Development of Natural Fibre-Reinforced Polymer Composites Ballistic Helmet Using Concurrent Engineering Approach: A Brief Review

Abstract

1. Introduction

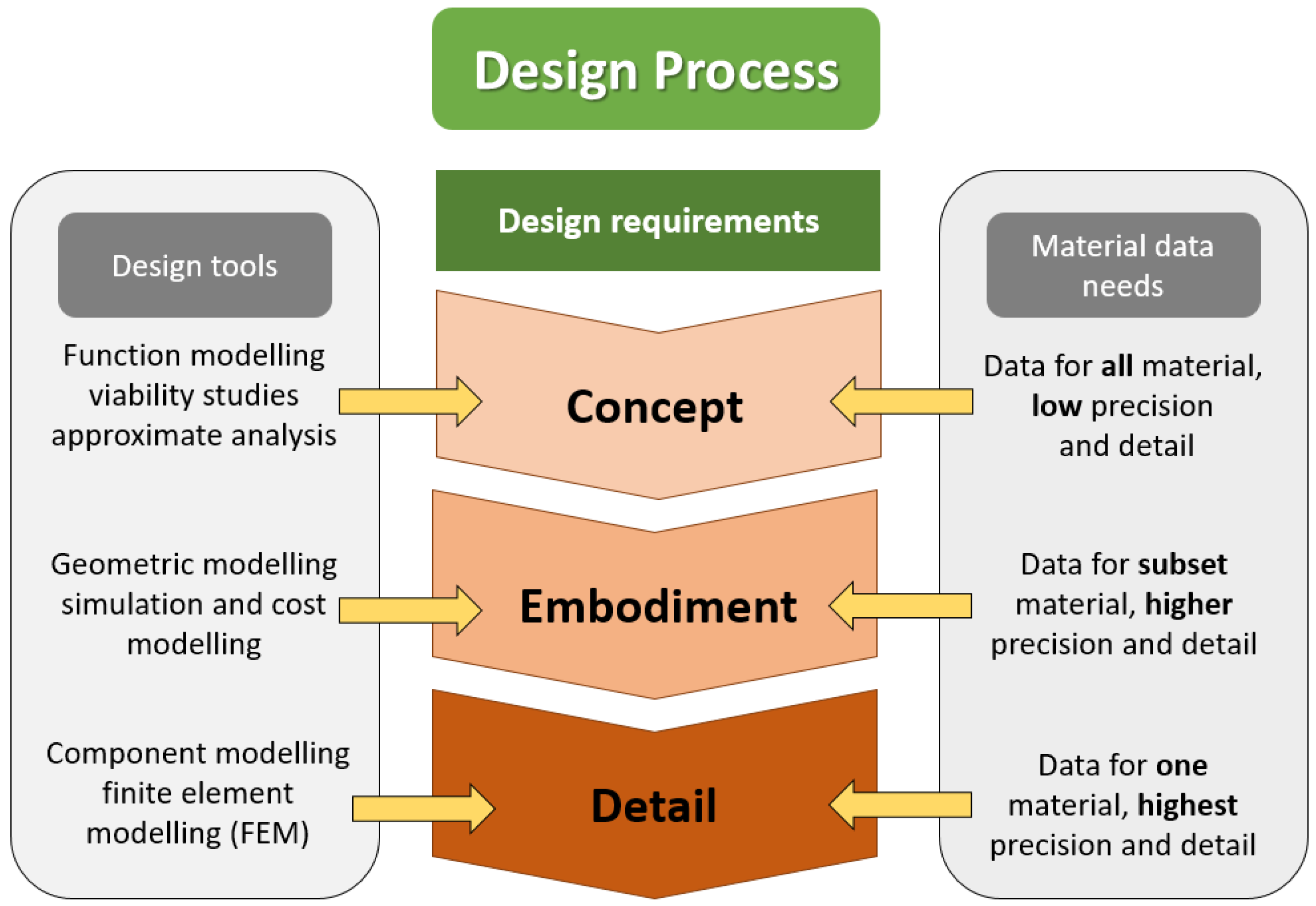

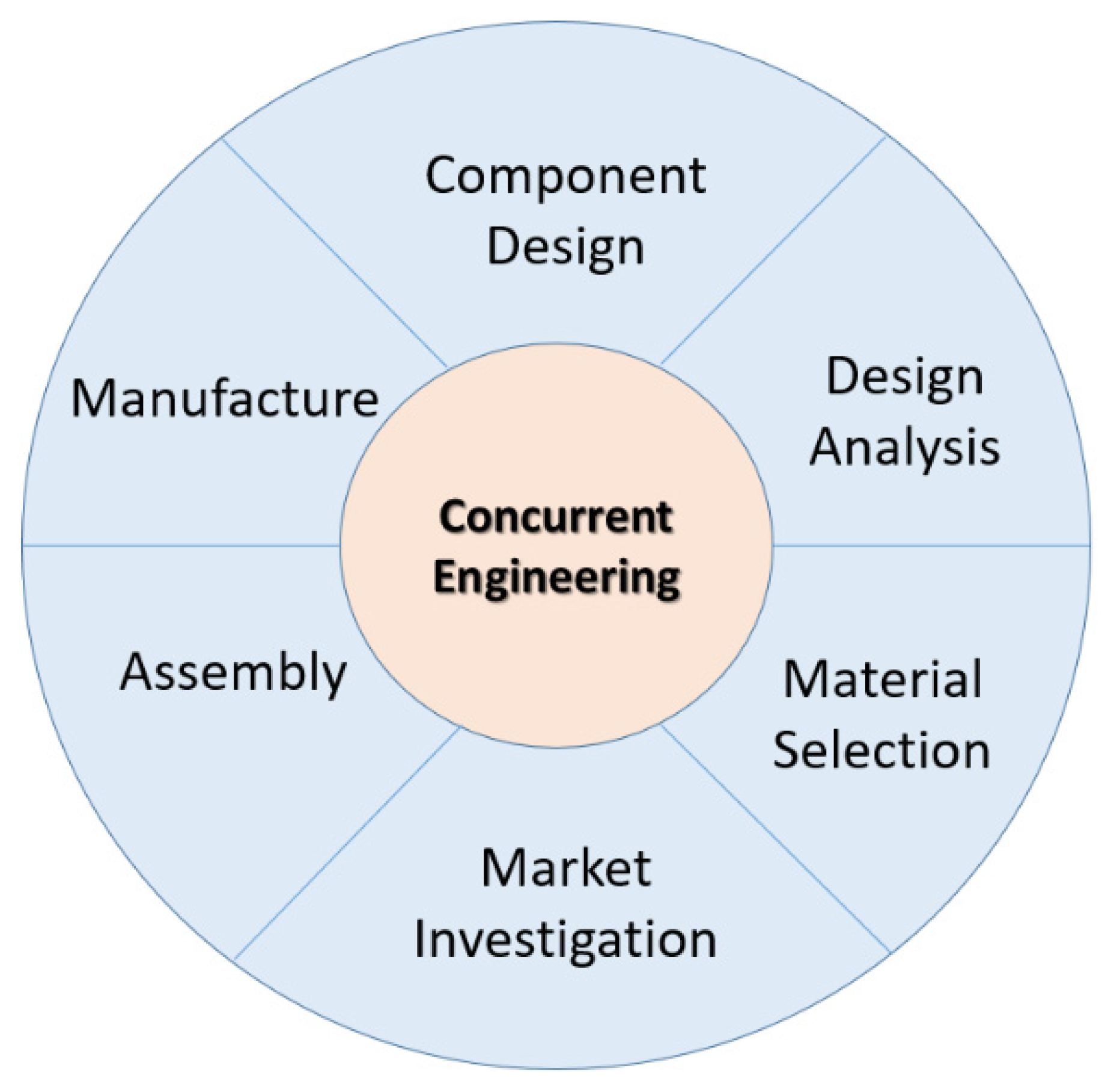

2. Product Design and Concurrent Engineering

3. Ballistic Helmet from Design Perspective

3.1. The Shell

3.2. The Comfort Foam

3.3. The Retention System (Strap)

| Author (Year) | Issue and Problems |

|---|---|

| [11] | Ergonomic viewpoint such as heat retention, maintainability and weight |

| [39] | The development of ballistic helmet design should also take into account other factors that affect the efficiency and the human body such as thermal comfort and thermal insulation. |

| [39] | For now the study of thermal insulation of ballistic helmets has not been done. |

| [40] | A common problem reported among PASGT users is heavy and uncomfortable ballistic helmets. |

| [33] | Future models or prototypes of ballistic helmets will need to use a thinner material to reduce weight, have better ventilation and have better material strength. |

| [33] | Alternative materials are necessary to reduce reliance on the use of ballistic resistance materials that are not environmentally friendly and economical. |

| [41,42] | Stated to have investigated the possibility of using natural based fibre and fillers for armor materials. |

| [34] | In recent years, researchers have begun to be interested in developing natural fibres as reinforcement in polymer matrices for defense applications and ballistic resistant composites. |

| [35] | There are several factors that influence the performance of ballistic helmets such as ergonomic aspects, energy absorption mechanisms as well as material systems that need to be studied comparatively by analyzing technical reports and published research articles. |

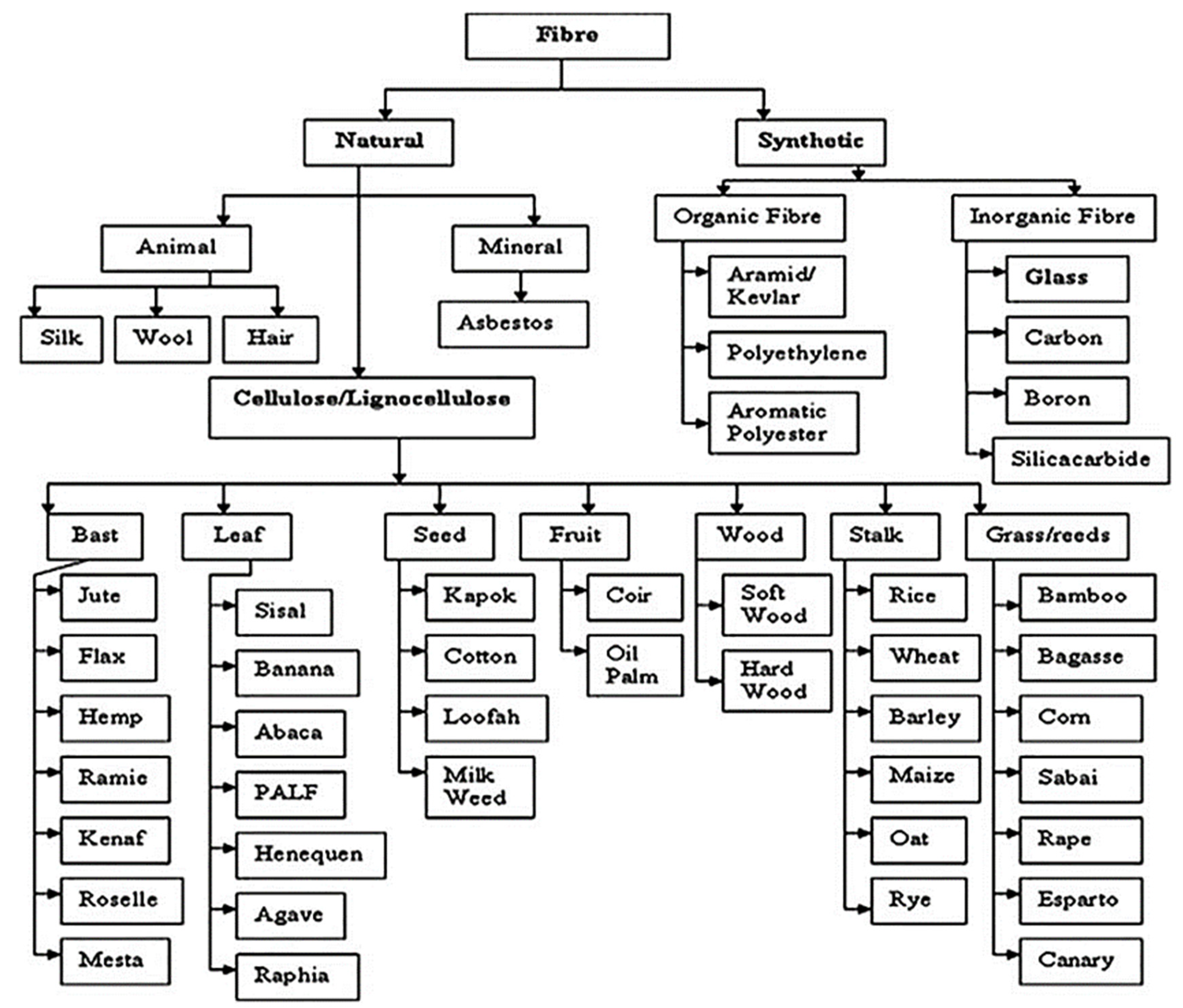

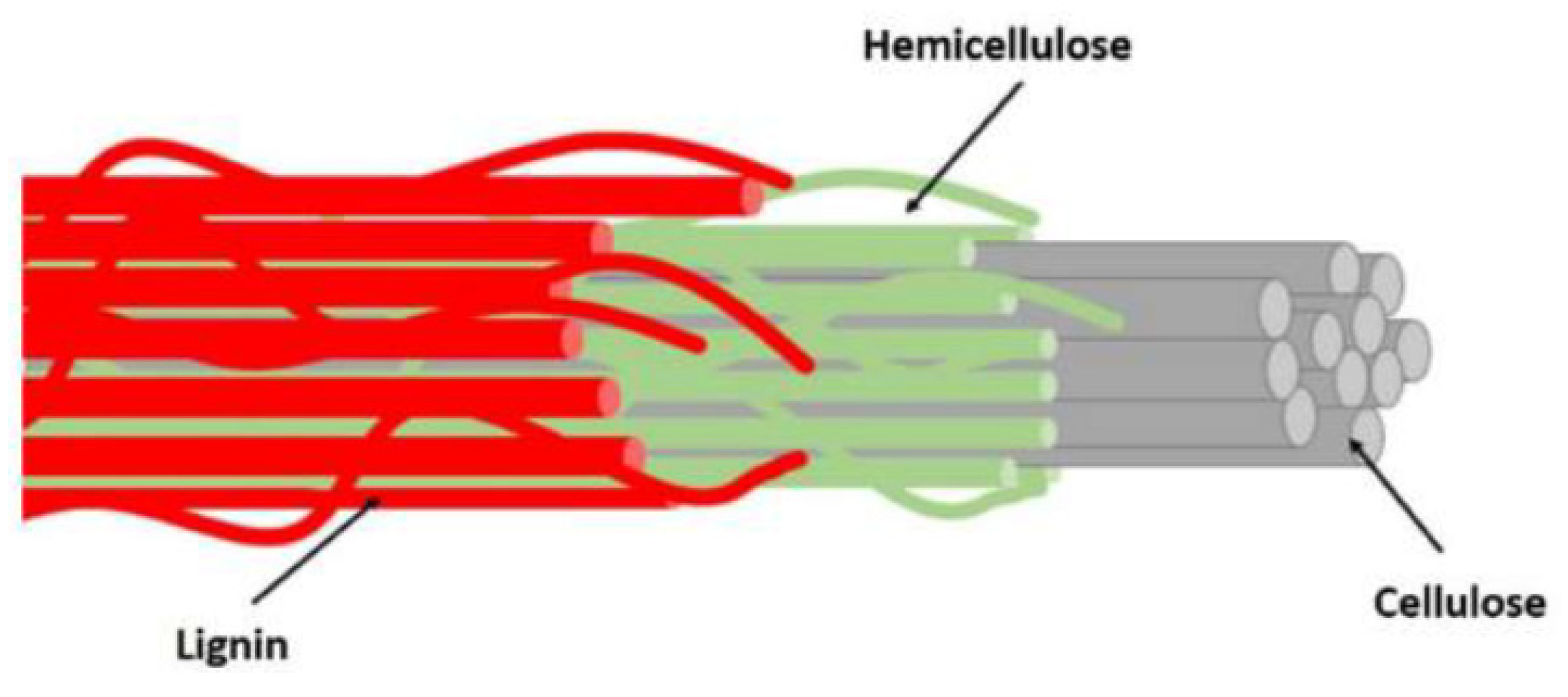

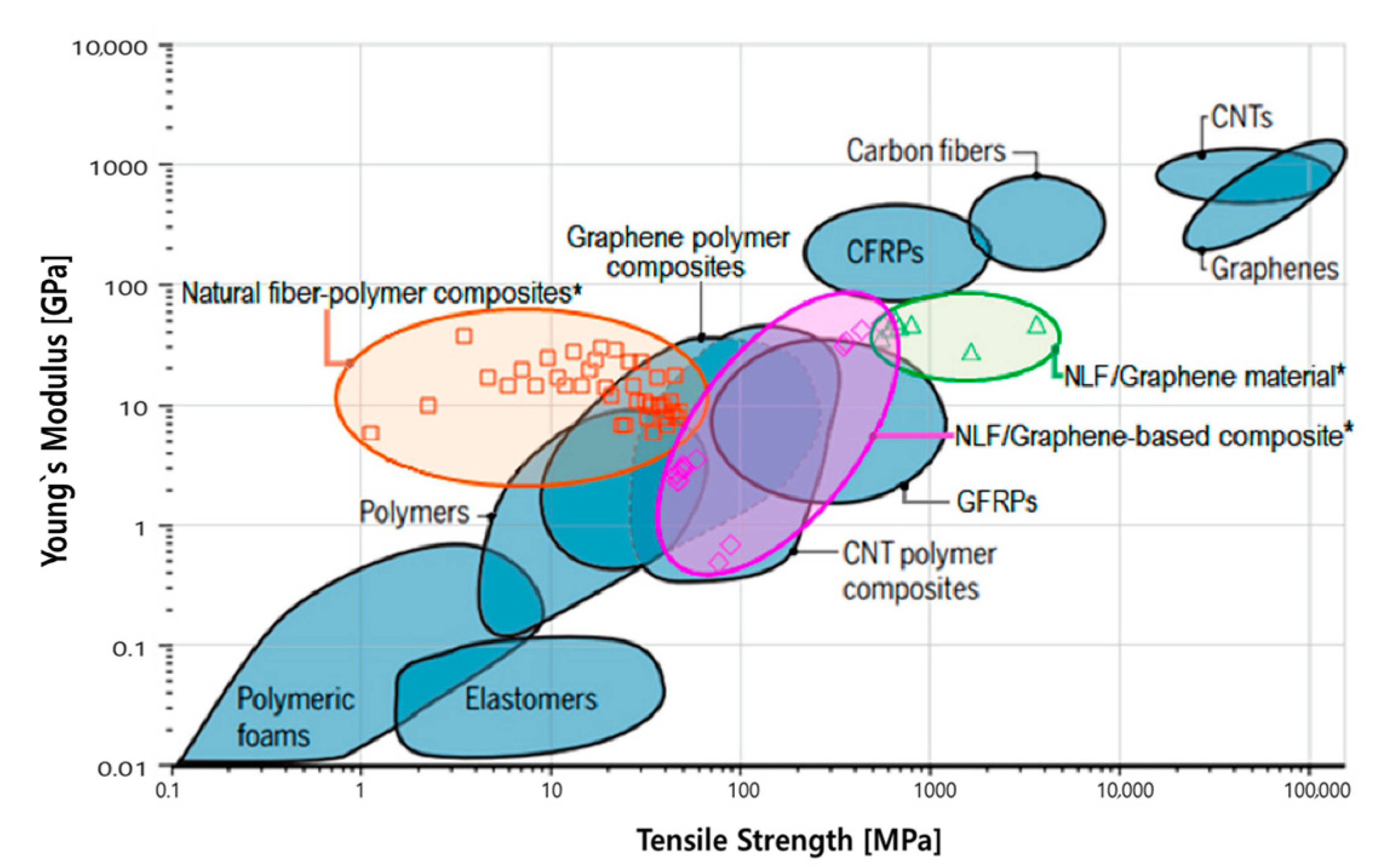

4. Implementation of Natural Fibre Composites toward Sustainable Development

5. Development Natural Fibre Hybrid Composite to Apply for Ballistic Helmet

6. CE for Natural Fibre-Composite Product Development

7. Integration of Industrial Design and Engineering in Ballistic Helmet Development

- Brainstorming;

- Biomimicry/biomimetics (Analysis of Natural Systems);

- Cross-industry innovation;

- Analysis of existing technical systems;

- Asking question method;

- Gallery method;

- Morphological chart method;

- Blue ocean strategy;

- Mind mapping; and

- Theory of Inventive Problem Solving (TRIZ)

8. The Role of Computational Modelling in the Development of Ballistic Helmet Design

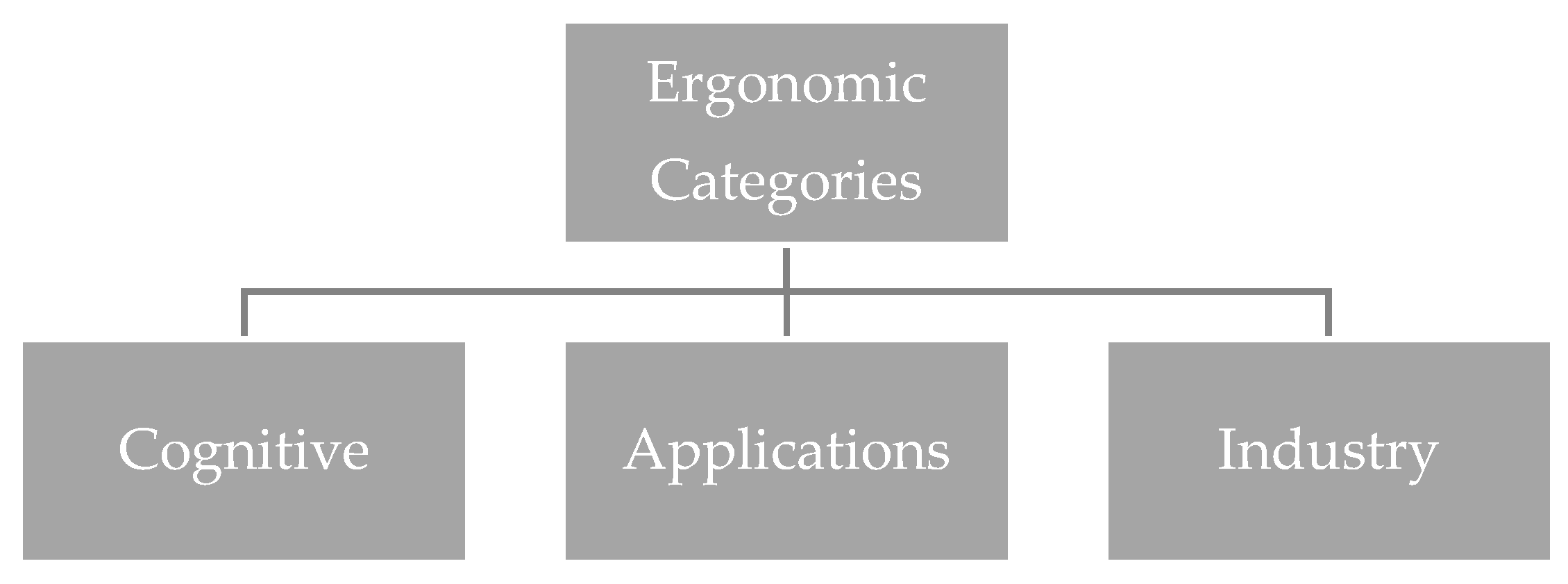

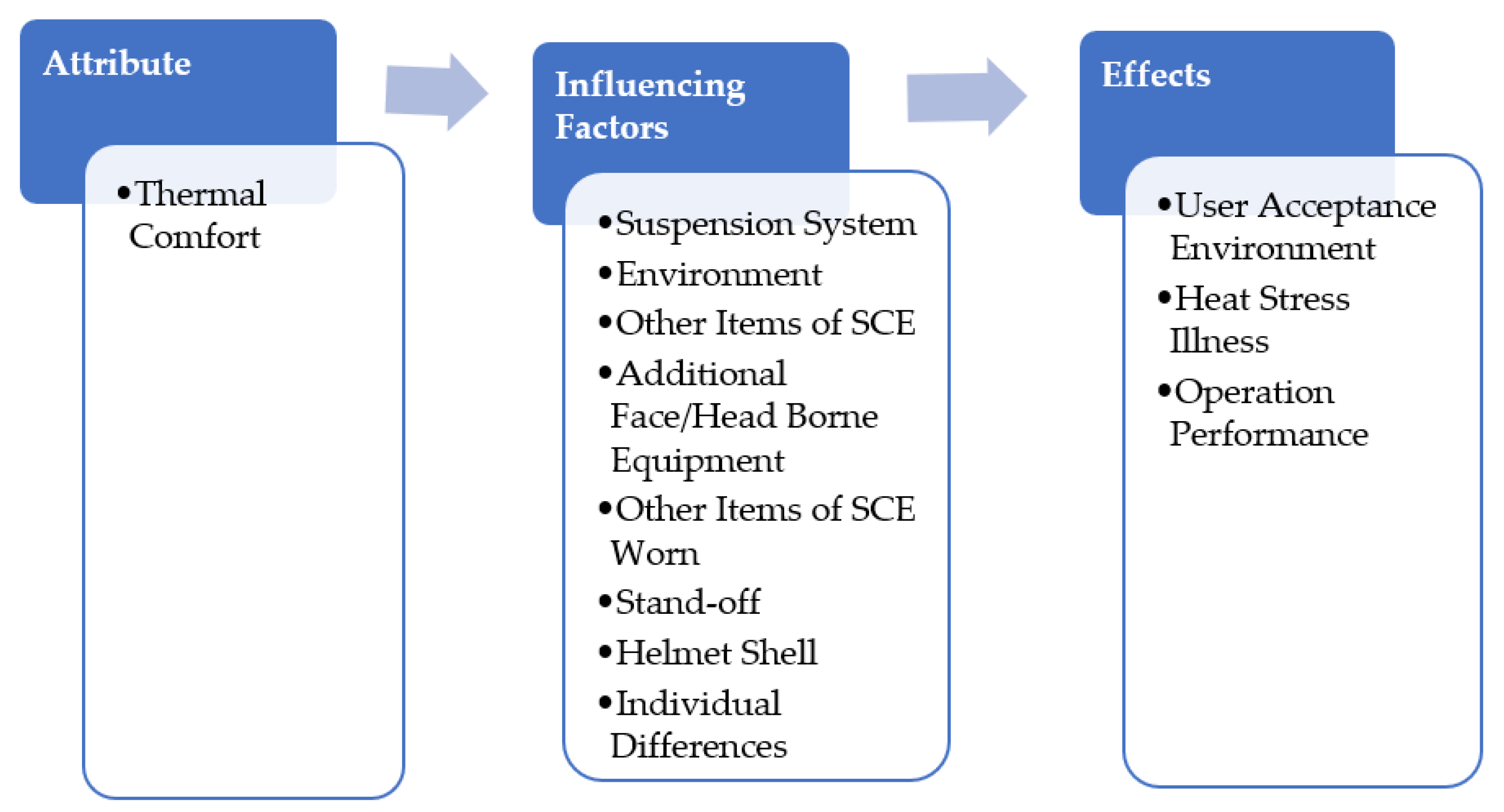

9. Ergonomic Aspects of Ballistic Helmet

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Isaksson, O.; Bertoni, A.; Levandowski, C.; Müller, J.; Wiklund, D.; Johansson, P.B.V. Virtual contextual validation of technologies and methods for product development. In Proceedings of the 14th International Design Conference (DESIGN 2016), Dubrovnik, Croatia, 16–19 May 2016; pp. 669–678. [Google Scholar]

- Bertoni, A.; Bertoni, M. Supporting early stage set-based concurrent engineering with Value Driven Design. In Proceedings of the Design Society: International Conference on Engineering Design, Delft, The Netherlands, 5–8 August 2019; Cambridge University Press: Cambridge, UK, 2019; Volume 1, pp. 2367–2376. [Google Scholar]

- Levandowski, C.E.; Jiao, J.R.; Johannesson, H. A two-stage model of adaptable product platform for engineering-to-order configuration design. J. Eng. Des. 2015, 26, 220–235. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Osman, M.R.; Nukman, Y. State of the art of the concurrent engineering technique in the automotive industry. J. Eng. Des. 2006, 17, 143–157. [Google Scholar] [CrossRef]

- Rahner, C.P. Analytical Evaluation of Impact Test Equipments to Simulate High Caliber Ballistic Threats. Master’s Thesis, Federal University of Santa Catarina, Florianópolis, Brazil, 2012. [Google Scholar]

- Salman, S.D.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Cardona, F. Ballistic impact resistance of plain woven kenaf/aramid reinforced polyvinyl butyral laminated hybrid composite. BioResources 2016, 11, 7282–7295. [Google Scholar] [CrossRef]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of Natural Fiber Reinforced Polymer Composites in Sandwich Structures: A Review on Its Mechanical Properties. Polymers 2021, 13, 423. [Google Scholar] [CrossRef] [PubMed]

- Nurazzi, N.M.; Shazleen, S.S.; Aisyah, H.A.; Asyraf, M.R.M.; Sabaruddin, F.A.; Mohidem, N.A.; Norrrahim, M.N.F.; Kamarudin, S.H.; Ilyas, R.A.; Ishak, M.R.; et al. Effect of silane treatments on mechanical performance of kenaf fibre reinforced polymer composites: A review. Funct. Compos. Struct. 2021, 3, 045003. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Aji, I.S.; Sapuan, S.M.; Zainudin, E.S.; Abdan, K. Kenaf fibres as reinforcement for polymeric composites: A review. Int. J. Mech. Mater. Eng. 2009, 4, 239–248. [Google Scholar] [CrossRef]

- Samil, F.; David, N.V. An ergonomic study of a conventional ballistic helmet. Procedia Eng. 2012, 41, 1660–1666. [Google Scholar] [CrossRef]

- Davis, S.E.; Milanese, S.; Furnell, A.; Grimmer, K. The Combat Helmet as a System: Development of a Systems Model to Manage Complexity in Ergonomics Assessment. In Contemporary Ergonomics and Human Factors; Routledge: Abingdon on Thames, UK, 2017; pp. 296–302. [Google Scholar]

- Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Ishak, M.R.; Sapuan, S.M.; Sharma, S.; Rashedi, A.; Razman, M.R.; Zakaria, S.Z.S.; et al. Product Development of Natural Fibre-Composites for Various Applications: Design for Sustainability. Polymers 2022, 14, 920. [Google Scholar] [CrossRef]

- Salwa, H.N.; Sapuan, S.M.; Mastura, M.T.; Zuhri, M.Y.M. Conceptual Design and Selection of Natural Fibre Reinforced Biopolymer Composite (NFBC) Takeout Food Container. J. Renew. Mater. 2021, 9, 803–827. [Google Scholar] [CrossRef]

- Salwa, H.N.; Sapuan, S.M.; Mastura, M.T.; Zuhri, M.Y.M. Life cycle assessment of sugar palm fiber reinforced-sago biopolymer composite takeout food container. Appl. Sci. 2020, 10, 7951. [Google Scholar] [CrossRef]

- Shaharuzaman, M.A.; Sapuan, S.M.; Mansor, M.R. Prioritizing the product design specification of side-door impact beam using analytic hierarchy process method. In Proceedings of the 5th Mechanical Engineering Research Day (MERD’18), Melacca, Malaysia, 3 May 2018; pp. 34–35. [Google Scholar]

- Prasad, B. Concurrent Engineering Fundamentals: Integrated Product and Process Organization, 1st ed.; Prentice-Hall International Series in Industrial and Systems Engineering: Upper Saddle River, NJ, USA, 1995; Volume 1, ISBN 978-0-13-147463-5. [Google Scholar]

- Hambali, A.; Sapuan, S.M.; Ismail, N.; Nukman, Y. Application of analytical hierarchy process in the design concept selection of automotive composite bumper beam during the conceptual design stage. Sci. Res. Essays 2009, 4, 198–211. [Google Scholar]

- Sapuan, S.M.; Maleque, M.A.; Hameedullah, M.; Suddin, M.N.; Ismail, N. A note on the conceptual design of polymeric composite automotive bumper system. J. Mater. Process. Technol. 2005, 159, 145–151. [Google Scholar] [CrossRef]

- Shaharuzaman, M.A.; Sapuan, S.M.; Mansor, M.R.; Zuhri, M.Y.M. Conceptual design of natural fiber composites as a side-door impact beam using hybrid approach. J. Renew. Mater. 2020, 8, 549–563. [Google Scholar] [CrossRef]

- Sapuan, S.M. Mind Mapping in Concept Generation of Composite Products. In Composite Materials Concurrent Engineering Approach; Elsevier: Amsterdam, The Netherlands, 2017; pp. 188–189. [Google Scholar]

- Benabdellah, A.C.; Benghabrit, A.; Bouhaddou, I.; Benghabrit, O. Design for relevance concurrent engineering approach: Integration of IATF 16949 requirements and design for X techniques. Res. Eng. Des. 2020, 31, 323–351. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Rihar, L.; Kušar, J. Implementing concurrent engineering and QFD method to achieve realization of sustainable project. Sustainability 2021, 13, 1091. [Google Scholar] [CrossRef]

- Arnette, A.N.; Brewer, B.L.; Choal, T. Design for sustainability (DFS): The intersection of supply chain and environment. J. Clean. Prod. 2014, 83, 374–390. [Google Scholar] [CrossRef]

- Sapuan, S.M. Concurrent Engineering in Natural Fibre Composite Product Development. Appl. Mech. Mater. 2015, 761, 59–62. [Google Scholar] [CrossRef]

- Haik, Y. Engineering Design Process; Brooks/Cole Publishing Company: Pacific Grove, CA, USA, 2003. [Google Scholar]

- Boyer, R.R.; Cotton, J.D.; Mohaghegh, M.; Schafrik, R.E. Materials considerations for aerospace applications. MRS Bull. 2015, 40, 1055–1066. [Google Scholar] [CrossRef]

- Yusof, N.S.B.; Sapuan, S.M.; Sultan, M.T.H.; Jawaid, M. Concept Generation of Sugar Palm/Glass Fiber Reinforced Thermoplastic Polyurethane Hybrid Composite Automotive Crash Box. J. Adv. Res. Mater. Sci. 2018, 49, 10–17. [Google Scholar]

- Johnson, K.W.; Langdon, P.M.; Ashby, M.F. Grouping materials and processes for the designer: An application of cluster analysis. Mater. Des. 2002, 23, 1–10. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design, 5th ed.; Elsevier: Amsterdam, The Netherlands, 2011; Volume 86, ISBN 9781856176637. [Google Scholar]

- Hamouda, A.M.S.; Sohaimi, R.M.; Zaidi, A.M.A.; Abdullah, S. Materials and design issues for military helmets. In Advances in Military Textiles and Personal Equipment; Elsevier: Amsterdam, The Netherlands, 2012; pp. 103–138. [Google Scholar]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, M.N.F.; Ilyas, R.A.; Sapuan, S.M. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, S.G.; Gao, X.-L.; Horner, S.E.; Zheng, J.Q.; David, N.V. Ballistic helmets—Their design, materials, and performance against traumatic brain injury. Compos. Struct. 2013, 101, 313–331. [Google Scholar] [CrossRef]

- Council, N.R. Review of Department of Defense Test Protocols for Combat Helmets; National Academies Press: Washington, DC, USA, 2014; ISBN 0309298695. [Google Scholar]

- Salvaterra, G. Evolution and Mechanics of and Head Protection. In Foundations of Sport-Related Brain Injuries; Springer: Berlin/Heidelberg, Germany, 2006; pp. 391–406. [Google Scholar]

- Hsieh, A.J.; Orlicki, J.A.; Beyer, R.L. Molecular Design of Novel Poly (Urethane-Urea) Hybrids as Helmet Pads for Ballistic and Blast Trauma Mitigation; Army Research Lab: Aberdeen, MD, USA, 2009. [Google Scholar]

- Zwolińska, M.; Bogdan, A.; Fejdyś, M. Influence of different types of the internal system of the ballistic helmet shell on the thermal insulation measured by a manikin headform. Int. J. Ind. Ergon. 2014, 44, 421–427. [Google Scholar] [CrossRef]

- Ivins, B.J.; Schwab, K.A.; Crowley, J.S.; McEntire, B.J.; Trumble, C.C.; Brown, F.H., Jr.; Warden, D.L. How satisfied are soldiers with their ballistic helmets? A comparison of soldiers’ opinions about the advanced combat helmet and the personal armor system for ground troops helmet. Mil. Med. 2007, 172, 586–591. [Google Scholar] [CrossRef]

- Risby, M.S.; Wong, S.V.; Hamouda, A.M.S.; Khairul, A.R.; Elsadig, M. Ballistic performance of coconut shell powder/twaron fabricagainst Non-armour piercing projectiles. Def. Sci. J. 2008, 58, 248. [Google Scholar] [CrossRef]

- Wambua, P.; Vangrimde, B.; Lomov, S.; Verpoest, I. The response of natural fibre composites to ballistic impact by fragment simulating projectiles. Compos. Struct. 2007, 77, 232–240. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Norrrahim, M.N.F.; Amir, A.L.; Nurazzi, N.M.; Ilyas, R.A.; Asrofi, M.; Rafidah, M.; Razman, M.R. Potential of Flax Fiber Reinforced Biopolymer Composites for Cross-Arm Application in Transmission Tower: A Review. Fibers Polym. 2022, 23, 853–877. [Google Scholar] [CrossRef]

- Asim, M.; Abdan, K.; Jawaid, M.; Nasir, M.; Dashtizadeh, Z.; Ishak, M.R.; Hoque, M.E.; Deng, Y. A review on pineapple leaves fibre and its composites. Int. J. Polym. Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Norrrahim, M.N.F.; Misenan, M.S.M.; Jenol, M.A.; Samsudin, S.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Supian, A.B.M.; Bangar, S.P.; et al. Natural Fiber-Reinforced Polycaprolactone Green and Hybrid Biocomposites for Various Advanced Applications. Polymers 2022, 14, 182. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Sabaruddin, F.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Abdul Khalil, H.P.S. The effects of unbleached and bleached nanocellulose on the thermal and flammability of polypropylene-reinforced kenaf core hybrid polymer bionanocomposites. Polymers 2020, 13, 116. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Rafidah, M.; Ilyas, R.A.; Razman, M.R. Potential application of green composites for cross arm component in transmission tower: A brief review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 28, 2675–2695. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Norrrahim, M.N.F.; Nurazzi, N.M.; Shazleen, S.S.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Recent advances of thermal properties of sugar palm lignocellulosic fibre reinforced polymer composites. Int. J. Biol. Macromol. 2021, 193, 1587–1599. [Google Scholar] [CrossRef]

- Zhan, M.; Wool, R.P.; Xiao, J.Q. Electrical properties of chicken feather fiber reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 229–233. [Google Scholar] [CrossRef]

- Cheung, H.Y.; Lau, K.T.; Pow, Y.F.; Zhao, Y.Q.; Hui, D. Biodegradation of a silkworm silk/PLA composite. Compos. Part B Eng. 2010, 41, 223–228. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical Performance and Applications of CNTs Reinforced Polymer Composites—A Review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Amir, A.L.; Nurazzi, N.M.; Norrrahim, M.N.F.; Asrofi, M.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Filament-wound glass-fibre reinforced polymer composites: Potential applications for cross arm structure in transmission towers. Polym. Bull. 2022, 1–26. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Nurazzi, N.M.; Sabaruddin, F.A.; Shazleen, S.S.; Norrrahim, M.N.F.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Mechanical properties of oil palm fibre-reinforced polymer composites: A review. J. Mater. Res. Technol. 2022, 17, 33–65. [Google Scholar] [CrossRef]

- Norfarhana, A.S.; Ilyas, R.A.; Ngadi, N. A review of nanocellulose adsorptive membrane as multifunctional wastewater treatment. Carbohydr. Polym. 2022, 291, 119563. [Google Scholar] [CrossRef]

- Suriani, M.J.; Zainudin, H.A.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M.; Ruzaidi, C.M.; Mustapha, R. Kenaf Fiber/Pet Yarn Reinforced Epoxy Hybrid Polymer Composites: Morphological, Tensile, and Flammability Properties. Polymers 2021, 13, 1532. [Google Scholar] [CrossRef] [PubMed]

- Suriani, M.J.; Radzi, F.S.M.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M.; Ruzaidi, C.M. Flammability, Tensile, and Morphological Properties of Oil Palm Empty Fruit Bunches Fiber/Pet Yarn-Reinforced Epoxy Fire Retardant Hybrid Polymer Composites. Polymers 2021, 13, 1282. [Google Scholar] [CrossRef] [PubMed]

- Mohd Nurazzi, N.; Khalina, A.; Sapuan, S.M.; Dayang Laila, A.H.A.M.; Rahmah, M.; Hanafee, Z. A review: Fibres, polymer matrices and composites. Pertanika J. Sci. Technol. 2017, 25, 1085–1102. [Google Scholar]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef]

- Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.; Anwar, U.M.K.; Siregar, J.P. Sugar palm (Arenga pinnata): Its fibres, polymers and composites. Carbohydr. Polym. 2013, 91, 699–710. [Google Scholar] [CrossRef]

- Misri, S.; Leman, Z.; Sapuan, S.M.; Ishak, M.R. Mechanical properties and fabrication of small boat using woven glass/sugar palm fibres reinforced unsaturated polyester hybrid composite. IOP Conf. Ser. Mater. Sci. Eng. 2010, 11, 012015. [Google Scholar] [CrossRef]

- Liang, S.; Gning, P.B.; Guillaumat, L. A comparative study of fatigue behaviour of flax/epoxy and glass/epoxy composites. Compos. Sci. Technol. 2012, 72, 535–543. [Google Scholar] [CrossRef]

- Acharya, S.K. Soma Dalbehera Study on mechanical properties of natural fiber reinforced woven jute-glass hybrid epoxy composites. Adv. Polym. Sci. Technol. 2014, 4, 1–6. [Google Scholar]

- Alias, A.H.; Norizan, M.N.; Sabaruddin, F.A.; Asyraf, M.R.M.; Norrrahim, M.N.F.; Ilyas, A.R.; Kuzmin, A.M.; Rayung, M.; Shazleen, S.S.; Nazrin, A.; et al. Hybridization of MMT/Lignocellulosic Fiber Reinforced Polymer Nanocomposites for Structural Applications: A Review. Coatings 2021, 11, 1355. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Aisyah, H.A.; Nordin, A.H.; Ngadi, N.; Zuhri, M.Y.M.; Asyraf, M.R.M.; Sapuan, S.M.; Zainudin, E.S.; Sharma, S.; Abral, H.; et al. Natural-Fiber-Reinforced Chitosan, Chitosan Blends and Their Nanocomposites for Various Advanced Applications. Polymers 2022, 14, 874. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S. Exploring the applicability of natural fibers for the development of biocomposites. Express Polym. Lett. 2021, 15, 193. [Google Scholar] [CrossRef]

- Vinod, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.R.; Siengchin, S.; Yagnaraj, Y.; Khan, S. Extraction and characterization of natural fiber from stem of cardiospermum halicababum. J. Nat. Fibers 2021, 18, 898–908. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Kinloch, I.A.; Jonghwan, J.L.; Robert, J.Y.; Pulickel, M.A. Composites with carbon nanotubes and graphene: An outlook. Science 2018, 362, 547–553. [Google Scholar] [CrossRef]

- Khan, T.; Sultan, M.T.B.H.; Ariffin, A.H. The challenges of natural fiber in manufacturing, material selection, and technology application: A review. J. Reinf. Plast. Compos. 2018, 37, 770–779. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.M.; Muhammad Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.H.; Ahmad, S.; Mahat, A.M.; Lee, C.L.; Aisyah, H.A.; et al. Fabrication, Functionalization, and Application of Carbon Nanotube-Reinforced Polymer Composite: An Overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef]

- Azammi, A.M.N.; Sapuan, S.M.; Ishak, M.R.; Sultan, M.T.H. Conceptual design of automobile engine rubber mounting composite using TRIZ-Morphological chart-analytic network process technique. Def. Technol. 2018, 14, 268–277. [Google Scholar] [CrossRef]

- Mansor, M.R.; Sapuan, S.M.; Hambali, A. Conceptual design of kenaf polymer composites automotive spoiler using TRIZ and Morphology Chart methods. Appl. Mech. Mater. 2015, 761, 63–67. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Comparison of Static and Long-term Creep Behaviors between Balau Wood and Glass Fiber Reinforced Polymer Composite for Cross-arm Application. Fibers Polym. 2021, 22, 793–803. [Google Scholar] [CrossRef]

- Syamsir, A.; Nadhirah, A.; Mohamad, D.; Beddu, S.; Asyraf, M.R.M.; Itam, Z.; Anggraini, V. Performance Analysis of Full Assembly Glass Fiber-Reinforced Polymer Composite Cross-Arm in Transmission Tower. Polymers 2022, 14, 1563. [Google Scholar] [CrossRef]

- Alhayek, A.; Syamsir, A.; Supian, A.B.M.; Usman, F.; Asyraf, M.R.M.; Atiqah, M.A. Flexural Creep Behaviour of Pultruded GFRP Composites Cross-Arm: A Comparative Study on the Effects of Stacking Sequence. Polymers 2022, 14, 1330. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, Morphological Chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 41, 2917–2932. [Google Scholar] [CrossRef]

- Živković, I.; Fragassa, C.; Pavlović, A.; Brugo, T. Influence of moisture absorption on the impact properties of flax, basalt and hybrid flax/basalt fiber reinforced green composites. Compos. Part B Eng. 2017, 111, 148–164. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Azmi, A.; Nurazzi, N.M.; Atiqah, A.; Atikah, M.S.N.; Ibrahim, R.; Norrrahim, M.N.F.; Asyraf, M.R.M.; Sharma, S.; Punia, S.; et al. Oxygen permeability properties of nanocellulose reinforced biopolymer nanocomposites. Mater. Today Proc. 2022, 52, 2414–2419. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Singh, J.; Ilyas, R.A.; Asyraf, M.R.M.; Razman, M.R. Critical Review of Biodegradable and Bioactive Polymer Composites for Bone Tissue Engineering and Drug Delivery Applications. Polymers 2021, 13, 2623. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Dayana, D.A.Z.N.; Amelia, J.J.N.; Rani, M.S.A.; Norrrahim, M.N.F.; Nurazzi, N.M.; Aisyah, H.A.; Sharma, S.; et al. Polymer composites filled with metal derivatives: A review of flame retardants. Polymers 2021, 13, 1701. [Google Scholar] [CrossRef]

- Roslan, Z.B.; Ramli, Z.; Razman, M.R.; Asyraf, M.R.M.; Ishak, M.R.; Ilyas, R.A.; Nurazzi, N.M. Reflections on Local Community Identity by Evaluating Heritage Sustainability Protection in Jugra, Selangor, Malaysia. Sustainability 2021, 13, 8705. [Google Scholar] [CrossRef]

- Ali, S.S.S.; Razman, M.R.; Awang, A.; Asyraf, M.R.M.; Ishak, M.R.; Ilyas, R.A.; Lawrence, R.J. Critical Determinants of Household Electricity Consumption in a Rapidly Growing City. Sustainability 2021, 13, 4441. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential natural fiber polymeric nanobiocomposites: A review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef] [PubMed]

- Azman, M.A.; Asyraf, M.R.M.; Khalina, A.; Petrů, M.; Ruzaidi, C.M.; Sapuan, S.M.; Wan Nik, W.B.; Ishak, M.R.; Ilyas, R.A.; Suriani, M.J. Natural Fiber Reinforced Composite Material for Product Design: A Short Review. Polymers 2021, 13, 1917. [Google Scholar] [CrossRef] [PubMed]

- Kadir Bilisik, A.; Turhan, Y. Multidirectional stitched layered aramid woven fabric structures and their experimental characterization of ballistic performance. Text. Res. J. 2009, 79, 1331–1343. [Google Scholar] [CrossRef]

- Walsh, S.M.; Scott, B.R.; Spagnuolo, D.M. The Development of a Hybrid Thermoplastic Ballistic Material with Application to Helmets; Army Research Lab: Aberdeen, MD, USA, 2005. [Google Scholar]

- Kaur, P.; Sandhu, K.S.; Bangar, S.P.; Purewal, S.S.; Kaur, M.; Ilyas, R.A.; Asyraf, M.R.M.; Razman, M.R. Unraveling the bioactive profile, antioxidant and dna damage protection potential of rye (Secale cereale) flour. Antioxidants 2021, 10, 1214. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Gujjala, R.; Ojha, S.; Acharya, S.K.; Pal, S.K. Mechanical properties of woven jute—Glass hybrid-reinforced epoxy composite. J. Compos. Mater. 2014, 48, 3445–3455. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Mechanical performance of woven kenaf-Kevlar hybrid composites. J. Reinf. Plast. Compos. 2014, 33, 2242–2254. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Senthamaraikannan, P.; Pradeep, S.; Saravanakumar, S.S.; Yogesha, B. A review on synthesis and characterization of commercially available natural fibers: Part-I. J. Nat. Fibers 2018, 16, 1132–1144. [Google Scholar] [CrossRef]

- Kadier, A.; Ilyas, R.A.; Huzaifah, M.R.M.; Harihastuti, N.; Sapuan, S.M.; Harussani, M.M.; Azlin, M.N.M.; Yuliasni, R.; Ibrahim, R.; Atikah, M.S.N.; et al. Use of Industrial Wastes as Sustainable Nutrient Sources for Bacterial Cellulose (BC) Production: Mechanism, Advances, and Future Perspectives. Polymers 2021, 13, 3365. [Google Scholar] [CrossRef] [PubMed]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Evaluation of Design and Simulation of Creep Test Rig for Full-Scale Crossarm Structure. Adv. Civ. Eng. 2020, 2020, 6980918. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Shahroze, R.M.; Johari, A.N.; Rafidah, M.; Ilyas, R.A. Creep test rig for cantilever beam: Fundamentals, prospects and present views. J. Mech. Eng. Sci. 2020, 14, 6869–6887. [Google Scholar] [CrossRef]

- Kamarudin, K.M.; Ridgway, K.; Hassan, M.R. Modelling Constraints in the Conceptual Design Process with TRIZ and F3. Procedia CIRP 2016, 39, 3–8. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of creep testing rig for full-scale cross arm using TRIZ-Morphological chart-analytic network process technique. J. Mater. Res. Technol. 2019, 8, 5647–5658. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. J. Mater. Res. Technol. 2020, 9, 2357–2368. [Google Scholar] [CrossRef]

- Ishak, N.M.; Sivakumar, D.; Mansor, M.R. The application of TRIZ on natural fibre metal laminate to reduce the weight of the car front hood. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 105. [Google Scholar] [CrossRef]

- Yusof, N.S.B.; Sapuan, S.M.; Sultan, M.T.H.; Jawaid, M. Conceptual design of oil palm fibre reinforced polymer hybrid composite automotive crash box using integrated approach. J. Cent. South Univ. 2020, 27, 64–75. [Google Scholar] [CrossRef]

- Mastura, M.T.; Sapuan, S.M.; Mansor, M.R.; Nuraini, A.A. Conceptual design of a natural fibre-reinforced composite automotive anti-roll bar using a hybrid approach. Int. J. Adv. Manuf. Technol. 2017, 91, 2031–2048. [Google Scholar] [CrossRef]

- Strong, B. Plastics: Materials and Processing, 3rd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2006; Volume 14, ISBN 0131145584. [Google Scholar]

- Pugh, S. Total Design: Integrated Methods for Successful Product Engineering. Qual. Reliab. Eng. Int. 1991, 7, 119. [Google Scholar] [CrossRef]

- Amir, A.L.; Ishak, M.R.; Yidris, N.; Zuhri, M.Y.M.; Asyraf, M.R.M. Advances of composite cross arms with incorporation of material core structures: Manufacturability, recent progress and views. J. Mater. Res. Technol. 2021, 13, 1115–1131. [Google Scholar] [CrossRef]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Influence of CaCO3 in pultruded glass fibre/unsaturated polyester composite on flexural creep behaviour using conventional and TTSP methods. Polimery 2020, 65, 46–54. [Google Scholar] [CrossRef]

- Sapuan, S.M. A conceptual design of the concurrent engineering design system for polymeric-based composite automotive pedals. Am. J. Appl. Sci. 2005, 2, 514–525. [Google Scholar] [CrossRef]

- Pei, E. Building a Common Language of Design Representations for Industrial Designers & Engineering Designers. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2009. [Google Scholar]

- Ulrich, K.T.; Eppinger, S.D. Concept Selection: Product Design and Development, 5th ed.; McGraw-Hill: New York, NY, USA, 2012; Volume 1, pp. 145–161. [Google Scholar]

- Kim, K.; Lee, K. Collaborative product design processes of industrial design and engineering design in consumer product companies. Des. Stud. 2016, 46, 226–260. [Google Scholar] [CrossRef]

- Hassan, A.; Hasri Yunardi, H. Integrasi Dalam Pembangunan Reka Bentuk. In Reka Bentuk Perindustrian: Pengurusan Pembangunan Idea; Dewan Bahasa dan Pustaka: Kuala Lumpur, Malaysia, 2010; pp. 36–37. [Google Scholar]

- Knoll, D.; Fortin, C.; Golkar, A. Review of concurrent engineering design practice in the space sector: State of the art and future perspectives. In Proceedings of the 2018 IEEE International Systems Engineering Symposium (ISSE), Rome, Italy, 1–3 October 2018; pp. 1–6. [Google Scholar]

- Thiruganasambanthan, T.; Ilyas, R.A.; Norrrahim, M.N.F.; Kumar, T.S.M.; Siengchin, S.; Misenan, M.S.M.; Farid, M.A.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Zakaria, S.Z.S.; et al. Emerging Developments on Nanocellulose as Liquid Crystals: A Biomimetic Approach. Polymers 2022, 14, 1546. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Mansor, M.R. Concurrent engineering approach in the development of composite products: A review. Mater. Des. 2014, 58, 161–167. [Google Scholar] [CrossRef]

- Hassan, A.; Hasri Yunardi, H. Faktor yang Mempengaruhi Reka Bentuk Semula Produk. In Pengenalan Reka Bentuk Perindustrian Pengurusan dan Pembangunan Idea; Dewan Bahasa dan Pustaka: Kuala Lumpur, Malaysia, 2010; pp. 100–103. [Google Scholar]

- National Research Council of the National Academies. Evolution of Combat Helmets. In Review of Department of Defense Test Protocols for Combat Helmets; National Academies Press: Washington, DC, USA, 2014; pp. 11–14. [Google Scholar]

- Marzuki, I. Proses Reka Bentuk Produk. In Reka Bentuk Produk; Dewan Bahasa dan Pustaka: Kuala Lumpur, Malaysia, 2013; p. 16. ISBN 978-983-46-1439-3. [Google Scholar]

- Sapuan, S.M. Introduction. In Composite Materials: Concurrent Engineering Approach; Butterworth-Heinemann: Oxford, UK, 2017; Volume 22, pp. 1–27. [Google Scholar]

- Dudin, S.; Ginting, R.; Ishak, A. Applying Computer Integrated Manufacturing for Productivity Improvement: A Literature Review. J. Sistem Tek. Ind. 2021, 23, 204–222. [Google Scholar]

- Zoya, L. Computer Integrated Product Manufacturing Development. Int. J. Sci. Eng. Res. 2020, 11, 231–236. [Google Scholar]

- Saunders, R.; Moser, A.; Matic, P. A computationally efficient computer-aided design strategy for iterative combat helmet design and analysis. J. Eng. Sci. Med. Diagn. Ther. 2019, 2, 021003. [Google Scholar] [CrossRef]

- Sharma, A.; Mukhopadhyay, T.; Rangappa, S.M.; Siengchin, S.; Kushvaha, V. Advances in Computational Intelligence of Polymer Composite Materials: Machine Learning Assisted Modeling, Analysis and Design. Arch. Comput. Methods Eng. 2022, 1–45. [Google Scholar] [CrossRef]

- Wei, H.; Zhao, S.; Rong, Q.; Bao, H. Predicting the effective thermal conductivities of composite materials and porous media by machine learning methods. Int. J. Heat Mass Transf. 2018, 127, 908–916. [Google Scholar] [CrossRef]

- Majerczak, K.; Wadkin-Snaith, D.; Magueijo, V.; Mulheran, P.; Liggat, J.; Johnston, K. Polyhydroxybutyrate: A review of experimental and simulation studies of the effect of fillers on crystallinity and mechanical properties. Polym. Int. Int. 2022. [Google Scholar] [CrossRef]

- Addo-Tenkorang, R. Concurrent Engineering (CE): A review literature report. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 19–21 October 2011; Volume 2, pp. 19–21. [Google Scholar]

- Muhammad Fauzi, Z. Pengenalan Ergonomik dalam Reka Bentuk Perindustrian. In Reka Bentuk Perindustrian Ergonomik; Dewan Bahasa dan Pustaka: Kuala Lumpur, Malaysia, 2017; pp. 1–2. [Google Scholar]

- Dul, J.; Bruder, R.; Buckle, P.; Carayon, P.; Falzon, P.; Marras, W.S.; Wilson, J.R.; van der Doelen, B. A strategy for human factors/ergonomics: Developing the discipline and profession. Ergonomics 2012, 55, 377–395. [Google Scholar] [CrossRef] [PubMed]

- Blanchard, B.S.; Fabrycky, W.J. Systems Engineering and Analysis, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2011; Volume 5. [Google Scholar]

- Djongyang, N.; Tchinda, R.; Njomo, D. Thermal comfort: A review paper. Renew. Sustain. Energy Rev. 2010, 14, 2626–2640. [Google Scholar] [CrossRef]

- Zingano, B.W. A discussion on thermal comfort with reference to bath water temperature to deduce a midpoint of the thermal comfort temperature zone. Renew. Energy 2001, 23, 41–47. [Google Scholar] [CrossRef]

- Bogerd, C.P. Physiological and Cognitive Effects of Wearing a Full-Face Motorcycle Helmet; ETH Zürich: Zürich, Switzerland, 2009. [Google Scholar]

- Azman, M.A.; Yusof, S.A.M.; Abdullah, I.; Mohamad, I.; Mohammed, J.S. Factors influencing face mask selection and design specifications: Results from pilot study amongst Malaysian umrah pilgrims. J. Teknol. 2017, 79, 7–15. [Google Scholar] [CrossRef][Green Version]

- Health and Safety Executive. The Six Basic Factor Thermal Comfort. Available online: https://www.hse.gov.uk/temperature/thermal/factors.htm (accessed on 15 February 2022).

| Timeline | 1915 | 1943 | 1980 | 2005 | 2012 |

|---|---|---|---|---|---|

| Helmet Design | Brodie Helmet | M1 Steel Pot | PASGT | ACH | ECH |

| Material | Rolled Steel | Fabric woven linear | Kevlar 29/PVB Phenolic | Kevlar 129/PVB Phenolic Twaron/ | UHMPE and Carbon Fibre |

| Helmet Threat(s) | Shrapnel | Fragmentation | Fragmentation 9 mm bullet | Fragmentation 9 mm bullet | Fragmentation 9 mm bullet and specified small arms |

| Areal Density | 2.2 psf | 2.2 psf | 2.2 psf | 2.2 psf | 2.0 psf |

| Tenacity | - | - | 23 g/d | 27 g/d | 37 g/d |

| Advantages | Disadvantages | |

|---|---|---|

| Natural Fibre | Lightweight | Flammable |

| Recyclable | Dimensional instability | |

| Improved specific mechanical properties | High moisture absorption | |

| Eco-friendly, carbon dioxide neutrality | Anisotropic behavior | |

| Do not generate any harmful gases during processing, low energy requirements during production | Limited processing temperature (~200–230 °C) | |

| Good thermal properties | Sensitive to UV | |

| Good acoustic properties | Fugal attack and microbial | |

| Low cost, availability, renewable resources, disposal by composting | Low strength than synthetic fibres, especially impact strength | |

| Non-abrasive and great formability | Variable quality, influenced by weather | |

| No dermal issue for their handling | Low durability | |

| Safer crash behaviour in tests | Poor fibre/matrix adhesion | |

| Synthetic fibres | Long lasting | Flammable |

| Readily pick-up to various dyes | Prone to heat damage | |

| Stretchable | Melt easily | |

| Waterproofing | Not eco-friendly | |

| Non biodegradability | Cause for microplastic pollution | |

| Moisture resistance | Not suitable for hot washing | |

| Strain and wear resistance | Poor insulation capacity | |

| High production | Moderate recyclability |

| Computer Integrated Manufacturing (CIM) | |

|---|---|

|

|

| Computational Applications | Function |

|---|---|

| SOLIDWORKS, Autodesk AutoCAD, Autodesk 3ds Max | Designing and modelling |

| ABAQUS, LS-DYNA, NASTRAN, PRONTO 3D | Material mechanical Testing |

| AUTODYN-3D | Ballistic limit and damage |

| 3D Computational Fluid Dynamics | Thermal Comfort |

| DIGIMAT and Autodesk® Helius Composite | Simulation for new composite |

| Main Factors | Basic Factors |

|---|---|

| Personal factors | Clothing insulation |

| Metabolic heat | |

| Environmental factors | Air temperature |

| Radiant temperature | |

| Air velocity | |

| Humidity |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asyraf, M.Z.; Suriani, M.J.; Ruzaidi, C.M.; Khalina, A.; Ilyas, R.A.; Asyraf, M.R.M.; Syamsir, A.; Azmi, A.; Mohamed, A. Development of Natural Fibre-Reinforced Polymer Composites Ballistic Helmet Using Concurrent Engineering Approach: A Brief Review. Sustainability 2022, 14, 7092. https://doi.org/10.3390/su14127092

Asyraf MZ, Suriani MJ, Ruzaidi CM, Khalina A, Ilyas RA, Asyraf MRM, Syamsir A, Azmi A, Mohamed A. Development of Natural Fibre-Reinforced Polymer Composites Ballistic Helmet Using Concurrent Engineering Approach: A Brief Review. Sustainability. 2022; 14(12):7092. https://doi.org/10.3390/su14127092

Chicago/Turabian StyleAsyraf, M. Z., M. J. Suriani, C. M. Ruzaidi, A. Khalina, R. A. Ilyas, M. R. M. Asyraf, A. Syamsir, Ashraf Azmi, and Abdullah Mohamed. 2022. "Development of Natural Fibre-Reinforced Polymer Composites Ballistic Helmet Using Concurrent Engineering Approach: A Brief Review" Sustainability 14, no. 12: 7092. https://doi.org/10.3390/su14127092

APA StyleAsyraf, M. Z., Suriani, M. J., Ruzaidi, C. M., Khalina, A., Ilyas, R. A., Asyraf, M. R. M., Syamsir, A., Azmi, A., & Mohamed, A. (2022). Development of Natural Fibre-Reinforced Polymer Composites Ballistic Helmet Using Concurrent Engineering Approach: A Brief Review. Sustainability, 14(12), 7092. https://doi.org/10.3390/su14127092