An Explorative Study of Circularity Practices in Swedish Manufacturing Companies

Abstract

:1. Introduction

2. Background

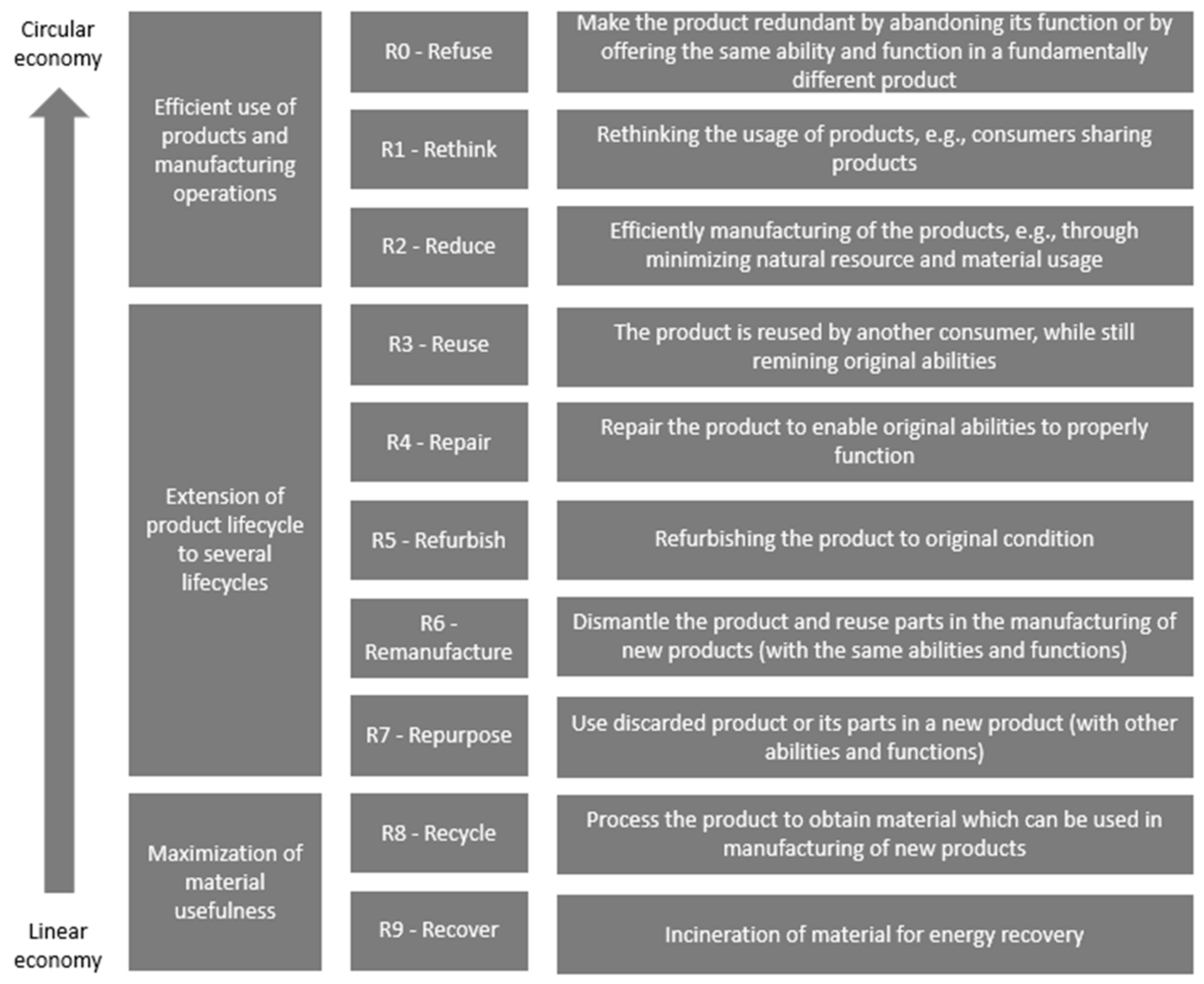

2.1. The R-Methodology and Circularity Practices

2.2. Sustainability Reporting in Sweden

3. State-of-the-Art Research

4. Methodology

4.1. Document Study

4.2. Sample Selection

4.3. Circularity Extraction, Data Coding, and Data Analysis

5. Findings

5.1. Circularity Practices in Manufacturing Companies

5.1.1. R0—Refuse

5.1.2. R1—Rethink

5.1.3. R2—Reduce

5.1.4. R3—Reuse

5.1.5. R4—Repair

5.1.6. R5—Refurbish

5.1.7. R6—Remanufacture

5.1.8. R7—Repurpose

5.1.9. R8—Recycle

5.1.10. R9—Recover

6. Discussion

6.1. Circularity Practices in Different Areas/Functions

6.2. Circularity Practice Level of Description

6.3. Extending the 10R Framework

7. Conclusions, Limitations, and Further Research

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Circularity Categories | Circularity Practices |

|---|---|

| R0—Refuse | |

| Refuse harmful materials in products | Transition from fossil fuels to biological sources for solvents and plastics |

| Refuse non-recyclable materials in products | No further description of practice mentioned |

| Refuse non-renewable resources | No further description of practice mentioned |

| R1—Rethink | |

| Apply sustainable chemical management | No further description of practice mentioned |

| Develop and adapt circular business models | Offering maintenance services; offering subscription services; through organizing product sharing; offering different business model setups for different customers based on need |

| Develop and launch circular innovations | Using new materials in products; applying clear principles for defining a circular innovation |

| Develop sustainable lubricants | Using lubricants based on vegetable oils; by offering changing reconditioned oil as a service, thus prolonging the lifetime of products |

| Use recyclable, recycled, renewable and sustainable materials in products | By recirculating materials into production processes. If materials cannot be recirculated internally, look for options for materials to be processed into by-products and sold externally. Thus creating new revenue streams for the company; following a clearly stated vision to include a percentage of recycled materials in new products; taking part in research projects; working closely with suppliers to develop the materials; Identifying efficient ways to measure and follow up an established vision; exploring alternative materials and production methods, e.g., Essity’s starting to produce tissues from wheat straw, a residual material from agriculture; promoting the use of recycled materials; establishing programs for coordinating and driving design and material related topics |

| Rethink packaging solutions | Carrying out projects, programs and initiatives in order to identify more sustainable packaging solutions |

| Use recyclable, recycled and renewable packaging materials | Improving the possibility of recycling the packaging materials; Developing alternative packaging materials; by initiating discussions with suppliers; replacing tailor-made packaging with recycled standard (e.g., pallets); adhering to local legislations regarding recycled materials; actively working with increasing recycling rate of consumer packaging; working with business partners in local markets to increase consumer awareness; working with preventive initiatives to reduce litters; launching programs to identify packaging solutions based on fossil-free materials |

| Rethink ways to enable customer sustainability | Registering product to Environmental Product Declaration (EPD), an independently verified document providing transparent and comparable information about environmental impacts of products from a lifecycle perspective. The EPD can be used by customers who want to minimize their carbon footprint; promoting recycling to customers; promoting initiatives against littering; increasing availability of spare parts |

| Rethink product design to make more sustainable and circular | Designing products for recycling; including recycling instructions for customers ensuring easy dismantling of product; designing out negative environmental impacts; using life cycles assessment to measure the products’ environmental impacts; developing and using tools for calculating carbon footprint of products which can be used during the design phase; setting goals for reducing carbon footprint for all design projects; driving the application of environmentally conscious design principles during product development lifecycle; developing guidelines for product development; developing tools for environmental evaluation; creating guideless for quantifying and communicating customers’ sustainability performance; designing products for recovery, either reusing or recycling (e.g., the EU End-of-Life Vehicle Directive) |

| Increase usage of renewable energy | Investing in solar panels; using heat from own production |

| Use new sustainable processes and technologies | Allocating funds for research and development; using electrically driven machines running on renewable energy, e.g., electric arc furnaces |

| Initiate new collaborations which support circularity | Using robotics and shared product data to scan waste for specific products and materials. Thus identifying recyclable portions and extract those; joining collaborations with the aim of accelerating the transition to a CE, e.g., the Ellen MacArthur foundation; collaborating with waste management suppliers to reduce waste and improve waste management; creating foundations, e.g., the Circular Bioeconomy Alliance.; creating action plans for circular economy; developing roadmaps to integrate circularity across the business; running ideation events to source ideas on how to apply a circular mindset across the value chain (result: a prioritized list of actions for implementation across medicine development, product manufacture, devices, packaging, logistics, facilities, and built assets and procurement); joining national research platforms (e.g., Treesearch); establishing repurchasing programs in collaboration with partners; joining collaborations which aids in coordinating efforts for CO2 reduction by bringing industries closer together, e.g., the CEO Alliance; promoting projects and investments; working continuously to identify partners who can make use of residual materials from production; joining recycling initiatives |

| Rethink transportation patterns | No further description of practice mentioned |

| Rethink ways to manage and evaluate supplier sustainability | Encouraging companies to integrate sustainability information into their reporting cycle, e.g., energy, waste, and water footprints; including energy management requirement for purchasing new machines; evaluating suppliers’ sustainability impacts through establishing environmental requirement for business partners, including manufacturing, transport, energy use, GHG emissions, chemicals in manufacturing, product chemical content, and water and waste management; evaluating suppliers’ sustainability impacts by establishing Circular Economy and Portfolio Sustainability programs; evaluating suppliers’ sustainability impacts by developing digital tools to support the assessment of suppliers CO2 impacts |

| R2—Reduce | |

| Reduce chemical usage | No further description of practice mentioned |

| Reduce energy usage | Developing innovative products which uses less energy; raising awareness and investing in efficient production equipment; including energy management requirements for purchasing new machines; establishing programs focusing on improving energy consumptions in the company’s facilities; annually setting up and following goals for improved energy efficiency; changing to more energy-efficient materials in the production; actively monitoring energy consumption; setting goals for energy efficiency and taking measures to achieve the goals; through reconditioning of products, since it leads to lower maintenance, costs and energy usage; using ISO certified energy management systems; by using a decentralized approach for improving the energy usage and integrating this with the company’s environmental management system; linking facilities’ energy efficiency to local maintenance strategies; setting group-wide energy targets; though energy recovery at manufacturing sites; through systematic energy management; continuously striving for energy efficiency; installing more energy-saving machines in the manufacturing; by establishing remanufacturing programs |

| Reduce fuel usage | At customers by offering lighter products, e.g., SSAB producing high-strength steel |

| Reduce GhG emissions | Through product design; having all division set own target for projects for new or redesigned products which will achieve a significant reduction in carbon footprint; through smart packaging solutions, reducing the air in packaging, thus increasing the utilization of space required during transports; by reducing size and weight of packaging materials; by integrating high-speed machines into important production phases; using low-carbon transport alternatives; reducing amount of business travels; scaling down waste at manufacturing sites; establishing programs for reducing CO2 emissions; using locally produced biogas; offering the service of reconditioning products; by producing products made from less raw materials, with lower weight and fuel consumption, increased load capacity and longer lifespans. thereby reducing GhG emissions in the use phase of the product; by producing high strength materials, resulting in lower weight and improved fuel economy for the customer; setting science based targets initiative approved targets for GhG emissions; utilizing residuals; using recycled materials as raw materials, thus reducing the need for virgin raw materials; Advancing and improving the manufacturing processes; using high quality materials; recirculating materials into the manufacturing processes, thus reducing the need for virgin raw materials; using larger share of recycled and bio-based materials; increasing resource utilization; minimizing waste; by efficient component value retention; developing new business opportunities; adapting to a circular economy (transforming product design and how products are produced); decreasing GhG emissions from production processes; carbon capturing; having an ongoing dialogue with suppliers to understand their roadmaps to reach carbon-neutral production; through remanufacturing programmes, restoring replaced parts to original specifications |

| Reduce packaging material | By harmonizing product components, e.g., ingredients and packaging as in the case of the diary manufacturer Arla Foods AB (Solna, Sweden); by reducing the number of stock-keeping units (SKUs); by setting clear targets to reduce selected packaging |

| Reduce pollution in air, land and water | Through product design |

| Reduce resource usage | Through increased resource efficiency by setting targets to lower process mass intensity (PMI); using metrics to measure raw material efficiency (e.g., PMI); by upgrading infrastructure and adapting the industry, including technologies and industrial processes; by integrating high-speed machines into important production phases; by ensuring that all raw materials are used, e.g., by finding solutions for how to use residual materials in other products; by seeing the products from a life cycle perspective; through productivity and quality-enhancing measures; by major investment programs in robotics and automation in low-cost countries; by striving for efficient resource management throughout the entire value chain; through innovation and product development; by increasing the process productivity; by enabling customers to send back products and reconditioning them; by creating and finding customer value through productivity which reliable products entails, e.g., as described by ABB, a company aiming at offering reliable rotation solutions.; by condition monitoring and data analysis, creating the possibility for products (e.g., bearings) to be removed from a demanding application and reconditioned before it breaks down; by utilizing residual materials; through remanufacturing programs; establishing materials saving programs (in production); reducing the material spill from production flows and feeding it back into manufacturing processes as raw materials (in production); by increasing the utilization degree of resources (in production) |

| Reduce hazardous waste | No further description of practice mentioned |

| Reduce waste sent to landfill | By using waste from production for recycling or extraction of energy; finding ways to utilize residual/slag products |

| Reduce waste sent for disposal | No further description of practice mentioned |

| Reduce waste in general | Through prevention, reduction, recycling and reusing waste; through product design; through well-preserving packaging; by setting ambitious targets; throughout the entire value chain |

| Reduce water usage | By innovative design of products; by improving processes; by extending the scope for water savings |

| R3—Reuse | |

| Reuse heat, steam from own production | By, e.g., using steam from mills in drying processes in sawmills; by recovering steam and hot water to generate electricity and heat. |

| Reuse residual materials from manufacturing | Reusing residual materials as raw materials in own production; by finding new functions for residual materials to be used as raw material in other products; through waste management with the aim to have new solutions for waste streams with the philosophy ‘every single step counts’ |

| Reuse metals | Through partaking in circular collaborations, e.g., ABB entering a local agreement to develop a process where all fractions (iron, copper and aluminium) in electric motors products can be recycled and reused in new products; through dismantling faulty or otherwise returned products and parts; through repurchasing programs; by changing from traditional manufacturing processes to electrical processes which uses scrap metals; through establishing a closed loop system with suppliers, e.g., Volvo Cars returning aluminium scrap from production to the suppliers, who in turn reuses is in their production |

| Reuse thermoplastics | No further description of practice mentioned |

| Reuse materials in general | Through examining the business opportunities for reusing materials; through product design fulfilling directives for reusability of materials |

| Reuse packaging material | No further description of practice mentioned |

| Reuse products | Establishing corporate divisions especially for repairing and reusing products.; by establishing a strategic direction in the portfolio offering to reuse products; by taking back products at end-of-life for refurbishing; by striving for a circular life cycle by investigating possibilities for creating a circular economy for products; through global agreements, creating new circular business, e.g., Volvo Buses and Stena Recycling, reusing bus batteries as energy storage units in buildings |

| Reuse resources | No further description of practice mentioned |

| Reuse in general | No further description of practice mentioned |

| Reuse waste (hazardous and non-hazardous) | No further description of practice mentioned |

| Reuse water | By establishing capital funds for natural resources reduction investing in projects to find solutions for reusing water; by finding other areas to use rejected water from production; by installing equipment to collect and filter rejected water; by using surface water to transport and wash products, thus being able to reuse the same water multiple times before purifying it in several steps in different combinations of mechanical, biological and chemical purifications. |

| R4—Repair | |

| Repair products | By establishing service centres for repairing products; by increasing the service-based business within the company |

| Repair in general | No further description of practice mentioned |

| R5—Refurbish | |

| Refurbish products | Through product design, enabling returning, renovating and reselling products.; through establishing a global network of technological service units; by primarily focusing on climate-intense components for taking back, refurbishing and reusing; by continuously identifying new components fit for refurbishing; by exploring opportunities for refurbishing of products where the company has established a strategic decision in its portfolio offering to do so; through commercial offerings; through buying back complete products to refurbish or remanufacture; by establishing specialized teams for refurbishing at specific centres; by establishing a second-hand market for the refurbished products; by establishing programs for extending products life cycles by upgrading the product at optimal intervals |

| R6—Remanufacture | |

| Remanufacture products | By establishing a strategy for how to manage products after their first life cycle; By establishing programs specifically for remanufacturing; by designing components to be remanufactured; by establishing buy back services, where customers can sell inactive or legacy products; by having rigorous check of all second-hand unit products; by having a global network of remanufacturing facilities; by completely remanufacturing products using original design plans, specifications and dimensional data, e.g., in the case of industrial robots, as in the case of ABB |

| Remanufacture in general | No further description of practice mentioned |

| R7—Repurpose | |

| Repurpose packaging materials | By purchasing cardboard shredder to shred packaging and use as padding for outgoing packages. |

| Repurpose products | By taking back products from customers and repurposing them. |

| Repurpose residual materials from manufacturing | By processing residual materials internally within the organization; by processing residual materials in by-products and sold externally |

| Repurpose waste (hazardous and non-hazardous) | No further description of practice mentioned |

| R8—Recycle | |

| Recycle energy from production | By feeding surplus energy into the grid; recycle energy flow in the production processes |

| Recycle heat from wastewater and machines | No further description of practice mentioned |

| Recycle excess material from production | No further description of practice mentioned |

| Recycle metals | Establishing repurchasing programs for recycling metals from older equipment at customers |

| Recycle thermoplastics | No further description of practice mentioned |

| Recycle materials in general | By buying back products from customers, dismantling the product and recycle materials which cannot be treated in other ways |

| Recycle packaging materials | By ensuring recyclability through product design |

| Recycle products | Through partaking in collaborative, industry-wide fosrums. For instance, those related to; Swedish companies which aim to increase the circular flow of materials throughout Swedish industry. ABB, Stena Recycling, Combitech, and Electrolux have, for example, worked together on a joint trial/pilot project that aims to improve the efficiency of the recycling process for electrical products; through partaking in circular collaborations, e.g., ABB entering a local agreement to develop a process where all fractions (iron, copper, and aluminium) in electric motors products can be recycled and reused in new products; by establishing a strategy for how to manage products after their first life cycle; by having a modular product design, thereby easing the disassembly of the product |

| Recycling in general | By establishing programs focusing on increasing recycling rate; by having all units within the company increase their recycling; by reporting the recycling within the company |

| Recycle waste (hazardous and non-hazardous) | No further description of practice mentioned |

| Water | With the intention of realizing water conservation |

| R9—Recover | |

| Energy recovery through incineration | Increasing transparency and drive improvement by having own sites being more specific about their waste disposal methods; by changing from landfill to waste incineration; by reporting incineration with and without energy recovery |

References

- Franco, M.A. Circular Economy at the Micro Level: A Dynamic View of Incumbents’ Struggles and Challenges in the Textile Industry. J. Clean. Prod. 2017, 168, 833–845. [Google Scholar] [CrossRef]

- Pitt, J.; Heinemeyer, C. Introducing ideas of a circular economy. In Environment, Ethics and Cultures; Stables, K., Keirl, S., Eds.; SensePublishers: Rotterdam, The Netherlands, 2015; pp. 245–260. [Google Scholar]

- Webster, K. What Might We Say about a Circular Economy? Some Temptations to Avoid If Possible. World Future J. Gen. Evol. 2013, 69, 542–554. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product Design and Business Model Strategies for a Circular Economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Bressanelli, G.; Saccani, N.; Perona, M.; Baccanelli, I. Towards Circular Economy in the Household Appliance Industry: An Overview of Cases. Resources 2020, 9, 128. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Johansson, G.; Sundin, E.; Wiktorsson, M. Sustainable Manufacturing, 1st ed.; Studentlitteratur AB: Lund, Sweden, 2019. [Google Scholar]

- United States Environmental Protection Agency. Sources of Greenhouse Gas Emissions. Available online: https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions (accessed on 16 November 2021).

- Statistiska Centralbyrån. Available online: https://scb.se/hitta-statistik/sverige-i-siffror/miljo/utslapp-av-vaxthusgaser (accessed on 23 September 2021).

- Jawahir, I.S.; Bradley, R. Technological Elements of Circular Economy and the Principles of 6R-Based Closed-Loop Material Flow in Sustainable Manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef] [Green Version]

- Alayón, C.; Säfsten, K.; Johansson, G. Conceptual Sustainable Production Principles in Practice: Do They Reflect What Companies Do? J. Clean. Prod. 2017, 141, 693–701. [Google Scholar] [CrossRef] [Green Version]

- Calzolari, T.; Genovese, A.; Brint, A. The Adoption of Circular Economy Practices in Supply Chains—An Assessment of European Multi-National Enterprises. J. Clean. Prod. 2021, 312, 127616. [Google Scholar] [CrossRef]

- Tiscini, R.; Martiniello, L.; Lombardi, R. Circular Economy and Environmental Disclosure in Sustainability Reports: Empirical Evidence in Cosmetic Companies. Bus. Strateg. Environ. 2022, 31, 892–907. [Google Scholar] [CrossRef]

- Carlsson Kanyama, A.; Carlsson Kanyama, K.; Wester, M.; Snickare, L.; Söderberg, I.L. Climate Change Mitigation Efforts among Transportation and Manufacturing Companies: The Current State of Efforts in Sweden According to Available Documentation. J. Clean. Prod. 2018, 196, 588–593. [Google Scholar] [CrossRef]

- Paulson, F.; Sundin, E. Inclusion of Sustainability Aspects in Product Development—Two Industrial Cases from Sweden. In Proceedings of the NordDesign 2018 Conference, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Wu, H.Q.; Shi, Y.; Xia, Q.; Zhu, W.D. Effectiveness of the Policy of Circular Economy in China: A DEA-Based Analysis for the Period of 11th Five-Year-Plan. Resour. Conserv. Recycl. 2014, 83, 163–175. [Google Scholar] [CrossRef]

- Badurdeen, F.; Iyengar, D.; Goldsby, T.J.; Metta, H.; Gupta, S.; Jawahir, I.S. Extending Total Life-Cycle Thinking to Sustainable Supply Chain Design. Int. J. Prod. Lifecycle Manag. 2009, 4, 49–67. [Google Scholar] [CrossRef]

- Bradley, R.; Jawahir, I.S.; Badurdeen, F.; Rouch, K. A Total Life Cycle Cost Model (TLCCM) for the Circular Economy and Its Application to Post-Recovery Resource Allocation. Resour. Conserv. Recycl. 2018, 135, 141–149. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Planbureau voor de Leefomgeving: The Hague, The Netherlands, 2017. [Google Scholar]

- Swedish Parliament. Årsredovisningslag (1995:1554). Available online: https://www.riksdagen.se/sv/dokument-lagar/dokument/svensk-forfattningssamling/arsredovisningslag-19951554_sfs-1995-1554#K6P10 (accessed on 27 January 2022).

- Ekonomifakta.se. Available online: https://www.ekonomifakta.se/fakta/foretagande/naringslivet/naringslivets-struktur/ (accessed on 27 January 2022).

- Swedish Companies Registration Office. Available online: https://bolagsverket.se/ff/foretagsformer/aktiebolag/arsredovisning/delar/hallbarhetsrapport-1.17962 (accessed on 27 January 2022).

- Confederation of Swedish Enterprise. FAQ: Vad Innebär Lagen Om Hållbarhetsrapportering? Available online: http://www.svenskhandel.se/contentassets/e87ba73606274d5e836a9957de534b1a/faq-lag-om-hallbarhetsrapport.pdf (accessed on 7 April 2022).

- Karaman, A.S.; Kilic, M.; Uyar, A. Green Logistics Performance and Sustainability Reporting Practices of the Logistics Sector: The Moderating Effect of Corporate Governance. J. Clean. Prod. 2020, 258, 120718. [Google Scholar] [CrossRef]

- Istudor, L.G.; Suciu, M.C. Bioeconomy and Circular Economy in the European Food Retail Sector. Eur. J. Sustain. Dev. 2020, 9, 501–511. [Google Scholar] [CrossRef]

- Janik, A.; Ryszko, A.; Szafraniec, M. Greenhouse Gases and Circular Economy Issues in Sustainability Reports from the Energy Sector in the European Union. Energies 2020, 13, 5993. [Google Scholar] [CrossRef]

- Marke, A.; Chan, C.; Taskin, G.; Hacking, T. Reducing E-Waste in China’s Mobile Electronics Industry: The Application of the Innovative Circular Business Models. Asian Educ. Dev. Stud. 2020, 9, 591–610. [Google Scholar] [CrossRef]

- Sihvonen, S.; Partanen, J. Eco-Design Practices with a Focus on Quantitative Environmental Targets: An Exploratory Content Analysis within ICT Sector. J. Clean. Prod. 2017, 143, 769–783. [Google Scholar] [CrossRef]

- Stewart, R.; Niero, M. Circular Economy in Corporate Sustainability Strategies: A Review of Corporate Sustainability Reports in the Fast-Moving Consumer Goods Sector. Bus. Strateg. Environ. 2018, 27, 1005–1022. [Google Scholar] [CrossRef] [Green Version]

- Rhein, S.; Sträter, K.F. Corporate Self-Commitments to Mitigate the Global Plastic Crisis: Recycling Rather than Reduction and Reuse. J. Clean. Prod. 2021, 296, 126571. [Google Scholar] [CrossRef]

- Sehnem, S.; Pandolfi, A.; Gomes, C. Is Sustainability a Driver of the Circular Economy? Soc. Responsib. J. 2020, 16, 329–347. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Delivering the Circular Economy: A Toolkit for Policymakers. Selection of Key Exhibition. 2013. Available online: https://www.sustainableislandsplatform.org/wp-content/uploads/EllenMacArthurFoundation_Policymakers-Toolkit_compressed.pdf (accessed on 16 November 2021).

- Govindan, K.; Hasanagic, M. A Systematic Review on Drivers, Barriers, and Practices towards Circular Economy: A Supply Chain Perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Södergren, B. Flaggskeppsfabriken—Styrkor i Svensk Produktion; Vinnova: Stockholm, Sweden, 2016. [Google Scholar]

- Blomsma, F.; Pieroni, M.; Kravchenko, M.; Pigosso, D.C.A.; Hildenbrand, J.; Kristinsdottir, A.R.; Kristoffersen, E.; Shabazi, S.; Nielsen, K.D.; Jönbrink, A.K.; et al. Developing a Circular Strategies Framework for Manufacturing Companies to Support Circular Economy-Oriented Innovation. J. Clean. Prod. 2019, 241, 118271. [Google Scholar] [CrossRef]

| # | Company | Manufacturing Industry | Report Structure | Report Language | Net Turnover (msek) |

|---|---|---|---|---|---|

| 1 | Volvo Group | Automotive | Integrated | English | 338,446 |

| 2 | LM Ericsson | Communication equipment | Separate | English | 232,390 |

| 3 | Volvo Cars | Automotive | Integrated | English | 184,417 |

| 4 | Scania CV | Automotive | Integrated | Swedish | 125,125 |

| 5 | Electrolux | Household appliances | Integrated | Swedish | 115,960 |

| 6 | Atlas Copco | Machines | Integrated | Swedish | 99,787 |

| 7 | AstraZeneca | Medicine | Separate | English | 87,469 |

| 8 | Sandvik | Engineering in mining/quarrying | Integrated | Swedish | 86,404 |

| 9 | SKF | Machines | Integrated | Swedish | 74,852 |

| 10 | Husqvarna | Machines | Separate | English | 41,943 |

| 11 | NIBE Industrier | Machines | Integrated | Swedish | 27,146 |

| 12 | SCA | Paper and packaging | Integrated | Swedish | 18,410 |

| 13 | Holmen | Paper and packaging | Integrated | Swedish | 16,327 |

| 14 | Arla Foods | Diary | Integrated | Swedish | 16,717 |

| 15 | Swedish Match | Tobacco | Separate | Swedish | 16,698 |

| 16 | Essity Hygiene and Health | Hygiene and health | Integrated | Swedish | 15,391 |

| 17 | SSAB EMEA | Metal | Integrated | English | 22,829 |

| 18 | BillerudKorsnäs | Paper and packaging | Integrated | Swedish | 14,519 |

| 19 | ABB | Electronics | Separate | English | 14,120 |

| 20 | Elekta | Electronics | Integrated | English | 13,860 |

| R | Circularity Category |

|---|---|

| R0—Refuse | Refuse harmful materials in products |

| Refuse non-recyclable materials in products | |

| Refuse non-renewable resources | |

| R1—Rethink | Apply sustainable chemical management |

| Develop and adapt circular business models | |

| Develop and launch circular innovations | |

| Develop sustainable lubricants | |

| Use recyclable, recycled, renewable, and sustainable materials in products | |

| Rethink packaging solutions | |

| Use recyclable, recycled, and renewable packaging materials | |

| Rethink ways to enable customer sustainability | |

| Rethink product design to make it more sustainable and circular | |

| Increase usage of renewable energy | |

| Use new sustainable processes and technologies | |

| Initiate new collaborations which support circularity | |

| Rethink transportation patterns | |

| Rethink ways to manage and evaluate supplier sustainability | |

| R2—Reduce | Reduce chemical usage |

| Reduce energy usage | |

| Reduce fuel usage | |

| Reduce GhG emissions | |

| Reduce packaging material | |

| Reduce pollution in air, land, and water | |

| Reduce resource usage | |

| Reduce hazardous waste | |

| Reduce waste sent to landfill | |

| Reduce waste sent for disposal | |

| Reduce waste in general | |

| Reduce water usage | |

| R3—Reuse | Reuse heat, steam from own production |

| Reuse residual materials from manufacturing | |

| Reuse metals | |

| Reuse thermoplastics | |

| Reuse materials in general | |

| Reuse packaging material | |

| Reuse products | |

| Reuse resources | |

| Reuse in general | |

| Reuse waste (hazardous and non-hazardous) | |

| Reuse water | |

| R4—Repair | Repair products |

| Repair in general | |

| R5—Refurbish | Refurbish products |

| R6—Remanufacture | Remanufacture products |

| Remanufacture in general | |

| R7—Repurpose | Repurpose packaging materials |

| Repurpose products | |

| Repurpose residual materials from manufacturing | |

| Repurpose waste (hazardous and non-hazardous) | |

| R8—Recycle | Recycle energy from production |

| Recycle heat from wastewater and machines | |

| Recycle excess material from production | |

| Recycle metals | |

| Recycle thermoplastics | |

| Recycle materials in general | |

| Recycle packaging materials | |

| Recycle products | |

| Recycling in general | |

| Recycle waste (hazardous and non-hazardous) | |

| Recycle water | |

| R9—Recover | Recover energy through incineration |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skärin, F.; Rösiö, C.; Andersen, A.-L. An Explorative Study of Circularity Practices in Swedish Manufacturing Companies. Sustainability 2022, 14, 7246. https://doi.org/10.3390/su14127246

Skärin F, Rösiö C, Andersen A-L. An Explorative Study of Circularity Practices in Swedish Manufacturing Companies. Sustainability. 2022; 14(12):7246. https://doi.org/10.3390/su14127246

Chicago/Turabian StyleSkärin, Filip, Carin Rösiö, and Ann-Louise Andersen. 2022. "An Explorative Study of Circularity Practices in Swedish Manufacturing Companies" Sustainability 14, no. 12: 7246. https://doi.org/10.3390/su14127246

APA StyleSkärin, F., Rösiö, C., & Andersen, A.-L. (2022). An Explorative Study of Circularity Practices in Swedish Manufacturing Companies. Sustainability, 14(12), 7246. https://doi.org/10.3390/su14127246