peak pressure distribution, (b) pressure impulse distribution, and (c) total pressure impulse of a filter bag.

It should be noted from Figure 4b that the pulse air discharged from 10 mm and 15 mm nozzles presents higher pressure impulses at PT2 compared to the pulse air emitted from nozzles with the larger diameters of 20, 25, and 30 mm. These findings can be explained by the fact that the larger nozzles create a more dramatic backflow due to the instant air passage with higher velocity and air density compared to that of the smaller nozzles, offsetting the positive pressure impulse obtained by pulse air expansion.

Figure 4c shows the total pressure impulse throughout the filter bag with different nozzle diameter conditions. Here, it is seen that the nipple nozzle with a diameter of 10 mm shows the best bag cleaning performance, though incomplete cleaning occurs at the upper part of the filter bag.

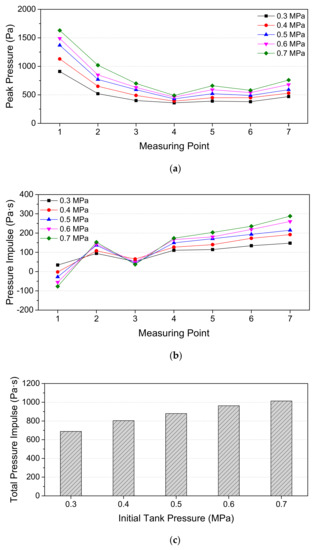

3.3. Influence of Initial Tank Pressure and Pulse Duration Time on the Filter Bag Cleaning Performance

Figure 5 shows the effect of initial tank pressure on the filter bag cleaning performance. In Figure 5a, it is seen that the peak pressure measured at the filter bag’s interior increased with the increment of the initial tank pressure. This is because the pressure of the pulse air emitted from the nozzle increases with an increase in the initial tank pressure, while restricting other operating parameters from any variation. Since the nozzle configuration is also fixed, the velocity of the pulse airflow remains constant, resulting in a gradual displacement of the pressure impulse distribution with increasing initial tank pressure, as shown in Figure 5b. Here, a sequential decrease in the pressure impulse, due to the augmentation of the negative pressure value and its residence time as initial tank pressure is increased, is presented at the top measuring point (PT1). In Figure 5c, the total pressure impulse along the filter bag seems to increase in accordance with the initial tank pressure in spite of backflow intensification in the upper-half part of the filter bag.

Figure 5.

Effect of the initial tank pressure on the (a) peak pressure distribution, (b) pressure impulse distribution, and (c) total pressure impulse of a filter bag.

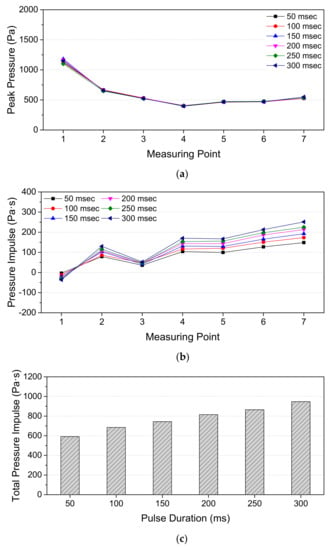

Figure 6 represents the effect of pulse duration on the pressure distribution of the filter bag. The pulse duration in this study was defined as the time the diaphragm valve was maintained open for the pulse air discharge. The pulse duration was varied to 50, 100, 150, 200, 250, and 300 ms. Figure 6a indicates that there was no remarkable difference in the static pressure monitored at each measuring point of the filter bag, since the operating parameters, such as pulse air pressure and nozzle diameter, were fixed. On the other hand, Figure 6b shows a progressive growth in the pressure impulse with increasing pulse duration, indicating the extension of the pulse air residence time with longer pulse durations. Therefore, it can be inferred that the elongation of pulse duration leads to an increase in the total pulse airflow, resulting in higher performance for the overall bag cleaning, as seen in Figure 6c. Additionally, it is noted that the extension of pulse duration plays a similar role to increasing the blow tube size in a pulse-jet air filter bag cleaning system.

Figure 6.

Effect of the pulse duration on the (a) peak pressure distribution, (b) pressure impulse distribution, and (c) total pressure impulse of a filter bag.

4. Conclusions

In this study, various parameters of a pulse-jet air filter bag cleaning system were examined from the perspective of the peak pressure and pressure impulse throughout a single bag to evaluate the influence of each parameter on the filter bag cleaning performance. Blow tube size, nozzle diameter, initial tank pressure, and pulse air duration were adopted as variables in the filter bag cleaning system. First, it was revealed that a larger blow tube size induces a greater amount of pulse-jet airflow and a longer pulse residence time, thereby resulting in a total pressure impulse increase. Second, the nozzle diameter has a proportional relationship with the peak pressure measured at the side wall of the filter bag. However, due to the pulse air flowrate acceleration according to the larger nozzle area, the pressure impulse, which corresponds to the pulse residence time, did not show significant variance with different nozzle diameters. Meanwhile, smaller nozzle diameters of 5, 10, and 15 mm obtained comparatively higher total pressure impulses than larger nozzles, due to the augmentation of the backflow occurrence with larger nozzles. Third, the initial tank pressure was found to directly affect the peak pressure and the amount of pulse airflow, leading to an increase in the total pressure impulse with a larger initial tank pressure. Lastly, pulse duration showed an effect of elongation of pulse residence time, which is similarly presented from enlargement of blow tube size. The overall experimental results indicate that increasing initial tank pressure is a convenient way to enhance the overall dust cleaning performance of pulse-jet systems, by increasing both peak pressure and pressure impulse at the same time. On the other hand, other system parameters such as blow tube size, nozzle diameter, and initial tank pressure can also be adjusted to obtain selectively desired enhancement of peak pressure or pressure impulse, according to the given system environment.

Author Contributions

Conceptualization, E.K. and Y.B.; methodology, E.K.; validation, E.K., Y.B., H.-S.B. and D.-J.K.; formal analysis, E.K.; investigation, E.K.; resources, Y.B.; data curation, E.K. and H.-S.B.; writing—original draft preparation, E.K.; writing—review and editing, E.K., Y.B. and H.-S.B.; visualization, E.K.; supervision, E.K. and Y.B.; project administration, D.-J.K.; funding acquisition, E.K. and Y.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available in the article.

Acknowledgments

This study was supported by Korea Environmental Industry and Technology Institute (KEITI, RE202201600), Republic of Korea.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jeon, K.J.; Jung, Y.W. A simulation study on the compression behavior of dust cakes. Powder Technol. 2001, 141, 1–11. [Google Scholar] [CrossRef]

- Saleem, M.; Krammer, G. Effect of filtration velocity and dust concentration on cake formation and filter operation in a pilot scale jet pulsed bag filter. J. Hazard. Mater. 2006, 144, 677–681. [Google Scholar] [CrossRef] [PubMed]

- Klingel, R.; Löffler, F. Influence of cleaning intensity on pressure drop and residual dust areal density in a pulse-jet fabric filter. In Proceedings of the Filtech Conference, London, UK, 15 September 1983; pp. 306–314. [Google Scholar]

- Sievert, J.; Löffler, F. Fabric cleaning in pulse-jet filters. Chem. Eng. Process. 1989, 26, 179–183. [Google Scholar] [CrossRef]

- Lu, H.C.; Tsai, C.J. Numerical and experimental study of cleaning process of a pulse-jet fabric filtration system. Environ. Sci. Techynol. 1996, 30, 3243–3249. [Google Scholar] [CrossRef]

- Simon, X.; Chazelet, S.; Thomas, D.; Bémer, D.; Régnier, R. Experimental study of pulse-jet cleaning of bag filters supported by rigid rings. Powder Technol. 2007, 172, 67–81. [Google Scholar] [CrossRef]

- Andersen, B.O.; Nielsen, N.F.; Walther, J.H. Numerical and experimental study of pulse-jet cleaning in fabric filters. Powder Technol. 2016, 291, 284–298. [Google Scholar] [CrossRef] [Green Version]

- Qian, Y.; Bi, Y.; Zhang, Q.; Chen, H. The optimized relationship between jet distance and nozzle diameter of a pulse-jet cartridge filter. Powder Technol. 2014, 266, 191–195. [Google Scholar] [CrossRef]

- Shim, J.; Joe, Y.H.; Park, H.S. Influence of air injection nozzles on filter cleaning performance of pulse-jet bag filter. Powder Technol. 2017, 322, 250–257. [Google Scholar] [CrossRef]

- Qian, Y.; Chen, H.; Dai, H.; Liu, T.; Kuang, T.; Bian, L. Experimental study of the nozzle settings on blow tube in a pulse-jet cartridge filter. Sep. Purif. Technol. 2018, 191, 244–249. [Google Scholar] [CrossRef]

- Lu, H.C.; Tsai, C.J. Influence of design and operation parameters on bag-cleaning performance of pulse-jet baghouse. J. Environ. Eng. 1999, 125, 583–591. [Google Scholar] [CrossRef]

- Tsai, C.J.; Tsai, M.L.; Lu, H.C. Effect of filtration velocity and filtration pressure drop on the bag cleaning performance of a pulse-jet baghourse. Sep. Sci. Technol. 2000, 35, 211–226. [Google Scholar] [CrossRef]

- Lu, H.C.; Tsai, C.J. Influence of different cleaning conditions on cleaning performance of pilot-scale pulse-jet baghouse. J. Environ. Eng. 2003, 129, 811–818. [Google Scholar] [CrossRef] [Green Version]

- Yan, C.; Liu, G.; Chen, H. Effect of induced airflow on the surface static pressure of pleated fabric filter cartridges during pulse jet cleaning. Powder Technol. 2013, 249, 424–430. [Google Scholar] [CrossRef]

- Qian, Y.; Bi, Y.; Zhang, M.; Chen, H.; Xu, G. Effect of filtration operation and surface treatment on pulse-jet cleaning performance of filter bags. Powder Technol. 2015, 277, 82–88. [Google Scholar] [CrossRef]

- Liu, X.; Shen, H. Effect of venturi structures on the cleaning performance of a pulse jet baghouse. Appl. Sci. 2019, 9, 3687. [Google Scholar] [CrossRef] [Green Version]

- Furumoto, K.; Narita, T.; Fukasawa, T.; Ishigami, T.; Kuo, H.P.; Huang, A.N.; Fukui, K. Influence of pulse-jet cleaning interval on performance of compact dust collector with pleated filter. Sep. Purif. Technol. 2021, 279, 119688. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, M.; Qian, Y.; Gne, F.; Song, J.; Chen, H. The relationship between peak pressure and residual dust of a pulse-jet cartridge filter. Powder Technol. 2015, 283, 302–307. [Google Scholar] [CrossRef]

- Lo, L.M.; Hu, S.C.; Chen, D.R.; Pui, D.Y.H. Numerical study of pleated fabric cartridges during pulse-jet cleaning. Powder Technol. 2010, 198, 75–81. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).