Abstract

Increased globalization and the surging count of the population across the world indicate the need for more sustainable supply chains, especially those allied with the food industry. Nowadays, the demand for processed food items is increasing and establishing new markets globally. The sequence of activities starting from the farm and ending at the fork determines the sustainability within processed food supply chain (FSC) dynamics. Emphasizing sustainability-based performance systems in the processed FSC marks an effective and efficient utilization of resources, strengthening the dimension of economic, environmental, and societal benefits. The presented work aimed to review the avenues for adopting sustainability in the actions of Indian processed FSCs. For the same relation hierarchical models, clustering the various key enactors of sustainability in processed FSCs, every functional tier was developed. This relational, hierarchical framework was contemplated by implying the Pythagorean fuzzy set. The proposed methodology handled the mutual interrelation between the enactors and the uncertainty associated with human judgments, establishing the sequence of sustainability enactors. Outcomes of the presented study have implications in developing the framework, policy formulation, decisional attributes, facilitating field practitioners in streamlining, and embedding sustainability within the actions of processed FSCs.

1. Introduction

It is expected that the world’s population count will reach the figure of nine to ten billion by the year 2050 [1]. Issues related to biodiversity, climatic changes, environmental changes, and financial disruptions are erupting gradually across the globe [2]. In this era, where the pace of development is attracting attention, a sustainable future is still a distant dream because of traditional business practices [3].

Food supply chains (FSCs) tend to link millions of stakeholders, such as farmers, processing units, governments, and non-government organizations, handling a variety of issues related to the political arena and economic causes at national and global levels [4]. A sustainable food supply chain (SFSC) refers to managing material, information, and capital flows underpinning the three dimensions of sustainable development, i.e., economic, environmental, and social [5]. Nowadays, sustainability is gaining importance in food industries because of the increasing burden of the rising population, surging pollution levels, and growing awareness among consumers [6]. Furthermore, it is projected that the global population will increase to up to nine billion by the year 2050, and agricultural production will need to be enhanced by 70 percent. This will account for 13.5 percent of the total greenhouse gas emissions, adding woes to the environmental concerns.

Furthermore, the increasing share of food wastage, due to the staggered dynamics of FSC performance systems, demands the adoption of sustainable practices within the scope of its dynamics [7]. Approximately one-third of the global food supply is wasted or is lost in operational tiers of FSCs [8]. In China, it is estimated that 190 kilocalories of food/person is wasted every day, and in India, 40% of food grains are wasted yearly because of inefficiencies in FSC management [9]. Hence, the adoption of sustainable practices within FSCs is the answer to food wastage and food loss. In addition, sustainable future concerns are correlated directly with food consumption and its production, as these underpin the Sustainable Development Goal (SDG12) of the United Nations [10].

The term sustainability encloses liabilities related to the environment, social perspectives, and financial concerns envisioned for future generations’ needs [11]. Developments provoking sustainability need to imply changes in the production systems of various society-centered organizations, rendering the optimum utilization of natural resources [12]. Sustainability bundles an optimized outcome to materialize social values, economic aims, and ecological concerns. Social values indicate consumers’ health and food safety for all, whereas economic values point towards a return on investment, which should be high, and ecological concerns emphasize reduced carbon footprints [13].

The presented work aimed to establish a robust framework clustering the various practices allied with the dynamics of FSCs, embedding and strengthening the pace of the adoption of sustainability. To achieve this, a hierarchical relational model was developed, in which the possible course of the sustainable action, at every working tier of a FSC, was explored and analyzed by the multi-criteria decision-making tool TODIM. TODIM is a Portuguese acronym for interactive multi-criteria decision making, elaborated as ‘tOmada de decisao interativa multicriterio’. The aforementioned methodology was extended under the aegis of Pythagorean fuzzy set theory to incorporate the judgemental values of the field experts related to the notions under consideration. Furthermore, the outcomes of the presented work are aimed at answering the following research questions (RQ):

RQ1: What are the key embedders of sustainability within the dynamics of a processed FSC performance system?

RQ2: How can one secure the interrelationship between the developed framework of sustainability and the multi-tier functioning of FSCs?

RQ3: How can one align the various walks of a processed FSC performance system with different operation feasibilities?

2. Literature Review

Nowadays, business organizations are working to adopt sustainability in their operations and tactics [14]. The rising demand from consumers for customization and quality is prompting FSC operations to shore up towards the path of sustainability. FSC activities are focused on food quality, food safety, and consumer health to overcome the threat of food scares. With increasing competitive spirits among various food industries, the burden of catering demand, simultaneous with quality consistency, quantity, and pricing strategies, is becoming difficult for companies. Hence, companies need to switch to sustainable processes for better market coordination and management in a holistic way [15]. In consensus, the work of Li et al. [16] reviewed sustainable food supply chains (SFSCs) underpinning recent value-addition developments. Murphy and Adair [17] explored the scope of sustainability in FSCs and highlighted the tactics undertaken by food industries to collaborate with sustainable needs. Garnett [18] found various problems and challenges, and ways to overcome them, for sustainability in FSC operations. Haass et al. [19] developed an algorithm incorporating an innovative distribution-based network with a tendency to reduce food wastage and lower carbon emissions by selecting technically smart containers for the movement of food. Raak et al. [20] considered 13 German-based food processing companies to assess food wastage and its accountability in quantifying sustainability. Sgarbossa and Russo [21] developed a sustainability-based model highlighting the generation of food waste and its reuse within FSCs. Heard et al. [22] explored the adoption of sustainability within FSCs by opting for autonomous, connected vehicles to distribute the commodities.

León-Bravo et al. [23] analyzed the sustainability in FSCs by opting for a two-fold approach based upon securing collaborations between partners and performance analysis of its working tiers, respectively. Becker and Ellis [24] explored the sustainability of agriculture-based FSCs based on ecological, social, and economic impacts. Furthermore, in many studies, the dimension of the economy had the highest impact on the implementation of various initiatives of sustainability, caused by opting for green supply chain practices [16,25,26]. Higgins et al. [27] applied mathematical-based optimization procedurals, considering the holistic perspective allied with the FSC to assess various sustainability-governing parameters. Zhu et al. [28] reviewed different operation research techniques to widen the scope of sustainability in a food supply chain performance system (FSCPS). Soysal et al. [29] focused on sustainability-based logistics in FSCs, pointing toward quantitative modeling. Garnett [30] detailed various ways to adopt sustainable practices with the aim of improvements in efficiency, demand fulfillment capacity, and good governing bodies. Green [31] claims that the adoption of sustainable practices within the food industry poses a big challenge for future aspects and shifts towards a risk-driven approach.

Nowadays, because of the high interlinkage between attributes and sub-attributes, optimization/outranking-based approach applications in the area of SSCM are becoming popular [32]. A broad spectrum of multi-criteria decision-making (MCDM) techniques includes solutions to various multi-attribute and objective problems. Linnemann et al. [33] used an MCDM-based analytical hierarchy process (AHP) to evaluate the alternatives governing FSC design and transparency improvements. Allaoui et al. [34] used an AHP-based two-stage objective hybrid approach meant for multi-objective optimization in designing SFSCs. Lahane and Kant [35] outranked various barriers, hurdling the dynamics of the circular supply chain by extending a hybrid combination of fuzzy-based AHP-DEMATEL methodology. Malek and Desai [36] developed a framework to prioritize the barriers to sustainable manufacturing. Sufiyan et al. [37] used a fuzzy-based decision-making trial and evaluation laboratory (DEMATEL) to evaluate mutual interactions among performance-based criteria in FSCs. Gardas et al. [38] (2018) used the MCDM technique, namely DEMATEL, to prioritize the causes behind post-harvest losses of food items in FSCs for attaining sustainability within the operation. Sharma et al. [39] assessed the mutual interrelationship between temperature monitoring trends in FSCs by implementing the methodology of DEMATEL.

Govindan et al. [40] developed a multi-objective-based model for a two-tier routing and locating problem for an SFSC, impacting costs and the environment. Azadnia et al. [41] formulated an approach comprising multi-objective-based programming, enabling sustainability in selecting suppliers and optimum lot sizing, tending to minimize costing and maximize profits of SFSCs. Kannan [42] assessed the role of various stakeholders and allied success factors for securing sustainability-based supplier selection. Tavana et al. [43] extended the methodology in the fuzzy environment for supplier selection engaged within the reverse supply chain. Oglethorpe [44] used a goal-programming-based technique that enabled decision makers to evaluate FSC strategies based on the dimensional goals of economy, ecology, and social needs. Bortolini et al. [45] formulated a programming model for sustainability in food distribution, costing related to operations, and carbon footprint generation within FSCs. Mehlawat et al. [46] assessed three tier-based sustainability perspectives in the distribution channel of the supply chain. Liu et al. [47] focused on the minimization of supply chain costs allied with the transportation of commodities by freezing mutual consensus between the operators. Nagurney and Nagurney [48] presented a model that aimed to optimize the network of an FSC by considering capacity constraints and costings by using a multi-criteria-based approach.

Few studies considered human dietary patterns to secure sustainable avenues of production and consumption by accounting for the cost of food, carbon emissions for the food, and nutrition [49,50,51]. Verkerk et al. [52] found that the design of FSC systems was directly associated with the perspective of human health and the nutritional value of food.

Model Development

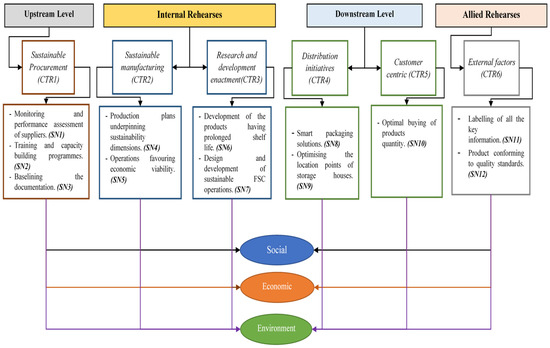

The presented work was aimed at clustering the various enactors of sustainability in the dynamics of a processed food supply chain. To achieve this, a holistic working approach was opted for in order to alter FSCs from their upstream to their downstream operational tiers, along with allied practices from the perspective of sustainability. Insights from the research literature cluster various sustainable practices allied with every tier in processed FSCs (refer Table 1). This led to the development of the relational hierarchical model detailed in Figure 2. For the ease of visualization during the course of mathematical contemplations, the tiers of the FSCs, which are representing the criteria here, are abbreviated as CTR1, CTR2 … and CTR6, whereas representative practices are notated as SN1, SN2, SN3 … and SN12, seeding the development of the proposed model.

Table 1.

Sustainable practices at a glance.

The developed relational hierarchical model comprised the various functional tiers of an FSC on the top hierarchy, which governed the sustainable practices, respectively. In the second level of the hierarchy, various practices governing sustainability in the considered functional tiers of an FSC were framed in relation to criteria in the top and alternatives in the bottom hierarchy. At the bottom, practices in the middle hierarchy were found to be equally likely to be dependent and have a close association with the social, environmental, and economic factors. In Figure 1 represents operational tiers that have a linkage with their relative set of sustainable practices. Whereas, every practice had a linkage with the bottom hierarchy constituents.

Figure 1.

Developed hierarchical framework for sustainability embedders in a processed food supply chain performance system.

3. Methodological Perspectives

The developed model was empirically analyzed to secure the primacy allied with the sustainable practices under consideration. For the same fundamentals, the Pythagorean-based fuzzy sets were extended with the methodology of TODIM, resulting in the establishment of primacies allied with the practices, owing to the perspectives bundled with the social, economic, and environmental dimensions.

3.1. Proposed Methodology: The Pythagorean-Based Fuzzy TODIM Approach

To tackle the uncertainties allied with decision making, Zadeh introduced fuzzy set theory. Incorporating the fundamentals of fuzzy sets enhances the accuracy of decision-making procedures [65,66]. This theory assigns a membership function with a value ranging from 0 for every element belonging to the universal discourse. Fuzzy set theory generalizes classical set theory by incorporating the intermediate values between the whole numbers. Extremities of the membership function values 0 and 1 of an element infer that it does not belong to a class, whereas other values showcase its closeness to the class. An advancement in fuzzy set theory put forward by Atanassov, which bundled the membership function and non-membership function , along with the margin of hesitancy (Ω) allied with human judgement, is recognized as the intuitionistic fuzzy set [67]. Mathematically, is a necessary and sufficient condition for the intuitionistic fuzzy set. However, for situations where , fundamentals of the intuitionistic set violate and constrain the measure of the uncertainties up to a specific level. To tackle the same issue, the Pythagorean fuzzy set (PFS) was proposed [68]. The PFS empowers decision makers to bundle the conditions of and . This allowed us to capture a broad spectrum of uncertainties allied with judgemental entities rather than the intuitionistic fuzzy set. Owing to this, the PFS is widely integrated with the multiple tools and techniques of decision making and analysis. Liang and Xu [69] extended the technique of TOPSIS with the fundamentals of the PFS for the assessment of the energy project selection mathematical model. Pérez-Domínguez et al. [70] integrated the technique of MOORA with the PFS for evaluating a multi-criteria-based problem. Mohagheghi et al. [71] exercised the PFS in the dynamics of a group decision-making problem by weighting the aggregates. Rahman et al. [72] bundled the Einstein aggregation operator, with the PFS for the assessment of the decisional entities. Garg [73] extended the score-function-based assessment to improve the outranking decision under the aegis of the PFS environment. Furthermore, extending the Pythagorean fuzzy set broadens the spectrum of the membership functional values allied with the human judgemental entities. Integrating the methodology of the TODIM with the fundamentals of Pythagorean fuzzy sets, enriches the decision outcomes by widening the scope of membership functional entities mutually aiding the evaluation of the dominance degree allied with the alternatives [74].

Furthermore, details of the various aspects allied with the Pythagorean fuzzy set are rendered as follows.

Definition 1.

Pythagorean fuzzy set [75]

If ‘X’ is assumed to be the universal discourse, comprising a typical Pythagorean fuzzy set depicted by the ‘PG’, then ‘PG’ is defined as follows:

where, and ) represent the degree of membership function and non-membership function, respectively, for within set PG. and ) must satisfy the necessary and sufficient condition .

Definition 2.

Let be three Pythagorean fuzzy numbers (PFNs) [76].

- I.

- II.

- III.

Definition 3.

[76]: Assume is a PFN, then its score function s() and accuracy function a() is defined as follows:

- I.

- If < , then .

- II.

- If = , then

- if < , then,

- if > , then,

- if , then, .

Multi-criteria decision making (MCDM) simplifies the procedures of decision making by enclosing the selection of an optimal alternative from the set of multiple alternatives based upon the governing criteria. Underpinning the same issue, the methodology of TODIM based upon the prospect’s theory was implied. TODIM finds the leading edge over existing MCDM techniques, such as the analytical hierarchical process (AHP), the technique of order preference by similarity to ideal solutions (TOPSIS), elimination and choice expressing reality (ELECTRE), etc., in terms of the mutual comparison of every alternative based upon which dominance degree allied with them was evaluated [77].

The proposed methodology seeded the judgemental insights, framed as the decision matrix. For the considered alternatives, ALRg (g = 1, 2, 3 … a) and criteria’s CREc (c = 1, 2, 3 … h), a mutual pairwise comparison of the alternatives and criteria was rendered in the decision matrix. This mCn ‘M’, refer to Equation (1).

where ‘mgc’ represents the performance value of alternative ‘ALR1’ over the criteria ‘CRE1’. These rating values needed to be normalized to remove the various extremities allied with the assigned rating values. The same implied formula is showcased in Equation (2), in which ‘NMgc’ depicts the normalized value of the alternative over the criteria under consideration.

The governing criteria were assessed for the evaluation of their relative weights (). The formulation of Equation (3) was structured, where ‘qc’ refers to criteria weights and ‘qcr’ indicates the highest value of the criteria weight.

The TODIM methodology evaluates the dominance degree () allied with the various alternatives under consideration. It is evaluated in lieu of the criteria under consideration, illustrated as ALRg over ALRj by implying the formula structure in Equations (4) and (5).

where is the gain of alternative ALRg over ALRj, similarly represents losses marked by the attenuation factor . Quantified values of the reveal the mutual dominances between the alternatives for the evaluation of its allied value of overall dominance degree , as shown in Equation (6).

Evaluated values of were used to establish the primacies of the alternatives under consideration.

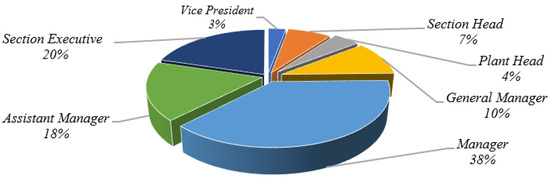

3.2. Numerical Illustration

The developed framework of sustainability in the processed FSCPS was contemplated by the proposed methodology, based upon the insights gained from the field practitioners. To execute it, the same practitioners working in the food processing units situated in Northern India were physically visited and brainstorming sessions were conducted. This gathered the sample size of the sixty-nine distinct experts, whose designation and responses shared in the percentage revealed in Figure 2. Experts rendered their viewpoints relative to the various enactors under consideration and explored various practicalities allied with them. After checking for the feasibility of the notions under consideration they were allied with the presented work and validated with the field practitioner. A questionnaire comprising rating points was developed and assessments were secured from the field experts. All the respondents had more than 5 years of work experience in the domain of processed FSCs and their allied operations. Furthermore, highlights of the data are showcased in the form of pie charts to enhance their visualization, see Figure 2.

Figure 2.

Respondent share.

Initially, experts validated the scope of the embedders of sustainability in the dynamics of FSCs. Later on, perception of the field practitioners was secured in the form of Pythagorean fuzzy set-based linguistic ratings, having the interpretation as shown in Table 2. This assessment seeded the development of the decision matrix in Table 3, in which the notation of the consecutively numbered SNs represent the enactors of the sustainability and CTR depicted its allied criteria, as detailed in Table 1.

Table 2.

Assessment of the rating points.

Table 3.

Developed decision matrix.

Ratings rendered in Table 3 were normalized by implying the formula mentioned in Equation (2). Normalized assessments were seeded for the evaluation of the distance between the alternatives relative to every criterion consecutively. Evaluated values are showcased in Table 4, in reference to criterion 1 under consideration. Similarly, it was also evaluated for the other criteria: CRT2, CRT3, CRT4, CRT5, and CRT6, respectively.

Table 4.

Distance relative to the CRT1.

Evaluation of the distances relative to every criterion succeeded in evaluation of the dominance degree allied with the sustainable practices under consideration. It was evaluated by exercising the formulation rendered in Equation (4), relative to every criterion. In Table 5, the dominance value of the sustainable practices relative to CRT1 is clustered.

Table 5.

Dominance degree of sustainable practices relative to CRT1.

Similarly, for CRT2, CRT3, CRT4, CRT5, and CRT6, respectively, the dominance degree was evaluated, seeding the development of the overall dominance degree matrix. For the same, the formula mentioned in Equation (5) was applied, and evaluated values are shown in Table 6.

Table 6.

Overall dominance degree of the sustainable practices.

4. Result and Discussions

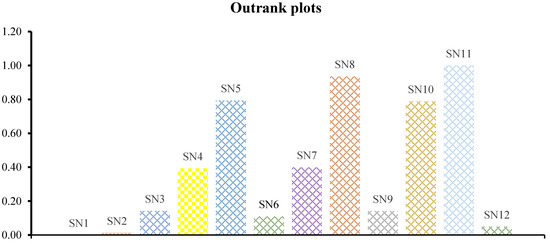

Outcomes of the analysis resulted in securing the primacy of the sustainability enactors under consideration, which were governed by the criteria under consideration and bound equal dependencies upon the dimensions of sustainability (social, economic, and environmental). Results grounded by the hybrid combination of the Pythagorean fuzzy set and TODIM secured the priority ordered as SN11 > SN8 > SN5 > SN10 > SN7 > SN4 > SN3 > SN9 > SN6 > SN12 > SN2 > SN1. The overall dominance degree was utilized to establish the priority of the various sustainable practices under consideration as shown in Table 7. Quantified values allied with the priority were plotted, aiding the ease of visualization of the results in Figure 3.

Table 7.

calculated values.

Figure 3.

Plots for the assessment of the practices.

It could be inferred from the plots that among all the embedders of sustainability in processed FSCs practice Labelling of all the key information (SN11), which outranked the others highly with a maximum value of 1.0000. Labeling defines the details associated with the processed food commodity, in terms of its ingredients, shelf life, manufacturer, and pricing. Generally, consumers presume sustainability as the insignia of environmental concerns. Labeling the key information of processed food items blurs this assumption and broadens the consumer’s thoughts, flipping awareness towards economic and social concerns. Product packaging material details, costing, and nutrient value assure of the quality as well as capture the consumer details towards the dimension of sustainability. It was estimated that in the United States of America (USA), labeling the details allied with the sustainability of processed food items, captured the market, as well as consumer choice over cheap spurious products, causing a surge of 12 percent in the year 2012 [78]. Furthermore, labeling the information built up the product share in the market, and found compliance with consumer choices. It is key to achieve widespread awareness about sustainability among the masses, from the urban to the rural geographical regimes, promoting avenues of sustainable FSC procedures. Such practices ensure the flow of quality-conforming food products at low prices, balancing the supply and demand patterns, respectively. Rendering smart packaging solutions in the dynamics of the processed FSC, reduces food losses, and promotes economic and technical efficiency in the products’ transits, enhancing the transparency in the operations. Smart packaging of food items determines the product storage environmental conditions, and safeguards products from pilferage and external contamination, as well as enables real-time monitoring protocols from remote locations. Enacting such solutions improves the shelf life of perishable food items, curtails food wastage, and promotes the economic viability of FSC operations.

Ramping up economically viable solutions, reduces costs and improves the profitability within FSCs. Ensuring food to all sections of the society and its pricing withholds the pillars of food safety and security. Lack of economic operations results in inflated prices for the essential food commodities, distorting the social concerns allied with it. Assuring economic operations reduces the carbon footprint and emission levels associated with the support systems, promoting sustainability in the journey from farm to fork. Such scenarios seed the design and development of sustainable FSC operations, where consumers favor optimal product buying and manufacturers make a shift towards production plans underpinning the dimensions of economic, social, and environmental perspectives. For the same, various operating protocols and procedurals need to be streamlined in the dynamics of processed FSCs. All the measures of sustainability beginning from the procurement and ending at the consumer need to be standardized and operating measures must be baselined. Procurement procedures, supplier selection, operating capacities, and location of the warehouses and distribution centers should be forced by accounting for the impacts of the environmental vulnerabilities, economic feasibilities, and socially susceptible scenarios.

Expediting the pace of the research and development activities within the working envelope of the supply chain activities will aid sustainability. Development of key constituents and framing product recipes, which can tend to overcome perishability and assure a prolonged shelf life, aid in packaging solutions and the design of a supply chain network tailored to seed the venues of sustainability. Assessment of a supplier’s performance and monitoring for underpinning the sustainability notions, as well as ensuring the flow of quality products through the tiers of the processed FSC network, bridges the gap between the supply and demand pattern.

5. Conclusions and Implications

The presented work is aimed at embedding sustainability within the dynamics of a processed food supply chain performance system, which addresses the prosperous avenues of its demand. Production and consumption of processed food items are increasing and capturing the market, irrespective of the geographical regime. To secure these prosperous avenues and feed the masses effectively and efficiently, sustainability needs to be embedded within FSCs. For the same reasons, various key practices enacting sustainability within the various working tiers in FSCs were clustered from the core of the research literature and further validated and judged by field practitioners. Hence, the outcomes of the presented work implied a two-fold approach, accumulating the insights of the research literature as well as the field practitioners to ground the various practical feasibilities allied with it. The outcomes of the proposed methodology of the TODIM, governed by the linguistics of Pythagorean fuzzy sets, resulted in the establishment of the priorities of the identified embedders of sustainability, from the developed relational hierarchal framework.

The presented work had its scope of implications in the multi-disciplinary domains, extending towards the working arenas of industry, academia, and government bodies. This study conceptualized the various aspects of sustainability within processed FSC dynamics, facilitating the managers and top management of the food processing industry to deepen their thoughts about these issues, by-passing the various misconceptions and dilemmas allied with it. Furthermore, the developed framework empowered managers to critically examine the scope of sustainability at every working tier in an FSC, in light of the practices under consideration. This aided in the development of various policies, strategic roadmaps, and decisional and tactical frameworks that pave the way for sustainability in the future course of the actions of an FSC. By the secured priority of the embedders under consideration, managers should ground the procedurals, detailing the labeling of key information on the product packaging, and measures in the direction of smart packaging solutions should be deliberated in a phased manner to mark the progress towards sustainable futuristic needs. Furthermore, a unified working approach between industry, academia, and ruling governments could flip the darker side allied with this domain. Academicians can collaborate with industries to render the various robust cost-effective technological solutions and upgrades, which could shun the darkness of the traditional practices in the operations. However, ruling governments should make the masses aware of the importance of a sustainable course of action. Various concerned bodies should streamline the various procedures and should enforce the rules governing sustainability in the journey from farm to fork. Various infrastructure needs should be fulfilled, and robust planning-based outcomes should be materialized by uniting the notions of industry needs and academic expertise to secure sustainable food supply chains. Hence, in a nutshell, the proposed framework and contemplation of sustainable practices diversified the scope of the various theoretical, practical, and multi-disciplinary implications.

Author Contributions

Conceptualization, A.S.A., J.S. and M.T.; Data curation, N.K.; Formal analysis, J.S. and A.B.; Funding acquisition, A.S.A.; Investigation, M.T., A.B. and M.R.N.M.Q.; Methodology, M.R.N.M.Q. and N.K.; Project administration, A.S.A. and M.R.N.M.Q.; Resources, A.S.A. and A.B.; Software, N.K.; Supervision, A.B.; Validation, J.S. and M.T.; Visualization, N.K.; Writing – original draft, J.S. and M.T.; Writing – review & editing, M.R.N.M.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Deanship of Scientific Research, King Khalid University, Kingdom of Saudi Arabia, and the grant number is R.G.P.2/178/43.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We would like to express our gratitude to the Deanship of Scientific Research, King Khalid University, Kingdom of Saudi Arabia for funding this work, as well as family, friends, and colleagues for their constant inspiration and encouragement.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Luthra, S.; Govindan, K.; Mangla, S.K. Structural model for sustainable consumption and production adoption—A grey-DEMATEL based approach. Resour. Conserv. Recycl. 2017, 125, 198–207. [Google Scholar] [CrossRef]

- de Souza, E.D.; Kerber, J.C.; Bouzon, M.; Rodriguez, C.M.T. Performance evaluation of green logistics: Paving the way towards circular economy. Clean. Logist. Supply Chain 2022, 3, 100019. [Google Scholar] [CrossRef]

- Sharma, J.; Tyagi, M.; Bhardwaj, A. Parametric review of food supply chain performance implications under different aspects. J. Adv. Manag. Res. 2020, 17, 421–453. [Google Scholar] [CrossRef]

- Sharma, J.; Tyagi, M.; Bhardwaj, A. Exploration of COVID-19 impact on the dimensions of food safety and security: A perspective of societal issues with relief measures. J. Agribus. Dev. Emerg. Econ. 2021, 11, 452–471. [Google Scholar] [CrossRef]

- Govindan, K. Sustainable consumption and production in the food supply chain: A conceptual framework. Int. J. Prod. Econ. 2018, 195, 419–431. [Google Scholar] [CrossRef]

- Benis, K.; Ferrão, P. Potential mitigation of the environmental impacts of food systems through urban and peri-urban agriculture (UPA)–A life cycle assessment approach. J. Clean. Prod. 2017, 40, 784–795. [Google Scholar] [CrossRef]

- Jurgilevich, A.; Birge, T.; Kentala-Lehtonen, J.; Korhonen-Kurki, K.; Pietikäinen, J.; Saikku, L.; Schösler, H. Transition towards circular economy in the food system. Sustainability 2016, 8, 69. [Google Scholar] [CrossRef] [Green Version]

- Kummu, M.; De Moel, H.; Porkka, M.; Siebert, S.; Varis, O.; Ward, P.J. Lost food, wasted resources: Global food supply chain losses and their impacts on freshwater, cropland, and fertiliser use. Sci. Total Environ. 2012, 438, 477–489. [Google Scholar] [CrossRef] [PubMed]

- Mangla, S.K.; Sharma, Y.K.; Patil, P.P.; Yadav, G.; Xu, J. Logistics and distribution challenges to managing operations for corporate sustainability: Study on leading Indian diary organizations. J. Clean. Prod. 2019, 238, 117620. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, K.M.; Kannan, D. Achieving sustainable development goals through identifying and analyzing barriers to industrial sharing economy: A framework development. Int. J. Prod. Econ. 2020, 227, 107575. [Google Scholar] [CrossRef]

- Amui, L.B.L.; Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Kannan, D. Sustainability as a dynamic organizational capability: A systematic review and a future agenda toward a sustainable transition. J. Clean. Prod. 2017, 142, 308–322. [Google Scholar] [CrossRef]

- McCormick, K.; Neij, L.; Mont, O.; Ryan, C.; Rodhe, H.; Orsato, R. Advancing sustainable solutions: An interdisciplinary and collaborative research agenda. J. Clean. Prod. 2016, 123, 1–4. [Google Scholar] [CrossRef]

- Ohlsson, T. Sustainability and food production. In Food Safety Management; Academic Press: Cambridge, MA, USA, 2014; pp. 1085–1097. [Google Scholar]

- Luthra, S.; Mangla, S.K. When strategies matter: Adoption of sustainable supply chain management practices in an emerging economy’s context. Resour. Conserv. Recycl. 2018, 138, 194–206. [Google Scholar] [CrossRef]

- Seuring, S.; Aman, S.; Hettiarachchi, B.D.; de Lima, F.A.; Schilling, L.; Sudusinghe, J.I. Reflecting on theory development in sustainable supply chain management. Clean. Logist. Supply Chain 2022, 3, 100016. [Google Scholar] [CrossRef]

- Li, D.; Wang, X.; Chan, H.K.; Manzini, R. Sustainable food supply chain management. Int. J. Prod. Econ. 2014, 152, 1–8. [Google Scholar] [CrossRef]

- Murphy, J.; Adair, P. Sustainable supply chain management in the Food Sector. Food Sci. Technol. 2013, 37–40. [Google Scholar]

- Garnett, T. Food sustainability: Problems, perspectives and solutions. Proc. Nutr. Soc. 2013, 72, 29–39. [Google Scholar] [CrossRef] [Green Version]

- Haass, R.; Dittmer, P.; Veigt, M.; Lütjen, M. Reducing food losses and carbon emission by using autonomous control—A simulation study of the intelligent container. Int. J. Prod. Econ. 2015, 164, 400–408. [Google Scholar] [CrossRef]

- Raak, N.; Symmank, C.; Zahn, S.; Aschemann-Witzel, J.; Rohm, H. Processing-and product-related causes for food waste and implications for the food supply chain. Waste Manag. 2017, 61, 461–472. [Google Scholar] [CrossRef]

- Sgarbossa, F.; Russo, I. A proactive model in sustainable food supply chain: Insight from a case study. Int. J. Prod. Econ. 2017, 183, 596–606. [Google Scholar] [CrossRef]

- Heard, B.R.; Taiebat, M.; Xu, M.; Miller, S.A. Sustainability implications of connected and autonomous vehicles for the food supply chain. Resour. Conserv. Recycl. 2018, 128, 22–24. [Google Scholar] [CrossRef]

- León-Bravo, V.; Caniato, F.; Caridi, M.; Johnsen, T. Collaboration for sustainability in the food supply chain: A multi-stage study in Italy. Sustainability 2017, 9, 1253. [Google Scholar] [CrossRef] [Green Version]

- Becker, J.; Ellis, J.D. The role of sustainability reporting in the agri-food supply chain. J. Agric. Environ. Sci. 2017, 6, 17–29. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Machado, V.C. The influence of green practices on supply chain performance: A case study approach. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Higgins, A.J.; Miller, C.J.; Archer, A.A.; Ton, T.; Fletcher, C.S.; McAllister, R.R.J. Challenges of operations research practice in agricultural value chains. J. Oper. Res. Soc. 2010, 61, 964–973. [Google Scholar] [CrossRef]

- Zhu, Z.; Chu, F.; Dolgui, A.; Chu, C.; Zhou, W.; Piramuthu, S. Recent advances and opportunities in sustainable food supply chain: A model-oriented review. Int. J. Prod. Res. 2018, 56, 5700–5722. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Meuwissen, M.P.; van der Vorst, J.G. A review on quantitative models for sustainable food logistics management. Int. J. Food Syst. Dyn. 2012, 3, 136–155. [Google Scholar]

- Garnett, T. Three perspectives on sustainable food security: Efficiency, demand restraint, food system transformation. What role for life cycle assessment? J. Clean. Prod. 2014, 73, 10–18. [Google Scholar] [CrossRef]

- Green, D.P. Sustainable food supply chains. J. Aquat. Food Prod. Technol. 2010, 19, 55–56. [Google Scholar] [CrossRef]

- Rohmer, S.U.K.; Gerdessen, J.C.; Claassen, G.D.H. Sustainable supply chain design in the food system with dietary considerations: A multi-objective analysis. Eur. J. Oper. Res. 2019, 273, 1149–1164. [Google Scholar] [CrossRef]

- Linnemann, A.R.; Hendrix, E.M.; Apaiah, R.; van Boekel, T.A. Food chain design using multi criteria decision making, an approach to complex design issues. NJAS-Wagening. J. Life Sci. 2015, 72, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Allaoui, H.; Guo, Y.; Choudhary, A.; Bloemhof, J. Sustainable agro-food supply chain design using two-stage hybrid multi-objective decision-making approach. Comput. Oper. Res. 2018, 89, 369–384. [Google Scholar] [CrossRef] [Green Version]

- Lahane, S.; Kant, R. Evaluating the circular supply chain implementation barriers using Pythagorean fuzzy AHP-DEMATEL approach. Clean. Logist. Supply Chain 2021, 2, 100014. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T.N. A framework for prioritizing the solutions to overcome sustainable manufacturing barriers. Clean. Logist. Supply Chain 2021, 1, 100004. [Google Scholar] [CrossRef]

- Sufiyan, M.; Haleem, A.; Khan, S.; Khan, M.I. Evaluating food supply chain performance using hybrid fuzzy MCDM technique. Sustain. Prod. Consum. 2019, 20, 40–57. [Google Scholar] [CrossRef]

- Gardas, B.B.; Raut, R.D.; Narkhede, B. Evaluating critical causal factors for post-harvest losses (PHL) in the fruit and vegetables supply chain in India using the DEMATEL approach. J. Clean. Prod. 2018, 199, 47–61. [Google Scholar] [CrossRef]

- Sharma, J.; Tyagi, M.; Bhardwaj, A. Parametric assessment of temperature monitoring trends in food supply chain performance system. In Optimization Methods in Engineering; Springer: Singapore, 2021; pp. 169–184. [Google Scholar]

- Govindan, K.; Jafarian, A.; Khodaverdi, R.; Devika, K. Two-echelon multiple-vehicle location–routing problem with time windows for optimization of sustainable supply chain network of perishable food. Int. J. Prod. Econ. 2014, 152, 9–28. [Google Scholar] [CrossRef]

- Azadnia, A.H.; Saman, M.Z.M.; Wong, K.Y. Sustainable supplier selection and order lot-sizing: An integrated multi-objective decision-making process. Int. J. Prod. Res. 2015, 53, 383–408. [Google Scholar] [CrossRef]

- Kannan, D. Role of multiple stakeholders and the critical success factor theory for the sustainable supplier selection process. Int. J. Prod. Econ. 2018, 195, 391–418. [Google Scholar] [CrossRef]

- Tavana, M.; Shaabani, A.; Di Caprio, D.; Bonyani, A. An integrated group fuzzy best-worst method and combined compromise solution with Bonferroni functions for supplier selection in reverse supply chains. Clean. Logist. Supply Chain 2021, 2, 100009. [Google Scholar] [CrossRef]

- Oglethorpe, D. Optimising economic, environmental, and social objectives: A goal-programming approach in the food sector. Environ. Plan. A 2010, 42, 1239–1254. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

- Mehlawat, M.K.; Kannan, D.; Gupta, P.; Aggarwal, U. Sustainable transportation planning for a three-stage fixed charge multi-objective transportation problem. Ann. Oper. Res. 2019, 1–37. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, S.; Du, Y.; Wang, H. Supply chain cost minimization by collaboration between liner shipping companies and port operators. Transp. J. 2016, 55, 296–314. [Google Scholar] [CrossRef]

- Nagurney, A.; Nagurney, L.S. Sustainable supply chain network design: A multicriteria perspective. Int. J. Sustain. Eng. 2010, 3, 189–197. [Google Scholar] [CrossRef]

- Macdiarmid, J.I.; Kyle, J.; Horgan, G.W.; Loe, J.; Fyfe, C.; Johnstone, A.; McNeill, G. Sustainable diets for the future: Can we contribute to reducing greenhouse gas emissions by eating a healthy diet? Am. J. Clin. Nutr. 2012, 93, 632–639. [Google Scholar] [CrossRef]

- Tran, N.; Bailey, C.; Wilson, N.; Phillips, M. Governance of global value chains in response to food safety and certification standards: The case of shrimp from Vietnam. World Dev. 2013, 45, 325–336. [Google Scholar] [CrossRef]

- Ribal, J.; Fenollosa, M.L.; García-Segovia, P.; Clemente, G.; Escobar, N.; Sanjuán, N. Designing healthy, climate friendly and affordable school lunches. Int. J. Life Cycle Assess. 2016, 21, 631–645. [Google Scholar] [CrossRef]

- Verkerk, R.; Schreiner, M.; Krumbein, A.; Ciska, E.; Holst, B.; Rowland, I.; De Schrijver, R.; Hansen, M.; Gerhäuser, C.; Mithen, R.; et al. Glucosinolates in Brassica vegetables: The influence of the food supply chain on intake, bioavailability and human health. Mol. Nutr. Food Res. 2009, 53 (Suppl. 2), S219. [Google Scholar] [CrossRef]

- Khan, A.U.; Ali, Y. Sustainable supplier selection for the cold supply chain (CSC) in the context of a developing country. Environ. Dev. Sustain. 2021, 23, 13135–13164. [Google Scholar] [CrossRef]

- Gupta, H.; Kusi-Sarpong, S.; Rezaei, J. Barriers and overcoming strategies to supply chain sustainability innovation. Resour. Conserv. Recycl. 2020, 161, 104819. [Google Scholar] [CrossRef]

- Fraser, I.J.; Schwarzkopf, J.; Müller, M. Exploring supplier sustainability audit standards: Potential for and barriers to standardization. Sustainability 2020, 12, 8223. [Google Scholar] [CrossRef]

- Mohammadi, M. Designing an integrated reliable model for stochastic lot-sizing and scheduling problem in hazardous materials supply chain under disruption and demand uncertainty. J. Clean. Prod. 2020, 274, 122621. [Google Scholar] [CrossRef]

- Dora, M.; Wesana, J.; Gellynck, X.; Seth, N.; Dey, B.; De Steur, H. Importance of sustainable operations in food loss: Evidence from the Belgian food processing industry. Ann. Oper. Res. 2020, 290, 47–72. [Google Scholar] [CrossRef] [Green Version]

- Long, Y.; Zhang, M.; Devahastin, S.; Cao, P. Progresses in processing technologies for special foods with ultra-long shelf life. Crit. Rev. Food Sci. Nutr. 2020, 62, 2355–2374. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, R.; Yen, P.; Agarwal, R.; Arshinder, K.; Bajada, C. Collaborative innovation and sustainability in the food supply chain-evidence from farmer producer organisations. Resour. Conserv. Recycl. 2021, 168, 105253. [Google Scholar] [CrossRef]

- Rezaei, J.; Papakonstantinou, A.; Tavasszy, L.; Pesch, U.; Kana, A. Sustainable product-package design in a food supply chain: A multi-criteria life cycle approach. Packag. Technol. Sci. 2019, 32, 85–101. [Google Scholar] [CrossRef] [Green Version]

- Rossi, T.; Pozzi, R.; Pirovano, G.; Cigolini, R.; Pero, M. A new logistics model for increasing economic sustainability of perishable food supply chains through intermodal transportation. Int. J. Logist. Res. Appl. 2021, 24, 346–363. [Google Scholar] [CrossRef]

- Chen, X.; Gao, Z.; McFadden, B.R. Reveal preference reversal in consumer preference for sustainable food products. Food Qual. Prefer. 2020, 79, 103754. [Google Scholar] [CrossRef]

- Todorovic, V.; Maslaric, M.; Bojic, S.; Jokic, M.; Mircetic, D.; Nikolicic, S. Solutions for more sustainable distribution in the short food supply chains. Sustainability 2018, 10, 3481. [Google Scholar] [CrossRef]

- McClements, D.J. Future foods: Is it possible to design a healthier and more sustainable food supply? Nutr. Bull. 2020, 45, 341–354. [Google Scholar] [CrossRef]

- Tyagi, M.; Kumar, P.; Kumar, D. Assessment of critical enablers for flexible supply chain performance measurement system using fuzzy DEMATEL approach. Glob. J. Flex. Syst. Manag. 2015, 16, 115–132. [Google Scholar] [CrossRef]

- Sharma, J.; Tyagi, M.; Panchal, D.; Bhardwaj, A. Dimensions Modelling for Reliable Indian Food Supply Chains. In Reliability and Risk Modeling of Engineering Systems; Springer: Cham, Switzerland, 2021; pp. 133–150. [Google Scholar]

- Ejegwa, P.A.; Awolola, J.A. Novel distance measures for Pythagorean fuzzy sets with applications to pattern recognition problems. Granul. Comput. 2021, 6, 181–189. [Google Scholar] [CrossRef]

- Yager, R.R. Pythagorean membership grades in multicriteria decision making. IEEE Trans. Fuzzy Syst. 2013, 22, 958–965. [Google Scholar] [CrossRef]

- Liang, D.; Xu, Z. The new extension of TOPSIS method for multiple criteria decision making with hesitant Pythagorean fuzzy sets. Appl. Soft Comput. 2017, 60, 167–179. [Google Scholar] [CrossRef]

- Pérez-Domínguez, L.; Rodríguez-Picón, L.A.; Alvarado-Iniesta, A.; Luviano Cruz, D.; Xu, Z. MOORA under Pythagorean fuzzy set for multiple criteria decision making. Complexity 2018, 2018, 2602376. [Google Scholar] [CrossRef]

- Mohagheghi, V.; Mousavi, S.M.; Vahdani, B. Enhancing decision-making flexibility by introducing a new last aggregation evaluating approach based on multi-criteria group decision making and Pythagorean fuzzy sets. Appl. Soft Comput. 2017, 61, 527–535. [Google Scholar] [CrossRef]

- Rahman, K.; Abdullah, S.; Ali, A.; Amin, F. Approaches to multi-attribute group decision making based on induced interval-valued Pythagorean fuzzy Einstein hybrid aggregation operators. Bull. Braz. Math. Soc. New Ser. 2019, 50, 845–869. [Google Scholar] [CrossRef]

- Garg, H. A linear programming method based on an improved score function for interval-valued Pythagorean fuzzy numbers and its application to decision-making. Int. J. Uncertain. Fuzziness Knowl.-Based Syst. 2018, 26, 67–80. [Google Scholar] [CrossRef]

- Ramooshjan, K.; Rahmani, J.; Sobhanollahi, M.A.; Mirzazadeh, A. A new method in the location problem using fuzzy TODIM. J. Hum. Soc. Sci. Res. 2015, 6, 1–13. [Google Scholar]

- Biswas, A.; Sarkar, B. Interval-valued Pythagorean fuzzy TODIM approach through point operator-based similarity measures for multicriteria group decision making. Kybernetes 2019, 48, 496–519. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Z. Extension of TOPSIS to multiple criteria decision making with Pythagorean fuzzy sets. Int. J. Intell. Syst. 2014, 29, 1061–1078. [Google Scholar] [CrossRef]

- Jayant, A.; Sharma, J. A comprehensive literature review of MCDM techniques ELECTRE, PROMETHEE, VIKOR and TOPSIS applications in business competitive environment. Int. J. of Curr. Res. 2018, 10, 65461–65477. [Google Scholar]

- Grunert, K.G.; Hieke, S.; Wills, J. Sustainability labels on food products: Consumer motivation, understanding and use. Food Policy 2014, 44, 177–189. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).