Almond Shells and Exhausted Olive Cake as Fuels for Biomass Domestic Boilers: Optimization, Performance and Pollutant Emissions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material and Characterization

2.2. Experimental Setup and Methodology

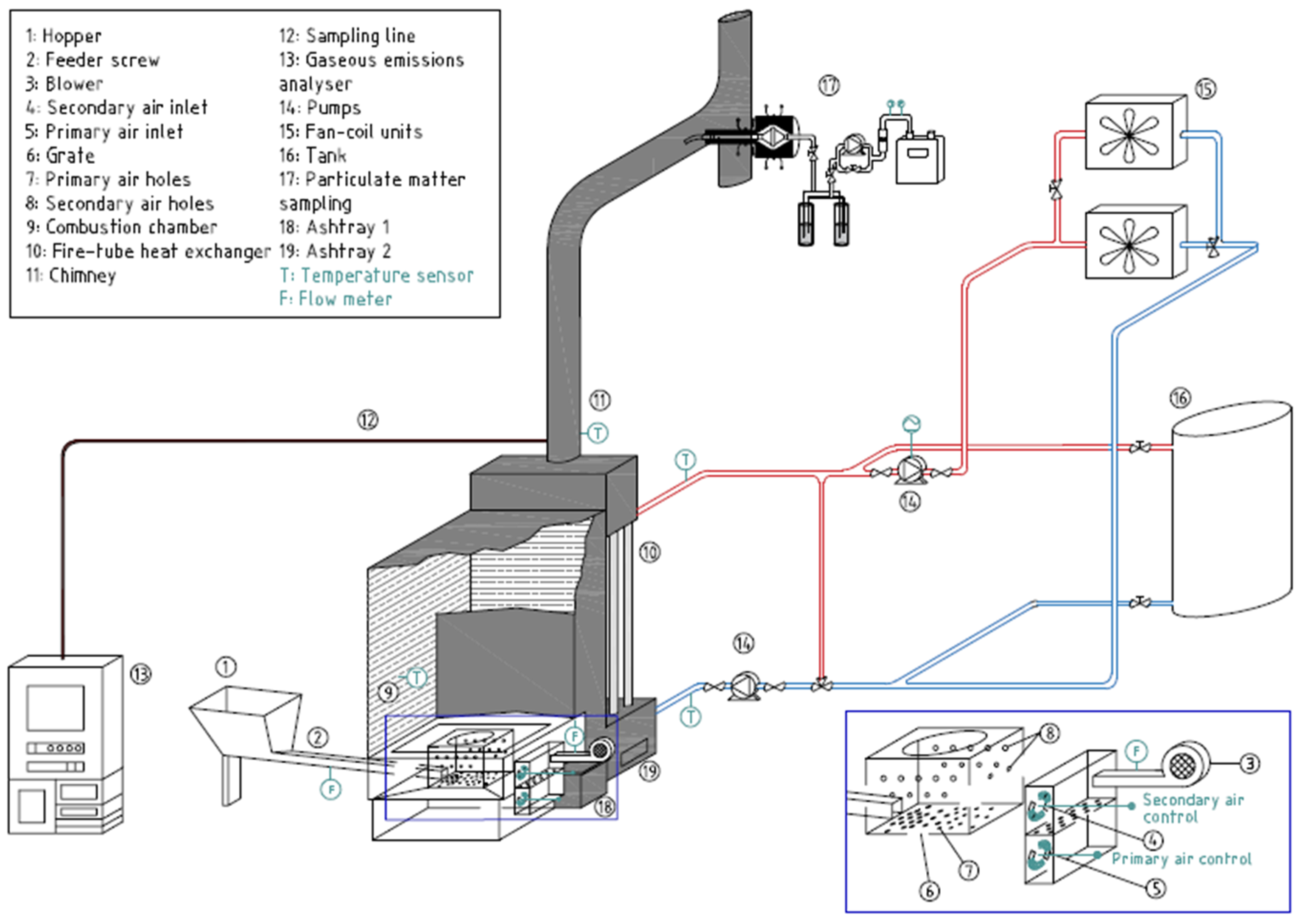

2.2.1. Boiler Description

2.2.2. Methodology

2.2.3. Statistical Experimental Design

3. Results and Discussion

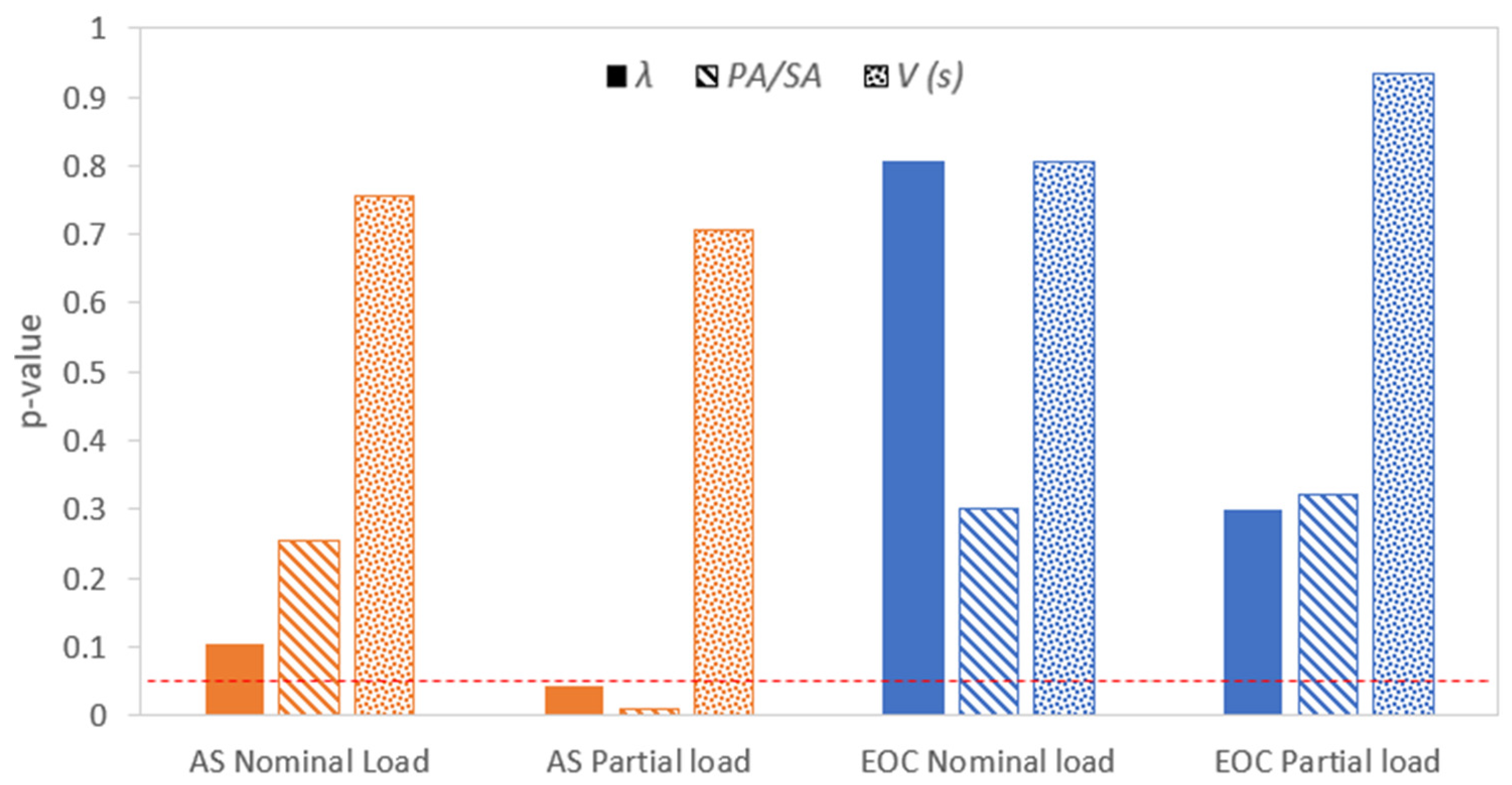

3.1. Statistical Results

- Parametric study (stage 1)

- Optimization (stage 2)

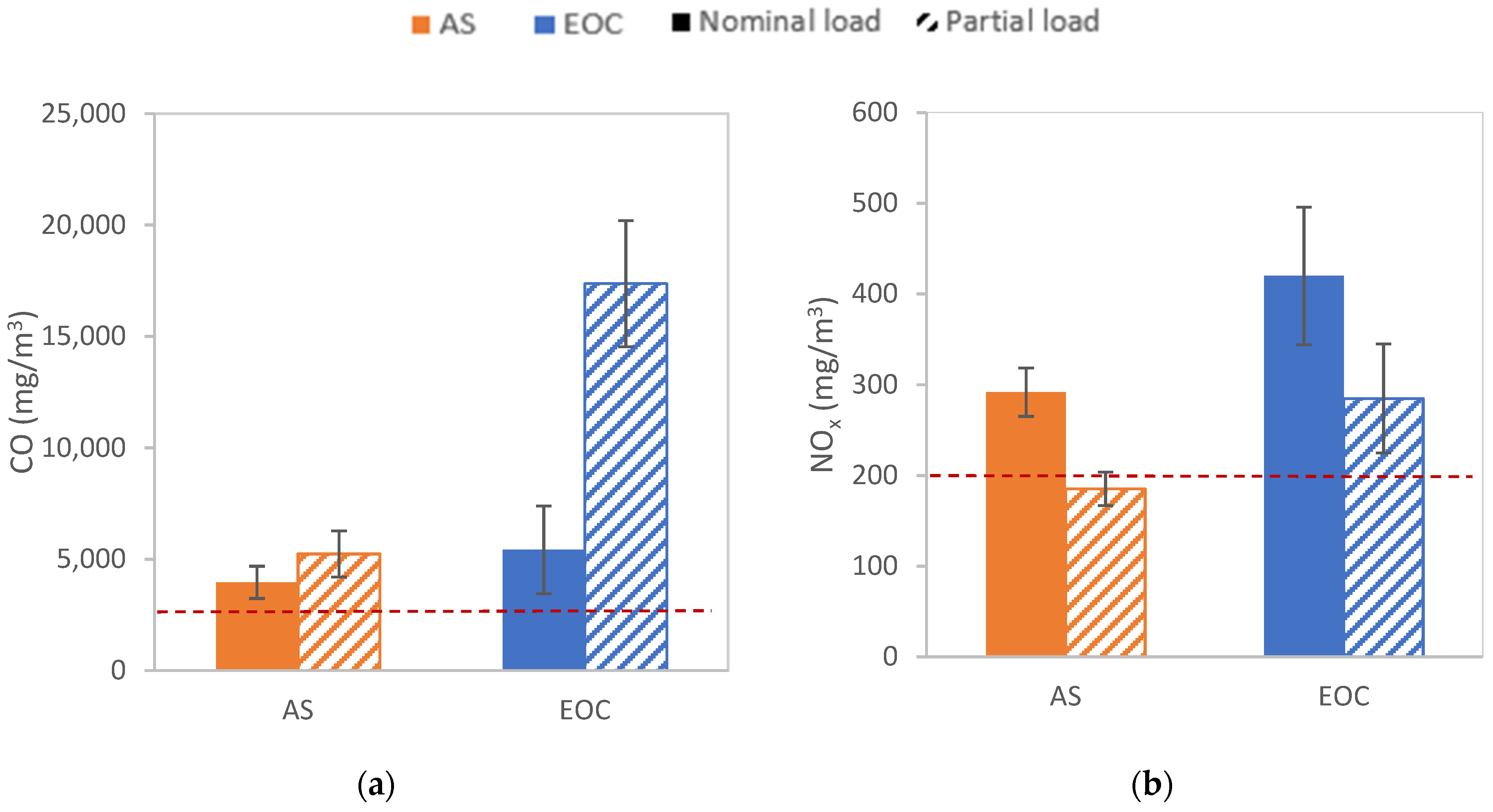

3.2. Gaseous and PM Emissions

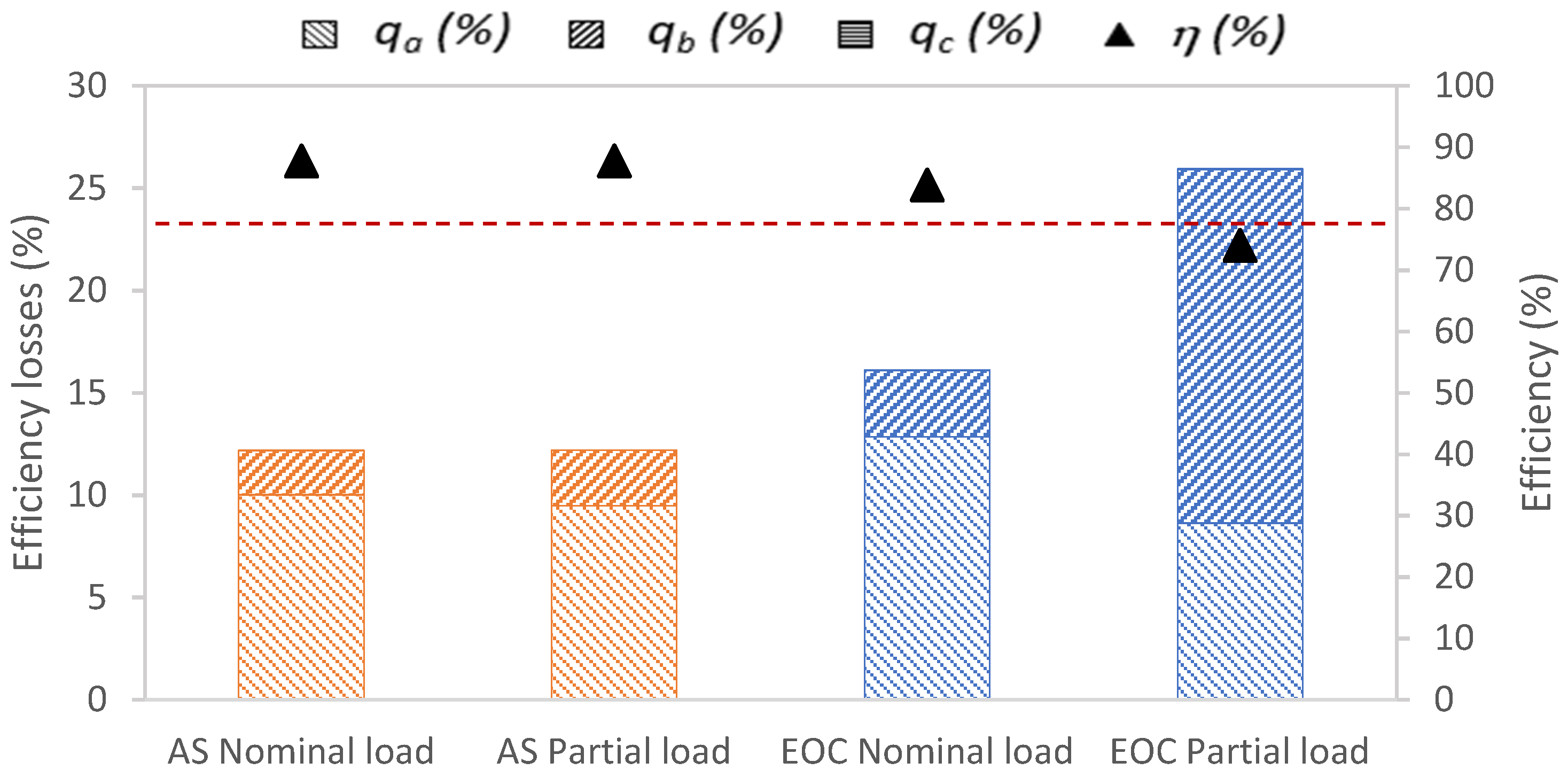

3.3. Efficiency

4. Conclusions

- -

- The required excess air (around 1.5) for both loads (~55 and ~24 kW) was higher than that typically used for woody biomass.

- -

- The optimal primary/secondary air ratio at nominal load was 20/80 for both fuels. However, this value changed to 50/50 for almond shells at a low load.

- -

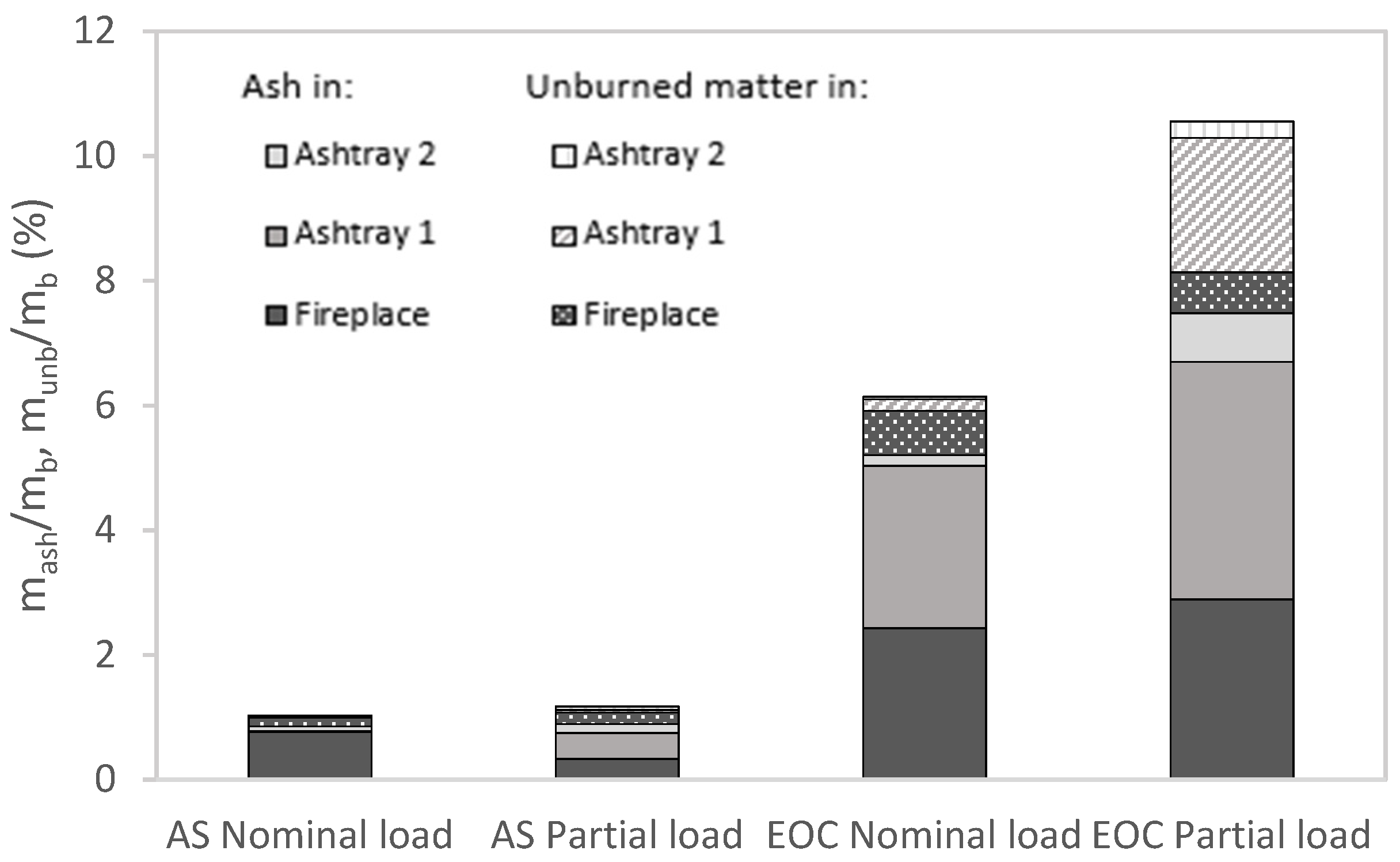

- Because of the very significant ash content of exhausted olive cake, a higher grate vibration frequency was required (20 s with respect to the 45 s needed by almond shells).

- -

- The boiler efficiency at the optimum operating conditions was above the minimum value of 77%, required by UNE-EN 303-5 for Class 3 boilers, except in exhausted olive cake at low load.

- -

- Regarding gaseous and particles emission, CO emissions were lower and NOx (mainly related to the fuel-N content) were higher at nominal load for both fuels because of a more complete combustion process. Moreover, PM emissions increased due to fuel particles entraining the flue gas.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| λ | Excess air |

| η | Boiler efficiency (%) |

| LHV | Lower heating value of the fuel (MJ/kg) |

| Tff | Fireplace fume temperature (°C) |

| Tcf | Chimney fume temperature (°C) |

| Ta | Ambient temperature (°C) |

| Ppar | Partial load power (kW) |

| Pnom | Nominal load power (kW) |

| qa | Sensible heat losses in the flue gas (%) |

| qb | Latent heat losses in the flue gas (%) |

| qc | Heat losses by unburned matter in the solid residue (%) |

| Qa | Sensible heat losses in the flue gas (kJ/kg) |

| Qb | Latent heat losses in the flue gas (kJ/kg) |

| Qc | Heat losses by unburned matter in the solid residue (kJ/kg) |

| C | Carbon content of the fuel (wt.%) |

| H | Hydrogen content of the fuel (wt.%) |

| N | Nitrogen content of the fuel (wt.%) |

| S | Sulphur content of the fuel (wt.%) |

| Cl | Chlorine content of the fuel (wt.%) |

| Cr | Carbon content of the residue with respect to the mass of fuel (wt.%) |

| W | Moisture content of the fuel (wt.%) |

| A | Residue passing through the grate (wt.% with respect to the fuel) |

| B | Unburned matter present in the waste with respect to the mass of residue (wt.%) |

| mash | Ash content of solid residues (kg) |

| munb | Unburned matter content of solid residues (kg) |

| mb | Total fuel feed to the boiler (kg) |

| AS | Almond shells |

| EOC | Exhausted olive cake pellet |

| PA | Primary air flow (%) |

| SA | Secondary air flow (%) |

| V | Grate vibration frequency (s) |

| PM | Particulate matter (mg/m3) |

| DoE | Design of Experiments |

| OF | Objective function |

| RSM | Response Surface Methodology |

References

- Directive (EU) 2018/2001 on the Promotion of the Use of Energy from Renewable Sources; 2018; pp. 141–144. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG (accessed on 27 April 2022).

- MITECO. National Integrated Energy and Climate Plan 2021–2030; 2021; Section III; p. 36796, (In Spanish). Available online: https://ec.europa.eu/info/energy-climate-change-environment/implementation-eu-countries/energy-and-climate-governance-and-reporting/national-energy-and-climate-plans_en (accessed on 27 April 2022).

- IDAE. Final Energy Consumption Balance. Available online: https://sieeweb.idae.es/consumofinal/bal.asp?txt=2019&tipbal=t (accessed on 27 April 2022).

- IDAE. Consumption by Use in the Residential Sector. Available online: https://informesweb.idae.es/consumo-usos-residencial/informe.php (accessed on 27 April 2022).

- FAOSTAT. Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 27 April 2022).

- Nussbaumer, T. Combustion and co-combustion of biomass: Fundamentals, technologies, and primary measures for emission reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2008; ISBN 978-1-84407-249-1. [Google Scholar]

- UNE-EN 303-5; Heating Boilers—Part 5: Heating Boilers for Solid Fuels, Manually and Automatically Stoked, Nominal Heat Output of up to 500 kW. European Committee for Standardization: Brussels, Belgium, 2022.

- UNE-EN 16510-1; Residential Solid Fuel Burning Appliances—Part 1: General Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2019.

- European Commission. Commission Regulation (EU) 2015/1189; 2015; Volume 193, pp. 100–114. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32015R1189 (accessed on 27 April 2022).

- Khodaei, H.; Guzzomi, F.; Patiño, D.; Rashidian, B.; Yeoh, G.H. Air staging strategies in biomass combustion-gaseous and particulate emission reduction potentials. Fuel Process. Technol. 2017, 157, 29–41. [Google Scholar] [CrossRef]

- Lamberg, H.; Sippula, O.; Tissari, J.; Jokiniemi, J. Effects of air staging and load on fine-particle and gaseous emissions from a small-scale pellet boiler. Energy Fuels 2011, 25, 4952–4960. [Google Scholar] [CrossRef]

- Zadravec, T.; Rajh, B.; Kokalj, F.; Samec, N. Influence of air staging strategies on flue gas sensible heat losses and gaseous emissions of a wood pellet boiler: An experimental study. Renew. Energy 2021, 178, 532–548. [Google Scholar] [CrossRef]

- Morán, J.C.; Míguez, J.L.; Porteiro, J.; Patiño, D.; Granada, E. Low-quality fuels for small-scale combustion boilers: An experimental study. Energy Fuels 2015, 29, 3064–3081. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical properties of solid biofuels-significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Wiinikka, H.; Gebart, R. Critical parameters for particle emissions in small-scale fixed-bed combustion of wood pellets. Energy Fuels 2004, 18, 897–907. [Google Scholar] [CrossRef]

- Friberg, R.; Blasiak, W. Measurements of mass flux and stoichiometry of conversion gas from three different wood fuels as function of volume flux of primary air in packed-bed combustion. Biomass Bioenergy 2002, 23, 189–208. [Google Scholar] [CrossRef]

- Monedero, E.; Portero, H.; Lapuerta, M. Combustion of poplar and pine pellet blends in a 50 kW domestic boiler: Emissions and combustion efficiency. Energies 2018, 11, 1580. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.B.; Goodfellow, J.; Nasserzadeh, V.; Swithenbank, J. Study on the transient process of waste fuel incineration in a full-scale moving-bed furnace. Combust. Sci. Technol. 2006, 177, 127–150. [Google Scholar] [CrossRef]

- Silva, J.P.; Teixeira, S.; Grilo, É.; Peters, B.; Teixeira, J.C. Analysis and monitoring of the combustion performance in a biomass power plant. Clean. Eng. Technol. 2021, 5, 100334. [Google Scholar] [CrossRef]

- Verma, V.K.; Bram, S.; Delattin, F.; de Ruyck, J. Real life performance of domestic pellet boiler technologies as a function of operational loads: A case study of Belgium. Appl. Energy 2013, 101, 357–362. [Google Scholar] [CrossRef]

- González, J.F.; González-García, C.M.; Ramiro, A.; Gañán, J.; González, J.; Sabio, E.; Román, S.; Turegano, J. Use of almond residues for domestic heating. Study of the combustion parameters in a mural boiler. Fuel Process. Technol. 2005, 86, 1351–1368. [Google Scholar] [CrossRef]

- Chandrasekaran, S.R.; Hopke, P.K.; Newtown, M.; Hurlbut, A. Residential-scale biomass boiler emissions and efficiency characterization for several fuels. Energy Fuels 2013, 27, 4840–4849. [Google Scholar] [CrossRef]

- UNE-EN ISO 18134-2; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. European Committee for Standardization: Brussels, Belgium, 2017; pp. 1–12.

- UNE-EN ISO 18134-3; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample. European Committee for Standardization: Brussels, Belgium, 2016.

- UNE-EN ISO 17828; Solid Biofuels—Determination of Bulk Density. European Committee for Standardization: Brussels, Belgium, 2016.

- UNE-EN ISO 14780; Solid Biofuels—Sample Preparation. European Committee for Standardization: Brussels, Belgium, 2018.

- UNE-EN ISO 18122; Solid Biofuels—Determination of Ash Content. European Committee for Standardization: Brussels, Belgium, 2016.

- UNE-EN ISO 18123; Solid Biofuels—Determination of the Content of Volatile Matter. European Committee for Standardization: Brussels, Belgium, 2016.

- UNE-EN ISO 16948; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. European Committee for Standardization: Brussels, Belgium, 2015.

- UNE-EN ISO 16994; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. European Committee for Standardization: Brussels, Belgium, 2017.

- UNE-EN ISO 18125; Solid Biofuels—Determination of Calorific Value. European Committee for Standardization: Brussels, Belgium, 2018.

- Serrano, C.; Portero, H.; Monedero, E. Pine chips combustion in a 50 kW domestic biomass boiler. Fuel 2013, 111, 564–573. [Google Scholar] [CrossRef]

- Röpke, K.; von Essen, C. Special Issue DoE in engine development. Qual. Reliab. Eng. Int. 2008, 24, 643–651. [Google Scholar] [CrossRef]

- Vera Candioti, L.; de Zan, M.M.; Cámara, M.S.; Goicoechea, H.C. Experimental design and multiple response optimization. Using the desirability function in analytical methods development. Talanta 2014, 124, 123–138. [Google Scholar] [CrossRef]

- Regueiro, A.; Jezerská, L.; Patiño, D.; Pérez-Orozco, R.; Nečas, J.; Žídek, M. Experimental study of the viability of low-grade biofuels in small-scale appliances. Sustainability 2017, 9, 1823. [Google Scholar] [CrossRef] [Green Version]

- Werther, J.; Saenger, M.; Hartge, E.U.; Ogada, T.; Siagi, Z. Combustion of agricultural residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Tissari, J. Fine Particle Emissions from Residential Wood Combustion. Ph.D. Thesis, University of Kuopio, Joensuu, Finland, 2008. Volume 24. [Google Scholar]

- Ozgen, S.; Cernuschi, S.; Caserini, S. An overview of nitrogen oxides emissions from biomass combustion for domestic heat production. Renew. Sustain. Energy Rev. 2021, 135, 110113. [Google Scholar] [CrossRef]

- Díaz-Ramírez, M.; Sebastián, F.; Royo, J.; Rezeau, A. Influencing factors on NOX emission level during grate conversion of three pelletized energy crops. Appl. Energy 2014, 115, 360–373. [Google Scholar] [CrossRef]

- Carvalho, L.; Wopienka, E.; Pointner, C.; Lundgren, J.; Verma, V.K.; Haslinger, W.; Schmidl, C. Performance of a pellet boiler fired with agricultural fuels. Appl. Energy 2013, 104, 286–296. [Google Scholar] [CrossRef]

- Wiinikka, H.; Gebart, R. The influence of fuel type on particle emissions in combustion of biomass pellets. Combust. Sci. Technol. 2005, 177, 741–763. [Google Scholar] [CrossRef]

- Pérez-Orozco, R.; Patiño, D.; Porteiro, J.; Míguez, J.L. Novel test bench for the active reduction of biomass particulate matter emissions. Sustainability 2020, 12, 422. [Google Scholar] [CrossRef] [Green Version]

| Almond Shells | Exhausted Olive Cake | |

|---|---|---|

| Moisture (wt. %, wet basis) | 13.43 | 8.39 |

| Bulk density (kg/m3, wet basis) | 398.86 ± 4.99 | 616.96 ± 0.18 |

| Proximate analysis (wt.%, dry basis) | ||

| Ash | 1.93 ± 0.10 | 8.92 ± 0.41 |

| Volatiles | 83.39 ± 4.27 | 80.85 ± 4.33 |

| Fixed carbon | 14.68 ± 4.17 | 10.16 ± 3.78 |

| Ultimate analysis (wt.%, dry basis) | ||

| C | 51.53 ± 0.31 | 50.65 ± 0.20 |

| H | 5.18 ± 0.11 | 5.41 ± 0.10 |

| N | 0.72 ± 0.15 | 1.30 ± 0.10 |

| S | 0.01 ± 0.00 | 0.18 ± 0.01 |

| Cl | 0.01 ± 0.01 | 0.32 ± 0.02 |

| LHV (MJ/kg, dry basis) | 18.82 ± 0.02 | 19.27 ± 0.12 |

| Almond Shells and Exhausted Olive Cake | ||||||||

|---|---|---|---|---|---|---|---|---|

| λ | 1.2 | 1.5 | 1.2 | 1.5 | 1.5 | 1.5 | 1.2 | 1.2 |

| PA/SA | 20/80 | 20/80 | 40/60 | 40/60 | 40/60 | 20/80 | 40/60 | 20/80 |

| V (s) | 45 | 20 | 20 | 45 | 45 | 20 | 20 | 45 |

| Almond Shells | |||||||

|---|---|---|---|---|---|---|---|

| 55 kW | λ | 1.4 | 1.5 | 1.5 | 1.3 | 1.3 | 1.4 |

| PA/SA | 20/80 | 30/70 | 10/90 | 10/90 | 30/70 | 20/80 | |

| V (s) | 45 | 45 | 45 | 45 | 45 | 45 | |

| 24 kW | λ | 1.5 | 1.6 | 1.6 | 1.4 | 1.4 | 1.5 |

| PA/SA | 40/60 | 50/50 | 30/70 | 30/70 | 50/50 | 40/60 | |

| V (s) | 20 | 20 | 20 | 20 | 20 | 20 | |

| Almond Shells | Exhausted Olive Cake | |||

|---|---|---|---|---|

| 55 kW | 24 kW | 55 kW | 24 kW | |

| λ | 1.5 | 1.6 | 1.5 | 1.5 |

| PA/SA | 20/80 | 50/50 | 20/80 | 20/80 |

| V (s) | 45 | 20 | 20 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Collado, R.; Monedero, E.; Casero-Alonso, V.M.; Rodríguez-Aragón, L.J.; Hernández, J.J. Almond Shells and Exhausted Olive Cake as Fuels for Biomass Domestic Boilers: Optimization, Performance and Pollutant Emissions. Sustainability 2022, 14, 7271. https://doi.org/10.3390/su14127271

Collado R, Monedero E, Casero-Alonso VM, Rodríguez-Aragón LJ, Hernández JJ. Almond Shells and Exhausted Olive Cake as Fuels for Biomass Domestic Boilers: Optimization, Performance and Pollutant Emissions. Sustainability. 2022; 14(12):7271. https://doi.org/10.3390/su14127271

Chicago/Turabian StyleCollado, Rocío, Esperanza Monedero, Víctor Manuel Casero-Alonso, Licesio J. Rodríguez-Aragón, and Juan José Hernández. 2022. "Almond Shells and Exhausted Olive Cake as Fuels for Biomass Domestic Boilers: Optimization, Performance and Pollutant Emissions" Sustainability 14, no. 12: 7271. https://doi.org/10.3390/su14127271

APA StyleCollado, R., Monedero, E., Casero-Alonso, V. M., Rodríguez-Aragón, L. J., & Hernández, J. J. (2022). Almond Shells and Exhausted Olive Cake as Fuels for Biomass Domestic Boilers: Optimization, Performance and Pollutant Emissions. Sustainability, 14(12), 7271. https://doi.org/10.3390/su14127271